Page 1

7300PA Modbus

Application Manual

TECO Frequency Inverter

7300PA MODBUS Slave

Communication Interface

APPLICATION MANUAL

Page 2

7300PA Modbus

Application Manual

Content

1. INTRODUCTION.................................................................................................................2

2. SPECIFICATION.................................................................................................................2

3. WIRING DIAGRAM.............................................................................................................3

4. INSTALLATION...................................................................................................................3

5. DESCRIPTION OF TERMINAL, LED, DIP SWITCH AND JUMPER..................................4

6. RELATED PARAMETERS FOR MODBUS COMMUNICATION.........................................5

7. CONNECTING INVERTER WITH HOST CONTROLLER...................................................6

8. PROTOCOL FORMAT ........................................................................................................7

9. MESSAGE FORMAT...........................................................................................................9

10. HOLDING REGISTER TAG LIST......................................................................................13

11. ERROR CODE..................................................................................................................24

12. EXAMPLE OF RS-485 COMMUNICA TION APPLICATION .............................................25

1/30

Page 3

7300PA Modbus

Application Manual

1. Introduction

This manual describes freature of PA-M communication card and the communication

methods between TECO frequency inverter 7300PA and host controllers (PC, PLC…)

using PA-M.

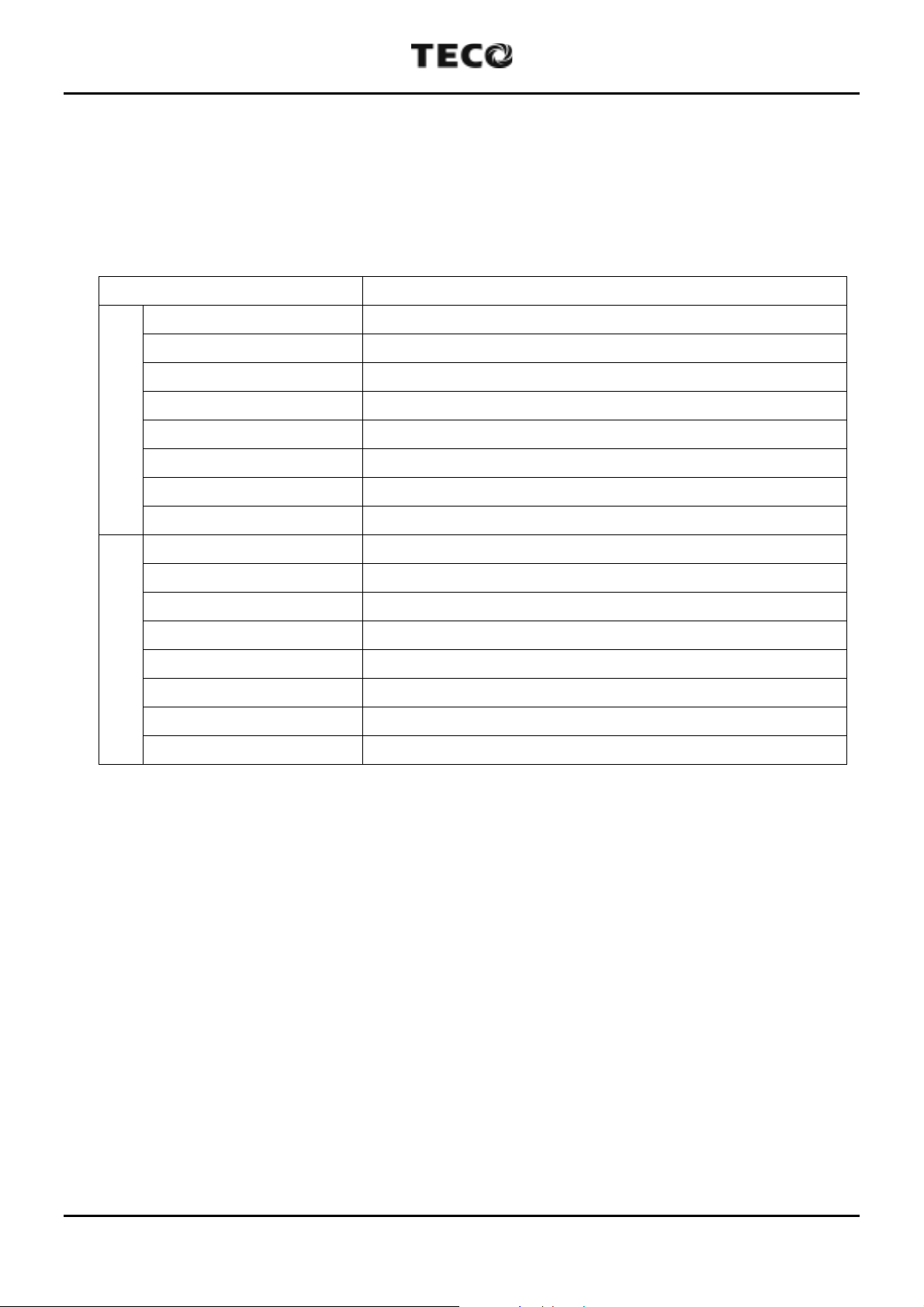

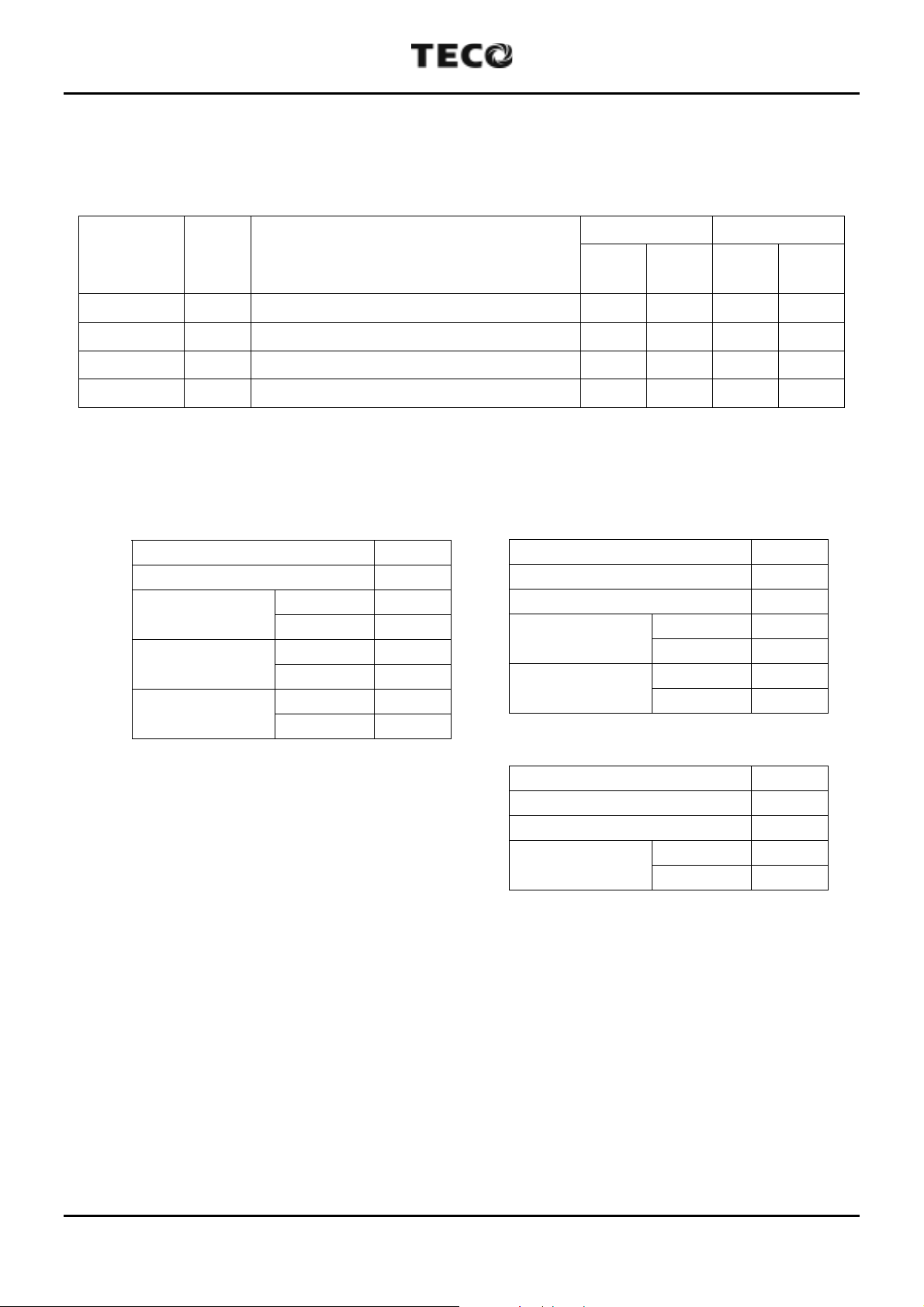

2. Specification

Part No. 4H300D2950006

Serial Interface RS-422/RS-485

Maximum Connection 32 MODBUS (RTU mode) salve standard

Baud Rate 2400/4800/9600/19200 (BPS)

Data Bit 8 Bit

Parity No Parity/Odd Parity /Even Parity

Stop Bit 1 Bit (Odd Parity, Even Parity)/2 Bit (No Parity)

Transmission

Distance (max.) 100m

Mode Half-Duplex

Connection Medium Shielded Twisted Pair Cable

RTS Repeater TTL Level

Photocoupler Isolation Common Mode Rejection VCM = 50V, dV/dt = 5000V/µsec

Error Check Cyclic Redundancy Check (CRC)

Access Data All Parameters of 7300PA

Terminal Resistors Onboard Switch Setting

Product Feature

Communication Status 2 LED Indication

Mechanical Size 64mm x 87mm

2/30

Page 4

7300PA Modbus

Application Manual

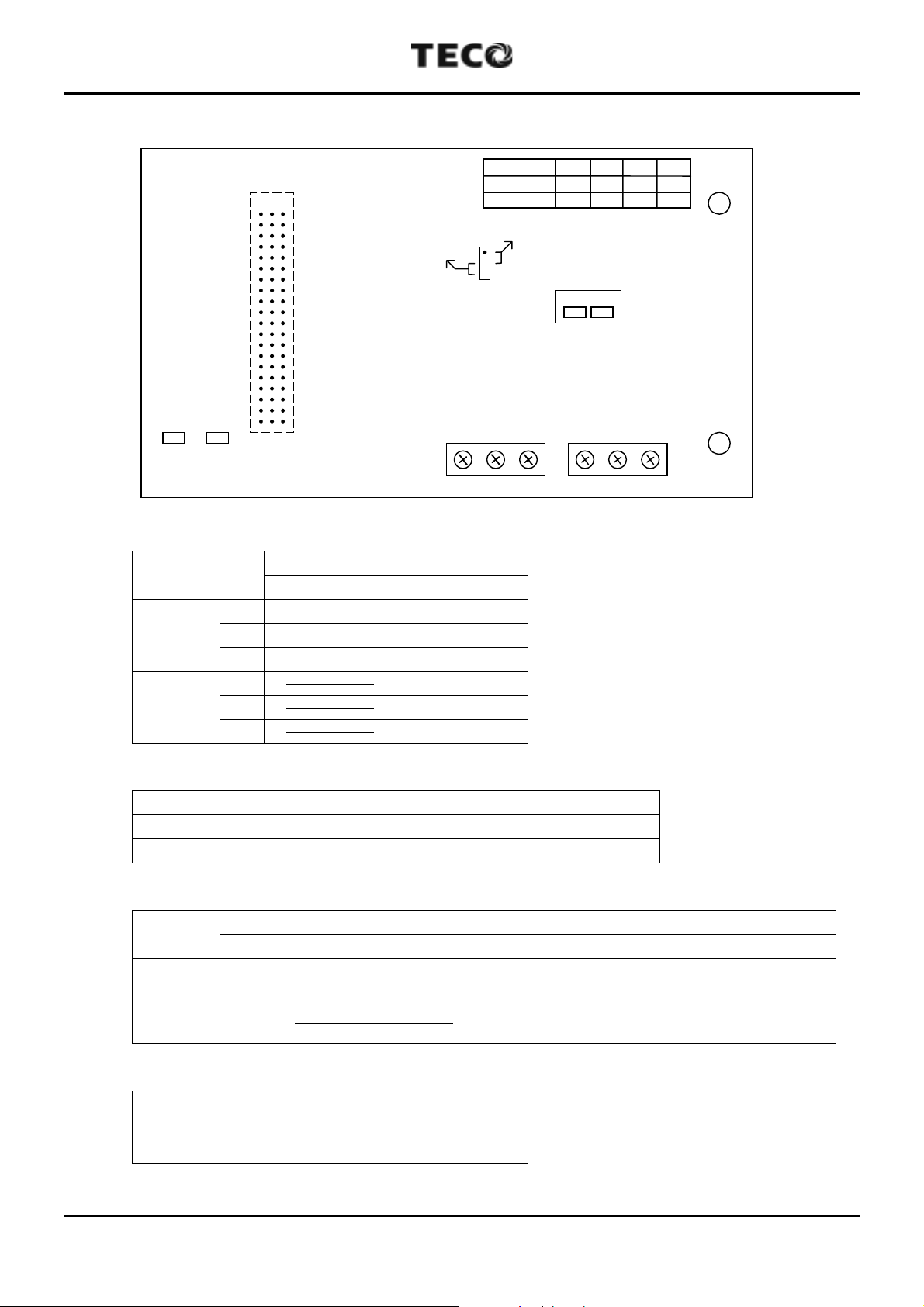

3. Wiring Diagram

(1) RS-485 interface (Set JP1 to "RS-485")

7300 PA

2CN

IM

(2) RS-422 interface (Set JP1 to "RS-422")

7300 PA

2CN

IM

PA-M

JP1

CN1

PA-M

JP1

CN1

RS-485

220

RS-422

220

220

SW1-1

Ω

SW1-1

Ω

SW1-2

Ω

1 (S+)

2 (S

E

1(TX+)

2(TX

E

1(RX+)

2(RX

E

TB1

)

)

-

)

-

P

Twist Pair Cable

TB1

P

TB2

P

Twist Pair Cable

Host Link

Host Link

4. Installation

(1) Turn off the inverter.

