Page 1

230V 1Ø 0.5 - 3HP

N3 INVERTER SERIES

Operating Manual

0.4 - 2.2kW

230V 3Ø 0.5 - 40HP

0.4 – 30kW

460V 3Ø 1 - 75HP

0.75 – 55kW

Revision: 2.03.05

Page 2

N3 Drive Operations Manual

Table of Contents

1.0 Introduction ..................................................................................................................................... 1

2.0 Product Inspection ......................................................................................................................... 2

2.1 Nameplate Layout ...................................................................................................................... 2

3.0 Operating Precautions ................................................................................................................... 3

3.1 Before Power up ......................................................................................................................... 3

3.2 During Power up ......................................................................................................................... 4

3.3 Before Operation ........................................................................................................................ 4

3.4 During Operation ........................................................................................................................ 5

4.0 Environment and Installation ........................................................................................................ 6

4.1 Inverter Mounting ........................................................................................................................ 6

Fig.4.1.1 Panel and Enclosure Placement ..................................................................................... 6

Fig 4.1.2 Din Rail Mounting Clearances ......................................................................................... 7

5.0 General Wiring Diagram (1 - 2 HP) ................................................................................................ 8

6.0 General Wiring Diagram (3 - 75 HP) .............................................................................................. 9

7.0 Power Terminals Designations and Ratings (Terminal Block TM1) ........................................ 10

7.1 Power Terminal Configuration TM1 .......................................................................................... 10

7.2 Power Terminal Block TM1 Electrical Ratings and Tightening Torques .................................. 11

8.0 Inverter Wiring .............................................................................................................................. 11

8.1 Input / Output Power Wiring Connections (Terminal TM1) ...................................................... 11

8.2 Input / Output Power Wiring Noise Suppression ...................................................................... 11

Fig. 8.2 Input / Output Power Wiring Noise Suppression ............................................................. 11

8.3 Motor Cable Length .................................................................................................................. 12

8.4 Cable Length vs Carrier Frequency ......................................................................................... 12

8.5 Inverter Grounding .................................................................................................................... 12

8.6 Input Power Wiring and Installation Recommendations with Examples .................................. 13

Fig. 8.6 Input Power Wiring and Installation Examples ................................................................ 13

9.0 Input / Output Power Section Block Diagram ............................................................................ 14

Fig. 9.0 Power Input / Output Block Diagrams ............................................................................. 14

10.0 Control Terminals (Terminal Block TM2) ................................................................................. 15

10.1 Control Terminal Designations (Terminal Block TM2) .......................................................... 15

10.2 Control Terminal Layout and Control Switches ..................................................................... 16

Fig. 10.2.1 Control Terminal TM2 Layout ................................................................................ 16

Fig. 10.2.2 Control Terminal TM2 Layout (Prior to Version 1.3) ............................................. 16

10.3 Control Terminal Wiring and Connections (Terminal TM2) .................................................. 16

11.0 Peripheral Power Devices .......................................................................................................... 17

12.0 Input Fuse Types and Ratings ........................................................................................... 18 - 19

13.0 Applicable specifications for circuit breakers and magnetic contactors ............................. 19

14.0 Reactor Input / Output Specifications ...................................................................................... 20

15.0 Braking Unit and Braking Resistor Selections ........................................................................ 21

16.0 EMC Filters .................................................................................................................................. 22

17.0 Keypad Key Functions and Navigation .................................................................................... 23

17.1 N3 Keypad ............................................................................................................................. 23

17.2 Keypad LED Functions .......................................................................................................... 23

17.3 Key Functions ........................................................................................................................ 24

17.4 Keypad Navigation ................................................................................................................ 25

17.4.1 Basic Keypad Control ................................................................................................. 25

17.4.2 Local / Remote Function.............................................................................................. 25

17.4.3 Setting Parameters b (Basic) and A (Advanced) ........................................................ 26

18.0 Control Mode Selection ............................................................................................................. 27

Cont.

Table of Contents

Page 3

N3 Drive Operations Manual

19.0 b (Basic) and A (Advanced)parameters defined .................................................................... 28

19.1 b (Basic) Parameter Summary ....................................................................................... 28 - 29

19.2 b (Basic) Parameter Details ........................................................................................... 30 - 33

19.3 A (Advanced) Parameter Summary ............................................................................... 34 - 46

19.4 A (Advanced) Parameter Details .................................................................................... 47 - 81

20.0 Option Modules and Cables ...................................................................................................... 82

Fig. 20.1 Remote Keypad .............................................................................................................. 82

Fig. 20.2 Remote Keypad Mounting Dimensions .......................................................................... 83

Fig. 20.3 RS485 Interface P/N SIF-485 ......................................................................................... 83

Fig. 20.4 RS232 Interface P/N SIF-232 ......................................................................................... 84

Fig. 20.5 Copy Module P/N SIF-MP .............................................................................................. 84

21.0 Error Display Codes ................................................................................................................... 85

21.1 Unresettable / Unrecoverable Errors ..................................................................................... 85

21.2 Automatically and Manually Recoverable Errors............................................................ 85 - 86

21.3 Manually Recoverable Errors Only (no auto-restart) ............................................................. 87

21.4 Set –up Configuration and Interface Errors .................................................................... 86 - 88

21.5 Keypad Errors ................................................................................................................. 88 - 89

22.0 Troubleshooting ......................................................................................................................... 89

22.1 General troubleshooting ........................................................................................................ 90

Flow Charts: ........................................................................................................................... 91 - 97

Fig. 22.1 Fault display troubleshooting ................................................................................. 91 - 92

Fig. 22.2 OC and OL fault troubleshooting .................................................................................. 93

Fig. 22.3 OV and LV fault troubleshooting .................................................................................. 94

Fig. 22.4 Motor will not run .......................................................................................................... 95

Fig. 22.5 Motor overheating ......................................................................................................... 96

Fig. 22.6 Instability ....................................................................................................................... 96

23.0 Routine periodic inspection ...................................................................................................... 97

Appendix A – Specifications ............................................................................................................. A1

AA.1 General Specifications ................................................................................................. A1 – A2

AA.2 Product (Model) Specifications .................................................................................... A3 – A4

Appendix B - Motor Internal Data List .............................................................................................. B1

Appendix C - N3 Envelope Dimensions and Weight Table vs Model No. .................................... C1

Appendix D –N3 Cover Removal Procedure for Various Frame Sizes ................................. D1 – D2

AD.1 Frame sizes 1 & 2 ................................................................................................................ D1

AD.2 Frame size 3 ........................................................................................................................ D1

AD.3 Frame size 4 ........................................................................................................................ D2

AD.4 Frames sizes 5 & 6 ............................................................................................................. D2

Appendix E- EMC Filter Dimensions ....................................................................................... E1 – E3

AE.1 FS Type ................................................................................................................................ E1

AE.2 KMF Type ............................................................................................................................. E2

AE.3 JUN Type .............................................................................................................................. E3

Appendix F- Inverter Parameter Setting List ................................................................................... F1

Appendix G- Version 1.3 Changes .......................................................................................... G1 – G2

Table of Contents Cont.

Page 4

N3 Drive Operations Manual

!

!

DANGER

Do not touch any circuit boards or components while the charge indicator is still on

after power is turned off. Wait until the charge indicator lamp is completely

extinguished. NOTE: The charge indicator lamp is located under the digital

operator

Do not connect or disconnect any wiring while power is present.

Do not test parts and signals on the circuit boards during the inverter operation.

Do not disassemble the inverter and modify any internal wires, circuits, or parts.

Ensure that the ground terminal of the inverter is bonded properly to earth ground.

For 200V class, ground to <100 Ω. For 400v class, ground to <10Ω.

!

CAUTION

Do not perform high voltage dielectric tests on any inverter parts, as damage to

these parts may can result.

Do not connect the AC input power supply to the motor terminals T1 (U), T2 (V),

and T3 (W) of the inverter.

Do not touch any circuit board without proper precautions as the CMOS ICs on the

inverter’s control board can be damaged due to static electricity.

1.0 Introduction

The N3 Inverter series is state of the art design using the latest control and power technologies. It is designed to

operate and control 3Ø induction motors in the hp range of 0.5 to 75 hp and voltage class of 230 or 460VAC. The

inverter can operate in the open loop vector, variable torque, or V/F mode; settable via programming. There are two

sets of parameters: b Basic, and A Advanced, allowing for flexible control in many different applications. The

membrane keypad in combination with a 3 digit 7 segment display allows for ease of programming and monitoring.

An optional communications module can be used for control and parameter setting using the MODBUS RTU protocol.

The N3 has been designed with easy access to the input power, output motor, and control terminals.

Before proceeding with the set-up and installation please take time to review this manual to ensure proper operation

and above all else, personnel safety. Should there be any problem in using the product that cannot be resolved with

the information provided in the manual, please contact your nearest TECO distributor or sales representative for

assistance.

SAFETY FIRST!

The inverter is an electrical product. For your safety, there are symbols “Danger” and “Caution” in this manual as a

reminder to pay attention to safety instructions on handling, installing, operating, and troubleshooting the inverter. Be

sure to follow the instructions for maximum safety.

DANGER - Indicates a potential hazard that could cause death

or serious personal Injury.

! CAUTION - Indicates that the inverter or the mechanical system

might be damaged.

Introduction & Safety 1

Page 5

N3 Drive Operations Manual

Input

Specification

Output

Specification

Model and

Motor Rating

CAUTION

Enclosure Type and Rating

: xxxxxxxxxxxx

: xxHP/xxkW

: AC x phase 50/60 Hz

: xxx-xxxV (+10%,-15%)

: xx.x A

: AC 3 phases 0-400 Hz

: 0 – xxxV

: xx.x A

Model

Motor Rating

INPUT

VOLTAGE

Amps

OUTPUT

VOLTAGE

Amps

2.0 Product Inspection

TECO’s inverters have all passed a functional factory test before delivery. Please check the following when you

receive and unpack the inverter:

Check for any damages that may have occured during transportation or handling. If there is damage, do not

apply power, and contact a TECO sales representative.

