TECO A510-2010-H3, A510-2020-H3, A510-2002-H, A510-2015-H3, A510-2003-H Instruction Manual

...Page 1

Page 2

I

Contents

Chapter 0...................................................................................................................0-1

0.1 Foreword......................................................................................................0-1

Chapter 1 Safety precautions..................................................................................1-1

1.1 Before supplying power................................................................................1-1

1.2 Wiring...........................................................................................................1-2

1.3 Before operation...........................................................................................1-2

1.4 Parameters setting.......................................................................................1-3

1.5 Operation.....................................................................................................1-3

1.6 Maintenance, Inspection and Replacement.................................................1-5

Chapter 2 Model Description...................................................................................2-1

2.1 Nameplate Data...........................................................................................2-1

2.2 Model Designation .......................................................................................2-1

Chapter 3 Ambient Environment And Installation.................................................3-1

3.1 Environment.................................................................................................3-1

3.2 Installation....................................................................................................3-3

3.2.1 Installation space...............................................................................3-3

3.2.2 External view of the product and warning label information...............3-4

3.2.3 Product Dismounting..........................................................................3-7

3.2.3.1 Standard type ..........................................................................3-7

3.2.3.2 Built-in filter type (440V 1 ~60HP)..........................................3-11

3.3 Wiring the peripheral devices of the inverter and related cautions.............3-13

3.4 Terminal Description..................................................................................3-17

3.5 Internal wiring diagram of main circuit........................................................3-22

3.6 Instrument for main circuit wiring and caution............................................3-23

3.7 Inverter Specifications................................................................................3-28

3.8 Overall Dimension drawing ........................................................................3-36

3.8.1 Standard Model................................................................................3-36

3.8.2 Built-in filter model (440V 1~60HP) .................................................3-40

Chapter 4 Software Index........................................................................................4-1

4.1 Keypad Description......................................................................................4-1

4.1.1 Panel Functions..................................................................................4-1

4.1.2 Display Description............................................................................4-2

4.1.3 LED Functional structure of LED seven-segment display..................4-4

4.1.4 Example of keypad operation.............................................................4-6

4.1.5 Operation Control...............................................................................4-8

4.2 Parameters list.............................................................................................4-9

4.3 Description of Parameter Functions...........................................................4-52

4.4 Description of Built-in PLC Function.........................................................4-210

4.4.1 Basic command .............................................................................4-210

Page 3

II

4.4.2 Basic command function................................................................4-211

4.4.3 Application command.....................................................................4-212

Chapter 5 Trouble Diagnosis and shooting...........................................................5-1

5.1 General........................................................................................................5-1

5.2 Fault detection function................................................................................5-1

5.3 Warning / self-diagnosis detection function..................................................5-5

5.4 Auto-tuning error........................................................................................5-11

5.5 PM motor auto-tuning error.........................................................................5-12

Chapter 6 Peripheral devices and option...............................................................6-1

6.1 List of braking resistor and braking detection module..................................6-1

6.2 AC reactor....................................................................................................6-3

6.3 Harmonic Filter.............................................................................................6-4

6.4 Noise filter....................................................................................................6-7

6.5 Output filter specification............................................................................6-10

6.6 Input power side Fuse specification...........................................................6-11

6.7 PG speed feedback card............................................................................6-12

6.8 Other..........................................................................................................6-14

6.9 Communication Interface Module (in development)...................................6-16

Appendix.....................................................................................................Appendix-1

Page 4

0-1

Chapter 0 Foreword

0.1 Foreword

To make full use of the inverter functions and ensure your safety, please read this

manual carefully. In case of any problems found in use, please contact local dealer or the

company's technical staff, our professionals will be happy to help you.

※ Caution on use

Inverter is a precision electronic product. For protecting your life and property, this

manual has been marked with "Warning", "Caution" to remind you of the safety precaution

issues in handling, installation, use and inspection. Please comply with it.

Warning

Inproper operation might cause serious personal injury.

Caution

Inproper operation might cause damage of inverter or

mechanical system.

Warning

¾ Avoid electrical shock! Since the DC capacitors inside the inverter discharges

completely in 5 minutes after the power supply is removed, please

disassemble or inspect it after 5 minutes when the power supply is removed.

¾ Wiring is not allowed when the power is supplied. Do not inspect the circuit

board when the inverter is in operation.

¾ Do not ass embly/disassemble or replace the internal wiring or circuit and parts

of the inverter by yourself.

¾ Make sure the earth terminal of the inverter is properly grounding.

Caution

¾ Do not carry out the dielectric voltage withstand test on the internal parts of

the inverter because they are easily damaged by high voltage.

¾ Connecting U/T1,V/T2 and W/T3 of inverter terminal to AC power is strictly

prohibited.

¾ CMOS integrated circuits of inverter circuit board are easily affected and

damaged by static electricity. Do not touch the circuit board.

Page 5

1-1

Chapter 1 Safety Precautions

1.1 Before supplying power

Warning

¾ The main circuit must be properly wiring. Single phase( R/L1, S/L2)/3-phase(R/L1,

S/L2, T/L3) are the input terminal of the power, which must not be mixed with

U/T1,V/T2 and W/T3 on use. In case of mixed use, supplying power will damage the

inverter.

Caution

¾ The power voltage must be the same as the input voltage of the inverter.

¾ When handling the inverter, do not draw the front cover directly. It is suggested to

handle the inverter body so as to prevent the front cover breaks off, avoiding the

inverter falling and causing injury or inverter damage.

¾ Please mount the inverter on noncombustible materials such as metal. Mounting on or

near the flammable materials is not allowed in case fire happened.

¾ If several inverters are mounted on a single control panel, the extra cooling fan shall

be added, so as to make the panel temperature below 40 ℃ and to prevent

overheating or fire.

¾ Please firstly turn off the power before disassemble or assemble the operator. Fix the

operator according to the indicating diagram to avoid operation failure or no display

due to improper operation.

Warning

¾ This product has passed the application level at IEC 61800-3 restricted areas. When

the product is used in some environments, there might be electromagnetic

interference. Therefore, appropriate test is recommended to be carried out before use

and grounding must be well done.

Caution

¾ Installation and use of the product must be conducted by a qualified professional

electrician.

¾ The product installation must be applied by the means of fixed wiring.

Page 6

1-2

1.2 Wiring

Warning

¾ Always turn OFF the input power supply before inverter installation or wiring terminals,

so as to avoid electric shock or fire.

¾ Wiring must be performed by an authorized person qualified in electrical work, to

avoid electric shock or fire.

¾ Make sure the grouding terminal is well grounded. (220 V class: Grounding

impedance shall be less than 100Ω, 460 V class: Grounding impedance shall be less

than 10Ω)

¾ Always test the operation of any emergency stop circuits after wiring. (Wiring is the

responsibility of the user.)

¾ Never touch the input/output lines directly with your hands or allow any line to contact

the Inverter case. Never short the circuits.

¾ Do not carry out the dielectric voltage withstand test on the inverter, which will cause

the semiconductor parts damage easily.

Caution

¾ Make sure the input power meets that of the inverter, in order to avoid injury or fire.

¾ Please connect the braking resistor and braking unit according to the related wiring

diagram in case fire occured.

¾ Please fasten the terminal screws based on specified torque so as to avoid fire.

¾ Do not connect the input power supply line to the output terminal of the inverter.

¾ Do not connect the magnetic contactor and solenoid switch contacts to the output

terminal.

¾ Do not connect the phase advancing capacitor or LC / RC filter to the output circuit.

¾ Ensure the interference generated by the inverter and motor will not affect peripheral

sensors or devices.

1.3 Before operation

Warning

¾ Make sure the inverter capacity is the same as the capacity set by inverter’s function

parameters 13—00 before supplying power.

¾ If the line length between the inverter and the motor exceeds 25 meters, it needs to

reduce the carrier frequency (11-01) or additionally equip a output filter to reduce the

over-voltage or oscillation at the load end, so as to avoid motor damage.

Page 7

1-3

1.4 Parameters setting

Caution

¾ When carry out the rotatable automatic tuning, do not connect the motor to the load

(mechanical device).

¾ When carry out the rotatable automatic tuning and the motor will rotate, make sure

around space of the motor is enough in order to avoid danger.

1.5 Operation

Warning

¾ Make sure the front external cover is completely installed in prior to turn on the power.

¾ Do not connect or disconnect the motor unit in operation, otherwise the inverter will

cause the inverter to trip because of over-current. The severe case will cause the

main circuit damage of the inverter.

¾ When the reset function is in operation, keep away from the machine. The machine

will restart after the fault is cleared.

¾ Do not operate the machine with wet hands.

¾ It provides a independent emergency stop switch. This switch will be enabled when

the parameter is being set (see 11-55).

¾ It provides an independent external hardware emergency switch, which emergently

shuts down the inverter output in the case of danger.

¾ Make sure the operation order is closed before reset warning.

¾ If choose to automatically restart after power recovery (07-00), the inverter will start

automatically after power is restored.

¾ Before automatic tuning, make sure the conditions of surrounding systems and

mechanical devices to ensure the safety of personnel.

¾ Never touch related terminals regardless of inverter in operation or in stop states to

avoid any danger.

¾ After the power is cut off, the fan might continue to rotate for some time.

Page 8

1-4

Caution

¾ Do not touch the heating elements such as heat sink, braking resistor, etc.

¾ The inverter enables easily the motor rotes from low speed to high speed. Please

make sure the allowable range of the motor and the machine.

¾ When the product is supported by the use of the braking module, please pay attention

to related settings for operation.

¾ Inspecting the circuit board signal should be avoided when the inverter is in operation.

Warning

¾ Avoid electrical shock! The internal DC capacitor of the inverter discharges in 5

minutes after the power is cut off. Therefore, carry out disasemmbly/assembly or

inspection after 5 minutes when the discharge completes.

Page 9

1-5

1.6 Maintenance, Inspection and Replacement

Warning

¾ Before the maintenance and inspection, make sure the power is cut off and the

indicator light of the power is off (make sure the DC voltage does not exceed 25 v).

¾ Since there are high voltage terminals in the inverter, do not touch these terminals

randomly.

¾ In the case of power on, be sure the protection cover is installed. In addition, when the

protection cover is disassembled, be sure to cut off the power by the circuit breaker.

¾ Only the designated professional can carry out the maintenance or parts replacement.

Caution

¾ The ambient temperature of the inverter should be from

-10

℃

to +40(60)

℃

95%RH

and the inverter shall be used in the non-condensing environment, free

from water dropping and metal dust in surrounding.

Disposal caution for the inverter

Caution

Treat as industrial waste when disposing of inverter and pay attention to the following

items:

¾ Burning electrolytic capacitors of the inverter main circuit and printed circuit board

might cause explosion;

¾ Burning the plastic parts such as inverter shell will produce toxic gases.

Page 10

2-1

Chapter 2 Model Description

A510 Series

■ 2.1 Nameplate Data:

Inverter Model and Motor Rating

Input Power Specifications

Output Power Specifications

Series No.

