TECO SG2-20VT-D, SG2-12HR-D, SG2-20HR-D, SG2-20VR-D, SG2-12HR-12D User Manual

...

SG2 Smart PLC

USER Manual

SG2 Programmable Logic Sma rt Relay

Apply to: SG2 firmware version 3.6,

PC client program software version 3.4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4KA72X023 I

Contents

Contents

.............................................................................................................................................................................I

Summary of changes...................................................................................................................................................... Ⅴ

Chapter 1: Getting Started...............................................................................................................................................1

Examination before Installation.............................................................................................................................. 3

Environmental Precautions............................................................................................................................. 3

SG2 Model Identification................................................................................................................................ 3

Quick Start Setup.................................................................................................................................................... 4

Install SG2 Client Software ............................................................................................................................ 4

Connect Power to SG2 smart relay................................................................................................................. 4

Connect Programming Cable.......................................................................................................................... 5

Establish Communication............................................................................................................................... 5

Write simple program......................................................................................................................................6

Chapter 2: Installation...................................................................................................................................................10

General Specifications .......................................................................................................................................... 11

Product Specifications...........................................................................................................................................14

Mounting............................................................................................................................................................... 15

Wiring................................................................................................................................................................... 17

K type Indicator Light........................................................................................................................................... 19

Chapter 3: Program T ools.............................................................................................................................................20

PC Programming Software “SG2 Client”............................................................................................................. 21

Installing the Software .................................................................................................................................. 21

Connecting the Software............................................................................................................................... 21

Start Screen................................................................................................................................................... 21

Ladder Logic Programming Environment.................................................................................................... 22

Menus, Icons and Status Bar................................................................................................................. 23

Programming......................................................................................................................................... 24

Simulation Mode................................................................................................................................... 25

Establish Communication ..................................................................................................................... 25

Writing Program to smart relay............................................................................................................. 26

Online Monitoring/Editing.................................................................................................................... 27

Operation menu..................................................................................................................................... 28

HMI/TEXT............................................................................................................................................ 29

Program Documentation ....................................................................................................................... 33

Analog Output Set…............................................................................................................................. 35

3-Row/5-Row........................................................................................................................................ 36

Data Register Set…............................................................................................................................... 37

View menu ............................................................................................................................................ 39

FBD Programming Environment.................................................................................................................. 40

Menu, Icons and Status Bar...................................................................................................................40

Programming......................................................................................................................................... 41

Simulation Mode................................................................................................................................... 42

Online Monitoring/Editing.................................................................................................................... 42

Symbol and Parameters list................................................................................................................... 43

Memory Cartridge (sold separately) ..................................................................................................................... 45

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4KA72X023 II

LCD Display and Keypad..................................................................................................................................... 46

Keypad.......................................................................................................................................................... 46

Original Screen ............................................................................................................................................. 47

LCD Display Main Menu.............................................................................................................................. 50

RTC Daylight saving setting.......................................................................................................................55

SG2 system error......................................................................................................................................... 59

Chapter 4: Parameter passing........................................................................................................................................ 60

SG2 inner data type............................................................................................................................................... 61

Passing parameter out of range.............................................................................................................................63

Chapter 5: Relay Ladder Logic Programming..............................................................................................................65

Common Memory Types....................................................................................................................................... 66

Specialty Memory T ypes.......................................................................................................................................69

Output Instructions................................................................................................................................................ 70

Analog memory type............................................................................................................................................. 71

Timer Instruction................................................................................................................................................... 72

Counter Instructions.............................................................................................................................................. 80

Real Time Clock (RTC) Instructions.................................................................................................................... 90

Comparator Instructions........................................................................................................................................ 98

HMI Display Instructions.................................................................................................................................... 100

PWM Output Instruction (DC Transistor Output Models Only)......................................................................... 103

IO Link/Remote I/O Instruction (SG2-20Vxxx model only).............................................................................. 106

MU (Modbus) (SG2-20Vxxx model only) ......................................................................................................... 109

SHIFT (shift output)............................................................................................................................................ 116

AQ (Analog Output) ........................................................................................................................................... 117

AS (Add-Subtract) .............................................................................................................................................. 119

MD (MUL-DIV)................................................................................................................................................. 120

PID (Proportion- Integral- Differential).............................................................................................................. 121

MX (Multiplexer)................................................................................................................................................ 125

AR (Analog-Ramp)............................................................................................................................................. 126

DR (Data register)............................................................................................................................................... 130

Chapter 6: Function Block Diagram Programming....................................................................................................132

FBD Instructions................................................................................................................................................. 133

FBD system memory space................................................................................................................................. 134

Analog................................................................................................................................................................. 136

Analog Input ............................................................................................................................................... 136

Analog Output............................................................................................................................................. 137

Coil Block Instruction......................................................................................................................................... 138

HMI............................................................................................................................................................. 139

PWM function block (only transistor output version).................................................................................140

IO Link function block................................................................................................................................ 142

SHIFT function block ................................................................................................................................. 144

Logic Block Instructions..................................................................................................................................... 145

AND Logic Diagram................................................................................................................................... 145

AND (EDGE) Logic Diagram .................................................................................................................... 145

NAND Logic Diagram............................................................................................................. ................... 146

NAND (EDGE) Logic Diagram.................................................................................................................. 146

OR Logic Diagram...................................................................................................................................... 146

NOR Logic Diagram................................................................................................................................... 147

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4KA72X023 III

XOR Logic Diagram................................................................................................................................... 147

SR Logic Diagram ...................................................................................................................................... 147

NOT Logic Diagram................................................................................................................................... 147

Pulse Logic Diagram................................................................................................................................... 148

BOOLEAN Logic Diagram ........................................................................................................................ 148

Function Block.................................................................................................................................................... 149

Timer Function Block................................................................................................................................. 150

Common Counter function block................................................................................................................ 158

High Speed Counter Function Block (DC Version Only) ........................................................................... 164

RTC Comparator Function Block ............................................................................................................... 166

Analog Comparator Function Block........................................................................................................... 171

AS (ADD-SUB) function block.................................................................................................................. 174

MD (MUL-DIV) function block................................................................................................................. 175

PID (Proportion- Integral- Differential) function block.............................................................................. 176

MX (Multiplexer) function block................................................................................................................ 177

AR (Analog-Ramp) function block............................................................................................................. 178

Example:..................................................................................................................................................... 181

DR (Data-Register) function block............................................................................................................. 182

MU (Modbus) function block ..................................................................................................................... 183

Chapter 7: Hardware Specification............................................................................................................................. 189

Normal Specification .......................................................................................................................................... 190

Product Specifications.........................................................................................................................................191

Power Specifications........................................................................................................................................... 192

Normal model machine Specifications....................................................................................................... 192

12V DC model Specifications..................................................................................................................... 193

24V AC model Specifications..................................................................................................................... 193

Power circuitry diagram.............................................................................................................................. 194

Input Specifications............................................................................................................................................. 195

100~240V AC model .................................................................................................................................. 195

24V AC model ............................................................................................................................................ 195

24V DC, 12 I/O model................................................................................................................................ 196

24V DC, 20 I/O model................................................................................................................................ 197

12V DC, 12 I/O model................................................................................................................................ 198

12V DC, 20 I/O model................................................................................................................................ 199

Output Specifications.......................................................................................................................................... 200

Output Port wiring notice.................................................................................................................................... 200

Light Load................................................................................................................................................... 200

Inductance Load.......................................................................................................................................... 201

Life of relay................................................................................................................................................. 201

Size diagram of SG2........................................................................................................................................... 202

Chapter 8: 20 Points RS485 type Models Instruction................................................................................................. 203

Communication function..................................................................................................................................... 204

Detail instruction................................................................................................................................................. 206

Remote IO function.............................................................................................................

........................ 206

IO Link Function......................................................................................................................................... 207

MU instruction (Modbus RTU master)....................................................................................................... 209

Modbus RTU slave function ....................................................................................................................... 211

SG2 Modbus protocol............................................................................................................ ..................... 211

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4KA72X023 IV

Chapter 9: Expansion Module.....................................................................................................................................213

Summarize .......................................................................................................................................................... 214

Power .................................................................................................................................................................. 216

Size...................................................................................................................................................................... 216

Digital IO Module............................................................................................................................................... 219

Analog Module ................................................................................................................................................... 223

Analog Input Module 4AI ........................................................................................................................... 223

T emperature Input Module 4PT.................................................................................................................. 224

Analog Output Module 2AO....................................................................................................................... 225

Communication Module ..................................................................................................................................... 227

MBUS Module............................................................................................................................................ 227

DNET Module............................................................................................................................................. 230

PBUS Module............................................................................................................................................. 233

EN01 (TCP/IP) Module.............................................................................................................................. 236

Appendix: Keypad Programming ............................................................................................................................... 242

Appendix A: Keypad programming in Ladder mode.......................................................................................... 243

Appendix B: Keypad programming in Ladder FUNCTION BLOCK................................................................ 247

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4KA72X023 V

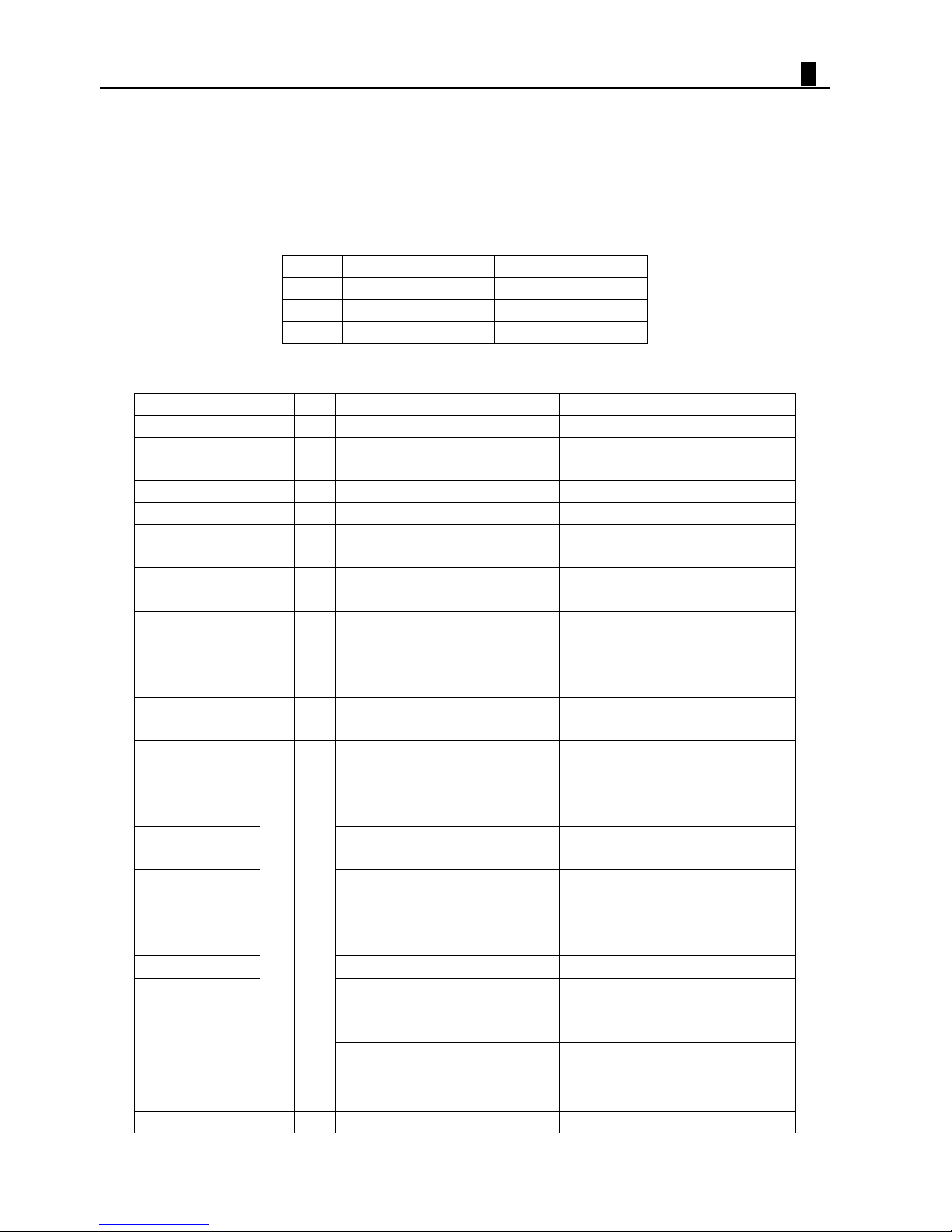

Summary of changes

This user manual is modified by firmware V3.0 and SG2 Client programming software V3.0. SG2 V3.0 adds some

new functions with firmware version V3.0 to strong SG2 function. The upgrade content is shown as the 2 tables

below simply. More information about idiographic function to see function instruction.

