800

596.8

KF8004

4

1800

TEFC, 4P 4160V 60HZ

OUTPUT FULL FRAME EFFICIENCY ROTOR Max. LoadPOWER FACTOR CURRENT TORQUE Safe Stall

Starting

LOAD SIZE FULL 3/4 1/2 FULL 3/4 1/2

HP (kW) LOAD LOAD LOAD LOAD LOAD LOAD

RPM (EG) % %

350

% % % %

94.8 93.9

85.1 81.3 71.5260 1787 5009B 95.0 77245 90 230H 177621 25 137

Rated

A %

Starting

345

NEMA

Starting

CODE

LETTER

A

Max. Time(s)

HOT COLD

% % SEC SEC

WR

lb-ft

( 4160V )

APPROX.

2

2

WR

lb-ft

2

WEIGHT

2

LBS

3740

730

735

736

350

443

437

591

612

699

874

936

997

1232

H

G

H

G

220

G

G

G

G

G

H

H

H

300 1786 5011B 95.0 94.9 94.2 86.4 83.0 74.2 69051 80G 220 22 27 2007

400

340 1788 5011B 95.0 94.8 94.1

450

375 1786 5011B 95.0 94.9 94.3 87.1 84.4 75.8 69563 80 220 23 28 2439

500

450 1787 5011B 95.2 95.1 94.6

600

520 1788 5810B 95.4 95.2 94.4 81.3 77.3 31 35 325667.5 65893 110

700

600 1788 5810B 95.6 95.4 94.7

800

670 1788 5810B 95.6 95.4 94.8 81.3 78.1 68.5 658 120 230787 30 33 4032

900

750 1790 6808B 95.6 95.1 93.9

1000

800 1789 6808B 95.8 95.3 94.2 79.1 75.2 65.1 639 120 220 22 24 4298

1070

850 1789 6810B 95.9 95.4 94.4

1140

930 1790 6810B 96.0 35 4878

1250

1120 1790 6810B 96.1 95.6 94.5

1500

1320 1790 6811B 96.3 95.9 95.0 81.2 78.2 69.4 234 58311095120 220 22 251724

1750

95.6 94.6 79.6 75.9 66.1 120 220 31

85.7 82.1 73.3 76558 90 230 222020 26 4840196

85.0 80.3 69.4 76677 90 230 285920 26 216

82.5 79.3 70.6 662 110 220

106

120

78.4 74.0 64.0 630 120 220 406123 25 556

139

146

80.2 76.5 67.4 650 120 220 452933 37 703

153

169

80.5 76.8 67.4 120 2201478 517429 33 954

201

NOTE:

1. Test standard:IEEE-112.

2. Tolerance:NEMA MG1.

3. Number of consec. starts:2 Cold 1 Hot.

4. Data presented in rating lists are typical values. Guaranteed values on request.

Legally binding performance and specification data is given to the end user once each order is confirmed.

5. This performance data is only for sinepower, not suitable for PWM power source.

6. The voltage and frequency combinations not included in performance data are quoted case by case.

168

201

291

378

640

734

4540

4930

5025

6865

365331 35 351

7000

7260

9365

9515

10625

10810

12180

13270

1439526 30 1189 64531971 H 120 22078.0 69.4 265 74396.5 96.1 95.3 81.32000 1500 1790 6812B

TECO Electric & Machinery Co., Ltd.

DWG NO.

