TECO L510-201-H1F-P, L510-2P2-H1F-P, L510-202-H1F-P, L510-2P2-H1-N, L510-203-H1F-P Operating Manual

...Page 1

L510 Series 100V

200V

400V

0.2~0.75KW

(0.25~1HP)

0.2~2.2KW

(0.25~3HP)

0.75~2.2KW

(1~3HP)

Microprocessor Controlled

IGBT Drive

Inverter Motor Speed Regulator

Operating Manual

Page 2

I

L510 Table of Contents

Chapter 0 Preface

0-1

0.1 Preface

0-1

Chapter 1 Safety Precautions

1-1

1.1 Before Power UP

1-1

1.2 During Power UP

1-2

1.3 Before Operation

1-2

1.4 During Operation

1-3

1.5 Inverter Disposal

1-3

Chapter 2 Part Number Definition

2-1

2.1 Model part number

2-1

2.2 Standard Product Specification

2-2

Chapter 3 Environment & Installation

3-1

3.1 Environment

3-1

3.2 Installation

3-2

3.2.1 Installation methods

3-2

3.2.2 Installation space

3-4

3.2.3 De-rating curve

3-5

3.3 Wiring guidelines

3-6

3.3.1 Power cables

3-6

3.3.2 Control cable selection and wiring

3-7

3.3.3 Wiring and EMC guidelines

3-8

3.3.4 Failure liability

3-9

3.3.5 Considerations for peripheral equipment

3-10

3.3.6 Ground connection

3-11

3.3.7 Inverter exterior

3-11

3.4 Specifications

3-12

3.4.1 Product Specifications

3-12

3.4.2 General Specifications

3-13

3.5 Standard wiring

3-15

3.5.1 Single phase(NPN input)

3-15

3.5.2 Single phase(PNP input)

3-16

3.5.3 Three phase(NPN input)

3-17

3.5.4 Three phase(PNP input)

3-18

3.6 Terminal Description

3-19

3.6.1 Description of main circuit terminals

3-19

3.6.2 Control circuit terminal description

3-20

3.7 Outline Dimensions

3-21

3.8 EMC filter Disconnection

3-23

Chapter 4 Software Index

4-1

4.1 Keypad Description

4-1

4.1.1 Operator Panel Functions

4-1

4.1.2 Digital Display Description

4-2

4.1.3 Digital Display Setup

4-4

Page 3

II

4.1.4 Example of Keypad Operation

4-6

4.1.5 Operation Control

4-8

4.2 Programmable Parameter Groups

4-9

4.3 Parameter Function Description

4-22

Chapter 5 Troubleshooting and Maintenance

5-1

5.1 Error Display and Corrective Action

5-1

5.1.1 Manual Reset and Auto-Reset

5-1

5.1.2 Keypad Operation Error Instruction

5-2

5.1.3 Special conditions

5-3

5.2 General troubleshooting

5-4

5.3 Troubleshooting of the inverter

5-5

5.3.1 Quick troubleshooting of the inverter

5-5

5.3.2 Troubleshooting for OC, OL error displays

5-7

5.3.3 Troubleshooting for OV, LV error

5-8

5.3.4 The Motor can not run

5-9

5.3.5 Motor Overheating

5-10

5.3.6 Motor runs unbalanced

5-11

5.4 Routine and periodic inspection

5-12

5.5 Maintenance

5-13

Chapter 6 Peripheral Components

6-1

6.1 Reactor Specifications

6-1

6.2 Electromagnetic Contactor and No fuse circuit breaker

6-1

6.3 Fuse Specification

6-1

6.4 Fuse Specification(UL Model Recommended)

6-1

6.5 Barking Resistor

6-2

Appendix I L510 Parameters Setting List

App1-1

Page 4

0-1

Chapter 0 Preface

0.1 Preface

To extend the performance of the product and ensure personnel safety, please read

this manual thoroughly before using the inverter. Should there be any problem in

using the product that cannot be solved with the information provided in the manual,

contact our technical or sales representative who will be willing to help you.

※Precautions

The inverter is an electrical product. For your safety, there are symbols such as

“Danger”, “Caution” in this manual as a reminder to pay attention to safety

instructions on handling, installing, operating, and checking the inverter. Be sure to

follow the instructions for highest safety.

Danger

Indicates a potential hazard that could cause death or serious

personal injury if misused.

Caution

Indicates that the inverter or the mechanical system might be damaged

if misused.

Danger

¾ Risk of electric shock. The DC link capacitors remain charged for five

minutes after power has been removed. It is not permissible to open the

equipment until 5 minutes after the power has been removed.

¾ Do not make any connections when the inverter is powered on. Do not check

parts and signals on circuit boards during the inverter operation.

¾ Do not disassemble the inverter or modify any internal wires, circuits, or

parts.

¾ Ensure that the Inveter Ground terminal is connected correctly.

Caution

¾ Do not perform a voltage test on parts inside the inverter. High voltage can

destroy the semiconductor components.

¾ Do not connect T1, T2, and T3 terminals of the inverter to any AC input

power supply.

¾

CMOS ICs on the inverter’s main board are susceptible to static electricity. Do

not touch the main circuit board.

Page 5

1-1

Chapter 1 Safety Precautions

1.1 Before Power Up

Danger

¾

Make sure the main circuit connections are correct. Single phase L1(L),L3(N), and

Three phase 200V L1(L),L2,L3(N); 400V : L1,L2,L3 are power-input terminals and

must not be mistaken for T1,T2 and T3. Otherwise, inverter damage can result.

Caution

¾ The line voltage applied must comply with the inverter’s specified input

voltage.(See the nameplate)

¾ To avoid the front cover from disengaging, or other damge do not carry the

inverter by its covers. Support the drive by the heat sink when transporting.

Improper handling can damage the inverter or injure personnel and should be

avoided.

¾ To avoid the risk of fire, do not install the inverter on a flammable object.Install on

nonflammable objects such as metal.

¾ If several inverters are placed in the same control panel, provide heat removal

means to maintain the temperature below 50 degree C to avoid overheat or fire.

¾ When disconnecting the remote keypad, turn the power off first to avoid any

damage to the keypad or the inverter.

Warning

¾ This product is sold subject to EN 61800-3 and EN 61800-5-1.

In a domestic environment this product may cause radio interference in which

case the user may be required to apply corrective measures.

Caution

¾ Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material. Only

suitably qualified personnel trained in the setup, installation, commissioning and

operation of the product should carry out work on the device/system.

¾ Only permanently-wired input power connections are allowed.

Page 6

1-2

1.2 During Power Up

Danger

¾ When the momentary power los s is longer than 2 seconds, the inverter will not

have sufficient stored power for its control circuit. Therefore, when the power is

re-applied, the run operation of the inverter will be based on the setup of

following parameters:

• Run parameters. 00-02 or 00-03.

• Direct run on power up. Parameter. 07-04 and the status of external run

switch,

Note-: the start operation will be regardless of the settings for parameters

07-00/07-01/07-02.

Danger. Direct run on power up.

If direct run on power up is enabled and inverter is set to external run

with the run FWD/REV switch closed then the inverter will restart.

Danger

Prior to use, ensure that all risks and safety implications are considered.

¾ When the momentary power loss ride through is selected and the power loss is

short, the inverter will have sufficient stored power for its control circuits to

function, therefore,when the power is resumed the inverter will automatically

restart depending on the setup of parameters 07-00 & 07-01.

1.3 Before Operation

Caution

¾ Make sure the model and inverter capacity are the same as that set in

parameter 13-00.

Note : On power up the supply voltage set in parameter 01-01 will flash on display

for 2 seconds.

Page 7

1-3

1.4 During Operation

Danger

¾ Do not connect or disconnect the motor during operation. Otherwise, It may

cause the inverter to trip or damage the unit.

Caution

¾ Do not touch heat radiating components such as heat sinks and brake resistors.

¾ The inverter can drive the motor from low speed to high speed. Verify the allowable

speed ranges of the motor and the associated machinery.

¾ Note the settings related to the braking unit.

¾ Risk of electric shock. The DC link capacitors remain charged for five minutes after

power has been removed. It is not permissible to open the equipment until 5

minutes after the power has been removed.

Caution

¾ The Inverter should be used in environments with temperature range from

(14-104℉) or (-10 to 40℃) and relative humidity of 95%.

Danger

¾ Make sure that the power is switched off before disassembling or checking

any components.

1.5 Inverter Disposal

Caution

Please dispose of this unit with care as an industrial waste and according to your

required local regulations.

¾ The capacitors of inverter main circuit and printed circuit board are considered as

hazardous waste and must not be burnt.

¾ The Plastic enclosure and parts of the inverter such as the cover board will release

harmful gases if burnt.

Danger

¾ To avoid electric shock, do not take the front cover off while power is on.

¾ The motor will restart automatically after stop when auto-restart function is enabled.

In this case, care must be taken while working around the drive and associated

equipment .

¾ The operation of the stop switch is different than that of the emergency stop switch.

The stop switch has to be activated to be effective. Emergency stop has to be

de-activated to become effective.

Page 8

2-1

Chapter 2 Part Number Definition

2.1 Model part number

L510 - 1P2 - H1 - N

Power supply

1:Single phase

3:Three phase

Specification

H:Standard Type

Supply voltage

1:100V Class

2:200V Class

4 : 400V Class

Horsepower

100V Class P2: 0.25 HP 400V Class 01: 1HP

P5: 0.5 HP 02 : 2HP

01: 0.75 HP 03: 3HP

200V Class P2: 0.25 HP

P5: 0.5 HP

01: 1 HP

02: 2 HP

03: 3 HP

Filter

F :Built-in

Blank:None

P:PNP

N:NPN

Internal Voltage

Blank : +12V Series

A:+24V Series

Page 9

2-2

2.2 Standard Product Specification

100V/200V (If the model is marked A, it means that it is built in the power supply of 24V; if not, then it

is built in the power supply of 12V.)

Model Filter

Model

Supply

Voltage

(Vac)

Frequency

(Hz)

(HP)

(KW)

NPN PNP

Built-in

None

L510-1P2-H1-N

0.25 0.2

◎ ◎

L510-1P5-H1-N

0.5 0.4

◎ ◎

L510-101-H1-N

1ph,

100~120V

+10%/-15%

1 0.75

◎ ◎

L510-2P2-H1F-P

0.25 0.2

◎ ◎

L510-2P5-H1F-P

0.5 0.4

◎ ◎

L510-201-H1F-P

1 0.75

◎ ◎

L510-202-H1F-P

2 1.5

◎ ◎

L510-203-H1F-P

3 2.2

◎ ◎

L510-2P2-H1-N

0.25 0.2

◎ ◎

L510-2P5-H1-N

0.5 0.4

◎ ◎

L510-201-H1-N

1 0.75

◎ ◎

L510-202-H1-N

2 1.5

◎ ◎

L510-203-H1-N

1ph,

200~240V

+10%/-15%

3 2.2

◎ ◎

L510-2P2-H3-N

0.25 0.2

◎

◎

L510-2P5-H3-N

0.5 0.4

◎ ◎

L510-201-H3-N

1 0.75

◎ ◎

L510-202-H3-N

2 1.5

◎ ◎

L510-203-H3-N

3ph,

200~240V

+10%/-15%

50/60Hz

3 2.2

◎ ◎

400V (Models of 400V machines are all marked A, built in the power supply of 24V.)