Check that the model and capacity of the inverter are the same as those specified in your purchase order. The

following describes the nameplate information.

NOTES:

2.1 Nameplate Layout

Product inspection & Nameplate Layout 2

Page 6

N3 Drive Operations Manual

!

CAUTION

The input voltage must comply with the inverter’s specified input voltage.(See

product nameplate)

!

CAUTION

To avoid the front cover from disengaging or other physical damage, do not

carry the inverter by its cover. Support the unit by its heat sink when

transporting. Improper handling can damage the inverter or injure personnel,

and should be avoided.

To avoid the risk of fire, do not install the inverter on or near flammable

objects. Install on nonflammable objects such as metal surfaces.

If several inverters are placed in the same control panel, provide adequate

ventilation to keep the temperature below 40°C (104°F) to avoid overheating

or fire.

When removing or installing the digital operator, turn off the power first, and

then follow the instructions in this manual to avoid operator error or loss of

display caused by faulty connections.

Warning

This product is sold subject to IEC 61800-3. In a domestic environment this

product may cause radio interference in which case the user may be required to

apply corrective measures.

!

CAUTION

To ensure the safety of peripheral devices, it is strongly recommended to install a

fast acting fuse on the power input side of the inverter. The specifications for fast

acting fuses are covered in Section 12.0.

!

DANGER

Make sure the applied voltage input connections are correct, L1 (L), L2, and

L3 (N) are power-input terminals and must not be connected to T1, T2, and T3.

Otherwise, inverter damage can result.

3.0 Operating Precautions

3.1 Before Power Up

Operating Precautions; Before Power UP 3

Page 7

N3 Drive Operations Manual

!

DANGER

Do not connect or disconnect any wiring on the inverter as bodily harm and /

or damage to the equipment may result.

When momentary power loss is greater than 2 seconds (the higher the HP

rating, the longer the time), the inverter can not sustain power to the control

circuit. Therefore, when power is restored, the operation of the inverter is

based on the setup of b000 / A015 and the condition of the external switches.

This is considered to be a restart.

When restarting, the operation of the inverter is based on the setup of

b000 and A015 and the condition of external switch (FWD / REV button).

NOTE: the start operation is not affected by parameters

A013/A014/A018/A019.

1. When b000=0000, the inverter will not run after restart.

2. When b000=0001 and the external (FWD / REV) switch is off, the

inverter will not run after restart.

3. When b000=0001, the external switch (FWD / REV button) is on, and

A015=0000, the inverter will run automatically after restart. In this case

after loss of power, turn off the external (FWD/REV) switch to avoid

damage to the equipment and injury to personnel after sudden

restoration of power.

For further information, please refer to the description and warnings of

parameter A015 covered in the advanced parameter section.

When the momentary power loss is less than 2 seconds, the inverter still has

enough storage power to support the control the circuit. Therefore, when

power is restored, the inverter will automatically restart depending on the setup

of A013 / A014.

!

CAUTION

Below situations are normal:

1. The inverter display will flash the AC input voltage for 1 second after power is applied.

2. After power is off, the inverter display will flash "LV" for 1 second when the inverter

is at Stop status and the inverter display will flash "LV-C" for 1 second when the

inverter is at Run status.

!

DANGER

Make sure only qualified personnel familiar with AC drives and having a full

understanding on parameter settings allowed to operate the equipment.

3.2 During Power up

3.3 Before Operation

Operating Precautions; During Power UP & Before Operation 4

Page 8

N3 Drive Operations Manual

!

DANGER

Do not connect or disconnect the motor during operation. The overcurrent circuit

will cause the inverter to trip or damage the equipment may result.

!

DANGER

Do not remove any protective covers as lethal voltages are present inside

the inverter.

The motor will restart automatically after stop when the auto-restart function is

on. In this case, use extreme caution while working near the motor or driven

equipment.

Note: The stop function is different from the emergency stop switch, which

must be set first to be effective.

!

CAUTION

Do not touch heat-generating components such as heat sinks and braking

resistors.

The inverter can operate the motor from low speed to high speed. Verify that

the allowable speed range of the associated machinery will tolerate this range.

Note the settings related to the `minimum braking resistor value.

Do not check signals on circuit boards while the inverter is operating.

!

CAUTION

After power is removed from the inverter, allow 5 minutes before disassembling or

checking any components or disconnecting wiring. The charge indicator lamp

which is located under the digital operator should not be illuminated.

3.4 During Operation

Operating Precautions; During Operation 5

Page 9

N3 Drive Operations Manual

PANEL

Correct

Fan

Fan

Enclosure

Enclosure

PANEL

Incorrect

Correct

Incorrect

N3

N3

N3

N3

N3

N3

Panel Mounting

Enclosure Mounting

Ambient Temperature: 14 -104 oF (-10oC - +40oC),

Without Cover: 14-122 oF (-10oC - +50oC)

Relative Humidity: 95% non-condensing

Altitude : < 3,281 ft. (1000m)

Avoid exposure to rain or moisture.

Avoid direct sunlight.

Avoid oil mist and salinity.

Avoid corrosive liquid and gas.

Avoid dust, lint fibers, and small metal

filings.

Keep away from radioactive and

flammable materials.

Avoid electromagnetic interference (soldering machines, power machines).

Avoid vibration (stamping, punching machines etc.). Add a vibration-proof pad if the

situation cannot be avoided.

If several inverters are placed in the same control panel, provide a heat removal means

to maintain ambient temperatures below 40oC.

4.0 Environment and Installation

The environment will directly affect the proper operation and the life span of the inverter. To ensure that the inverter

will give maximum service life, please comply with the following environmental conditions:

4.1 Inverter Mounting

When mounting and installing one or more inverters on a panel or in an enclosure, ensure that the placements and

clearances are correct. (see Fig.’s 4.1.1 and 4.1.2). Also make sure that the inverter(s) are mounted vertically to

maximize air flow to the heatsink. To further increase airflow, the dust cover on the inverter(s) may be removed,

provided that the environment is free from contaminants.

Fig. 4.1.1 Panel and Enclosure Placements

Cont.

Environment & Installation; Inverter Mounting 6

Page 10

N3 Drive Operations Manual

N3

FRONT

2.0 in

2.0 in

4.8 in

4.8 in

2.0 in

N3

Fig. 4.1.2 Mounting Clearances

NOTES:

Environment & Installation; Inverter Mounting Cont. 7

Page 11

N3 Drive Operations Manual

T1(U)

T2(V)

T3(W)

L1(R)

L2(S)

L3(T)

RUN / STOP

S1

S2

S3

S4

S5

3 Ø

INDUCTION MOTOR

MULTIFUNCTION

DIGITAL INPUTS

(See parameters A050 – A057)

+10V

AIN / S7

COM

(0V)

E

E

R1A

R1B

R1C

R2A

R2C

N3

INVERTER

SHIELD

SHIELD

N3 General Wiring Diagram

1 - 2 HP and (3-75 HP prior to Version 1.3)

0 - 10 VDC

ANALOG

OUTPUT

(See parameters

A103 & A104)

MULTIFUNCTION RELAY

OUTPUTS

Dry contacts rated

(250 VAC / 30 VDC @ 2A)

(See parameters A105 & A106)

+24V

COM

RUN / STOP or REV / FWD

For SOURCE mode connect

to +24V and set SW1 to the

PNP position.

For SINK mode connect to

COM and set SW1 to the NPN

position. (Factory Default)

+FM

COM

S6 / AI2

(0V)

(0V)

SW1

NPN

PNP

SW3

I

V

SW2

BR

DC Choke

Braking

Resistor

P1

Braking

Resistor

P

_

B1/P

B2

DC Power

Supply

_

DC Power Supply

or

External Braking Unit

+

230V: 0.5 – 10 HP

460V: 1 – 15 HP

230V: 15 – 20 HP

460V: 20 HP

230V: 25 – 40 HP

460V: 25 – 75 HP

NOTE GROUND CONNECTION

RESISTANCE TO BE 230V CLASS: ≤100Ω

460V CLASS: ≤10Ω

PE

E

E

Ground Terminal

Designation

TERMINAL DESIGNATIONS FOR

POWER DEVICE INPUTS FOR

VARIOUS HORSEPOWER.

(See Sec. 7.0 for further details)

CON 1

CON 2

OPTION CARD

CONNECTOR

TM2

TM2

(See Sec. 10.0 for further details)

S5 can be configured for pulse

input. ( A054 = 0019) (See

also parameter A098)

The AIN / S7 input terminal can be

configured as an Analog input:

SW2 = V (0-10VDC) or *(2 - 10VDC)

SW2 = I (0 - 20 mA) or *(4 - 20 mA)

*(See Note)

AIN/S7 can also be configured as a

digital input .

Example – An external pot is

connected to the AIN terminal as

shown providing 0 - 10 VDC input

2K

L1(R)

L2(S)

L3(T)

Magnetic

Contactor

MCCB

AC

Reactor

Fast Acting

Fuses

PE

PE

S6 / AI2 can be configured as a digital

or analog input.

SW3 = V (0-10VDC) or (2 - 10VDC)

SW3 = I (0 - 20 mA) or (4 - 20 mA)

(See parameters *A049, (A050 – A056),

A097 & A154)

*A049 – Version 1.3 or later)

*Note: For versions prior to 1.3, to set AIN (2-10V) or

(4-20mA), parameters A92-A96 were used. For

versions 1.3 or higher it can be set directly with

parameter A154. Also see parameters A050 - A056.

