TECO seachill tr5, seachill tr10, seachill tr20, seachill tr30, seachill tr15 Operator's Manual

...Page 1

P

age 1

operators’

manual for all models:

TR5 TR10 TR15

TR20 TR30

TR60

Page 2

P

age

2

P

age 3

Purchased From

Date Purchased

Date Installed

Table of Contents

Safety ........................................................................... 4

Notes:

About This Manual

This manual covers basic operation and maintenance for all current models

of the Teco SeaChill under normal operating conditions. For more detailed

information or uses not covered in this manual please contact us.

Contact Us

United Kingdom distributor:

TradeMark Aquatics Ltd

Tel: 01509 26233 0

info@trademarkaquatics.co.uk

www.trademarkaquatics.co.uk

Model Number

Serial Number

Specifications

. . .. . . . .. . . . . . . . . . . . . .. . . . . . .

5

F

eatures . . .. . . . .. . . . . . . . . . . . . .. . . . . . .

6-7 Rec

eiving and Inspection

. . .. . . . .. . . . . . . . . . . . . .. . . . . . .

8

Parts

List . . .. . . . .. . . . . . . . . . . . . .. . . . . . .

9-10

Installation and As

sembly

. . .. . . . .. . . . . . . . . . . . . .. . . . . . .

11-14

Oper

ation and Settings

. . .. . . . .. . . . . . . . . . . . . .. . . . . . .

15-17

Maint

enance

. . .. . . . .. . . . . . . . . . . . . .. . . . . . .

18-22

Troubleshooting

. . .. . . . .. . . . . . . . . . . . . .. . . . . . .

23

Page 3

P

age 4 P

age 5

Flow Rate

T

ank Siz

e

Dimensions

C

onnections

300

litres

180 - 600 gph

90 - 200 g 130 - 400 g

17" x 10 5/8" x 17 3/4"

5/8" or 3/4" Quick Disc

onnect

Teco chille rs are

desig ned and built with safety as a prim e consid er

ation ; indu stry-accepted

safety f

actors have been used in the desig n. Each chille r

is

inspec ted at

the f

act

ory f

or

safety and operation. Any necessary adjustments are made before shipment. Follow

the main tenance

sched ules outli ned in this manua l for

optim um perfo rmance

and safe

operation. Any repairs should be done only by qualified perso

nnel with proper training and

t

ools.

Car

efull y r

ead

all

safety r

equir ements before inst allation , opera tion or main tenanc

e.

The requirements are essential to ensure safe operation. Failure to follow these guidelines

v

oids the warranty and may r

esult in chill er damage or

persona l injur y.

•

Do

not install or try to r

epair a chiller that has been damaged in shipment.

See Receiving

And

Inspection for instructions.

• Turn off and unplug the chiller before pr

eforming any work. Electricity

has the pot

ential to

cause personal injury or equipment damage.

•

Do

not operate

the chiller at temperatures above

the maximum ambient temperature (95˚F

/35˚C)

•

Always supply electrical power that complies with the v

oltage

shown on the data label.

below the electrical outlet - this prevents water from reaching the outlet in the ev

ent of a leak.

• It is

rec

ommended that this pr

oduct be used with an

RCD (residual current device)

outlet.

•

Do

not look directly at an illuminated UV

light. (if installed)

•

Do

not operate

chiller without water flo

wing thr

ough it.

• Never

allow

heater to be on without water flo

wing though the chiller.

•

Do

not run pressurized

water thr

ough chiller. Chillers are designed to accept water flow from

recir

culating pumps. Pressure

pumps or high-pressure

water lines

will

damage

the chiller. If

in

doubt about your pump, c

ontact the pump manufacturer.

Safety

Specifications

Watts

200 230

420

•

Work on the refrigeration system must be done only by a licensed refrigeration technician.

Volts/Hz

110/60

•

Do not plug into wall socket without the housing in place.

dB / dB

(silent Mode)

39 / 37 40 / 38

41/ 39

•

Configure the electrical cord to include a “drip loop” - a loop section of chord that hangs

Weight

15 kg 39.5

lb.

44 lb.

HP

Amps

1/2 1

7.2

8.6

W

atts

818

980

110/60

111 lb.