Model Filter

Model

Supply

Voltage

(Vac)

Frequency

(Hz)

(HP) (KW)

NPN PNP

Built-in

None

L510-401-H3-N A 1 0.75

◎ ◎

L510-402-H3-N A 2 1.5

◎ ◎

L510-403-H3-N A 3 2.2

◎ ◎

L510-401-H3F-P A 1 0.75

◎ ◎

L510-402-H3F-P A 2 1.5

◎ ◎

L510-403-H3F-P A

3ph,

380~480V

+10%/-15%

50/60Hz

3 2.2

◎ ◎

Suitable for use on a circuit capable of delivering not more than 5,000 rms symmetrical amperes,

120/240 volts maximum. The voltage shall be 120 for 100-120 V, 240 for 200-240 V, 480 for

380-480V rated units.

Page 10

3-1

Chapter 3 Environment & Installation

3.1 Environment

Installation environment has a direct affect on the correct operation and the life expectancy of the

inverter, Install the inverter in an environment complying with the following conditions:

Protection

Protection

class

IP20, NEMA/UL Open Type

Suitable environment

Operating

temperature

-10~40°C (-10~50°C with fan)

If several inverters are installed in the same control panel, ensure

adequate spacing and provide the necessary cooling and ventilation for

successful operation.

Storage

temperature

-20~60°C

Relative

Humidity

Max 95% (without condensation)

Notice prevention of inverter freezing up.

Shock

1G. (9.8m/s²) for 20Hz and below.

0.6G (5.88m/s²) from 20Hz to 50Hz

Installation site

Install in an environment that will not have an adverse effect on the operation of the unit

and ensure that there is no exposure to areas such as that listed below:-

¾ Direct sunlight, Rain or moisture

¾ Oil mist and salt

¾ Dust, lint fibbers, small metal filings and corrosive liquid and gas

¾ Electromagnetic interference from sources such as welding equipment

¾ Radioactive and flammable materials

¾ Excessive vibration from machines such as stamping, punching machines

¾ Add a vibration-proof pads if necessary

Tightening torque for terminals

Chart 3-1

TM1 TM2

Cable Size Cable Size

Tightening torque Tightening torque Model

AWG mm²

kgf.cm Ibf.in Nm

AWG mm²

kgf.cm Ibf.in Nm

Frame1

14 12.15 1.37

Frame2

22~10 0.34~6

12.24 10.62 1.2

24~12 0.25~4 4.08 3.54 0.4

Page 11

3-2

3.2 Installation

3.2.1 Installation methods

Frame1. Mounting on a flat surface.

Din rail type installation:

Din rail kit includes a plastic and a metal adaptor plates.

Assembly Steps:-

1) Attach the metal adaptor plate to the inverter base with the screws provided.

2) Attach the plastic Din rail adaptor to the metal adaptor plate.

3) Push the plastic adaptor forward to lock into position.

Disassembly Steps:-

1) Unlock by pushing the snap hooks

2) Retract and remove the plastic Din rail adaptor.

3) Unscrew the metal plate &Remove

Note:

JN5-DIN-L01 (Frame 1 Din rail kit part number), including the following parts

1. Metal plate adaptor

2. Plastic adaptor

3. Chamfer head screw: M3×6

Screw: M4

1. Metal plate adapto

r

2. Plastic adaptor

Snap hooks

1. Metal plate adaptor

2. Plastic adapto

r

Snap hooks

3. screws

3. screws

Assembly:-

Disassembly:-

Page 12

3-3

Frame 2. Mounting on a flat surface.

Din rail type installation:

Din rail kit includes a plastic adaptor plate as an attachment for the inverter base.

Refere to Diagram below:-

Din Rail Mounting & Dismounting as shown in the diagram below:-Use a 35mm Din Rail.

Plastic adaptor plate.

JN5-DIN-L02 (Frame 2 Din rail kit part number)

Mounting

Dismounting

Assembly:-

Disassembly:-

Plastic Adaptor plate

Snap hook

Middle Snap hook

Screw: M4

Page 13

3-4

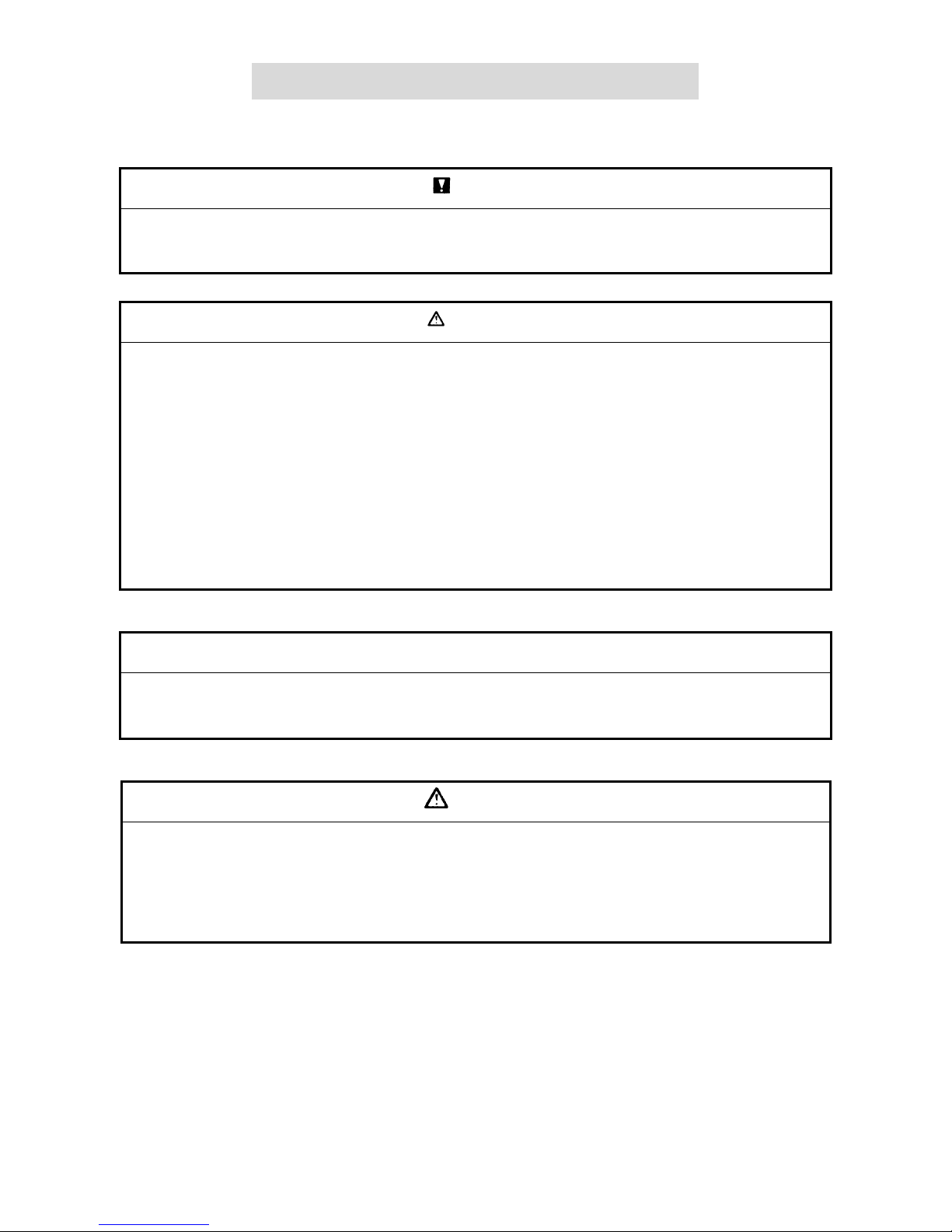

3.2.2 Installation space

Provide sufficient air circulation space for cooling as shown in examples below.

Install the Inverter on surfaces that provide good heat dissipation.

Single unit Installation

Install the inverter verticality to obtain effective cooling.

Frames1 & 2.

Side by side Installation

5cm 5cm

12cm

12cm

Front view

CONTROL

PANEL

Fan Fan

Side view

Provide the necessary

physical space and cooling

based on the ambient

temperature and the heat

loss in the panel

CONTROL

PANEL

5cm

Page 14

3-5

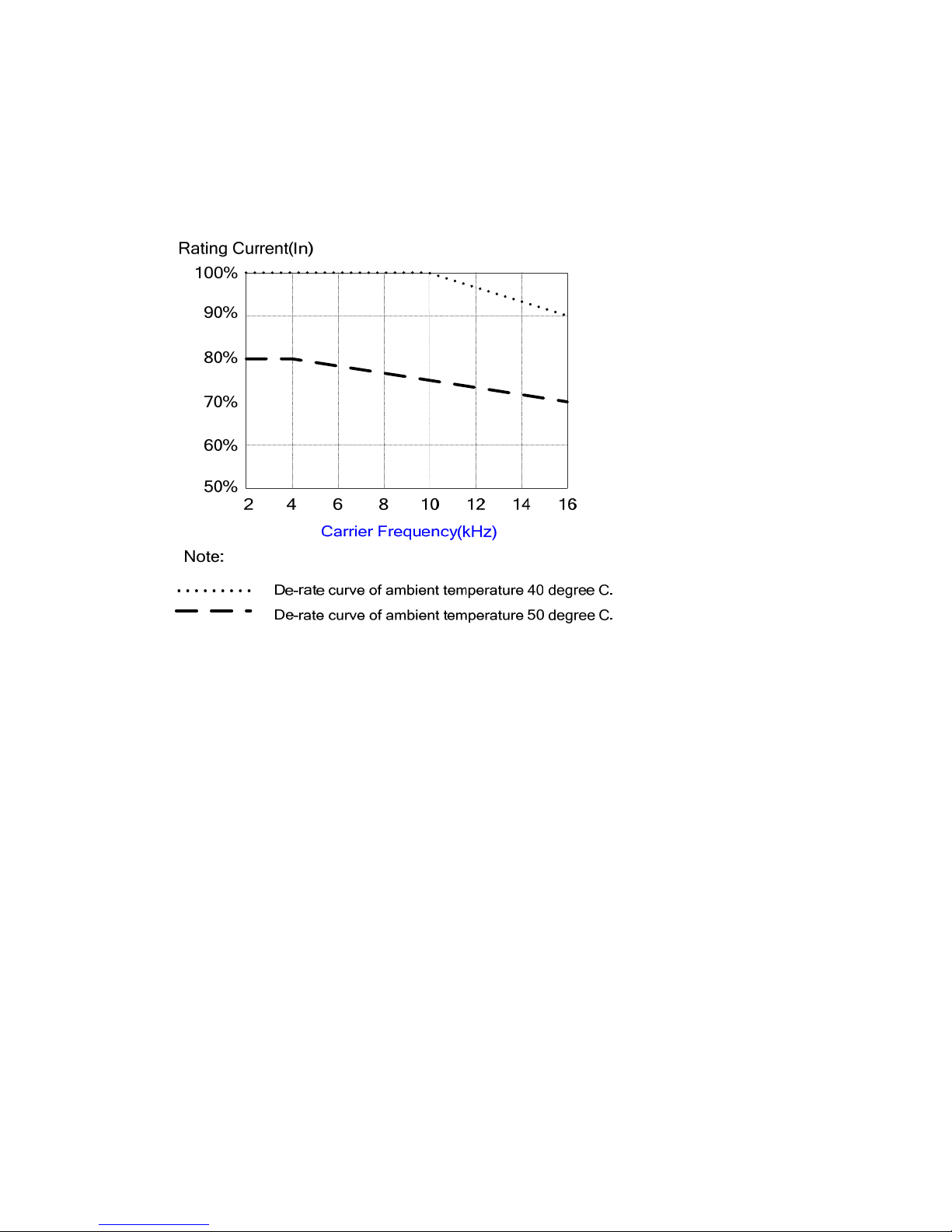

3.2.3 De-rating curve

Curves below show the applicable output current de-rate due to setting of carrier

frequency and the ambient operating temperatures of 40 and 50 degree C.

