Page 1

Automotive Equipment

Instruction Manual

EN

TYRE CHANGERS

TECO 22 - TECO 23

TECO 25 - TECO 27 Special

Version 2.2 - April 2016

Page 2

2 User’s manual - TECO 22 - 23 - 25 - 27 Special

Elaborazione graca e impaginazione

Ufcio Pubblicazioni Tecniche

I

diritti di traduzione, di memorizzazione elettronica, di

riproduzione e di adattamento totale o parziale con qualsiasi

mezzo (compresi microlm e copie fotostatiche) sono riservati.

Le informazioni contenute in questo manuale sono soggette a

variazioni senza preavviso.

A

ll rights of total or partial translation, electronic storage,

reproduction and adaptation by any means (including

microlm and photocopies) are reserved.

The information in this manual is subject to variation without

notice.

L

es droits de traduction, de mémorisation électronique, de

reproduction et d’adaptation totale ou partielle par n’importe

quel moyen (y compris microlms et copies photostatiques)

sont réservés.

Les informations contenues dans ce manuel sont sujettes à

des variations sans préavis.

A

lle Rechte der Übersetzung, elektronischen Speicherung,

Vervielfältigung und Teil- oder Gesamtanpassung unter

Verwendung von Mitteln jedweder Art (einschließlich Mikrolm

und fotostatische Kopien) sind vorbehalten.

Die im vorliegenden Handbuch enthaltenen Informationen

können jederzeit ohne Vorankündigung geändert werden.

Q

uedan reservados los derechos de traducción, de memori-

zación electrónica, de reproducción y de adaptación total o

parcial con cualquier medio (incluidos microlmes y fotocopias).

Las informaciones que se incluyen en este manual están sujetas

a variaciones sin aviso previo.

English

Italiano

Español

Deutsch

Français

Page 3

User’s manual - TECO 22 - 23 - 25 - 27 Special 3

ORIGINAL INSTRUCTIONS

CONTENTS

INTRODUCTION .............................................................................................4

TRANSPORT, STORAGE AND HANDLING ................................................... 5

UNPACKING/ASSEMBLY ...............................................................................6

HOISTING/HANDLING ....................................................................................6

INSTALLATION ...............................................................................................7

ELECTRICAL AND PNEUMATIC CONNECTIONS .........................................8

SAFETY REGULATIONS ................................................................................9

DESCRIPTION ..............................................................................................10

MANUFACTURER’S LABEL .........................................................................10

TECHNICAL DATA ....................................................................................... 11

STANDARD ACCESSORIES ........................................................................12

ACCESSORIES SUPPLIED ON DEMAND ...................................................12

SPECIFIED CONDITIONS OF USE ..............................................................12

MAIN OPERATING PARTS ........................................................................... 13

WARNING SIGNALS .....................................................................................15

PRACTICAL HINTS .......................................................................................16

USE ............................................................................................................... 17

DEMONTAGE ................................................................................................ 18

MONTAGE ..................................................................................................... 19

INFLATION ....................................................................................................20

MAINTENANCE ............................................................................................ 21

ENVIRONMENTAL INFORMATION ..............................................................24

INFORMATION AND WARNINGS ABOUT OIL .............................................25

RECOMMENDED FIRE-EXTINGUISHING DEVICES ..................................26

GLOSSARY ...................................................................................................27

TROUBLE SHOOTING ................................................................................. 27

ELECTRICAL SYSTEM DIAGRAM ...............................................................28

PNEUMATIC SYSTEM DIAGRAM ................................................................31

Page 4

4 User’s manual - TECO 22 - 23 - 25 - 27 Special

INTRODUCTION

The purpose of this manual is to furnish the owner and operator with a set of practical, safe instructions on the use and maintenance of the TECO tyre changer.

Follow all the instructions carefully and the machine will give you the efcient and long-lasting service

that has always characterized TECO products, making your work considerably easier.

The following points dene the levels of danger regarding the machine, associated with the warning

captions found in this manual:

DANGER

Refers to immediate danger with the risk of serious injury or even death.

WARNING

Dangers or unsafe procedures that can cause serious injury or even death.

CAUTION

Dangers or unsafe procedures that can cause minor injuries or damage to property.

Read these instructions carefully before powering up the machine. Keep this manual and all illustrative

material supplied with the machine in a folder near the tyre changer where it is readily accessible for

consultation by the machine operators.

The technical documentation supplied is considered an integral part of the machine; and must always

accompany the equipment if it is sold or transferred to a new owner.

The manual is only to be considered valid for the model with the serial number indicated on the

nameplate applied to it.

WARNING

Observe the contents of this manual: the producer declines all liability in the case of uses of

the machine not specically described and authorized in this manual.

WARNING

This machine must be used only by qualied and authorized personnel. A qualied operator

is construed as a person who has read and understood the tyre changer manufacturer’s

instructions as well as the tyres and wheel rims manufacturers’, is suitably trained, and is

conversant with safety and adjustment procedures to be adhered to during operations. Use

of the machine by unskilled staff may constitute a serious risk for the operator and for the

nal user of the product processed (the wheel rim and tyre assembly).

NB:

Some of the illustrations in this manual have been taken from photographs of prototypes: standard

production machines may vary in some respects.

These instructions are intended for people with basic mechanical skills. We have therefore omitted

detailed descriptions of procedures such as how to loosen or tighten the xing devices on the machine. Do not attempt to perform operations unless properly qualied and with suitable experience.

In case of need, contact an authorized Service Centre for assistance.