V

olts/Hz

110/60 W

eight

96 lb. Flow

Rate

270 -

810 gph T

ank Size

up to

750 gallons

up to

1300 g

allons Dimensions

24" x

15" x 22"

C

onnections

1"

TR60 TR30

HP

1/8

1/5 1/3

Amps 2.5 2.6 3.9

TR20 TR15 TR10

HP

1/12

Amps

1.9

W

atts 180

V

olts/Hz 110/60

W

eight

14 kg

Flow Rate

500 l/hr

T

ank Size up to 150 litres

Dimensions

12.5" x 9

.5" x 13.5"

C

onnections

16mm or 20ml

Quick Disc

onnect

TR5

Page 4

P

age 6 P

age

7

H

B

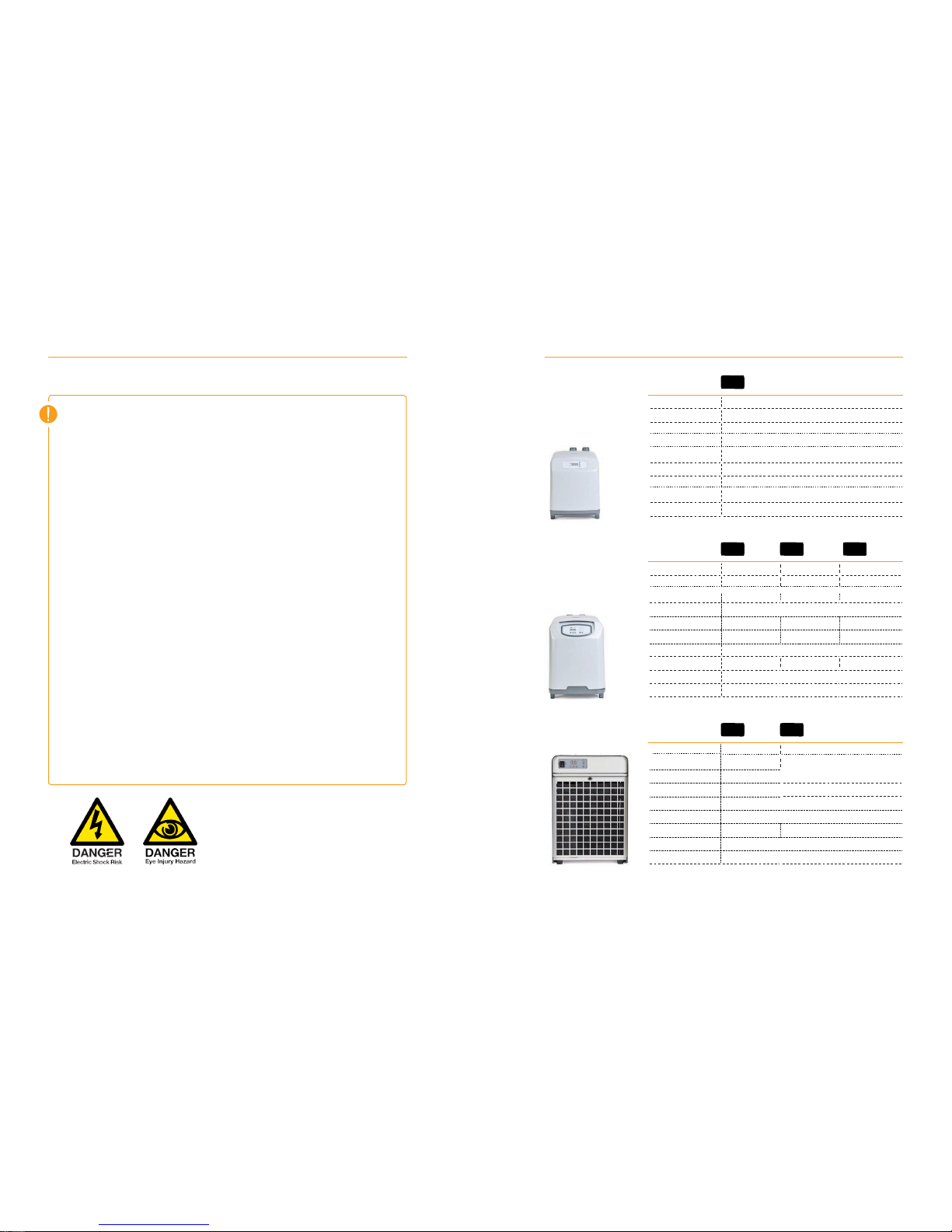

Features

J

A

Ventilation Grate

B

Air Filter

C

Control Panel

J

D

In Port

F

E

Out Port

L

F

Power Socket

D E

G

UV Port(s)