3A057M047E

REV.01

2/4

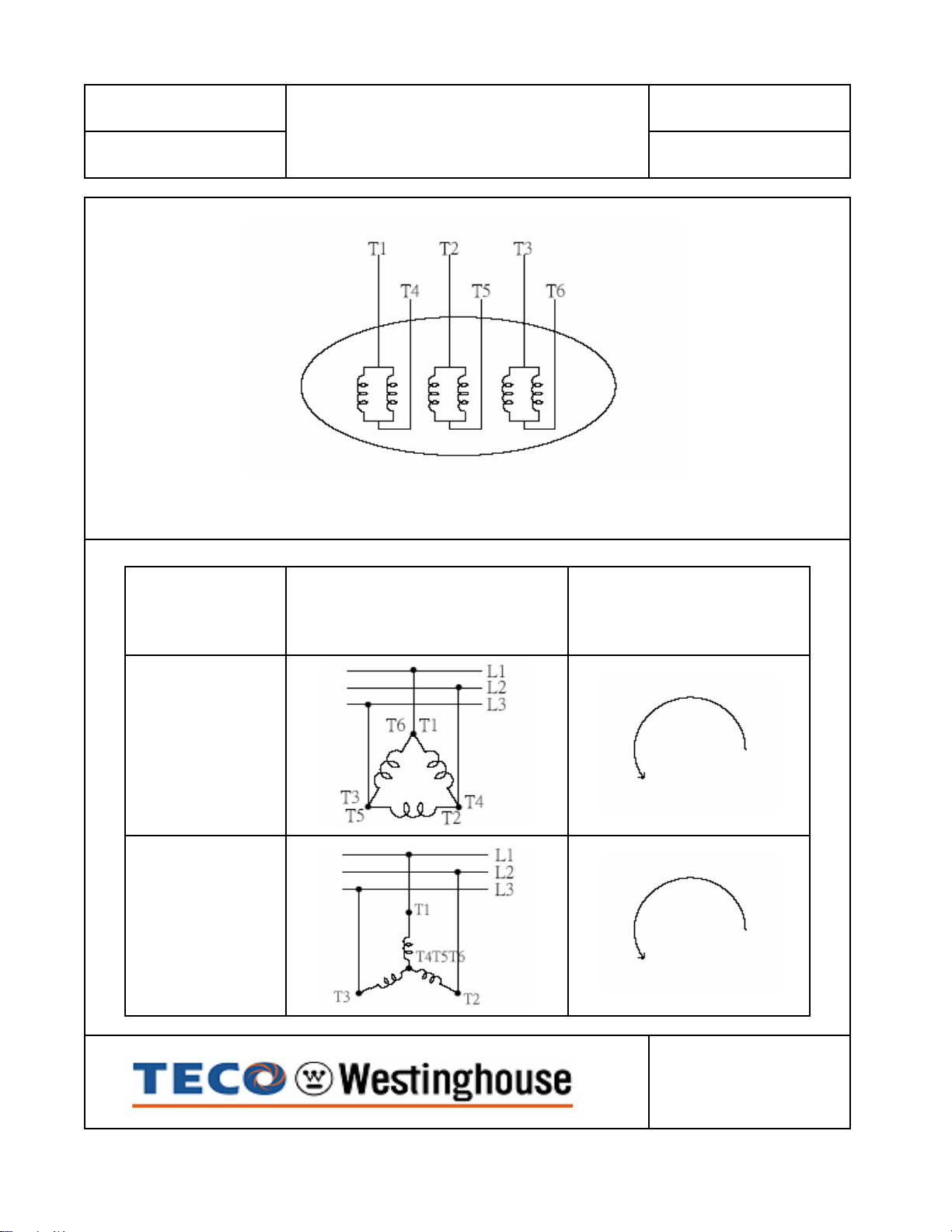

ROTATION

DATE: CATALOG NO.:

CONNECTION DIAGRAM

August 10, 2010

VOLTAGE CONNECTION

KF9004

SCHEMATIC DIAGRAM - 6 LEADS

(VIEWED FROM

2300

4160

DRIVE END)

DWG. NO.

3A061H475

OPERATION

&

MAINTENANCE

MANUAL

FOR

THREE PHASE

INDUCTION

MOTORS

Frame Size 5000 and Larger

INDEX PAGE

1. INTRODUCTION.......................................................................................................... 1

2. ACCEPTING, INSPECTION, STORAGE, TRANSPORTATION ................................. 2

3. INSTALLATION ........................................................................................................... 4

3.1 Site and environment for motor installation ...................................................... 4

3.2 Foundation ............................................................................................................ 4

3.3 Installation of shaft coupling............................................................................... 6

3.4 Installation of belt drive ....................................................................................... 9

3.5 Conveyance with chain or gear........................................................................... 10

3.6 Electrical connections ......................................................................................... 11

4. OPERATION ................................................................................................................ 12

4.1 Examination before starting ................................................................................ 12

4.2 Starting operation................................................................................................. 15

5. MAINTENANCE........................................................................................................... 17

