Page 1

TEXp EXpLOSION pROOF FAMILy

AEHHXV/AEHHXU, NEMA PREMIUM [XP]

AEHHXG/AEHHXF, NEMA PREMIUM, FOOTED C-FACE (1 HP - 100 HP)[XP_C]

AEUHXG/AEUHXF, NEMA PREMIUM, ROUND BODY C-FACE (1 HP - 75 HP)[XPV_C]

APPLICATIONS:

z Grain Elevators z Applications Where Explosive Gases are Present

z Pumps z Applications Where Explosive Dusts/ Grains are Present

z Blowers

FEATURES:

z Output Range: 1 - 400 HP

z Speed: 3600, 1800, 1200 & 900 RPM

z Enclosure: Totally Enclosed Fan Cooled - Explosion Proof (IP55)

z Voltage: 230/460V (Usable on 208V); 150HP and Larger is 460V Only

z Three Phase, 60 Hz, 1.15 Service Factor (Continuous); 50 Hz, 1.0 Service Factor (Continuous)

z Class I, Div. 1, Group C & D and Class II, Groups E, F and G - Temp Code T2D/T3B Up to and Including F# 256T

z Class I, Div. 1, Group D and Class II, Groups E, F and G - Temp Code T2D/T3B for F# 284T and Larger

z UL File: E84757

z CSA File: #64671

z Class F Insulation

z Class B Temperature Rise

z NEMA Design B Torques

z Standard with Klixon 9700K Temperature Limiting Switch, 1 per Phase

z Grounding Terminal Inside Main Conduit Box

z Oversized Main Conduit Box Rotatable in 90 Degree Increments - F1 Mounted

z Dual Drilled Back Feet on 447/9 and 5007/9 Frames

z Designed for 40˚C Ambient Temperature

z Designed for 3300 ft. Elevation

(3)

(2)

z Bi-Directional Rotation

z Cast Iron Frame, Fan Cover, End Brackets and Main Conduit Box

z Capable of Withstanding Explosion Force as Required by UL

z Stainless Steel Breather Drains with Bronze Filters (For Horizontal Mount Only)

z 1045 Carbon Steel Shaft

z Aluminum Die Cast Squirrel Cage Rotor Construction through 449 Frame; Fabricated Copper Bar on 5000 Frame

z Aluminum Die Cast Squirrel Cage Rotor Construction

z Paint System: Phenolic Rust Proof Base Plus Polyurethane Top Coat

z Paint Color: Dark Blue - Munsell 5 PB 4.5/2

z Double Shielded Bearings Pre-Packed with MULTEMP SRL for F# 140T - 280T (Non-regreasable)

z High Quality Ball (or Roller) Bearings Regreasable with Mobil Polyrex™ EM for F# 280TS and Larger

z Bronze Flinger on Both Ends

z Cast Iron Inner and Outer Bearing Caps for F#280TS and Larger

z Stainless Steel Nameplate

z Suitable for Inverter Use per NEMA MG-1

z UL Listed for Inverter Duty

(4,5)

Part 31.4.4.2

(4,5)

z Inverter Duty Magnet Wire Capable of Withstanding Voltage Spikes of up to 2200 Volts

z Inverter Duty Speed Ranges: VT = 3 - 60 Hz CT for 140T - 210T Frames = 10 - 60 Hz

CT for 250T - 320T Frames = 13 - 60 Hz CT for 260T - 440T Frames = 16 - 60 Hz

z 9 Leads for 5 HP and Smaller; 12 Leads for 7.5 HP to 125 HP; 6 Leads for 150 HP and Larger

(1)

Effective 07-08-18

Supercedes 03-24-17

EXTRAS/ OPTIONS:

Please refer to pages 147 - 154 for common modifications that can be performed.

Notes:

(1) Available in 575V. TWMC carries minimal 575V stock; please check availability to ensure required motors are in stock.

Ratings may be available from our Canadian warehouses and/or our factory. Pricing and leadtime may vary.

(2) Consult a Stock Product Application Specialist for suitability in higher ambient environments.

(3) Consult a Stock Product Application Specialist for suitability at higher elevations.

(4) Motor Service Factor is 1.0 when operated on a VFD.