(Optional Accessory)

H

Heater Port(s) (Optional Accessory)

C

I

UV Ballast(s)

J

Compressor

A

H

G

K

Heat Exchanger

L

Condenser

M

Vent

Fan(s)

J

M

K

TR10

TR15

D E

TR20

M

L

A

K

TR30

A

F

C

B E D

I

I

H/G

TR30

TR60

TR60

M

L

J

K

TR5

TR5

TR10

TR15

TR20

Page 5

P

age 8 P

age 9

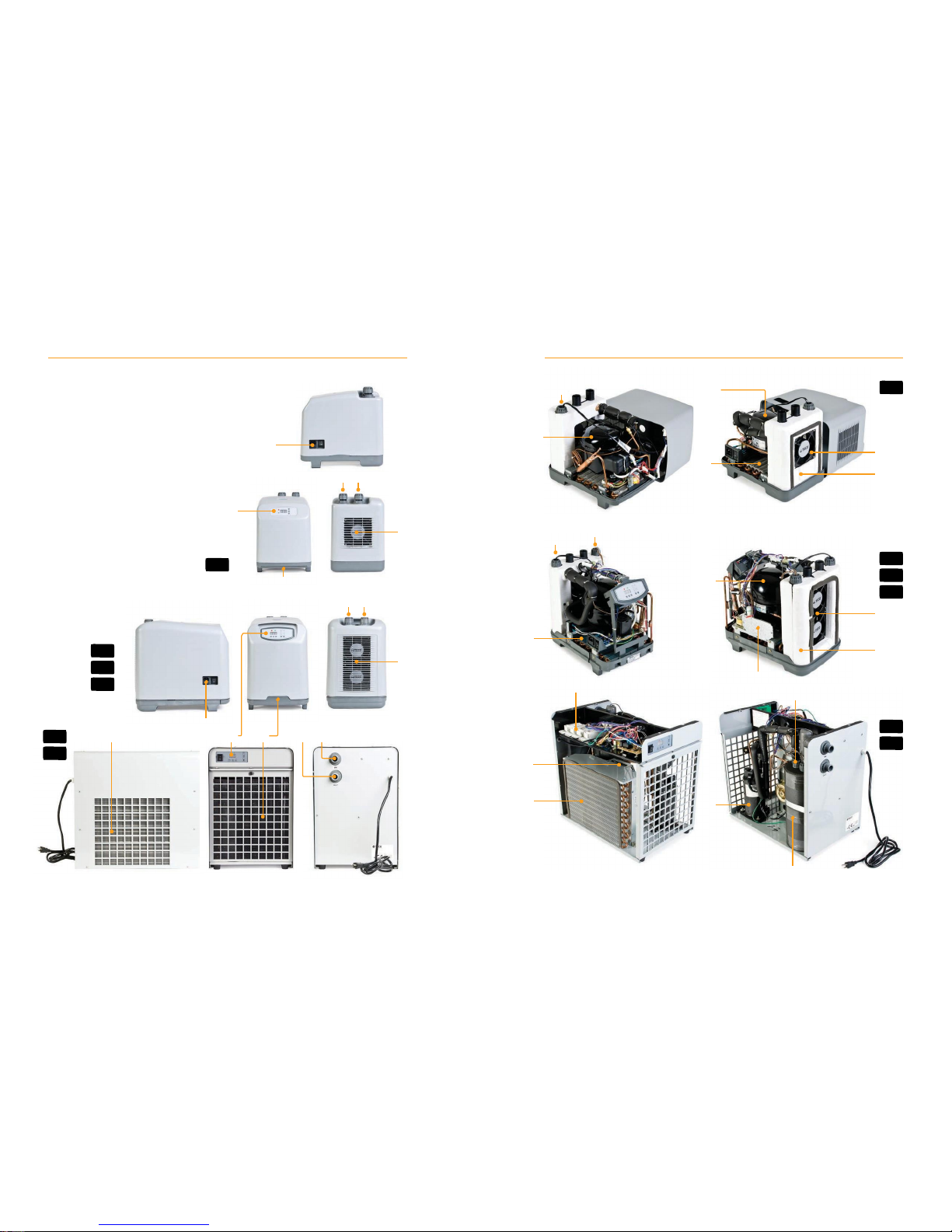

W

asher

TR10 TR15 TR20

TR5

TR30 TR60

Receiving and Inspection

Included Parts List

1

Inspe ct the chiller clo sely upon rec eipt.

Record any indicatio n of damage and contact seller immediately.

2

Save the box and packing mater ials

If your chiller ever needs to be repaired or servic ed, you will need to ship it in the original box.

3

Record your Model and Serial Number for easy referen ce

There is a space on the first page of this manual to record this informat ion. You may be asked

for the serial number when calling for support .

In / Out Plugs

Located in the in/out ports of the

chiller (2) Attached to chiller

Shutoff Valve

(2)

Elbow

chiller (2) Attached to chiller

Ring Nut

Attached to chiller (2)

WARNING:

When the chillers are inverted during maintenance or shipping, you must let the unit

sit for at least 30 minutes upright to allow the coolant to settle: failure to do this before

O Ring

Attached to chiller (2)

Ring Nut

turning on the chiller may result in damage to the compressor.

Serial and Model Number Location

Housing Ring Nut

Attached to chiller (2)

Housing Gasket

Attached to chiller (2)

Located in the in/out ports of the

chiller (2) Attached to chiller

Located in the in/out ports of the

chiller (2) Attached to chiller

Power Cord

TR30/60 - Power Cord is attached to chiller

Fuse

1 installed, 1 spare

Air Filters

1 installed, washable / reusable

Bottom

Front , Underneath the Air Filter

Air filter must be removed to

access the serial and model number

Back