(2) Insert attached 2 locking

supports into the 7300PA

control board.

(3) Mount the PA-M commu-

nication interface to the

control board, with the holes

in the right side aligned to

the locking supports, and

the connector CN1 aligned

to 2CN of control board.

CN1 in PA-M

2CN in control

board

Locking

Support

3/30

Page 5

7300PA Modbus

RS-48

Application Manual

5. Description of Terminal, LED, DIP Switch and Jumper

Receive

(1) Terminal

Terminal

TB1

TB2

CN1

5

LED2LED1

Send

TB1 TB2E12 E34

Function

RS-485 RS-422

1S+ TX+

2S

-

TX

E Shield Shield

3 ------------------- RX+

4 ------------------- RX

-

E ------------------- Shield

JP1

RS-485

RS-422

RS-422

1234

S+ S---

TX+ TX-RX+ RX

SW1

-

(2) LED

LED Description

Receive Flash while data are being received from PLC.

Send Flash while data are being sent from PLC.

(3) DIP Switch (ON : enable terminal resistor, OFF : disable terminal resistor)

DIP

Switch

SW1-1

Control terminal resistor between S+

RS-485 RS-422

and S-.

SW1-2 ----------------------------------

Description

Control terminal resistor between

TX+ and TX -.

Control terminal resistor between

RX+ and RX-.

(4) Jumper

Jumper Description

RS-422 RS-422 Communication Interface.

RS-485 RS-485 Communication Interface.

4/30

Page 6

7300PA Modbus

Application Manual

6. Related parameters for MODBUS communication

(1) Node address (*1)

Sn-23 = 1~31 Inverter Node Address (Default = 1)

(2) Baud rate (*1)

Sn-24 = 00

= 01

= 10

= 11

(3) Parity Check (*1)

Sn-24 = --00 No Parity (Default = --00)

=

(4) Stopping Method while RS485 Communication Fault/Alarm.

Sn-08 = 00

= 10

= 11

--

--

--

--

--

01 Even Parity

= --10 Odd Parity

--

=

11 Reserved

--

--

= 01

--

--

2400 BPS

4800 BPS

9600 BPS

19200 BPS (Default = 11--)

Decelerating to stop by Bn-02 (Default = 00--)

Coasting to stop

Decelerating to stop by Bn-04

Continuous operation

(Can be stopped by STOP Key if Sn-05 =

(5) Time-out Check

Cn-31 = 00.0 s Don’t care

= 0.1 - 25.5 Checked Error (Default = 01.0 s)

(6) Source of Run/Stop command and Frequency reference

---

Sn-08 =

=

=

=

(Default =

*1 The change will be effective in the next start time after turning off the inverter.

0 Frequency reference is from RS-485.

---

1 Frequency reference is from Operator or Terminal.

--0-

--1-

Run/Stop command is from RS-485.

Run/Stop command is from Operator or Terminal.

--

11)

---

0)

5/30

Page 7

7300PA Modbus

Application Manual

7. Connecting inverter with host controller

(1) Operation procedure

A. Turn on the inverter, set the related parameters and turn off the inverter.

B. Turn on the inverter again.

C. Connect inverter and host controller.

D. Host controller sends communication message.

(2) Communication status indication of inverter

While Run/Stop command and/or Frequency reference is from RS-485 (Sn-08), and the

inverter does not receive any message from host controller after power on 1 seconds,

the inverter will display "Call" and flash. This message will disappear while inverter has

received messages from host controller.

While Run/Stop command and/or Frequency reference is from RS-485 (Sn-08), the

time-out detection is enabled (Cn-31 <> 0) and the inverter does not receive any

message from host controller in time specified by Cn-31, the inverter will display

"CPF21".

While Run/Stop command and/or Frequency reference is from RS-485 (Sn-08), the

inverter receives any message with incorrect communication format. (Baud rate, parity,

data bit and stop bit) the inverter will display "CPF22".

Bit 2, 3 of parameter Sn-08 will decide the display format and operation of “CPF21",

“CPF22".

= 11

--

--

--

--

Decelerating to stop by Bn-02 (fault “CPF21”/“CPF22” light up)

Coasting to stop (fault “CPF21”/“CPF22” light up)

Decelerating to stop by Bn-04 (fault “CPF21”/“CPF22” light up)

Continuous operation (alarm “CPF21"/"CPF22" flash)

Sn-08 = 00

= 01

= 10

6/30

Page 8

7300PA Modbus

Application Manual

8. Protocol Format

(1) A message of MODBUS RTU mode contains 4 parts: slave address, function code,

data and CRC-16 character. The interval between two messages needs 3.5

characters transferring time.

T1 T2 T3 T4

T1~T4 : 3.5 Characters transferring time at least

(2) Following is the data bit format for MODBUS RTU mode. (LSB will be sent first)

Even/Odd Parity Start 1 2 3 4 5 6 7 8 Parity Stop

No Parity Start 1 2 3 4 5 6 7 8 Stop Stop

(3) Slave Address

Parameter Sn-23 can set the node address of each inverter (1~31). Every slave stand

can receive the message sent from host controller. Only the corresponding one returns

the message to master.

If the slave address of receiving message is 0, all slave stands will execute this

Slave

Address

LSB

Bit0 Bit1 Bit2 Bit3 Bit4 Bit5 Bit6 Bit7 Bit8 Bit9

Function

Code

Data

Character

CRC-16

Character

T1 T2 T3 T4

MSB

Bit10

command and do not return the message to master. This message can only use for

Register 0001H and 0002H.

(4) Function Code

Code Function Note

03H Read Data of Holding Register ------------------06H Write Data to Single Register the Slave Address can be 0

08H Loop Test ------------------10H Write Data to Holding Register the Slave Address can be 0

(5) Data Characters

Detail descriptions will be discussed in "Message Format" section (p.9-12) because it

depends on the function code.

7/30

Page 9

7300PA Modbus

Application Manual

(6) CRC-16 data

CRC-16 Generation Procedure.

A. Load a 16-bit register with FFFFH. Call this the CRC register.

B. Exclusive OR the first 8-bit byte of the message with the low order byte of the 16-bit

CRC registers, putting the result in the CRC register.

C. Shift the CRC register one bit to the right (toward the LSB), zero filling the MSB.

Extract and examine the LSB.

D.If LSB is 0, repeat procedure C (another shift).

If LSB is 1, Exclusive OR the CRC register with the polynomial value A001H.

E. Repeat procedure C, D until eight shifts has been performed.

While this is done, a complete byte will have been processed.

F. Repeat procedure B-E to the following byte of the message until all bytes of the

message is processed.

Now, the value of CRC register is the CRC-16 data.

G. When the CRC is placed into the message, it upper and lower bytes must be

swapped.

(7) Inverter return messages

A. Please refer to the “Message Format” in next page about inverter returning

messages for more detail descriptions.

B. It needs 5ms to return messages after inverter had received normal message from

host controller.

C. In next two cases, inverter does not return any message :

(a) There is any error detected in received data message (parity error, framing error,

overrun error or CRC-16 error).

(b) Slave Address character is different to parameter Sn-36 (Inverter Slave No.).

