Page 1

TECO Instruction Manual

Squirrel Cage Induction Motors

Whilst Motors are installed awaiting commissioning they must be adequately

protected against the elements, all external components in particular the shaft

extension and external labyrinth seals at the drive end must be fully covered

to avoid water ingress entering the motor body whilst stationery.

Please ensure that both the non drive end and drive end antifriction bearings

are fully purged with sufficient grease at first start up/commissioning

with the recommended grade and quantity of grease.

Page 2

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

2

TECO Electric & Machinery Co. Ltd.

Table of Contents

Table of Contents ................................................................................................ 2

Chapter 1: MOTOR DESCRIPTION .................................................................... 4

Chapter 2: TECHNICAL DATA ............................................................................ 5

Chapter 3: INSTALLATION AND COMMISSIONING .......................................... 6

3.1. INSPECTION UPON RECEIPT. ...............................................................6

3.2. STORAGE ............................................................................................6

3.3. TRANSPORTATION ..............................................................................9

3.4. INSTALLATION. ................................................................................. 10

3.5. MOUNTING. ...................................................................................... 10

3.6. COUPLING & ALIGNMENT. ................................................................. 10

3.7. INSTALLATION FOR BELT DRIVE ........................................................ 13

3.8. ELECTRICAL CONNECTIONS ............................................................... 13

3.9. AUXILIARY DEVICES .......................................................................... 15

Chapter 4: OPERATING INSTRUCTIONS......................................................... 17

4.1. EXAMINATION BEFORE START. .......................................................... 17

4.2. STARTING OPERATION. ..................................................................... 19

4.3. CAUTIONARY POINTS TO NOTE: ........................................................ 21

Chapter 5: ROUTINE MAINTENANCE ................................................................ 23

5.1. IMPORTANCE OF DAILY INSPECTION.................................................. 23

5.2. POINTS TO NOTE WHEN STARTING.................................................... 23

5.3. TEMPERATURE RISE. ......................................................................... 23

5.4. VIBRATION. ...................................................................................... 24

5.5. NOISE. ............................................................................................. 25

5.6. ODOUR. ............................................................................................ 26

5.7. MEASUREMENT OF THREE PHASE CURRENT. ...................................... 26

5.8. MOTOR APPEARANCE. ....................................................................... 27

Chapter 6: PERIODIC MAINTENANCE ............................................................ 28

6.1. REGULAR INSPECTION & MAINTENANCE. ........................................... 28

6.2. CLEANING OF COILS, DRYING & VARNISHING TREATMENT. ................ 31

Page 3

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

3

6.3. VARNISH. ......................................................................................... 33

6.4. KEY POINTS FOR MAINTENANCE & INITIAL OPERATION INSPECTION AFTER

LONG STORAGE. ............................................................................... 33

6.5. RECORDS OF OPERATION AND MAINTENANCE. ................................... 35

6.6. POINTS TO NOTE ON DISASSEMBLY. .................................................. 36

Chapter 7: BEARINGS ..................................................................................... 37

7.1. MAINTENANCE OF ROLLING BEARING. ............................................... 37

7.2. NOISE OF BEARING. .......................................................................... 42

7.3. VIBRATION. ...................................................................................... 42

7.4. REGULAR INSPECTION. ..................................................................... 42

Chapter 8: Troubleshooting. ........................................................................... 44

8.1. FAULT FINDING & RECOGNITION ....................................................... 44

Page 4

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

4

Chapter 1: MOTOR DESCRIPTION

This manual applies to Teco model series types as follows:

AEEB, AEVB, AEHB, AEMB, AEUB, AEHD, AEJE, AFJE, AEJU, AEJH and AFJH.

The motors are of Cast Iron Construction, Totally Enclosed Fan Cooled, Squirrel

Cage Induction type designed for operation on a 415/1000/3,300/6,600V/ 3 Phase

50Hz supply system equipped with grease lubricated anti friction type bearings.

SAFETY WARNING

The following instruction address the more common situations

encountered in motor installation, operation and maintenance. For the

TECO warranty to remain valid, the motor must be installed and

operated in strict accordance with the outline drawing, motor nameplate

and these instructions and must not be altered or modified in any

unauthorized manner.

During the installation & operation of motors in heavy industrial

applications there is a danger of live electrical parts and rotating parts.

Therefore to prevent injury and/or damage the basic planning work for

transport, assembly, installation & operation needs to be carried out by

authorized and competent personnel. Points in this manual that are

boxed and headed “DANGER”, “CAUTION” or “NOTE"(see below) should

be observed as they indicate possible danger to personnel and/or the

potential of equipment damage.

This prompt is used when there is an immediate hazard that WILL

result in severe personal injury or death if correct procedures are not

followed.

This prompt is used to warn against potentially unsafe practices that

COULD result in personal injury and/or property damage if correct

procedures are not followed.

This prompt is used when an operation, condition, or information is of

sufficient importance to warrant highlighting

Page 5

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

5

Chapter 2: TECHNICAL DATA

This manual covers a power outputs ranging through to 1500kW with varying

frame sizes and speeds etc.

For motor technical data refer to appropriate motor data sheet.

Page 6

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

6

Chapter 3: INSTALLATION AND COMMISSIONING

3.1. INSPECTION UPON RECEIPT.

Check the following points upon receipt:

a. Is the nameplate rating identical to your order?

b. Do dimensions and colour comply with your specification?

c. Are the nameplate ratings for the heater, temperature detector etc.

identical with what you ordered?

d. Is there any damage due to transportation?

e. Is the original transportation shaft lock fitted to the drive end shaft?

f. Are all accessories in good order?

g. If there are any specific requirements, please check if they conform with

your specification.

3.2. STORAGE

When storing motor, the following procedures should be undertaken.

3.2.1. Place.

a. It should be dry, well-ventilated and not subject to direct sunlight, dust or

corrosive gas.

b. It should not be located close to a boiler or freezer.

c. It should be entirely free from vibration and have easy access.

d. Motor should be stored on pallets to prevent moisture ingress.

3.2.2. During storage, the insulation resistance should be kept above the specified

values as follows:-

a. Stator: Above 50MΩ measured with 1000VDC megger.

b. If the motor has absorbed moisture as evidenced by low insulation

resistance, it must be dried with external heat until it is thoroughly dry and

the value of insulation resistance exceeds the minimum requirements.

c. Measurement of insulation resistance should be performed once every

month.

d. Anti-condensation heaters should always be connected where fitted.

Page 7

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

7

3.2.3 Insulation resistance test should be performed before making high voltage

test.

a. Use 500VDC megger to measure insulation resistance.

i. Stator: Over 50MΩ between windings.

ii. Stator: Over 50MΩ between windings and earth.

b. High Voltage Test

i. This test can be undertaken only after the values of insulation resistance in

item 3.2.3 (a) are assured.

ii. The value of testing voltage is (1000 + 2E) X 0.8 where E: rated voltage.

3.2.4. Care should be taken to keep parts such as the fitting surface, key, shaft

extension and axial centre hole free of any foreign matter. Grease should

also be generously applied to stop rust.

3.2.5. The shaft should also be rotated by hand a few revolutions once per month.

3.2.6. If practical, a test run should be performed once every three months.

3.2.7. Clean the motor thoroughly, and replenish grease before the machine is put

back to operation.

3.2.8. The ventilation system should be covered to avoid the entry of foreign

matter or insects. It should be thoroughly cleaned before use.

3.2.9. Make sure the hoisting hook is correctly connected to eye bolts or lugs of

motors before hoisting.

Parts such as fan cowl, terminal boxes, etc. which have their

own lifting facilities can only carry their own weight.

They should not be used for lifting the entire motor.