Note: Color and appearance of actual parts may vary slightly

TR30 TR60

TR5 TR10 TR15 TR20

NO

TE:

Our Quality Control

proc

edure

includes running water thr

ough the chiller to test the

c

ooling capacity. There

may be r

esidual water in the unit due to this method of testing,

this

is

normal.

Page 6

P

age 10 P

age 11

Optional Parts

Installation and Assembly

Flow Indi cator

400 W Heater Kit - TR5 Only

15 W UV Sterilizer Kit

Teco SeaChill Chillers are intended for indoor operation. Do not expose chiller to outside elements or direct

sources of heat. Maximum allowed ambient temperature is 95°F/35°C. Do not operate chiller in temperatures

over 95°F/35°C.

If the chiller is placed in an enclosed space (a cabinet or aquarium stand) it must have an air inlet as well as

a ventilation outlet. The air inlet should be at least the same size and dimensions as the air outlet and can be

placed to face the sides or front of the chiller.

Chiller must have a space of at least 8 in/20 cm between the ventilation grate and the wall for proper ventilation

to take place. If the chiller is inside of an enclosed aquarium stand the chiller will need to be 8 in/20cm from the

walls of the stand. If ventilation grate or fans must be placed closer than 8 in/20 cm to the wall, it is necessary

to create a ventilation outlet the same size and shape as the chiller ventilation grate or fans in the wall.

Required Parts and Tools (not Included)

Flexible Tubing

Pump with the recommended flow rate (see flow-rate specs on page 5)

Teflon Plumbers Tape (for PVC plumbing) or pipe thread sealant with Teflon

Tools you may need:

(for maintenance) Tongue & Groove Pliers, flat-head screwdriver, Phillips-head screwdriver, pliers

15 W Replacement UV Lamp

400 W Heater

Kit

ALL MODELS

W

ARNING:

The SeaChill w

ill produce excessive heat and not work properly if not placed in a

well ventilated area. C

ompressor

damage may occour.