AC Input Voltage

5.0 General Wiring Diagram 1 - 2 HP

N3 General Wiring Diagram.( All HP’s prior to Ver.1.3) 8

Page 12

N3 Drive Operations Manual

T1(U)

T2(V)

T3(W)

L1(R)

L2(S)

L3(T)

RUN / STOP

S1

S2

S3

S4

S5

3 Ø

INDUCTION MOTOR

MULTIFUNCTION

DIGITAL INPUTS

(See parameters A050 – A057)

AI2

AIN / S7

E

E

R1A

R1B

R1C

R2A

R2C

N3

INVERTER

SHIELD

SHIELD

N3 General Wiring Diagram

3 – 40 HP at 230V and 3 – 75 HP at 460V (Version 1.3 or later)

0 - 10 VDC

ANALOG

OUTPUT

(See parameters

A103 & A104)

MULTIFUNCTION RELAY

OUTPUTS

Dry contacts rated

(250 VAC / 30 VDC @ 2A)

(See parameters A105 & A106)

+24V

24G

RUN / STOP or REV / FWD

For SOURCE mode connect

to +24V and set SW1 to the

PNP position.

For SINK mode connect to

COM and set SW1 to the NPN

position. (Factory Default)

+FM

AGND

S6

SW1

NPN

PNP

SW3

I

V

SW2

Braking

Resistor

_

B1/P

B2

DC Power

Supply

_

DC Power Supply

or

External Braking Unit

+

230V: 25 – 40 HP

460V: 25 – 75 HP

230V: 15 – 20 HP

460V: 20 HP

NOTE GROUND CONNECTION

RESISTANCE TO BE 230V CLASS: ≤100Ω

460V CLASS: ≤10Ω

E

E

Ground Terminal

Designation

TERMINAL DESIGNATIONS FOR

POWER DEVICE INPUTS FOR

VARIOUS HORSEPOWER.

(See Sec. 7.0 for further details)

CON 1

CON 2

OPTION CARD

CONNECTOR

TM2

TM2

(See Sec. 10.0 for further details)

S5 can be configured for pulse

input. ( A054 = 0019) (See

also parameter A098)

The AIN / S7 input terminal

can be configured as an

Analog input:

SW2 = V (0 -10VDC)

SW2 = I (0 - 20mA)

AIN / S7 can also be

configured as a digital input.

(see parameters A056, (A092

– A096) & A154)

Example – An external pot is

connected to the AIN terminal as

shown providing 0 - 10 VDC input

2K

L1(R)

L2(S)

L3(T)

Magnetic

Contactor

MCCB

AC

Reactor

Fast Acting

Fuses

AGND

3 – 40 HP at 230V

&

3 – 75 HP at 460V

AC Input Voltage

AI2 Analog input input terminal:

SW3 = V (0 -10VDC) or (0 - 20mA)

SW3 = I (2-10VDC) or (4-20 mA)

(Ver. 1.3 or later)

(See parameters A049, A097, (A050

– A056) & A154)

6.0 General Wiring Diagram 3 – 75 HP*

*. For 3 - 75HP prior to Version 1.3. please refer to Wiring Diagram 5.0

N3 General Wiring Diagram (3-75 HP Ver.1.3 or later) 9

Page 13

N3 Drive Operations Manual

R/L1 S/L2 T/L3

B1/P

_

B2

UT1 VT2

WT3

Power Dynamic To Motor

230V 3Ø: 15 – 20 HP

460V 3Ø: 20 HP

R/L1 S/L2

T/L3

_

UT1

VT2

WT3

+

230V 3Ø : 25 - 40 HP

460V 3Ø : 25 - 75 HP

Fig.7.1 Power Terminal Configuration TM1

Terminal Connections

R/L1 – S/L2 – T/L3

U/T1 – V/T2 – W/T3

B1/P – B2

B1/P –

_

Terminal Connections

–

_

+

External DC Supply

Or External Braking

Unit.

230V 1Ø: 0.5 – 1 HP

Terminal Connections

(L) – (N)

L1 – L2 – L3

T1 – T2 – T3

P1 – BR

P1 – P *

PE

A)

C)

D)

TM1

TM1

TM1

Do Not remove the

Factory Installed

Jumper between

Terminals P – P1

unless a DC reactor

is being installed.

CAUTION

230V 3Ø: 0.5 – 2 HP

460V 3Ø: 1 – 2 HP

230V 1Ø: 0.5 – 1 HP

3Ø Motor Output

Braking Resistor Connection

DC Reactor Connections

Earth Ground

3Ø Input Power

3Ø Motor Output

Braking Resistor

External DC Supply

R/L1 – S/L2 – T/L3

U/T1 – V/T2 – W/T3

3Ø Input Power

3Ø Motor Output

L1(L)

L2

L3(N)

T1

T2

T3

PEPE

BRP

P1

(L) – (N)

L1 – L2 – L3

T1 – T2 – T3

P1 – BR

P1 – P *

230V 3Ø: 3 – 10 HP

460V 3Ø: 3 – 15 HP

230V 1Ø: 2 – 3 HP

3Ø Motor Output

Braking Resistor Connection

DC Reactor Connections

Terminal Connections

L1 L2 L3(N)

P1

BR

T1 T2

T3

Power Dynamic To Motor

P

TM1

230V 1Ø: 2 – 3 HP

B)

Do Not remove the Factory Installed Jumper between

Terminals P – P1 unless a DC reactor is being installed.

CAUTION

!

!

*

*

7.0 Power Terminals Designations and Ratings (Terminal Block TM1)

Depending on inverter ratings, the power terminals (TM1) can have one of three configurations. These are shown as

A), B), C) and D) in Fig. 7.1. Section 7.2 covers the electrical ratings and tightening torques of the terminals.

Do Not over tighten terminal screws. (See Sec. 7.2)

Use the proper wire size for terminal connections.

Use proper termination techniques.

7.1 Power Terminal Configuration TM1

Power Terminal Designations & Ratings (TM1) 10

Page 14

N3 Drive Operations Manual

Horsepower

Phase

Ø

Power source

Volts

Amps

Tightening Torque

Lb-ft / KG-M

Lb-in / KG-CM

0.5 & 1

1

200-240V

600

15A

0.59 / 0.08

7.10 / 8.20

2 3 1& 2

3

380-480V

3, 5, 7.5, 10 &15

3

200-240V

40A

1.5 / 0.21

18.00 / 20.28

2 & 3

1

3, 5, 7.5, 10 &15

3

380-480V

15,20, & 25

3

200-240V

80A

1.84 / 0.3

22.1 / 30

20,25, & 30

3

380-480V

60A

30

3

200-240V

100A

4.42 / 0.66

53.1 / 66

40 & 50

3

380-480V

40

3

200-240V

150A

60 & 75

3

380-480V

Inverter Input

Voltage

Horsepower

240 V

0.5,1, & 2

3 & 5

7.5 & 10

X

15, 20, &

25

30

40

480 V

1, 2, 3, & 5

7 & 10

15

20 , 25 & 30

X

40 & 50

60 & 75

*AWG / mm2

#14 / 2.0

#12 / 3.5

#10 / 5.5

#6 / 14

#4 / 22

#2 / 30

#1 /50

N3

IM

MCCB

Power

Source

Noise

Filter

Grounded

Metal Conduit

Noise

Filter

Grounded Metal

Enclosure

Signal Cable

11.8 in. / 30 cm

(Separate signal wiring from power leads

by a minimum of 30 cm / 11.8 in..)

7.2 Power Terminal Block TM1 Electrical Ratings and Tightening Torques

Table7.1 Electrical Ratings and Tightening Torques

8.0 Inverter Wiring

8.1 Input / Output Power Wiring Connections (Terminal TM1)

Table 8.1 Input / Output Power Wire Size vs Horsepower

* Wire size shown is based on maximum terminal size. Please consult the NEC or local

codes for the proper size to be used.

Use only copper wires. Proper diameter wire should be based on ratings at +105°C.

The minimum voltage rating of wiring is: 300V for 230VAC and 600V for 460VAC.

For safety reasons do not use under sized wiring.

8.2 Input / Output Power Wiring Noise Suppression

Electrical noise or EMI can be generated from the input power lines and or the output power leads to the motor.

This can interfere with the function of surrounding equipment as well as the inverter’s own control wiring. Fig. 8.2

shows an example of filters and shielding schemes to help minimize any radiated EMI.

Fig. 8.2 Input / Output Power Wiring Noise Suppression

Cont.

Power Terminal Designations & Ratings (TM1) Cont. & Inverter Wiring 11

Page 15

N3 Drive Operations Manual

Cable length between the

inverter and motor

ft / m

< 75 / 22.9

< 150/45.7

< 300 / 91.4

> 300 / 91.4

Recommended carrier

frequency allowed

<=16KHz

<=12KHz

<=8KHz

<= 5KHz

Setting of parameter

A044

<=16

<=12

<=8

<=5

N3 N3

N3

N3 N3 N3

a) Correct

b) Correct

N3 N3 N3

c) Incorrect

Loop

8.3 Motor Cable Length

The length of the cables between the motor and inverter can cause a significant phase to phase voltage

reduction at the motor due to the voltage drop across the cables. To calculate this reduction, apply the following

formula:

Phase-to-phase voltage drop (V) = 3 ×resistance of wire (Ω/km) × length of line m) × current×10-3.

(km=3280 x feet) (m=3.28 x feet )

8.4 Cable Length vs Carrier Frequency

The allowable setting of the PWM carrier frequency is also determined by motor cable length and on is specified

in the following table.

Table 8.2 Cable Length vs Carrier Frequency

8.5 Inverter Grounding

The proper grounding scheme for one or more inverters is very important to ensure personnel safety as well as

equipment performance. The following will discuss the proper grounding procedures.

The grounding resistance for the 230V class; <100, the 460V class; <10.

The ground wire size (AWG) is per electrical code.

Do Not share a ground with any other equipment with high current loads such as welding machines, presses,

etc. Connect the inverter to its own dedicated ground.

Do Not make a loop when several inverters share a common ground point (See Fig. 8.5c).