Page 8

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

8

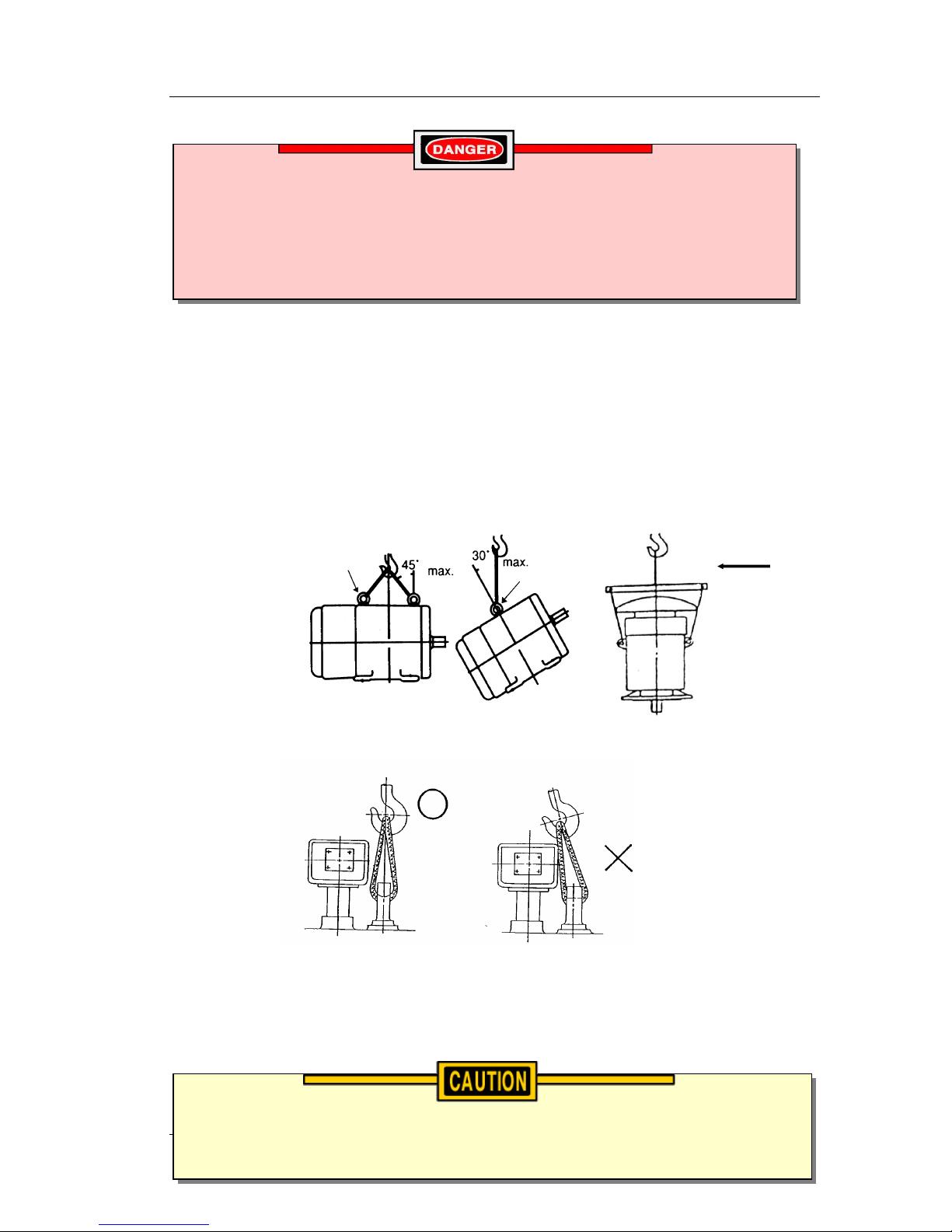

3.2.10. Points to note when hoisting:

a. Do not twist steel wires.

b. Make sure eye bolts have been firmly screwed in.

c. Keep the sling vertical when moving/lifting motor.

Fig. 1

Please keep the sling vertical when lifting / moving the motor.

Fig. 2

An accident could occur if the motor eyebolt/lifting hook is overloaded.

They are suitable for the motor weights only.

Do not lift motor and load combined with motor lifting hook.

Motor is fitted with lifting points (arrowed). These points are designed to lift

motor weight only.

Do not use other hooks or handles to lift motor.

Page 9

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

9

3.3. TRANSPORTATION

To keep the rotating parts of motor from moving, thus causing damage

during Transportation, they should be held securely as follows:

3.3.1. Motors fitted with a retaining plate/bracket to secure the shaft must have it

fitted during transportation. Please retain this device for future

transportation of the motor.

3.3.2. After receiving motor, remove all securing studs, nuts, etc. before putting

motor into operation. (Fig.3)

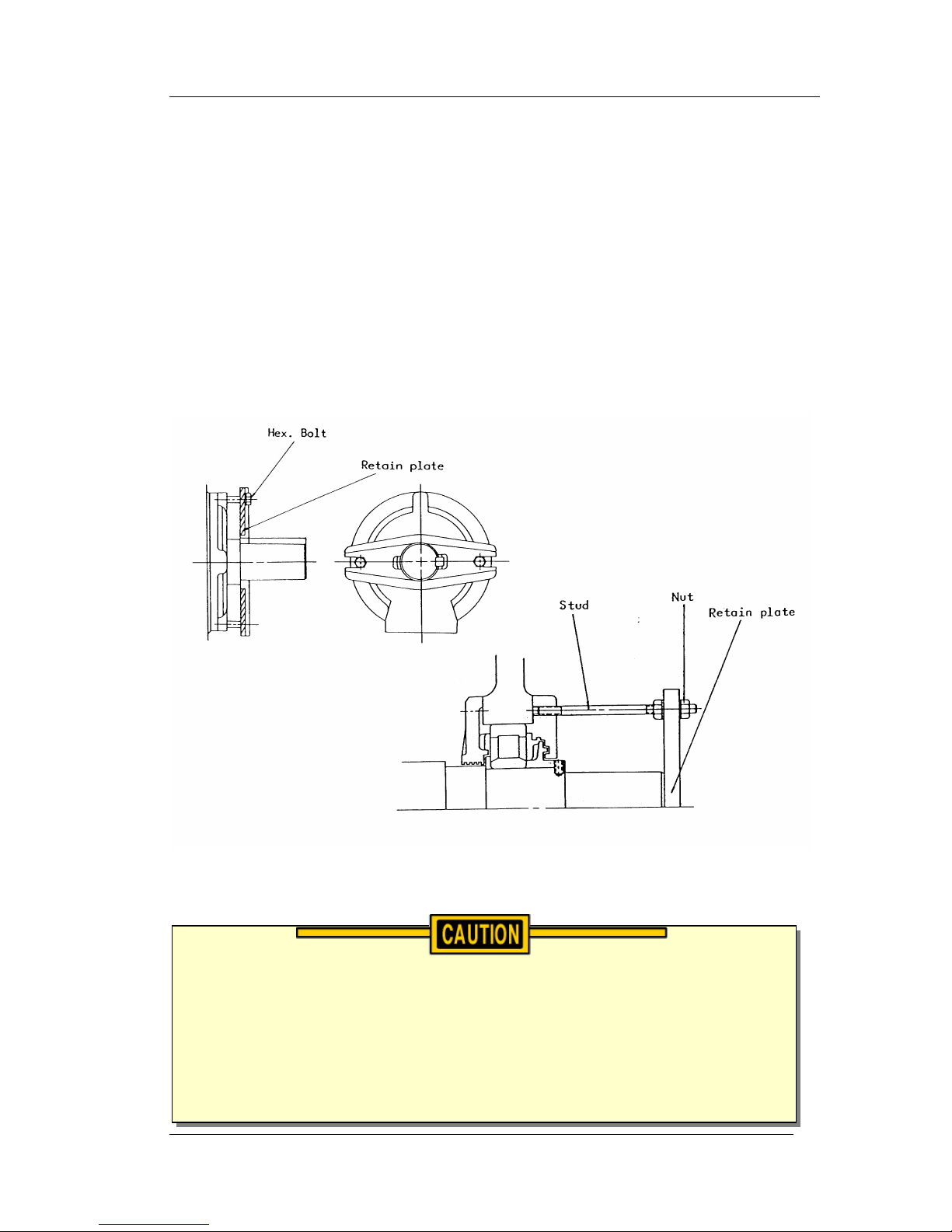

Fig 3

Shaft Locks are fitted as standard and these should be fitted during

installation and should only be removed once the pulleys and guards are

ready to be fitted. The motor must not be transported without the shaft lock

fitted, damage to bearings caused by shaft locks being removed or moisture

ingress whilst awaiting commissioning is not covered under motor warranty.

Page 10

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

10

3.4. INSTALLATION.

3.4.1. Site conditions for motor installation:

Standard site conditions for installation of motors are as follows:

a. Ambient temperature: -20

0

C~400C.

b. Humidity: Relative humidity below 90% RH for totally enclosed type.

c. Elevation: Below 1000 metres.

d. Should the installation be in an industrial zone, it should be free of explosive

gases and liquids.

e. Foundation should be strong so as not to induce vibration.