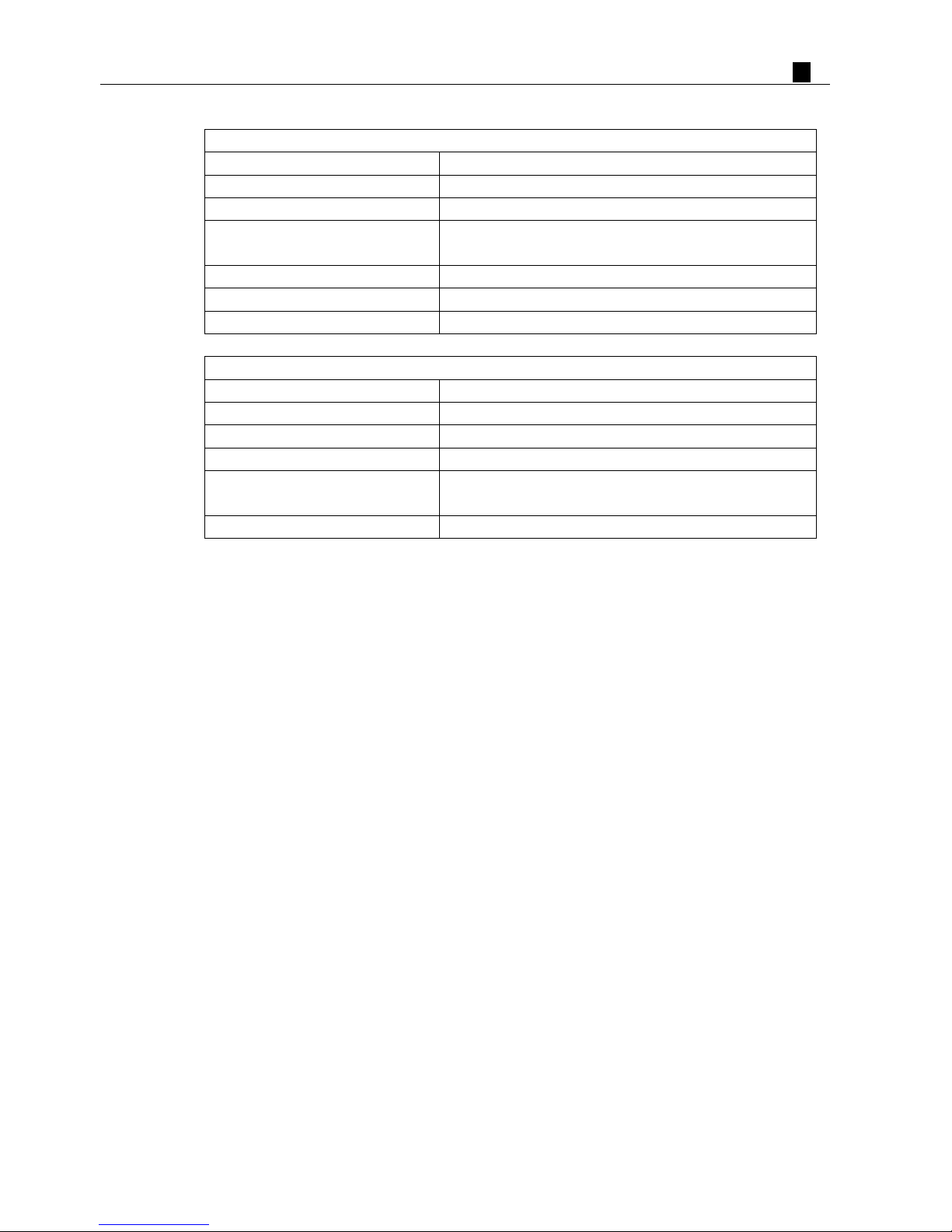

Edit and Display

SG2 V3.0 SG2 V2.x

Ladder 300 lines 200 lines

FBD 260blocks 99blocks

LCD 4 lines * 16 characters 4 lines * 12 characters

Contact and function block

input out put SG2 V3.0 SG2 V2.x

Auxiliary relay M M M 63(M01~M3F) 15(M1~MF)

Auxiliary relay N N N 63(N01~N3F) Ladder: NO

FBD: 15(N1~NF)

temperature input AT 4(AT01~AT04) NO

analog output AQ 4(AQ01~AQ04) NO

PWM P 2(P01~P02, P01 adds PLSY mode) 1(P1: PWM)

HMI 31(H01~H1F) 15(H1~HF)

Timer T T Ladder: 31(T01~T1F)

FBD: 250(T01~TFA)

15(T1~TF)

Counter C C Ladder: 31(C01~C1F)

FBD: 250(C01~CFA)

15(C1~CF)

RTC R R Ladder: 31(R01~R1F)

FBD: 250(R01~RFA)

15(R1~RF)

Analog Comparator G G Ladder: 31(G01~G1F)

FBD: 250(G01~GFA)

15(G1~GF)

AS(Add-Sub) Ladder: 31(AS01~AS1F)

FBD: 250(AS01~ASFA)

NO

MD(Mul-Div) Ladder: 31(MD01~MD1F)

FBD: 250(MD01~MDFA)

NO

PID Ladder: 15(PI01~PI0F)

FBD: 30(PI01~PI1E)

NO

MX(Multiplexer) Ladder: 15(MX01~MX0F)

FBD: 250(MX01~MXFA)

NO

AR(Analog Ramp) Ladder: 15(AR01~AR0F)

FBD: 30(AR01~AR1E)

NO

DR(Data Register) 240(DR01~DRF0) NO

MU(MODBUS)

NO NO

Ladder: 15(MU01~MU0F)

FBD: 250(MU01~MUFA)

NO

Logic function: BOOLEAN NO Block

B B

260(B001~B260)The capability o

f

each block is alterable, and the total

capability of block is 6000bytes

99(B01~B99)The capability of each

block is fixed

PM05(3rd) PM05(3rd) can be used with all PM05 can not be used with SG2 V3.x

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4KA72X023 VI

version of SG2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 1

Chapter 1: Getting Started

Examination before Installation...............................................................................................................................3

Environmental Precautions ..............................................................................................................................3

SG2 Model Identification................................................................................................................................3

Quick Start Setup.....................................................................................................................................................4

Install SG2 Client Software.............................................................................................................................4

Connect Power to SG2 smart relay..................................................................................................................4

Connect Programming Cable...........................................................................................................................5

Establish Communication................................................................................................................................5

Write simple program......................................................................................................................................6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 2

The SG2 tiny smart Relay is an electronic device. For safety reasons, please carefully read and follow the

paragraphs with "WARNING" or "CAUTION" symbols. They are important safety precautions to be aware of while

transporting, installing, operating, or examining the SG2 Controller.

WARNING: Personal injury may result from improper operation.

CAUTION: The SG2 smart relay may be damaged by improper operation.

Precaution for Installation

Compliance with the installation instructions and the user manual is absolutely necessary. Failure to comply

could lead to improper operation, equipment damage or in extreme cases even death, serious bodily injury or

considerable damage to property.

When installing the open-board models, insure that no wiring or foreign materials can fall into the exposed

circuits and components. Damage to equipment, fire, or considerable damage to property could result.

Always switch off power before you wire, connect, install, or remove any module.

The wiring for the SG2 smart relay is open and exposed. For the open-board models, all electrical components

are exposed. For this reason, it is recommended the SG2 smart relay be installed in an enclosure or cabinet to prevent

accidental contact or exposure to the electrical circuits and components.

Never install the product in an environment beyond the limits specified in this user manual such as high

temperature, humidity, dust, corrosive gas, vibration, etc.

Precaution for Wiring

Improper wiring and installation could lead to death, serious bodily injury or considerable damage to property.

The SG2 smart relay should only be installed and wired by properly experienced and certified personnel.

Make sure the wiring of the SG2 smart relay meets all applicable regulations and codes including local and

national standards and codes.

Be sure to properly size cables for the required current rating.

Always separate AC wiring, DC wiring with high-frequency switching cycles, and low-voltage signal wiring.

Precaution for Operation

To insure safety with the application of the SG2 smart relay, complete functional and safety testing must be

conducted. Only run the SG2 after all testing and confirming safe and proper operation is complete. Any potential

faults in the application should be included in the testing. Failure to do so could lead to improper operation,

equipment damage or in extreme cases even Death, serious bo dily injury or considerable damage to property.

When the power is on, never contact the terminals, exposed conductors or electrical components. Failure to

comply could lead to improper operation, equipment damage or in extreme cases even death, serious bodily injury or

considerable damage to property.

It is strongly recommended to add safety protection such as an emergency stop and external interlock circuit in

case the SG2 smart relay operation must be shut down immediately.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 3

Examination before Installation

Every SG2 smart relay has been fully tested and examined before shipment. Please carry out the following

examination procedures after unpacking your SG2 smart relay.

• Check to see if the model number of the SG2 matches the model number that you ordered.

• Check to see whether any damage occurred to the SG2 during shipment. Do not connect the SG2 smart relay to the

power supply if there is any sign of damage.

Contact

if you find any abnormal conditions as mentioned above.

Environmental Precautions

The installation site of the SG2 smart relay is very important. It relates directly to the functionality and the life

span of your SG2. Please carefully choose an installation site that meets the following requirements:

• Mount the unit vertically

• Environment temperature: -4°F - 131°F (-20°C - 55°C)

• Avoid placing SG2 close to any heating equipment

• Avoid dripping water, condensation, or humid environment

• Avoid direct sunlight

• Avoid oil, grease, and gas

• Avoid contact with corrosive gases and liquids

• Prevent foreign dust, flecks, or metal scraps from contacting the SG2 smart relay

• Avoid electric-magnetic interference (soldering or power machinery)

• Avoid excessive vibration; if vibration cannot be avoided, an anti-rattle mounting device should be installed to

reduce vibration.