W

ARNING:

Before cutting a v

entilation hole or grate in an aquarium stand, contact the stand

manufacturer to insure

that you

will

not compromise the structural int

egrity of the stand.

Page 7

P

age 12 P

age 13

Valve Assembly

Plumbing

1

Unscrew the Ring Nuts for the

shut off valves from the chiller

inlet and outlet. Remove the In/

Out plugs from the In/Out ports

of the chiller. Remove the O-rings

SeaChill Chillers can be plumbed using flexible plastic tubing or hard

plumbed using PVC.

Flexible Tubing

Above photos are of a TR5 model

from In/Out plugs. (do not discard

In/Out plugs– store for use should

you ever need to transport or ship

the chiller to another location).

2

Slide the Ring Nuts onto the Shut

Off Valves past the two small clips

of plastic projecting from the side

of the Shut Off Valves.

Note: Once Ring Nut s have been

pushed past the plastic clips on the Sh ut

Off Valves, do not rem ove Ring Nut

from Shu t Off Valves, this will break the

plastic clips, causing the valve to leak.

3

Roll the O Rings onto the Shut

Off Valve below the Ring Nut.

Do not push O Ring past plastic

clips on Shut Off Valves.

4

Place the Shut Off Valve into

the Outlet of the chiller, do not

use much force. Hand tighten

the Ring Nuts to seat the O-Ring

and attach the Shut Off Valve

Securely to the chiller.

Note: the first nipple on the Shut O ff

Valves will take 5/8” id tu bing. The

seco nd, l arger nip ple will accept 3/4” id

tubin g. R emove comp resss ion fittin g fo r

5/8” tubin g befo re us ing 3/4” tubing.

Use t he tubing size you prefer.

1

PVC

1

2

3

4

Attach flexible plastic tubing from the pump to the chiller

by sliding tubing over nipple on Shut Off Valves. Tighten

Compression Fitting over the end of the flexible plastic tubing

by turning fitting counter-clockwise until tubing is secure.

Note: If the chiller should ever need maintenance, it will be necessary to remove the

chiller cover. Do not hard plumb PVC to the chiller. Plan ahead and use ball valves or

gate valves to allow water flow to be shut off. Install unions to allow for the removal

of the chiller cover.

Recommende d PVC part s

(may be either schedule 40 or schedule 80 PVC)

For installation using PVC solvent socket type fittings:

•

1” FPT x Slip adapters (2)

•

1” PVC pipe, 1” Slip x Slip Ball Valves (2)

•

1” Slip X Slip Unions (2)

•

Teflon tape or pipe thread sealant with Teflon

Unscrew the Ring Nuts for the shut off valves from the chiller inlet

and outlet. Remove the In/Out Plugs from the In/Out ports of

the chiller (do not discard In/Out plugs – store for use should you

ever need to transport or ship the chiller to another location).

Keep the Housing Ring Nuts in place, wrap the male threaded

inlet and outlet from the chiller in Teflon tape or pipe thread

sealant with teflon to prevent leaks. Wrap Teflon tape at least

twice around threads. Check carefully for leaks. Slow leaks

may occur.

Screw the 1” FPT x Slip adapters over inlet and outlet to chiller.

Tighten firmly but do not use excessive force.

Assemble the remaining PVC as you wish making sure you can

easily unscrew the 1” FPT x Slip adapters to maintenance the

chiller if necessary.

ALL MODELS

W

ARNING: Do Not

Ov

ertighten T

hreaded

C

omponents to

Chiller:

T

ighten

firmly but do not use

excessive force.

Use t

ools and

mat

erials appr

opriate for use

with plastic components.

TR5 TR10 TR15 TR20

W

ARNING:

Do Not Ov

ertighten The

Shutoff Valves or Ring Nuts

The

shut-off v

alves should be able to r

otate

easily after tight

ening; overtight

ening may

cause water leaks or

permanently damage

your chiller.

Page 8

P

age 14 P

age 15

Typical Installations

Submersible Pump Installation

Closed Loop

Water is being run through the chiller

Operating Your Chiller

Starting Your Chiller

by a separate pump and returned

back to the sump.