Page 15

3-6

3.3 Wiring Guidelines

3.3.1 Power Cables.

Supply power cable must be connected to TM1 terminal block, terminals L1(L) and L3(N) for

single phase 200V supply, L1(L), L2, L3(N) for three phase 200V supply and L1, L2, L3 for

three phase 400V supply.

Motor cable must be connected to TM1 terminals. T1, T2, T3.

Warning:- Connection of Supply line cable to terminals T1,T2& T3 will result in serious

damage to the drive components.

Example power connections:- Inverter with dedicated power line.

Inverter IM

Power

MCCB

¾

Install a Supply RFI filter or Isolation transformer when the power source is shared

with other high power electrical equipment as shown below.

Inverter IM

Machine

Insulation transformer

Power

MCCB

¾ The maximum rms symmetrical amperes and voltage are listed as follows:

Device Rating

voltage HP

Short circuit Rating Maximum Voltage

110V 0.2~1 5000A 120V

220V 0.2~3 5000A 240V

440V 1~3 5000A 480V

¾ Electrical ratings of terminals:

Horsepower Power Specification Voltage (Volt) Current(A)

0.25/0.5/1 220V 30

1 110V 20

2/3 220V

300

30

1/2/3 440V 600 28

Inverter IM

Machine

RFI

Filter

Power

MCCB

Page 16

3-7

3.3.2 Control Cable selection and Wiring.

Control cables should be connected to terminal block TM2.

Choose power & Control cables according to the following criteria:-

¾ Use copper wires with correct diameter and temperature rating of 60/75°C.

¾ Minimum cable voltage rating for 200V type inverters should be 300VAC.

¾ Route all cables away from other high voltage or high current power lines

to reduce interference effects.

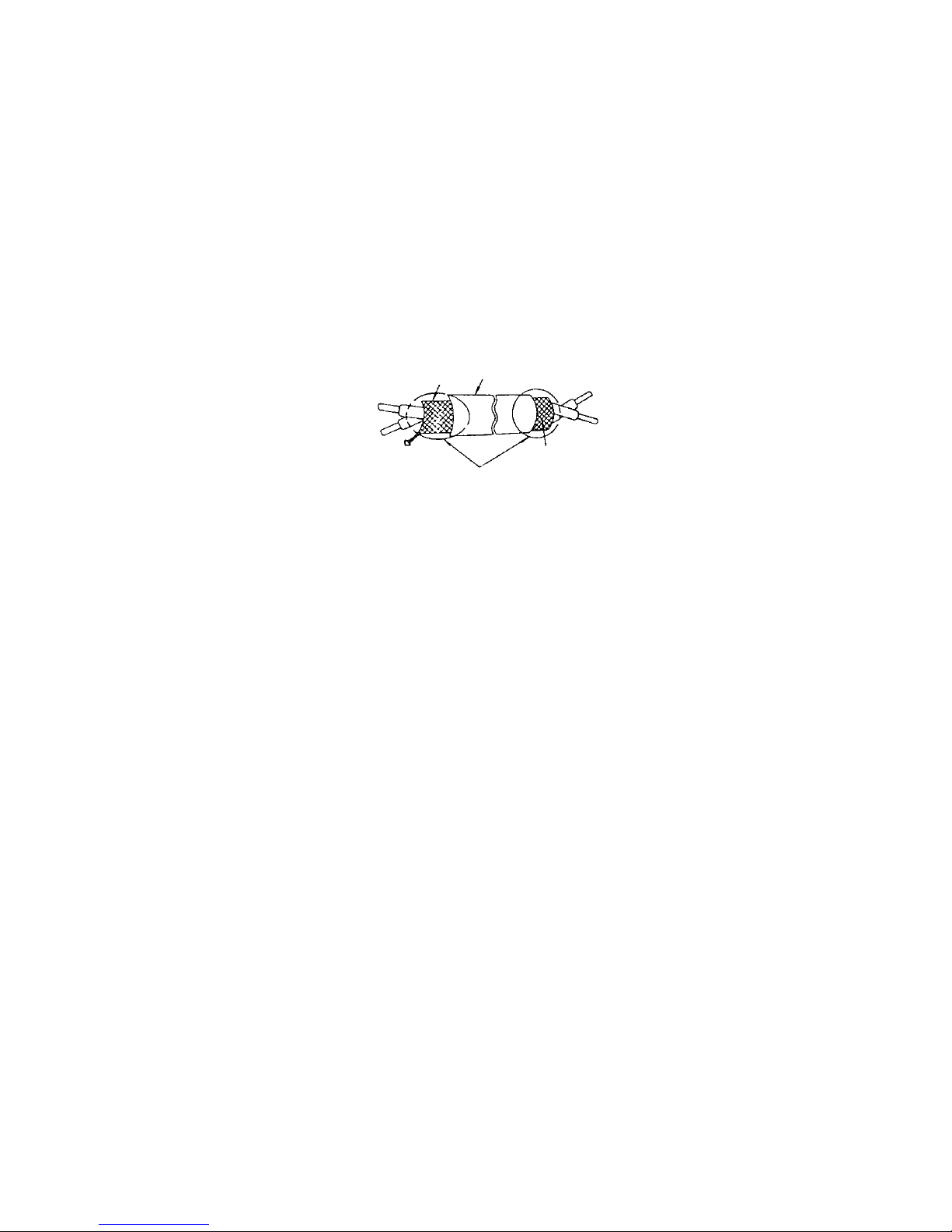

Use a twisted pair shielded cable and connect the shield (screen) wire to the ground

terminal at the inverter end only. Cable length should not exceed 50 meters.

Shielding sheath

Protective covering

Connect the shield to inverter

ground terminal

Do not connect this end

Page 17

3-8

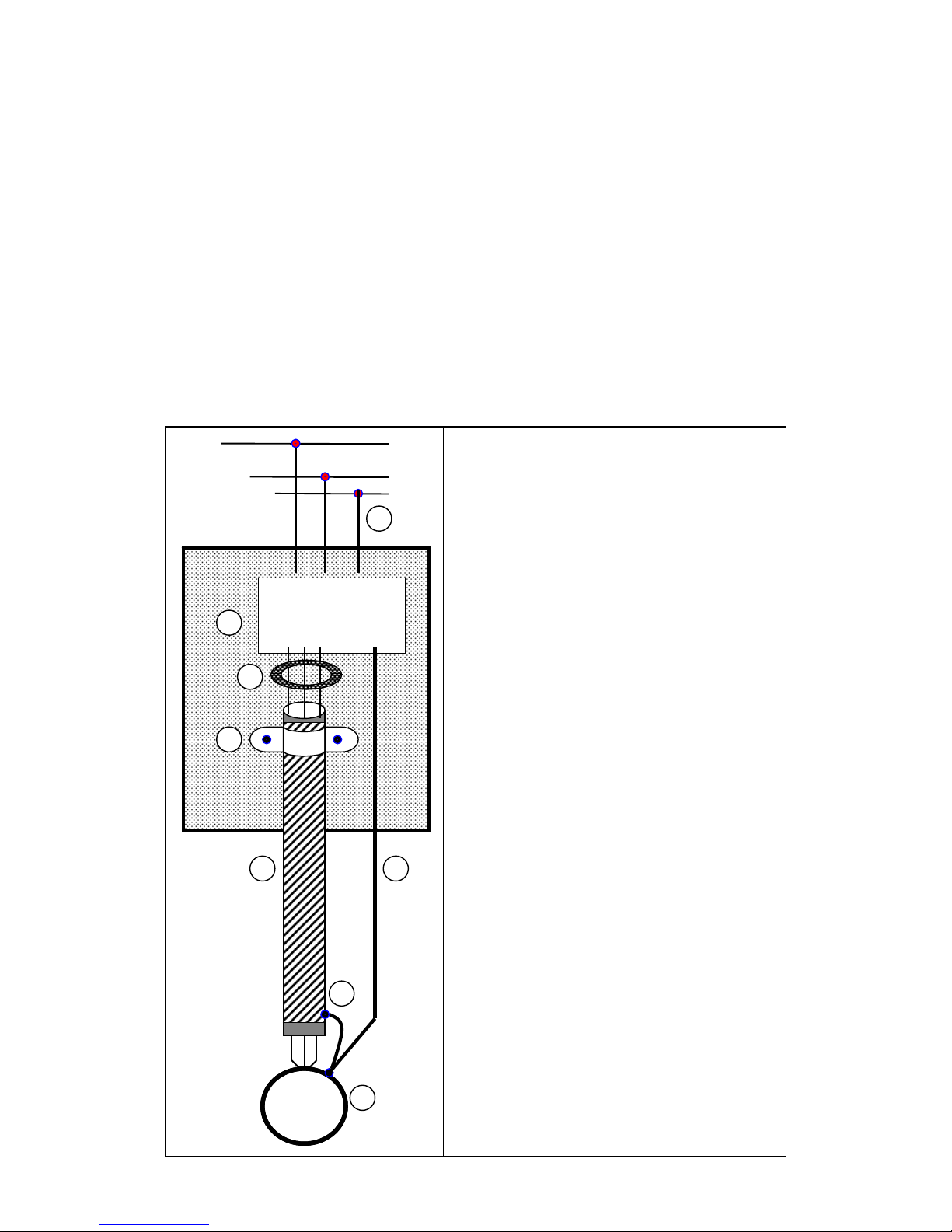

3.3.3 Wiring and EMC guidelines.

For effective interference suppression, do not route power and control cables in the same

conduit or trucking.

To prevent radiated noise, motor cable should be put in a metal conduit. Alternatively an

armored or shielded type motor cable should be used.

For effective suppression of noise emissions the cable armor or shield must be grounded at

both ends to the motor and the inverter ground. These connections should be as short as

possible.

Motor cable and signal lines of other control equipment should be at the least 30 cm apart.

L510 has a built in Class “A” EMC filter to first Environment Restricted. (Category C2).

For some installations such as residential,(Category C1) an optional external Class “B” type

filter will be necessary. Please consult your local supplier.

Typical Wiring.

5 6

7

8

Drive

2

3

1

4

1.Protective Earth Conductor.

Conductor size for enclosure &

Back plate must comply with the local electrical

standards. Min 10mm².

2.Back plate. Galvanised steel (Unpainted).

3.Ferrite core / Output reactor

ferrite cores can be used to reduce

radiated noise due to long motor cables.

If ferrite core is used loop motor wires, 3 times

round the core. Install core as close to the

inverter as possible

Output reactors provide additional

benefit of reducing dv/dt for protection of motor

windings.