8/30

Page 10

7300PA Modbus

Application Manual

9. Message Format

7300PA supports 4 MODBUS Function codes only.

Table 1 Message Length

Host Query Inverter Return

Function

Code

Function

Byte

(Min.)

Byte

(Max.)

Byte

(Min.)

Byte

(Max.)

Data Read 03H Read Data from Holding Register 8 8 7 37

Data Write 06H Write Data to Single Holding Register 8 8 8 8

Loop Test 08H Loop Test 8 8 8 8

Data Write 10H Write Data to Holding Register 11 41 8 8

(1) Read Command : Read data of Holding Register

Host Query

Slave Address 01H

Function Code 03H

Head Address

(*1)

Access Count

(*2)

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Low Byte D5H

Inverter Return (Normal)

Slave Address 01H

Function Code 03H

Data Byte Count 02H

Data Value

High Byte 00H

Low Byte 00H

CRC-16

Low Byte B8H

High Byte 44H

High Byte CAH

Inverter Return (Error Detected)

Slave Address 01H

80H + Function Code 83H

Error Code (*3) 03H

CRC-16

Low Byte 01H

High Byte 31H

*1 Refer to p.13-23 to see the holding register tag list.

*2 Host controller can read 16 registers at most in each transferring message.

*3 Refer to p.24 to see the error code.

9/30

Page 11

7300PA Modbus

Application Manual

(2) Write Command : Write Data to Single Holding Register

Host Query

Slave Address (*1) 01H

Function Code 06H

Address (*2)

Data Value

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Low Byte 19H

High Byte CAH

Inverter Return (Normal)

Slave Address 01H

Function Code 06H

Address

Data Value

CRC-16

Inverter Return (Error Detected)

Slave Address 01H

80H + Function Code 86H

Error Code (*3) 01H

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Low Byte 19H

High Byte CAH

Low Byte 83H

High Byte A0H

*1 If slave address is 0 (valid for address 0001H and 0002H only), all slave inverters

will execute this command but do not return message to master.

*2 Refer to p.13-23 to see the holding register tag list.

*3 Refer to p.24 to see the error code.

• Parameters modified will not be saved to EEPROM Automatically. We can save

parameters to EEPROM by writing data to address 0900H.

10/30

Page 12

7300PA Modbus

Application Manual

(3) Loop Test Command (test inverter communication status)

Host Query

Slave Address

Function Code

Test Code

Test Data (*1)

CRC-16

*1 The test data is arbitrary.

High Byte

Low Byte 00H

High Byte

Low Byte 55H

Low Byte

High Byte 94H

01H

08H

00H

AAH

5EH

Inverter Return (Normal)

Slave Address

Function Code

Test Code

Test Data

CRC-16

Inverter Return (Error Detected)

Slave Address

80H + Function Code

Error Code (*2)

CRC-16

High Byte

Low Byte

High Byte

Low Byte

Low Byte

High Byte 94H

Low Byte

High Byte C0H

01H

08H

00H

00H

AAH

55H

5EH

01H

88H

01H

87H

*2 Refer to p.24 to see the error code.

11/30

Page 13

7300PA Modbus

Application Manual

(4) Write Holding Register Command (*4)

Host Query

Slave Address (*1) 01H

Function Code 10H

Head address

(*2)

Access Count

(*3)

Data Byte Count (*4) 02H

Data Value

CRC-16

*1 If the slave address of host query message is 0, all slave inverters will execute this

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Low Byte 67H

High Byte 41H

Inverter Return (Normal)

Slave Address 01H

Function Code 10H

Head address

Access Count

(*1)

CRC-16

Inverter Return (Error Detected)

Slave Address 01H

80H+Function Code 90H

Error Code (*5) 03H

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Low Byte 50H

High Byte 09H

Low Byte 0CH

High Byte 01H

command but do not return message to master.

*2 Refer to p.13-23 to see the holding register tag list.

*3 Host controller can write 16 registers at most in each transferring message.

*4 Data Byte Count = 2 * Access Count.

*5 Refer to p.24 to see the error code.

• Parameters modified will not be saved to EEPROM Automatically. We can save

parameters to EEPROM by writing data to address 0900H.

12/30

Page 14

7300PA Modbus

Application Manual

10. Holding Register Tag List

(1) Control Data Register (Read / Write)

Address

HEX DEC

0001H 1

0002H 2 Frequency Reference (100/1Hz) p.15

0003H 3 Reserved

0004H 4 Reserved

0005H 5 Reserved

0006H 6 Reserved

0007H 7 Reserved

0008H 8 Reserved

0009H 9

000AH 10 Analog Output Command 1 (255/10V) p.15

000BH 11 Analog Output Command 2 (255/10V) p.15

000CH 12 Reserved

000DH 13 Reserved

000EH 14 Reserved

000FH 15 Reserved

Operation

Signals

Multifunction

Output

Command

Function Description

0 RUN Command

1 REV Command

2 External Fault

3 Fault Reset

4 Multifunction Ref 1

5 Multifunction Ref 2

6 Multifunction Ref 3

7 Multifunction Ref 4

8-15 Reserved

0 Relay Output (R2A-R2C) Output

1 Digital Output (DO1) Output

2 Relay Output (R1A-R1C) Output

3-15 Reserved

Ref.

Page

p.14

p.15

*1 Control Data Register can be used for Salve Address '0' write-in message.

13/30

Page 15

7300PA Modbus

Application Manual

Address

HEX DEC

Function Description

0001H 1 Operation Signals

BIT Function Description

2 (*1) 1 : Run (RUN), 0 : Stop (STOP)

2 (*1) 1 : Reverse Run (REV), 0 : Forward Run (FWD)

2 (*2) External Fault (EB) : Invert output OFF, Fault Output ON

3 Fault Reset (RESET)

4 (*3)

5 (*3)

6 (*3)

7 (*3)

Multifunction Ref. 1

(By Sn-15 setting, Initial setting : multi-step speed ref. 1)

Multifunction Ref. 2

(By Sn-16 setting, Initial setting : multi-step speed ref. 2)

Multifunction Ref. 3

(By Sn-17 setting, Initial setting : jogging ref.)

Multifunction Ref. 4

(By Sn-18 setting, Initial setting : external baseblock)

8-15 Reserved

*1 This register becomes effective by setting Sn-08 (run mode selection 5) to --0-.

*2 External baseblock function is OR operation of command from bit 2 (EB) and command by

inverter external terminal

3

. "Emergency stop" is possible by external terminal 3 even

while inverter is running by MODBUS.

*3 Multifunction Ref. 1-4 are OR operation of command from bit 4-7 and command by inverter

external terminals

5-8

.

14/30

Page 16

7300PA Modbus

Application Manual

Address

HEX DEC

0001H 1 Frequency Reference (100/1Hz)

• This register becomes effective by setting Sn-08 (run mode selection 5) to ---0.

Address

HEX DEC

0009H 9 Multifunction Output Command

BIT Function Description

0 1 : R2A-R2C ON, 0 : R2A-R2C OFF

1 1 : DO1 ON, 0 : DO1 OFF

2 1 : R1A-R1C ON, 0 : R1A-R1C OFF

4-15 Reserved

• These bits become effective by setting Sn-20-22 (Sn-20 for bit 0, Sn-21 for bit 1 and Sn-22 for

bit 2) to 15.