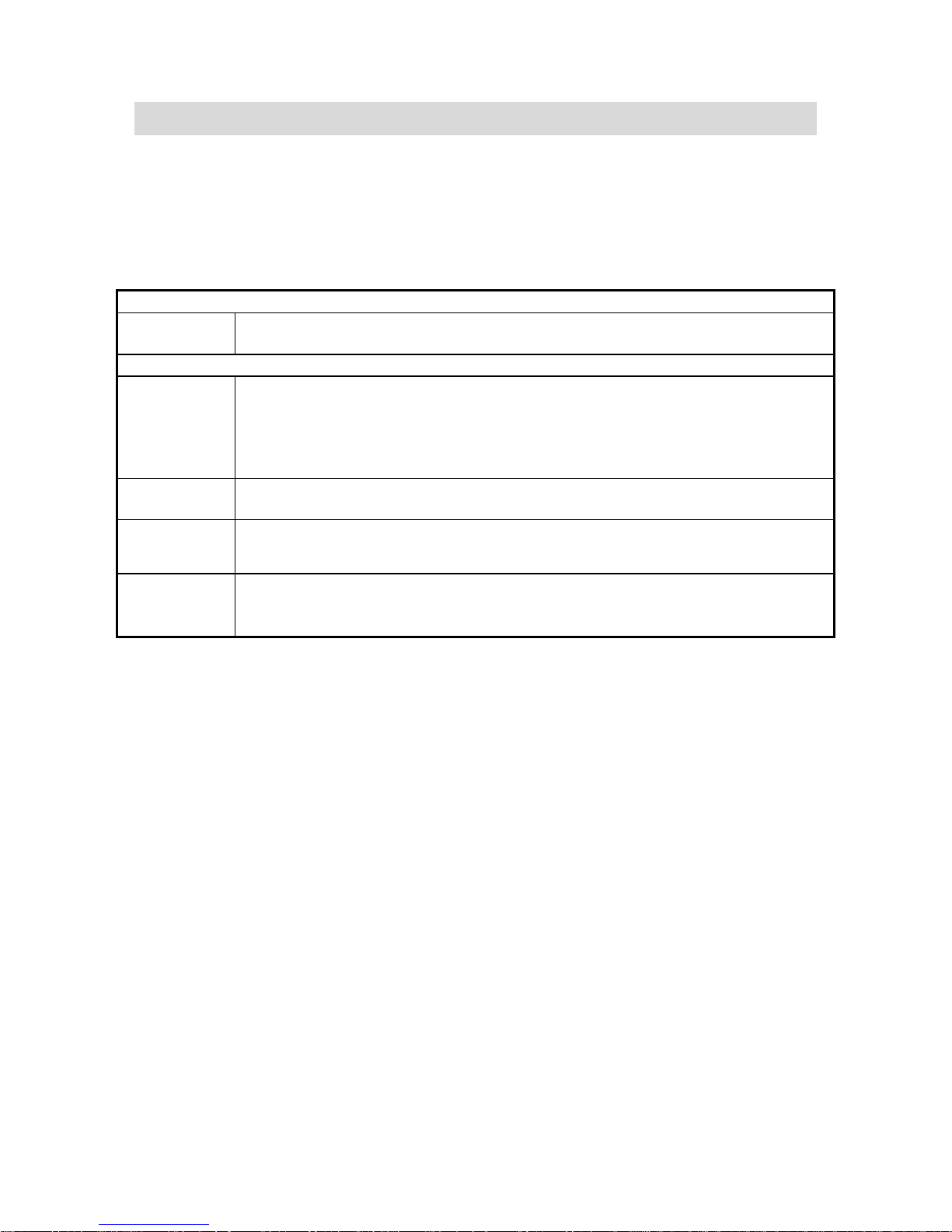

■ 2.2 Model Designation:

UL and CE Marks

-

A510

A510 Series

4

Voltage Rating:

2: 220V

4: 440V

6: 690V

010 - H3F

Motor Rating:

001: 1HP

002: 2HP

∫

150: 150HP

175: 175HP

215: 215HP

∫

535: 535HP

670: 670HP

Power Source Phase:

Blank: Both by single

and three phase

3: For Three phase

Noise Filter:

Blank: No RFI

F: RFI Bulit-in

Type:

H: Standard

(LED operator)

C: Drawing

(LCD operator)

(S/N Barcode)

(P/N Barcode)

Page 11

2-2

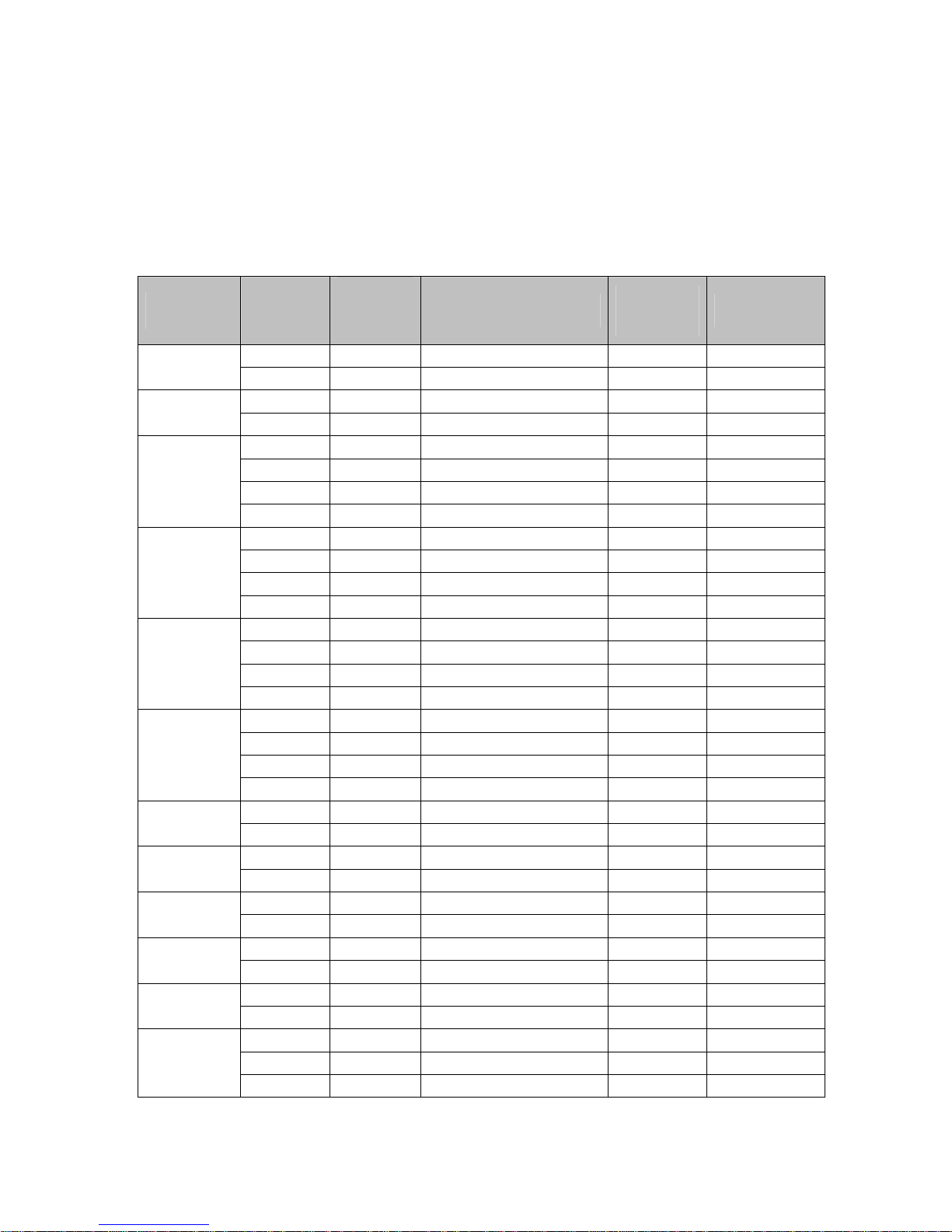

Model list:

Filter

Built-in

Inverter model

(Model for

standard

products)

Voltage(Vac)

Applied

frequency

(Hz)

Horse

Power

(Hp)

Applied

Motor

(KW)

with without

A510-2001-H 1 0.75

◎

A510-2002-H 2 1.5

◎

A510-2003-H

1ph/3ph,

200~240V

+10%/-15%

3 2.2

◎

A510-2005-H3 5 3.7

◎

A510-2008-H3 7.5 5.5

◎

A510-2010-H3 10 7.5

◎

A510-2015-H3 15 11

◎

A510-2020-H3 20 15

◎

A510-2025-H3 25 18.5

◎

A510-2030-H3 30 22

◎

A510-2040-H3 40 30

◎

A510-2050-H3 50 37

◎

A510-2060-H3 60 45

◎

A510-2075-H3 75 55

◎

A510-2100-H3 100 75

◎

A510-2125-H3 125 94

◎

A510-2150-H3

3ph,

200~240V

+10%/-15%

150 112

◎

A510-4001-H3 1 0.75

◎

A510-4001-H3F 1 0.75

◎

A510-4002-H3 2 1.5

◎

A510-4002-H3F 2 1.5

◎

A510-4003-H3 3 2.2

◎

A510-4003-H3F 3 2.2

◎

A510-4005-H3 5 3.7

◎

A510-4005-H3F 5 3.7

◎

A510-4008-H3 7.5 5.5

◎

A510-4008-H3F 7.5 5.5

◎

A510-4010-H3 10 7.5

◎

A510-4010-H3F 10 7.5

◎

A510-4015-H3 15 11

◎

A510-4015-H3F 15 11

◎

A510-4020-H3 20 15

◎

A510-4020-H3F 20 15

◎

A510-4025-H3 25 18.5

◎

A510-4025-H3F 25 18.5

◎

A510-4030-H3 30 22

◎

A510-4030-H3F 30 22

◎

A510-4040-H3 40 30

◎

A510-4040-H3F 40 30

◎

A510-4050-H3 50 37

◎

A510-4050-H3F

3ph,

380~480V

+10%/-15%

50/60Hz

50 37

◎

Page 12

2-3

A510-4060-H3 60 45

◎

A510-4060-H3F 60 45

◎

A510-4075-H3 75 55

◎

A510-4100-H3 100 75

◎

A510-4125-H3 125 94

◎

A510-4150-H3 150 112

◎

A510-4175-H3 175 130

◎

A510-4215-H3 215 160

◎

A510-4250-H3 250 185

◎

A510-4300-H3 300 220

◎

A510-4375-H3 375 280

◎

.The short-circuit capacity of the inverter is 5000A/240V or below 5000A/480V, 220V for

model of 200~240V; 440V for model of 380~480V; 690V for model of 575~690V

.220V 125HP (94KW) and 440V 250HP (185KW) or higher are being developed.

.690V is being developed.

Page 13

3-1

Chapter 3 Ambient Environment And Installation

3.1 Environment

The installing environment of the inverter directly affects its functions and the service

life. Therefore, the installation environment must meet the following conditions:

Protection

Protection

Class

IP20/NEMA 1, IP00

Applicable environment

Operating

Temperature

-10~40 (℃ With the dust-protection cover open, the applicable operation

temperature (-10~50 )) (℃ full load) can reach maximum of 60℃. But it is

required to de-rating 2% of the rated current for increasing one degree.

For multiple inverters installed side by side in the plate, please pay

attention to the placement to facilitate heat radiating.

Storage

Temperature

-20~70℃

Humidity

RH should be 5% to 95%, free of condensation or water droplets.

(Follow IEC60068-2-78 standard)

Shock

Maximum acceleration: 1.2G (12m/s2), from 49.84 to 150 Hz

Displacement amplitude : 0.3mm (peak value), from 10 to 49.84 Hz

(Follow IEC60068-2-6 standard)

Installation site

The product shall be installed in the environment for easy operation, avoiding to be

exposed to the following environments:

¾ Avoid direct sunlight

¾ Avoid rain drops or wet environment

¾ Avoid oil mist and salt erosion

¾ Avoid corrosive liquid and gas

¾ Avoid dust, lint fibers, and small metal filings.

¾ Avoid electromagnetic interference (soldering machine, power machine)

¾ Keep away from radioactive and flammable materials

¾ Avoid vibration (punch). Please add a vibration-proof pad to reduce vibration if it can

not be avoided

Page 14

3-2

Screw Torques for terminals

To comply with UL standards, you shall use UL approved copper wires (rated 75 ° C)

and round crimp terminals (UL Listed products) in the following table when connecting the

main circuit terminal. TECO recommends using crimp terminals manufactured by

NICHIFU Terminal Industry Co., Ltd and the terminal crimping tool recommended by the

manufacturer for crimping terminals and the insulating sleeve.