Fig. 8.5 Inverter Grounding

Inverter Wiring; Input Power Wiring 12

Page 16

N3 Drive Operations Manual

N3

IM

MCCB

Power

Source

N3

IM

MCCB

Power

Source

General

Noise

Filter

Machine

N3

IM

MCCB

Power

Source

Machine

General

Noise

Filter

N3

IM

MCCB

Power

Source

Special

Noise

Filter

Machine

N3

MCCB

Power

Source

Machine

IM

Isolation

Transformer

a) Dedicated Power Source

b) Special Noise Filter

c) Isolation Transformer

d) General Noise Filter

CORRECT

INCORRECT

or

8.6 Input Power Wiring and Installation Recommendations with Examples

Fig. 8.6 shows input power installation recommendations with correct and incorrect examples.

When possible the inverter should be connected to a dedicated input power source. (Fig. 8.6 a)

When the inverter is sharing a power source with other equipment, either install a special input noise filter,

(Fig. 8.6b) or an isolation transformer, (Fig. 8.6c) to isolate other loads.

Using a general purpose noise filter may not give sufficient results as shown in (Fig. 8.6d) below.

Fig. 8.6 Input Power Wiring and Installation Examples

Inverter Wiring; Input Power Wiring 13

Page 17

N3 Drive Operations Manual

Control

Circuit

Cooling Fan

+

_

L1(L)

L2

L3 (N)

T1

T2

T3

DC /DC

Converter

PE

Control

Circuit

Cooling Fan

C.M. Choke

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

DC /DC

Converter

E

Control

Circuit

Cooling Fan

C.M. Choke

DC /DC

Converter

+24VDC

+

_

E

+

_

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

B) 230V: 25 HP and 440v : 25 – 30 HP

C) 230V: 30 - 40 HP and 440v : 40 – 75 HP

A) 230V 1Ø: 0.5 – 3 HP, 230V 3Ø: 0.5 – 10 HP and 460V 3Ø: 1 - 15 HP

9.0 Input / Output Power Section Block Diagram

The following Fig. 9.0 A), B) and C) show the basic configuration of the power sections for the range of horsepower

and input voltages. This is shown for reference only and is not a detailed depiction.

Fig. 9.0 Power Input / Output Block Diagrams

Input / Output Power Section Block Diagram 14

Page 18

N3 Drive Operations Manual

Terminal

Description

R2A

Multifunctional output relay (Form A - N.O.)

Contact rating:

(250VAC or 30VDC @ 1A)

Contact function:

(refer to parameters A105 & A106)

R2B

R1C

Common contact

Multifunctional output relay

(Form C)

R1B

Normal close contact

R1A

Normal open contact

10V

Frequency knob (VR) power source terminal. 10 mA max. (Do not use for other functions)

AIN / S7

Analog signal input terminal (0 -10Vdc / 4 - 20mA), or multifunction input terminals S7

(H level:>8V, L level:<2V, PNP only) (refer to parameter A056 description)

AI2

Analog signal input (0 - 10V / 0 – 20 mA) 0r 2 – 10V / 4 – 20 mA) 3 - 75 HP: (For Ver. 1.3

or later only)

24V

Common for digital inputs, S1-S5 (S6, S7) in PNP (Source) input. (SW1 is set to PNP input)

50 mA max. (Do not use for other functions)

COM

0.5 - 2 HP & (3 – 75HP prior to Ver. 1.3): Common for analog input /output signals and for

digital S1 - S5 inputs in NPN (Sink) input. (SW1 set to NPN input)

*24G

Common for digital S1 – S6 inputs in NPN (Sink) input. ( SW1set to NPN input)

*AGND

Common for analog inputs AIN & AI2 and analog output FM+

FM+

Multifunction analog output signal, 0-10VDC @ 2mA max. (refer to parameter A103

description)

S1

Multifunction digital input terminals(refer to parameters A050 - A054 description)

S2

S3

S4

S5

Multifunction digital input terminal (Same as S1 – S4) or can be used as a pulse train input

to control output frequency. (refer to parameter A054=0019 description). Input pulse level

19.2V min. to 24.7V max.

S6 / AI2

0.5 - 2 HP& (3 – 75HP prior to Ver. 1.3): Multifunction input terminal (digital terminal high

level:>8V, Low level:<2V, PNP only) or analog input terminal AI2 (0 -10Vdc / 4 - 20mA).

( refer to A055 description)

10.0 Control Terminals (Terminal Block TM2)

The following table shows the control terminal designations for terminal block TM2. Refer to the parameter section of

this manual and to General Wiring Diagrams 5.0 and 6.0 for further explanation of the functions and connections.

Table 10.1 Control Terminal Designations (Terminal Block TM2)

* 3 - 75 HP: (For Ver. 1.3 or later only, see Appendix G for further details)

Cont.

Control Terminals (TM2); Terminal Layout & Wiring 15

Page 19

N3 Drive Operations Manual

R2B

R2A

S6

S5 S4 S3 S2 S1

R1AR1B

R1C

AIN

10V

24V

FM+

COM

0.5 – 10 HP (230V) 1 – 15 HP (460V)

SW2

R2B

R2A

S6

S5 S4 S3 S2 S1

R1AR1B

R1C

AIN

10V 24V

FM+

COM

COM COM

15 – 40 HP (230V) 20 – 75 HP (460V)

R2B

R2A

S6

S5 S4 S3 S2 S1

R1AR1B

R1C

AIN

10V

24V

FM+

COM

0.5 – 2 HP (230V) 1 – 2 HP (460V)

Fig. 10.2.2 Control Terminal TM2 Layout (Prior to Version 1.3)

Fig. 10.2.1 Control Terminal TM2 Layout

R2B

R2A

S6

S5 S4 S3 S2 S1

R1AR1B

R1C

AIN

10V

AGND

24V

FM+

AI2

24G

SW1 - Sets the input digital terminals S1-S7 for Sink (NPN) or Source (PNP) logic.

SW2 - Sets the analog input terminal AIN for voltage (V) or current (I).

SW3 – Sets the analog input terminal AI2 (Ver. 1.3 or later) or the multifunctional terminal S6/AI2 (prior to Ver.1.3) for voltage (V) or current (I).

Please refer to General Wiring Diagrams 5.0 and 6.0 for further information.

SW1

NPN

PNP

SW3

I

V

SW2

Control Switches

Control Board

3 – 40 HP (230V) 3 – 75 HP (460V)

R2B

R2A

S6

S5 S4 S3 S2 S1

R1AR1B

R1C

AI2

10V

AIN

24V

FM+

AGND

24G

Version 1.4 and above

Version 1.3

Shield

Twisted Pair

Wrap with insulating Tape

Ground Shield at Inverter

end

ONLY

DO NOT

Ground Shield at

this end

10.2 Control Terminal Layout (Terminal Block TM2) and Control Switches

10.3 Control Terminal Wiring and Connections (Terminal TM2)

Control wiring is connected to terminal TM2. Select the proper wire and rating in accordance with the following:

Use copper wire only. The proper wire diameter should be based on ratings at +105°C.

AWG #18 is recommended.

To minimize EMI (electromagnetic interference), route control cables at least 12 in. from any power cables.

Do not run control wiring in the same conduit with power and motor wiring.

Depending on signal levels, shielded - twisted pair wiring is recommended as shown in the Fig. below.

For nominal values of input / output signals, follow the requirements of class 2 wiring

Control Cable, Shielded Twisted Pair

Control Terminals (TM2); Terminal Layout & Wiring Cont. 16

Page 20

N3 Drive Operations Manual

~

~

~

Power Supply

M

C

C

B

Molded

Circuit

Breaker

Magnetic

Contactor

AC

Reactor

Fast

Acting

Fuse

Input Noise

Filter

N3

Inverter

Ground

Induction

Motor

Ground

Output Noise

Filter

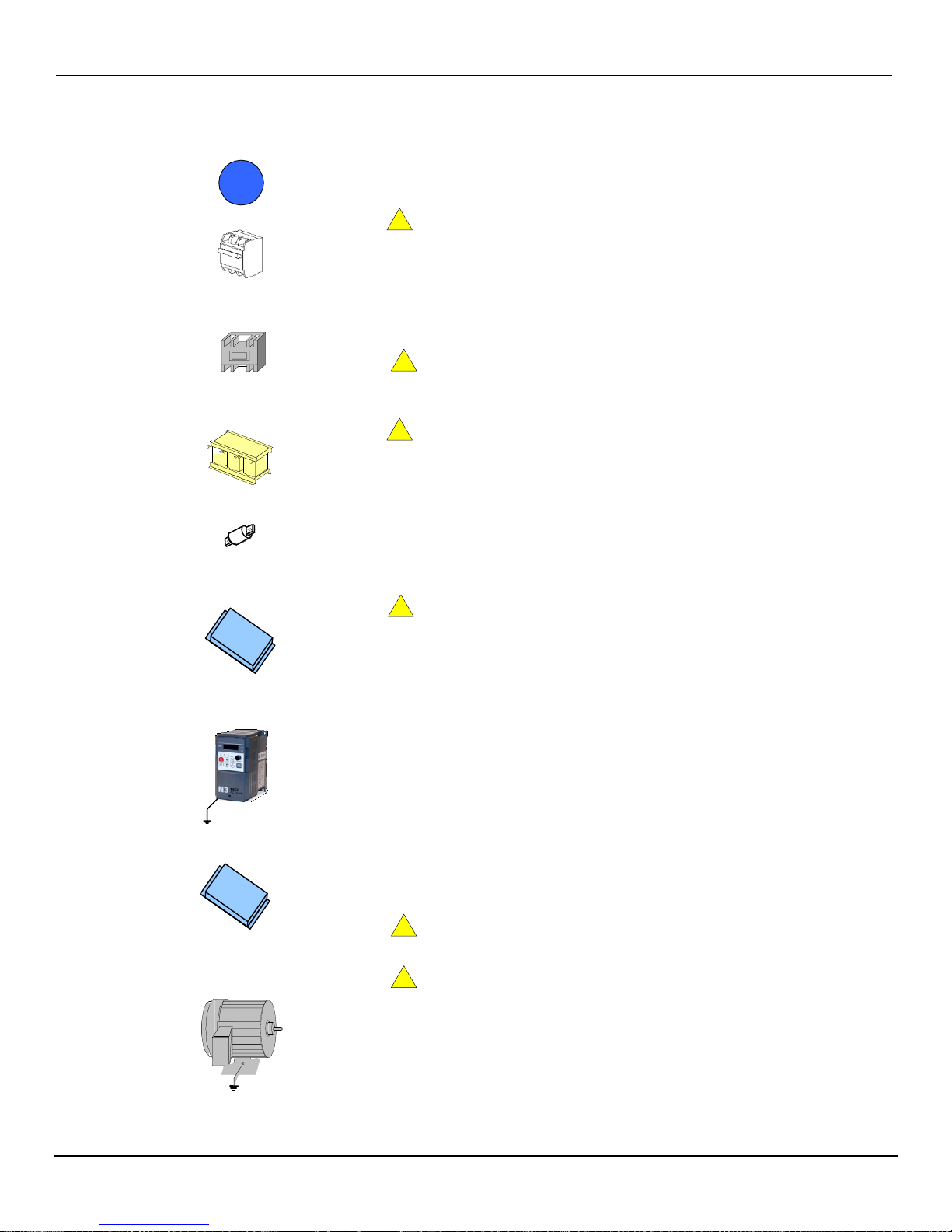

Power supply:

!