3.4.2. Ventilation and Space.

a. Installation should be well ventilated.

b. The area should be large enough to facilitate heat dissipation and

maintenance.

3.4.3. Foundation.

Use rigid and solid sole plate or common bed as the foundation.

3.5. MOUNTING.

3.5.1. An adequate motor support (which is the responsibility of others) is very

important. It must have sufficient rigidity to maintain alignment between

the motor and its driven load. Inadequate or improperly designed motor

supporting structures can lead to serious vibration and alignment problems.

3.6. COUPLING & ALIGNMENT.

Two pole motors and motors larger than Frame 315M must not be coupled to

the driven equipment by means other than direct connection.

Please refer to TECO if belt connection is to be used.

Page 11

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

11

3.6.1. Installation.

Field application of a coupling to the motor shaft should follow the

procedures recommended by the coupling manufacturer. Under no

circumstances may the motor shaft be modified as to configuration or

diameter without the approval of Teco Australia. The motor shaft extension

must not be subjected to either extreme heat or cold during coupling

installation. If it is necessary to exert axial force on the shaft, either

continuously or intermittently, during coupling application, it must be

properly restrained axially to prevent bearing damage.

3.6.2. After the motor has been properly aligned with the driven equipment and

the hold down bolts have been installed and tightened, at least two dowel

pins should be installed diagonally opposite motor feet.

3.6.3 Alignment.

In aligning the motor (and rotor) axially with the driven equipment,

consideration should be given to the axial shaft expansion and increase in

shaft centre line height due to thermal effects.

Shaft height growth (change in shaft centre line elevation) for TEFC

machines can be calculated as follows,

Growth =(0.0005) x (motor foot to shaft centre line dimension [in mm]).

The exposed rotating parts should be covered to prevent accidents.

Motors must always be accurately aligned. Incorrect alignment can lead to

bearing failure, vibration and even shaft fracture. As soon as bearing

failure or vibration is detected, the alignment should be checked.

Page 12

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

12

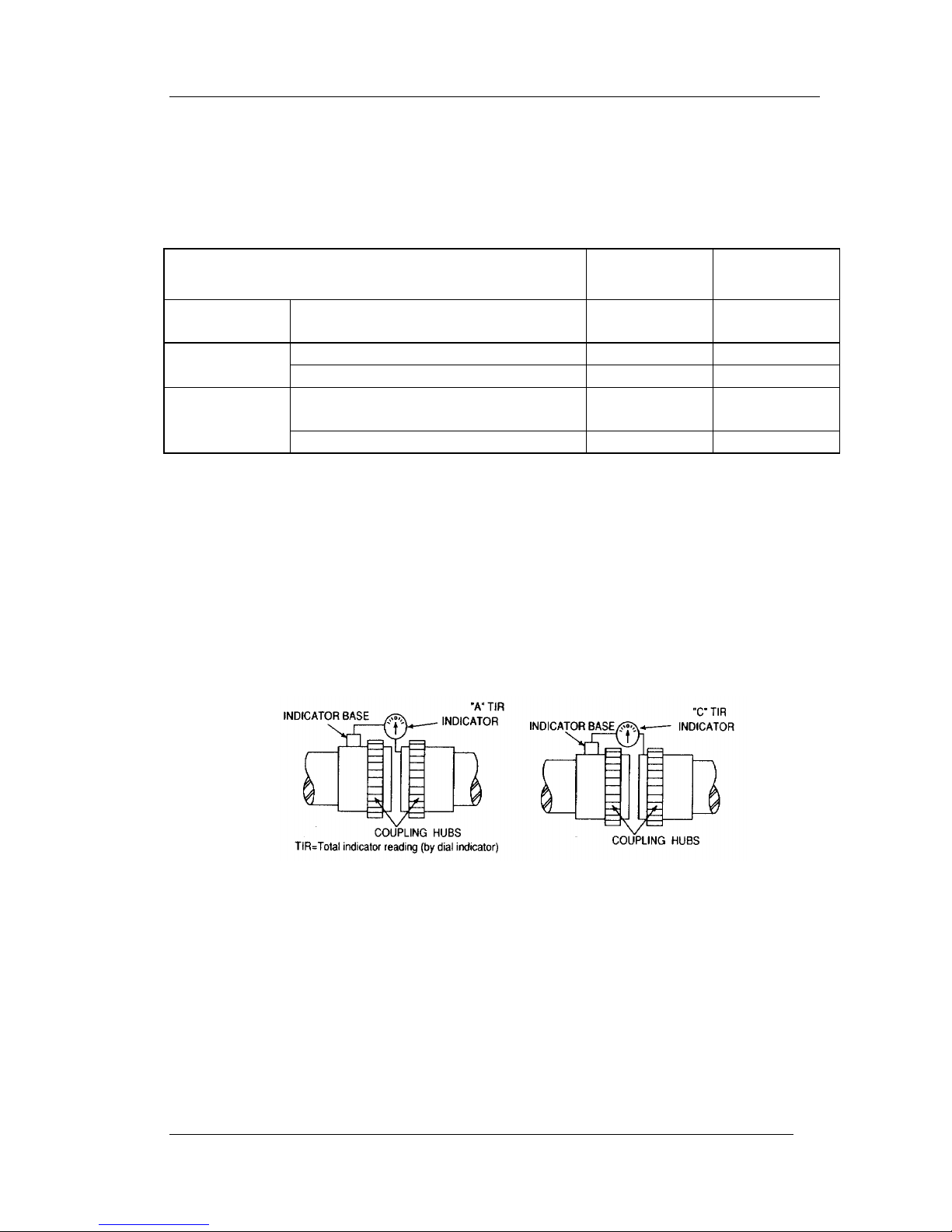

3.6.4 It is desirable, in normal operation that the motor operates, so that no axial

force is exerted on the coupling.

The motor shaft and the driven shaft should be aligned within the following

tolerances in both angular and parallel alignment (refer Table 1).

Units in mm

TIR

Total Indicated

Runout

Solid

Coupling

Flexible

coupling

Dimension C

Medium, Low speed up to 2500

RPM

0.04

0.05

High speed over 2500 RPM

0.03

0.03

Dimension A

Medium, Low speed up to 2500

RPM

0.03

0.04

High speed over 2500 RPM

0.03

0.03

Table 1

3.6.5 Angular misalignment is the amount by which the centre lines of the driver

and driven shaft are skewed. It can be measured using a dial indicator set

up as shown in fig 4. The couplings are rotated together through 360

degrees so that the indicator does not measure runout of the coupling hub

face. The shaft should be forced against either the in or out extreme of

their end float while being rotated.

Fig. 4 Fig. 5

3.6.6 Parallel misalignment is the amount by which the centre lines of the driver

and the driven shafts are out of parallel. It can be measured using the dial

indicator as shown in fig. 5. Again the couplings are rotated together

through 360 degrees so that the indicator does not measure runout of the

coupling hub outside diameter.

Page 13

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

13

3.6.7 After the motor has been properly aligned with the driven equipment and

the hold down bolts have been installed and tightened, at least two dowel

pins should be installed diagonally opposite motor feet.

3.7. INSTALLATION FOR BELT DRIVE

3.7.1. Small, medium and large motors within frame sizes up to and including 315

frame are designed for use with belt transmission or direct coupling.

3.7.2. The diameter ratio between conveyance sheaves should not be greater 5 to

1 for flat belts, and 8 to 1 for V-belts. It is also advisable to limit the belt

velocity to under 35m/sec to limit belt abrasion and vibration. The smaller

the outer diameter of the V-belt sheave, the greater the shaft bending

stress will be. If bending stress is in excess of the shaft fatigue stress, the

shaft may break. If concerned please inform TECO of the size of the

sheaves and belt details for checking.

3.8. ELECTRICAL CONNECTIONS

3.8.1. The rated conditions of operation for the motors are as shown by the

nameplate. Within the limits given below, of voltage and frequency variation

from the nameplate values, the motor will continue to operate but with

Place the sheave and belt as close as possible to the motor body and

shaft shoulder to reduce the bending moment and improve shaft life.