Page 5

User’s manual - TECO 22 - 23 - 25 - 27 Special 5

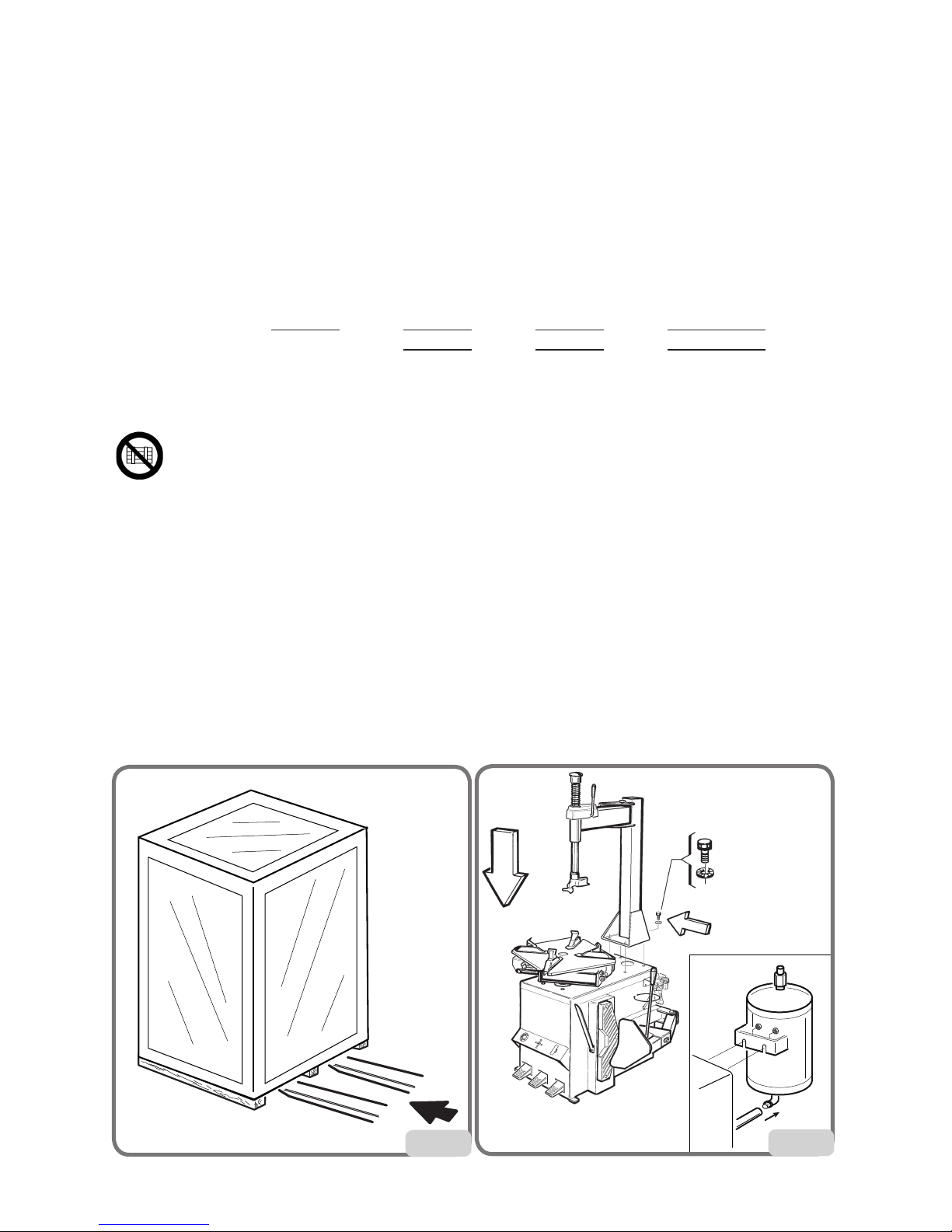

TRANSPORT, STORAGE AND HANDLING

Conditions for transporting the machine

The tyre changer must be transported in its original packing and stowed in the position shown on

the external packing.

- Packing dimensions (Teco 22 - 23 - 25 - 27 Sp.):

• width ................................................................................................................................765 mm

• depth ...............................................................................................................................980 mm

• height ...............................................................................................................................970 mm

- Weight of the machine with packing (Teco 22 - 23 - 25 - 27):

• standard ............ (TECO 22: 170kg; TECO 23: 183kg; TECO 25: 193kg; TECO 27 Sp.: 200kg)

• t.i. version ......................................(TECO 23: 198kg; TECO 25: 208kg; TECO 27 Sp.: 215kg)

Ambient conditions for machine transport and storage

Temperature: -25° ÷ +55°C.

WARNING

Do not stack other goods on top of the packing to avoid damaging it.

Handling

To move the packing, insert the tines of a fork-lift truck into the slots on the base of the packing itself

(pallet) (g. 1).

ATTENTION

Carry out the moving operations with great care, paying attention to move the packaged machine

only from the side clearly indicated on the packaging.

Failure to follow these recommendations may result in damage to the machine and put the operator’s

safety at risk.

Before moving the machine, refer to the HOISTING/HANDLING section.

1

1a

Page 6

6 User’s manual - TECO 22 - 23 - 25 - 27 Special

UNPACKING/ASSEMBLY

WARNING

Take utmost care when unpacking, assembling, hoisting and installing the machine as described

in this heading.

Keep the original packing in good conditions to be used if the equipment has to be shipped in the

future and make sure that the machine has not suffered damage in transit.

Failure to comply with these instruction may damage the machine and risk the operator’s safety.

Remove the upper part of the packing.

Proceed with the following operations:

- Remove the tower (horizontal + vertical arms) from their position on the pallet.

- Fit the tower into the threaded holes.

- Fasten the tower on the machine’s body with the screw; do not forget to interpose the not ched

washers wihch allow the electric continuity of the machine.

- Assemble the bead breaker with the proper pin and fasten it with the locknut until there is a slight

resistance in the rotation of the bead breaker.

- Connect the tank union to the air connection pipeline provided, securing it with a band clamp.

Fix the air tank to the machine (g.1a).(T.I. version only).

HOISTING/HANDLING

To remove the machine from the pallet :

Lift the machine sideways enough to insert the forks of the fork-lift truck between the machine and

the pallet as showed in g.2.

At this point is possible to release the working arm removing the cord which binds the arm to the

turntable.This hoisting point must be used whenever you need to change the installation position of

the machine. Do not attempt to move the machine until it has been disconnected from the electricity

and compressed air supply systems.

2

®

3

800

800

700

®

Page 7

User’s manual - TECO 22 - 23 - 25 - 27 Special 7

INSTALLATION CLEARANCES

WARNING

The installation site must be chosen in strict compliance with the relevant regulations regarding

Safety in the workplace.

IMPORTANT: for correct, safe use of the equipment, users must ensure a lighting level of at least

300 lux in the place of use.

CAUTION

The installation of the machine must be performed in a dry area which must be protected

from adverse weather conditions.

Install the tyre changer in the chosen work position, complying with the minimum clearances shown

in g. 3, adjust the height of the bead breaking support foot so that the machine is correctly positioned on the ooring.

Place the machine so that the plug-socket combination is easily accessible.

The machine must be placed on a horizontal surface, preferably concrete or tiled oor. Do not install

on unstable or damaged surfaces.

The surface on which the machine rests must withstand the loads transmitted during operation. The

surface must have a load-carrying capacity of at least 500 kg/m2.

Ambient working conditions

- Relative humidity 50% (temp. 40°C) ÷ 90% (temp. 20°C) without condensation.

- Temperature 5°C ÷ 40°C.

WARNING

Use of the machine in a potentially explosive atmosphere is not permitted.