5.1 Major points in regular inspection and maintenance........................................ 17

5.2 Motor windings ..................................................................................................... 18

5.3 Cleaning of the interior of the motor .................................................................. 18

5.4 Cleaning of the exterior of the motor.................................................................. 19

5.5 Maintenance of anti-friction bearings ................................................................. 19

5.5.1 Frequency of re-lubrication..........................................................................19

5.5.2 Kinds of grease ............................................................................................ 20

5.5.3 Grease quantity ............................................................................................ 20

5.5.4 Re-greasing .................................................................................................. 20

5.5.5 Oil re-lubrication .......................................................................................... 22

5.5.6 Cleaning and installation of bearings ........................................................ 23

5.6 Maintenance of sleeve bearings.......................................................................... 24

5.6.1 Daily inspection............................................................................................ 24

5.6.2 Regular examination .................................................................................... 24

5.6.3 Disassembly ................................................................................................. 25

5.6.4 Re-assembly ................................................................................................. 26

5.7 Maintenance of slip rings (for Wound Rotor only) ............................................ 27

5.8 Maintenance of non-reverse ratchet mechanism (Vertical Motors only) 29

6. FAULT FINDING AND RECOGNITION ........................................................................31

1. INTRODUCTION

This and the following instruction address the more common situations encountered in motor

installation, operation and maintenance. For the TWMC motor warranty to be and to remain in

effect, the motor must be installed and operated in strict accordance with the outline drawing,

motor nameplates and these instructions and must not be altered or modified in any unauthorized

manner.

During the installation and operation of motors in heavy industrial applications there is a danger of

live electrical parts and rotating parts. Therefore to prevent injury and/or damage the basic

planning work for installation, transportation, assembly, operation, etc... needs to be done and

checked by authorized and competent personnel only.

Since these instructions cannot cover every installation, operation, and maintenance the following

points should be considered and checked.

● The technical data and information on permissible use such as assembly, connection,

ambient and operating conditions given in the related catalogue, operating instructions,

nameplates and other production documentation.

● The general erection and safety regulations.

● The local and plant-specific specifications and requirements.

● The proper use of transport, lifting devices and tools.

● The use of personal protective equipment.

Following indications should be observed when reading these instructions.

Safety instructions are marked as follows:

Warning of electric hazards for personnel.

Warning of dangers for personnel.

ATTENTION!

Warning of damage for the motor or installation.

3

2. ACCEPTING, INSPECTION, STORAGE, TRANSPORTATION

2.1 Inspection upon receipt

Check the following points upon receipt:

• Are the nameplate ratings identical with what you ordered?

• Are dimensions and color in compliance with your specifications?

• Are the nameplate ratings for space heater, thermal protector, temperature detector, etc.

identical with what you ordered?

• Is there any damage?

• Are all accessories and accompanying instruction manuals in good order?

• Please ensure that the arrow head indicator really indicates direction of rotation.

• If there is any specific requirements, please ensure they are in conformity with your

specifications.

2.2.1

Storage

When motors are not in operation, the following precautionary measures should be undertaken to

assure best performance.

2.2.2

Place

(a) High and dry, well ventilated without direct sun, dust or corrosive gas.

(b) Not located near a boiler or freezer.

(c) Entirely free from vibration and easy movement.

(d) Motors should be put on pallets to prevent moisture.

2.2.3

Motors should be well-shielded form dust, but under well-ventilated circumstances.

2.2.4 Moisture prevention

Since moisture can be very detrimental to electrical components, the motor temperature should

be maintained about 3ºC above the dew point temperature by providing either external or internal

heat. If the motor is equipped with space heaters, they should be energized at the voltage shown

by the space heater nameplate attached to the motor. Incandescent light bulbs can be placed

within the motor to provide heat. However, if used, they must not be allowed to come in contact

with any parts of the motor because of the concentrated hot spot that could result.

2.2.5

Even during storage, the insulation resistance should be kept above the specified values.

(a) For measurement of insulation resistance and acceptable standard values, please refer

to measures stated in 4.1.2 “Measurement of insulation resistance”.

(b) Insulation resistance test should be performed once every three months.

2

2.2.6

ATTENTION!