Do not hammer the conveyance devices such as coupling, belt sheaves, chain

wheels, gears, pulleys etc. onto the motor shaft. Those shaft fitments should

be fitted and removed only by means of suitable devices. Heat shrinking may

be a better alternative to avoid damaging bearings and other components.

Page 14

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

14

performance characteristics that may differ from those at the rated

conditions:

+/- 10% of rated voltage

+/- 5% of rated frequency

+/- 10% combined voltage and frequency variation so long as frequency

variation is no more than +/- 5% of rated value.

Operating the motor at voltage and frequencies outside of the above limits

can result in both unsatisfactory motor performance and damage to/or

failure of the motor.

3.8.2. Motor connections should be carried out in accordance with the details

applicable to the appropriate supply voltage as shown on the motor

nameplate and should be undertaken by suitably qualified personnel.

3.8.3. The main lead box furnished with the motor has been sized to provide

adequate space for the make up of the connections between the motor lead

cables and the incoming power cables.

3.8.4. The motors are provided with grounding pads and/or bolts for the

connection of earthing.

The bolted joints between the motor lead and the power cables must be

made and insulated in a workman-like manner following the best trade

practices and in accordance with the minimum requirements of the current

Australian Standards.

The motor must be grounded by a proper connection to the electrical

grounding system and in accordance with the minimum requirements of the

Australian Standards.

Motors fitted with insulated bearings and rotor grounding brushes which are

used on VVVF Drives must be effectively earthed to the supply system.

Page 15

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

15

3.9. AUXILIARY DEVICES

3.9.1. Please refer to your specification and the motor nameplate to determine if

the motor is fitted with thermal winding protection devices.

The following are the most common:

One set (one per phase – total 3 off) of PTC winding thermistors.

Two sets (two per phase – total 6 off) of PTC winding thermistors.

One set (one per phase – total 3 off) of PT100 winding Resistance

Temperature Detectors (RTD’s).

Two sets (two per phase – total 6 off) of PT100 winding Resistance

Temperature Detectors (RTD’s).

3.9.2. Where specified motors may also be equipped with PT100 bearing

Resistance Temperature Detectors (RTD’s).

3.9.3. Thermistors are positive temperature coefficient type (1000 ohm @ tripping

temperature) refer to specification table for tripping temperature.

They are a tripping device only and not a temperature detector.

Thermistor leads should be connected to an appropriate thermistor control

relay from a reputable supplier.

3.9.4. RTD’s where fitted are of the platinum type (PT100) with a reference

temperature of 0°C at 100.

RTD leads should be connected to an appropriate motor protection system

from a reputable supplier.

Recommended temperature settings for RTD’s are as per table 2 below.

DEVICE

TYPE

LOCATION

ALARM

TRIP

RTD

PLATINIUM 100 @ 0OC

WINDING

1400C

1500C

RTD

PLATINIUM 100 @ 0OC

DE & NDE BEARING

900C

950C

Table 2

Page 16

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

16

3.9.5. Where specified motors may be equipped with internal space heaters (check

for nameplate), to prevent the ingress of moisture into the motor insulation

system whilst motor is idle.

The incoming supply to the heaters should be in accordance with the details

contained on the heater nameplate.

The heater circuit should be inter-locked with the motor starter so as to de-

energise heaters when the motor is running.

Thermistors and/or RTD’s should not be meggered or tested at a

voltage above 2.5Volts.

Anti Condensation Heaters may be LIVE when the motor is switched

off. Isolate supply at all times before working on the motor.

Should the motor thermal protection circuit trip indicating over

temperature the cause/s should be thoroughly investigated before a

restart is attempted.

Failure to do so may lead to permanent damage or failure of the motor.

Page 17

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

17

Chapter 4: OPERATING INSTRUCTIONS

4.1. EXAMINATION BEFORE START.

4.1.1. After motor is installed the following points should be noted:a. Check all wiring is correct and in accordance with connections appropriate to the

supply voltage as shown on motor nameplate.

b. Is the incoming cable size adequate?

c. Are all connections tight and properly insulated?

d. Check the rating of fuses, starter/contactor are correct & operating normally.

e. Check motor is correctly earthed especially if supplied via a VVVF drive.

f. Make sure starter/switches are set in correct position.

g. Check heater circuit if fitted is de-energised when motor is in operation.

h. Check bearings are filled with the correct quantity and grade of grease.

4.1.2. Measurement of insulation resistance.

a. Rated voltage below 1000V, measure with 500VDC megger.

b. In accordance with IEEE-43 clause 9.3 standards, refer to following formula:

R (M) = > (Rated Voltage + 1) x 10

1000

c. If a new winding has a low insulation resistance reading moisture ingress is

generally the problem. Drying the winding through the proper application of

heat will normally increase the insulation resistance to an acceptable level.

Following are several accepted methods for applying heat to a winding:

i. If the motor is equipped with anti condensation heaters these can be can be

energised to heat the winding.

ii. Direct current (as from a DC welder) can be passed through the winding. The

total current should not exceed approximately 50% of rated full load current.

Delta wound motors have six leads and the three phases should be connected

into one series circuit.

iii. Heated air can be either blown directly into the motor or into a temporary

enclosure surrounding the motor. The source of heated air should preferably

Page 18

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

18

be electrical as opposed to fuelled (such as kerosene) where a malfunction of

the fuel burner could result in carbon deposits entering the motor.

iv. Insulation resistance measurements can be made while the winding is being

heated. However, they must be corrected to 400C for evaluation since the

actual insulation resistance will decrease with increasing temperature. As an

approximation for a new winding, the insulation resistance will approximately

halve for each 100C increase in insulation temperature above the dew point

temperature.

d. Should the resistance fail to attain the specified value even after drying,

careful examination should be undertaken to eliminate all other possible

causes, if any.

4.1.3. Power Supply

a. Is the capacity of the power supply adequate?

b. Do voltage and frequency of supply match with those on the nameplate?

c. Voltage variation should be confined to within +/-10% of the rated value

and the phase to phase voltages should be balanced.

Caution must be exercised, when heating the motor with any source

of heat other than self-contained space heaters, to raise the

winding temperature at a gradual rate to allow any entrapped

moisture to vaporise and escape without rupturing the insulation.

The entire heating cycle should extend over 15-20 hours.

Ensure adequate guarding is provided so live parts cannot be touched.

Page 19

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

19

4.1.4. Bearing Lubrication

Grease Lubricated Type.

a. Refer to the section “Maintenance of Bearing” for maintenance procedures

and grease type.

4.1.5. Other Points to note

a. Make sure the transmission system, including belts, screws, bolts, nuts and

set pins are in good condition.

b. Dismantle all locks which fasten the moveable parts of the motor during

transportation, and turn the shaft by hand (if practical) to check if it moves

freely.

c. Check if there is any evidence of foreign matter inside the motor before

starting.

d. Make sure the items above are examined. Test the motor with or without

load. Record and check according to “Maintenance” at 15 minute intervals

during the first three hours of operation. Then conduct regular examinations

after longer intervals. If problems are experienced test without load to

ascertain whether it is a load, structure, alignment or motor issue.

4.2. STARTING OPERATION.

4.2.1. Starting Load.

The initial test involves running the motor without load. Unless specified, a

motor is designed to start with light load, which is then gradually increased

to full load, as the motor accelerates to full speed.

4.2.2. Starting.

The bearings are initially lubricated with the correct grade of grease at

the factory. After installation, long storage and at initial start

up/commissioning the bearings must be fully purged with new grease.

Please refer to section 7.

Page 20

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

20

a. Motor can be restarted if the initial start fails. Three attempts are

permissible when the motor is at ambient (cold) temperature. Two starts in

succession are permitted when motor is at normal running temperature.

Smaller motors have a more frequent starting cycle.

b. Should an additional start be necessary beyond the conditions stated above,

the following restrictions should be noted:

i. Let the motor cool down for 60 minutes before a full load restart.

ii. Let the motor cool down for 30 minutes before a no load restart.

iii. Two inching starts can be regarded as one normal start.

c. If the motor rotor fails to start turning after two seconds, shut off power

supply immediately. This can result from:

i. Too low a voltage at the motor terminals.

ii. The load is too large for motor rating.

iii. The load has seized mechanically.

iv. Electrical connections incorrect.

v. Single phase power has been applied.

vi. Any combination of the above.

Note – Investigate thoroughly and take corrective action before attempting a

restart.