Make sure the correct voltage is applied to avoid damaging the

inverter.

Molded-case circuit breaker (MCCB) or fused disconnect:

A molded-case circuit breaker or fused disconnect must be installed

between the AC source and the inverter that conforms to the rated

voltage and current of the inverter to control the power and protect the

inverter.

!

Do not use the circuit breaker as the run/stop switch for the

inverter.

Ground fault detector / breaker:

!

Install a ground fault breaker to prevent problems caused by

current leakage and to protect personnel. Select current range up to

200mA, and action time up to 0.1 second to prevent high frequency

failure.

Magnetic contactor:

Normal operations do not need a magnetic contactor. When

performing functions such as external control and auto restart after

power failure, or when using a brake controller, install a magnetic

contactor.

!

Do not use the magnetic contactor as the run/stop switch for

the inverter.

AC line reactor for power quality:

When inverters are supplied by a high capacity (above 600KVA)

power source, an AC reactor can be connected to improve the power

factor.

Install Fast Acting Fuse:

To protect peripheral equipment, install fast acting fuses in

accordance with the specifications in Sec.12.0.

Input and output noise filter:

A filter must be installed when there are inductive loads affecting the

inverter.

Inverter:

Output terminals T1, T2, and T3 are connected to U, V, and W

terminals of the motor. If the motor runs in reverse while the inverter

is set to run forward, swap any two terminals connections for T1, T2,

and T3.

!

To avoid damaging the inverter, do not connect the output

terminals T1, T2, and T3 to AC input power.

!

Connect the ground terminal properly. (230V series: Rg <100;

460V series: Rg <10.)

11.0 Peripheral Power Devices

The following describes some of the precautions that should be followed when selecting peripheral power devices.

Peripheral Power Devices 17

Page 21

N3 Drive Operations Manual

220V class (1Ø)

N3-2

HP

KW

KVA

100% CONT

Output AMPS

(A)

Max.RK5

FUSE Rating(A)

Max. CC or T

FUSE

Rating(A)

P5-CS

0.5

0.4

1.2

3.1

10

20

01-CS

1

0.75

1.7

4.5

15

30

02-CS

2

1.5

2.9

7.5

20

40

03-CS

3

2.2

4.0

10.5

25

50

220V class (3 Ø)

N3-2

HP

KW

KVA

100% CONT

Output AMPS

(A)

Max.RK5

FUSE Rating(A)

Max. CC or T

FUSE

Rating(A)

P5-C

0.5

0.4

1.2

3.1 8 10

01-C

1

0.75

1.7

4.5

12

15

02-C

2

1.5

2.9

7.5

15

20

03-C

3

2.2

4.0

10.5

20

30

05-C

5

3.7

6.7

17.5

30

50

07-C

7.5

5.5

9.9

26

50

60

10-C

10

7.5

13.3

35

60

70

15-N1

15

11.0

20.6

48

80

100

20-N1

20

15.0

27.4

64

100

125

25-N1

25

18.5

34.0

80

125

150

30-N1

30

22.0

41.0

96

160

200

40-N1

40

30.0

54.0

130

200

250

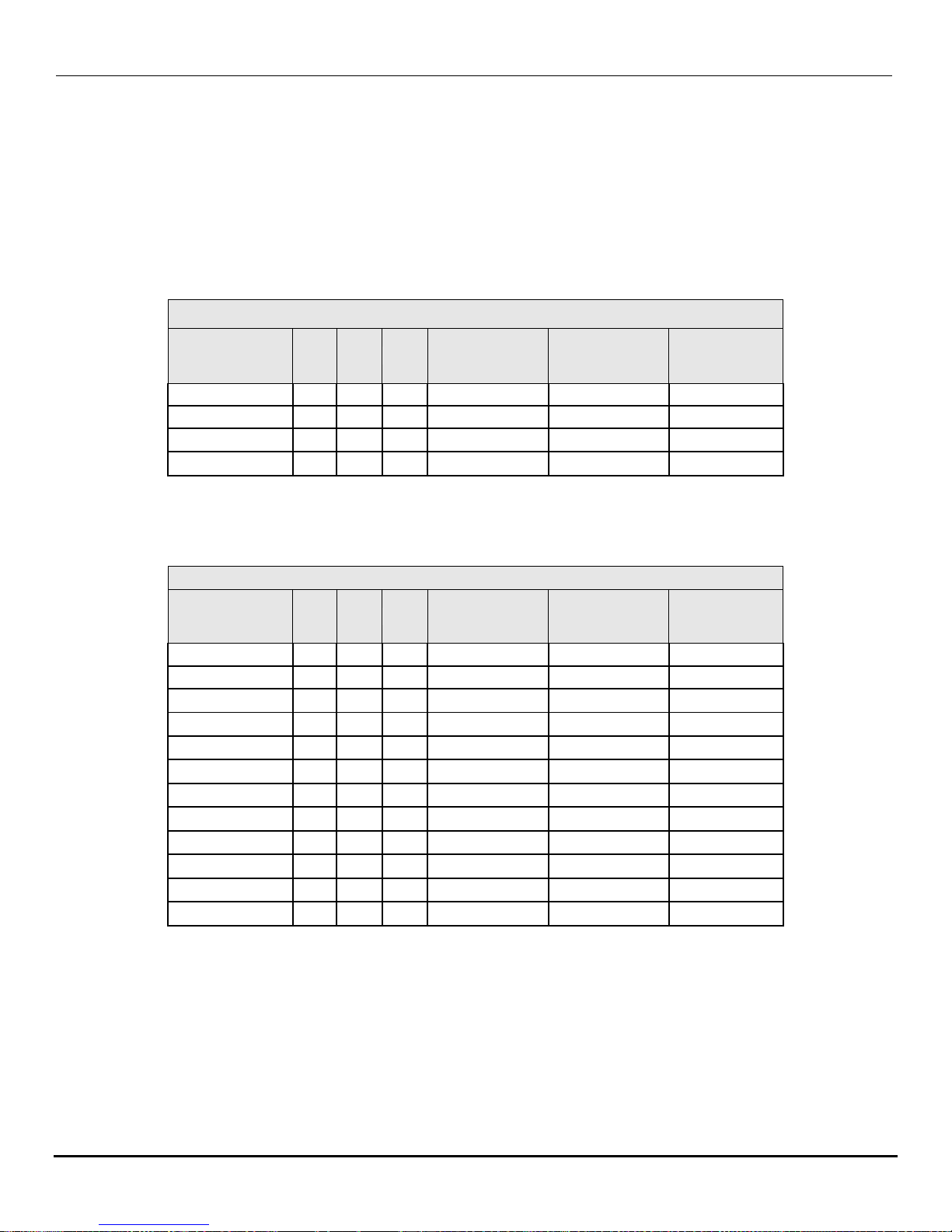

12.0 Input Fuse Types and Ratings

Inverter input fuses are provided to disconnect the inverter from input power in the event of a component failure in the

inverter’s power circuitry. The inverter’s electronic protection circuitry is designed to clear inverter output short circuits

and ground faults without blowing the inverter input fuses. The table on the next page shows the N3 input fuse ratings.

To protect the inverter most effectively, use fuse types RK5 or CC/T with a current-limit function.

Table 12.1A (1Ø) Input Fuse Types and Ratings

Table 12.1B (3 Ø) Input Fuse Types and Ratings

NOTES:

Cont.

Input Fuse Types & Ratings 18

Page 22

N3 Drive Operations Manual

440V class (3 Ø)

N3-4

HP

KW

KVA

100% CONT

Output AMPS

(A)

Max.RK5

FUSE Rating(A)

Max. CC or T

FUSE

Rating(A)

01-C

1

0.75

1.7

2.3 6 10

02-C

2

1.5

2.9

3.8

10

15

03-C

3

2.2

4.0

5.2

10

20

05-C

5

3.7

6.7

8.8

20

30

07-C

7.5

5.5

9.9

13

25

35

10-C

10

7.5

13.3

17.5

30

50

15-C

15

11.0

20.6

25

50

60

20-N1

20

15.0

27.4

32

60

70

25-N1

25

18.5

34.0

40

70

80

30-N1

30

22.0

41.0

48

80

100

40-N1

40

30.0

54.0

64

100

125

50-N1

50

37.0

68.0

80

125

150

60-N1

60

45.0

82.0

96

150

200

75-N1

75

55.0

110.0

128

200

250

!

CAUTION

TECO bears no responsibility for failures caused by the following conditions:

(1) A molded-case circuit breaker is not installed, or an improper or overrated

breaker is used between the power source and the inverter.

(2) A magnetic contactor, a phase capacitor, or a surge suppressor between the

inverter and the motor.