If the motor is not in operation for a long period (one week and above) after installation or has

been in operation but stopped for a period of time, the following precautions must be taken.

(a) Protect the motor as measures stated in 2.2.4.

(b) Insulation resistance test should be performed as stated in 2.2.5.

2.2.7 Bearing protection

(a) If the motor has been provided with a shaft shipping brace to prevent shaft movement

during transit, it must be removed before operating the motor. It is very important that

this brace be re-installed exactly as it was originally, before the motor is moved from

storage or any time when the motor is being transported. This prevents axial rotor

movement that might damage the bearings.

(b) Motors equipped with sleeve bearings are shipped from the factory with the bearing oil

reservoirs drained. In storage, the oil reservoirs should be properly filled to the center of

the oil level gauge with a good grade of rust inhibiting oil. This will keep the bearing

journals well oiled to prevent rusting. The motor shaft should be rotated several

revolutions every month ensuring the shaft does not come to rest in its original position.

While the shaft is rotating, it should be pushed to both extremes of the endplay.

(c) Motors with anti-friction bearings are properly lubricated with the correct grade of grease

at the factory and no further greasing is required in storage. The shaft should be rotated

several revolutions every month to maintain proper distribution of the grease within the

bearings.

(d) Tilt-pad bearings are a type of sleeve bearing used in special design applications. Due to

the nature of this bearing, a loose oil ring for delivering lubricant cannot be provided.

Therefore, during the storage internal, oil must be periodically manually introduced into

the pads and housing to prevent the occurrence of oxidation of the precision machined

components.

(1) Remove the pipe plug from the bearing cap located above the tilt-bearing shell.

(2) Pour in approximately one cup of oil every month and rotate the shaft a few

revolutions about every two (2) weeks.

(3) For long periods of storage, the oil that accumulates in the housing should be

removed.

2.2.8

Care should be taken to keep parts such as fitting surfaces, key, shaft extension and axial

central hole from any collision with foreign matter. Grease should also be generously

applied to prevent rusting.

2.2.9 Transportation

To keep the rotating parts of motors from moving, thus preventing damage and scratching during

transportation, they should be held securely with a locking device. Remove all transit clamps

before operating the motor. It is very important that this device be reinstalled exactly as it was

originally, before the motor is moved from storage or any time when the motor is being

transported. The vertical mounting type motors should be transported in the vertical position.