Wire size

mm2 (AWG)

Terminal

screw size

Model of

the round

crimp

terminal

Fastening torque

kgf.cm (in.lbs)

Model of

insulating

sleeve

Model of

crimp tool

M3.5 R1.25-3.5 8.2 to 10 (7.1 to 8.7) TIC 1.25 NH 1

0.75 (18)

M4 R1.25-4 12.2 to 14 (10.4 to 12.1) TIC 1.25 NH 1

M3.5 R1.25-3.5 8.2 to 10 (7.1 to 8.7) TIC 1.25 NH 1

1.25 (16)

M4 R1.25-4 12.2 to 14 (10.4 to 12.1) TIC 1.25 NH 1

M3.5 R2-3.5 8.2 to 10 (7.1 to 8.7) TIC 2 NH 1 / 9

M4 R2-4 12.2 to 14 (10.4 to 12.1) TIC 2 NH 1 / 9

M5 R2-5 22.1 to 24 (17.7 to 20.8) TIC 2 NH 1 / 9

2 (14)

M6 R2-6 25.5 to 30.0 (22.1 to 26.0) TIC 2 NH 1 / 9

M4 R5.5-4 12.2 to 14 (10.4 to 12.1) TIC 5.5 NH 1 / 9

M5 R5.5-5 20.4 to 24 (17.7 to 20.8) TIC 5.5 NH 1 / 9

M6 R5.5-6 25.5 to 30.0 (22.1 to 26.0) TIC 5.5 NH 1 / 9

3.5/5.5

(12/10)

M8 R5.5-8 61.2 to 66.0 (53.0 to 57.2) TIC 5.5 NH 1 / 9

M4 R8-4 12.2 to 14 (10.4 to 12.1) TIC 8 NOP 60

M5 R8-5 20.4 to 24 (17.7 to 20.8) TIC 8 NOP 60

M6 R8-6 25.5 to 30.0 (22.1 to 26.0) TIC 8 NOP 60

8 (8)

M8 R8-8 61.2 to 66.0 (53.0 to 57.2) TIC 8 NOP 60

M4 R14-4 12.2 to 14 (10.4 to 12.1) TIC 14 NH 1 / 9

M5 R14-5 20.4 to 24 (17.7 to 20.8) TIC 14 NH 1 / 9

M6 R14-6 25.5 to 30.0 (22.1 to 26.0) TIC 14 NH 1 / 9

14 (6)

M8 R14-8 61.2 to 66.0 (53.0 to 57.2) TIC 14 NH 1 / 9

M6 R22-6 25.5 to 30.0 (22.1 to 26.0) TIC 22 NOP 60/ 150H

22 (4)

M8 R22-8 61.2 to 66.0 (53.0 to 57.2) TIC 22 NOP 60/ 150H

M6 R38-6 25.5 to 30.0 (22.1 to 26.0) TIC 38 NOP 60/ 150H

30/38 (3 / 2)

M8 R38-8 61.2 to 66.0 (53.0 to 57.2) TIC 38 NOP 60/ 150H

M8 R60-8 61.2 to 66.0 (53.0 to 57.2) TIC 60 NOP 60/ 150H

50 / 60 (1 / 1/

0)

M10 R60-10 102 to 120 (88.5 to 104) TIC 60 NOP 150H

M8 R70-8 61.2 to 66.0 (53.0 to 57.2) TIC 60 NOP 150H

70 (2/0)

M10 R70-10 102 to 120 (88.5 to 104) TIC 60 NOP 150H

M10 R80-10 102 to 120 (88.5 to 104) TIC 80 NOP 150H

80 (3/0)

M16 R80-16 255 to 280 (221 to 243) TIC 80 NOP 150H

M10 R100-10 102 to 120 (88.5 to 104) TIC 100 NOP 150H

M12 R100-12 143 to 157 (124 to 136) TIC 100 NOP 150H

100 (4/0)

M16 R80-16 255 to 280 (221 to 243) TIC 80 NOP 150H

Page 15

3-3

3.2 Installation

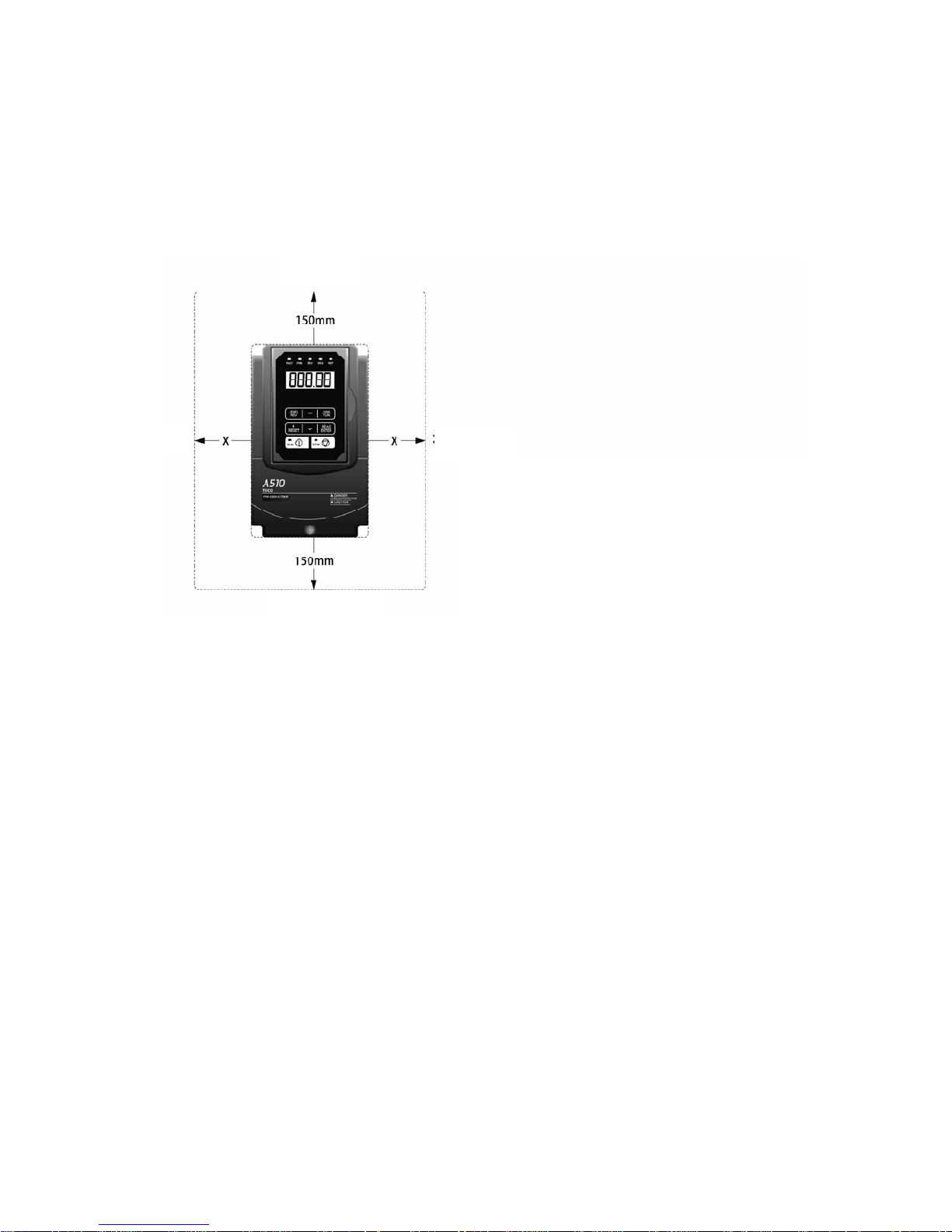

3.2.1 Installation space

(1) Please install the A510 inverter in vertical direction, leaving enough space to

ensure the cooling effect, shown in Figure 3.1.

Avoid the upside-down or horizontal installation.

Figure 3.1 A510 Installation Space

(2) The temperature of inverter’s radiator cooling fins may reach 90 ℃ in operation.

Therefore, the contact surface for the inverter installation shall be made by the high-

temperature-resistant material.

When the inverter is operating in the power distribution box, the environment must be

ventilated and the environmental temperature must be less than +40 ° C.

Up side

Down side

Right

Left

X= for the inverter capacity of 18.5kW (including the

smaller capacity), the minimum width is recommended

as 100mm.

X= for the inverter capacity of 22 kW (including the

higher capacity), the minimum width is recommended

as 200mm.

Page 16

3-4

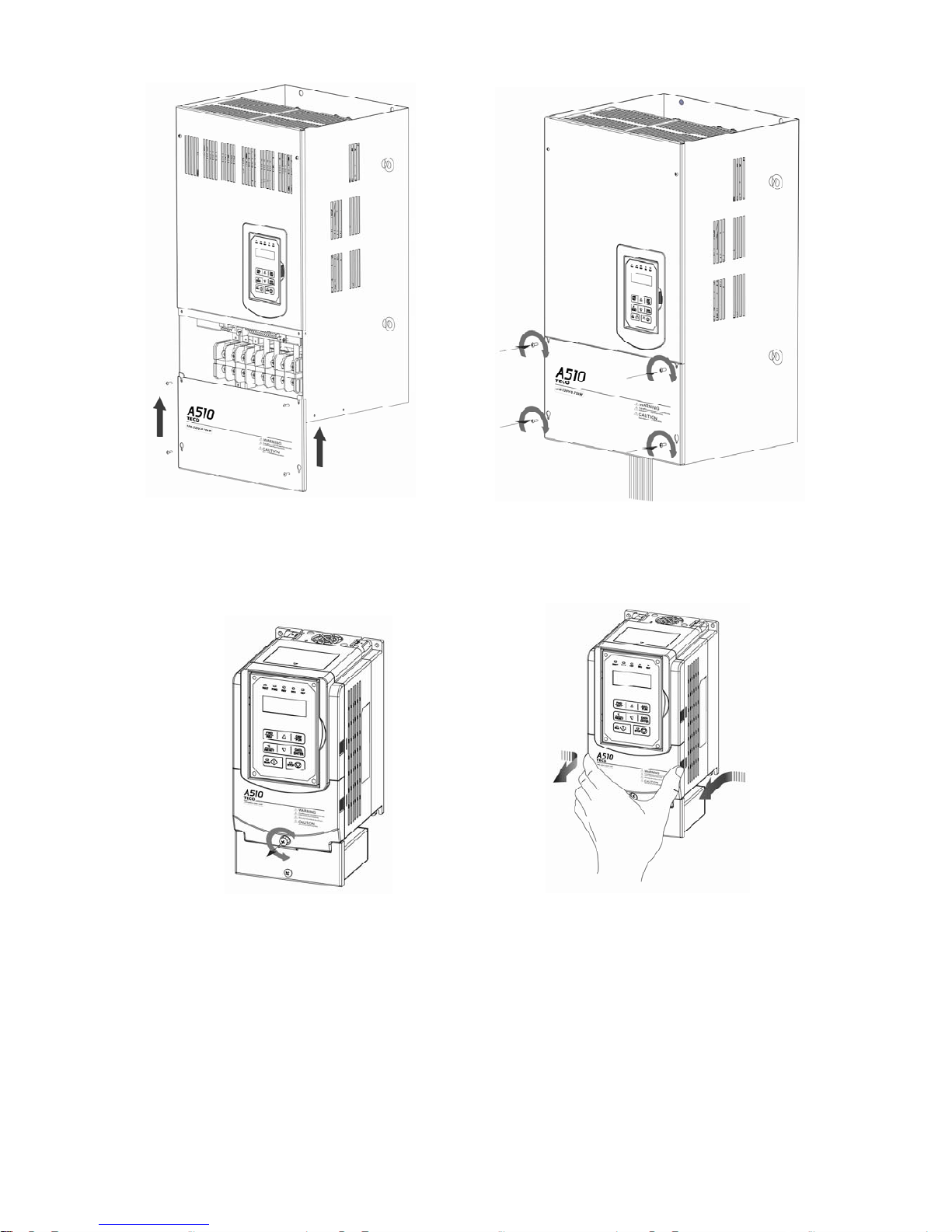

3.2.2 External view of the product and warning label information

External view and part name of A510 inverter:

(a) 220V 1-5HP/440V 1-7.5HP

(Wall-mounted type, IEC IP 00) (Wall-mounted type, IEC IP20, NEMA1)

Caution

The installing environment of the inverter directly affects its functions and the service

life. Therefore, the installation environment should be taken into account when installing

A510 inverter:

• Ambient temperature : -10 ℃~ +40 (NEMA 1 ℃ external installation type)

• Avoid rain, humidity or direct sunlight.