4.2.3. Direction of Rotation.

a. Motors are generally bi-directional. Some 2 pole and low noise motors are

uni directional only. If motor is uni-directional the fan cowl will be fitted with

a direction of rotation arrow.

b. If direction of rotation must be changed on a bi-directional motor, cut

power and wait until the motor stops, then interchange any two of the three

incoming phase leads.

4.2.4. Power Supply. Voltage/Current.

a. Check if the voltage and frequency of the power supply are identical to that

shown on the nameplate.

Page 21

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

21

b. Voltage variation should be confined to within +/-10% of nameplate

voltage, and the three phase voltages should be balanced.

c. Check if the phase currents of the motor, without load, are within +/-5% of

the average values.

4.2.5. Frequency.

Frequency variation should be confined to within +/-5% of the nameplate

frequency. The aggregate variation of voltage and frequency should be

confined to within +/-10% of the absolute value of the rating.

4.2.6. Run Up Time.

4.3. CAUTIONARY POINTS TO NOTE:

4.3.1. Bearings:

a. The motor is fitted with grease lubricated bearings. Following initial start up

the bearing temperatures should be closely monitored. A rapid rate of rise

in bearing temperature is more indicative of impending trouble, however,

when greasing an expected higher temperature is normal and should

equalize after a period of time.

b. When the rate of bearing temperature rise is less than 1°C per half hour,

the bearing temperature is considered to be stabilised.

c. If the total bearing temperature exceeds 100°C, the motor should be shut

down immediately and subsequent checks be undertaken.

The Run Up time is longer for motors connected to a load with a large inertia.

However, if the run up time exceeds what is deemed normal or there is

abnormal noise, the motor and load should be examined to establish the

cause before attempting a restart.

Page 22

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

22

4.3.2. Vibration:

a. The ideal values generally for motors are figures below 2.8mm/sec.

If vibration exceeds this level, an examination of the motor, load, structure

etc, should be made to determine the cause, the first check to undertake

would be to run the motor un-coupled and check if the vibration is still

evident, see section 5.4 Vibration.

4.3.3. Starting:

a. If the motor acceleration time exceeds the typical ramp time for this

application, shut off the power immediately.

Investigate thoroughly and take corrective action before attempting to

restart.

b. It should be recognised that each start of an induction motor subjects the

motor to current greater than full load current with resulting heating of the

stator and rotor windings. Each start can produce more heat than is

produced and dissipated by the motor under a full load condition.

c. The starting duty for which the motor is designed must not be exceeded if

long motor life is expected. Abnormally low terminal voltage and/or

excessive load torque during motor start up can cause lengthened

acceleration times during which the rotor ventilation is reduced. This can

cause rotor damage or lead to shortened rotor life.

Page 23

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

23

Chapter 5: ROUTINE MAINTENANCE

5.1. IMPORTANCE OF DAILY INSPECTION.

5.1.1. Normally electric motors do not fail suddenly. It happens over time, and

regular inspection will detect a problem before a serious situation develops.

If operators in the plant are alert, faults can be detected early and action

taken to eliminate trouble.

Daily inspection, can be performed without interrupting the end user’s

normal operation.

5.1.2. Do not overlook any minor irregularities. If necessary, stop the machine

immediately to check and repair. Essentially, inspections should be

performed by the operator daily. But a maintenance technician should also

check the machine once a week together with the operator.

5.2. POINTS TO NOTE WHEN STARTING.

a. Check power supply to see if voltage and frequency are normal.

b. Is starter set at starting position?

c. Are there sparks during start?

d. Is the motor accelerating normally?

5.3. TEMPERATURE RISE.

5.3.1. The temperature of a motor is often determined by measuring the

temperature of the frame. This is not indicative of actual internal

winding operating temperature, however, this method can often be

referred to and compared with previous readings. If the temperature is

found to be higher than usual please check the following possibilities.

DO NOT MAKE TEMPERATURE READINGS WITH THE SENSE OF TOUCH.

Often the temperature of a motor is determined by touch. Human hands can only

tolerate temperatures below 600C. Most motors safely operate at temperatures

greater than this, therefore, the sense of touch should not be used. Temperature

readings by hand are also inaccurate. Readings should be made using a

thermometer probe or non-contact infra red thermometer.

Page 24

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

24

5.3.2. Main causes of high temperature:

a. Motor Conditions

i. Voltage and frequency variation of power source is in excess of

tolerance.

ii. Unbalanced three phase voltage, open circuit or poor contact.

iii. Insufficient or excessive lubrication.

iv. Abnormal frequency of starts.

v. Single-phasing due to open circuit or short circuit.

vi. Damaged starter or improper operation.

vii. Blocked ventilation ducts.

viii. Motors cooling vents blocked.

b. Due to load or mechanical conditions:

i. Overload.

ii. Defective transmission coupling.

iii. Poor installation causing overload.

iv. High ambient temperature or radiant heat emitted from driven load

or surroundings.

5.4. VIBRATION.

5.4.1. Main causes inducing vibration:

i. Unbalanced load.

i. Misalignment of couplings.

ii. Unbalanced belt-sheaves.

iii. Improper couplings with belts or chains.

iv. Unsuitable foundation or poor installation.

v. Unbalanced motor rotor.

vi. Serious abrasion to motor or load machine drive bearing.

vii. Defective bearing or subsequent bearing damage.

5.4.2. No matter what causes the vibration, if it is not eliminated, the following

faults may develop:

i. Bearing damage.

Page 25

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

25

ii. Deformation of shaft.

iii. Loose parts or couplings.

5.5. NOISE.

5.5.1. Points to Note.

Not all noise is the result of a fault or abnormality. For instance, wind and

slight electromagnetic sounds are perfectly normal. They will remain at the

same level no matter how long the motor is in operation. Generally the

louder the noise, the larger the vibration amplitude will be.

5.5.2. Bearing Sound.

i. Bearing noise is a guide to the condition of the motor bearings

without dismantling the motor.

ii. Normal bearing sound in general is continuous, not intermittent. The

sound may tend to increase with the age of the bearings, but its

increase is gradual and hardly noticeable by the ear.

iii. Abnormal bearing sound is intermittent, rarely continuous.

iv. Some motors will emit noise when unloaded or after greasing due to

skating. This is normal and temporary.

5.5.3. Abnormal bearing sound generally develops from the following causes:

i. Foreign matter in grease.

ii. Scratches on the contact surface of the bearing.

iii. Rust on the contact surfaces of the bearing due to moisture ingress.

iv. Poor quality of grease or wrong type of grease.

v. Insufficient grease (the sound could be continuous).

5.5.4. Causes of abnormal electromagnetic sound:

i. Single phasing.

ii. Short circuit in windings.

iii. Unbalanced air gap resulted from serious bearing wear.

Page 26

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

26

5.6. ODOUR.

5.6.1. Causes of motor odours:

i. Short circuit or over current causing overheating of varnish.

ii. Poor lubrication due to insufficient or contaminated grease.

5.7. MEASUREMENT OF THREE PHASE CURRENT.

5.7.1. Causes & effects

When load current is above the rating on the nameplate, it means the

motor may be overloaded. However, the cause of over current is not

confined to overloading, but may be caused by poor coupling installation,

transmission structure, excessive high or low voltage, etc.

a. Causes of unbalanced three phase current.

i. Unbalanced three phase voltage.

ii. Open circuit in power distribution lines.

iii. Poor switch contact.

iv. Open or short circuit in winding.

v. Open circuit at power transformer.

b. Effects:

i. Overheating of the windings causing fire or short circuit.

ii. Vibration of motor.

iii. Reduction of motor output torque.

c. Causes of wavering of ammeter indicator:

The characteristics of devices such as compressor or press are apt to cause

wavering of the indicator. Other causes are,

i. Poor contact of switches.

ii. Uneven mechanism.

iii. Unbalanced air gap due to serious bearing aberration.

iv. Broken conductors of squirrel cage rotor.

Page 27

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

27

5.8. MOTOR APPEARANCE.

5.8.1. Reasons for Cleaning

a. Excessive dust or oil accumulation on the motor surface leading to the

clogging of ventilation channels between cooling ribs will reduce the motors

cooling efficiency.

b. Keeping the motor and equipment clean will improve appearance and

longevity.

Motors should never be cleaned or disturbed whilst the motor is in

operation.