Disclaim of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

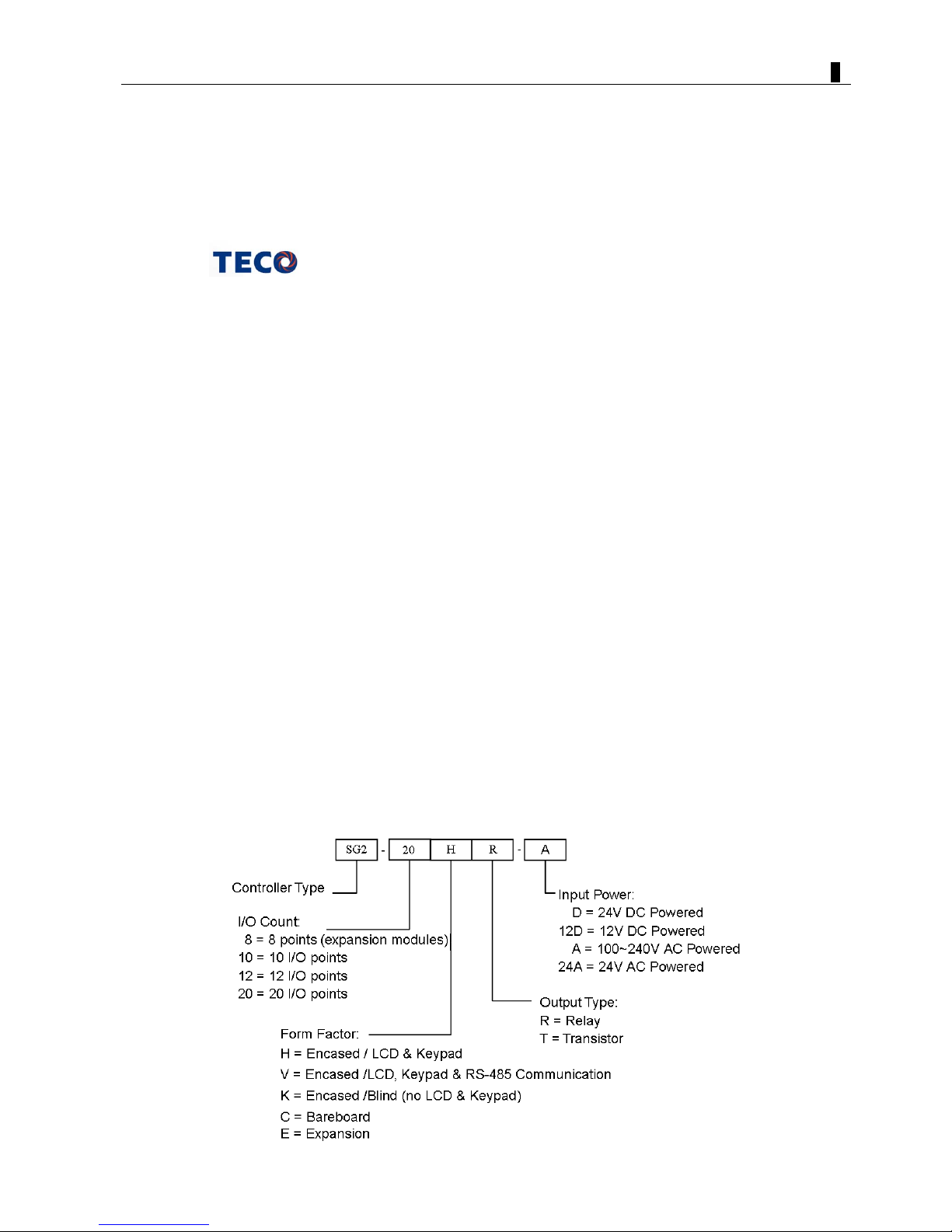

SG2 Model Identification

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 4

Quick Start Setup

This section is a simple guide for connecting, programming and operating your new SG2 smart relay. This is not

intended to be the complete instructions for programming and installation of your system. Refer to other sections in

the manual for more detailed information.

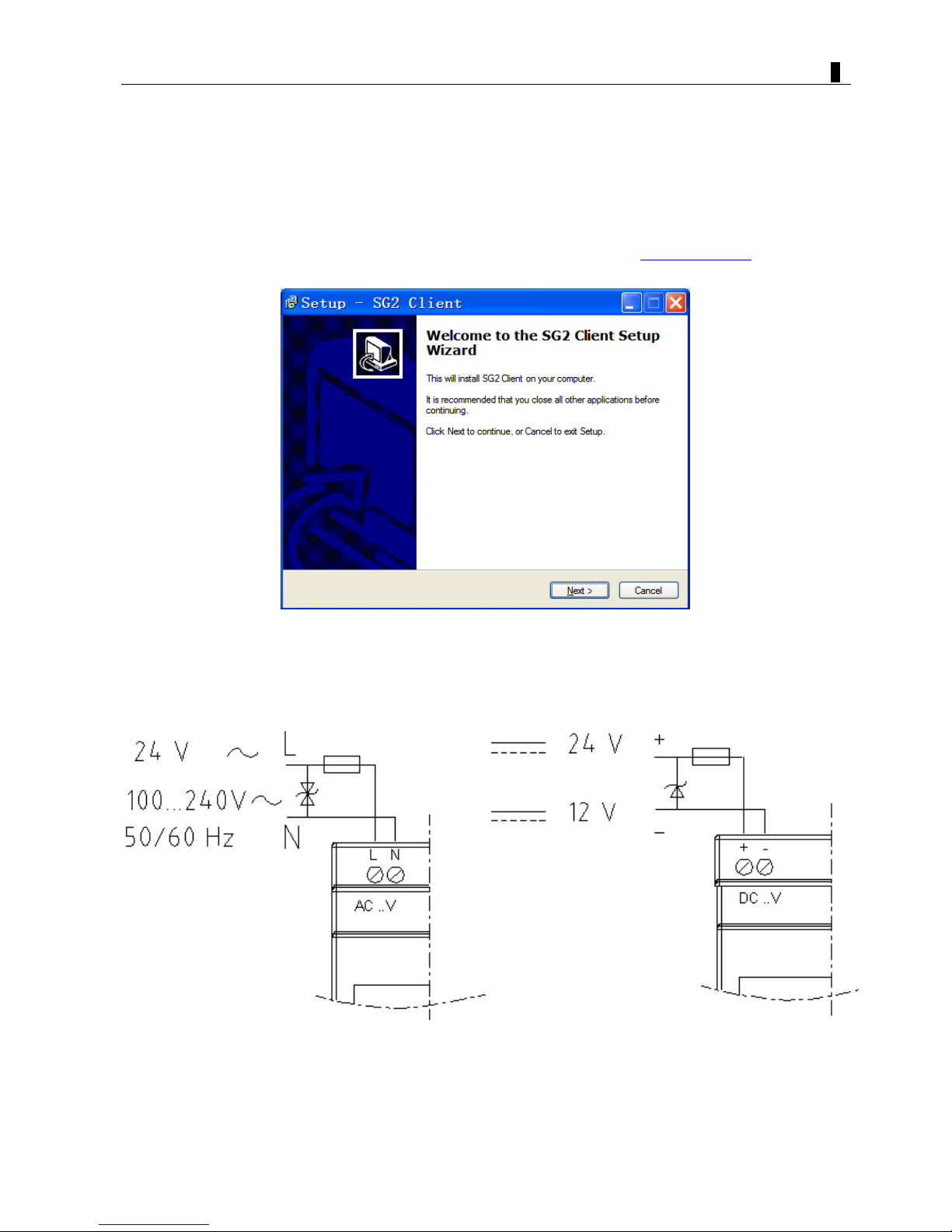

Install SG2 Client Software

Install the SG2 Client Software from CD or from the free internet download at www.teco.com.tw

Connect Power to SG2 smart relay

Connect power to the Smart Relay using the below wiring diagrams for AC or DC supply for the applicable

modules. See “Chapter 2: Installation” for complete wiring and installation instructions.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 5

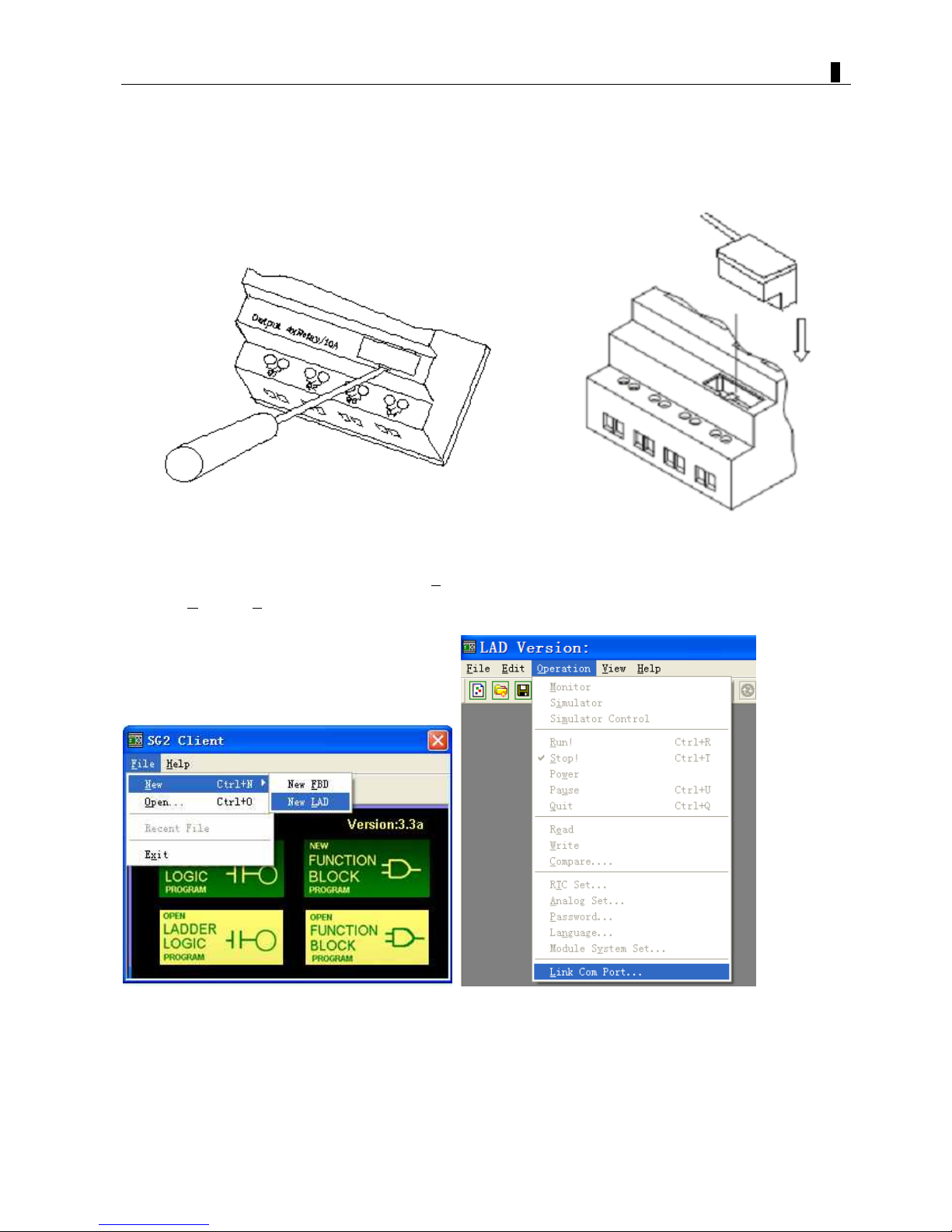

Connect Programming Cable

Remove the plastic connector cover from the SG2 using a flathead screwdriver as shown in the figure below.

Plug in the plastic connector end of the programming cable into the SG2 smart relay as shown in the figure below.

Connect the opposite end of the cable to an RS232 serial port or USB port on the computer.