(5) Precautions should be taken to eliminate or reduce shaft currents that may be imposed on the motor by the VFD as stated per NEMA MG-1. Part 31.

(6) Extras/Modification options are limited on TEXP Products. See page 147 for additional details.

Page 2

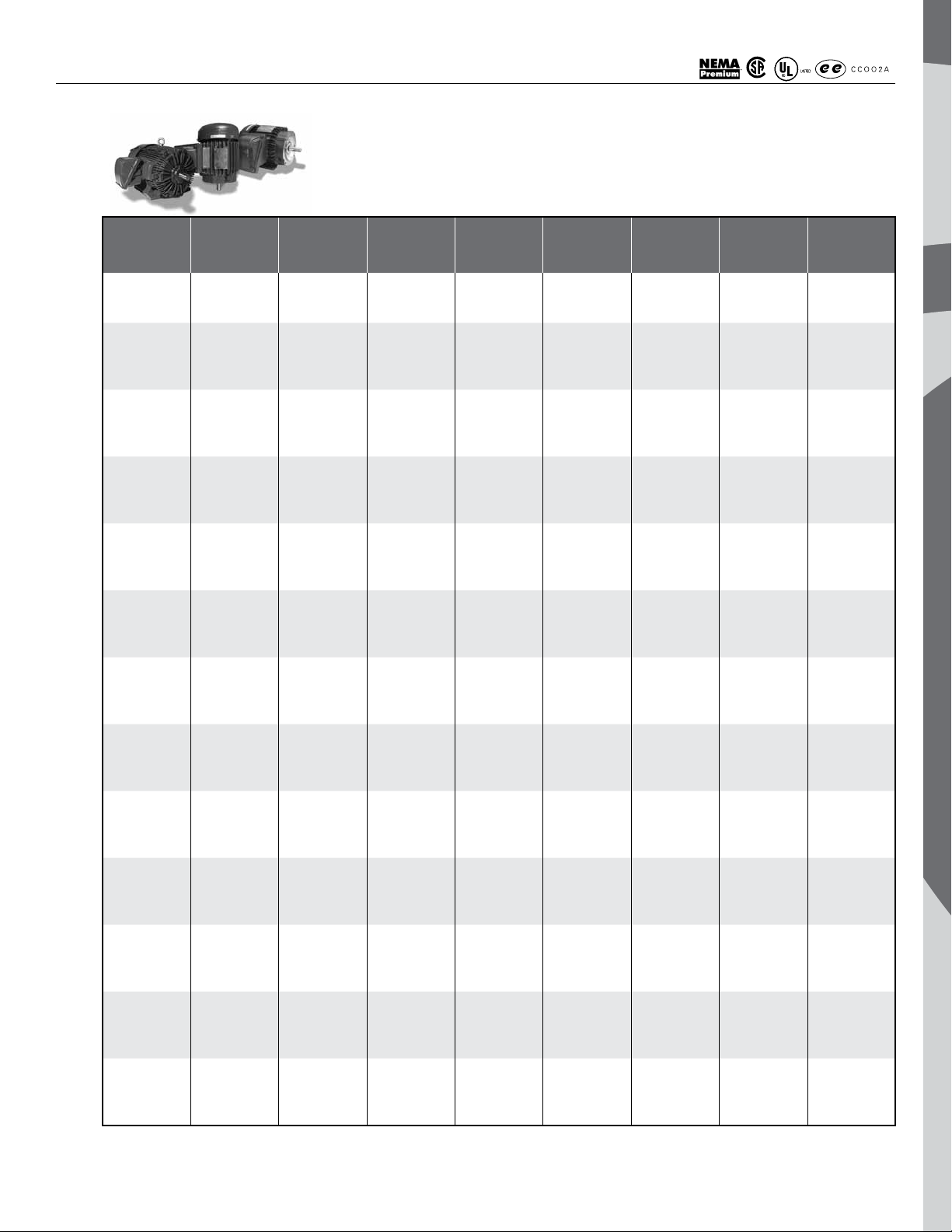

TEXp EXpLOSION pROOF

AEHHXV/AEHHXU, NEMA PREMIUM [XP]