Function Description

Function Description

Address

HEX DEC

000AH 10 Analog Output Command 1 (255/10V)

000BH 11 Analog Output Command 2 (255/10V)

• These registers become effective by setting Sn-26-27 (Sn-26 for register 000A, Sn-27 for

register 000B) to 10.

Function Description

15/30

Page 17

7300PA Modbus

Application Manual

(2) Monitor Data Register (Read Only)

Address

HEX DEC

Function Description

0 Running

1 Reverse Running

2 Inverter Ready

3 Major Fault

0020H 32 Status Signals

4 Reserved

5 Relay Output (R2A-R2C) Output

6 Digital Output (DO1) Output

7 Relay Output (R1A-R1C) Output

8-15 Reserved

Overcurrent or Ground Fault

0

(OC, GF)

1 Overvoltage (OV)

2 Inverter Overload (OL1, OL2)

3 Inverter Overheat (OH)

4 Reserved

5 Reserved

0021H 33 Fault Contents

6 Reserved

7 External Fault (EFxx)

8 Control Circuit Fault (CPFxx)

9 Motor Overload (OL3)

10 Reserved

11 Reserved

12 Power Loss or MC defective (UVx)

13-15 Reserved

0022H 34 Reserved

0023H 35 Frequency Reference (100/1Hz)

0024H 36 Output Frequency (100/1Hz)

0025H 37 Reserved

0026H 38 Reserved

0027H 39 Output Current (10/1A)

0028H 40 Output Voltage (1/1V)

0029H 41 Main Speed (VIN+AIN) A/D Converted Value (1023/10V)

002AH 42 AUX. Speed A/D Converted Value (1023/10V)

0 1 : Terminal 1 is close

1 1 : Terminal 2 is close

2 1 : Terminal 3 is close

3 1 : Terminal 4 is close

002BH 43

Digital Input

Terminal Value

4 1 : Terminal 5 is close

5 1 : Terminal

6 1 : Terminal

7 1 : Terminal

6

7

8

is close

is close

is close

8-15 Reserved

Ref.

Page

p.18

p.18

16/30

Page 18

7300PA Modbus

Application Manual

Address

HEX DEC

002CH 44 Inverter Status

002DH 45

002EH 46 Reserved

002FH 47 Reserved

0030H 48 Reserved

0031H 49 Main Circuit DC Voltage (1/1V)

0032H 50 Reserved

0033H 51 Reserved

0034H 52 Reserved

0035H 53 Reserved

0036H 54 Reserved

0037H 55 Reserved

0038H 56 Reserved

0039H 57 Reserved

003AH 58 Reserved

003BH 59 Reserved

003CH 60 Reserved

003DH 61 Reserved

003EH 62 Reserved

003FH 63 Reserved

Digital Output

Terminal Value

Function Description

0 Running

1 During Zero Speed

2 During Frequency Coincidence

3 Arbitrary Frequency Coincidence

4 Frequency Detection 1

5 Frequency Detection 2

6 Inverter Ready

7 Undervoltage Detecting

8 Output Baseblock

9 Frequency Reference Mode

10 Run Command Mode

11 Overtorque Detection

12 Frequency Reference Missing

13 Reserved

14 Major Fault

15 Reserved

0 1 : R2A-R2C ON

1 1 : DO1-DCOM ON

2 1 : R1A-R1C ON

3-15 Reserved

Ref.

Page

p.19

17/30

Page 19

7300PA Modbus

Application Manual

Address

HEX DEC

Function Description

0020H 32 Status Signals

BIT Function Description

0 1 : Running, 0 : Stop

1 1 : Reverse Run, 0 : Forward Run

2 1 : Inverter Operation Ready (*1)

3 1 : Major Fault (Except CPF00, CPF01)

4 Reserved

5

6

7

Multifunction Output 1 (R2A-R2C)

(By Sn-20 setting. Default setting : during running)

Multifunction Output 2 (DO1-DCOM)

(By Sn-21 setting, Default setting : zero speed)

Multifunction Output 3 (R1A-R1C)

(By Sn-22 setting, Default setting : agreed frequency)

8-15 Reserved

*1 This bit will be set to 1 when the inverter is in the DRIVE mode and there is no alarm, fault or

baseblock.

Address

HEX DEC

0021H 33 Fault Contents

BIT Function Description

0 Overcurrent (OC) or Ground Fault (GF)

1 Overvoltage (OV)

2 Inverter Overload (OL1, OL2)

3 Inverter Overheat (OH)

4-6 Reserved

7 External Fault (EF3, EF5, EF6, EF7, EF8)

Control Circuit Fault (CPF02)

8

EEPROM fault (CPF03)

EEPROM BCC CODE Error (CPF04)

CPU ADC Fault (CPF05)

9 Motor Overload (OL3)

10-11 Reserved

Main circuit low voltage or momentary power loss

12

protection (UV1)

Control circuit low voltage (UV2)

Man circuit soft charge contactor defective (UV3)

13-15 Reserved

Function Description

18/30

Page 20

7300PA Modbus

Application Manual

Address

HEX DEC

002CH 44 Inverter Status

BIT Function Description

0 1 : Running

1 1 : During Zero Speed

1 : During Frequency Coincidence

2

3

4

5

6 1 : Inverter Operation Ready (*2)

7 1 : Undervoltage Detecting

8 1 : Output Baseblock

9

10

11

12 1 : Frequency Reference is Missing

13 Reserved

14 1 : Major Fault (Except CPF00, CPF01)

15 Reserved

Freq. Ref -

(

Cn-22

1 : Arbitrary Frequency Coincidence

Frequency Coincidence and

(Cn-21 - Cn-22) < Output Freq. <

1 : Frequency Detection 1

Output Freq. > Cn-21 (*1)

1 : Frequency Detection 2

Output Freq. < Cn-21 (*1)

0 : Frequency Reference is from RS-485.

1 : Frequency Reference is from Operator or terminal.

0 : RUN/STOP Command is from RS-485.

1 : RUN/STOP Command is from Operator or terminal.

1 : Overtorque Detection

(Detection Level : Cn-26, Detection Time : Cn-27)

Function Description

< Output Freq. <

)

Freq. Ref +

(

Cn-22

(Cn-21 + Cn-22)

)

*1

Cn-22

Output

Frequency

Frequency

Detection 1

*2 This bit will be set to 1 when the inverter is in the DRIVE mode and there is no alarm, fault or

baseblock.