• Avoid corrosive liquid or gas, dust and metal filings

• Avoid vibration; Keep away from electromagnetic interference

• For multiple inverters installed in one plate, please equip with a fan for heat radiating

in order to make the surrounding temperature of the inverter lower than 40 . ℃

Warning Information

Warning Information

Type Specification

label

Front cove

r

Digital operato

r

Nameplate and

barcode

Nameplate

and barcode

Terminal cove

r

Fan cover

Mounting hole

Mounting hole

Fan cover

Front cove

r

Digital operato

r

Anti-dust cove

r

Heat sink

Heat sink

Type Specification

label

Terminal cover

Page 17

3-5

(b) 220V 7.5-25HP/440V 10-30HP

(Wall-mounted type, IEC IP 00) (Wall-mounted type, IEC IP20, NEMA1)

(c) 220V 30-40HP/440V 40-60HP

(Wall-mounted type, IEC IP20, NEMA1)

Front cover

Mounting hole

Mounting hole

Nameplate

and barcode

Nameplate

and barcode

Terminal cover

Digital operator

Digital operator

Front cover

Anti-dust cover

Warning Information

Warning Information

Terminal cover

Type Specification

label

Type Specification

label

Mounting hole

Front cover

Digital operator

Terminal cover

Nameplate

and barcode

Warning Information

Type Specification

label

Lifting lugs(4 pcs)

Page 18

3-6

(d) 220V 50-100HP/440V 75-215HP

(wall-mounted type,IEC IP 00) (wall-mounted type, IEC IP20, NEMA1)

Figure 3.2 External view of A510

Must be sure to read the warning information on the front cover, see Figure 3.3

Figure 3.3 Warning information label

Warning Information

Warning Information

Lifting Lugs

(4 pcs)

Nameplate

and barcode

Digital operator

Terminal cover

Type Specification

label

Terminal cove

r

Nameplate

and barcode

Lifting Lugs

(4 pcs)

Front cover

Front cove

r

Mounting hole

Mounting hole

Anti-dust cover

Type Specification

label

Wiring box

Digital operator

Page 19

3-7

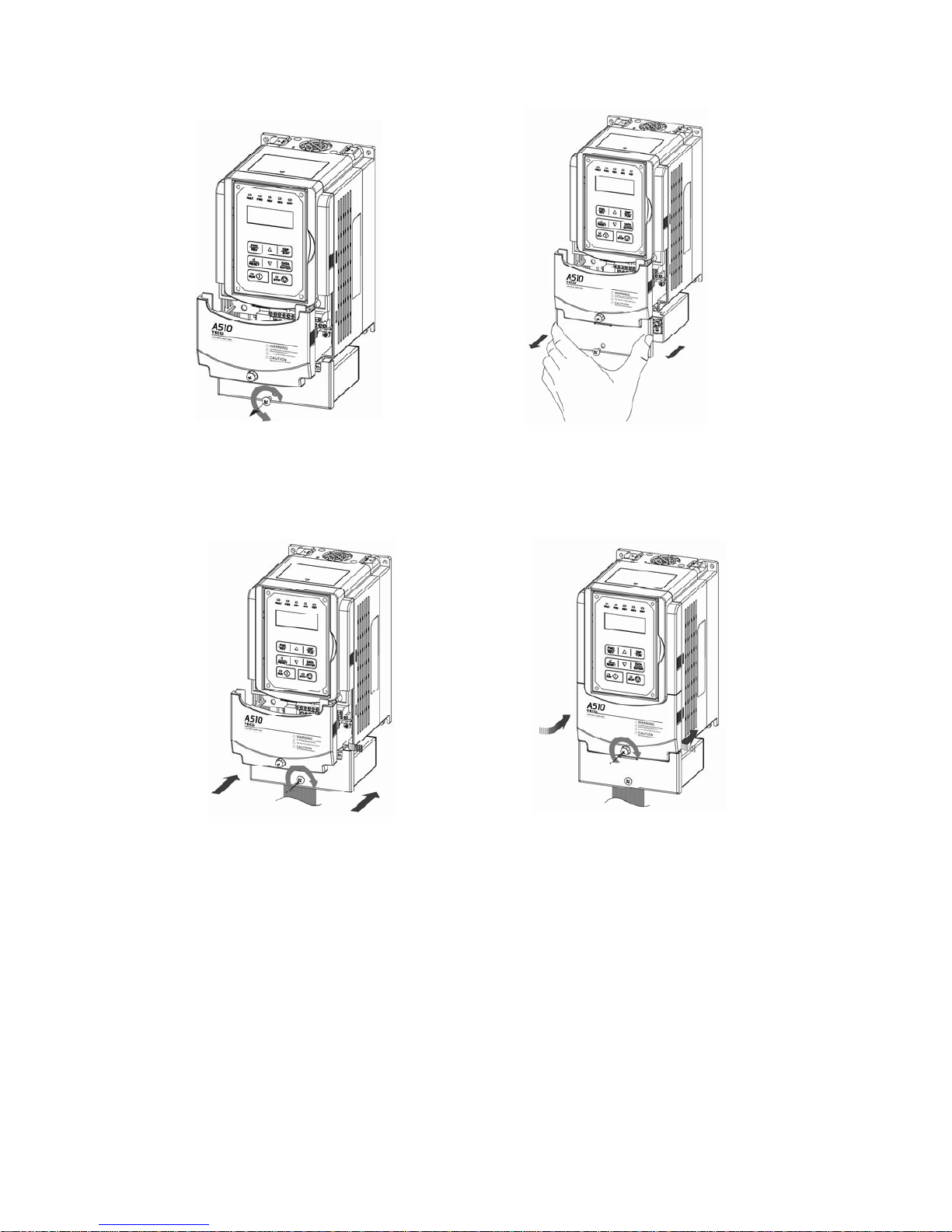

3.2.3 Product Dismounting

Disassembly/assembly steps for various models of A510, as shown in following:

3.2.3.1 Standard type

(a) 220V 1-5HP/440V 1-7.5HP

Step 1: Loose screws Step 2: Disassemble external cover

Caution

For A510 wiring, it is not necessary to disassemble the digital operator. First to

loose screws of the external cover and take off the cover, then you can carry out the

wiring work to the internal terminals of the inverter.

• Models of 220V 1-25HP and 440V 1-30HP are plastic shell. It is suggested to loose

screws of the external cover and take off the cover. When wiring is completed,

assemble the external cover of terminals and fasten screws.

• Models of 220V 30HP-100HP and 440V 40~215HP are metal shell. It is suggested to

loose screws of the external cover and take off the cover. When wiring is completed,

assemble the external cover of terminals and fasten screws.

Page 20

3-8

Step 3: Wiring and assemble the cover Step 4: Fasten screws

(b) 220V 7.5-25HP/440V 10-30HP

Step 1: Loose screws Step 2: Disassemble external cover

Page 21

3-9

Step 3: Wiring and assemble the cover Step 4: Fasten screws

(c) 220V 30-40HP/440V 40-60HP

Step 1: Loose screws Step 2: Disassemble external cover

Page 22

3-10

Step 3: Wiring and assemble the cover Step 4: Fasten screws

(d) 220V 50-100HP/440V 75-215HP

Step 1: Loose screws Step 2: Disassemble external cover

Page 23

3-11

Step 3: Wiring and assemble the cover Step 4: Fasten screws

3.2.3.2 Built-in filter type (440V 1 ~60HP)

Step 1: Loose screws Step 2: Disassemble external cover

Page 24

3-12

Step 3: Loose screws of filter Step 4: Disassemble the external cover of the filter

Step 5: Wiring and assemble the filter cover, Step 6: Fasten screws

then fasten screws

Page 25

3-13

3.3 Wiring the peripheral devices of the inverter and related

cautions

Cautions

1. After the power is cut off, while the “CHARGE” indicator of the inverter is still on, it

means the discharge of the capacitor has not been completed. Don’t touch the circuit

or replace components at this time.

2. Never wire or disassemble/assemble internal connectors of inverter when the power

is supplied.

3. Prohibit connecting U,V and W of inverter output terminals to AC power.

4. Terminal E of the inverter must be well grounded.

5. Since semiconductor components are easily damaged by high voltage, do not carry

out the high voltage withstand test on internal components of A510 inverter.

6. CMOS IC of the inverter control board is easily affected and damaged by static

electricity, thus, do not touch the control board.

Cautions

1. When wiring, please refer to the table for choosing appropriate wire diameter. If the

main circuit line is too long, pay attention to the voltage drop which can not exceed 2%

of the rated voltage.

Phase voltage drop V△ =

3 ×wire resistance (Ω/km)×wiring distance (m)×current

(A)×10-3

2. In case of a long wire between the inverter and the motor, please reduce the carrier

frequency appropriately (parameters 11-01).

Cautions

To ensure the security of the interface device, it is recommended that a fast-acting fuse

be added at the input side of the inverter, especially for high-power systems. The

specification of applied fast-acting fuse can be referred to Section 6.6.