A

B

5

4

®

Page 8

8 User’s manual - TECO 22 - 23 - 25 - 27 Special

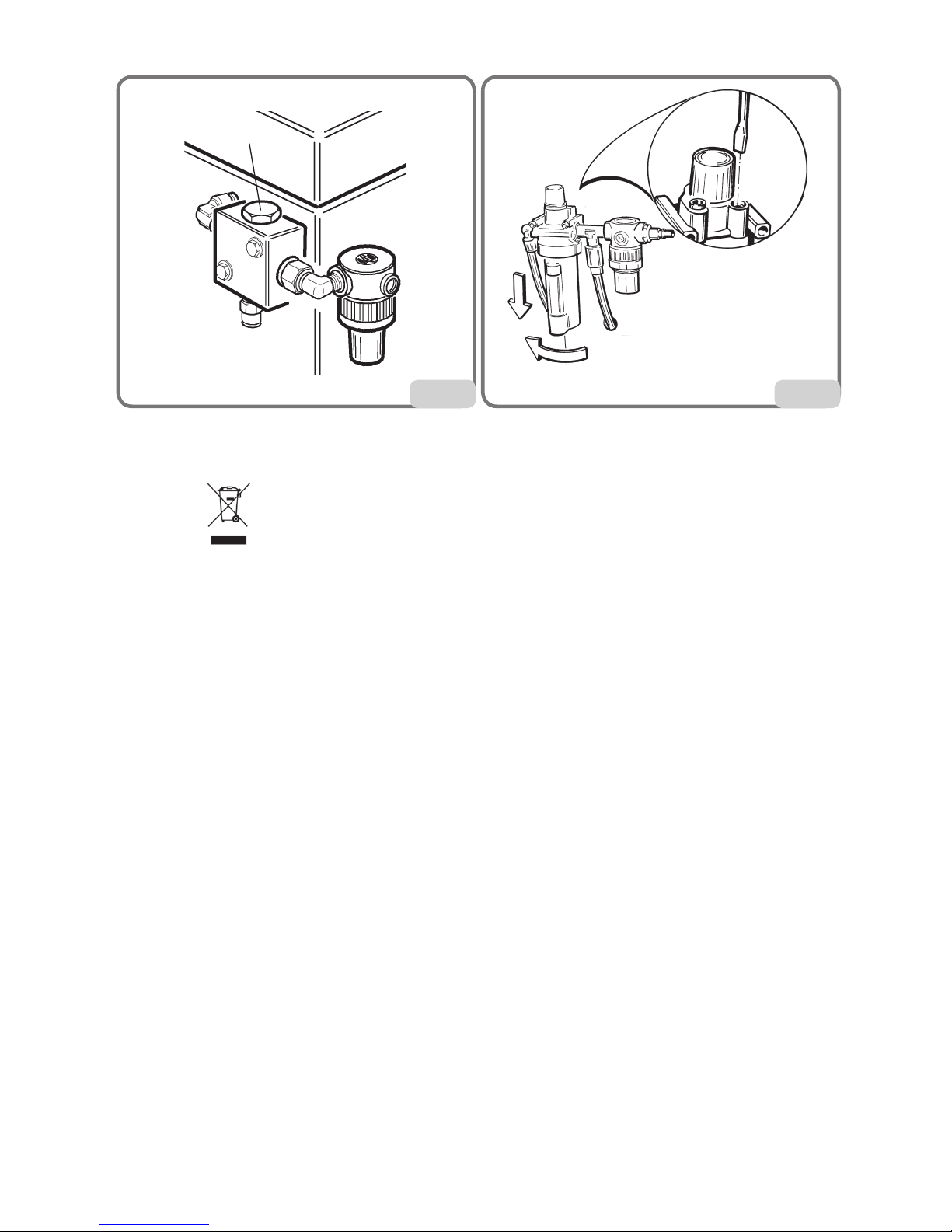

ELECTRICAL AND PNEUMATIC CONNECTIONS

WARNING

All operations required for the electrical connections of the equipment must be carried out

exclusively by a quali ed electrician.

Before connecting the air supply system, make sure the machine is set up as in g. 4:

pedal totally downwards.

- The electrical supply must be suitably sized in relation to:

• the machine input power as speci ed in the corresponding machine data plate;

• the distance between the machine and the power supply hook-up point, so that voltage drops

under full load do not exceed 4% (10% during start-up) compared with the rated voltage speci ed

on the data plate.

- The operator must:

• t a power plug on the power supply lead in compliance with the relevant safety standards (A g 5);

• Connect the machine to an ef cient grounding circuit in compliance with the relevant electric stan-

dards, provided with a circuit breaker (residual current set to 30mA);

• t fuses to protect the power supply line, rated as indicated on the general wiring diagram in this

manual.

- In order to prevent the machine from being used by unauthorized personnel, it is advisable to

disconnect the power supply plug when the machine remains idle (switched off) for long periods.

WARNING

A good grounding connection is essential for correct operation of the machine.

NEVER connect the earth wire to a gas or water pipe, telephone line or any other unsuitable

objects.

Check that the pressure and ow-rate provided by the compressed air system are compatible with

those required for proper operation of the machine - see “Technical Data” section. For correct machine

operation the compressed air supply line must provide a pressure range from no less than 8 bar to

no more than 16 bar.

Connect the compressed air system by means of a supply pipe connected to the intake of the air

treatment unit on the REAR SIDE of the machine base.

Check that there is air lubrication oil in the Lubricating unit; re ll if there is little or no oil. Use SAE20 oil.

The customer must provide an air cut-off valve upstream of the air treatment and regulating device

supplied with the machine.

WARNING

Connection 1 should be considered as an emergency valve to

disconnect the machine from the air line ( g.6)

1

6

Page 9

User’s manual - TECO 22 - 23 - 25 - 27 Special 9

SAFETY REGULATIONS

The equipment is intended for professional use only.

WARNING

Only one operator may work on the equipment at a time.

WARNING

Failure to comply with the instructions and danger warnings may seriously injure operators

and any other person present near the machine. Do not operate the machine until you have

read and understood all the danger, warning and caution notices in this manual.

This machine must be used only by qualied and authorized personnel. A qualied operator is construed

as a person who has read and understood the manufacturer’s instructions, is suitably trained, and

is conversant with safety and adjustment procedures to be adhered to during operations. Operators

must not use the machine under the inuence of alcohol or drugs which may affect their capacity.

The operator must, in all cases:

- Be able to read and understand all the information in this manual.

- Have a thorough knowledge of the capabilities of this machine.

- Keep unauthorized persons well clear of the area of operation.

- Make sure the machine has been installed in compliance with all relevant regulations and legislation.

- Make sure that all machine operators are suitably trained, that they are capable of using the

equipment correctly and that they are adequately supervised.

- Never leave nuts, bolts, tools or any other equipment on the tyre changer as they may become

entrapped between moving parts.

- Not touch power lines or the inside of electric motors or any other electrical equipment before

making sure the power supply has been disconnected.

- Read this manual carefully and learn how to use the machine correctly and safely.

- Always keep this user and maintenance manual in an easily accessible place and consult it

whenever necessary.

WARNING

Do not remove or deface the Danger, Warning or Instruction decals. Replace any missing or

illegible decals. If one or more decals have been detached or damaged, replacements can be

obtained from your nearest dealer.

- When using and servicing the machine, observe the standardized industrial accident

prevention regulations for high voltages.

- Any unauthorized alterations or changes made to the machine shall automatically release the

manufacturer from any liability for damage or accidents attributable to such modications.

Specically,tampering with or removing the safety devices is a breach of the regulations for Safety

in the workplace.

- User must wear personal protective equipment such as gloves, safety footwear and goggles.

WARNING

When operating or servicing the equipment, tie back long hair and do not wear loose-tting clothes,

ties, necklaces, rings or wristwatches which could become entrapped by moving parts.

Page 10

10 User’s manual - TECO 22 - 23 - 25 - 27 Special

DESCRIPTION

The machine is a electro-pneumatic tyre changer semi-automatic, to be used with wheels with drop

centre featuring weights and dimensions as described in the technical data section.

It is designed to work effectively on:

- Conventional wheels;

- Reverse rim wheels or wheels without central hole (use optional kit);

- Run-at tyres with reinforced sidewalls*.

* WARNING: There are specically studied procedures for this type of wheels.

NB: It may be difcult and sometimes impossible to clamp and/or demount wheels of Vintage

cars (cars out of production for over 30 years), some types of rally wheels and non-standardized

street wheels.

The machine is solidly constructed. It operates with the wheel in a vertical position for bead breaking

and horizontal for mounting and demounting tyres. All machine movements are controlled by the

operator by means of the pedals.