1

0

Cn-21

1

Cn-22

Output

Frequency

Frequency

Detection 2

Cn-21

0

1

0

19/30

Page 21

7300PA Modbus

Application Manual

(3) Inverter Parameter Register (An, Bn : Read/Write, Others : Read Only)

Address Parameter

HEX DEC No. Description Unit

System Parameters Sn

0101H 257 Sn-01 Inverter Capacity Selection

0102H 258 Sn-02 V/f Curve Selection

0103H 259 Sn-03 Operation Status

0104H 260 Sn-04 Operation Mode Select 1

0105H 261 Sn-05 Operation Mode Selection 2

0106H 262 Sn-06 Operation Mode Selection 3

0107H 263 Sn-07 Operation Mode Selection 4

0108H 264 Sn-08 Operation Mode Selection 5

0109H 265 Sn-09 Operation Mode Selection 6

010AH 266 Sn-10 Protective Characteristic Selection 1

010BH 267 Sn-11 Protective Characteristic Selection 2

010CH 268 Sn-12 Protective Characteristic Selection 3

010DH 269 Sn-13 Protective Characteristic Selection 4

010EH 270 Sn-14 Protective Characteristic Selection 5

010FH 271 Sn-15 Terminal

0110H 272 Sn-16 Terminal

0111H 273 Sn-17 Terminal

0112H 274 Sn-18 Terminal

5

6

7

8

Function

Function

Function

Function

0113H 275 Sn-19 Terminal AUX Function

0114H 276 Sn-20 Terminal R2A-R2C Function

0115H 277 Sn-21 Terminal D01 Function

0116H 278 Sn-22 Terminal R1A Function

0117H 279 Sn-23 Inverter station address

0118H 280 Sn-24 RS-485 communication protocol setting

0119H 281 Sn-25 LCD Language displayed selection

011AH 282 Sn-26 Multi-Function Analog Output A01 Function Selection

011BH 283 Sn-27 Multi-Function Analog Output A02 Function Selection

011CH 284

011DH 285

-

-

Reserved

Reserved

011EH 286 Sn-30 Pump Operation Mode Selection

011FH 287 Sn-31 PA-PID Card Relay 2 Control

0120H 288 Sn-32 PA-PID Card Relay 3 Control

0121H 289 Sn-33 PA-PID Card Relay 4 Control

0122H 290 Sn-34 PA-PID Card Relay 5 Control

0123H 291 Sn-35 PA-PID Card Relay 6 Control

0124H 292 Sn-36 PA-PID Card Relay 7 Control

0125H 293 Sn-37 PA-PID Card Relay 8 Control

0126H 294 Sn-38 Parameter copy

Notes

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

20/30

Page 22

7300PA Modbus

Application Manual

Address Parameter

HEX DEC No. Description Unit

Control Parameters Cn

0200H 512 Cn-01 Input Voltage 0.1V

0201H 513 Cn-02 Max. Output Frequency 0.1Hz

0202H 514 Cn-03 Max. Output Voltage 0.1V

0203H 515 Cn-04 Max. Voltage Frequency 0.1Hz

0204H 516 Cn-05 Middle Output Frequency 0.1Hz

0205H 517 Cn-06 Voltage At Middle Output Frequency 0.1V

0206H 518 Cn-07 Min Output Frequency 0.1Hz

0207H 519 Cn-08 Voltage At Min. Output Frequency 0.1V

0208H 520 Cn-09 Motor Rated Current 0.1A

0209H 521 Cn-10 DC Injection Braking Starting Frequency 0.1Hz

020AH 522 Cn-11 DC Braking Current 1%

020BH 523 Cn-12 DC Injection Braking Time At Stop 0.1s

020CH 524 Cn-13 DC Injection Braking Time At Start 0.1s

020DH 525 Cn-14 Frequency Command Upper Bound 1%

020EH 526 Cn-15 Frequency Command Lower Bound 1%

020FH 527 Cn-16 Frequency Jump Point 1 0.1Hz

0210H 528 Cn-17 Frequency Jump Point 2 0.1Hz

0211H 529 Cn-18 Frequency Jump Point 3 0.1Hz

0212H 530 Cn-19 Jump Frequency Width 0.1Hz

0213H 531 Cn-20 Digital Operator Display Unit 1

0214H 532 Cn-21 Frequency Agree Detection Level 0.1Hz

0215H 533 Cn-22 Frequency Agree Detection Width 0.1Hz

0216H 534 Cn-23 Carrier Frequency Upper Limit 0.1KHz

0217H 535 Cn-24 Carrier Frequency Lower Limit 0.1KHz

0218H 536 Cn-25 Carrier Frequency proportion Gain 1

0219H 537 Cn-26 Overtorque Detection Level 1%

021AH 538 Cn-27 Overtorque Detection Time 0.1s

021BH 539 Cn-28 Stall Prevention Level During Acceleration 1%

021CH 540

021DH 541 Cn-30 Stall Prevention Level During Running 1%

021EH 542 Cn-31 Communication Fault Detection Time 0.1s

021FH 543 Cn-32 Frequency Detection 1 Level 0.1Hz

0220H 544 Cn-32 Frequency Detection 2 Level 0.1Hz

0221H 545

0222H 546

0223H 547 Cn-36 Number of Auto Restart Attempt 1

0224H 548 Cn-37 Power Loss Ride-through Time 0.1s

0225H 549 Cn-38 Speed Search Detection Level 1%

0226H 550 Cn-39 Speed Search Time 0.1s

0227H 551 Cn-40 Min. Baseblock Time 0.1s

0228H 552 Cn-41 V/F Curve in Speed Search 1%

0229H 553 Cn-42 Voltage Recovery Time 0.1s

022AH 554 Cn-43 PID Integral Upper Bound 1%

-

-

-

Reserved

Reserved

Reserved

-

-

-

Notes

21/30

Page 23

7300PA Modbus

Application Manual

Address Parameter

HEX DEC No. Description Unit

022BH 555 Cn-44 PID Primary Delay Time Constant 0.1s

022CH 556 Cn-45 Energy-Saving Volt. Upper Limit (60Hz) 1%

022DH 557 Cn-46 Energy-Saving Volt. Upper Limit (6Hz) 1%

022EH 558 Cn-47 Energy-Saving Volt. Lower Limit (60Hz) 1%

022FH 559 Cn-48 Energy-Saving Volt. Lower Limit (6Hz) 1%

0230H 560 Cn-49 Tuning Operation Voltage Limit 1%

0231H 561 Cn-50 Tuning Operation Control Cycle 0.1s

0232H 562 Cn-51 Tuning Operation Volt. Step (100% output Volt) 0.10%

0233H 563 Cn-52 Tuning Operation Volt. Step (5% output Volt) 0.10%

0234H 564

0235H 565

0236H 566

0237H 567

0238H 568

0239H 569 Cn-58 Energy-Saving Coefficient K2 (60Hz) 0.01

023AH 570 Cn-59 Energy-Saving Coefficient Reduction ratio (6Hz) 1%

023BH 571 Cn-60 Motor Code

023CH 572

023DH 573 Cn-62 Auto Restart Time Interval 1s

023EH 574 Cn-63 Motor Overheat protection time 1s

Order Parameters On

0300H 768 On-01 Control Status 1

0301H 769 On-02 Control Status 2

0302H 770 On-03 Control Status 3

0303H 771

0304H 772

0305H 773

0306H 774 On-07 Hunting Prevention gain 0.01

0307H 775 On-08 Hunting Prevention limit 1%

0308H 776 On-09 Effective current detection filter time constant 1(3.5ms)

0309H 777

030AH 778 On-11 ON-DELAY TIME 1(0.25µs)

030BH 779 On-12 ON-DELAY Compensated value 1(0.25µs)