Page 26

3-14

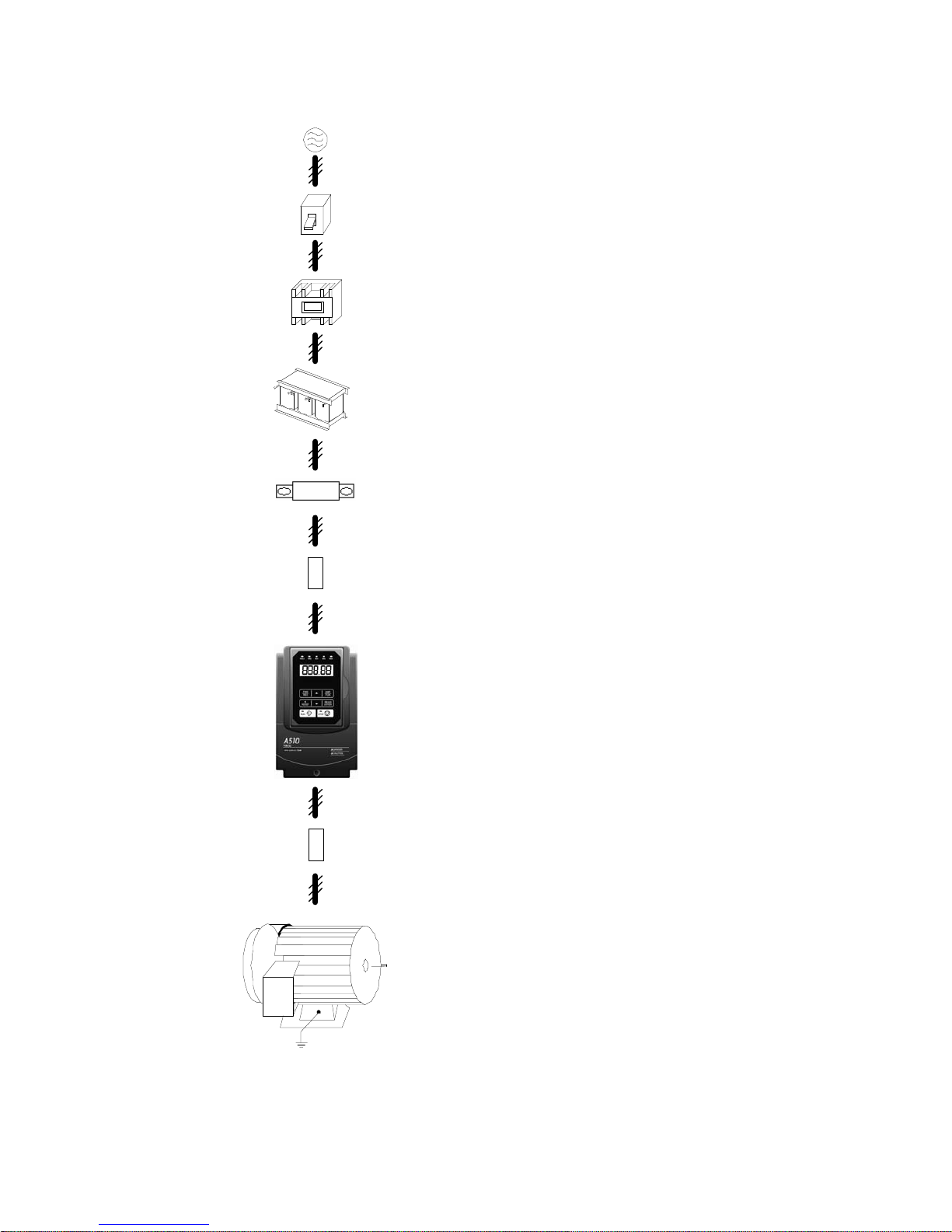

Examples for wiring the periphery devices of A510 are shown in the following:

電源

無熔絲開關 NFB

(及漏電斷路器)

電磁接觸器

AC 電抗器

輸入側雜訊

濾波器

變頻器

零相雜訊濾波器

三相感應

馬達

外加高速保險絲

■ No fuse breaker (NFB) and Leakage Circuit

Breaker

‧ Please refer to table 3 for choosing NFB of

appropriate current.

‧ Do not use NFB to control the start/stop of the

inverter.

‧ If a leakage circuit breaker is added for leakage

protection, its current sensitivity shall be more

than 200mA and action time more than 0.1 (VTYPE), so as to avoid high-frequency

malfunction.

■ Electromagnetic contactor

‧ It can not add the electromagnetic contactor for

general use. However, for the application

requiring external sequence control or

automatic restart function after power cut, an

electromagnetic contactor is required.

‧ Please avoid using electromagnetic contactor

for the start/stop control of the inverter as

possible.

■ AC reactor

‧ In case of further improving the power factor or

suppress the external surge, an AC reactor can

be additionally equipped.

■ Fast acting fuse

‧ To protect interface devices, it is necessary to

add a fast acting fuse (fuse specification will be

referred to Section 6.6)

■ Input Noise filter

‧ A510 is matched with TECO special filter,

meeting the EN 55011 class A criterion.

‧ The selection of input noise filter can be

referred to Section 6.4)

■ Inverter

‧ Terminal R,S,T at input side have no phase

sequence requirement, thus they can be

arbitrarily exchanged.

‧ Terminal E must be well grounded.

Power supply

No Fuse Breaker

(NFB) and Leakage

Circuit Breaker

Electromagnetic

contactor

AC reactor

Fast acting fuse

Input Noise filter

Inverter

Zero-phase

noise filter

3-phase

induction

motor

Page 27

3-15

■ Zero-phase noise filter

‧ Adding a zero-phase noise filter at the output

side of the inverter can decrease the radiated

interference and induced noise.

‧ Please refer to Section 6.5

■ Motor

‧ If an inverter drives multiple motors, the rated

current of the inverter must be greater than the

total current that all motors operate at the same

time.

‧ Motor and inverter must be grounded

respectively.

Page 28

3-16

■ Wiring

The following is the standard wiring diagram for the A510 inverter ( indicates ◎ main

circuit terminal ,○ indicates control circuit terminal ). Locations and symbols of the wiring

terminal block might be different due to different models of A510. The description of main

circuit terminal and control circuit terminal can be referred to table 1 and 2.

3.4 Functional description of terminals

MCNFB

B1/P B2

煞車電阻

R/L1

S/L2

S1

S2

S8

S7

S6

S5

S4

S3

類比輸出1

多

機

能

接

點

輸

入

24V

數位信號電源端子

24VG

數位信號共同端子

故障重置

正向運轉/停止

多段速指令1

寸動指令

外部Base block

Source(PNP)

SW3

AO1

AO2

GND

E

CN3

類比輸出2

E

T/L3

U/T1

V/T2

W/T3

CN6 (RJ45)

1

2

脈波指令輸入

遮蔽線連接端子

GND 類比信號共同端子

E

+12V

類比輸入用電源

AI1 多機能類比輸入

(-10~10V/0~10V, 20K

AI2 多機能類比輸入

P

P

DO2

DOG

S(+)

S(-)

PI

PO

-12V 類比輸入用電源

P

P

IM

R2C

R1A

R1B

R1C

R2A

F1

F2

安全輸入接點

+12V, 20mA

(-10~10V/0~10V/4~20mA, 250

32K Hz. Max.

I , 出廠設定

SW2

主迴路電源

出

廠

設

定

外

部

類

比

輸

入

-10V~0~10V

4~20mA/0~10V

0V

Sink(NPN), 出廠設定

脈波輸入

反向運轉/停止

UP/增頻率命令

DOWN/減頻率命令

第三種接地

電阻值100

以下

類比信號輸出1, 2

(DC 0~10V)

選購擴充卡(PG卡)

多機能繼電器輸出

250VAC, 1A以下

30VDC, 1A以下

多機能光耦輸出

(DC 48V/50mA, Open Collector)

多機能脈波輸出

32k Hz. Max.

GND

RS485通訊埠

DO1

表隔離線,

表雙絞芯隔離絞線

P

端子符號 表示主迴路,

表示

控制迴路

*2

*1

*3

*5

*6

*5

*1:僅220V 1~25HP與440V 1~30HP(含)以下容量內建剎晶體機種主回路提供B2端子,可直接於B1, B2間連接煞車電阻。

備註說明:

*2:多機能數位輸入接點S1~S8,可透過開關SW3設置成Source(PNP)或Sink(NPN)模式。

*3:多機能類比輸入2(AI2),可透過開關SW3設置成電壓命令輸入(0~10V/-10~10V)或電流命令輸入(4~20mA)。

*4

*4:安全輸入接點F1, F2間需短接變頻器始可正常輸出,使用安全輸入時,請務必拆下F1-F2間的短接線。

*5:僅220V 3HP與440V 5HP(含)以上機種,提供-12V, R2A-R2C與PO-GND端子。

*6:僅220V 2HP與440V 3HP(含)以下機種,提供DO2端子。

*5

Braking resistor

F

ast acting fuse

Main circuit power

Default setting

Forward rotation/stop

Reversal rotation/stop

Up command

Down command

Multi-step speed

command 1

Fault reset

Jog command

External base block

Multi-function input

Default setting

Analog output 1

Analog output 2

The third type grounding.

Resistance lower than 100

ohm.

Analog signal output 1, 2

Option Card (PG)

Multi-function relay output

Power terminal of digital signal

250VAC, under 1A

30VDC, under 1A

Multi-function pulse output

RS485 Communication port

Multi-function photocoupler output

AI1 Multi-function analog input

(-10~10V/0~10V, 20KΩ)

AI2 Multi-function analog input

(-10~10V/0~10V/4~20mA, 250Ω)

Default

setting

Safety input contact

GND Mutual terminal of analog signal

-12V Power of analog input

+12V Power of analog input, +12v,20mA

PI Pulse command input 32K Hz. Max.

Pulse input

E

x

t

erna

l

ana

l

og

i

npu

t

Connection terminal of shielding wire

24VG Mutual terminal of digital signal

Means Isolated twisted twire

Means

isolated

wire

Terminal symbol ◎ indicates main circuit,

○ indicates control circuit

Remark:

*1: Only the master circuit of 220V1~25HP and 440 V1~30HP (included) or models of lower capacity with built-in braking resistor provide terminal B2.

The braking resistor can be connected directly between B1 and B2.

*2: The multi-function digital input terminals S1~S8 can be set to Source (PNP) or Sink (NPN) mode through the SW3.

*3: Multi-function analog input 2 (AI2) can be set to the voltage command input (0-10/-10-10v) or the current command input (4~20mA) through the

SW3.

*4: Safety input connector F1 and F2 should be shorted so that the inverter outputs properly. When the safety input is used, please be sure to remove

the short-pin between F1 and F2.

*5: Only 220 V 3HP and 440 v 5HP (included) or models above, provide terminals -12V, R2A-R2C and PO-GND.

*6. Only 220 V 2HP and 440 v 3HP (included) or models below, provide terminal DO2.

Page 29

3-17

3.4 Terminal Description

Table 1 Major Circuit Terminals

Terminal

mark

220V: 1~25HP

440V: 1~30HP

220V: 30~100HP

440V: 40~215HP

R/L1

S/L2

T/L3

Power supply of the main terminal ( single phase, only

connect R-S)

B1/P

B2

-

\

• B1/P-\: DC power

supply

• B1/P-B2: externally

connected braking resistor

⊕

-

• ⊕ -\: DC power

supply or

connect braking

detection

module

U/T1

V/T2

W/T3

Inverter output

E

Grounding terminal (the third type grounding)

■ Main Circuit Terminal Layouts

˙220V : 1 ~ 2HP , 440V : 1 ~ 3HP

R/L1 S/L2 T/L3

B1/P

U/T1 V/T2

W

/

T3B2

˙220V : 3 ~ 5HP , 440V : 5 ~ 7.5HP

R

/L1

S

/L2

T

/L3

B1/P B2

U

/T1V/T2

Power In

Dynamic Brake

To Motor

W

/T3

CHARGE

˙220V : 7.5~10HP , 440V : 10 ~ 15HP

R

/L1S/L2T/L3

E

B1/P

B2

Power In

Dynamic Brake

CHARGE

U

/T1V/T2W/T3

E

To Moto

r

B1/R

Page 30

3-18

˙220V : 15~25HP , 440V : 20 ~ 30HP

R/L1 S/L2 T/L3 U/T1 V/T2

W

/

T3B1/P B2

˙220V : 30 ~40HP , 440V : 40 ~ 60HP

R/L1 S/L2 T/L3 U/T1 V/T2

W

/

T3

˙220V : 50~60HP, 440V : 75~100HP

˙220V : 75~100HP, 440V : 125~215HP

Page 31

3-19

Table 2 Main circuit terminals

Type Terminal terminal function Signal level

S1

Forward rotation─ stop command

(default), multi-function input terminals * 1

S2

Reversal rotation- stop command

(default), multi-function input terminals * 1

S3

UP increases command(default), multifunction input terminals * 1

S4

DOWN reduces command(default), multifunction input terminals * 1

S5

Multi-step speed frequency command 1,

multi-function input terminal* 1

S6

fault reset input, multi-function input

terminal * 1

S7

JOG frequency command, multi-function

input terminal * 1

Digital

input

signal

S8

External B.B.(Base Block) input, multifunction input terminal * 1

24 VDC, 8 mA optocoupler isolation

(maximum voltage of 30

Vdc, input impedance of

9.03kΩ optocoupler)

24V

Digital signal SOURCE sharing point

(SW3 switched to SOURCE )

24V

Power

supply

24VG

Common terminal of Digital signals

Common point of digital signal SINK

( SW3 switched to SINK )

±15%,

Maximum output

current: 250mA( the sum

of all load )

+12V Power for speed setting

+12V

( Maximum current ,

20mA)

-12V

Only above 220V 3HP/ 440V 5HP

(include) support this terminal function

-12V

(Maximum current, 20mA)

AI1

Voltage mastering speed command (010V input)/(-10V~10V input)

From 0 to +10V,

From -10V to +10V

(Input impedance : 20KΩ)

(11bit + 1 symbol,

resolution)

AI2

Multi-function analog input terminals *2,

can use SW2 to switch voltage or current

input (0~10V)/(4-20mA)

From 0 to +10V,

From -10V to +10V

(Input impedance: 20KΩ)

From 4 to 20 mA

(Input impedance:

250KΩ)

(11bit + 1 symbol,

resolution)

GND Analog signals sharing terminal ----

Analog

input

signal

E

Shielding wire’s connecting terminal

(Ground)

----

Page 32

3-20

Type Terminal terminal function Signal level

AO1

Multi-function analog output terminals *3

(0~10V output)

AO2

Multi-function analog output terminals *3

(0~10V output)

Analog

output

signal

GND Analog signals sharing terminal

From 0 to 10V,

( Maximum current,

20mA )

(PWM 10KHz

resolution )

PO

Pulse output, BW 32KHz, only above

220V 3HP/ 440V 5HP (include) support

this terminal function.