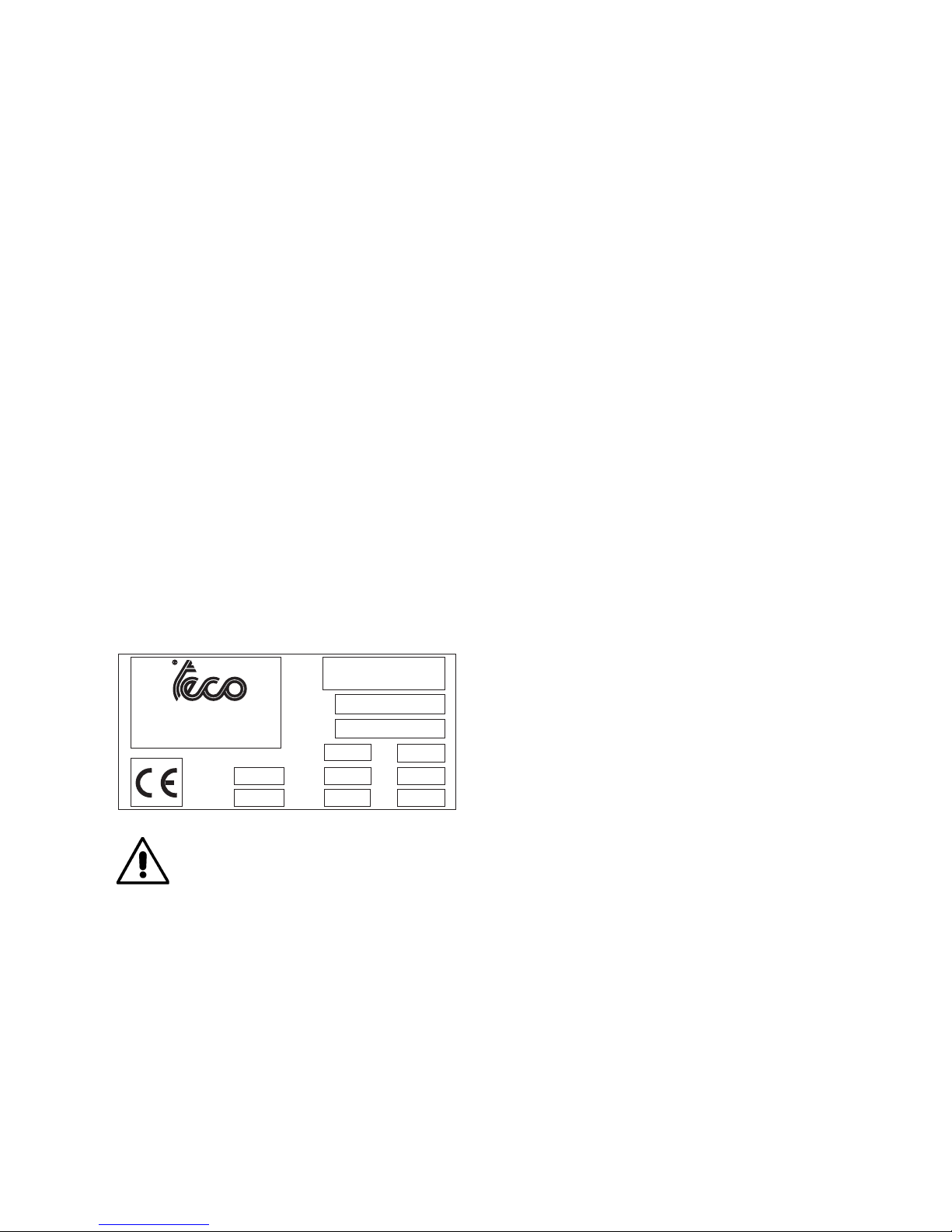

MANUFACTURER’S LABEL

Each machine carries a plate with its identication and some technical data.

As well as the manufacturer’s details, it indicates:

Mod. - Machine model;

V - power supply voltage in Volts;

A - Input voltage in Amperes;

kW - Absorbed power in kW;

Hz - Frequency in Hz;

Ph - Number of phases;

bar - Operating pressure in bar;

Serial No. - Machine serial number;

EC - EC marking.

Mod.

Ser. N.

Volt

Kw

Amp.

Year

Weight

Ph

Hz

Bar

Automotive Equipment

TECO s.r.l. Via Pio La Torre 10

42015 Correggio (R.E.) - ITALY

tel. 0522/631562 - fax 0522/642373

WARNING

It is forbidden to modify or remove the data in the plate.

Page 11

User’s manual - TECO 22 - 23 - 25 - 27 Special 11

TECHNICAL DATA

- Overall dimensions (Teco 22 - Teco 23 - Teco 25 - Teco 27 Sp. - see g. 7):

• Length ............................................................................................. 900/1200 (t.i.) min 1260 max

• Width .............................................................................................................. 820 min 1200 max

• Height ........................................................................................................... 1520 min 1820 max

- Table top clamping capacity (Teco 22 - Teco 25):

• inside clamping .................................................................................................................. 13”-21”

• outside clamping ................................................................................................................. 10”-18”

- Table top clamping capacity (Teco 23):

• inside clamping .................................................................................................................. 13”-23”

• outside clamping ................................................................................................................. 10”-20”

- Table top clamping capacity (Teco 27 Sp.):

• inside clamping .................................................................................................................. 14”-24”

• outside clamping ................................................................................................................. 12”-22”

- Rim width: ............................................................................................................................335 mm

- Maximum tyre diameter: ....................................................................................................1000 mm

- Bead breaking pressure: ................................................................................................... .2900 Kg

- Air pressure ........................................................................................................................8-10 Bar

- Motor electrical features:

• 1ph version - 1 speed 220V - 50Hz ................................................................. 6A - 0,75 kW

• 3ph version - 1 speed 230V - 50Hz ............................................................. 2,8A - 0,55 kW

• 3ph version - 1 speed 400V - 50Hz ............................................................. 1,6A - 0,55 kW

• 3ph version - 2 speed 230V - 50Hz ................................................... 5,3/6,8A - 0,8/1,1 kW

• 3ph version - 2 speed 400V - 50Hz ................................................... 2,8/4,4A - 1,1/1,5 kW

- Weight (Teco 22) ...................................................................................................................150 kg

- Weight (Teco 23) ................................................................................................163 kg (178 kg t.i.)

- Weight (Teco 25) ................................................................................................173 kg (188 kg t.i.)

- Weight (Teco 27 Sp.) .........................................................................................185 kg (200 kg t.i.)

- Weight of electrical/ electronic components: ........................................................................ 11,5 kg

- Noise level: A-weighted sound pressure level (LpA) at the working position ...... < 70 dB (A)±3dB(A)

The noise levels indicated correspond to emission levels and do not necessarily represent safe

operating levels. Although there is a relationship

between emission levels and exposure levels,

thiscan not be used reliably to establish whether

or not further precautions are necessary. The

factors which determine the level of exposure

to which the operator is subject to include the

duration of the exposure, the characteristics of

the workplace, other sources of noise, etc. The

permitted exposure levels may also vary according to the country. However, this information will

enable machine users to make a more accurate

assessment of hazard and risks.

7

Min 820 - Max 1200

Min 1520 - Max 1820

Min 900/1200 - Max 1260

(t.i.)