External Pump Installation

Inline

In this installation the chiller is

plumbed between the main return

pump and the tank. Be sure that

the flow rate is not too high in this

situation. If it is, use a ball valve off of

the main line into the chiller to slow

the water flow.

1

Open the Shut Off Valves by rotating the valve

counterclockwise.

2

Turn on the pump from the aquarium to the chiller.

3

Check for leaks and adjust as needed.

4

Make sure water is circulating through the chiller at an

appropriate rate. (see chart)

5

Plug the chiller Power Supply Cable into the chiller and the

other end into an appropriate compatible source of electricity.

6

Turn power switch on.

Relocation after Installation

Canister Filter

In this installation water travels

through the canister filter into the

chiller where it is returned into

the aquarium. With this type of

installation filter the aquarium water

before it passes through the chiller to

reduce build up in the chiller.

1

Rotate the Shut Off Valves to the closed position.

2

Loosen the ring nuts for shut off valves.

3

Remove shut off valves from chiller inlet and outlet.

4

You may then move the chiller to another location

Note: If you are mo ving the chiller a long dist ance, it may be ne cessary

to place t he in/out plugs in t he in/out ports o f the chiller . Be sure to put

o-rings on in/out pl ugs before you put th em in the in/o ut por ts.

Note: These setup diagrams are intended to provide general examples of common plumbing arrangements, this does not cover all possible situations.

Pump, tubing, plumbing accessories are not included.

TR5

TR10,

TR15,

TR20

TR30, TR60

150gph - 27

0gph

180gph -

600gph

27

0gph - 810gph

ALL MODELS

PUMP

PUMP

PUMP

ALL MODELS

Page 9

P

age 16 P

age 17

Setting & Controlling Your Chiller

Setting & Controlling Your Chiller

Control Panel

All Teco Seachill models share the

same control functionality. The

following directions apply to all models,

with exceptions for Silent Mode, UV

Sterilizer, and Heater for models that do

not have those functions.

Silent Mode

1

Press “SILEN T”

when the chiller is on. Silent mode slows the

ventilation fan, causing the chiller to become quieter. Press “SILENT”

again to turn silent mode off.

Note: We strongly suggest using the silent function sparingly because it

reduces the cooling capability of the chiller considerably.

UV Sterilizer

1

Press “UV” If the optional UV sterilizer is installed, pressing the

UV button will activate the sterilizer. The green led light on the UV will

illuminate to indicate the UV light is on.

Note: If the optional UV kit is not installed the light will flash on and off

UV Sterilizer is not availble on the TR5.

Switching from Fahrenheit to Centigrade

Setting Temperature

The unit has been factory set at 77˚F, to change this setting follow the

steps outlined below.

1

Turn on the chiller. The power switch is located on the side of

the chiller near the power cord, the TR30 and TR60’s switch is

located on the control panel. Once power has been turned on the

chiller will begin to operate after approximately five seconds. The

display will show the current temperature of the a quarium water

passing through the chiller.

2

Push “SET” The display will change from the current

temperature to the set temperature.

3

Push up or dow n arr ow to chang e temperatu re.

Using the up and down arrows, set the controller to the desired

water temperature. The temperature will be set automatically

five seconds after you release the button.

4

Once the chiller reaches the set temperature the unit will enter

stand-by mode; both the lights above the temperature display will

be off. When the temperature changes the chiller or heater will

cycle on as appropriate.

Note: Illumin ated gre en LED indi cates chil ler is ope rational, illumin ated red LED

indicat es heate r is opera tional. (For units with ins talled heater s).

1

Press and hold both up

and

down arrows simu ltaneously

for 10 seconds. The display will automatically change from degrees

Fahrenheit to degrees Centigrade. To change back, repeat process.

Changing Temperature Display

The chiller reads the temperature from the water passing

through it, a thermometer reading directly from the tank may

be reading a different temperature depending on your specific

setup. Use this function if you would like to match the chiller’s

thermometer to a separate thermometer.

1

Press and hold “SET” for 10 secon ds.

The display will show a value of 1 or 1.5 (do not change this setting)

2

Press “SET” again

The water temperature (not the set point) will be displayed.