Establish Communication

a. Open the SG2 Client software and select “New L

AD” as shown below left.

b. Select “Operation/Link Com Port…” as shown below right.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 6

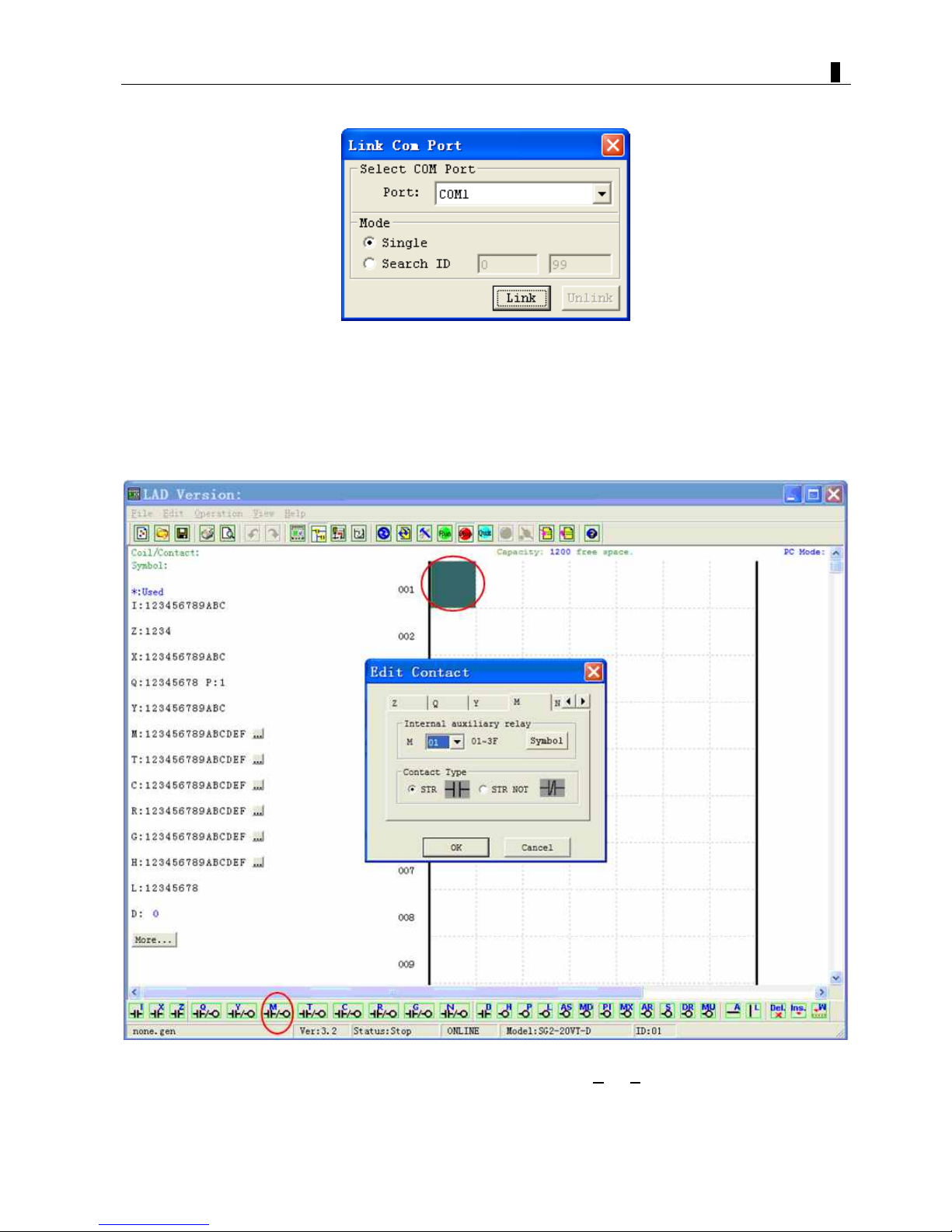

c. Select the correct Com Port number where the programming cable is connected to the computer then press the

“link” button.

d. The SG2 Client will then begin to detect the connected smart relay to complete its connection.

Write simple program

a. Write a simple one rung program by clicking on the leftmost cell at line 001 of the programming grid, then click

on the “M” contact icon on the ladder toolbar, as shown below. Select M01 and press the OK button.

See “Chapter 4: Ladder Programming instructions” for complete instruction set definitions.

Note: If the ladder toolbar is not visible at the bottom of the screen, select V

iew/Ladder Toolbar fr om the menu to

enable.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 7

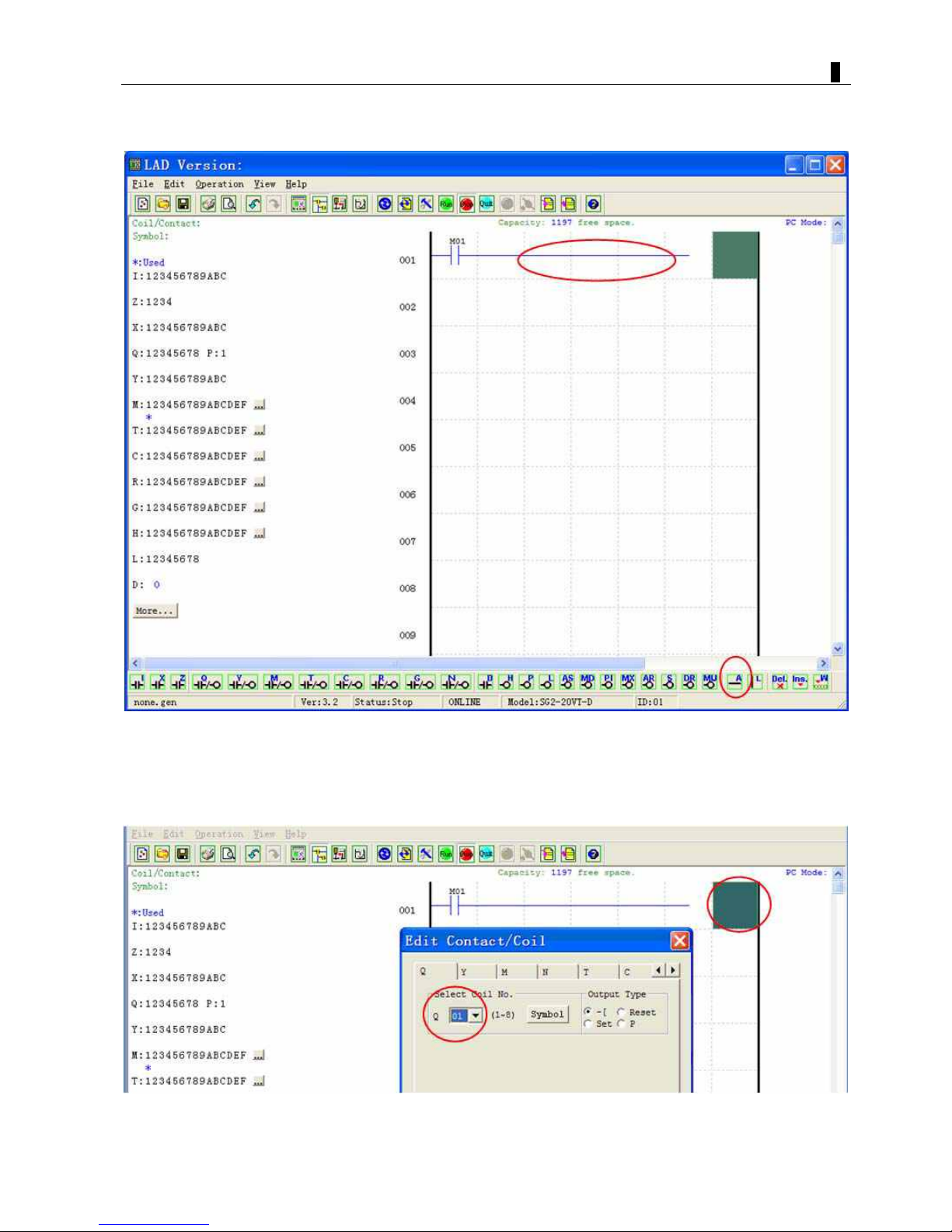

b. Use the “A” key on your keyboard (or the “A” icon on the ladder toolbar) to draw the horizontal circuit line from

the M contact to the right most cell, as shown below.

c. Select the “Q” coil icon from the ladder toolbar and drop it on the right most cells. Select Q01 from the dialog and

press OK as shown below. See “Chapter 4: Ladder Programming instructions” for complete instruction set

definitions.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 8

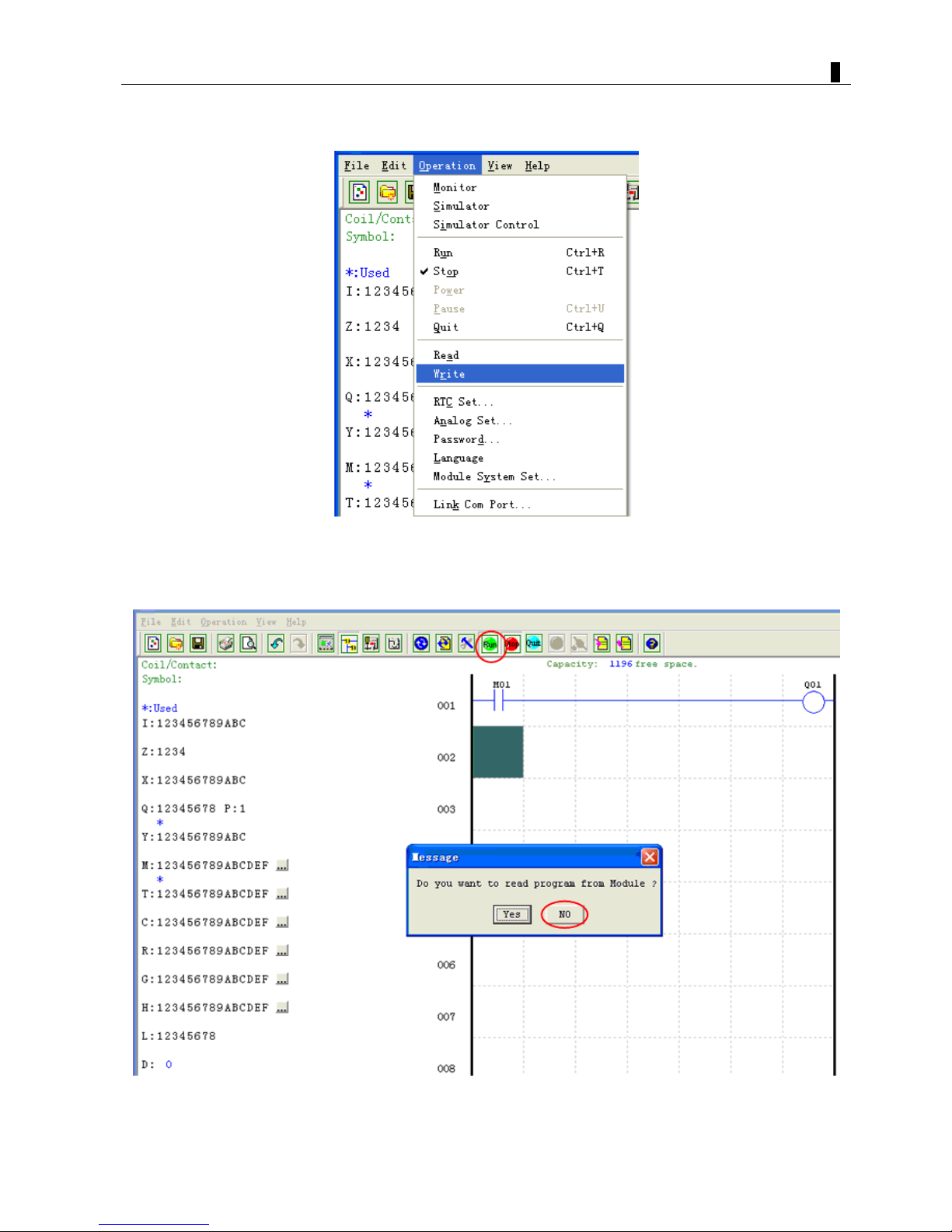

d. Test the simple program. From the Operation menu, select the Write function and write the program to the

connected smart relay as shown below.