Page 12

12 User’s manual - TECO 22 - 23 - 25 - 27 Special

STANDARD ACCESSORIES

044900800.........................................................................................................................Tyre lever

040000100.......................................................................................................................Brush (BR)

3-01523 ................................................................................................................Grease 4Kg (TG4)

ACCESSORIES ON DEMAND

100012100........................................................................................................................... UWA 24

(Adapters to increase the turntable clamping capacity (to be used in combination with US TPH)

100012000................................................................................................................................ UMA

Universal motorcycle adapters

100001500.................................................................................................................................CRA

Adapters for convex rims

8-11600005............................................................................................................................. PLS 2

(Pneumatic wheel lift complete with roller rest)

SPECIFIED CONDITIONS OF USE

The TECO tyre changers has been designed exclusively for mounting and demounting tyres, using

the tools the machines are equipped with, following the instructions in this manual.

WARNING

Any other operation carried out on the machine is considered as improper use and shall be

construed as negligence.

These machines are equipped with an ination system independent from any other function described

above. Take great care when using it (read the INFLATION chapter).

WARNING

You are strongly advised not to use equipment

or tools not originally manufactured by TECO .

Figure 8 shows the positions assumed by the operator

during the various stages of work with the machine.

A Bead breaker

B Tyre demounting and mounting

C Ination area.

WARNING

Keep hands well away from machine moving

parts.

WARNING

To stop the machine in an emergency:

- disconnect the power supply plug;

- isolate the compressed air supply network by disconnecting the (quick-coupling) shut-off valve (g. 6).

8

C

B

A

Page 13

User’s manual - TECO 22 - 23 - 25 - 27 Special 13

MAIN OPERATING PARTS

WARNING

Get to know your machine: the best way to prevent accidents and obtain top performance is to get

to know exactly how it works. Learn the function and location of all the controls. Check carefully that

each of the controls operates properly. To avoid any risk of accidents and injuries, the machine must

be installed and operated correctly and serviced regularly.

The machine main operating parts are shown in g. 9:

1 Reverse control pedal

2 Turntable

3 Bead breaker pedal

4 Bead breaker arm

5 Clamp control pedal

6 Clamp

7 Vertical arm

8 Horizontal arm

10 Mounting bar

11 Inating gun with pressure gauge

12 Pressure regulator

13 Wheel support

14 Bead breaker

15 Grease container holder

16 Mounting head

17 Tyre lever

18 Air lubricator

19 Inator pedal for t.i. version

20 Inating unit

21 Air tank

22 Body

23 Tyre deating push button

Page 14

14 User’s manual - TECO 22 - 23 - 25 - 27 Special

9

13

14

11

22

standard version

12

t.i. version

(tubeless inating)

18

10

16

6

2

7

4

17

3

5

1

8

15

21

19

20

23

Page 15

User’s manual - TECO 22 - 23 - 25 - 27 Special 15

WARNING SIGNALS

PAY THE UTMOST ATTENTION TO THE WARNING LABELS ATTACHED TO THE MACHINE.

USING THE MACHINE WITHOUT READING THE WARNING SIGNALS MAY BE

SERIOUSLY DANGEROUS FOR THE OPERATOR.

DANGER OF CRUSHING PARTS OF THE

BODY BETWEEN THE BEAD BREAKER AND

THE MACHINE

C

DANGER OF HAND CRUSHING

BETWEEN CLAMP AND RIM.

DANGER OF HAND CRUSHING

BETWEEN MOUNTING HEAD

AND WHEEL.

D

CAUTION: AIR BLAST.

MAX. AIR SUPPLY LINE

PRESSURE 16 BAR

E

INFLATING GUN CONNECTION.

DO NOT DIRECTLY CONNECT

THE COMPRESSOR.

(only on standard version)

CAUTION: ELECTRIC CURRENT

DANGER OF CRUSHING PARTS OF THE

BODY BETWEEN THE BEAD BREAKER AND THE

WHEEL.

DANGER OF CRUSHING PARTS OF THE

BODY BETWEEN THE BEAD BREAKER ARM

AND THE MACHINE.

A

CAUTION: TOWER TILTING

000103700

000103500

000103000

000103100

000102800

F

000102700

G

000103600

H

I

J

000103400

000103200

000103300

B

®

D

G

B

H

I

J

F

A

C

E

Page 16

16 User’s manual - TECO 22 - 23 - 25 - 27 Special

Preliminary checks

Check that there is a pressure of at least 8 bar on the pressure gauge of the Filter Regulator +

Lubricator unit.

Check that the machine has been adequately connected to the power mains.

Deciding from which side of the wheel the tyre must be demounted

See g. 10.

Find the position of the drop centre A on the wheel rim. Find the largest width B and the smallest width C.

The tyre must be demounted or mounted with the wheel positioned on the turntable with the side

with the smallest width C facing upward.

Special instructions

Some types of wheels on the market require special procedures and precautions which differ from

the standard procedure.

This applies in particular to the following types of wheels:

Alloy rim wheels: some wheels have alloy rims where the drop centre A is very small or non-existent g. 10-B. These rims are not approved by the DOT (Department of Transportation) standards - these

initials certify that tyres comply with the safety standards adopted by the United States and Canada

(these wheels cannot be sold in these markets).

DANGER

Take utmost caution when mounting the tyre. The rim and/or the tyre may be damaged

accidentally, with the risk of the tyre exploding during the ination stage.

European style high-performance wheels (asymmetric curvature) - g.10-C: some European

wheels have rims with very pronounced curvature C, except in the area of the valve hole A where the

curvature is less pronounced B. On these wheels the bead must rst be broken in correspondence

with the valve hole, on both the top and bottom sides of the wheel.

Wheels with low pressure indicator system - g.10-D.

CC

A

B

A

B

A

C

C

A

B

D

C

A

B

10

Page 17

User’s manual - TECO 22 - 23 - 25 - 27 Special 17

USE

BEAD BREAKING

-Fully close the turntable clamps acting on pedal 5 fig. 9.

-Remove the weights from the rim.

-Fully deate the tyre, removing the valve

- Adjust the rim rest depending on wheel diameter

-Place the wheel as shown in g. 11 and take the blade near the bead, keeping the necessary safety

distance between the rim and the bead breaker blade, so that the latter works on the tyre and not

on the rim.

-Press pedal 3 (g 9) to activate the bead breaker and free the bead from the rim.

Release the pedal. Pressing the bead breaker pedal (3 g. 9) the arm moves (4 g.9) and it may be

dangerous (crushing danger); pay the utmost attention during bead breaking.

Repeat this operation on the other side of the wheel.

It may be necessary to break the bead at several points to free it completely.

WHEEL CLAMPING

-Check if there are any weights left on the rim; if so, remove them.

-Thoroughly lubricate the sides of the tyre around the entire circumference of the lower and upper

bead to facilitate the demounting and avoid damaging the beads (g.12).

-Tilt the tower backwards.

-Depending on the diameter of the rim, close the four clamps if the rim is to be clamped from inside

or open them if the rim is to be clamped from outside. Place the wheel on the turntable, push it lightly

down and act on the control pedal to lock the wheel in its proper position (g. 13).

Acting on the turntable pedal (3 g.9) closes the clamps and may be dangerous (danger of hand

crushing). During rim clamping, do not keep the hands under the tyre.

11

12

Page 18

18 User’s manual - TECO 22 - 23 - 25 - 27 Special

• Tool positioning (g.14 - 15)

- Set the mounting bar in work position and let the

mounting head touch the edge of the rim.

- Adjust the position of the operating arm by

turning the handwheel on the pole unit the tool

has moved 2 to 3 mm away from the edge of the

rim.