4.Metal Cable clamp. no more than 150mm from

the inverter.

Note: If no enclosure & back plate is used then

connect the cable shield by a good 360 º

termination to the Inverter output terminal E.

5.Screened (Shielded four core cable).

6.Separate Protective Earth wire, routed outside

motor cable separated be at least 100mm.

Note:- this is the preferred method specially

for large output cables and long length.

Multi-core screened (3 core & protective

earth) can be used for small power and short

length.

7.Connect the cable shield by a good

360º termination and connect to the motor

protective earth terminal.

This link must be as short as possible.

8.Motor Earth terminal(Protective Earth).

L1(L)

L3(N)

E

L1(L)

L3(N)

E

E

T1 T2

T3

PE

M

Page 18

3-9

3.3.4 Failure liability

¾ Teco bears no responsibility for any failures or damaged caused to the inverter if the

recommendations in this instruction manual have not been followed specifically

points listed below,

¾ If a correctly rated Fuse or Circuit breaker has not been installed between the power

source and the inverter.

¾ If a magnetic contactor, a phase capacitor, burst absorber and LC or RC circuits have

been connected between the inverter and the motor.

¾ If an incorrectly rated three-phase squirrel cage induction motor has been used

Note:

When one inverter is driving several motors, the total current of all motors running

simultaneously must be less than the rated current of the inverter, and each motor

has to be equipped with a correctly rated thermal overload relay.

Page 19

3-10

3.3.5 Considerations for peripheral equipment

(

Power

Ensure that the supply voltage is correct.

A molded-case circuit breaker or fused disconnect

must be installed between the AC source and the

inverter

Circuit

Breaker

& RCD

Use a molded-case circuit breaker that conforms to

the rated voltage and current of the inverter.

Do not use the circuit breaker as the run/stop switch

for the inverter.

Residual Current Circuit Breaker(RCD)

Current setting should be 200mA or above and the

operating time at 0.1 second or longer to prevent

malfunctions.

Magnetic

contactor

Normally a magnetic contactor is not needed.

A contactor can be used to perform functions such

as external control and auto restart after power

failure.

Do not use the magnetic contactor as the run/stop

switch for the inverter.

AC reactor for

power quality

improvement

When a 200V/400V inverter with rating below 15KW

is connected to a high capacity power source

(600KVA or above) then an AC reactor can be

connected for power factor improvement and

reducing harmonics.

Input noise

filter

L510 inverter has a built-in filter to Class “A” first

Environment. (CategoryC2)

To satisfy the required EMC regulations for your

specific application you may require an additional

EMC filter.

Inverter

Connect the single phase power to Terminals, L1(L)

& L3(N) and three phase power to Terminals :

(200V : L1(L),L2,L3(N) or 400V : L1,L2,L3)

Warning! Connecting the input terminals T1, T2,

and T3 to AC input power will damage the inverter.

Output terminals T1, T2, and T3 are connected to U,

V, and W terminals of the motor.

To reverse the motor rotation direction just swap

any two wires at terminals T1, T2, and T3.

Ground the Inverter and motor correctly.

Ground Resistance for 200V power<100 Ohms.

Motor

Three-phase induction motor. Voltage drop on

motor due to long cable can be calculated.

Volts drop should be < 10%.

Phase-to-phase voltage drop (V) =

3 ×resistance of wire (Ω/km)×length of line

(m)×current×10

-3

Page 20

3-11

3.3.6 Ground connection

Inverter Ground terminal must be connected to installation ground correctly and

according to the required local wiring regulations.

¾ Ground cable size must be according to the required local wiring

regulations. Ground connection should be as short as possible.

¾ Do not share the ground of the inverter with other high current loads (Welding

machine, high power motors). Ground each unit separately.

¾ Ensure that all ground terminals and connections are secure

¾ Do not make ground loops when several inverters share a common ground point.

Note: Please leave at least 5cm while installing inverter side by side in order to provide

enough cooling space.

(a) Correct (b) Correct (c) Incorrect

3.3.7 Inverter exterior

RS485 Communication Port

Operator panel

TM2

TM1

Ground terminal

Page 21

3-12

3.4 Specifications

3.4.1 Product Specifications

100V Class : Single phase

Model : L510-□□□-H1-N □

1P2 1P5 101

Horse power (HP)

0.25 0.5 1

Suitable motor capacity (KW)

0.2 0.4 0.75

Rated output current (A)

1.8 2.6 4.3

Rated capacity (KVA)

0.68 1.00 1.65

Input voltage range(V)

Single Phase : 100~120V,50/60HZ

Allowable voltage fluctuation

+10%-15%

Output voltage range(V)

Three phase 0~24 0 V

Input current (A)*

9.5 13 19

Allowable momentary power loss time (S)

1.0 1.0 1.0

Enclosure

IP20

(If the model is marked A, it means that it is built in the power supply of 24V; if not, then it is built in

the power supply of 12V.)

200V Class : Single phase. F : Standards for built-in filter

Model : L510-

□□□-H1-N □

(L510-

□□□-H1F-P □)

2P2 2P5 201 202 203

Horse power (HP) 0.25 0.5 1 2 3

Suitable motor capacity (KW) 0.2 0.4 0.75 1.5 2.2

Rated output current (A) 1.8 2.6 4.3 7.5 10.5

Rated capacity (KVA) 0. 6 8 1 . 00 1.65 2.90 4.00

Input voltage range(V) Single Ph a s e : 200~240V,50/60HZ

Allowable voltage fluctuation

+10%-15%

Output voltage range(V) Three phase 0~240 V

Input current (A) 4.9 7.2 11 15.5 21

Allowable momentary power loss time (S) 1.0 1.0 1.0 2.0 2.0

Enclosure I P 2 0

(If the model is marked A, it means that it is built in the power supply of 24V; if not, then it is built in

the power supply of 12V.)

200V Class : Three phase

Model L510-

□□□-H3-N □

2P2 2P5 201 202 203

Horse power (HP) 0.25 0.5 1 2 3

Suitable motor capacity (KW) 0.2 0.4 0.75 1.5 2.2

Rated output current (A) 1.8 2.6 4.3 7.5 10.5

Rated capacity (KVA) 0.68 1.00 1.65 2.90 4.0 0

Input voltage range(V)* Three phase : 200 ~ 2 4 0 V , 5 0 / 60HZ

Allowable voltage fluctuation

+10%-15%

Output voltage range(V) Three phase 0~240 V

Input current (A) 3.0 4 . 0 6.4 9 . 4 1 2 . 2

Allowable momentary power loss time(S) 1.0 1.0 1.0 2.0 2.0

Enclosure I P 2 0

(If the model is marked A, it means that it is built in the power supply of 24V; if not, then it is built in

the power supply of 12V.)

Page 22

3-13

400V Class : Single phase. F : Standards for built-in filter

Model : L510-

□□□-H3-N A

(L510-

□□□-H3F-P A)

401 402 403

Horse power (HP) 1 2 3

Suitable motor capacity (KW) 0.75 1.5 2.2

Rated output current (A) 2.3 3.8 5.2

Rated capacity (KVA) 1 . 7 2 . 9 4 .0

Input voltage range(V) Three Pha s e : 380~480V,50/60HZ

Allowable voltage fluctuation

+10%-15%

Output voltage range(V) Three phase 0~480 V

Input current (A) 4 . 2 5 .6 7.3

Allowable momentary power loss time (S) 2 . 0 2.0 2. 0

Enclosure I P 2 0

(Models of 400V machines are all marked A, built in the power supply of 24V.)

*The input current is calculated value at full rated output current.

3.4.2 General Specifications

Item

L510

Control Mode

V/F Control + Auto-torque compensation function

Range 0.01~650.00Hz

Digital input : 0.01Hz

Setting resolution

Analog input : 0.06Hz/60Hz

Keypad : Set directly with▲▼ keys or the VR (Potentiometer)

on the keypad

External Input Terminals:

AVI(0/2~10V), ACI(0/4~20mA)input

Multifunction input up/down function(Group3)

Setting

Setting frequency by Communication method.

Frequency

Frequency limit

Lower and upper frequency limits

3 -skip frequency settings.

Keypad run, stop button

External terminals:

Multi- operation-mode 2 / 3 wire selection

Jog operation

Run

Operation set

Run signal by communication method.

V / F curve setting

6 fixed curve and one customized curve

Carrier frequency

1~16KHz(default 5KHz)

Acceleration and

deceleration control

2 off Acc / dec time parameters.

4 off S curve parameters.

Multifunction input

19 functions (refer to description on group3)

Multifunction output

14 functions (refer to description on group3)

Multifunction analog

output

5 functions (refer to description on group3)

Commonly

Control

Main features

Overload Detection, 8 preset speeds, Auto-run, Acc/Dec

Switch (2 Stages), Main/Alt run Command select, Main/Alt

Frequency Command select, PID control, torque boost, V/F

start Frequency ,Fault reset, Firemode.

Page 23

3-14

LED

Display: parameter/parameter value/frequency/line speed/DC

voltage/output voltage/output current/PID feedback/input and

output terminal status/Heat sink temperature/Program

Version/Fault Log.

Display

LED Status Indicator

For run/stop/forward and reverse.

Overload Protection

Integrated motor and Inverter overload protection.

Over voltage 100V/200V : Over 410V, 400V : Over 820V

Under voltage 100V/200V : Under 190V, 400V : Under 380V

Momentary Power Loss

Restart

Inverter auto-restart after a momentary power loss.

Stall Prevention

Stall prevention for Acceleration/ Deceleration/ and

continuous Run.

Short-circuit output

terminal

Electronic Circuit Protection

Protective

Functions

Grounding Fault Electronic Circuit Protection

Other protective

functions

Overheat protection, carrier frequency following as temperature

decreases, fault contact output, reverse limitation, unattended

start protection (USP) , times of automatic reset setting,

parameters locking and etc.

Protective

functions

International

authentication

CE/UL

communication control

Standard built in RS485 communication (Modbus), and it can

make control at one to one or one to more.