030CH 780

030DH 781

030EH 782 On-15 Power detection filter changing width 1%

030FH 783 On-16 Power detection filter time constant 1(7ms)

0310H 784 On-17 Motor phase to phase resistance 0.001Ω

0311H 785 On-18 Torque Compensation of care loss 1W

0312H 786 On-19 Torque Compensation limit 1V

0313H 787 On-20 Motor Constant R1 0.001Ω *1

0314H 788 On-21 Motor Constant R2 0.001Ω *1

0315H 789 On-22 Motor Constant L 0.001mH *1

0316H 790 On-23 Motor Constant Rm 0.001mΩ/ω *1

0317H 791 On-24 Motor Constant Lm 0.01mH *1

-

-

-

-

-

-

-

-

-

-

-

-

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Notes

22/30

Page 24

7300PA Modbus

Application Manual

Address Parameter

HEX DEC No. Description Unit

Frequency Command An

0400H 1024 An-01 Frequency Command 1 0.01Hz *2

0401H 1025 An-02 Frequency Command 2 0.01Hz *2

0402H 1026 An-03 Frequency Command 3 0.01Hz *2

0403H 1027 An-04 Frequency Command 4 0.01Hz *2

0404H 1028 An-05 Frequency Command 5 0.01Hz *2

0405H 1029 An-06 Frequency Command 6 0.01Hz *2

0406H 1030 An-07 Frequency Command 7 0.01Hz *2

0407H 1031 An-08 Frequency Command 8 0.01Hz *2

0408H 1032 An-09 Jog Frequency Command 0.01Hz *2

Parameters Groups Can Be Changed during Running Bn

0500H 1280 Bn-01 Acceleration Time 1 0.1s *2

0501H 1281 Bn-02 Deceleration Time 1 0.1s *2

0502H 1282 Bn-03 Acceleration Time 2 0.1s *2

0503H 1283 Bn-04 Deceleration Time 2 0.1s *2

0504H 1284 Bn-05 Analog Frequency Cmd. Gain 0.10% *2

0505H 1285 Bn-06 Analog Frequency Cmd. Bias 0.10% *2

0506H 1286 Bn-07 Auto torque Boost Gain 0.1 *2

0507H 1287 Bn-08 Multi-Function Analog Output A01 Bias 0% *2

0508H 1288 Bn-09 Multi-Function Analog Output A02 Bias 0.10% *2

0509H 1289 Bn-10 Monitor No. After power ON

050AH 1290 Bn-11 Multi-Function Analog Output A01 Gain 1% *2

050BH 1291 Bn-12 Multi-Function Analog Output A02 Gain 0.01 *2

050CH 1292 Bn-13 PID Detection Gain 0.01 *2

050DH 1293 Bn-14 PID Proportional Gain 10% *2

050EH 1294 Bn-15 PID Integral Gain 0.1s *2

050FH 1295 Bn-16 PID Differential Time 0.01s *2

0510H 1296 Bn-17 PID Bias 1% *2

0511H 1297 Bn-18 PID sleep Frequency 0.01Hz *2

0512H 1298 Bn-19 PID sleep/Wake-up Delay Time 0.1s *2

0513H 1299 Bn-20 PID Wake Up Frequency 0.01Hz *2

0514H 1300 Bn-21 PID Detected Value Display Bias 0.001 *2

0515H 1301 Bn-22 PID Detected Value Display Gain 0.001 *2

0516H 1302 Bn-23 F req. Command Upper-Bound Delay Time 1s *2

0517H 1303 Bn-24 F req. Command Lower-Bound Delay Time 1s *2

0518H 1304 Bn-25 MC ON/OFF Delay Time 0.01s *2

0519H 1305 Bn-26 Pump ON/OFF Detection Level 0.1% *2

Enter Command

900H 2304 Save An, Bn, Sn and Cn to EEPROM.

-

-

Notes

*2

*3

*1 These parameters can not be saved to EEPROM.

*2 These parameters can be written in DRV mode or PRG mode.

*3 Writing data 0000H to this address in PRG mode can save parameter (except On-20 - 24) to

EEPROM.

• All parameters can be read in PRG mode or DRV mode, and parameters without note *1 can

be written in PRG mode only.

23/30

Page 25

7300PA Modbus

Application Manual

11. Error Code

Code Description Possible Cause

00H CRC Code Error CRC Word (High or Low Byte) Error

01H Function Code Error Function code is not 03H, 06H, 08H or 10H.

02H Register Address Error

03H Access Count Error

21H Register Write Error

22H Data Value Error Data value is out of range in writing message.

Not Response UART Error Parity, Overrun, Frame error.

Not Response Data Format Error

Register address is not in the range that can be

accessed.

The Access Count is more than 16.

"Access Count" in writing command (10H) does

not match the amount of actual data.

Write Cn ,Sn or On parameter during DRIVE

mode

Data string is not correct. (Incomplete Message,

"Data Byte Count" in writing command (10H)

does not match the amount of actual data.)