Page 28

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

28

Chapter 6: PERIODIC MAINTENANCE

6.1. REGULAR INSPECTION & MAINTENANCE.

6.1.1. Major points in regular inspection and maintenance:

a. Routine inspection and maintenance are usually performed by operators

with the sense of touch, sight, smell and simple meters. But it is difficult to

detect trouble such as insulation deterioration etc. unless the motor is

stopped and checked.

b. Replacement of worn-out parts will increase longevity and prevent

breakdown.

c. Regular inspection and maintenance is important in preventing breakdown

and lengthening service life.

c. Owing to the varied uses and environments motors are placed in, it is

difficult to set periods for regular inspection and maintenance. However, it

has to be performed at least once every 6 months. Generally, the inspection

time is determined by the following factors:

High temperatures may arise under operating conditions on the motor

surfaces, so that touching should be prevented or avoided.

Keep away from moving and live parts.

Unless deemed necessary, do not remove guards whilst assessing the

motor.

For safety, properly trained personnel must only carry out maintenance

and repairs.

Some testing, such as insulation resistance, usually requires the motor

to be fully stopped and isolated from any power supply/supplies.

Page 29

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

29

i. Ambient conditions.

ii. Start and stop frequency.

iii. Trouble with components affecting motor functions.

iv. Parts which wear (eg. bearings).

v. The important position of a motor in operation of a factory, mine etc.

should be fully recognised. Therefore, its condition should be monitored,

especially when it is operating in severe conditions.

6.1.2. Motor Windings.

a. For measurement of insulation resistance and tests to determine quality of

insulation resistance, please refer to measures stated in Section 4.1.2.

b. Inspection of coil end:

i. Grease and dust accumulated on coil may cause insulation

deterioration and a reduction in cooling efficiency.

ii. Moisture.

iii. Discolouring from original colour. Overheating mainly causes this.

c. Stator wedges, is there any change from their original position?

d. Is the tie wire at the coil ends in correct position with no movement?

6.1.3. Bearings.

a. Please refer to section 7 for bearing maintenance.

6.1.4. Cleaning the interior of the motor.

a. After a motor has been in operation for some time, accumulation of dust,

carbon powder and grease etc., on the inside is unavoidable, and may

cause damage. The inside should therefore, be regularly cleaned and

examined to assure reliable performance.

b. Points to note during cleaning:

i. If using compressed air or a blower (Typically for squirrel cage only).

Compressed air should be free of moisture.

Maintain air pressure at 4kg/cm

2

, since high pressure can cause

damage to coils.

Page 30

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

30

ii. Vacuum – Recommended for wound rotor/slip ring type.

Vacuum cleaning can be used, both before and after other methods of

cleaning, to remove loose dirt and debris. It is a very effective way to

remove loose surface contamination from the winding. Vacuum cleaning

tools should be non-metallic to avoid any damage to the winding insulation.

iii. Wiping.

Surface contamination on the winding can be removed using a soft, lint-free

cloth. If the contamination is oily, the cloth can moistened (not dripping

wet) with a safety type petroleum solvent. In hazardous locations, a solvent

such as inhibited methyl chloroform may be used, but must be used

sparingly and immediately removed. While this solvent is non-flammable

under ordinary conditions, it is toxic and proper health and safety

precautions should be followed while using it.

6.1.5. Clean the exterior of the motor.

a. The inlet air openings should not be allowed to accumulate any dirt,

dust, slurry, lint, etc. that could restrict free air movement.

b. Totally enclosed fan cooled motors require special cleaning

consideration. The external fan must be cleaned thoroughly since any

dirt build up not removed can lead to balance issues and vibration.

Solvents of any type should never be used on windings provided with

abrasion protection. Abrasion protection is a grey, rubber-like coating

applied to the winding end-turns.

Adequate ventilation must always be provided in any area where solvents

are being used to avoid the danger of fire, explosion or health hazards. In

confined areas (such as pits), each operator should be provided with an air

line respirator, a hose mask, or self-contained breathing apparatus.

Operators should wear goggles, aprons and suitable gloves. Solvents and

their vapours should never be exposed to open flames or sparks and

should always be stored in approved safety containers.

Page 31

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

31

6.1.6. Checking motor installation and coupling.

a. Installation:

i. Is foundation solid?

ii. Are all bolts and/or nuts tight and in good order?

b. Coupling:

i. Is coupling in good order?

ii. Are fasteners tight and in good order?

6.2. CLEANING OF COILS, DRYING & VARNISHING TREATMENT.

Age, constant heating and cooling and other factors may cause insulation

deterioration. Also, salt deposits or grease may lower insulation resistance.

Steam cleaning, drying and re-varnishing may be necessary if the motor has

been flooded or showing deterioration from age.

6.2.1. Cleaning:

a. If the coils are slightly contaminated, compressed air, cloth or a nylon brush

can be used to do the cleaning. However, when contamination is serious,

thorough washing has to be performed. The cleaning methods are as

follows:

b. Cleaning with water:

i. This method is applicable to motors having been immersed in water or

insulated with no cotton yarn and paper materials.

ii. After washing, dry immediately.

iii. Cleaning with steam.

If the motor has been immersed in sea-water or a chemical solution, clean

with steam after washing thoroughly.

Steam pressure must be kept between 2 – 4 kg/cm

2

. High pressure may

cause insulation damage.

Motors should never be cleaned or disturbed whilst the motor is in

operation.

Page 32

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

32

c. Steam temperature should be maintained between 50

0

C – 800C.

d. After cleaning, dry immediately.

6.2.3. Drying Method.

a. Application:

i. Drying after cleaning.

ii. Motor has absorbed moisture.

b. Hot air method (using heater and blower).

i. Parts to be dried are surrounded inside a steel plate leaving an inlet and an

outlet for hot air. Hot air will enter the inlet to dry parts (stator, rotor, etc.),

and will leave via the outlet carrying away moisture.

ii. The temperature within the area surrounded by the steel plate should be

maintained at 900C – 1000C.

c. Drying with infrared ray lamp:

i. Install the infrared ray lamp in a baking area surrounded with steel plate

with openings at the bottom.

ii. This method can cause partial overheating. So attention must be paid to the

parts heated and the temperature must be kept below 1000C.

d. Drying method with electric current:

i. The winding must have a minimum insulation resistance above 0.5MΩ

measured with 500VDC megger before using this method so as to avoid a

short circuit.

ii. Lock the rotor (short the secondary winding of the wound rotor motor),

apply rated voltage of approximately 5% - 10% to the winding.

iii. Temperature control settings:

Squirrel cage rotor induction motor: 700C – 800C for the stator.

e. Measurement of insulation resistance.

i. Measure the insulation resistance periodically during drying.

ii. At the initial stage of drying, insulation resistance may decline slightly.

When it returns to normal, the drying process is complete.

iii. When the current method is applied, be sure to turn off the power to

measure insulation resistance.

Page 33

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

33

6.3. VARNISH.

Kind of Varnish

JIS-W-25 or W-28 are highly recommended.

a. Method of Varnish Treatment

i. Dipping method: Immerse windings completely into varnish until no

air bubbles appear.

ii. Pouring Method: Pour varnish completely over windings

Note: Let varnish drip to dry after dipping or pouring. Changing position of

the motor will obtain an even coverage.

b. Curing of Varnish

i. Set oven temperature at 110oC.

ii. Curing time should be 12 – 16 hours

iii. Ensure ventilation is adequate during curing. Combustible gases are

present.

To ensure adequate insulation the above procedure should be repeated.

6.4. KEY POINTS FOR MAINTENANCE & INITIAL OPERATION

INSPECTION AFTER LONG STORAGE.

6.4.1. If the motor has been out of service in excess of three months, careful

inspection should be made before putting the motor into operation again.

6.4.2. When the motor is not in operation, the following precautionary measures

should be undertaken:

The place for storage should be dry and well-ventilated. If the motor has to

be placed at work site for some time, it should be completely covered and

stored on pallets to prevent dust and moisture contamination.

Inspection and maintenance prior to storage.

Please refer to “Regular Inspection and Maintenance” (Section 6.1).

Page 34

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

34

6.4.3. Items to be examined prior to initial operation.

a. Cleaning:

Outside of motor.

Motor interior.

b. Measurement of insulation resistance:

Measurement of insulation resistance and standards to determine quality if

Insulation resistance, please refer to measures stated in Section 4.1.2.