N3 model

N3-2XX - Y

P5-CS

01-CS

02-CS

03-CS

05-C

07-C

10-C

15-N1

20-N1

25-N1

30-N1

40-N1

Molded-case

circuit breaker

made by TECO

TO-50E

10A

TO-50E

20A

TO-50E

30A

TO-50E

30A

TO-50E

30A

TO-50E

50A

TO-100S

60A

TO-100S

100A

TO-100S

100A

TO-225S

150A

TO-225S

175A

TO-225S

175A

Magnetic

contactor (MC)

made by TECO

CU-11

CU-16

CU-18

CU-27

CU-50

CU-65

CU-80

CN-100

CN-125

N3 model

N3-4XX - Y

01-C/02-C/03-C/05-C

07-C

10-C

15-C

20-N1

25-N1

30-N1

40-N1

50-N1

60-N1

75-N1

Molded-case circuit

breaker made by

TECO

TO-50E

15A

TO-50E

20A

TO-50E

30A

TO-50E

50A

TO-100S

50A

TO-100S

75A

TO-100S

100A

TO-100S

100A

TO-125S

125A

TO-225S

175A

TO-225S

175A

Magnetic contactor

(MC) made by TECO

CU-11

CU-16

CU-18

CU-27

CU-38

CU-50

CU-50

CU-65

CU-80

CN-100

CN-125

Table 12.1C (3 Ø) Input Fuse Types and Ratings

NOTE: Fuse ratings are based on 250V fuses for 230V inverters and 600v for 460V inverters.

13.0 Applicable Specifications for Circuit Breakers and Magnetic Contactors

The following tables show the specifications for molded case circuit breakers and magnetic contactors vs N3 models.

Table 13.1A (230V)

Table 13.1B (460V)

Input Fuse Types & Ratings Cont., Circuit Breakers & Magnetic Contactors 19

Page 23

N3 Drive Operations Manual

N3 Model

(240V)

AC inductance at

AC input side

N3 Model

(460V)

AC inductance at

AC input side

Current

(A)

Inductance

(mH)

Current (A)

Inductance

(mH)

2P5

5.0

2.1

401

2.5

8.4

201

5.0

2.1

402

5.0

4.2

202

10.0

1.1

403

7.5

3.6

203

15.0

0.71

405

10.0

2.2

205

20.0

0.53

407

15.0

1.42

207

30.0

0.35

410

20.0

1.06

210

40.0

0.265

415

30.0

0.7

215

60.0

0.18

420

40.0

0.53

220

80.0

0.13

425

50.0

0.42

225

90.0

0.12

430

60.0

0.36

230

120.0

0.09

440

80.0

0.26

240

160.0

0.07

450

90.0

0.24

460

120.0

0.18

475

150.0

0.15

N3 Model

AC inductance at input side

Current (A)

Inductance

(mH)

(240V)

2P5

3.1

5.65

201

4.5

3.89

202

7.5

2.33

203

10.5

1.67

205

17.5

1.00

207

26

0.67

210

35

0.50

(460V)

401

2.3

15.22

402

3.8

9.21

403

5.2

6.73

405

8.8

3.98

407

13

2.69

410

17.5

2.00

415

25

1.40

14.0 Reactor Input / Output Specifications

The specifications for the input (AC Power side) and output (DC to Motor side) reactors are as shown in the following

tables.

Table 14.1 Input Reactor Specifications

Table 14.2 Output Reactor Specifications

Input & Output Reactor Specifications 20

Page 24

N3 Drive Operations Manual

N3

Inverter

Model

Braking Unit

Braking Resistor

per braking unit

Suitable Motor

Capacity

Braking resistor

Specification

Braking

Resistor Duty

Cycle (%)

Braking

torque

(%)

Resistor dimension

(L x W x H) mm

(inches)

Model

Qty

Type

(HP)

(KW)

(W)

(Ω)

2P5

- - JNBR-150W200

0.5

0.4

150

200

10

238

251*28*60

(9.88*1.10*2.36)

201

- - JNBR-150W200

1

0.75

150

200

10

119

251*28*60

(9.88*1.10*2.36)

202

- - JNBR-150W100

2

1.5

150

100

10

119

251*28*60

(9.88*1.10*2.36)

203

- - JNBR-260W70

3

2.2

260

70

10

115

274*34*78

(10.79*1.34*3.07)

205

- - JNBR-390W40

5

3.7

390

40

10

119

395*34*78

(10.79*1.34*3.07)

207

- - JNBR-520W30

7.5

5.5

520

30

10

108

400*40*100

(15.7*1.57*3.94)

210

- - JNBR-780W20

10

7.5

780

20

10

119

400*40*100

(15.7*1.57*3.94)

215

-

-

JNBR-2R4KW13R6

15

11

2400

13.6

10

117

535*50*110 (Qty 2)

(21.1*1.96*4.33)

220

- - JNBR-3KW10

20

15

3000

10

10

119

615*50*110 (Qty 2)

225

JNTBU-230

1

JNBR-4R8KW8

25

18.5

4800 8 10

119

535*50*110 (Qty 4)

(21.1*1.96*4.33)

230

JNTBU-230

1

JNBR-4R8KW6R8

30

22

4800

6.8

10

117

535*50*110 (Qty 4)

(21.1*1.96*4.33)

240

JNTBU-230

2

JNBR-3KW10

40

30

3000

10

10

119

615*50*110 (Qty 2)

(24.21*1.96*4.33)

401

- - JNBR-150W750

1

0.75

150

750

10

126

251*28*60

(9.88*1.10*2.36)

402

- - JNBR-150W400

2

1.5

150

400

10

119

251*28*60

(9.88*1.10*2.36)

403

-

-

JNBR-260W250-

3

2.2

260

250

10

126

274*34*78

(10.79*1.34*3.07)

405

-

-

JNBR-400W150-

5

3.7

400

150

10

126

395*34*78

(10.79*1.34*3.07)

407

-

-

JNBR-600W130-

7.5

5.5

600

130

10

102

470*50*100

(15.7*1.57*3.94)

410

- - JNBR-800W100

10

7.5

800

100

10

99

535*50*110

(24.21*1.96*4.33)

415

-

-

JNBR-1R6KW50

15

11

1600

50

10

126

615*50*110

(24.21*1.96*4.33)

420

-

-

JNBR-1R5KW40

20

15

1500

40

10

119

615*50*110

(24.21*1.96*4.33)

425

JNTBU-430

1

JNBR-4R8KW32

25

18.5

4800

32

10

119

535*50*110 (Qty 4)

(21.1*1.96*4.33)

430

JNTBU-430

1

JNBR-4R8KW27R2

30

22

4800

27.2

10

117

535*50*110 (Qty 4)

(21.1*1.96*4.33)

440

JNTBU-430

1

JNBR-6KW20

40

30

6000

20

10

119

615*50*110 (Qty 4)

(24.21*1.96*4.33)

450

JNVPHV-0060

1*5

JNBR-9R6KW16

50

37

9600

16

10

119

535*50*110 (Qty 8)

(21.1*1.96*4.33)

460

JNVPHV-0060

1*5

JNBR-9R6KW13R6

60

45

9600

13.6

10

117

535*50*110 (Qty 8)

(21.1*1.96*4.33)

475

JNTBU-430

2

JNBR-6KW20

75

55

6000

20

10

126

615*50*110 (Qty 4)

(24.21*1.96*4.33)

15.0 Braking Unit and Braking Resistor Selections

Formula for brake resistor: W= ( Vpnb * Vpnb ) * ED% / R

1. W: braking resistor power (Watts)

2. Vpnb: braking voltage (220V=380VDC, 440V=760VDC)

3. ED%: braking effective period

4. R: braking resistor rated ohms

5. Alternative selection choice: 450: (JNTBU-430 + JNBR-4R8KW32) 2, 460: (JNTBU-430 + JNBR-4R8KW27R2) 2

Above 25HP, please add Braking Transistor Units: 200V JNTBU-230, 400V JNTBU-430, and 400V JUVPHV-0060

For more detailed information, please contact TECO.

When installing a braking unit and resistor, ensure that there is adequate clearance and ventilation.

Braking Unit & Braking Resistor Selections 21

Page 25

N3 Drive Operations Manual

Inverter Model

Rating

(INPUT)

Filter Model

Second Environment

First Environment

Restricted Distribution

First Environment

Unrestricted Distribution

N3

2P5-CS

1 170 -264V

--

Built in

FS 6146-11-07

201-CS

1 170-264V

--

Built in

FS 6146-11-07

202-CS

1 170-264V

--

Built in

FS 6146-27-07

203-CS

1 170 -264V

--

Built in

FS 6146-27-07

2P5-CS

1 170 -264V

--

FS 6146-11-07

--

201-CS

1 170-264V

--

FS 6146-11-07

--

202-CS

1 170-264V

--

FS 6146-27-07

--

203-CS

1 170 -264V

--

FS 6146-27-07

--

2P5-C

3 170 -264V

--

FS 6147-8.9-07

--

201-C

3 170 -264V

--

FS 6147-8.9-07

--

202-C

3 170 -264V

--

FS 6147-8.9-07

--

203-C

3 170 - 264V

--

FS 6147-19-07

--

205-C

3 170 - 264V

--

FS 6147-19-07

--

207-C

3 170 - 264V

--

FS 6147-39-07

--

210-C

3 170 -264V

--

FS 6147-39-07

--

401-C

3 323 -528 V

--

Built in

FS 6149-4.6-07

402-C

3 323 -528 V

--

Built in

FS 6149-4.6-07

403-C

3 323 -528 V

--

Built in

FS 6149-10-07

405-C

3 323 -528 V

--

Built in

FS 6149-10-07

407-C

3 323 -528 V

--

Built in

FS 6149-28-07

410-C

3 323 -528 V

--

Built in

FS 6149-28-07

415-C

3 323 -528 V

--

Built in

FS 6149-28-07

401-C

3 323 -528 V

--

FS 6149-4.6-07

--

402-C

3 323 -528 V

--

FS 6149-4.6-07

--

403-C

3 323 -528 V

--

FS 6149-10-07

--

405-C

3 323 -528 V

--

FS 6149-10-07

--

407-C

3 323 -528 V

--

FS 6149-28-07

--

410-C

3 323 -528 V

--

FS 6149-28-07

--

415-C

3 323 -528 V

--

FS 6149-28-07

--

420-N1

3 323 -528 V

JUNF34048S-MA

--

--

425-N1

3 323 -528 V

KMF370A

--

--

430-N1

3 323 -528 V

KMF370A

--

--

440-N1

3 323 -528 V

KMF3100A

--

--

450-N1

3 323 -528 V

KMF3100A

--

--

460-N1

3 323 -528 V

KMF3150A

--

--

475-N1

3 323 -528 V

KMF3180A

--

--

16.0 EMC Filters

The inverters use PWM (Pulse Width Modulation) in the output power section which results in rapid on / off switching

of the solid state power devices (IGTB transistors). Because of this, unwanted EMI (Electromagnetic Interference) and

RFI (Radio Frequency Interference) is produced which may affect other equipment. The use of EMC filters listed in

the following table is used to control this interference within limits set forth by the following standards.