e. Select the RUN icon from the toolbar, and select “No” when the pop-up message asks “Do you want to read

program from module?”, as shown below.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 1: Getting Started 9

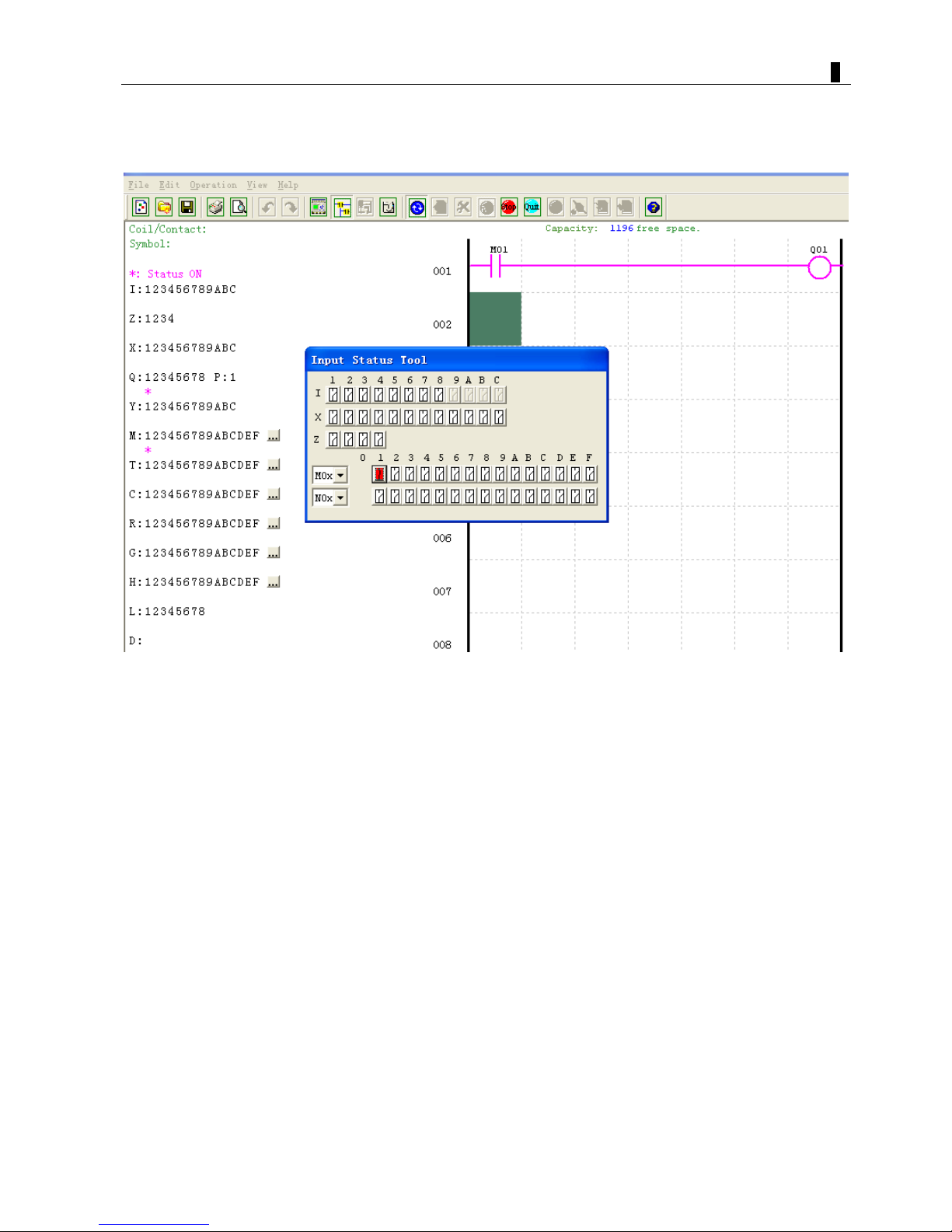

f. On the Input Status dialog, click on M01 to activate the contact M01 which will turn ON the Output Q01 as shown

below. The highlighted circuit shows the active part, and the first Output (Q01) on the connected smart relay will be

ON. See “Chapter 3: Programming Tools” for more detailed software information.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 10

Chapter 2: Installation

General Specifications .......................................................................................................................................... 11

Product Specifications...........................................................................................................................................14

Mounting............................................................................................................................................................... 16

Wiring................................................................................................................................................................... 18

K type Indicator Light........................................................................................................................................... 20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 11

General Specifications

SG2 is a miniature smart Relay with a maximum of 44 I/O points and can be programmed in Relay Ladder

Logic or FBD (Function Block Diagram) program. The SG2 can expand to its maximum I/O count by adding 3

groups of 4-input and 4-output modules.

Power Supply

Input Power Voltage Range

24V DC Models: 20.4-28.8V

12V DC Models: 10.4~14.4V

AC Models: 85-265V

24V AC Models: 20.4-28.8V

Power Consumption

24VDC: 12-point :125mA

20-point: 185mA

12VDC: 12-point: 195mA

20-point: 265mA

100-240VAC: 100mA

24VAC: 290mA

Wire Size (all terminals) 26 to 14 AWG

Programming

Programming languages Ladder/Function Block Diagram

Program Memory 300 Lines or 260 Function Blocks

Programming storage media Flash

Execution Speed 10ms/cycle

LCD Display 4 lines x 16 characters

Timers

Maximum Number Ladder: 31; FBD: 250

Timing ranges 0.01s–9999min

Counters

Maximum Number Ladder: 31; FBD: 250

Highest count 999999

Resolution 1

RTC (Real Time Clock)

Maximum Number Ladder: 31; FBD: 250

Resolution 1min

Time span available week, year, month, day, hour, min

Analog compare

Maximum Number Ladder: 31; FBD: 250

Compare versus other inputs

Numeric values or function block current value, such as

Analog input(A), Timer, Counter, Temperature Input (AT),

Analog Output (AQ), Analog*gain + Offset, AS, MD,

PI, MX, AR , DR …

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 12

Environmental

Enclosure T yp e IP20

Maximum Vibration 1G according to IEC60068-2-6

Operating Temperature Range -4° to 131°F (-20° to 55°C)

Storage Temperature Range -40° to 158°F (-40° to 70°C)

Maximum Humidity 90% (Relative, non-condensing)

Vibration 0.075mm amplitude, 1.0g acceleration

Weight

8-point:190g

10,12-point: 230g (C type: 160g)

20-point: 345g (C type: 250g)

Agency Approvals CUL, CE, UL

Digital Inputs

Current consumption

3.2mA @24VDC; 4mA @12VDC

1.3mA @100-240VAC

3.3mA @24VAC

Input Signal ”OFF” Threshold

24VDC: < 5VDC; 12VDC: < 2.5VDC

100-240VAC : < 40VAC

24VAC: <6VAC

Input Signal ”ON” Threshold

24VDC: > 15VDC 12VDC: > 7.5VDC

100-240VAC : > 79VAC

24VAC: >14VAC

Input On delay

24, 12VDC: 5ms

240VAC: 25ms 120VAC: 50ms

24VAC: 5ms

Input Off Delay

24, 12VDC: 3ms

240VAC: 90/85ms 50/60Hz

120VAC: 50/45ms 50/60Hz

24VAC: 3ms

Transistor device compatibility PNP, 3-wire device only

High Speed Input frequency 1kHz

Standard Input frequency < 40 Hz

Required protection Inverse voltage protection required

Analog Inputs

Resolution

Basic unit: 12 bit

Expansion unit: 12bit

Voltage Range acceptable

Basic unit: Analog input: 0-10VDC voltage,

24VDC when used as discrete input;

Expansion unit: Analog input: 0-10VDC voltage or

0-20mA current

Input Signal ”OFF” Threshold < 5VDC (as 24VDC discreet input)

Input Signal ”ON” Threshold > 9.8VDC (as 24VDC discreet input)

Isolation None

Short circuit protection Yes

T ot al number available

Basic unit: A0 1-A 04

Expansion unit: A05-A08

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 13

Relay Outputs

Contact material Ag Alloy

Current rating 8A

HP rating 1/3HP@120V 1/2HP@250V

Maximum Load

Resistive: 8A /point

Inductive: 4A /point

Maximum operating time 15ms (normal condition)

Life expectancy (rated load) 100k operations

Minimum load 16.7mA

Transistor Outputs

PWM max. output frequency 1.0kHz (0.5ms on,0.5ms off)

Standard max. output frequency 100Hz

Voltage specification 10-28.8VDC

Current capacity 1A

Maximum Load

Resistive: 0.5A/point

Inductive: 0.3A/point

Minimum Load 0.2mA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 14

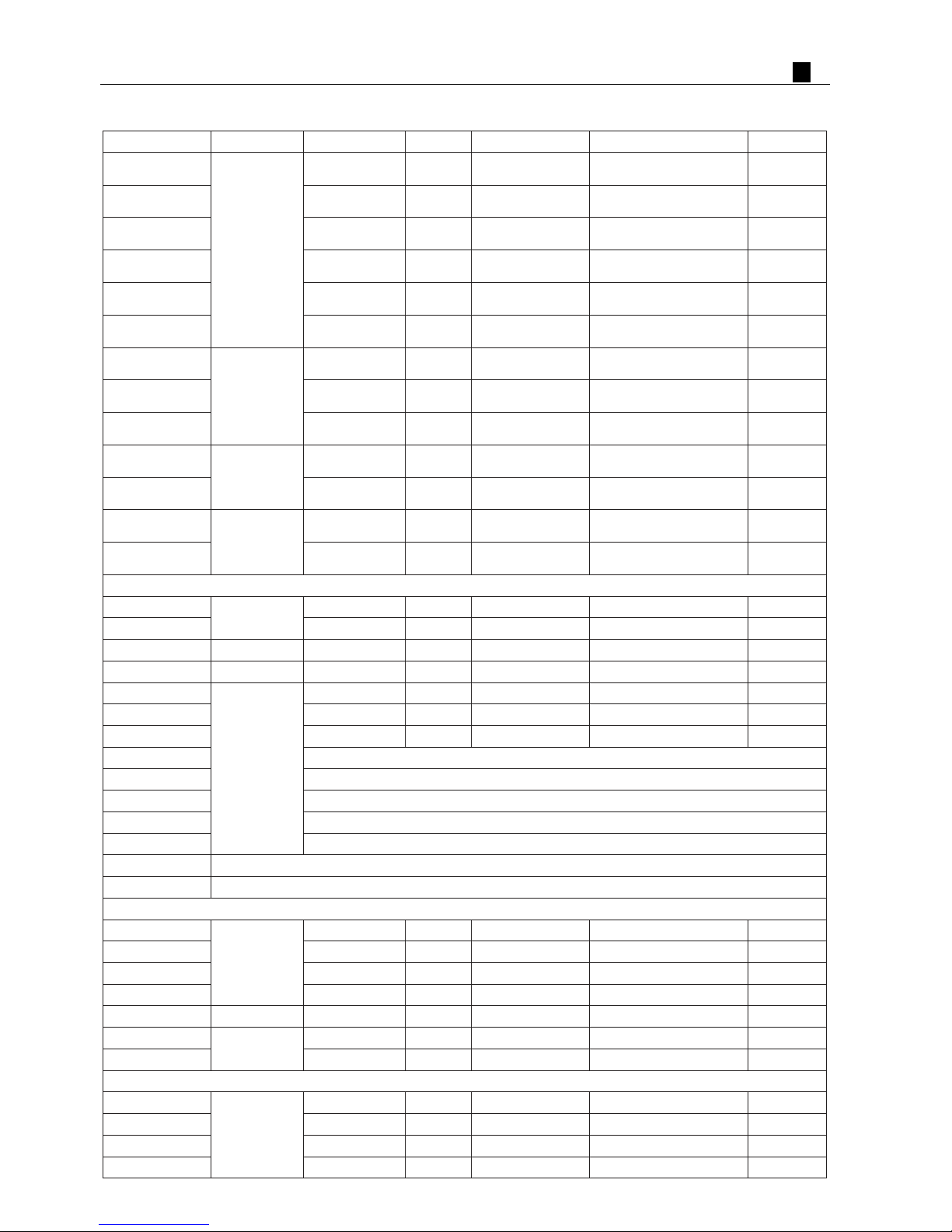

Product Specifications

Part # Input Power Inputs Outputs Display & Keypad RS-485 Communications Max I/O

SG2-12HR-D 6 DC, 2 Analog 4 Relay

√, Z01-Z04

N

/A 36 + 4 *1

SG2-12HT-D 6 DC, 2 Analog 4 Trans.