3

Push up or down arrow to change temperatur e.

After five seconds, the setting is entered into memory and the display

will return to full brightness. The unit will now function normally with the

new calibrated temperature.

TR10 TR15 TR20

TR10 TR15 TR20 TR30 TR60

ALL MODELS

ALL MODELS

TR5 TR10

TR15

TR20

TR30 TR60

ALL MODELS

Page 10

P

age 18 P

age 19

Cleaning the Air Filter

Removing Housing

Remove the filter from the bottom of the chiller.

Use a screwdriver to turn the plastic bolt 90˚

clockwise. (so the slot is verti cal to the ground)

This unlocks the ventilation grate and allows

you to remove the air filter.

1

Turn off and unplug the chiller. 2 Remove shut off valves by

unscrewing ring nuts. Remove housing ring nuts and gaskets.

You may need to

use a wrench or pliers to loosen the ring nuts,we recommend placing a cloth over

the ring nut to prevent damage to the plastic. 3 Pull out the air filter.

Unscrew and remove screws on the b ottom.

Use a phillips head screwdriver. You

may have to move the chiller to the edge of a table to do this.

4

Remove the housing.

Housing will remain attached to chiller via electric cables. Grasp the

bottom of the chiller and the edge of the power socket, pull up and turn housing over and to the side. Do not

operate the chiller until housing is replaced.

It is essential to keep the air filter on the SeaChill clean. A clean air filter will e nsure the unit is running at

maximum efficiency. All units have a sensor that will alert you if the air filter is being blocked. If the digital

display reads “AL1” this means the a ir filter is dirty or obstructed, and should be cleaned immediately.

1

For prope r operation , clean the filte r onc e per month.

2

Use a vacuum clean er or rinse the filte r unde r a sink unt il filt er is clean.

Do not use soap or o ther

cleaning chemica ls. Do not allow chiller to run for extended period s of time without an air filter.

1

Turn off and unplug the chiller. 2 Remove shut off valves b y unscrewing ring n uts Remove

housing ring nuts and gaskets.

You may need to use a wrench or pliers to loosen the ring nuts, we recommend

placing a cloth over the ring nut to prevent damage to the plastic 3 Pull out the air filter. Remove the

housing. First pull up on the case at the bottom, then pull up by gripping the back and the front control panel

recess. Do not operate the chiller until housing is replaced.

1

Turn off and unplug the chiller. 2 Remove screws from housin g. Sli de ho using about 8" (20 cm

back. Unplug green ground wire from housi ng. Slide the housing off.

Keep the plastic washers t hat come

with the housing screws, these prevent chipping of the housing powder coat. 3 Slide Ho using

completel y off. Do not operate the chiller until housing is repla ced.

TR30 TR60

TR10 TR15 TR20

TR30 TR60

TR5 TR5 TR10 TR15 TR20

Page 11

P

age 20 P

age 21

Changing the Fuse

Changing UV Bulb

Fuse Clip

1

Turn off and unplug the chiller before changing the fuse.

2

Remove the fuse holder from socket using a flathead screwdriver.

3

Remove blown fuse from clip and discard.

Fuse Holder

It is time to replace the UV L amp

when the AL2 code flashe s on the

control panel

4

Push out t he spare fuse ( contained in the fuse holder) , place new fuse in the clip, replace fuse holder.

1

Turn off chille r and unplug the chiller, Remove the housi ng (see directions on p.19)

2

Unscre w the ring nut for the UV ste rilizer po rt.

Changing the Fuse

Spare Fuse

Note: Some wires were removed for these photos

TR10 TR15 TR20

TR5 TR10 TR15 TR20

TR30 TR60

Page 12

P

age 20 P

age 21

3

Remove rub ber stoppe r fro m the quartz sle eve

4

Unplu g the old UV la mp from the 4-pin soc ket., remove and disc ard lamp.

5

Slide new UV lam p into quar tz sle eve, plug into 4-p in socke t, ret urn rubber stopper into

sleeve

Do not touch the glass of the UV bulb with your bare hands .

6

Tighte n ring nut over qua rtz sleeve

7

Replac e housing and air filter. Replace ring nuts and valves.