32KHz(max), +12V

output

(load: 2.2kΩ)

Pulse

output

signal

GND Analog signals sharing terminal ----

PI

Pulse command input, frequency width

of 32KHz

L: from 0.0 to 0.5V

H: from 4.0 to 13.2V

0 - 32 KHz(max)

(impedance:3.89 KΩ)

Pulse

input

signal

GND Analog signals sharing terminal ----

DO1

DO2

(F1 only)

Multi-function(open collector resistor)

output: in operation, zero speed,

frequency consistency, consistency at

any frequency, output frequency ,

preparation completion, low-voltage

detection, output breaker, rotation and

frequency command, over-torque

detection, abnormal, low-voltage,

Overheat, motor overload, inverter

overload, retrying, communication error,

timing functional output device……

48Vdc, 2~50mA

Opto-coupling output

Digital

output

DOG

Sharing terminal of the open collector

transistor

R1A

R1B

R1C

Relay A contact (multi-function output

terminal)

Relay B contact (multi-function output

terminal)

Relay common terminal,

With the same function as DO1/DO2

Terminal capacity:

at 250Vac, 10 mA~1A

at 30Vdc, 10 mA~1A

Relay

output

R2A-R2C

(above

F2)

With the same function as DO1/DO2

Terminal capacity:

at 250Vac, 10 mA~1A

at 30Vdc, 10 mA~1A

F1

on: free rotation with safe input

off: general rotation

(if use external safety switch to stop, you

must remove the short circuit pin.)

24Vdc, 8mA, pull-high

safety

input

F2 Safety command common terminal 24V Ground

S (+)

RS-485

port

S (-)

RS485/MODBUS

Opto-coupler isolation,

differential input and

output

Grounding

E (G)

Grounding to earth

Shield the connecting terminal

----

Page 33

3-21

*1:Multi-function digital input can be referred to the manual.

*2:Multi-function analog input can be referred to the manual.

*3:Multi-function analog output can be referred to the manual.

Caution

‧ Maximum output current capacity of the terminal 12V is 20mA.

‧ Multi-function analog output AO1 and AO2 are special for the analog output of meter.

Please don’t use them to the analog signal output of feedback control.

‧ Control board’s 24V & ±12V just been used for internal control, please don’t connect

to external other devices to use.

Page 34

3-22

3.5 Internal wiring diagram of main circuit

Various models of A510’s internal wiring diagram of main circuit are shown as the

following:

1. 220V:1HP 440V: 1~2HP

2. 220V: 2~25HP 440V: 3~30HP

3. 220V: 30~40HP 440V: 40~60HP

4. 220V: 50~60HP 440V: 75~100HP

5. 220V: 75HP, 100HP 6. 440V: 125HP, 150HP, 175HP, 215HP

E

U(T1)

W(T3)

V (T2)

S

(L2)

T(L3)

E

○─

CONTROL

CIRCUITS

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

B1/P

SPS

B2

E

○

─

CONTROL

CIRCUITS

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

B1/P

SPS

B2

E

○

─

CONTROL

CIRCUITS

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

SPS

○┼

N

P

DCL

C/B

SPS

R(L1)

E

N

P

DCL

SPS

C/B

AC/DC

W(T3)

R(L1)

T(L3)

S

(L2)

U(T1)

V(T2)

E

N

P

DCL

SPS

C/B

AC/DC

R(L1)

S(L2)

T(L3)

U(T1)

V (T2)

W(T3)

Page 35

3-23

3.6 Instrument for main circuit wiring and caution

■ Instrument for main circuit wiring

Whether the MC should be installed or not is depended on the actual requirement,

while the NFB must be installed between the AC supply and power input ports R, S, T of

A510. If a leakage breaker is additionally added for protection to avoid the malfunction of

leakage breaker, its current sensitivity shall be over 200mA, and acting time over 0.1

seconds.

Table 3 Wiring instrument for 220V/440V class

A510 Model wire diameter (mm2)

Power

horse

power

(HP)

*1

Rated

KVA

Rated

current

(A)

HD/ND

Main

circuit

*2

Grounding

line

E(G)

Control

line

*3

NFB

*4

MC*4

1HP 1.9 5/6

2~5.5 2~5.5 0.5~2

TO-50EC(15A) CU-11

2HP 3 8/9.6

2~5.5 3.5~5.5 0.5~2

TO-50EC(20A) CU-11

220V

1 Ø/3Ø

3HP 4.2 11/12

3.5~5.5 3.5~5.5 0.5~2

TO-50EC(30A) CU-11

5.4HP 6.7 17.5/21 5.5 5.5

0.5~2

TO-50EC(30A) CU-16

7.5HP 9.5 25/30 8

5.5~8 0.5~2

TO-100S(50A) CU-18

10HP 12.6 33/40 8

5.5~8 0.5~2

TO-100S(50A) CU-25

15HP 17.9 47/56 14 8

0.5~2

TO-100S(100A) CU-50

20HP 22.9 60/69 22 8

0.5~2

TO-100S(100A) CU-65

25HP 28.6 73/79 22 14

0.5~2

TO-225S(100A) CU-80

30HP 32.4 85/110 38 14

0.5~2

TO-225S(150A) CN-100

40HP 43.8 115/138 60 22

0.5~2

TO-225S(175A) CN-125

50HP 55.3 145/169 80 22

0.5~2

TO-225S(200A) CN-150

60HP 68.6 180/200 100 22

0.5~2

TO-225S(225A) CN-180

75HP 81.9 215/250 150 22

0.5~2

TO-400S(300A) CN-300

100HP 108 283/312 200 38

0.5~2

TO-400S(400A) CN-300

125HP 132 346/360

220V

3 Ø

150HP 158 415/450

1HP 2.6 3.4/4.1

2~5.5 2~5.5 0.5~2

TO-50EC(15A) CU-11

2HP 3.2 4.2/5.4

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-11

3HP 4.2 5.5/6.9

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-11

5.4HP 7 9.2/11.1

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-18

7.5HP 11.3 14.8/17.5

3~5.5 3.5~5.5 0.5~2

TO-50EC(20A) CU-18

10HP 13.7 18/23 5.5 5.5

0.5~2

TO-50EC(30A) CU-25

15HP 18.3 24/31 8 8

0.5~2

TO-100S(50A) CU-25

20HP 23.6 31/38 8 8

0.5~2

TO-100S(50A) CU-35

25HP 29.7 39/44 8 8

0.5~2

TO-100S(50A) CU-50

30HP 34.3 45/58 14 8

0.5~2

TO-100S(75A) CU-50

40HP 45.7 60/72 22 8

0.5~2

TO-100S(100A) CU-65

50HP 57.2 75/88 22 14

0.5~2

TO-100S(100A) CU-80

60HP 69.3 91/103 38 14

0.5~2

TO-225S(150A) CN-100

75HP 85.4 118/145 60 22

0.5~2

TO-225S(175A) CN-125

100HP 114 150/165 80 22

0.5~2

TO-225S(225A) CN-150

125HP 137 180/208 150 22

0.5~2

TO-400S(300A) CN-300

150HP 165 216/250 150 22

0.5~2

TO-400S(300A) CN-300

440V

3 Ø

175HP 198 260/296 200 30

0.5~2

TO-400S(400A) CN-300

Page 36

3-24

A510 Model wire diameter (mm

2

)

Power

horse

power

(HP)

*1

Rated

KVA

Rated

current

(A)

HD/ND

Main

circuit

*2

Grounding

line

E(G)

Control

line

*3

NFB

*4

MC*4

215HP 225 295/328 250 30

0.5~2

TO-400S(400A) CN-300

250HP 270 352/380

300HP 317 415/470

375HP 400 523/585

*1: Fixed torque load shall prevail.

*2: The main circuit contains R/L1, S/L2, T/L3 , U/T1, V/T2, W/T3, B1/P, B2, \, ♁。

*3: Control line is the terminal wire on the control board.

*4: The NFB and MCB listed in the table are of TECO product numbers, products with

same rated specification of other brands are available. To reduce electrical noise

interference, please ensure that R-C surge absorbe

r (R: 10Ω/5W, C: 0.1μf/1000VDC)

are added at both sides of MCB coil.

*5: 220V 125HP/ 440V 250HP or above is being developed.

Page 37

3-25

For the external wiring, please attention to the followings:

(A) Control Circuit wiring:

(1) Control circuit wiring (control terminal) must be isolated from main circuit wiring (R,

S, T, U, V, W) and other power lines, so as to avoid electrical noise interference.

(2) Contact output terminal R1A, R1B, R1C (or R2A, R2C) must be isolated from

terminal c~j, A01, A02, GND, DO1, DO2, DOG, +12V-, -12V, AI1, AI2, GND

when wiring.

(3) In order to avoid the electrical noise interference, the control circuit wiring must

adopt shielding isolation twisted wire, please refer to the following diagram; the

wiring distance should not exceed 50m.

接至變頻器控制端子E

遮蔽隔離線

護套

此端遮蔽線

不連接

以絕緣膠帶包覆

Figure 3 Isolation twisted wire treatment

When connecting the output contact of the multi-function optocoupler to the relay, it is

necessary to add flywheel diode in parallel to both sides of the relay coil, as shown in the

following diagram.

Figure 4 Optical coupler output contacts connected inductive load

g

飛輪二極體

Flywheel diode

(above 100V 100mA)

48V max.

g

50 mA max.

A

510

外部配線回路

External wiring circuit

Connected to the control terminal E of

inverter

Protective covering

Shielding isolation wire

Do not connect the shielding isolation wire at

this side

Wrapped with insulating tape

Page 38

3-26

(B) Main Circuit wiring :

(1) It doesn’t need to consider the phase sequence for input power R, S, T.

(2) Prohibit connecting U,V and W of inverter output terminals to AC power.

(3) Inverter output terminal U, V and W are connected to the motor terminal U, V, W. If

the inverter executes forward rotation instruction while the motor rotates in reversal

direction, simply exchange any two wires of U, V, W is enough.

(4) Never connect the inverter output terminal to the capacitor or LC,RC noise filter of

improving the power factor.

(C) Grounding wire :

(1) Grounding terminal (E) is grounded to the earth by the third type grounding way.