Operating temperature -10~50℃

Storage temperature -20~60℃

Humidity under 95%RH ( no condensation)

Shock

Under 20Hz, 1G(9.8m/s²)20~50Hz 0.6G(5.88m/s²)

Specifications of EMC complying with the first type of environment of EN61800-3

Specifications of LVD complying with the demand of EN50178

Security level UL508C

Environment

Protection level IP20

Page 24

3-15

3.5 Standard wiring

3.5.1 Single phase (NPN input)

AC Power

source

L1(L)

S2

S3

S4

+

T1

T2

T3

S5

COM

S1

-

Frequency

reference or PID

Multi-function input

Fuse

Inverter

output

Ground

E

Main

Switch

Power

input

RS485

Pin1 to Pin 8

AO

AGND

+

-

L3(N)

RB

RA

Multi-function output

0~10V

CON2

10V

AVI (0~10V)

ACI (0~20mA)

AGND

AO

Relay output

250VAC/1A

(30VDC/1A)

M

1:Data+

2:Data3:Data+

4:Reserved

5:Reserved

6:Data7:5V

8:GND

Model:

100V : L510-1P2-H1-N

□ / L510-1P5-H1-N □ / L510-101-H1-N □

200V : L510-2P2-H1-N

□ / L510-2P5-H1-N □ / L510-201-H1-N □

L510-202-H1-N

□ / L510-203-H1-N □

Page 25

3-16

3.5.2 Single phase (PNP input)

AC Power

source

L1(L)

S2

S3

S4

+

T1

T2

T3

S5

+12V

S1

-

Frequency

reference or PID

Multi-function input

Fuse

Inverter

output

Ground

E

Main

Switch

Power

input

RS485

Pin1 to Pin 8

AO

AGND

+

-

L3(N)

RB

RA

Multi-function output

0~10V

CON2

10V

AVI (0~10V)

ACI (0~20mA)

AGND

AO

Relay output

250VAC/1A

(30VDC/1A)

M

1:Data+

2:Data3:Data+

4:Reserved

5:Reserved

6:Data7:5V

8:GND

+24V (A)

Model:

200V : L510-2P2-H1F-P

□ / L510-2P5-H1F-P □ / L510-201-H1F-P □

L510-202-H1F-P

□ / L510-203-H1F-P □

Page 26

3-17

3.5.3 Three phase (NPN input)

AC Power

source

L1(L)

S2

S3

S4

+

T1

T2

T3

S5

COM

S1

-

Frequency

reference or PID

Multi-function input

Fuse

Inverter

output

Ground

E

Main

Switch

Power

input

RS485

Pin1 to Pin 8

AO

AGND

+

-

RB

RA

Multi-function output

0~10V

CON2

10V

AVI (0~10V)

ACI (0~20mA)

AGND

AO

Relay output

250VAC/1A

(30VDC/1A)

M

L3(N)

L2

1:Data+

2:Data3:Data+

4:Reserved

5:Reserved

6:Data7:5V

8:GND

P

BR

P

BR

P, BR for 400 series

Model:

200V : L510-2P2-H3-N

□ / L510-2P5-H3-N □ / L510-201-H3-N □

L510-202-H3-N

□ / L510-203-H3-N □

400V : L510-401-H3-N A / L510-402-H3-N A / L510-403-H3-N A

Page 27

3-18

3.5.4 Three phase (PNP input)

AC Power

source

L1(L)

S2

S3

S4

+

T1

T2

T3

S5

+24V (A)

S1

-

Frequency

reference or PID

Multi-function input

Fuse

Inverter

output

Ground

E

Main

Switch

Power

input

RS485

Pin1 to Pin 8

AO

AGND

+

-

RB

RA

Multi-function output

0~10V

CON2

10V

AVI (0~10V)

ACI (0~20mA)

AGND

AO

Relay output

250VAC/1A

(30VDC/1A)

M

L3(N)

L2

1:Data+

2:Data3:Data+

4:Reserved

5:Reserved

6:Data7:5V

8:GND

+12V

P

BR

P

BR

P, BR for 400 series

Model:

400V : L510-401-H3F-P A / L510-402-H3F-P A / L510-403-H3F-P A

Page 28

3-19

3.6 Terminal Description

3.6.1 Description of main circuit terminals

Terminal symbols TM1 Function Description

L1(L)

L2

L3(N)

Main power input, L1(L)/L2/L3(N)

P*

BR*

externally connected braking resistor

T1

T2

T3

Inverter output, connect to U, V, W terminals of motor

Ground terminal

*P,BR for 400V series

Single phase

Note: the screw on L2 terminal is removed for the single phase input supply models.

Three phase

Three phase (400V series)

L1(L) L2 L3(N) T1 T2 T3

L1(L) L2 L3(N) T1 T2 T3

L1 L2 L3 P BR T1 T2 T3

Page 29

3-20

3.6.2 Control circuit terminal description

Terminal symbols TM1 Function Description

RA

RB

Relay output terminal, Specification: 250VAC/1A(30VDC/1A)

COM

S1~S5 (COMMON) 【NPN】

+12V / +24V

S1~S5 (COMMON) 【PNP】(Model Name + A : 24V)

S1

S2

S3

S4

S5

Multi-function input terminals(refer to group3)

10V Built in Power for an external speed potentiometer

AVI Analog voltage input, Specification : 0~10VDC/ 2-10V

ACI Analog current input, Specification : 0/4~20mA

AO Multi function analog output terminal. Maximum output 10VDC/1mA

AGND Analog ground terminal

NPN:

PNP:

Page 30

3-21

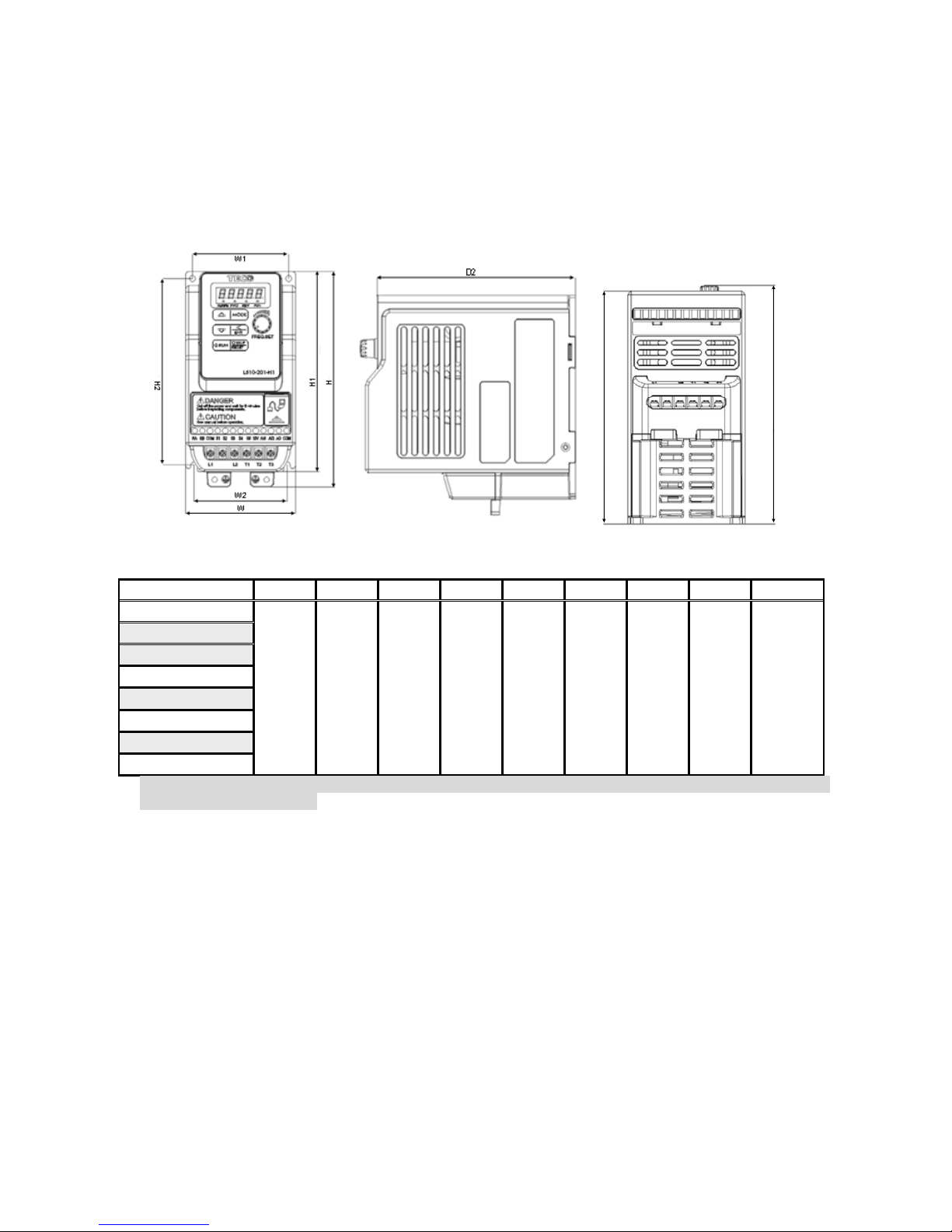

3.7 Outline Dimensions

(unit: mm)

Frame1

D1DD1

D

Unit : mm(inch)

Model W W1 W2 H H1 H2 D D1

Weight

L510-1P2-H1 □

L510-1P5-H1 □

L510-2P2-H1(F) □

L510-2P5-H1(F) □

L510-201-H1(F) □

L510-2P2-H3 □

L510-2P5-H3 □

L510-201-H3 □

72

(2.83)

63

(2.48)

61

(2.40)

141

(5.55)

131

(5.16)

122

(4.80)

139.2

(5.48)

136

(5.35)

0.9kg

(If the model is marked A, it means that it is built in the power supply of 24V; if not, then it is built in

the power supply of 12V.)

F : Built-in EMC filter

Page 31

3-22

Frame2

Unit : mm(inch)

Model W W1 W2 H H1 H2 D D1

Weight

L510-101-H1 □

L510-202-H1(F) □

L510-203-H1(F) □

L510-202-H3 □

L510-203-H3 □

L510-401-H3(F) A

L510-402-H3(F) A

L510-403-H3(F) A

118

(4.65)

108

(4.25)

108

(4.25)

144

(5.67)

131

(5.16)

121

(4.76)

147.3

(5.80)

144.2

(5.68)

1.6kg

(If the model is marked A, it means that it is built in the power supply of 24V; if not, then it is built in

the power supply of 12V. Models of 400V machines are all marked A, built in the power supply of

24V)

F : Built-in EMC filter

Page 32

3-23

3.8 EMC Filter Disconnection

EMC filter may be disconnected:

Inverter drives with built-in EMC filter are not suitable for connection to certain type of

supply systems, such as listed below; in these cases the RFI filter can be disabled.

In all such cases consult your local electrical standards requirements.

IT type supply systems (ungrounded) & certain supply systems for medical

equipment.

For ungrounded supply systems If the filter is not disconnected the supply system

becomes connected to Earth through the Y capacitors on the filter circuit. This could

result in danger and damage to the Drive.

Disconnection steps:

1. Remove EMC filter protection cover by screwdriver.

2. Remove EMC line by pliers.

Note:- Disconnecting the EMC filter link will disable the filter function, please consult your local

EMC standards requirement..

① ②

Page 33

4-1

Chapter4 Software Index

4.1 Keypad Description

4.1.1 Operator Panel Functions

Type Item Function

Main digital displays

Frequency Display, Parameter, voltage, Current,

Temperature, Fault messages.

Digital

display &

LEDs

LED Status

Hz/RPM: ON when the frequency or line speed is displayed.

OFF when the parameters are displayed.

FWD: ON while the inverter is running forward. Flashes

while stopped.

REV: ON while the inverter is running reverse. Flashes

while stopped.

FUN: ON when the parameters are displayed. OFF when

the frequency is displayed.

Variable

Resistor

FREQ SET Used to set the frequency

RUN RUN: Run at the set frequency.

STOP/RESET

(Dual function keys)

STOP: Decelerate or Coast to Stop.

RESET: Use to Reset alarms or resettable faults.

▲

Increment parameter number and preset values.

▼

Decrement parameter number and preset values.

MODE Switch between available displays

Keys

On Keypad

</ENTER

(Dual function keys,

a short press for left

shift function, a long

press for ENTER

function)

“<” Left Shift:

Used while changing the parameters or parameter values

ENTER:

Used to display the preset value of parameters and for saving

the changed parameter values.