√, Z01-Z04

N

/A 36 + 4 *1

SG2-20HR-D 8 DC, 4 Analog 8 Relay

√, Z01-Z04

N

/A 44 + 4 *1

SG2-20HT-D 8 DC, 4 Analog 8 Trans.

√, Z01-Z04

N

/A 44 + 4 *1

SG2-20VR-D 8 DC, 4 Analog 8 Relay

√, Z01-Z04

Built-in MODBUS 44 + 4 *1

SG2-20VT-D

24 VDC

8 DC, 4 Analog 8 Trans.

√, Z01-Z04

Built-in MODBUS 44 + 4 *1

SG2-12HR-12D 6 DC, 2 Analog 4 Relay

√, Z01-Z04

N

/A 36 + 4 *1

SG2-20HR-12D 8 DC, 4 Analog 8 Relay

√, Z01-Z04

N

/A 44 + 4 *1

SG2-20VR-12D

12 VDC

8 DC, 4 Analog 8 Relay

√, Z01-Z04

Built-in MODBUS 44 + 4 *1

SG2-10HR-A 6 AC 4 Relay

√, Z01-Z04

N

/A 34 + 4 *1

SG2-20HR-A

100-240 VAC

12 AC 8 Relay

√, Z01-Z04

N

/A 44 + 4 *1

SG2-12HR-24A 8 AC 4 Relay

√, Z01-Z04

N

/A 36 + 4 *1

SG2-20HR-24A

24VDC

12 AC 8 Relay

√, Z01-Z04

N

/A 44 + 4 *1

Expansion Modules and Accessories

SG2-8ER-D 4 DC 4 Relay N/A

N

/A

N

/A

SG2-8ET-D

24VDC

4 DC 4 Trans. N/A

N

/A

N

/A

SG2-8ER-A 100-240VAC 4 AC 4 Relay N/A

N

/A

N

/A

SG2-8ER-24A 24VAC 4 AC 4 Relay N/A

N

/A

N

/A

SG2-4AI 4 Analog

N

/A

N

/A

N

/A

N

/A

SG2-4PT 4 Analog

N

/A

N

/A

N

/A

N

/A

SG2-2AO

N

/A 2 AnalogN/A

N

/A

N

/A

SG2-MBUS Communications Module, RS-485 ModBus RTU slaver

SG2-DNET Communications Module, DeviceNet Group2 slaver

SG2-PBUS Communications Module, Profibus-DP slaver

EN01 Communications Module, TCP/IP

GSM

24 VDC

Communications Module, EGSM 900MHz, DCS1800MHz

SG2-PL01 SG2 Programming Cable, SG2 Programming software

SG2-PM05(3rd) SG2 Memory cartridge

OEM “Blind” Models, No Keypad, No Display

SG2-12KR-D 6 DC, 2 Analog 4 Relay X

N

/A 36

SG2-12KT-D 6 DC, 2 Analog 4 Trans. X N/A 36

SG2-20KR-D 8 DC, 4 Analog 8 Relay X

N

/A 44

SG2-20KT-D

24VDC

8 DC, 4 Analog 8 Trans. X

N

/A 44

SG2-12KR-12D 12VDC 6 DC, 2 Analog 4 Relay X

N

/A 36

SG2-10KR-A 6 AC 4 Relay X N/A 34

SG2-20KR-A

100-240VAC

12 AC 8 Relay X

N

/A 44

OEM “Baseboard” Models, No Keypad, No Display, No Expansion

SG2-12CR-D 6 DC, 2 Analog 4 Relay X

N

/A 12

SG2-12CT-D 6 DC, 2 Analog 4 Trans. X N/A 12

SG2-20CR-D 8 DC, 4 Analog 8 Relay X

N

/A 20

SG2-20CT-D

24VDC

8 DC, 4 Analog 8 Trans. X

N

/A 20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 15

SG2-10CR-A 6 AC 4 Relay X N/A 10

SG2-20CR-A

100-240VAC

12 AC 8 Relay X

N

/A 20

※ If module with keypad and display, Max IO can be added keypad input Z01-Z04.

※ More information about Product Specifications to see “chapter 6: Hardware Specification”.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 16

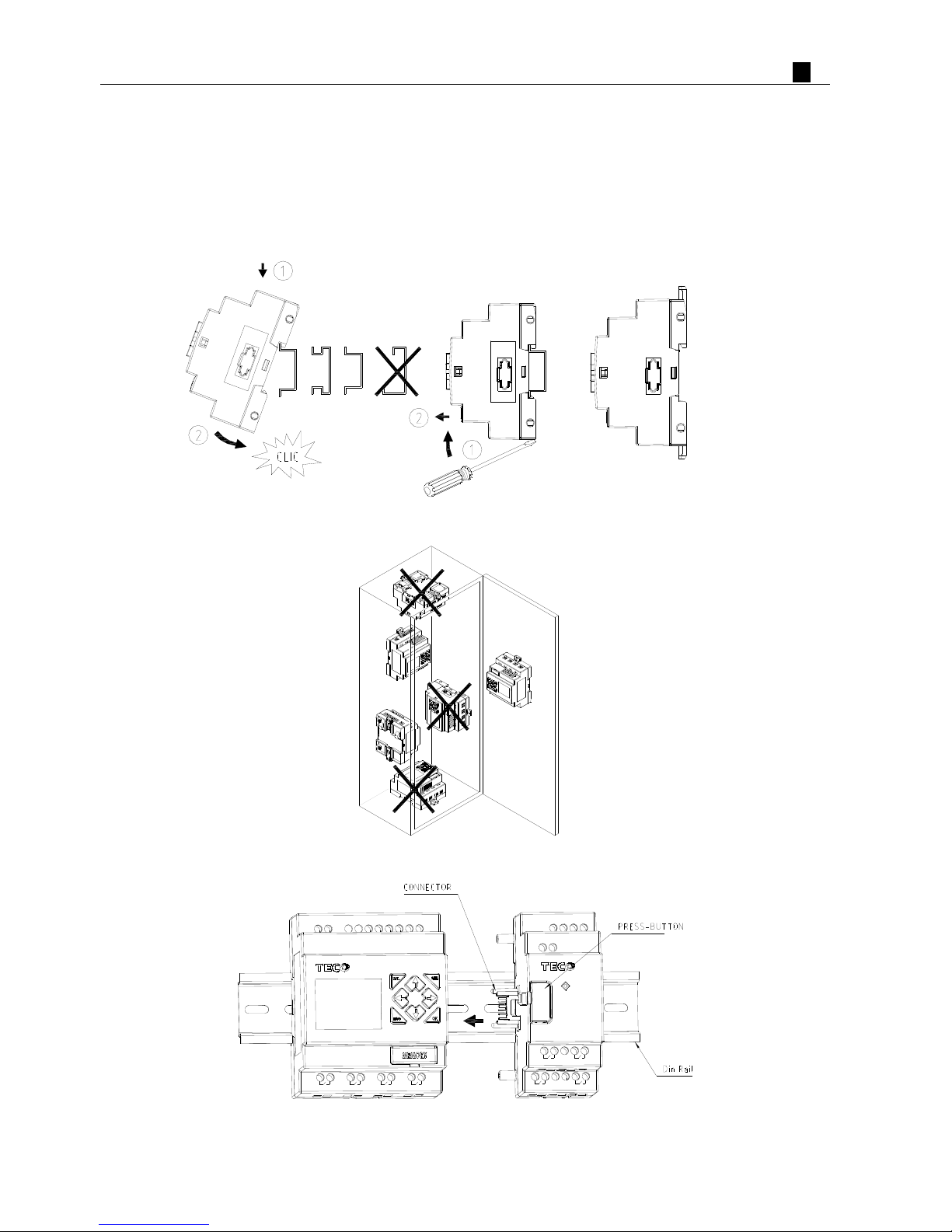

Mounting

DIN-rail Mounting

The SG2 smart relay should always be mounted vertically. Press the slots on the back of the SG2 and expansion

module plug CONNECTOR onto the rail until the plastic clamps hold the rails in place. Then connect the expansion

module and CONNECTOR with the Master (press the PRESS-BUTTON simultaneously)

SG2-8ER-A

Output 4 x Relay / 8A

Q1 Q2 Q3 Q4

DC 24V Input 8 x DC(A1,A2 0~10V)