5

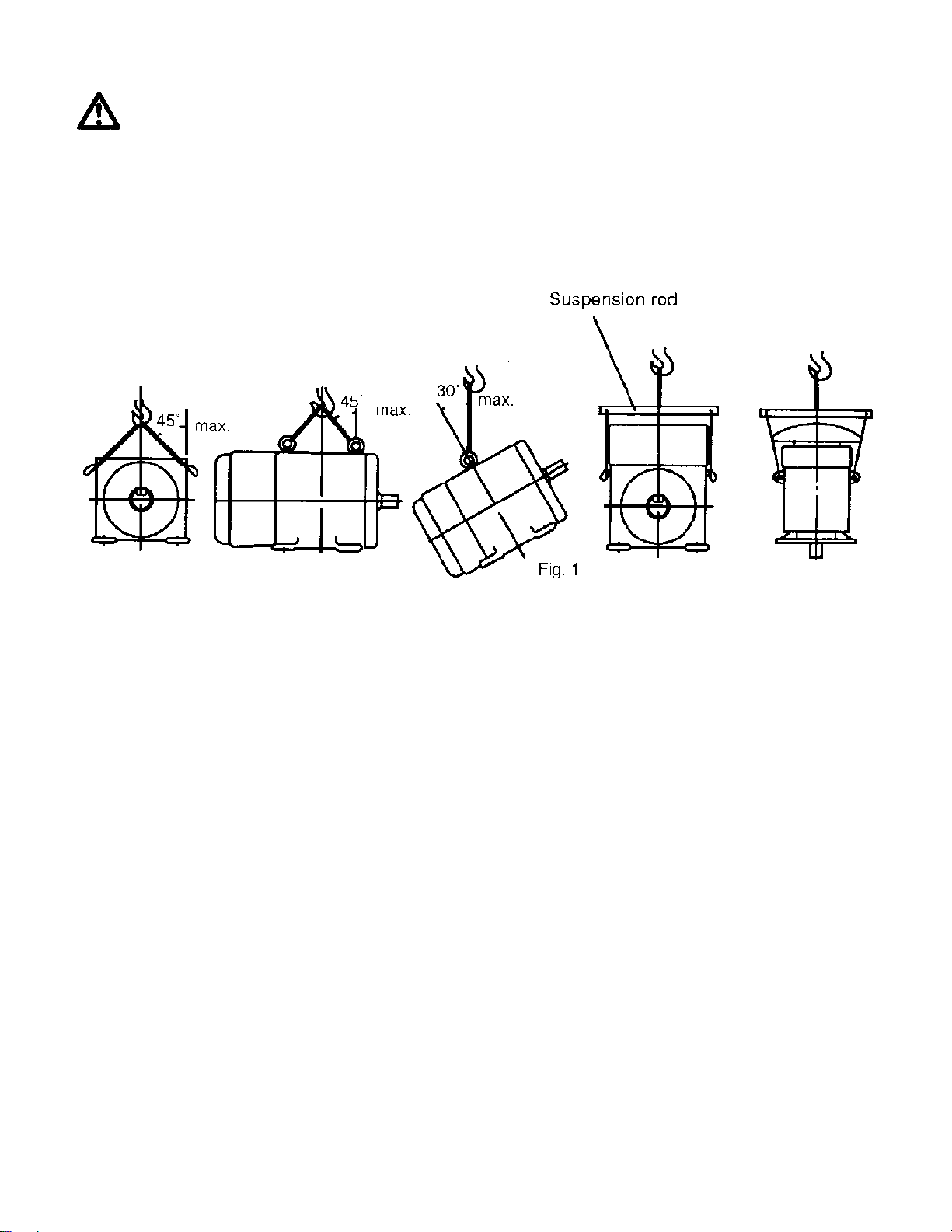

Do not use the hoisting hook/eyebolts to lift more than the motor itself. They are

and the sling angle is correct.

designed to support the motor only. Make sure the hoisting hook is correctly

attached to the eyebolt(s)/lug(s) and that they are fully screwed in before hoisting.

Also note such parts as fan cover, ventilation box, bracket, slip-ring, etc. may have

their own hoisting lugs which can only carry their own weight. Nothing extra

should be attached while hoisting.

Do not twist the steel wires and make sure the eyebolts have been firmly screwed

3 INSTALLATION

Motor installation – site and environment

3.1.1

Standard environment and site conditions for the installation of motors are usually set as follows:

(a) Ambient temperature: -10~40ºC

(b) Humidity: Relative humidity below 90%RH for totally enclosed types, and below 80%RH

for semi-enclosed types.

(c) Elevation: below 1000 meters or 3300 feet.

(d) Harmful gases, liquids, dusts, high moisture should be absent.

(e) Foundations should be strong and free of vibration.

If there are any special environmental conditions, please inform TWMC prior ordering.

3.1.2 Ventilation and space

(a) Installation area should be well ventilated.

(b) The installation space should be large enough to facilitate heat dissipation and

maintenance.