(grounding resistance of 100Ω or less)

(2) Inverter grounding wire can not be grounded together with high-current loads such

as welding machines and high-powered motors and so on. They must be grounded

respectively.

(3) Grounding wire size follows the specification of electrical equipment technical

basis. The shorter grounding wire is, the better it is.

(4) If several inverters are grounded jointly, please refer to the following diagrams for

grounding. Do not form a circuit in grounding.

(a) 良 (b) 良 (c) 不良

Figure 5 Grounding ways of several A150 jointly

(a) Good

(b) Good (c) Not Good

Page 39

3-27

◎ Determine wire size

When choosing wire, a consideration of the voltage drop caused by the wire is a

must.

Voltage drop is calculated as shown below. In general, the voltage drop shall be

controlled below 2% of the rated voltage. Voltage drop between wires (V) = × wire

resistance (Ω / km) × wiring length (m) × current (A) × 10-3

◎ AC reactor for parallel power coordination

If the capacity exceeds 600kVA, please add AC reactor to the input side of the

inverter in series. AC power can be used for power coordination and power factor

improvement.

◎ Wiring length between the inverter and the motor

If the total length between the inverter and the motor, the inverter itself and other

peripheral devices will be affected because the high-frequency carrier frequency (ie,

the IGBT ON / OFF switching frequency) of the inverter will increase the leakage

current between wiring and the ground. As a result, if the wiring length between the

inverter and the motor is very long, please modestly reduce the carrier frequency, as

shown below.

Wiring distance between

the inverter and the

motor

<30m 30m ~ 50m

50m

~100m

100m≧

Allowable carrier

frequency

(set values of 11-01 )

16kHz(max) 10kHz(max) 5kHz(max) 2kHz(max)

Page 40

3-28

3.7 Inverter Specifications

Basic Specifications

(a) 220V class

Inverter capacity (HP)

1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150

Rated output Capacity (KVA)

1.9 3 4.2 6.7 9.5 12.6 17.9 22.9 28.6 32.4 43.8 55.3 68.6 81.9 108 132 158

Rated output

current (A)

5 8 11 17.5 25 33 47 60 73 85 115 145 180 215 283 346 415

Heavy-load

type

H.D.(150%/1

min)

Maximum

applicable

motor

*1

HP

(KW)

1

(0.75) 2 (1.5) 3 (2.2) 5 (3.7)

7.5

(5.5)10(7.5)15(11)

20

(15)

25

(18.5)

30

(22)

40

(30)

50

(37)

60

(45)

75

(55)

100

(75)

125

(90)

150

(110)

Rated output

current (A)

6 9.6 12 21 30 40 56 69 79 110 138 169 200 250 312 360 450

Standardload type

N.D.(120%/1

min)

Maximum

applicable

motor

*1

HP

(KW)

1.5

(1.1) 3 (2.2) 4 (3)

7.5

(5.5)

10

(7.5)

15

(11)

20

(15)

25

(18.5)

30

(22)

40

(30)

50

(37)

60

(45)

75

(55)

100

(75)

125

(90)

150

(110)

175

(130)

The maximum output voltage

(V)

3-phase, 200V~240V

Output rated

The maximum output

frequency (Hz)

Based on parameter setting 0.1~400.0(1200.0) Hz

Rated voltage, frequency

Single/3-phase

200V~240V,

50/60Hz

3-phase 200V~240V, 50/60Hz

Allowable voltage fluctuation -15% ~ +10%

Power

Allowable frequency

fluctuation

±5%

(b) 440V class

Inverter capacity (HP)

1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 175 215

Rated output Capacity (KVA)

2.6 3.2 4.2 7 11.3 13.7 18.3 23.6 29.7 34.3 45.7 57.2 69.3 85.4 114 137 165 198 225

Rated output

current (A)

3.4 4.2 5.5 9.2 14.8 18 24 31 39 45 60 75 91 118 150 180 216 260 295

Heavy-load

type

H.D.(150%/

1min)

Maximum

applicable motor

*1

HP (KW)

1

(0.75

)

2

(1.5

)

3

(2.2

)

5

(4)

7.5

(5.5)

10

(7.5)

15

(11)

20

(15)

25

(18.

5)

30

(22)

40

(30)

50

(37)

60

(45)

75

(55)

100

(75)

125

(90)

150

(110)

175

(132)

215

(160)

Rated output

current (A)

4.1 5.4 6.9 11.1 17.5 23 31 38 44 58 72 88 103 145 165 208 250 296 328

Standardload type

N.D.(120%/

1min)

Maximum

applicable motor

*1

HP (KW)

2

(1.5)

3

(2.2

)

4

(3)

7.5

(5.5)

10

(7.5)

15

(11)

20

(15)

25

(18.5

)

30

(22)

40

(30)

50

(37)

60

(45)

75

(55)

100

(75)

125

(90)

150

(110)

175

(132)

215

(160)

250

(185)

The maximum output voltage

(V)

3-phase 380V~480V

Output rated

The maximum output

frequency (Hz)

Based on parameter setting 0.1~400.0(1200.0) Hz

Rated voltage, frequency 3-phase 380V ~ 480V, 50/60Hz

Allowable voltage fluctuation -15% ~ +10%

Power

Allowable frequency

fluctuation

±5%

Page 41

3-29

Inverter capacity (HP) 250 300 375

Rated Output capacity (KVA) 270 317 400

Rated output

current (A)

370 450 523

Heavy-load

type

H.D.(150%/

1min)

Maximum

applicable motor

*1

HP (KW)

250

(185)

300

(220)

375

(280)

Rated output

current (A)

435

15 600 Standardload type

N.D.(120%/

1min)

Maximum

applicable motor

*1

HP (KW)

270

(200)

335

(250)

425

(315)

The maximum output voltage

(V)

3-phase 380V~480V

rated Output

The maximum output

frequency (Hz)

Based on parameter

setting 0.1~400.0

Hz

Rated voltage, frequency

3-phase 380V ~

480V, 50/60Hz

Allowable voltage fluctuation -15% ~ +10%

Powe

r

Allowable frequency

fluctuation

±5%

* 1 Take standard 4-pole induction motor as the base.

* 2 HD (heavy load type): 150% / 1 min, 200% / 2sec, carrier range: 2KHZ ~ 16KHZ , the factory

setting is 8KHZ (220V ~ 20HP / 440V ~ 30HP).

* 3 HD (heavy load type): 150% / 1 min, 200% / 2sec, carrier range: 2KHZ ~ 12KHZ, the factory

setting is 5KHZ (440V 40 ~ 50HP).

* 4 HD (heavy load type): 150% / 1 min, 200% / 2sec, carrier range: 2KHZ ~ 12KHZ, the factory

setting is 6KHZ (220V 25HP).

* 5 HD (heavy load type): 150% / 1 min, 200% / 2sec, carrier range: 2KHZ ~ 12KHZ, the factory

setting is 5KHZ (220V 30 ~ 40HP).

* 6 HD (heavy load type): 150% / 1 min, 200% / 2sec, carrier range: 2KHZ ~ 10KHZ , the factory

setting is 5KHZ (220V 50 ~ 100HP/440V 60 ~ 175HP).

* 7 HD (heavy load type): 150% / 1 min, 200% / 2sec carrier range: 2KHZ ~ 8KHZ, the factory setting

is 3KHZ (440V 215HP).

* 8 ND (standard load type): 120% / 1 min, carrier range: 2KHZ ~ 16KHZ, the factory setting is 2KHZ.

* 9 A510 model is designed to use in heavy load conditions, the factory setting takes HD (heavy load

type) as the base.

* 10 if it is greater than factory carrier frequency, you need to adjust the load current based on the de-

rating curve.

* 11. 220V 125HP / 440V 250HP models or above are being developed.

Page 42

3-30

The following shows maximum frequencies under different control modes.

Load

mode

Control

mode

Other settings

Maximum

frequency

maximum frequency set to

400Hz (00-31 = 0)

400Hz

V/F

V/F + PG

maximum frequency set to

1200Hz (00-31 = 1)

1200Hz

220V 1~10HP, 440V

1~15HP

150Hz

220V 15~25HP, 440V

20~30HP

110Hz

SLV

220V 30~100HP, 440V

40~375HP

100Hz

SV unlimited 400Hz

Heavy

load

(00-27=0)

PMSV unlimited 400Hz

maximum frequency set to

400Hz (00-31 = 0)

120Hz Slight

load

(00-27=1)

V/F

V/F + PG

maximum frequency set

to1200Hz (00-31 = 1)

1200Hz

Page 43

3-31

General Specifications

Operation mode Seven-segment display * 5 + LED keypad (it is allowable to buy LCD keypad with parameter copy function)

Control mode V/F, V/F+PG, SLV, SV, PMSV, PMSLV with space vector PWM mode

Frequency control range 0.1Hz~400.0Hz(1200.0Hz)

Frequency accuracy

(Temperature change)

Digital references: ±0.01%(-10 ~ +40 )℃ , Analog references: ±0.1% (25 ±10)℃℃

Speed control accuracy ±0.1%( vector control(SV)),±0.5%( vector control without sensor)

Frequency setting

resolution

Digital references:0.01Hz , Analog references: 0.06Hz/60Hz

Output frequency

resolution

0.01Hz

Overload Tolerance

rated output current 150%/1 min, 200%/2sec(H.D mode),120%/1 min (N.D mode), factory setting of 150%/1 min,

200%/2sec

frequency setting signal DC 0 ~ +10V / 4 ~ 20mA or DC-10V~+10V and pulse –type command frequency

Acceleration / deceleration

time

0.0~6000.0 second (separately set acceleration and deceleration time )

Voltage, frequency

characteristics

Can arbitrarily set V / f curve based on parameters

Braking torque About 20%

Main control functions

Auto tuning, Zero Servo, torque control, position control, Droop, Soft-PWM, over-voltage protection, dynamic braking,

speed search, frequency traversing, instantaneous power fault restart, PID control, automatic torque compensation, slide

difference compensation, RS-485 communication standard, speed feedback control, simple PLC function, 2 sets of analog

output, safety switch.

Control characteristics

Other functions

Accumulated record of power supply time and operation time, 4 sets of fault history record and the latest fault record

state, energy-saving function setting, single phasing protection, smart braking,DC braking, Dwell, S curve acceleration and

deceleration, Up / Down operation, MODBUS communication type, output of pulse multiple, display of any engineering

unit, Local / Remote switching keys, SINK / SOURCE input interface option

Stall protection

Action current can be set (in acceleration or constant speed, it can be set separately. In deceleration, it can be set with /

without)

Instantaneous over current

(OC) and output shortcircuit (SC) protection

It stops when the current exceeds 200% of the inverter rated current.

Inverter overload

Protection (OL2)

inverter rated current is 150%/1 min., in case of 200%/2sec, it stops (H.D type),carrier of the factory setting is 8~2KHZ.

In case of 120%/1 min, it stops(N.D. type), carrier of the factory setting is 2KHZ。

Motor overload (OL1)

protection

Electrical overload protection curve

Over voltage(OV)

protection

If the main circuit DC voltage is over 410V (220V class) / 820V (440V class), the motor stops running.

Under voltage (UV) If the main circuit DC voltage is under 190V (220V class) / 380V (440V class), the motor stops running.

Automatic restart after

instantaneous power fault

Power fault exceeds 15ms

You can set the function of automatic restart after instantaneous power fault in 2sec

Overheat protection(OH) Use temperature detector for protection

Ground Fault

protection(GF)

Use current detector for protection

Protection in charge state When main circuit DC voltage 50V≧ , the CHARGE LED is on.

Protection functions

Output Phase Loss

Protection (OPL)

If the OPL function acts, the motor stops rotation automatically.