Effective 07-08-18

Supercedes 03-24-17

CATALOG NO. HP RPM FRAME FL EFF (%) FL PF (%)

XP0014 1 1800 143T 85.5 68.0 1.61 64

XP0016 1 1200 145T 82.5 66.0 1.72 93

XP0018 1 900 182T 77.0 58.5 2.08 108

XP1/52 1.5 3600 143T 84.0 84.0 1.99 78

XP1/54 1.5 1800 145T 86.5 75.5 2.15 80

XP1/56 1.5 1200 182T 87.5 63.0 2.55 125

XP1/58 1.5 900 184T 78.5 60.5 2.96 120

XP0022 2 3600 145T 85.5 87.0 2.52 68

XP0024 2 1800 145T 86.5 78.0 2.78 80

XP0026 2 1200 184T 88.5 69.0 3.07 148

XP0028 2 900 213T 84.0 64.0 3.48 187

XP0032 3 3600 182T 87.5 90.0 3.57 130

XP0034 3 1800 182T 89.5 81.0 3.87 135

XP0036 3 1200 213T 89.5 80.0 3.92 240

XP0038 3 900 215T 85.5 66.0 4.98 211

XP0052 5 3600 184T 88.5 91.0 5.81 153

XP0054 5 1800 184T 89.5 84.0 6.23 145

XP0056 5 1200 215T 90.2 81.0 6.41 235

XP0058 5 900 254T 86.5 72.0 7.52 330

XP7/52 7.5 3600 213T 89.5 87.0 9.02 235

XP7/54 7.5 1800 213T 91.7 86.5 8.85 200

XP7/56 7.5 1200 254T 91.0 82.0 9.41 365

XP7/58 7.5 900 256T 86.5 81.5 11.4 376

XP0102 10 3600 215T 90.2 87.0 11.9 250

XP0104 10 1800 215T 91.7 87.5 11.7 265

XP0106 10 1200 256T 91.0 81.5 12.6 420

XP0108 10 900 284T 89.5 73.5 14.2 488

XP0152 15 3600 254T 91.0 92.0 16.8 400

XP0154 15 1800 254T 92.4 85.0 17.9 390

XP0156 15 1200 284T 91.7 83.0 18.5 575

XP0158 15 900 286T 89.5 78.0 20.1 530

XP0202 20 3600 256T 91.0 92.0 22.4 440

XP0204 20 1800 256T 93.0 85.5 23.6 455

XP0206 20 1200 286T 91.7 84.0 24.3 600

XP0208 20 900 324T 90.2 81.0 25.6 708

XP0252 25 3600 284TS 91.7 92.0 27.7 460

XP0254 25 1800 284T 93.6 85.0 29.4 585

XP0256 25 1200 324T 93.0 83.0 30.3 825

XP0258 25 900 326T 90.2 79.5 32.6 781

XP0302 30 3600 286TS 92.4 92.0 33.0 583

XP0304 30 1800 286T 93.6 85.5 34.3 565

XP0306 30 1200 326T 93.0 83.0 36.4 787

XP0308 30 900 364T 91.7 77.5 39.5 946

XP0402 40 3600 324TS 93.0 91.0 44.3 805

XP0404 40 1800 324T 94.1 85.5 46.6 708

XP0406 40 1200 364T 94.1 86.0 46.3 980

XP0408 40 900 365T 91.7 76.5 53.4 1,019

XP0502 50 3600 326TS 93.6 91.0 55.0 890

XP0504 50 1800 326T 94.5 85.5 57.9 925

XP0506 50 1200 365T 94.1 83.5 59.6 1,125

XP0508 50 900 404T 93.0 80.5 62.5 1,287

FL AMPS

(460V)

APPROX.

SHIPPING

WT. (lbs.)

Notes:

(1) Data subject to change without notice.