EMC Standard 89/336/EEC

EMI Radio Standard – EMS Immunity Standard

EN 61800-3 1996/A11 : 2000 First Environmental Unrestricted Distribution (Class B)

EN 61800-3 1996/A11 : 2000 First Environmental Restricted Distribution

Note: Please refer to Appendix D for dimensional information for the various type EMC filters.

EMC Filters 22

Page 26

N3 Drive Operations Manual

Output frequency

control potentiometer

(when selected)

4 digit 7 segment

LED display

Membrane keys

LED indicators

LED indicators

LED

STATUS

DESCRIPTION

SEQ (Sequence

OFF

Run Command Source is from the keypad (b000=0000)

(factory default)

ON

Run Command Source is from external terminal (b000=0001),

or RS485 communication control (b000=2)

FRQ (Frequency)

OFF

Frequency Command Source is from the keypad

(b004=0000) (factory default)

ON

Frequency Command Source is from potentiometer on

keypad (b004=1), external analog signal (b004=0002), up /

down frequency control using MFIT (S1-S6) (b004=0003) or

RS485 communication control (b004=0004)

*FWD (Forward)

ON

Drive is running in the forward direction

Flashing

Drive is in the stop mode

REV (Reverse)

ON

Drive is running in the reverse direction

Flashing

Drive is in the stop mode

FUN (Function)

ON

Entering A or b parameters

*Hz/RPM

ON

Display is showing output frequency

VOLT

ON

Display is showing motor voltage (b014=0001), DC bus

voltage (B015=0001) or PID feedback voltage (b016=0001)

AMPS

ON

Display is showing motor current (b013=0001)

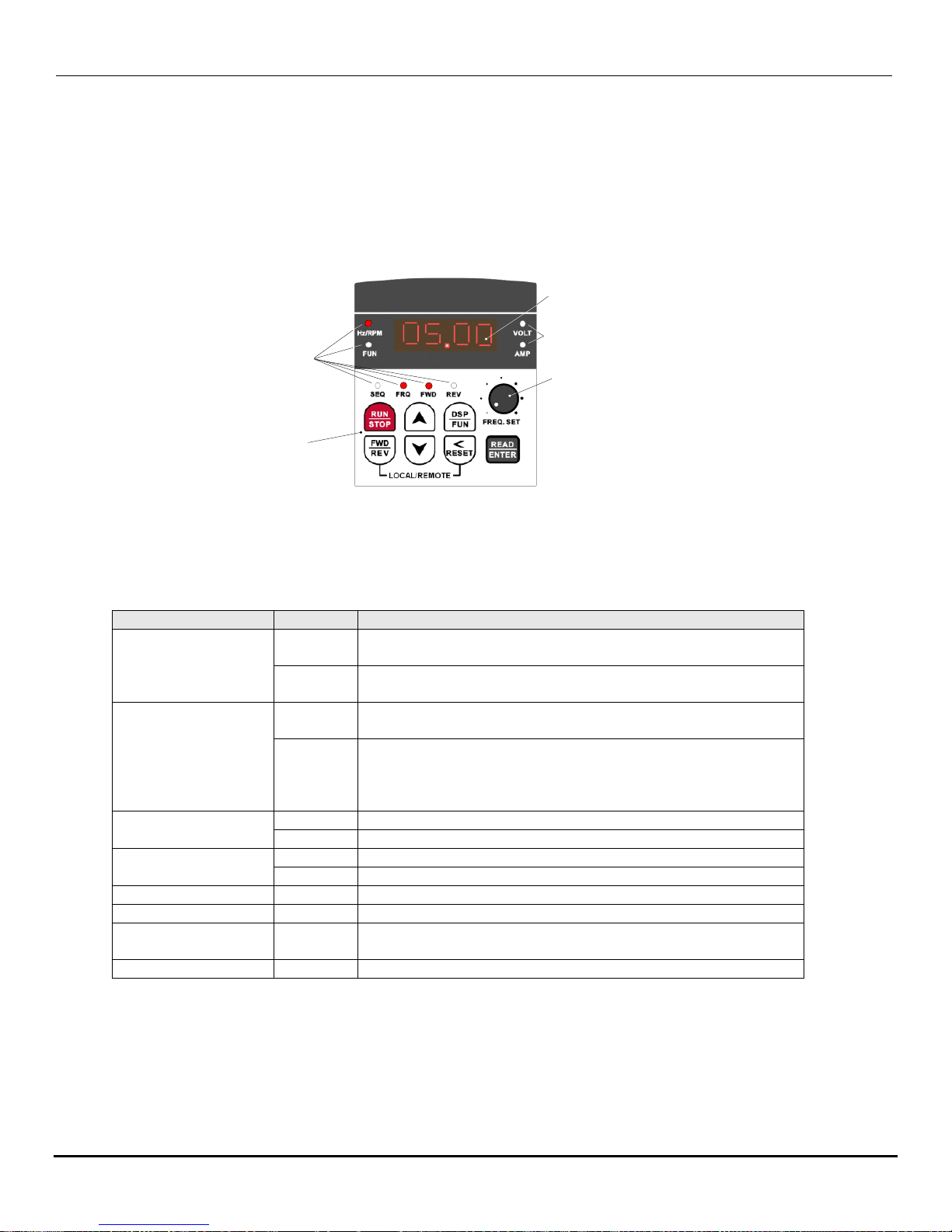

17.0 Keypad Key Functions and Navigation

The N3 keypad, provides all the necessary functions to allow full control of the N3 inverter. The keypad has

membrane type keys and a 7 - segment 4 - digit LED display. Also located on the keypad is a potentiometer that can

be used to control inverter output frequency when selected as the control source. A remote keypad is available as an

option, and is covered more in detail in the Option Modules Sec. 20.0.

17.1 N3 Keypad

Fig. 17.1 N3 Keypad

17.2 Keypad LED Functions

Table 17.1

*Note – On initial powerup (factory default), the only LEDs that are on are Hz/RPM and FWD.

Keypad Functions & Navigation; Key Functions 23

Page 27

N3 Drive Operations Manual

UP / DOWN

· Sets the inverter output frequency when using the keypad mode.

· Sets the value of the 4 display digits to set the *A and b parameters.

* Access to the A parameters must be enabled. (see Sec. 17.4.3)

RUN / STOP

· Controls the output of the inverter when selected in the keypad mode. It is an on /

off toggle function.

DISPLAY / FUNCTION

· Toggles the display between the inverter output selected value (Hz etc.) and the *A

and b parameter lists. Also when AMPS and or VOLTS are selected for display, the

key will sequence through to display Hz/RPM, A and b parameter lists, AMPS or

VOLTS.

READ / ENTER

· Used to READ and /or save (ENTER) *A and b parameters.

STOP

RUN

FUN

DSP

FWD

REV

FWD / REV

· Controls the direction of the motor ( inverter output) when selected in the keypad

mode. It is an on / off toggle function.

· Used in conjunction with the RESET / SCROLL key to toggle between Local and

Remote operation.

RESET

RESET / SCROLL

· Resets the inverter after a fault

· Scrolls through the position of the 4 display digits to set the *A and b parameters.

· Used in conjunction with the FWD / REV key to toggle between Local and Remote

operation.

READ

ENTER

!

CAUTION

Do not use any sharp or potentially damaging objects to operate the keypad.

17.3 Key Functions

The keys are multifunctional, providing for both control of the inverter when keypad mode is selected (default) and

access in setting various parameters. The key functions are as follows.

Table 17.2

NOTES:

Keypad Functions & Navigation; Key Functions 24

Page 28

N3 Drive Operations Manual

Initial Power-up

Input Voltage

(Vac)

Display

flashing

Initial output

frequency

(Hz)

Display flashing

in STOP mode

Display steady

in RUN mode

Fig. 17.2 Basic Keypad Control

Approx. 2 sec.

Reset after

Fault clear

STOP

RUN

Up

Down

RESET

Select digit position

Select digit value

Output frequency control

0 – 50/60 Hz in 0.01Hz increments

FWD

REV

STOP

RUN

STOP

Local / Remote Function

In Local mode:

· The RUN command is controlled by the RUN / STOP key.

· FREQUENCY command

If b004 = 0000: The UP/DOWN keys control the output frequency.

If b004 = 0001: The front panel potentiometer controls the output frequency.

FWD

REV

RESET

In Remote mode:

· The RUN command is controlled via the function set by (b000)

· The frequency command is set by the function set by (b004)

To toggle between Local / Remote press the keys simultaneously.

17.4 Keypad Navigation

When attempting to control and set various parameters for the inverter it would be useful for the user to become

familiar with keypad navigation and to go through a few function changes before making the final settings.