Location

Indoor (protected from corrosive gases and dust)

Ambient temperature

-10~+40 without de℃ -rating (IP20/NEMA1), -10~+50 (IP00), with de℃ -rating, its maximum operation temperature is

60℃

Storage temperature -20~+70℃

Humidity 95%RH or less ( no condensation )

Environment

Specification

Altitude and vibration altitude of 1000 meters or lower, below.5.9m/s2(0.6G)

Communication function RS-485 standard with built-in (MODBUS) (RJ45)

PLC function Built-in

EMI protection The added noise filter is in line with EN61800-3 , 400V 215HP or below can be built in.

EMS protection Follows EN61800-3

Option open pole/wire drive/PM encoder feedback card

Page 44

3-32

Derating curve based on the carrier

(a) 220Vmodel

220V 25HP

ND

HD

HD of

80%

0 2KHz 6KHz 12KHz

220V ~20HP

ND

HD

HD of

80%

0 2KHz 8KHz 16KHz

(Fc)

220V 30~40HP

ND

HD

HD of

80%

0 2KHz 5KHz 12KHz

(Fc)

(Iout)

(Iout)

(Iout)

(Fc)

Page 45

3-33

(b) 440V model

440V ~30HP

ND

HD

HD of

60%

0 2KHz 8KHz 16KHz

(Fc)

220V 50~100HP

ND

HD

HD of

80%

0 2KHz 5KHz 10KHz

(Iout)

(Fc)

440V 40~50HP

ND

HD

HD of

80%

0 2KHz 5KHz 12KHz

(Iout)

(Iout)

(Fc)

Page 46

3-34

440V 215~250HP

ND

HD

HD of

70%

0 2KHz 3KHz 8KHz

440V 60~175HP

ND

HD

HD of

70%

0 2KHz 5KHz 10KHz

ND

HD

80% of HD

0 2KHz 5KHz

220V 125~150HP

440V 300~375HP

(Iout)

(Fc)

(Iout)

(Iout)

(Fc)

(Fc)

Page 47

3-35

Set the descending rated curve based on temperature

.

ND

HD

60% of ND

60% of HD

0 40 ℃ 60 ℃

Rated current

Temperature

Page 48

3-36

3.8 Overall Dimension drawing

3.8.1 Standard Model

(a) 220V :1-5HP/440V :1-7.5HP

Dimension (mm)

Inverter Model

W H D W1 H1 t d GW(kg) Reactor

A510-2001-H 130 215 150 118 203 5 M5 2.2

A510-2002-H 130 215 150 118 203 5 M5 2.2

A510-2003-H 140 279 177 122 267 7 M5 3.8

A510-2005-H3 140 279 177 122 267 7 M5 3.8

A510-4001-H3 130 215 150 118 203 5 M5 2.2

A510-4002-H3 130 215 150 118 203 5 M5 2.2

A510-4003-H3 130 215 150 118 203 5 M5 2.2

A510-4005-H3 140 279 177 122 267 7 M5 3.8

A510-4008-H3 140 279 177 122 267 7 M5 3.8

with option

DCL

(b) 220V :7.5-25HP/440V :10-30HP

Page 49

3-37

Dimension (mm)

Inverter Model

W H D W1 H1 t d GW(kg) Reactor

A510-2008-H3 210 300 215 192 286 1.6 M6 6.2

A510-2010-H3 210 300 215 192 286 1.6 M6 6.2

A510-2015-H3 265 360 225 245 340 1.6 M6 10

A510-2020-H3 265 360 225 245 340 1.6 M6 10

A510-2025-H3 265 360 225 245 340 1.6 M6 10

A510-4010-H3 210 300 215 192 286 1.6 M6 6.2

A510-4015-H3 210 300 215 192 286 1.6 M6 6.2

A510-4020-H3 265 360 225 245 340 1.6 M6 10

A510-4025-H3 265 360 225 245 340 1.6 M6 10

A510-4030-H3 265 360 225 245 340 1.6 M6 10

with option

ACL

(c) 220V :30-40HP/440V :40-60HP

Dimension (mm)

Inverter Model

W H D W1 H1 t d GW(kg) Reactor

A510-2030-H3 284 525 252 220 505 1.6 M8 30

A510-2040-H3 284 525 252 220 505 1.6 M8 30

A510-4040-H3 284 525 252 220 505 1.6 M8 30

A510-4050-H3 284 525 252 220 505 1.6 M8 30

A510-4060-H3 284 525 252 220 505 1.6 M8 30

with option

ACL

Page 50

3-38

(d) 220V :50-100HP/440V :75-215HP(IP00)

Dimension (mm)

Inverter Model

W H D W1 H1 t d GW(kg) Reactor

A510-2050-H3 344 580 300 250 560 1.6 M8 40.5

A510-2060-H3 344 580 300 250 560 1.6 M8 40.5

A510-2075-H3 459 790 324.5 320 760 1.6 M10 74

A510-2100-H3 459 790 324.5 320 760 1.6 M10 74

A510-4075-H3 344 580 300 250 560 1.6 M8 40.5

A510-4100-H3 344 580 300 250 560 1.6 M8 40.5

A510-4125-H3 459 790 324.5 320 760 1.6 M10 74

A510-4150-H3 459 790 324.5 320 760 1.6 M10 74

A510-4175-H3 459 790 324.5 320 760 1.6 M10 74

A510-4215-H3 459 790 324.5 320 760 1.6 M10 74

DCL

STANDARD

INCLUDED

Page 51

3-39

(e) 220V :50-100HP/440V :75-215HP(IP20)

Dimension (mm)

Inverter Model

W H D W1 H1 t d GW(kg) Reactor

A510-2050-H3 348.5 740 300 250 560 1.6 M8 44

A510-2060-H3 348.5 740 300 250 560 1.6 M8 44

A510-2075-H3 463.5 1105 324.5 320 760 1.6 M10 81

A510-2100-H3 463.5 1105 324.5 320 760 1.6 M10 81

A510-4075-H3 348.5 740 300 250 560 1.6 M8 44

A510-4100-H3 348.5 740 300 250 560 1.6 M8 44

A510-4125-H3 463.5 1105 324.5 320 760 1.6 M10 81

A510-4150-H3 463.5 1105 324.5 320 760 1.6 M10 81

A510-4175-H3 463.5 1105 324.5 320 760 1.6 M10 81

A510-4215-H3 463.5 1105 324.5 320 760 1.6 M10 81

DCL

STANDARD

INCLUDED

Note: 250HP or above are being developed

Page 52

3-40

3.8.2 Built-in filter model (440V 1~60HP)

(a) 440V :1-7.5HP

Dimension (mm)

Inverter Model

W H D W1 H1 H2 t d GW(kg) Reactor

A510-4001-H3F 130 265 150 118 203 215 5 M5 2.83

A510-4002-H3F 130

265

150 118 203 215 5 M5 2.83

A510-4003-H3F 130

265

150 118 203 215 5 M5 2.83

A510-4005-H3F 140 349 177 124 266 279 7 M5 4.72

A510-4008-H3F 140 349 177 124 266 279 7 M5 4.72

with option

ACL

(b) 440V :10-30HP

Page 53

3-41

Dimension (mm)

Inverter Model

W H D W1 H1 H2 t d GW(kg) Reactor

A510-4010-H3F 210 385 215 192 286 300 1.6 M6 7.72

A510-4015-H3F 210 385 215 192 286 300 1.6 M6 7.72

A510-4020-H3F 265 480 225 245 340 360 1.6 M6 11.6

A510-4025-H3F 265 480 225 245 340 360 1.6 M6 11.6

A510-4030-H3F 265 480 225 245 340 360 1.6 M6 11.6

with option

DCL

(c) 440V :40-60HP

Dimension (mm)

Inverter Model

W H D W1 H1 H2 t d GW(kg) Reactor

A510-4040-H3F 284 695 252 220 505 525 1.6 M8 32.24

A510-4050-H3F 284 695 252 220 505 525 1.6 M8 32.24

A510-4060-H3F 284 695 252 220 505 525 1.6 M8 32.24

with option

ACL

Page 54

4-1

Chapter 4 Software Index

4.1 Keypad Description

4.1.1 Panel Functions

Type Name Functions

Main display area

Display frequency, parameter voltage, current, temperature and

abnormity and ect.

Display

LED status display

FAULT: When the inverter has a warning or fault message, the

indicator lights up.

FWD: When the inverter is in forward rotation status, the

indicator lights up.

(long bright light while inverter running, flicker while

inverter stopping)

REV: When the inverter is in reversal rotation status, the

indicator lights up.

(long bright light while inverter running, flicker while

inverter stopping)

SEQ: When inverter’s run command source is set to external

control, the indicator lights up.

REF: When inverter’s frequency command source is set to

external control, the indicator lights up.

RUN RUN: Enable the inverter run operation.

STOP STOP: Enable the inverter stop operation.

▲

It is used for frequency and parameter setting.

▼ It is used for frequency and parameter setting.

FWD/REV

This key is used for switching motor’s rotation direction. FWD

indicator on means the motor is rotating in forward direction;

REV indicator on means the motor is rotating in reversal

direction.

DSP/FUN

It is use for switching dispay interface, based on the loop of

frequency screen Æfunction selectionÆmonitor parameterÆ

frequency screen.

</RESET

“<” is left shift key. It is used for changing parameter or value.

RESET key:when a fault is detected, it plays reset function .

Keys

(8 keys)

READ/ENTER

Switch to enter the functions and set internal value, as well as

modify parameter setting and confirm the writing.

Page 55

4-2

4.1.2 Display Description

Digital and letter display

Actual LED Display Actual LED Display Actual LED Display Actual LED Display

0

A

L

Y

1

B

n

-

2

C

o

°

3

D

P

_

4

E

q

.

5

F

r

6

G

S

7

H

t

8

I

u

9

J

V

Description of seven-segment display

Actual output frequency

Display mode of frequency

command

Modification mode of

frequency command

LED lights on LED flashes

Position the flashing location

(change the position )

In Idle status: Seven-segment LED display is for frequency setting, all LEDs are flashing. If UP / DOWN

key is pressed, it will enter the modification mode and the user can change the frequency command. The

flashing position will change according to the </ RESET key. Press READ / ENTER key to write

frequency command and switch to the status of frequency display mode. If the READ / ENTER key is not

pressed within 5 seconds under frequency modification mode, it will switch back to frequency display

mode.

In operating status: Seven-segment LED shows the actual output frequency, its LED is constant

lighting. If UP / DOWN key is pressed, it will enter the frequency command modification mode. The

flashing position will change according to the </ RESET key. If the inverter is in operation, after press

READ / ENTER key to write frequency command, it switches immediately to the status of actual output

frequency display mode.

Page 56

4-3

LED dispay

Seven-segment display Description

1. Display the set frequency in idle status.

2. Display the actual output frequency in operation status.

Display parameter code

Display the setting value of parameter

Display

input voltage

Display inverter

current.

Display DC Bus Voltage

Display temperature

Display PID feedback value. The displayed digit is set by 12-01.

Error display, refer to Chapter 5 Troubleshooting and maintenance

Display AI1 / AI2 input (0~100%)

Description of indicator lighting and flashing

Lighting flashing

Manual

identification

Manual

identification

Light of displaying

fault

Lighted on when fault

occurred

FWD Indicating light

FWD

Lighted on in forward

operation status

FWD

It will flash when

it doesn’t operate

under the

forward

command.

REV Indicating light

REV

Lighted on in reversal

operation status

It will flash when

it doesn’t operate

under the

reversal

command.

Page 57

4-4

Indicating light of

operation command

by external control

Lighted on when the

operation command is

set to external control.

Indicating light of

frequency command

by external control

Lighted on when the

frequency command is

set to external control.

Indicating light of

operation

Lighted on under

operation status

It will flash in idle

status.

Indicating light of stop

Lighted on under stop

status

It will flash in DC

braking process.

4.1.3 Functional structure of LED seven-segment display