24/30

Page 26

7300PA Modbus

Application Manual

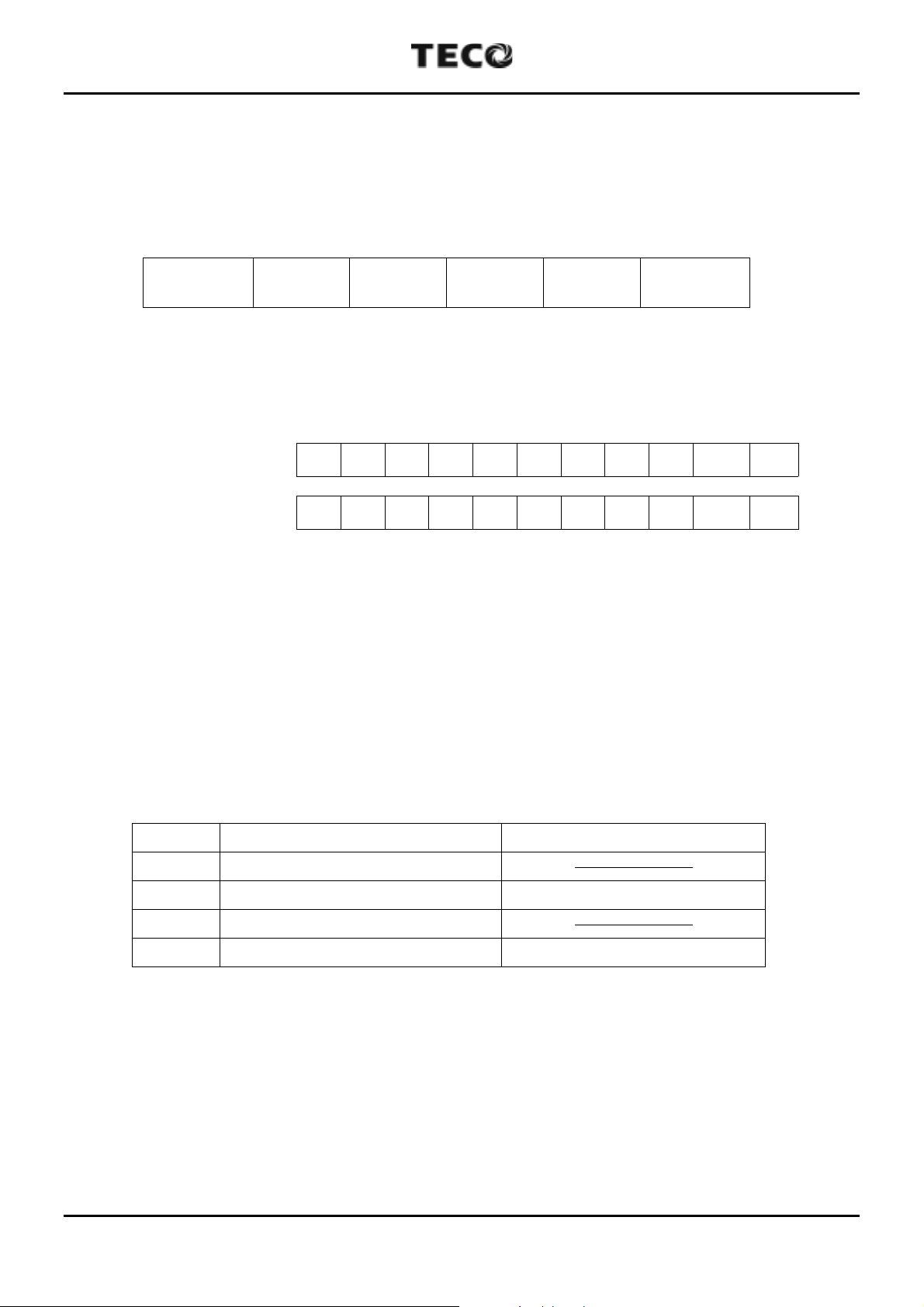

12. Example of RS-485 Communication Application

Host Controller can control the inverter 7300PA via RS-485 serial communication and let the

inverter operating as following

Output

Frequency (Hz)

60

30

FWD

-30

REV

Digital Output

DO1-DCOM

ON

OFF

Digital Output

R1A-R1C

Step 1

ON

OFF

Step 2 Step 3 Step 4

(1) Run 7300PA forward with 60Hz. Set DO1-DCOM.

(2) Run 7300PA forward with 30Hz. Clear DO1-DCOM. Set R1A-R1C.

(3) Run 7300PA reverse with 30Hz. Set R1A-R1C.

(4) Stop 7300PA. Set R1A-R1C.

25/30

Page 27

7300PA Modbus

Application Manual

(1) Set inverter parameters

Sn-23 = 1 (Inverter Slave Address), Sn-24

Cn-31 = 0.0s (Disable time-out check)

Sn-08 = 1100

--

(11

(

: Continue Running while RS-485 communication fault occurs)

--

00 : Run/Stop and frequency reference from RS-485)

Sn-21 = 0F (DO1-DCOM Output Reserved), Sn-22 = 0F (R1A-R1C Output Reserved)

(2) Turn off the inverter and turn it on again (For Sn-23 and Sn-24 are modified). and

program host controller to operate in step 1-4 and desired operation can be done by

inverter.

26/30

Page 28

7300PA Modbus

Application Manual

Step 1 : Run 7300PA forward with 60Hz. Set DO1-DCOM.

Host Query

Slave Address 01H

Function Code 10H

Head Address

Access Count

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 09H

Data Byte Count 12H

Data Value 1

Data Value 2

Data Value 3

Data Value 4

Data Value 5

Data Value 6

Data Value 7

Data Value 8

Data Value 9

CRC-16

High Byte 00H

Low Byte 01H

High Byte 17H

Low Byte 70H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 02H

Low Byte B1H

High Byte 2BH

Inverter Return

Slave Address 01H

Function Code 10H

Head Address

Access Count

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 09H

Low Byte 51H

High Byte CFH

Data Value 1 of Address 0001H = 0001H : Run 7300PA Forward.

Data Value 2 of Address 0002H = 1770H : Speed Reference 60.00Hz.

Data Value 9 of Address 0009H = 0002H : Set DO1-DCOM.

• When Inverter received this message , it will start, accelerate to 60Hz in forward direction

and set digital output terminal DO1-DCOM.

27/30

Page 29

7300PA Modbus

Application Manual

Step 2 : Run 7300PA forward with 50% Speed. Clear DO1-DCOM. Set RA-RB-RC.

Host Query

Slave Address 01H

Function Code 10H

Head Address

Access Count

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 09H

Data Byte Count 12H

Data Value 1

Data Value 2

Data Value 3

Data Value 4

Data Value 5

Data Value 6

Data Value 7

Data Value 8

Data Value 9

CRC-16

High Byte 00H

Low Byte 01H

High Byte 0BH

Low Byte B8H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 04H

Low Byte F1H

High Byte B6H

Inverter Return

Slave Address 01H

Function Code 10H

Head Address

Access Count

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 09H

Low Byte 51H

High Byte CFH

Data Value 1 of Address 0001H = 0001H : Run 7300PA Forward.

Data Value 2 of Address 0002H = 0BB8H : Speed Reference 30.00Hz.

Data Value 9 of Address 0009H = 0004H : Set R1A-R1C. Clear DO1-DCOM.

• When Inverter received this message, it will decelerate to 30.00Hz in forward direction,

clear the digital output terminal DO1-DCOM and set the digital output R1A-R1C.

28/30

Page 30

7300PA Modbus

Application Manual

Step 3 : Run 7300PA reverse with 50% Speed. Set RA-RB-RC.

Host Query

Slave Address 01H

Function Code 10H

Head Address

Access Count

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 09H

Data Byte Count 12H

Data Value 1

Data Value 2

Data Value 3

Data Value 4

Data Value 5

Data Value 6

Data Value 7

Data Value 8

Data Value 9

CRC-16

High Byte 00H

Low Byte 03H

High Byte 0BH

Low Byte B8H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 00H

High Byte 00H

Low Byte 04H

Low Byte 50H

High Byte D6H

Inverter Return

Slave Address 01H

Function Code 10H

Head Address

Access Count

CRC-16

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 09H

Low Byte 51H

High Byte CFH

Data Value 1 of Address 0001 = 0003H : Run 7300PA Reverse.

Data Value 2 of Address 0002 = 0BB8H : Speed Reference 30.00Hz

Data Value 9 of Address 0009 = 0004H : Set R1A-R1C.

• When Inverter received this message, it will run at 30.00 Hz in reverse direction, clear

the digital output terminal DO1-DCOM and set the digital output R1A-R1C.

29/30

Page 31

7300PA Modbus

Application Manual

Step 4 : Stop 7300PA. Set R1A-R1C.

Host Query

Slave Address 01H

Function Code 10H

Head Address

Access Count

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Data Byte Count 02H

Data Value 1

CRC-16

High Byte 00H

Low Byte 00H

Low Byte A7H

High Byte 81H

Head Address

Access Count

CRC-16

Inverter Return

Slave Address 01H

Function Code 10H

High Byte 00H

Low Byte 01H

High Byte 00H

Low Byte 01H

Low Byte 50H

High Byte 09H

Data Value1 of Address 0000H = 0000H : Stop 7300PA.

• When inverter received this message, it will stop and decelerate to zero speed, digital

output terminal DO1-DCOM and R1A-R1C do not change their status.

30/30

Loading...

Loading...