SG2-12HR-D

+

-

I1 I2I4I3

I5

A1I6 A2

Input

4

× AC

L N

Run

AC 100~240V

X4X1 X2 X3

Output 4 x Relay / 8A

Y1 Y2

Y3 Y4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 17

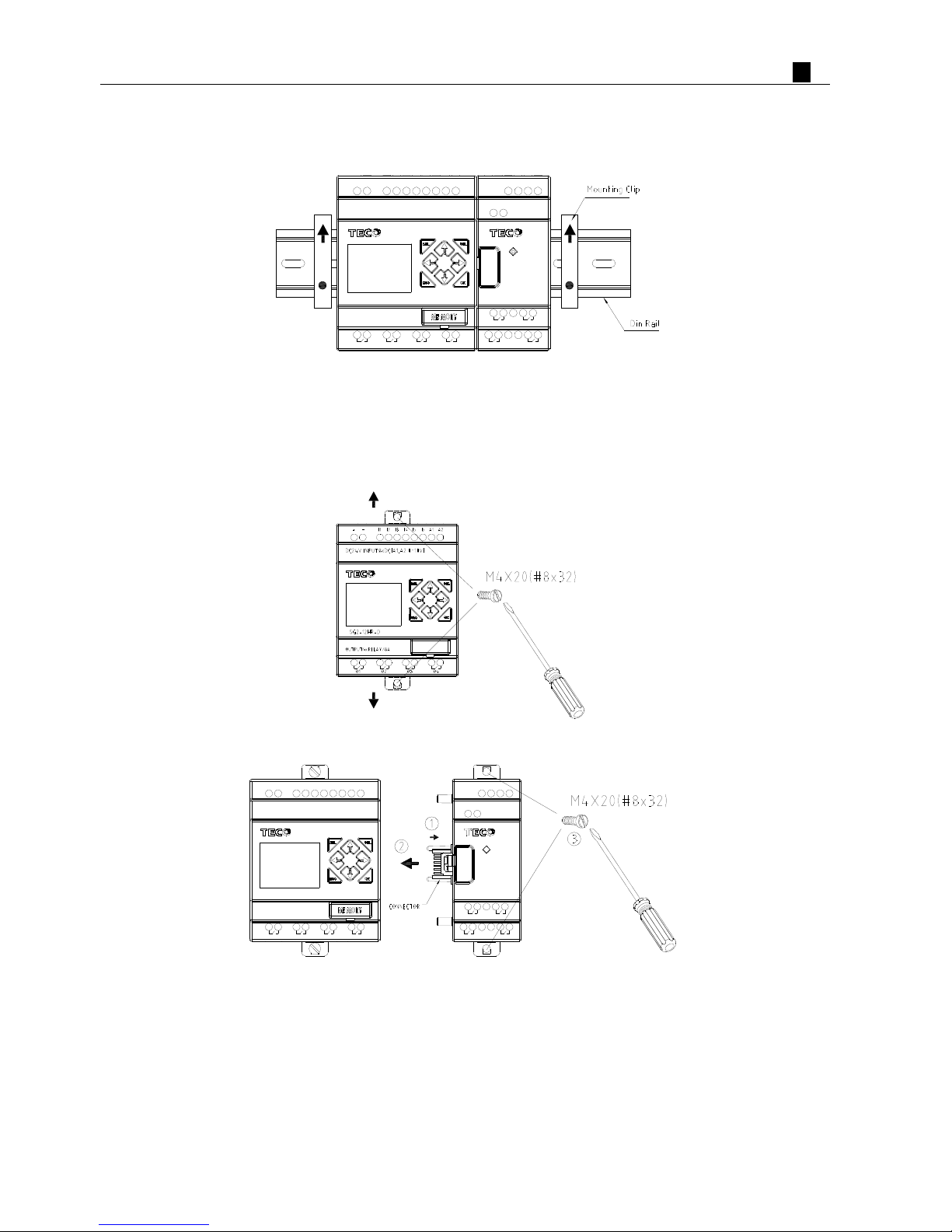

It is recommended to apply a DIN-rail end clamp to hold the SG2 in place.

Q3Q1

Output 4 x Relay / 8A

SG2-12HR-D

Q2

SG2-8ER-A

Q4

DC 24V Input 8 x DC(A1,A2 0~10V)

+

-

I1 I3I2 I4

Input

4

× AC

A2I6I5 A1

Run

AC 100~240V

N

L

X2X1 X3 X4

Output 4 x Relay / 8A

Y1 Y2

Y4Y3

Direct Mounting

Use M4 screws to direct mount the SG2 as shown. For direct installation of the expansion module, slide the

expansion module and connect with the Master after the Master is fixed.

Q2

Output 4 x Relay / 8A

SG2-12HR-D

Q1

Y1 Y2

Q3 Q4 Y3 Y4

SG2-8ER-A

Output 4 x Relay / 8A

Run

DC 24V Input 8 x DC(A1,A2 0~10V)

+

-

I1 A2I3I2 I4 I6I5 A1

Input

4

× AC

AC 100~240V

LN

X1

X3X2 X4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 18

Wiring

WARNING: The I/O signal cables should not be routed parallel to the power cable, or in the same cable trays

to avoid the signal interference.

To avoid a short circuit on the load side, it is recommended to connect a fuse between each output terminals

and loads.

Wire size and Terminal Torque

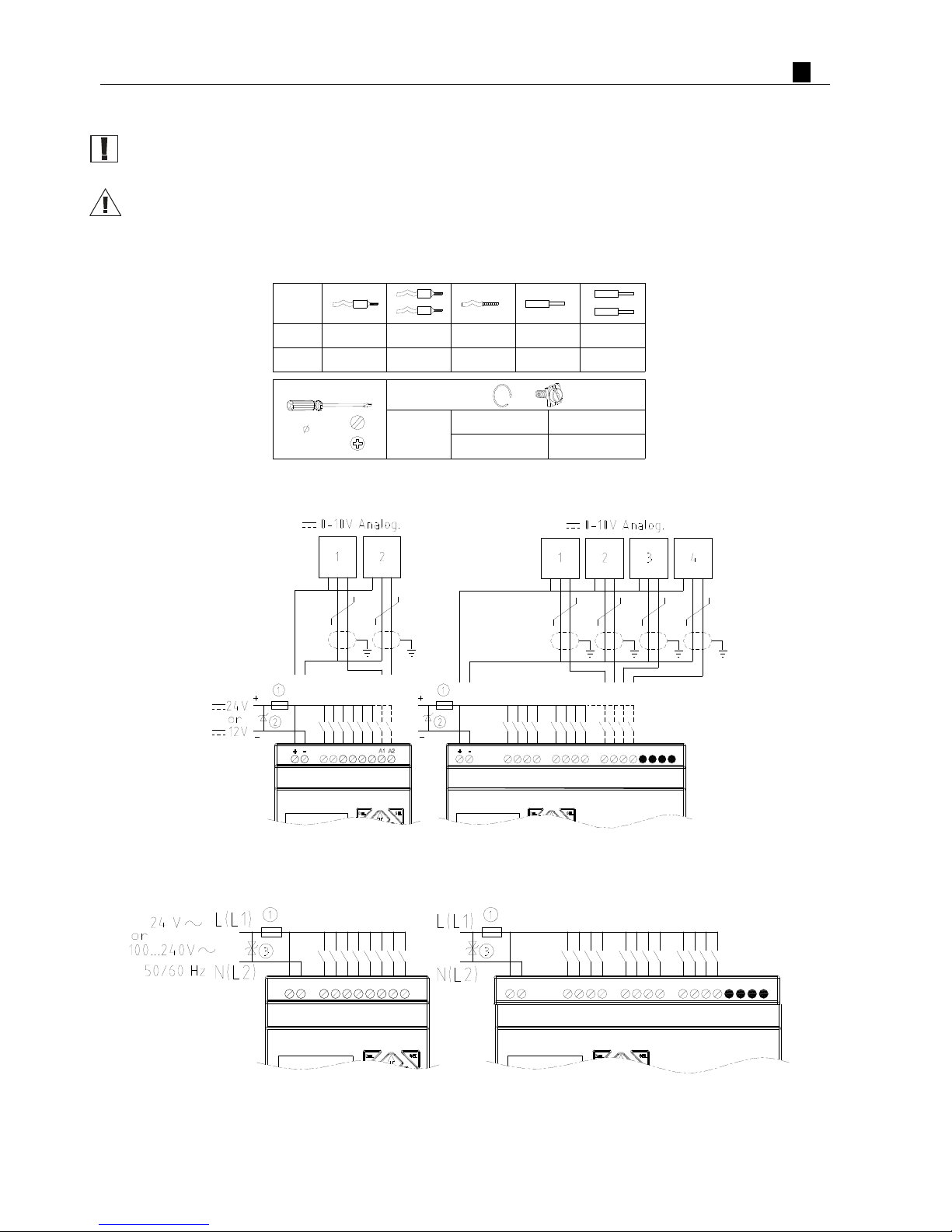

Input 12/24V DC

Input 100~240V /24V AC

26...1626...1426...1426...1826...16

AWG

3.5

(0.14in)

lb-in

Nm

0.6

5.4

0.14...1.5

mm

2

0.14...1.50.14...2.50.14...0.75 0.14...2.5

C

C

10/12 POINTS 20 POINTS

+

-

A1 A2

-

+

A2

A1

A3

A4

12 POINTS 20 POINTS

A1 A3A2 A4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 19

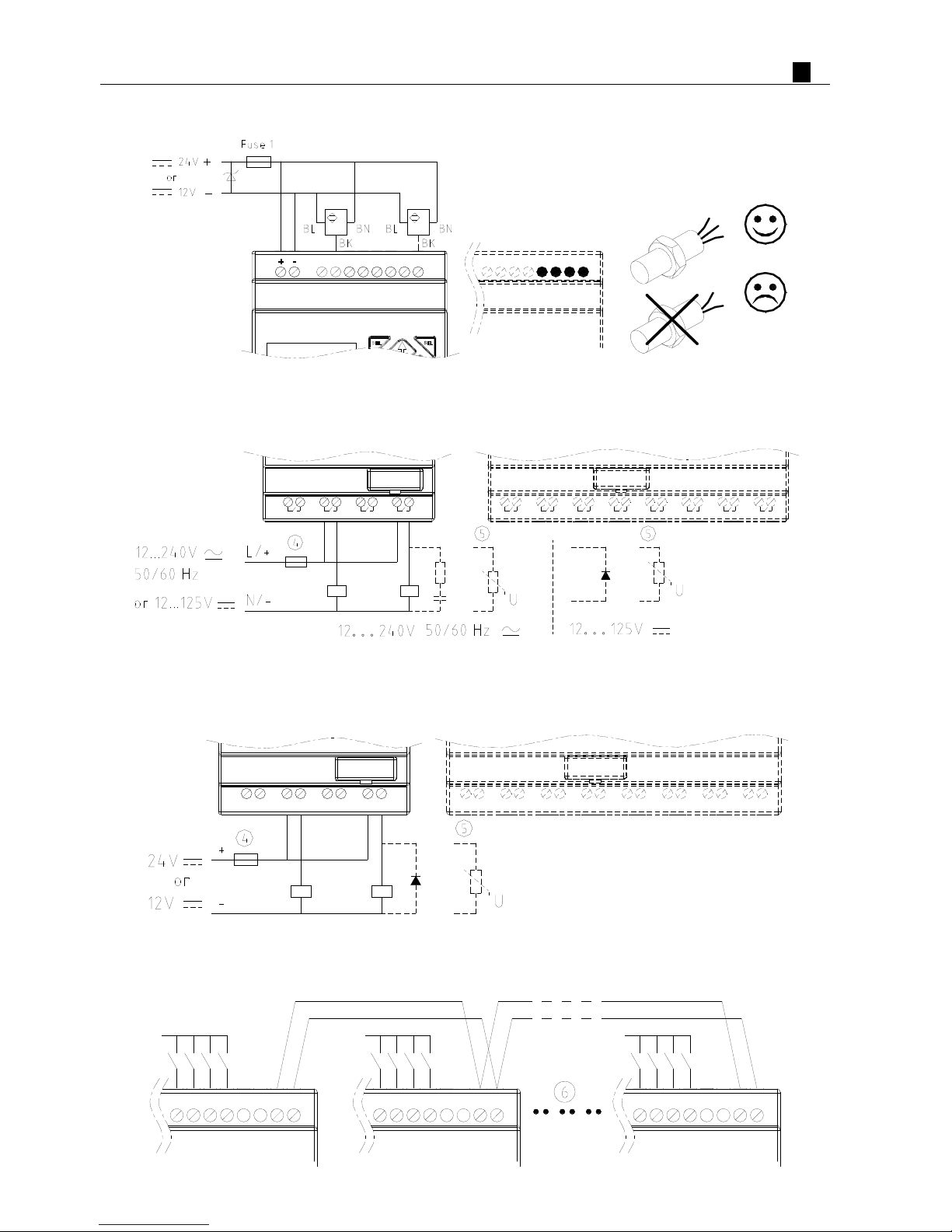

Sensor Connection

Output (Relay)

Output 4 x Relay / 8A

Q1 Q4Q3Q2

Output 8 x Relay / 8A

Q6Q2 Q3Q1 Q4 Q5 Q8Q7

Output (Transistor)

OUTPUT 8 x TR / 0.5A

Q1 Q2

Q4Q3Q1 Q2

OUTPUT 4 x TR / 0.5A

-

+

-

+

-

+

-

+

+

-

+

-

Q8Q7Q5 Q6Q3 Q4

+

--

++

-

++

--

+

-

IO Link OR Remote I/O Link

A2A3 A4A1 A2 A1

RS485

BA A3 A4

RS485

BA A3A1 A2 AB

RS485

A4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 2 Installation 20

The power supply and the I/O supply should share the same power source. Only short circuit the first and the last

module.