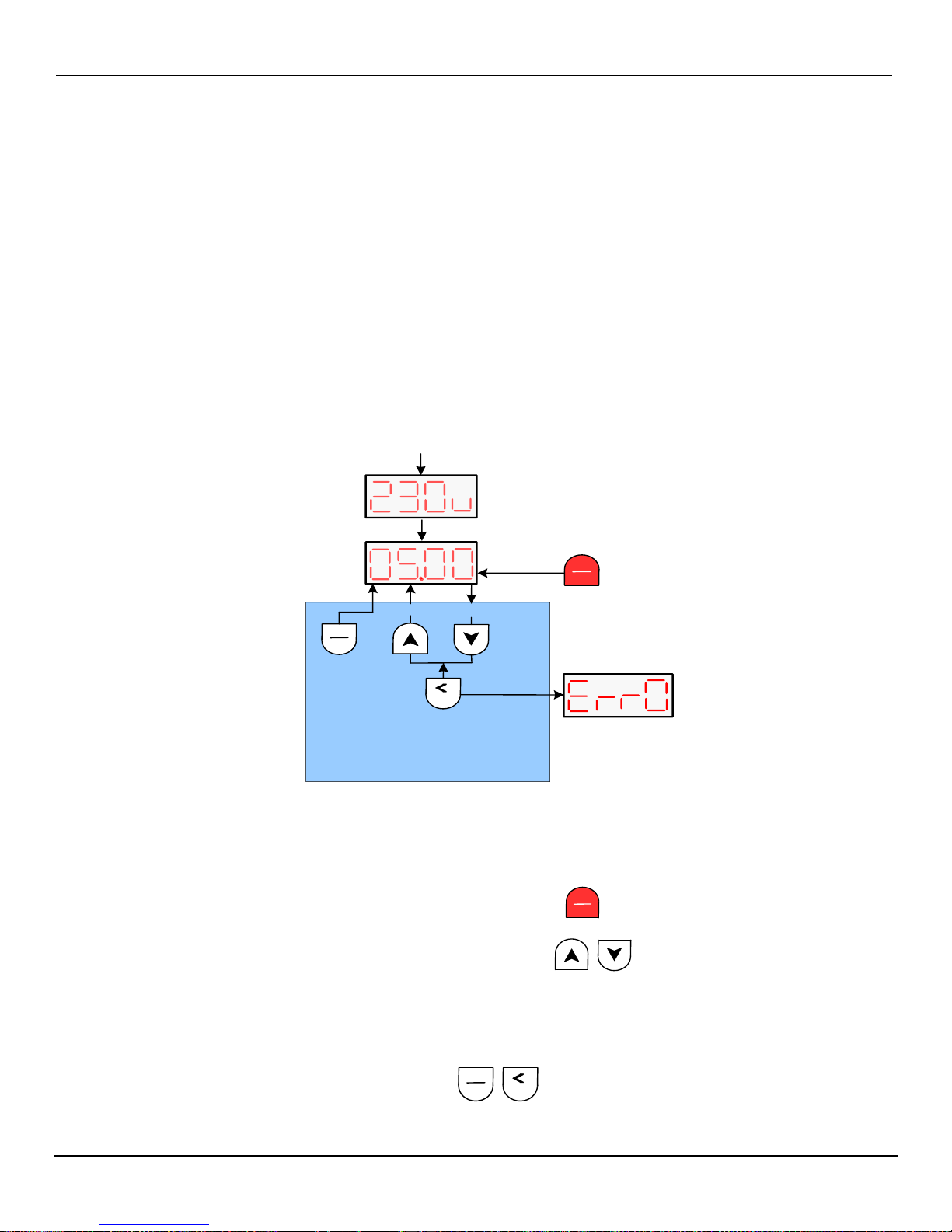

17.4.1 Basic Keypad Control (Factory Default, b000=0000 & b004=0000)

In its basic form as received from the factory, the inverter output is controlled from the keypad. Please refer to the A

and b parameter list (Sec. 19.0) to view the factory default settings for the various parameters. When the inverter is

powered up, the display will be flashing and momentarily show the inverter input voltage. The flashing display will

then switch to a minimum output frequency of 05.00Hz, the FWD LED will be flashing and the Hz/RPM LED will be on.

By pressing the STOP / RUN key the output is active (RUN) and the display is on solid as is the FWD LED. Using the

< / RESET key to select the digit position and the UP/DOWN keys to select the digit value, the output frequency

may then be set from 00.0 to 50.0/60.0Hz with minimum increments of 00.1Hz. The FWD/REV key may be toggled to

set the output direction. Both the output frequency and the output direction can be set when the inverter is in the RUN

or STOP mode. When the RUN/STOP key is toggled to STOP, the set frequency is displayed and the display is again

flashing. The < / RESET key also functions to initiate a RESET after a Fault is cleared.

17.4.2 Local / Remote Function

Keypad Functions & Navigation; Basic Keypad Control 25

Page 29

N3 Drive Operations Manual

RESET

Scroll from

b000 to b016

b parameters

displayed

Scroll to function

or code value

Display flashes

Then returns to

parameter selected

Parameter

function or value

saved

Toggles display between the set output

frequency (main display) and b or A

parameters (

when A is activated

)

To enter the A parameters, select

b011 and then 0001

Returns to b menu

Fig. 17.3 Setting b (Basic) and A (Advanced) Parameters

FUN

DSP

READ

ENTER

READ

ENTER

Up

Down

RESET

Select digit position

Select digit value

Scroll from

A000 to A181

Scroll to function

or code value

Display flashes

Then returns to

parameter selected

Parameter

function or value

saved

READ

ENTER

READ

ENTER

Up

Down

RESET

Select digit position

Select digit value

Returns to A menu

Select Leftmost digitSelect A

A parameters

displayed

FUN

DSP

Press at any time to

return to the main

display

READ

ENTER

Display flashes

Then returns to

parameter selected

17.4.3 Setting Parameters b(Basic) and A(Advanced)

The accessing and setting of parameter groups b and A will be discussed next.

Important ! The A (Advanced) parameters are not directly accessible and must be enabled by setting

parameter b011=0001.

Setting b (Basic) parameters

The basic parameters b can be accessed in two ways; the keypad or through the MODBUS protocol using an

optional communications module. Here only keypad access will be described. Before proceeding, refer to the b and

A parameter list (Sec. 19.0) and note that some parameters must be changed with the inverter in the STOP mode

while others can be changed in either the RUN or STOP mode. Also changing certain parameters may also affect

other functions and should be considered before making those changes.

To enter the b parameters, press the DSP/ FUN key; the display should show b000. Using the

> / RESET key to select the digit position and the Λ / V keys to select the value, enter the parameter to be set and

then press the READ / ENTER key to save; the display should momentarily flash End and return to the parameter

selected.

Setting A (Advanced) parameters

As previously mentioned, the A parameters are not directly accessible and must be enabled. To do this, select

parameter b011 and then Code = 0001 (Enable). Press the READ / ENTER key to save; the display should be

showing b011. Using the > / RESET key scroll to b000 position and then press the Λ key; A000 will be displayed.

Using the same procedure in setting the b parameters scroll to the desired A parameter and select the code or

function to be set and then press the READ / ENTER key to save. After all parameter changes have been made,

press the DSP/FUN key to return the main display show the output frequency.

Keypad Functions & Navigation; Setting b & A Parameters 26

Page 30

N3 Drive Operations Manual

Control Mode

Variable Torque

A000=1

Vector Control

Parameters to be Set:

A001 Motor rated voltage

A002 Motor rated current

A003 Motor HP

A004 Motor rated speed

A005 Motor rated frequency

A007 AC line input voltage

Perform auto tuning : A006=1

Parameters that can be Set:

B009 V/f Pattern

A129 Torque boost

A130 Motor no load current

A131 Motor rated slip

A132 Max. output frequency

A133 Max. output voltage

A134 Medium output frequency

A135 Medium output voltage

A136 Min. output frequency

A137 Min. output voltage

Suitable motor current A002

(OL1 reference)

General Vector

A000=0

V/f Control

A000=2

(Factory Default)

END

Select Control Mode

18.0 Control Mode Selection

The N3 inverter series has three control modes:

1. General Vector Control.

2. VT (Variable torque) Vector Control (Special for Fans and Pumps).

3. V/f Control (Factory default).

The user can select one of these control modes by following the flow chart below and setting the parameters as

shown. When vector control is selected the motor HP must match the inverter rating.

The V/f control mode should be used when the following conditions apply.

(1) Using one inverter to drive several motors simultaneously.

· In this case the rated inverter output current must equal or exceed the sum total of all of the motors

(2) The motors’ nameplate information is unknown or the motor ratings are not standard.

(3) The specifications of the inverter and motor differ by more than 1 HP.

In V/f control, A001 - A005 max. & min. values are determined by the TECO standard motor specification limit.

When parameter A000 = 2 (V/f control), the keypad will display ‘Err2’ if Auto tuning is performed.

connected.

· The correct V/f pattern must be set by parameters A132 – A137.

· In this case the inverter will set the motor characteristics in accordance with a standard TECO motor.

Control Mode Selection 27

Page 31

N3 Drive Operations Manual

Parameter

No.

LCD Display

Description

Range/Code

Factory

Setting

Remarks

b000

Run Source

Run Command

Source Selection

0000: Keypad

0001: External Run/Stop Control

0002: Communication

0000

b001

MFIT Run

Mode

Run/StopForward/Reverse

Operation Mode

with External

Terminals

0000: Forward/Stop-Reverse/Stop

0001: Run/Stop-Forward/Reverse

0002: 3-Wire Control Mode Run/Stop

0000

b002

Reverse

Oper

Reverse Prohibit

operation

0000: Enable Reverse Command

0001: Disable Reverse Command

0000

b003

Stopping

Method

Stopping Method

Selection

0000: Deceleration-to- Stop with

DC Injection Braking (Rapid

Stop)

0001: Coast to a Stop

0000

19.0 b (Basic) and A (Advanced) parameters defined.

The N3 inverter has two programmable function parameter categories; A (Advanced) and b (Basic) which are

described in detail in this section. It is important to note that while the parameters are set individually, they are

interactive with other parameters and must be considered when adjusting the value. It would be prudent on the users’

part to consider all parameters that are to be changed for a particular application before setting the individual values.

Note that the Advanced parameters are designated with an uppercase A, where the Basic parameters are designated