Page 34

4-2

4.1.2 Digital display Description

Alpha numerical display format

Digit

LED

Letter

LED

Letter

LED

Symbol

LED

0

A

n

-

1

b

o

°

2

C

P

_

3

d

q

.

4

E

r

5

F

S

6

G

t

7

H

u

8

J

V

9

L

Y

Digital display indication formats

Actual output frequency Set frequency

Digits are lit Continually Preset digits flashing Selected digit flashing

Page 35

4-3

LED display examples

Display

Description

In stop mode shows the set frequency

In run mode shows the actual output frequency

Selected Parameter

Parameter Value

Output Voltage

Output Current in Amps

DC Bus voltage

Temperature

PID feedback value

Error display

Analogue Current / Voltage ACID / AVI . Range ( 0~1000)

LED Status description

LED Indicator light Status

Frequency / line

speed Indicator

Hz/RPM

On

Menu mode indicator

FUN

On while not displaying frequency or line speed

FWD indicator

FWD

On while running

forward

FWD

Flashing while

stopped in

Forward mode.

REV indicator light

REV

On while running

reverse

REV

Flashing while

stopped in

Reverse mode

Hz/RPM

Fun

FWD

REV

FWD

REV

Page 36

4-4

4.1.3 Digital display set up

On power up digital display screens will be as shown below.

MODE

2sec later

Power supply

frequency

parameter

MODE

User selectable display formats:

12- 00 Display Mode

0 0 0 0 0

high

Low

Each of the above 5 digits can be set to any of the selections below from 0 to 7

【0】:Disable display 【1】:output Current

【2】:output Voltage 【3】:DC voltage

【4】:Temperature 【5】:PID feedback

Range

【6】:AVI 【7】:ACI

The highest bit of 12-00 sets the power on the display, other bits set the selected display from range

0-7.as Listed above.

Example1: Set parameter 12- 00=【10000】to obtain display format shown below.

MODE

MODE MODE

2sec later

display:Power supply

Output Current

Set frequency

parameter

Page 37

4-5

Example 2. Set parameter 2: 12- 00=【12345】 to obtain the display format shown below.

MODE

MODE

2sec later

MODE

MODE

MODE

MODE

MODE

Temperature

< 4 >

PIDfeedback

< 5 >

Output Current

< 1 >

Parameter

DC voltage

< 3 >

Output Voltage

< 2 >

Set Frequency

Display: Power supply

Increment/ Decrement key functions:

1.“

▲”/ “▼” :

Short time press

Long time press

T1

T2

Quick pressing of these keys will Increment or Decrement the selected digit by one.

Extended pressing will Increment or Decrement the selected digit continuously.

2.“</ENT” Key functions :

“</ENT”

short press for left shift

function

“</ENT”

long press for ENT

functi on

T1

T2

Quick pressing of this key will display the preset value of the parameter selected.

Extended pressing of this key will save the altered value of the selected parameter.

Page 38

4-6

4.1.4 Example of keypad operation

Example1: Modifying Parameters

Short time press

</ENT once

Short time press

</ENT twice

Short time

press

once

Long time press

</ENT once

Frequency

Short time

press

once

Long time press

</ENT once

Short time press

MODE once

▲

▲

Page 39

4-7

Example2: Modifying the frequency from keypad in run and stop modes.

Modify frequency in stopping

Modify frequency in operating

2sec later

2sec later

Short time press

</ENT once

Press RUN

5sec later

or long time press

</ENT once

Long time press

</ENT once

Without

pressing the

button

</ENT,

After 5

seconds to

return

Short time press

</ENT once

Power Supply

Power supply

Actual frequency

Actual frequency

Short time press

</ENT once

Short time press

</ENT once

Short time press

▲ once

Short time press

</ENT once

Short time press

</ENT once

Short time press

▲ once

Set frequency display Set frequency display

Modify bit<unit>

Modify bit<ten>

Modify bit<hundred>

Modify bit<hundred+1>

Modify bit<hundred+1>

Modify bit<hundred>

Modify bit<ten>

Modify bit<unit>

Note: frequency command setting will be limited to the range set by parameters for lower &

upper frequency.

Modify frequency is stopping

Modify frequency is stopping

Power supply Power supply

2sec later 2sec later

Set frequency display

Set frequency display

Press run

Short time press

</ENT once

Short time press

</ENT once

A

ctual frequency

Short time press

</ENT once

Short time press

</ENT once

Short time press

</ENT once

Short time press

</ENT once

Short time press

▲once

Short time press

▲once

5 sec later or long

time press </ENT

once

Long time press

</ENT once

Modify bit<unit>

Modify bit<unit>

Modify bit<ten>

Modify bit<ten>

Modify bit<hundred>

Modify bit<hundred>

Modify bit<hundred+1>

Modify bit<hundred+1>

A

ctual frequency

Without pressing

the button </ENT,

A

fter 5 seconds to

return

Page 40

4-8

4.1.5 Operation Control

Stop

Run

Stop

Actual

Output

frequency

Power

on

REV FWD

Run

REV

FWD

Stop

FWDFWD

FWD

FWD FWD

FWD

FWD

FWD

LED

REV

LED

REV

REV REV REV

REV

REV

REV

Page 41

4-9

4.2 Programmable Parameter Groups

Parameter Group No. Description

Group 00 Basic parameters

Group 01 V/F Pattern selections & setup

Group 02 Motor parameters

Group 03 Multi function digital Inputs/Outputs

Group 04 Analog signal inputs/ Analog output

Group 05 Preset Frequency Selections.

Group 06 Auto Run(Auto Sequencer) function

Group 07 Start/Stop command setup

Group 08 Drive and motor Protection

Group 09 Communication function setup

Group 10 PID function setup

Group 11 Performance control functions

Group 12 Digital Display & Monitor functions

Group 13 Inspection & Maintenance function

Parameter notes for Parameter Groups

*1

Parameter can be adjusted during running mode

*2

Cannot be modified in communication mode

*3

Does not change with factory reset

*4

Read only

Page 42

4-10

Group 00- The basic parameters group

No. Description Range

Factory

Setting

Unit Note

00-00

Reserved

00-01

Motor rotation

0:Forward

1:Reverse

0 - *1

0:Keypad

1:External Run/Stop Control

00-02

Main Run

Source Selection

2:Communication

0 -

0:Keypad

1:External Run/Stop Control

00-03

Alternative Run

Source Selection

2:Communication

0 -

0: Forward/Stop-Reverse/Stop

1: Run/Stop-Reverse/Forward

00-04

Operation modes for

external terminals

2: 3-Wire Control Mode-Run/Stop

0 -

0:Keypad

1:Potentiometer on Keypad

2:External AVI Analog Signal Input

3:External ACI Analog Signal Input

4:External Up/Down Frequency

Control

5:Communication setting Frequency

00-05

Main Frequency

Source Selection

6:PID output frequency

0 -

0:Keypad

1:Potentiometer on Keypad

2:External AVI Analog Signal Input

3:External ACI Analog Signal Input

4:External Up/Down Frequency

Control

5:Communication setting Frequency

00-06

Alternative Frequency

Source Selection

6:PID output frequency.

4 -

00-07

Main and Alternative

Frequency Command modes

0: Main Or Alternative Frequency

1: Main frequency+Alternative

Frequency

0 -

00-08

Communication

Frequency Command

0.00~650.00 Hz *4

00-09

Frequency command

Save mode

(Communication mode)

0:Save the frequency before power

down

1:Save the communication frequency

0 -

0:by Current Frequency Command

1:by 0 Frequency Command

00-10

Initial Frequency

Selection ( keypad mode)

2:by 00-11

0 -

00-11

Initial Frequency

Keypad mode

0.00~650.00 50.00/60.00 Hz

00-12

Frequency Upper Limit 0.01~650.00 50.00/60.00 Hz

00-13

Frequency Lower Limit 0.00~649.99 0.00 Hz

00-14

Acceleration Time 1 0.1~3600.0

10.0

s

*1

00-15

Deceleration Time 1 0.1~3600.0

10.0

s

*1

00-16

Acceleration Time 2 0.1~3600.0

10.0

s

*1

00-17

Deceleration Time 2 0.1~3600.0 10.0 s *1

00-18

Jog Frequency 1.00~25.00 2.00 Hz *1

00-19

Jog Acceleration Time 0.1~25.5

0.5

s

*1

00-20

Jog Deceleration Time 0.1~25.5

0.5

s

*1

Page 43

4-11

Group 01- V/F Pattern selection & Setup

No. Description Range

Factory

Setting

Unit Note

01-00

Volts/Hz Patterns 1~7 1/4 -

01-01

V/F Max voltage

200V:198.0~256.0

400V:323.0~528.0

220.0/440.0 Vac

01-02

Max Frequency 0.20 ~ 650.00 50.00/60.00 Hz

01-03

Max Frequency Voltage Ratio 0.0 ~ 100.0 100.0 %

01-04

Mid Frequency 2 0.10 ~ 650.00 25.00/30.00 Hz

01-05

Mid Frequency Voltage Ratio 2 0.0 ~ 100.0 50.0 %

01-06

Mid Frequency 1 0.10 ~ 650.00 10.00/12.00 Hz

01-07

Mid Frequency Voltage Ratio 1 0.0 ~ 100.0 20.0 %

01-08

Min Frequency 0.10 ~ 650.00 0.50/0.60 Hz

01-09

Min Frequency Voltage Ratio 0.0 ~ 100.0 1.0 %

01-10

Volts/Hz Curve Modification

(Torque Boost)

0 ~ 10.0 0.0 % *1

01-11

V/F start Frequency 0.00~10.00 0.00 Hz

Group 02- Motor parameters

No. Description Range

Factory

Setting

Unit Note

02-00

Motor No Load Current

----

A *3

02-01

Motor Rated Current

(OL1) ----

A

02-02

Motor rated Slip

Compensation

0.0 ~ 100.0 0.0 % *1

02-03

Motor Rated Speed

----

Rpm

02-04

Motor Rated Voltage

---- Vac *4

Page 44

4-12

Group 03- Multi function Digital Inputs/Outputs

No. Description Range

Factory

Setting

Unit Note

03-00

Multifunction Input Term. S1 0:Forward/Stop Command or Run /Stop

0 -

03-01

Multifunction Input Term. S2

1:Reverse/Stop Command Or

REV/FWD 1 -

03-02

Multifunction Input Term. S3

2:Preset Speed 1 (5-02) 8 -

03-03

Multifunction Input Term. S4

3:Preset Speed 2 (5-03) 9 -

4:Preset Speed 4 (5-05)

6:Jog Forward Command

7:Jog Reverse Command

8:Up Command

9:Down Command

10:Acc/Dec 2

11:Acc/Dec Disabled

12:Main/Alternative Run Command

select

13:Main/Alternative Frequency

Command select

14:Rapid Stop ( Decel to stop)

15:Base Block

16:Disable PID Function

17:Reset

03-04

Multifunction Input Term. S5

18:Auto Run Mode enable

17 -

03-05

Reserved

03-06

Up/Down frequency band 0.00~5.00 0.00 Hz

0:When Up/Down is used, the preset

frequency is held as the inverter stops,

and the UP/Down function is disabled.

1:When Up/Down is used, the preset

frequency is reset to 0 Hz as the

inverter stops.