Measurement of insulation resistance.

6.4.4. Drying: If the motor has absorbed moisture, it must be dried.

6.4.5. Examination of bearings.

Turn the motor shaft by hand (if practical) to see if it rotates smoothly and

if there is any unusual noise.

6.4.6. Replenishment of grease. (Refer to bearing maintenance Section 7).

6.4.7. Switches and starters.

Clean off dust and any foreign matter etc.

Check if the operation is normal.

Are the moving parts functioning smoothly?

Check if all bolts and nuts are tight and in good order.

6.4.8. Examination and maintenance of standby motor.

Important: The purpose of a standby motor is to substitute as an

emergency motor if the motor in operation breaks down, this motor should

not be exposed to induced vibration whilst stationery.

It is important to always maintain the standby motor in top condition.

Maintenance should be performed strictly according to items and notes

stated previously.

Page 35

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

35

6.5. RECORDS OF OPERATION AND MAINTENANCE.

6.5.1. Objective:

a. Fully understand the site conditions of the motor in operation and discover

any abnormalities in advance.

b. Prevent the neglect and act of maintenance.

c. Map pertinent maintenance plans after fully understanding the operation of

motor.

d. Assess the life of parts to determine the quantity of spare parts to be kept.

e. To plan the number of spare motors and replace or repair the motors in

operation according to a schedule.

6.5.2. Records of operation.

a. A maintenance card in table form is acceptable.

b. Principle contents:

i. Serial number of machine

ii. Model

iii. Three phase voltage

iv. Three phase current

v. Temperature of a motor in operation

vi. Ambient temperature, humidity, weather, date and time

vii. Time of start and stop

viii. Special remarks

ix. Operator’s name

Page 36

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

36

6.6. POINTS TO NOTE ON DISASSEMBLY.

a. Disassemble according to the pre-set steps.

b. Necessary tools should be ready before disassembly.

c. Mark the disassembled parts so as to facilitate re-assembly.

d. Place parts, bolts and nuts etc, in a box to avoid misplacing.

e. Avoid damage to heavy parts during transportation.

f. Dust accumulation on coil-end, ducts etc., should be cleaned during

disassembly.

g. Coat parts with light oil.

h. Note if there is any shaft deflection or bearing damage when re-assembling.

i. Disassemble and assemble bearing according to the bearing maintenance

manual.

For safety and to prevent equipment damage properly trained

personnel must only carry out maintenance and repairs.

Page 37

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

37

Chapter 7: BEARINGS

7.1. MAINTENANCE OF ROLLING BEARING.

7.1.1. General.

Bearings play a very important role in motor performance. It is essential to

keep bearings in good order for the motor to operate at optimum

performance. For this reason, please maintain bearings according to this

manual.

7.1.2. Motors within frame sizes D180 and below are complete with sealed for life

Bearings. (Unless the specification dictates these need to be re-greasible)

This type of bearing is a non maintainable item and has been pre packed

with grease and fitted with containment shields at point of manufacture.

These bearings do not require greasing for the life of the bearing.

7.1.3. Motors within frame sizes D200 and larger are equipped with through flush

greasing facilities.

Grease replenishment is required, if the motor has been out of service for 3

months or more and should also be carried out on initial start and at regular

intervals thereafter.

a. Replenishment of grease is recommended when the motor is running.

b. Clean the grease nipple and open the grease drain (if applicable) prior to

greasing. Restore after greasing.

c. A slight leakage of grease between the flinger and bearing cover is normal

and assists in totally sealing the bearing from ingress of dust and foreign

matter.

Whilst Motors are installed awaiting commissioning they must be adequately

protected against the elements, all external components in particular the shaft

extension and external labyrinth seals at the drive end must be fully covered

to avoid water ingress entering the motor body whilst stationery.

Please ensure that both the non drive end and drive end antifriction bearings

are fully purged with sufficient grease at first start up/commissioning

with the recommended grade and quantity of grease.

Page 38

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

38

7.1.4. Grease Lubricated Type.

Keeping the bearing lubricant in top condition is extremely important in the

maintenance of bearings. It is a prerequisite of extended bearing life to

replenish grease using the correct grade, quantity and time interval, please

do not mix different types of grease.

The reasons for grease replenishment are:

a. Assure the rolling contact surface has no metal to metal contact.

b. Form a lubrication membrane on the rolling contact surface to reduce noise.

c. Purge the motor of old and contaminated grease, please ensure that the

grease in the discharge chute is pliable and will allow new grease to enter.

d. The presence of the correct grade and quantity of grease reduces corrosion,

protects and seals the bearing and lowers vibration.

7.1.5. Grease replenishment period:

The life of grease varies depending on model, speed, temperature,

operational conditions etc., it is, therefore, impossible to determine the

exact time interval for replenishment.

However, under normal conditions the greasing interval is shown in Table 3

can be used as a guide.

Page 39

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

39

Bearing

Number

Speed(RPM)

600

720

750

900

1000

1200

1500

1800

NU2XX

14

14000

12500

12000

10500

9500

8000

6000

4500

NU3XX

15

13500

12000

11500

11000

9000

7000

5500

4000

16

13000

11500

11000

9500

8500

6500

5000

3500

17

12500

11000

10500

9000

8000

6000

4500

3000

18

12000

10500

10000

8500

7500

5500

4000

2500

20

11000

9500

9000

7000

6000

4500

3000

2000

22

10000

8500

8000

6000

5500

4000

2500

1500

24

9000

7500

7000

5500

4500

3500

2000

1500

26

8500

7000

6500

5000

4000

3000

1500

1000

28

8000

6000

6000

4500

3500

2500

1000

500

30

7000

5500

5500

4000

3000

2000

1000

500

32

6500

5000

5000

3500

2500

1500

500

500

34

6000

4500

4500

3000

2500

1500

500 36

5500

4000

4000

2500

2000

1000

500 38

5000

4000

3500

2500

1500

1000

500 40

5000

3500

3000

2000

1500

1000

44

4000

3000

2500

1500

1000

500

48

3500

2500

2500

1000

1000

500

Table 3.

Remarks:

a. Please refer to lubrication nameplate fitted and follow the

recommended schedule stated.

Bearing

Number

Speed(RPM)

600

720

750

900

1000

1200

1500

1800

3000

3600

62XX

10

19000

18000

17500

16500

15500

14500

12500

11000

6000

4500

63XX

12

18000

17000

16500

15000

14500

13000

11000

9000

4500

3500

72XX

13

17500

16500

16000

14500

14000

12000

10000

8500

4000

3000

73XX

14

16500

15500

15000

13500

12500

11000

9000

7000

3500

2500

15

16500

15500

15000

13500

12500

11000

9000

7000

3000

2000

16

16000

15000

14500

13000

12000

10500

8500

6500

2500

1500

17

16000

14500

14000

12500

11500

10000

8000

6000

2500

1500

18

15500

14000

13500

12000

11000

9500

7500

5500

2500

1500

20

14500

13000

12500

11000

10000

8500

6000

4500

22

13500

12000

11500

10000

9000

7500

5500

4000

24

13000

11500

11000

9000

8000

6500

4500

3500

26

12000

10500

10000

8500

7500

6000

4000

3000

28

11500

10000

9500

8000

7000

5500

3500

2500

30

11000

9500

9000

7000

6500

4500

3000

2000

32

10500

8500

8500

6500

5500

4000

3000

2000

34

10000

8000

8000

6000

5500

4000

2500

1500

36

9500

7500

7500

5500

5000

3500

38

9000

7000

7000

5000

4500

3000

Page 40

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

40

b. The data as shown in Table 3 and/or lubrication nameplates are the

maximum recommended intervals under good conditions, please

consider site conditions, as a shortening of these periods may be

necessary.

7.1.6. Type of grease:

TECO motors can utilise different types of grease including Shell Gadus &

Mobil Polyrex EM Grease which has been selected based on the proposed

application.

Please check on the lubrication nameplate to confirm the type of grease

installed. Please use identical grease when servicing or alternatively

lubricants of different brands that have been established as being

equivalent in the areas of composition, physical properties and thickeners.

7.1.7. Amount of grease replenishment:

Amount of grease replenishment depends on the type, size and construction

and the bearings. For the maximum quantity used in one replenishment of

each bearing, as a guide, please refer to Table 4.