8

Open shut off valve s, rest art pump and check for leaks. Turn UV on by pressing UV button.

9

Hold dow n UV butt on for 10 seconds to reset AL2 code.

1

Turn off chi ller and unpl ug the chiller, Remove the hous ing

(see directions on previous page)

2

Remove the blue plastic cover fr om fuse, remove old fuse from clips

WARNING:

Do not touch the glass of the UV b ulb with your bare hands.

Oils on your hands will dramatically decrease the lifespan of the UV lamp. Use a clean

3

Install new fuse, replace blue plastic cover, replace chiller housing .

cloth to

handle the lamp during installation.

Page 13

Changing UV Bulb

Troubleshooting

It is time to replace the UV L amp

when the AL2 code flash es on the

control panel

1

Turn off chiller and unplug the chiller, Remove the housing (see directions on p.18)

2

Unscre w the ring nut for the UV sterili zer port.

3

Remove rub ber stopp er from the qu artz sleeve

4

Unplu g the old UV lamp fro m the 4-pin sock et., remove and discard lam p.

5

Slide new UV lamp into qua rtz sleeve, pl ug into 4-pin socket, retu rn rubber stopper into sleeve

Do not touch the glass of the UV bulb with your bare hands .

6

Tighte n ring nut over quar tz sleeve

7

Replac e housin g and screws

8

Open sh ut off valves, res tart pump an d check for lea ks. Turn UV on by pre ssing UV button.

9

Hold do wn UV button for 10 seconds to reset AL2 code.

1

Press and hold “SET” for 10 seconds.

The display will show a value of 1 to 20 - this is the current set differential

Page 22

2

Use the arrow Keys to change the set dif ferential

The set differential reflects the number of degrees variance upward

from the set temperature you wish to allow. For example, if you have the

set temperature at 25° C, but do not want the chiller to turn on until it

reaches 27° C, set the differential value to 2. The default setting allows

a variance of 1° C from the set temperature before the chiller turns on.

This value is intended to protect the compressor from excessive wear.

Page 23

TR30 TR60

W

ARNING:

Do not t

ouch the glass of

the UV bulb with y

our bare hands.

Oils on your hands

will

dramatically decr

ease the

lif

espan of the UV lamp. Use a

clean

cloth to handle the lamp during installation.

Pr

oblem Cause Solution

Display

does not light up

No

Electricity

Check that the power supply cable

is c

orrectly

c

onnected to both the chiller and outlet. Check that

the power switch is

ON. Check that the fuse

is

intact.

Dirty

Air F

ilter

C

lean Air F

ilter as

described on page 18.

Ambient T

emperatur

e

is too

high

L

ower the ambient temperature to

below 95° F/35° C

Obstruct

ed

V

entilation

Grate

R

emove

the obstruction or

cr

eate a ventilation hole.

Broken Fan

C

ontact info@trademarkaquatics.co.uk

UV lamp

R

eplace

the UV lamp with an appr

opriate TECO

UV

r

eplac

ement, available at www.tecous.com

W

ater temperatur

e

pr

obe has been

damaged

C

ontact info@trademarkaquatics.co.uk

C

ompres

sor overload

pr

obe

is

damaged

Check air

filter, check that v

entilation fans are

running.

C

ontact info@trademarkaquatics.co.uk

T

emperature

displa

yed

is

not correct

W

ater

is

losing or

g

aining heat thr

ough

long and/or un-

insulated tubing

R

educe

length of tubing, insulate

the tubing.

Check for

obstructions in tubing

Check that the pump

is

working

W

ater may not be

cir

culating thr

ough chiller correctly

Chiller

does not come on

until aquarium temperatur

e

is several degrees higher

than set point

T

emperature

offset

is

incorrect

R

eset temp diff

erential - see instructions below

W

ater flow

thr

ough chiller

has slo

wed

Calcium Buildup

Disc

onnect chiller from

aquarium. Run a 50% solution

of vinegar and water thr

ough chiller for 24 hours t

o

dissolve

buildup. T

horoughly flush chiller with Ro/DI

before connecting to aquarium.

Page 14

P

age 24

Loading...

Loading...