03-07

Up/Down Frequency modes

2:When Up/Down is used, the preset

frequency is held as the inverter stops,

and the UP/Down is available.

0 -

03-08

S1~S5 scan confirmation 1~400. Number of Scan cycles 20 1ms

xxxx0:S1 NO xxxx1:S1 NC

xxx0x:S2 NO xxx1x:S2 NC

xx0xx:S3 NO xx1xx:S3 NC

x0xxx:S4 NO x1xxx:S4 NC

03-09

S1~ S5 switch type select

0xxxx:S5 NO 1xxxx:S5 NC

00000 -

03-10

Reserved

0:Run

1:Fault

2:Setting Frequency Agree

3:Frequency Agree (3-13±3-14)

4:Output Frequency Detection1(> 3-13)

5:Output Frequency Detection2(< 3-13)

6:Auto-Restart

7:Momentary AC Power Loss

8:Rapid Stop

9:Base Block

10:Motor Overload Protection(OL1)

11:Drive Overload Protection(OL2)

12:Reserved

03-11

Output Relay(RY1)

13:Output Current Agree

0 -

Page 45

4-13

14:Brake Control

03-12

Reserved

03-13

Output frequency detection

level (Hz)

0.00~650.00 0.00 Hz *1

03-14

Frequency Detection band

0.00~30.00 2.00 Hz *1

03-15

Output Current Agree

Setting

0.1~15.0 0.1 A

03-16

Current Agree Delay Time

0.1~10.0 0.1 s

03-17

External Brake Release

level

0.00~20.00 0.00 Hz

03-18

External Brake Engage

Level

0.00~20.00 0.00 Hz

03-19

Relay Output function type

0:A (Normally open)

1:B (Normally close)

0 -

※ “NO” indicates normally open, “NC” indicates normally closed.

Group 04- Analog signal inputs/ Analogue output functions

No. Description Range

Factory

Setting

Unit Note

AVI ACI

0:0~10V 0~20mA

1:0~10V 4~20mA

2:2~10V 0~20mA

04-00

AVI/ACI analog Input

signal type select

3:2~10V 4~20mA

0 -

04-01

AVI Signal Verification

Scan rate

1~400 100 1ms

04-02 AVI Gain

0 ~ 1000 100 % *1

04-03 AVI Bias

0 ~ 100 0 % *1

04-04 AVI Bias Selection

0: Positive 1: Negative 0 - *1

04-05 AVI Slope

0: Positive 1: Negative 0 - *1

04-06

ACI Signal Verification

Scan rate

1~400 100 1ms

04-07

ACI Gain 0 ~ 1000 100 % *1

04-08

ACIBias 0 ~ 100 0 % *1

04-09

ACI Bias Selection 0: Positive 1: Negative 0 - *1

04-10

ACI Slope 0: Positive 1: Negative 0 - *1

04-11

Analog Output

mode(AO)

0: Output Frequency

1: Frequency Command

2: Output Voltage

3: DC Bus Voltage

4: Motor Current

0 - *1

04-12

Analog Output AO Gain

(%)

0 ~ 1000 100 % *1

04-13

Analog Output AO Bias

(%)

0 ~ 1000 0 % *1

04-14

AO Bias Selection

0: Positive

1: Negative

0 - *1

04-15

AO Slope

0: Positive

1: Negative

0 - *1

Page 46

4-14

Group 05- Preset Frequency Selections.

No. Description Range

Factory

Setting

Unit Note

0: Common Accel/Decel

Accel/Decel 1 or 2 apply to all speeds

05-00

Preset Speed Control

mode Selection

1: Individual Accel/Decel Accel/ Decel

0-7 apply to the selected preset

speeds (Acc0/Dec0~ Acc7/Dec7)

0 -

05-01

Preset Speed 0

(Keypad Freq)

5.00 Hz

05-02

Preset Speed1 (Hz)

5.00 Hz *1

05-03

Preset Speed2 (Hz)

10.00 Hz *1

05-04

Preset Speed3 (Hz)

20.00 Hz *1

05-05

Preset Speed4 (Hz)

30.00 Hz *1

05-06

Preset Speed5 (Hz)

40.00 Hz *1

05-07

Preset Speed6 (Hz)

50.00 Hz *1

05-08

Preset Speed7 (Hz)

0.00 ~ 650.00

50.00 Hz *1

05-09

~

05-16

Reserved

05-17

Preset Speed0-Acctime

10.0 s *1

05-18

Preset Speed0-Dectime

10.0

s

*1

05-19

Preset Speed1-Acctime

10.0

s

*1

05-20

Preset Speed1-Dectime

10.0

s

*1

05-21

Preset Speed2-Acctime

10.0

s

*1

05-22

Preset Speed2-Dectime

10.0

s

*1

05-23

Preset Speed3-Acctime

10.0

s

*1

05-24

Preset Speed3-Dectime

10.0

s

*1

05-25

Preset Speed4-Acctime

10.0

s

*1

05-26

Preset Speed4-Dectime

10.0

s

*1

05-27

Preset Speed5-Acctime

10.0

s

*1

05-28

Preset Speed5-Dectime

10.0

s

*1

05-29

Preset Speed6-Acctime

10.0

s

*1

05-30

Preset Speed6-Dectime

10.0

s

*1

05-31

Preset Speed7-Acctime

10.0

s

*1

05-32

Preset Speed7-Dectime

0.1 ~ 3600.0

10.0

s

*1

Page 47

4-15

Group 06- Auto Run(Auto Sequencer) function

No. Description Range

Factory

Setting

Unit Note

06-00

Auto Run

(sequencer)

mode selection

0: Disabled.

1: Single cycle.

(Continues to run from the Unfinished

step if restarted).

2: Periodic cycle.

(Continues to run from the unfinished

step if restarted).

3: Single cycle, then holds the speed Of

final step to run.

(Continues to run from the unfinished

step if restarted).

4: Single cycle.

(Starts a new cycle if restarted).

5: Periodic cycle.

(Starts a new cycle if restarted).

6: Single cycle, then hold the speed of

final step to run

(Starts a new cycle if restarted).

0 -

06-01

Auto _ Run Mode

frequency command 1

0.00 Hz *1

06-02

Auto _ Run Mode

frequency command 2

0.00 Hz *1

06-03

Auto _ Run Mode

frequency command 3

0.00 Hz *1

06-04

Auto _ Run Mode

frequency command 4

0.00 Hz *1

06-05

Auto _ Run Mode

frequency command 5

0.00 Hz *1

06-06

Auto _ Run Mode

frequency command 6

0.00 Hz *1

06-07

Auto _ Run Mode

frequency command 7

0.00~650.00

0.00 Hz *1

06-08

~

06-15

Reserved

06-16

Auto_ Run Mode

running time setting 0

0.0 s

06-17

Auto_ Run Mode

running time setting 1

0.0 s

06-18

Auto_ Run Mode

running time setting 2

0.0 s

06-19

Auto_ Run Mode

running time setting 3

0.0 s

06-20

Auto_ Run Mode

running time setting 4

0.0 s

06-21

Auto_ Run Mode

running time setting 5

0.0 s

06-22

Auto_ Run Mode

running time setting 6

0.0 s

06-23

Auto_ Run Mode

running time setting 7

0.0 ~ 3600.0

0.0 s

06-24

~

06-31

Reserved

06-32

Auto_ Run Mode

running direction 0

0 -

06-33

Auto_ Run Mode

running direction 1

0: Stop

1: Forward

2: Reverse

0 -

Page 48

4-16

06-34

Auto_ Run Mode

running direction 2

0 -

06-35

Auto_ Run Mode

running direction 3

0 -

06-36

Auto_ Run Mode

running direction 4

0 -

06-37

Auto_ Run Mode

running direction 5

0 -

06-38

Auto_ Run Mode

running direction 6

0 -

06-39

Auto_ Run Mode

running direction 7

0 -

Group 07- Start/Stop command setup

No. Description Range

Factory

Setting

Unit Note

07-00

Momentary Power

Loss and Restart

0: Momentary Power Loss and Restart disable

1: Momentary power loss and restart enable

0 s

07-01

Auto Restart Delay

Time

0.0~800.0

0.0 s

07-02

Number of Auto

Restart Attempts

0~10

0 -

07-03

Reset Mode Setting

0: Enable Reset Only when Run Command is

Off

1: Enable Reset when Run Command is On or

Off

0 -

07-04

Direct Running After

Power Up

0: Enable Direct run on power up

1: Disable Direct run on power up

1 -

07-05 Delay-ON Timer 1.0~300.0

1.0 s

07-06

DC Injection Brake

Start Frequency

(Hz) In Stop mode

0.10 ~ 10.00

1.5 Hz

07-07

DC Injection Brake

Level (%) In stop

mode

0 ~20

5 %

07-08

DC Injection Brake

Time (Seconds)

In stop mode

0.0 ~ 25.5

0.5 s

07-09

Stopping Method

0: Deceleration to stop

1: Coast to stop

0

Page 49

4-17

Group 08- Drive & Motor Protection functions

No. Description Range

Factory

Setting

Unit Note

08-00

Trip Prevention Selection

xxxx0: Enable Trip Prevention During

Acceleration

xxxx1: Disable Trip Prevention During

Acceleration

xxx0x: Enable Trip Prevention During

Deceleration

xxx1x: Disable Trip Prevention During

Deceleration

xx0xx: Enable Trip Prevention in Run

Mode

xx1xx: Disable Trip Prevention in Run

Mode

x0xxx: Enable over voltage Prevention

in Run Mode

x1xxx: Disable over voltage Prevention

in Run Mode

00000 -

08-01

Trip Prevention Level

During Acceleration (%)

50 ~ 200 200

08-02

Trip Prevention Level

During Deceleration (%)

50 ~ 200 200

08-03

Trip Prevention Level In

Run Mode (%)

50 ~ 200 200

Inverter

Rated

Current

100%

08-04

over voltage Prevention

Level in Run Mode

350~390 380 VDC

08-05

Electronic Motor

Overload Protection

Operation Mode

0: Enable Electronic Motor Overload

Protection

1: Disable Electronic Motor Overload

Protection

1 -

08-06

Operation After

Overload Protection is

Activated

0: Coast-to-Stop After Overload

Protection is Activated

1: Drive Will Not Trip when Overload

Protection is Activated (OL1)

0 -

08-07

Over heat Protection

(cooling fan control)

0: Auto (Depends on temp.)

1: Operate while in RUN mode

2: Always Run

3: Disabled

1 -

0: AVR function enable

1: AVR function Disable

2: AVR function disable for stop

3: AVR function disable for deceleration

4: AVR function disable for stop and

deceleration.

08-08

AVR Function

(Auto Voltage

Regulation)

5: When VDC>(360V/740V), AVR

function disable for stop and

deceleration.

4 -

08-09

Input phase lost

protection

0: Disabled

1: Enabled

0 -

Page 50

4-18

Group 09- Communication function setup

No. Description Range

Factory

Setting

Unit Note

09-00

Assigned

Communication

Station Number

1 ~ 32 1 - *2*3

09-01

RTU code /ASCII

code select

0:RTU code

1:ASCII code

0 - *2*3

09-02

Baud Rate Setting

(bps)

0:4800

1:9600

2:19200

3:38400

2 bps *2*3

09-03

Stop Bit Selection

0:1 Stop Bit

1:2 Stop Bits

0 - *2*3

09-04

Parity Selection

0:Without Parity

1:With Even Parity

2:With Odd Parity

0 - *2*3

09-05

Data Format

Selection

0: 8-Bits Data

1: 7-Bits Data

0 - *2*3

09-06

Communication

time-out detection

time

0.0 ~ 25.5

0.0 s

09-07

Communication

time-out operation

selection

0:Deceleration to stop

(00-15: Deceleration time 1)

1:Coast to stop

2: Deceleration to stop

(00-17: Deceleration time 2)

3: continue operating

0 -

09-08

Error 6 verification

time.