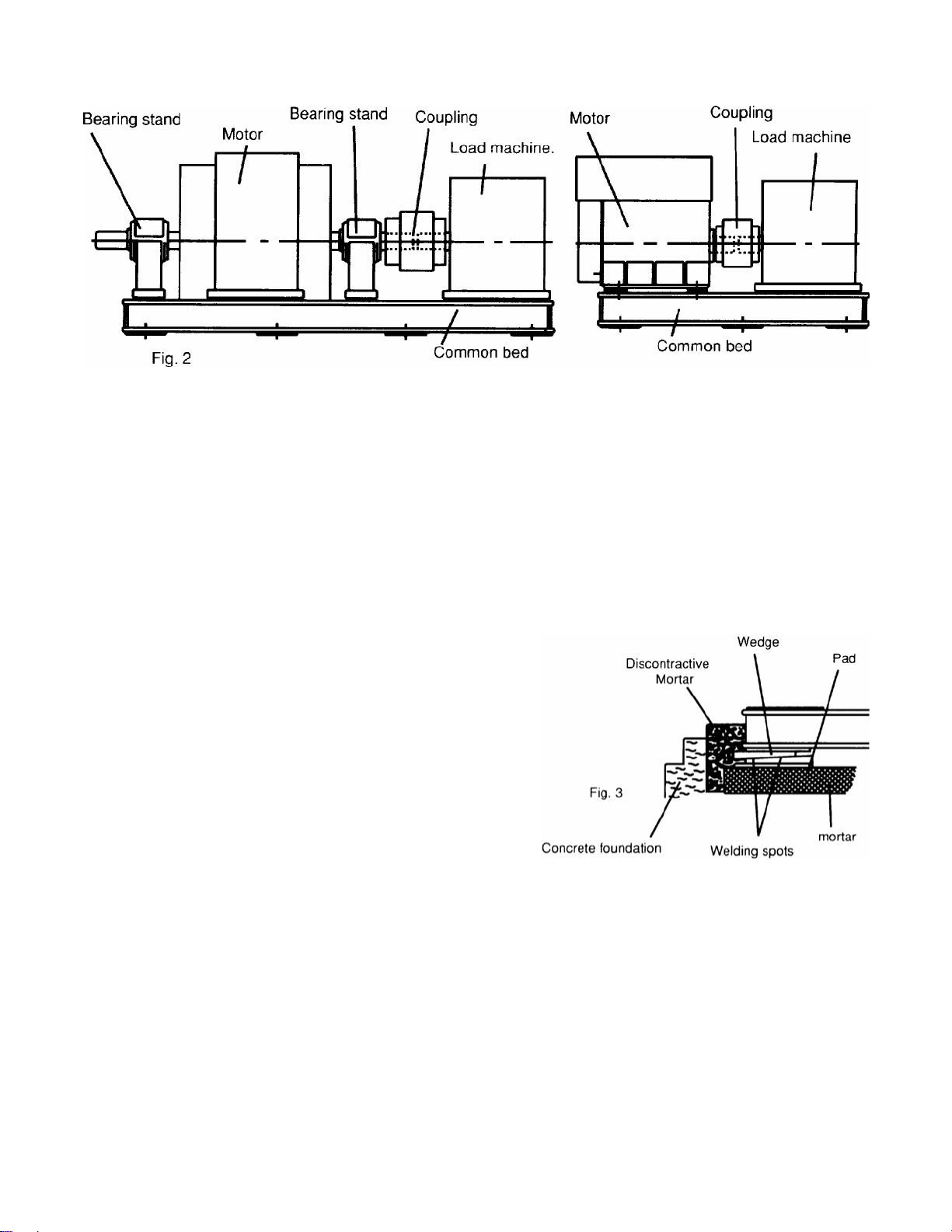

3.2 Foundation

3.2.1

Use rigid and solid sole plate or common bed as foundation.

For best motor performance, it is advisable to use a sole plate or common bed, particularly when

using a shaft coupling.

6

3.2.2 Installation

(a) Select an appropriate foundation surface for the sole plate or common bed, which will be,

considered the ultimate level.

(b) Align the position of the common bed with reference to that level.

(c) Align the level accuracy at least at four points such as bearing mounting, shaft extension

etc. The accuracy should be within 0.04mm or .0015 inches

(d) Sole plate or common bed should be embedded in concrete foundation as illustrated in Fig.

3. Stiff pads should also be installed beneath the wedges, which are welded together at

various spots about 400-500mm (15.75-1 9.70 inches) apart. This will enable the foundation

to evenly carry the weight of the whole motor.

(e) The base should be sturdy and rigid to keep it

flat and level.

(f) Make s ure t he m ort ar and con cret e are

completely dry, and the precision of the level is

acceptable, and then set the motor on the

mounting foundation.

(g) Accurately install shaft couplings, belt sheaves

etc., then weld the wedges solid to prevent any

change in position.

3.2.3 The foundation of vertical induction

motors: (Also the foundation of pump)

(a) Foundation of motor/pump must be rigid and secure to provide adequate support. There

must be no vibration, twisting, misalignment etc. due to inadequate foundations.

(b) A massive concrete foundation is preferred in order to minimize vibration. Rigidity and

stability are enhanced by prop plate and foundation bolt. As shown in Fig. 4.

7

Loading...

Loading...