- Pull the lever placed on the horizontal arm until

the mounting bar is locked; the mounting head

will automatically move 2/3 mm. away from the

edge of the rim, thus protecting it from damage.

DEMOUNTING

- Position the tyre lever between the mounting

head and the tyre bead and lift the bead above the forward portion of the mounting head itself.

- Make the turntable rotate clockwise by pressing the relevant pedal lightly and repeatedly, then

keep the pedal continuously pressed.

- Rotate the wheel through one turn and at the same time press down with a hand on the side of

the tyre opposite to the mounting head, in order to position the bead in the central groove of the

rim.

- If the wheel has an inner tube, remove it after swinging the horizontal arm + mounting bar in

non-work position.

- Repeat the above described procedures to take out the second bead. Then move the horizontal

arm + mounting bar in non-work position and take the tyre off the rim.

13

14

15

Page 19

User’s manual - TECO 22 - 23 - 25 - 27 Special 19

MOUNTING

CAUTION

Always check that the tyre/rim combination is correct in terms of compatibility (tubeless tyre on

tubeless rim; tube type tyre on tube type rim) and geometrical size (keying diameter, cross-section

width, Off-Set and shoulder prole) before mounting.

Also check that rims are not deformed, that their xing holes have not become oval, that they are

not scaled or rusty and that they do not have sharp burrs on the valve holes.

Check that the tyre is in good condition with no signs of damage.

• Tyre preparation (g. 18)

- Grease both the tyre beads.

- Place the tyre on the rim

• Head positioning

- Set the mounting bar in work position

NB: The tool is already in the correct position for mounting the tyre, unless the type of rim

has been changed.

16

17

18

19

Page 20

20 User’s manual - TECO 22 - 23 - 25 - 27 Special

• Lower bead mounting

- Place the bottom bead of the tyre underneath the tool and at the same time apply a little pressure

to

the tyre by hand while starting to rotate the wheel (pedal 1) for easier bead insertion.

- Rotate until tyre mounting is complete.

• Upper bead positioning (g. 19)

- Position the upper tyre bead.

Take care that the tyre does not slip underneath the tool.

• Upper bead mounting

- Rotate the wheel using pedal 5 to start mounting the upper bead. Press manually the tyre bead to

keep it inserted in the channel until the bead assembly is successfully completed.

- Return the tool into its rest position.

NOTE: for oversized (more than 19’’) or particularly tough wheels, it is recommended the use of the

pneumatic bead presser. In this case the following procedure must be applied:

• Tyre ination

- For ination, see “INFLATION” section.

• Tilt the tower backwards in non-work position.

• Free the wheel from the clamps and remove it from the tyre changer.

INFLATION

WARNING

Ination is well known to be a dangerous operation. It must be carried out in accordance with

the instructions below. Safety goggles with plain lenses and safety footwear must be worn.

CAUTION

During this operation, noise levels assessed at 85 dB(A) may occur. Operators are advised

to wear hearing protection devices.

DANGER

Although the machine limits the pressure, it does not provide sufcient protection if the tyre

bursts during ination.

Failure to comply with the instructions below will render tyre ination dangerous.

DANGER

NEVER exceed the pressure recommended by the tyre manufacturer. Tyres may burst if they

are inated beyond these limits or their structures may incur serious damage not visible at

the time. KEEP YOUR HANDS AND THE WHOLE BODY WELL AWAY FROM THE TYRE DURING

INFLATION. Make sure you are concentrated during this operation and check tyre pressure

continuously to avoid excess ination. A bursting tyre can cause serious injuries or even death.

- Release the wheel from the sliding clamps on the table top.

- Pull the horizontal arm all away out.

- Lower the vertical bar till it touches the rim.

- Lock the horizontal and vertical arms in the positions described on Fig.2.4.

- Connect the Doyfe ination chuck (32) on the air hose to the valve stem.

- Inate the tyre by using the inaction gun

Page 21

User’s manual - TECO 22 - 23 - 25 - 27 Special 21

Inating tubeless tyres

(T.I. versions only)

WARNING

Before carrying out the operations described below, always make sure that there is no dirt,

dust or other impurities on the jaws near the air outlet holes.

- Make sure that the wheel is secured to the table top with inside clamping.

- Pull the horizontal arm all away out.

- Lower the vertical bar till it touches the rim.

- Lock the horizontal and vertical arms in the positions described on Fig.20.

- Connect the Doyfe inator chuck on the air hose to the valve stem.

- Hold the tyre with your hands and lift it until there is a slight gap between the lower bead and bottom

edge of the rim in order to close the upper bead and the top of the rim.

- Press the ination pedal fully down for a short period to the bead seating position (g.20). The tyre

will expand and the beads will seat.

- Continue to press the pedal in the ination position (g.21) until the beads are completely sealed.

Note: to improve the operation of the tubeless tyre ination system the compressed air line pressure

must be between 8/10 bar.

MAINTENANCE

CAUTION

The “Spare parts” handbook does not authorize users to carry out work on the machine with the

exception of those operations expressly described in the user manual. It only enables users to

provide the technical assistance service with precise information in order to minimize delays.

WARNING

TECO declines all liability for claims deriving from the use of non-original spare parts or

accessories.

CAUTION

Any operation intended to modify the setting value of the relief valves or pressure limiter is forbidden.

The manufacturer declines all liability for damage resulting from tampering with these valves.

20

21

Page 22

22 User’s manual - TECO 22 - 23 - 25 - 27 Special

WARNING

Before proceeding with any adjustment or maintenance activity, disconnect the machine from

the air supply and electrically insulate the machine by means of an omnipolar disconnection

device. Make sure that all the mobile parts are locked.

CAUTION

In case of replacement of the power supply cable, follow the indications listed in the table

below for the most appropriate cable choice:

SUPPLY CABLE TYPE NR OF WIRES WIRE SECTION

400/3/50

400/3/60

230/3/50

230/3/60

200/3/50

200/3/60

FROR 450-750V

UNEL 35011

3 - phase

1 - grounding 1mm

2

240/1/50

230/1/50

220/1/60

FROR 450-750V

UNEL 35011

1 - phase

1 – neutral

1 - grounding

1,5mm

2

115/1/60

UL 1569 300V

105°C

1 - phase

1 – neutral

1 - grounding

AWG 14

CAUTION

Do not remove or modify any parts of this equipment except in the case of service operations.

DANGER

When the machine is disconnected from the air supply system, the devices marked with the

warning sign shown above may remain pressurised.

- The lter+regulator+lubricator (Teco 27 Sp.) is equipped with a semiautomatic condensation drain

device. This device operates automatically whenever the compressed air supply to the machine

is cut off. Drain the condensation manually (push-button d, g 22 ) when the level exceeds the

mark X, g. 22.

- Clean the top plate of the turntable every week: remove any accumulated dirt and clean with

environmentally-friendly solvents.

- Monthly checks (Teco 25 - Teco 27 Sp.):

• Clean the arms of the tool-carrying head, the bead breaking unit and the relative travel screws

with environmentally-friendly solvents only. Lubricate.

• Check the oil level in the air lubricator (g. 22) and, if necessary, top up with non-detergent

SAE20 oil to the indicated level Z.

• Clean with a dry cloth. Avoid contact with solvents.

Page 23

User’s manual - TECO 22 - 23 - 25 - 27 Special 23

• Check the oil ow-rate through the transparent cover K (correct ow-rate: 1 drop of oil every

4 bead breaking cycles). Adjust if necessary by turning the set screw Y g. 22.