Page 3

TEXp EXpLOSION pROOF

AEHHXV/AEHHXU, NEMA PREMIUM [XP]

Effective 07-08-18

Supercedes 03-24-17

CATALOG NO. HP RPM FRAME FL EFF (%) FL PF (%)

XP0602 60 3600 364TS 93.6 93.0 64.5 1,015

XP0604 60 1800 364T 95.0 88.0 67.2 1,010

XP0606 60 1200 404T 94.5 86.0 69.1 1,322

XP0608 60 900 405T 93.0 81.0 74.6 1,408

XP0752 75 3600 365TS 93.6 93.0 80.7 1,085

XP0754 75 1800 365T 95.4 88.0 83.6 1,110

XP0756 75 1200 405T 94.5 86.5 85.9 1,540

XP0758 75 900 444T 93.0 81.0 93.2 1,650

XP1002 100 3600 405TS 94.5 92.0 108 1,495

XP1004 100 1800 405T 95.4 90.0 109 1,545

XP1006 100 1200 444T 95.0 83.5 118 1,920

XP1006R 100 1200 444T 95.0 83.5 118 1,920

XP1008 100 900 445T 93.0 81.0 124 1,800

XP1252 125 3600 444TS 95.0 86.0 143 1,800

XP1254 125 1800 444T 95.4 85.0 144 1,970

XP1254R 125 1800 444T 95.4 85.0 144 1,970

XP1256 125 1200 445T 95.0 84.0 147 2,100

XP1256R 125 1200 445T 95.0 84.0 147 2,100

XP1258 125 900 447T 93.6 82.5 152 2,500

XP1258R 125 900 447T 93.6 82.5 152 2,500

XP1502 150 3600 445TS 95.0 87.0 170 1,940

XP1504 150 1800 445T 95.8 85.0 173 2,120

XP1504R 150 1800 445T 95.8 85.0 173 2,120

XP1506 150 1200 447T 95.8 84.5 174 2,120

XP1506R 150 1200 447T 95.8 84.5 174 2,120

XP1508 150 900 449T 93.6 82.5 182 2,880

XP1508R 150 900 449T 93.6 82.5 182 2,880

XP2002 200 3600 447TS 95.4 89.0 221 2,300

XP2004 200 1800 447T 96.2 87.0 224 2,620

XP2006 200 1200 449T 95.8 85.0 230 2,850

XP2006R 200 1200 449T 95.8 85.0 230 2,450

XP2008 200 900 5007B 94.1 80.4 248 3,920

XP2008R 200 900 5007C 94.1 80.4 248 3,920

XP2502 250 3600 449TS 95.8 89.8 272 2,720

XP2504 250 1800 449T 96.2 88.0 277 2,870

XP2506 250 1200 5007B 95.8 87.0 281 4,010

XP2506R 250 1200 5007C 95.8 87.0 281 4,010

XP2508 250 900 5009B 94.5 81.0 306 4,360

XP2508R 250 900 5009C 94.5 81.0 306 4,360

XP3002 300 3600 449TS 95.8 90.2 325 2,920

XP3004 300 1800 449T 96.2 88.0 332 2,950

XP3006 300 1200 5009B 95.8 87.3 336 4,310

XP3006R 300 1200 5009C 95.8 87.3 336 4,310

XP3502 350 3600 5007A 95.8 88.0 389 4,200

XP3504 350 1800 5007B 96.2 87.7 388 4,400

XP3506 350 1200 5009B 95.8 87.4 391 4,520

XP3506R 350 1200 5009C 95.8 87.4 391 4,520

XP4002 400 3600 5009A 95.8 88.3 443 4,350

XP4004 400 1800 5009B 96.2 87.7 444 4,500

Notes:

(1) Data subject to change without notice.

FL AMPS

(460V)

APPROX.

SHIPPING

WT. (lbs.)

Page 4

TEXp EXpLOSION pROOF

AEHHXG/AEHHXF, NEMA PREMIUM, FOOTED C-FACE (1 HP - 100 HP)[XP_C]

AEUHXG/AEUHXF, NEMA PREMIUM, ROUND BODY C-FACE (1 HP - 75 HP)[XPV_C]

Effective 07-08-18

Supercedes 03-24-17

HP RPM FRAME FL EFF (%) FL PF (%)