1 ~ 20

3

09-09

Drive Transmit

delay Time(ms)

5 ~ 65

5 ms

Page 51

4-19

Group10- PID function Setup

No. Description Range

Factory

Setting

Unit Note

10-00

PID target value selection

(when 00-03\00-04=6

,this function is enabled)

0:Potentiometer on Keypad

1: Analog Signal Input. (AVI)

2: Analog Signal Input. (ACI)

3: Frequency set by communication

4: KeyPad Frequency parameter

10-02

1 - *1

10-01

PID feedback value selection

0:Potentiometer on Keypad

1: Analog Signal Input. (AVI)

2: Analog Signal Input. (ACI)

3: Frequency set by communication

2 - *1

10-02 PID Target (keypad input) 0.0~100.0

50.0 % *1

10-03

PID Mode Selection

0:Disabled

1: Deviation D Control.

FWD Characteristic.

2: Feedback D Control

FWD Characteristic.

3: Deviation D Control

Reverse Characteristic.

4: Feedback D Control

Reverse Characteristic.

0 -

10-04

Feedback Gain Coefficient

0.00 ~ 10.00 1.00 % *1

10-05

Proportional Gain 0.0 ~ 10.0 1.0 % *1

10-06

Integral Time 0.0 ~ 100.0 10.0 s *1

10-07

Derivative Time 0.00 ~ 10.00 0.00 s *1

10-08

PID Offset

0: Positive

1: Negative

0 - *1

10-09

PID Offset Adjust 0 ~ 109 0 % *1

10-10

PID Output Lag Filter Time

0.0 ~ 2.5 0.0 s *1

10-11

Feedback Loss Detection

Mode

0: Disabled

1: Enabled - Drive Continues to

Operate After Feedback Loss

2: Enabled - Drive "STOPS"

After Feedback Loss

0 -

10-12

Feedback Loss Detection

Level

0 ~ 100

0 %

10-13

Feedback Loss Detection

Delay Time

0.0 ~25.5

1.0 s

10-14 Integration Limit Value

0 ~ 109

100 % *1

10-15

Integral Value Resets to Zero

when Feedback Signal Equals

the Target Value

0:Disabled

1: 1 Second

30: 30 Seconds (0 ~ 30)

0 -

10-16

Allowable Integration Error

Margin (units)(1unit = 1/8192)

0 ~ 100

0 -

10-17 PID Sleep Frequency Level

0.00~650.00

0.00 Hz

10-18

PID Sleep Function Delay

Time

0.0 ~25.5

0.0 s

10-19 PID Wake up frequency Level

0.00 ~ 650.00

0.00 Hz

10-20

PID Wake up function Delay

Time

0.0 ~ 25.5

0.0 s

10-21 Max PID Feedback Setting

0 ~999

100 - *1

10-22

Min PID Feedback Setting 0 ~999 0 - *1

Page 52

4-20

Group11- Performance Control functions

No. Description Range

Factory

Setting

unit Note

11-00

Reverse operation control

0: Reverse command is enabled

1: Reverse command is disabled

0 -

11-01

Carrier Frequency (kHz) 1~16 5 KHz

11-02

Carrier mode Selection

0: Mode0, 3phase PWM modulation

1: Mode1, 2phase PWM modulation

2: Mode2, 2phase random PWM

modulation

0 -

11-03

Carrier Frequency

Reduction by temperature

rise

0:disabled

1:enabled

0 -

11-04

S-Curve Acc 1 0.0 ~ 4.0 0.00 s

11-05

S-Curve Acc 2 0.0 ~ 4.0 0.00 s

11-06

S-Curve Dec 3 0.0 ~ 4.0 0.00 s

11-07

S-Curve Dec 4 0.0 ~ 4.0 0.00 s

11-08

Skip Frequency 1 0.00 ~ 650.00 0.00 Hz *1

11-09

Skip Frequency 2 0.00 ~ 650.00 0.00 Hz *1

11-10

Skip Frequency 3 0.00 ~ 650.00 0.00 Hz *1

11-11

Skip Frequency

Bandwidth (±)

0.00 ~ 30.00 0.00 Hz *1

Group12 Digital Display & Monitor functions

No. Description Range

Factory

Setting

Unit Note

00000 ~77777.

Each digit can be set to 0 to 7

0: Default display

(frequency¶meters)

1:Output Current

2:Output Voltage

3:DC voltage

4:Temperature

5:PID feedback

6:Analog Signal Input. (AVI)

12-00

Extended Display Mode

7:Analog Signal Input. (ACI)

00000 - *1

0: Integer (xxx)

1:One decimal Place (xx.x)

12-01

PID Feedback Display

format

2:Two Decimal Places (x.xx)

0 - *1

0:xxx-1:xxxpb (pressure)

12-02

PID Feedback Display

Unit Setting

2:xxxfl (flow)

0 - *1

12-03

Custom Units (Line

Speed) Value

0~65535 1500/1800 RPM *1

0:Drive Output Frequency is Displayed

1:Line Speed. Integer.(xxxxx)

2:Line Speed..One Decimal Place

(xxxx.x)

3:Line Speed.Two Decimal Places

(xxx.xx)

12-04

Custom Units (Line

Speed) Display Mode

4:Line Speed.Three Decimal Places

(xx.xxx)

0 - *1

Page 53

4-21

Group12 Digital Display & Monitor functions

No. Description Range

Factory

Setting

Unit Note

12-05

Inputs and output

Logic status display

( S1 to S5) & RY1

S1 S2 S3 S4 S5

RY1

----- - *4

Group 13 Inspection & Maintenance functions

No. Description Range

Factory

Setting

unit Note

13-00

Drive Horsepower

Code

---- - - *3

13-01

Software Version ---- - - *3*4

13-02

Fault Log

(Last 3 Faults)

---- - - *3*4

13-03

Accumulated Operation

Time1 1

0~23 - hour *3

13-04

Accumulated Operation

Time1 2

0~65535 ---- day *3

13-05

Accumulated Operation

Time Mode

0:Time Under Power

1:Run Mode Time Only

0 - *3

13-06

Parameter Lock

0: Enable all Functions

1: Preset speeds 05-01~05-08 cannot

be changed

2: All Functions cannot be changed

Except for Preset speeds

05-01~05-08

3: Disable All Function

0 -

13-07

Parameter Lock Code 00000~65535 00000 -

13-08

Reset Drive to Factory

Settings

1150: Reset to factory setting. 50Hz

system.

1160: Reset to factory setting. 60Hz

system.

00000 -

Page 54

4-22

4.3 Parameter Function Description

00- Basic parameter group

00- 01 Motor Direction Control

Range

【0】: Forward

【1】: Reverse

¾ 00 - 01 Is valid in key pad mode only.

Note※ : When Reverse function is disabled by parameter 11- 00=1 setting 00-01 to 1 .” LOC” will be

displayed

00- 02 Main Run Command Source selection

00- 03 Alternative Run Command Source selection

Range

【0】: Keypad

【1】: External Run/Stop Control

【2】: Communication

¾ Parameter 00 - 02/00- 03 sets the inverter operation command source. For switching between

00-02 and 00-03, use any of the external inputs S1 to S5 and set the relevant parameters

(03-00~03-04) to [12]. refer to parameter group3.

00- 04 Operation modes for external terminals

Range

【0】: Forward/stop-reverse/stop

【1】: Run/stop-forward/reverse

【2】: 3-wire control mode -run/stop

¾ 00-04 Is valid when Run command is set to External mode by 00- 02/00- 03 =1.

2-wire operation mode:

Set 00-04=【0/1】first, before setting (03-00,03-04) to[0] or [1]

00-04= 【0】Set external terminals (03-00 to 03-04) function to 0 for FWD/Stop or Set to 1 for

REV/Stop.

00-04= 【1】Set external terminals (03-00 to 03-04) function to 0 for Run/Stop or Set to 1 for

FWD/REV.

3-wire operation mode:

00-04 =【2】Terminals S1, S2, S3 are used in a combination to enable 3 wire run/stop mode.

Settings for 03-00, 03-01, 03–02 will not be effective. (refer to Group 03)

00- 05

Main Frequency Command Source Selection

00- 06 Alternative Frequency Command Source Selection

Range

【0】:UP/DOWN of Keypad

【1】:Potentiometer on Keypad

【2】:External AVI Analog Signal Input

【3】:External ACI Analog Signal Input

【4】:External Up/Down Frequency Control

【5】:Communication setting Frequency

【6】:PID Output frequency

¾ When 00-06 =[6], frequency command source is output of the PID.

00- 07 Main and Alternative Frequency Command Modes

Range

【0】:Main Or Alternative Frequency.

【1】:Main frequency + Alternative Frequency

¾ When 00-07=【0】, the frequency source is set by the Main frequency parameter 00-05 (Default)

or by the Alternative frequency parameter 00-06.

Use any of the external terminals S1 to S5 and set the relevant parameter 03-00 to 03-04 =【13】to

switch from main to Alternative source.

¾ When 00 - 07 =【1】The Frequency command will be the result of setting of Main & alternative

frequencies.

Page 55

4-23

00- 08 Communication Frequency Command

Range

【0.00~650.00】Hz

¾ This parameter can be used to set frequency command

¾ This parameter can be used to read the set frequency in communication mode

¾ This parameter is only effective in the communication mode.

00- 09 Frequency Command save on power down (Communication mode)

Range

【0】:disable

【1】:enable

¾ 00-09=【0】 Keypad frequency is saved.

¾ 00-09=【1】 Frequency set by communication is saved.

00-10 Initial Frequency Selection

Range

【0】:By Current Freq Command

【1】:By Zero Freq Command

【2】:By 00-11

00-11 Initial Frequency Setpoint

Range

【0.00~650.00】Hz

¾ This parameter is only effective in keypad mode..

¾ When 00-10=【0】,the initial frequency will be current frequency.

¾ When 00-10=【1】,the initial frequency will be 0.

¾ When 00-10=【2】,the initial frequency will be as set by parameter 00-11.

00-12 Frequency Upper limit

Range

【0.01~650.00】Hz

00-13 Frequency Lower limit

Range

【0.00~649.99】Hz

¾ When 00-13 and the command frequency are both set to 0.00, if RUN is pressed ” Stpo” is

displayed.

¾ When Frequency command is > than preset in 00-13 inverter output will ramp up from 0.00 to the

command frequency.

¾ When 00-13> 0, and the frequency command value ≤ 00-13, inverter output will ramp up from

preset in lower limit to the command frequency.

Frequency upper limit

Frequency Lower limit

0

Hz

T

Page 56

4-24

00-14 Acceleration time 1

Range

【0.1~3600.0】 s

00-15 Deceleration time 1

Range

【0.1~3600.0】s

00-16 Acceleration time 2

Range