- Monthly checks (Teco 22 - Teco 23):

• Clean and lubricate with naphta the horizontal arm and mounting bar.

• Disconnect the machine from the pneumatic circuit.

• Remove cap 1 and let a few drops of non-detergent (SAE 20) in using an ampoule.

• put cap 1 back on and tighten rmly.

• Check the stretch of the motor/reduction gear driving belt; using the machine, such belt

may become loosen and worn out.

CAUTION

Keep the working area clean.

Never use compressed air, jets of water or solvent to remove dirt or deposits off the machine.

When cleaning, take care not to create and raise dust as far as possible.

22

a

b

c

e

d

x

Page 24

24 User’s manual - TECO 22 - 23 - 25 - 27 Special

ENVIRONMENTAL INFORMATION

The following disposal procedure shall be exclusively applied to the machines having the crossed-out

bin symbol

on their data plate.

This product may contain substances that can be hazardous to the environment or to human health

if it is not disposed of properly.

We therefore provide you with the following information to prevent releases of these substances and

to improve the use of natural resources.

Electrical and electronic equipment should never be disposed of in the usual municipal waste but

must be separately collected for their proper treatment.

The crossed-out bin symbol, placed on the product and in this page, remind you of the need to

properly dispose of the product at the end of its life.

In this way it is possible to prevent that a not specic treatment of the substances contained in these

products, or their improper use, or improper use of their parts may be hazardous to the environment

or to human health. Furthermore this helps to recover, recycle and reuse many of the materials used

in these products.

For this purpose the electrical and electronic equipment manufacturers and dealers set up proper

collection and treatment systems for these products.

At the end of life of your product contact your dealer to have information on the collection arrangements.

When buying this new product your dealer will also inform you of the possibility to return free of

charge another end of life equipment as long as it is of equivalent type and has fullled the same

functions as the supplied equipment.

A disposal of the product different from what described above will be liable to the penalties prescribed

by the national provisions in the country where the product is disposed of.

We also recommend you to adopt further measures for environment protection: recycle the internal and

external packing of the product and properly dispose of dead batteries (if contained in the product).

With your help the amount of natural resources used to produce electrical and electronic equipment

can be reduced, the use of landlls for the disposal of the products, minimized, and the quality of life

improved by preventing that potentially hazardous substances are released into the environment.

23

1

TECO 22 -23

24

TECO 25

Page 25

User’s manual - TECO 22 - 23 - 25 - 27 Special 25

INFORMATION AND WARNINGS ABOUT OIL

Disposing of old oil

Do not dispose of used oil in sewers, storm drains, rivers or streams; collect it and consign it to an

authorized disposal company.

Oil spills or leaks

Contain the spilt product from spreading using soil, sand or any other absorbent material.

Degrease the contaminated area with solvents, taking care to disperse solvent fumes. The residual

cleaning material must be disposed of as prescribed by law.

Precautions for the use of oil

- Avoid contact with the skin.

- Do not allow oil mists to form or spread in the atmosphere.

- Observe the following elementary health precautions:

• protect against oil splashes (appropriate clothing, protective guards on machines);

• wash frequently with soap and water; do not use cleaners or solvents that can irritate your skin

or remove its natural protective oil;

• do not dry hands with dirty or greasy rags;

• change clothing if impregnated with oil, and in any case at the end of every working shift;

• do not smoke or eat with greasy hands.

- Also adopt the following preventive and protective equipment:

• gloves resistant to mineral oils, with lining;

• goggles, in case of splashes;

• aprons resistant to mineral oils;

• screens to protect against oil splashes.

Mineral oil: first aid procedures

- Swallowing: seek medical attention, providing the characteristics of the type of oil swallowed.

- Inhalation: in case of exposure to high concentrations of fumes or mists, take the affected person

to the open air and seek medical attention immediately.

- Eyes: rinse with plenty of running water and seek medical attention as soon as possible.

- Skin: wash with soap and water.

RECOMMENDED FIRE-EXTINGUISHING DEVICES

For guidance on the most suitable type of extinguisher, refer to the table below:

Dry mate-

rials

Flamma-

ble

liquids

Electrical

equip-

ment

Water YES NO NO

Foam YES YES NO

Powder YES* YES YES

CO

2

YES* YES YES

YES* Use only if more appropriate extinguishers are not at hand or when the re is small.

WARNING

This table contains general instructions intended to be used as guidelines for users. Contact

the manufacturer for details of the applications of each type of extinguisher.

Page 26

26 User’s manual - TECO 22 - 23 - 25 - 27 Special

GLOSSARY

Air delivery regulator: Union allowing regulation of the air ow.

Beading: Operation which takes place during ination and ensures perfect centring between the

bead and the rim edge.

Bead breaking: Operation in which the bead of the tyre is detached from the edge of the rim.

Bead pressing gripper: A tool intended for use when mounting the top bead. It is tted so that it

grips the shoulder of the rim and holds the tyre top bead inside the drop centre. It is generally used

for mounting low prole tyres.

Tubeless Inator: An ination system which simplies inating tubeless tyres.

Bead: The edge of the tyre that remains in contact with the rim when the tyre is installed.

Tubeless: A tyre without an inner tube..

TROUBLE SHOOTING

CAUTION

In case of unexpected failure, electrically insulate the machine by means of an omnipolar disconnection device.

Turntable not turning

Feeding plug not connected or defective.

- Check the plug.

Machine not powered.

- Restore the electric connections.

Defective inverter.

- Replace the inverter (skilled staff needed in this case).

Motor shorted.

- Replace the motor (skilled staff needed in this case).

Belt broken.

- Replace belt.

Rotation control pedal fails to return to central position

Control spring broken.

• Replace the control spring.

Bead breaker pedal and table top pedal do not return to home position

Control spring broken.

- Renew the spring.

No oil in lubricator.

- Top up lubricator with SAE20 non-detergent oil.

Air leak inside the machine

Air leak from bead breaker cock.

- Renew the cock.

- Renew bead breaker cylinder.

Air leak from the table top cock.

- Renew table top cylinder.

- Renew swivel connector.

Page 27

User’s manual - TECO 22 - 23 - 25 - 27 Special 27

Bead breaker cylinder lacks force, fails to break beads and leaks air

Silencer plugged.

- Renew silencer.

Cylinder seals worn.

- Renew seals.

- Renew bead breaker cylinder.

Bead breaker cylinder leaks air around the rod

Air gaskets worn.

- Replace gaskets.

- Replace bead breaker cylinder.

Table top will not rotate in either direction

Inverter faulty.

- Replace inverter.

Belt broken.

- Renew belt.

Gear unit broken.

- Renew gear unit.

Gear unit noisy. The table top makes 1/3 of a spin and then stops

Gear unit seizing.

- Replace gear unit.

Table top fails to clamp wheels

Table top does not clamp rim.

- Renew table top cylinder.

Table top mounts or demounts wheels with difficulty

Insufcient belt tension.

- Adjust tension or replace belt.

Tyre pressure gauge needle fails to return to 0

Pressure gauge faulty or damaged.

- Replace pressure gauge.

WARNING

The “Spare parts” handbook does not authorize users to carry out work on the machine

with the exception of those operations expressly described in the user manual. It only

enables users to provide the technical assistance service with precise information in order

to minimize delays.