Please refer to lubrication nameplate fitted and follow the recommended

quantity stated.

7.1.8. Key points to note with grease filling:

Filling method for grease relief type bearing.

Use a good quality grease gun to pump grease through the grease nipple

into the bearings. The old contaminated grease is forced to drain out of the

discharge chute. While greasing it is recommended that the greasing

procedure is undertaken whilst the motor is running. The discharge outlet

may not be visible on some models, grease should be pumped in at the

recommended quantity and the sound of bearing should return to normal.

It is advisable to grease when the motor is operating as old grease is

expelled more easily.

Page 41

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

41

Bearing No.

Amount of

replenishment

Bearing No.

Amount of

replenishment

62XX

72XX

NU2XX

222XX

6210

30g

63XX

73XX

NU3XX

223XX

6310

40g

6212

40

6312

60

6213

50

6313

80

6214

50

6314

80

6215

60

6315

100

6216

60

6316

100

6217

80

6317

120

6218

80

6318

120

6220

100

6320

160

6222

120

6322

220

6224

120

6324

270

6226

140

6326

300

6228

160

6328

400

6230

180

6330

450

6232

200

6332

500

6234

250

6334

600

6236

300

6336

700

6238

350

6338

800

6240

400

6340

900

6244

450

6344

900

6248

500

6348

900

Table 4.

*Fill new grease until it displaces the old grease completely.

Do not grease the motor whilst it is at standstill. If there is a draw-out

device for grease, draw out the used grease after greasing, please leave

excess grease on the rake as this will further protect the exit port from

moisture entry.

7.1.9. Temperature of bearing.

Temperature of the bearing will rise slightly, but this is temporary while

greasing and will return to normal a few minutes after greasing. Brief

temperature variations are of no concern, grease should be pumped in

sparingly to avoid excess temperatures being experienced.

WARNING

Stay clear of rotating parts while relubricating motor when it is in

operation.

Page 42

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

42

7.1.10. Selection of grease gun.

There are two types of grease gun. High pressure lever type and hand press

type. As the hand press type has a lower force, grease replacement will

take more time. Greasing can be achieved quickly by using a lever type gun,

however, care should be taken to adjust the pressure and rate to avoid

excessive grease entry which may enter the motor’s interior.

7.2. NOISE OF BEARING.

a. Normal noise.

Noise is congenital to movement of the bearing. Generally bearing noise

that has a continuous rhythm with no sudden change is normal.

b. Abnormal noise.

It is difficult to detect the early stages of bearing failure with the human

ear. It takes a lot of experience and a sharp ear to detect abnormal noise.

Any sudden change in bearing noise should be investigated. Motors with

roller bearings at the drive end can emit more rotational noise than a ball

bearing and it is normal to hear skating/skidding of the rolling elements.

7.3. VIBRATION.

If the vibration of the bearing is unusually high, please test with vibroscope.

The preferred level for vibration should be below 2.8mm/sec. If the values

exceed this figure, an investigation should be undertaken to find and rectify

the problem.

7.4. REGULAR INSPECTION.

7.4.1. Regular monthly inspection.

Grease replenishment (refer to Section 7.1) and the motor lubrication plate.

Page 43

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

43

7.4.2. Regular yearly inspection.

It is important to undertake regular inspection every year when the machine

is out of service for maintenance.

7.4.3. Inspection Notes.

a. Electrical etching.

When there are dark spots on bearing surface or outside the face of outer

ring and / or inside face of bearing housing, please check with a microscope

to see if they look like pock marks or fish scales which could be the result of

electrical etching due to poor installation etc.

b. Motors on VVVF Drives.

All TECO motors are suitable for running on VVVF drives, however, this does

depend on the application, kilowatt demand and speed range. TECO

recommend that when motors of 280/315 frame and above be fitted with at

least an insulated bearing at the non drive end and rotor grounding brush

fitted at the drive end, this is not categorical that this feature must be fitted,

purely a recommendation based on TECO’s experience, please consult with

the engineering specification whether the motor supplied requires this

feature.

c. Precision of installation.

The degradation of the bearing may be the result of misalignment due to

sinking foundations etc, after the motor has been in use for a long period.

Regularly check and record the alignment of couplings, and make

adjustments as necessary.

The bearing is a high precision component, it is important to avoid ingress

of dust, moisture and foreign matter. A hammer or similar object must not

be used during the cleaning and installation of the bearing.

Page 44

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

44

Chapter 8: Troubleshooting.

8.1. FAULT FINDING & RECOGNITION

Kind of

Fault

Symptom

Cause

Remedy

Fail to

start without

load

Motionless

And soundless

Power-off

Consult power

company

Switch-off

Switch-on

No fuse

Install fuse

Broken wires

Check wires and

repair

Broken lead

Check leads and

repair

Faulty winding

Check winding and

repair

Fuse blowing –

(Circuit Breaker

trips off, slow

start with

electromagneti

c noise

Short circuit

Check circuit

Incorrect wiring

Check wiring

Poor contact in circuit

switches

Check and repair

Broken wiring

Check and repair

Poor contact of

starting switch

Check and repair

Incorrect connection

of starting switch

Check and repair

Overload

after start

Fuse blowing –

Fail to restart

due to circuit

breaker

tripping

Insufficient capacity

of fuse or breaker

Replace fuse or

breaker

Overload

Lighten load

High load at low

voltage

Check circuit

capacity and reduce

load

Page 45

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

45

Kind of Fault

Symptom

Cause

Remedy

Overload after start

Overheating

of Motor

Overload or

Intermittent

Overload

Lighten Load

Under-voltage

Check circuit capacity

and power source

Over-voltage

Check power source

Ventilation duct

clogged

Remove the foreign

matter in the duct

Ambient

temperature

exceeds 450C

Lower ambient

temperature

Friction between

rotor and stator

Repair

Fuse blowing

(Single phase

rotating)

Install the specified

fuse

Poor contact of

circuit switches

Check and repair

Poor contact of

starting switch

Check and repair

Unbalanced three

phase voltage

Check circuit or

consult power

company

Speed falls

sharply

Voltage drop

Check circuit and

power source

Sudden overload

Check machine

Single phase

rotating

Check circuit and

repair

Switch overheat

Insufficient

capacity of switch

Replace switch

High load

Lighten load

Page 46

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

46

Kind of Fault

Symptom

Cause

Remedy

Overload after

start

Bearing Overheat

Misalignment

between motor

and load

Re-align

Not enough

grease

Fully purge

bearings with

grease

High bearing

noise

Replace damaged

bearing

Noise

Electro-magnetic

noise induced by

electricity

Occurrence from

first operation

Check noise not

normal

Sudden sharp

noise and

smoking

Short circuit of

windings. Repair.

Bearing noise

Not enough

grease

Fully purge

bearings with

grease

Deterioration of

grease

Clean bearing

and re-grease

Excessive noise

Replace the

damaged bearing

Mechanical noise

caused by

machinery

Loose belt sheaf

Adjust key and

lock the screw

Loose coupling

Adjust the

position of

couplings and

tighten

Loose screw

Tighten screw

Fan rubbing

Adjust fan

position

Page 47

Teco Installation and Maintenance Manual

TEFC Squirrel Cage Induction Motors

Teco Electric and Machinery Company

Manual Number: IOM ~ TEFC Rev.01

47

Kind of Fault

Symptom

Cause

Remedy

Noise

Mechanical noise

caused by

machinery

Rubbing as a result

of ingress of

foreign matter

Clean motor

interior and

ventilation ducts

Wind noise

Noise induced by

air flowing through

ventilation ducts

Induced by

conveyance

machine

Repair machine

Vibration

Electro-magnetic

vibration

Short circuit of

windings

Repair

Open circuit of

rotor

Repair

Vibration

Unbalanced rotor

Repair

Unbalanced fan

Repair

Mechanical

vibration

Broken fan blade

Replace fan

Un-symmetrical

centres between

belt sheaf

Align central points

Central points of

couplings do not lie

on the same level

Adjust the central

points of couplings

on the same level

Improper mounting

installation

Lock the mounting

screw

Motor mounting

bed is not strong

Reinforce mounting

bed

Remarks:

i. Circuit switches: This includes knife switch, electromagnetic switch, fuse and

other connection switches etc.

ii. Starting switches: This includes Delta-Star starter, compensate starter,

reactance starter, resistor starter, starting controllers etc.