1 1800 143TC 85.5 73.0 1.50 64 XP0014C

1 1200 145TC 82.5 65.5 1.70 93 XP0016C

1.5 3600 143TC 84.0 83.5 2.00 78 XP1/52C

1.5 1800 145TC 86.5 78.0 2.10 80 XP1/54C

1.5 1200 182TC 87.5 63.5 2.50 125 XP1/56C

2 3600 145TC 86.5 86.0 2.50 68 XP0022C

2 1800 145TC 86.5 78.0 2.80 80 XP0024C

2 1200 184TC 88.5 70.5 3.00 148 XP0026C

3 3600 182TC 88.5 90.0 3.50 130 XP0032C

3 1800 182TC 89.5 84.0 3.70 135 XP0034C

3 1200 213TC 89.5 78.0 4.00 240 XP0036C

5 3600 184TC 88.5 92.5 5.70 153 XP0052C

5 1800 184TC 89.5 85.5 6.10 145 XP0054C

5 1200 215TC 91.0 82.5 6.20 235 XP0056C

7.5 3600 213TC 91.0 89.0 8.70 235 XP7/52C

7.5 1800 213TC 91.7 86.5 8.90 200 XP7/54C

7.5 1200 254TC 91.0 80.5 9.60 365 XP7/56C

10 3600 215TC 91.0 89.5 11.50 250 XP0102C

10 1800 215TC 91.7 88.0 11.60 241 XP0104C

10 1200 256TC 91.0 80.5 12.80 420 XP0106C

15 3600 254TC 92.4 91.5 16.60 400 XP0152C

15 1800 254TC 92.4 88.0 17.30 390 XP0154C

15 1200 284TC 92.4 83.5 18.20 575 XP0156C

20 3600 256TC 92.4 92.5 21.90 440 XP0202C

20 1800 256TC 93.0 87.5 23.00 455 XP0204C

20 1200 286TC 91.7 84.0 24.30 600 XP0206C

25 3600 284TSC 92.4 91.0 27.80 460 XP0252C

25 1800 284TC 93.6 86.0 29.10 585 XP0254C

25 1200 324TC 93.0 83.0 30.30 825 XP0256C

30 3600 286TSC 92.4 91.0 33.20 583 XP0302C

30 1800 286TC 93.6 87.5 34.30 565 XP0304C

30 1200 326TC 93.0 80.5 37.50 787 XP0306C

40 3600 324TSC 94.1 90.0 44.20 805 XP0402C

40 1800 324TC 94.1 86.0 46.30 708 XP0404C

40 1200 364TC 94.1 86.5 46.00 980 XP0406C

50 3600 326T

50 1800 326TC 94.5 87.0 56.90 925 XP0504C

50 1200 365TC 94.1 86.0 57.80 1,125 XP0506C

60 3600 364TSC 94.1 93.0 64.20 1,015 XP0602C

60 1800 364TC 95.0 86.5 68.40 1,010 XP0604C

60 1200 404TC 94.5 87.0 68.30 1,322 XP0606C

75 3600 365TSC 94.5 93.0 79.90 1,085 XP0752C

75 1800 365TC 95.4 86.5 85.1 1,110 XP0754C

75 1200 405TC 94.5 86.5 85.9 1,540 XP0756C

100 3600 405TSC 95.4 92.0 107.0 1,495 XP1002C

100 1800 405TC 95.4 87.5 112.0 1,545 XP1004C

Notes:

(1) Data subject to change without notice.

SC 94.1 91.0 54.70 890 XP0502C

FL AMPS

(460V)

APPROX.

SHIPPING

WT. (lbs.)

CATALOG NO.

FOOTED C-FACE ROUND BODY C-FACE

CATALOG NO.

XPV0014C

XPV0016C

XPV1/52C

XPV1/54C

XPV1/56C

XPV0022C

XPV0024C

XPV0026C

XPV0032C

XPV0034C

XPV0036C

XPV0052C

XPV0054C

XPV0056C

XPV7/52C

XPV7/54C

XPV7/56C

XPV0102C

XPV0104C

XPV0106C

XPV0152C

XPV0154C

XPV0156C

XPV0202C

XPV0204C

XPV0206C

XPV0252C

XPV0254C

XPV0256C

XPV0302C

XPV0304C

XPV0306C

XPV0402C

XPV0404C

XPV0406C

XPV0502C

XPV0504C

XPV0506C

XPV0602C

XPV0604C

XPV0606C

XPV0752C

XPV0754C

XPV0756C

~

~

Loading...

Loading...