Page 28

28 User’s manual - TECO 22 - 23 - 25 - 27 Special

1

3 5

7

9 11

2

4

6

8

10 12

0

RL

3 Ph ~

L2

L3

PE

XS1

SPINA E PRESA

Plug & Socket

INVERTITORE COMMUTATORE DI POLARITA’

Reverse Polarity Switch

x 11-12

x 9-10

x 7-8

x 5-6

x 3-4

x 1-2

L 0 R

1

2

3

L1

ELEMENTI - Elements

CONTATTI - Contacts

W2

U1

U2

V2

V1

W1

W2

U1

U2

V2

V1

W1

200-220-240V

380-415-440V

MORSETTIERA Junction Box

F

F

F

Power

Phase

400V / 3 / 50 Hz - 0,55 kW 500V, 4A

400V / 3 / 50 Hz - 0,75 kW 500V, 6A

230V / 3 / 50 Hz - 0,55 kW 250V, 10A

230V / 3 / 50 Hz - 0,75 kW 250V, 10A

200V / 3 / 50 Hz - 0,75 kW (Japan) 250V, 10A

F: Fuse

Page 29

User’s manual - TECO 22 - 23 - 25 - 27 Special 29

1

3 5

7

9 11

2

4

6

8

10 12

0

RL

1 Ph ~

C

L1

N

PE

XS1

SPINA E PRESA

Plug & Socket

INVERTITORE COMMUTATORE DI POLARITA’

Reverse Polarity Switch

x 11-12

x 9-10

x 7-8

x 5-6

x 3-4

x 1-2

L 0 R

1

2

3

ELEMENTI - Elements

CONTATTI - Contacts

F

F

Power

Phase Neutral

230V / 1 / 50 Hz 250V, 16A 250V, 16A

240V / 1 / 50 Hz 250V, 16A 250V, 16A

220V / 1 / 60 Hz 250V, 16A 250V, 16A

115V / 1 / 60 Hz 250V, 20A 250V, 20A

F: Fuse

W2

U1

U2

V2

V1

W1

C

8

12

3

2

MORSETTIERA Junction Box

Page 30

30 User’s manual - TECO 22 - 23 - 25 - 27 Special

0

R

L1

3 Ph ~

L2

L3

PE

XS1

SPINA E PRESA

Plug & Socket

INVERTITORE COMMUTATORE DI POLARITA’

Reverse Polarity Switch

L1

ELEMENTI - Elements

CONTATTI - Contacts

1

3 5

7

9 11

2

4

6

8

10

12

13

15

17 19 21 23

14

16

18

20

22 24

L2

23-24

x

x x 21-22

x 19-20

x 17-18

x x 15-16

x x 13-14

x 11-12

x 9-10

x 7-8

x x 5-6

x x 3-4

x 1-2

L2 L1 0 R

1

2

3

4

5

6

V2U2W2

W1

V1

U1

PE

22

13

15

24

9

11

F

F

F

Power

Phase

400V / 3 / 50 Hz 500V, 6A

230V / 3 / 50 Hz 250V, 16A

400V / 3 / 60 Hz 500V, 6A

230V / 3 / 60 Hz 250V, 12A

F: Fuse

28

Page 31

User’s manual - TECO 22 - 23 - 25 - 27 Special 31

29

REF. DESCRIZIONE DESCRIPTION

01 INNESTO RAPIDO MASCHIO QUICK UNION

02 GRUPPO FRL WATER SEPARATOR AND PRESSURE REGUL+LUBRIFICATOR

03 VALVOLA GONFIAGGIO RAPIDO QUICK INFLATING VALVE

04 PISTOLETTA DI GONFIAGGIO INFLATING GUN AND GAUGE

05 VALVOLA STALLONATORE BEAD BREAKING VALVE

06 VALVOLA SCARICO RAPIDO QUICK DISCHARGED VALVE

07 CILINDRO STALLONATORE BEAD BREAKING CYLINDER

08 VALVOLA AUTOCENTRANTE SELF-CENTERING CHUCK VALVE

09 RACCORDO GIREVOLE ROTATING UNION

10 CILINDRO AUTOCENTRANTE SELF-CENTERING CHUCK CYLINDER

11 VALVOLA DI GONFIAGGIO INFLATING VALVE

12 VALVOLA A MEMBRANA VALVE

13 VALVOLA DI SICUREZZA SAFETY VALVE

14 UNITA’ DI GONFIAGGIO INFLATE UNION BOX

8-16 bar

MAX 10 bar

01

02

03

04

05

06

07

08

09

10

10

SCHEMA PNEUMATICO STD

Pneumatic STD Diagram

8-16 bar

MAX 10 bar

MAX 11 bar

01

02

03

11

05

06

07

08

09

10

10

SCHEMA PNEUMATICO T.I.

Pneumatic T.I. Diagram

12

13

14

09

Page 32

EC DECLARATION OF CONFORMITY

WE,

Teco Srl

Via Pio La Torre 10

42015 Correggio (RE)

Italy,

DECLARE UNDER OUR SOLE AND EXCLUSIVE RESPONSIBILITY THAT THE MACHINE:

TYPE:

tyre changer

MODEL:

SERIAL No.:

serial number

TO WHICH THIS STATEMENT REFERS AND FOR WHICH WE HAVE PREPARED AND HOLD THE RELATIVE TECHNICAL BOOKLET, COMPLIES WITH THE BASIC REQUISITES DEFINED BY THE FOLLOWING EUROPEAN UNION

DIRECTIVES:

- 2006/42/EC;

- 2014/35/EU;

- 2014/30/EU;

- 2011/65/EU;

- 2014/29/EU*.

*Only valid for the version with T.I.

THE FOLLOWING HARMONISED STANDARDS HAVE BEEN APPLIED TO VERIFY COMPLIANCE WITH THE FOLLOWING DIRECTIVES:

EN ISO 12100:2010; EN 60204-1:2006/AC:2010; EN 61000-6-2:2005/AC:2005;

EN 61000-6-3:2007/A1:2011/AC:2012

Correggio, 01/04/2016

TECHNICAL DIRECTOR

Ing. Mauro Barbetti

THE TECHNICAL DOSSIER RELATIVE TO CONSTRUCTION WILL BE KEPT AND WILL BE RENDERED AVAILABLE

BY ING. MAURO BARBETTI, C/O TECO SRL, VIA PIO LA TORRE , 10 42015 CORREGGIO (RE) ITALY.

IMPORTANT:THIS DECLARATION SHALL NO LONGER APPLY IF CHANGES ARE MADE TO THE PRODUCT WITH

RESPECT TO ITS CONFORMATION AT THE TIME OF SALE OR IF CHANGES ARE MADE TO THE COMPONENTS

WITHOUT THE PRIOR AUTHORIZATION OF THE MANUFACTURER, OR IN THE CASE OF NON-COMPLIANCE

WITH THE INFORMATION CONTAINED IN THE USER MANUAL.

THE MODEL FOR THIS DECLARATION COMPLIES WITH WHAT IS SET FORTH IN EN ISO/IEC 17050-1 AND EN

ISO/IEC 17050-2

Page 33

Page 34

Page 35

Page 36

Automotive Equipment

Teco Srl - Via Pio La Torre, n°10

42015 Correggio (RE) Italy

www.teco.it - www.tecorus.ru

www.youtube.com/user/TECOsrl

Telephone: +39.0522.631562

Fax: +39.0522.642373

E-mail: teco@teco.it

Loading...

Loading...