When I/O link, the net can connect 8 products in max. (ID: 0-7).

When Remote I/O is available, it only can connect 2 products max (Master & Slaver).

※ More information about RS485 Model communication to see “Chapter 7 20 Points RS485 type Models

Instruction”.

①-1A quick-blowing fuse, circuit-breaker or circuit protector

②-Surge absorber (43V DC)

③-Surge absorber (Input 24VAC:43V; Input 100~240VAC:430V AC)

④-Fuse, circuit-breaker or circuit protector

⑤-Inductive load

⑥-Comply with standard: EIA RS-485.

K type Indicator Light

There is an indicator light to indicate the status of SG2 (K type) smart, and the below table shows the

relationship between the light an d the SG2 status.

State of light Description

Power up, SG2 is stopping

Flicker slow(1Hz), SG2 is running

Flicker quick(5Hz), SG2 is under failure status

—Flash error

—Illogicality in user program

—Expansion model error

—RTC error

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 3 Program Tools 20

Chapter 3: Program Tools

PC Programming Software “SG2 Client”.........................................................................................................21

Installing the Software .................................................................................................................................. 21

Connecting the Software............................................................................................................................... 21

Start Screen ................................................................................................................................................... 21

Ladder Logic Programming Environment .................................................................................................... 22

Menus, Icons and Status Bar................................................................................................................. 23

Programming......................................................................................................................................... 24

Simulation Mode................................................................................................................................... 25

Establish Communication ..................................................................................................................... 25

Writing Program to smart relay............................................................................................................. 26

Online Monitoring/Editing.................................................................................................................... 27

Operation menu..................................................................................................................................... 28

HMI/TEXT............................................................................................................................................ 29

Program Documentation ....................................................................................................................... 33

Analog Output Set…............................................................................................................................. 35

3-Row/5-Row........................................................................................................................................ 36

Data Register Set…............................................................................................................................... 37

View menu ............................................................................................................................................ 39

FBD Programming Environment .................................................................................................................. 40

Menu, Icons and Status Bar................................................................................................................... 40

Programming......................................................................................................................................... 41

Simulation Mode................................................................................................................................... 42

Online Monitoring/Editing.................................................................................................................... 42

Symbol and Parameters list................................................................................................................... 43

Memory Cartridge (sold separately)................................................................................................................. 45

LCD Display and Keypad................................................................................................................................... 46

Keypad .......................................................................................................................................................... 46

Original Screen ............................................................................................................................................. 47

LCD Display Main Menu.............................................................................................................................. 50

RTC Daylight saving setting....................................................................................................................... 55

SG2 system error......................................................................................................................................... 59

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 3 Program Tools 21

PC Programming Software “SG2 Client”

T he SG2 Client programming software provides two edit modes, Ladder Logic and Function Block Diagram

(FBD). The SG2 Client software includes the following features:

1. Easy and convenient program creation and editing.

2. Programs can be saved on a computer for archiving and reuse. Programs can also be uploaded directly from a SG2

and saved or edited.

3. Enables users to print programs for reference and review.

4. The Simulation Mode allows users to run and test their program before it is loaded to the controller.

5. Real-time communication allows the user to monitor and force I/O on the SG2 smart relay operation during RUN

mode.

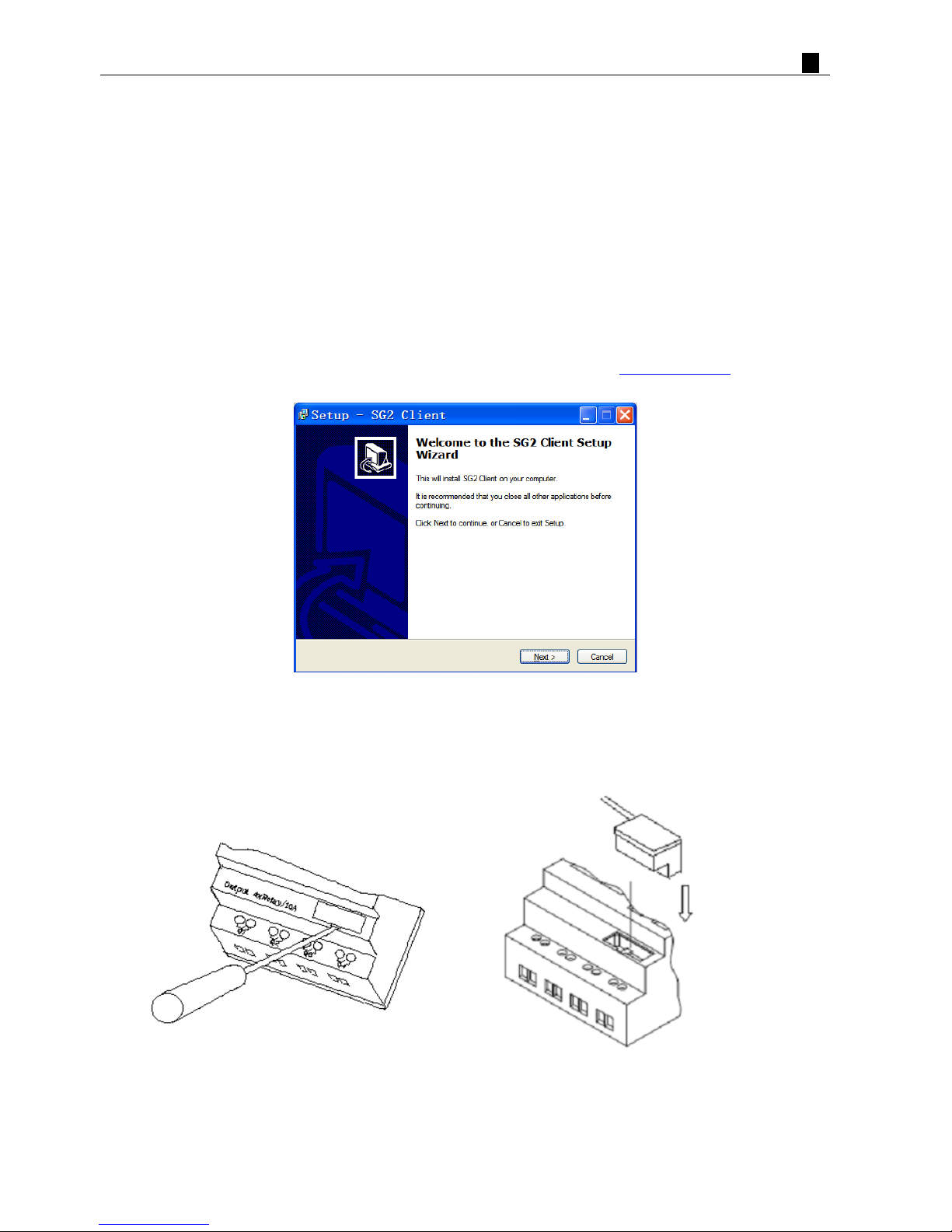

Installing the Software

Install the SG2 Client Software from CD or from the free internet download at www.teco.com.tw

Connecting the Software

Remove the plastic connector cover from SG2 using a flathead screwdriver as shown in the figure below. Insert

the plastic connector end of the programming cable into the SG2 smart relay as shown in the figure below. Connect

the opposite end of the cable to an RS232C serial port on the computer.

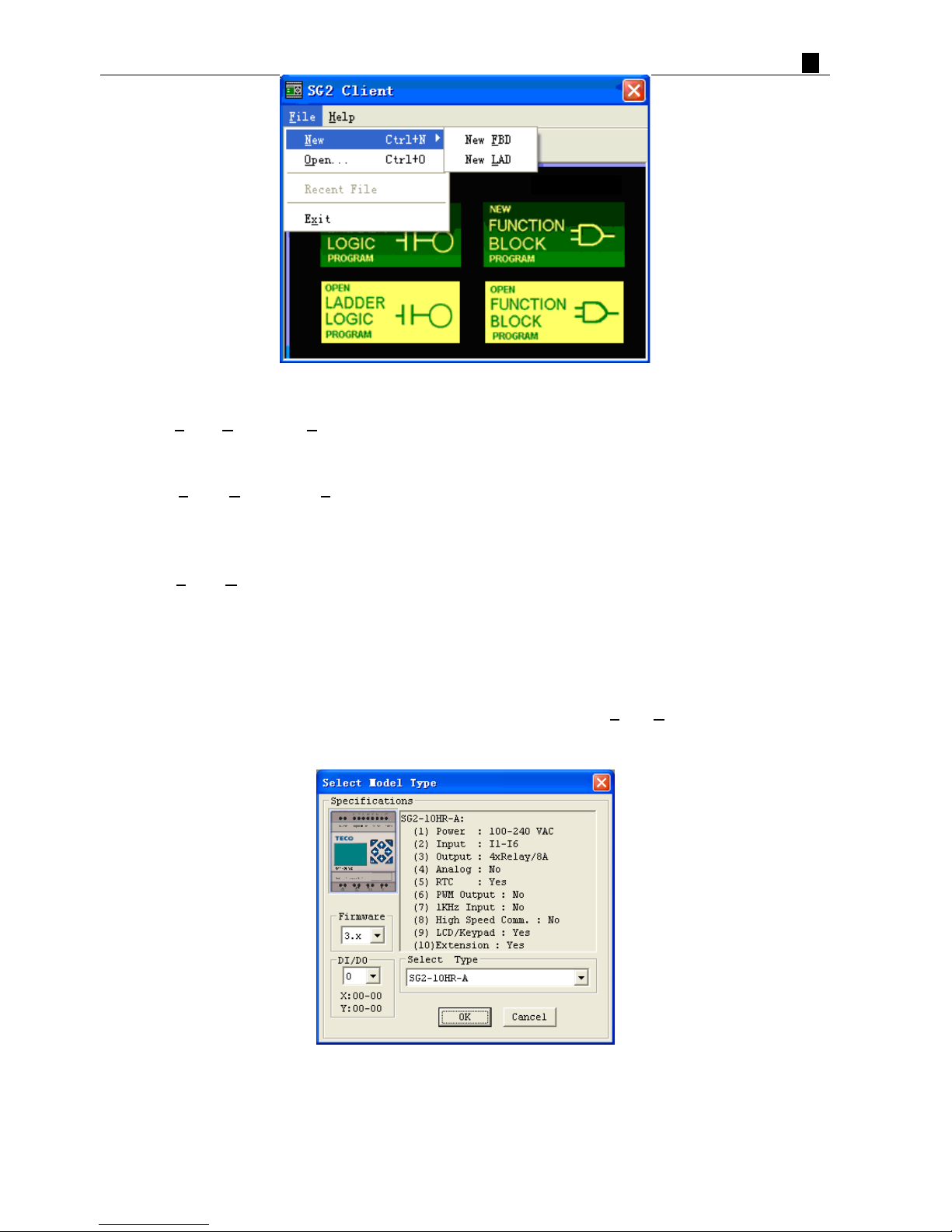

Star t Screen

Run the SG2 Client software and the below Start screen will be displayed. From this screen, you can perform the

following functions

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chapter 3 Program Tools 22

New Ladder Program

Select F

ile -->New -->New LAD to enter the development environment for a new Ladder program

.

New FBD Program

Select F

ile -->New -->New FBD to enter the development environment for a new FBD (Function Block

Diagram) program.

Open Existing File

Select F

ile -->Open to choose the type of file to open (Ladder or FBD), and choose the desired program file,

and then click Open.

Ladder Logic Programming Environment

The Ladder Logic Programming Environment includes all the functions for programming and testing the SG2

using the Ladder Logic programming language. To begin a new program select F

ile-->New, and select the desired

model of SG2, and the number of connected expansion units if applicable, as shown below.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...