Tecnoware EVO STAR 120, EVO STAR 60, EVO STAR 150, EVO STAR 200, EVO STAR 250 Installation And User Manual

...

EVO STAR

Uninterruptible Power Supply

EVO STAR 60 – 800 KVA

Installation and User Manual

________________________________________________________________________________

EVO STAR 60-800

1

.

Copyright 2007 TECNOWARE s.r.l. All rights reserved.

All trademark are property of their respective owners.

TECNOWARE s.r.l.

www.service.tecnoware.com

This manual has been printed and edited by TECNOWARE s.r.l.

________________________________________________________________________________

EVO STAR 60-800

2

INDEX

INTRODUCTION...................................................................................................5

WARNING ............................................................................................................6

EMERGENCY PROCEDURES ...................................................................................7

1 IDENTIFYING PACKAGED U.P.S. .......................................................................8

1.1 VERIFYING THE GOODS..........................................................................................................................8

2 HANDLIND, STORING AND POSITIONING .........................................................9

2.1 HANDLING...................................................................................................................................................9

2.2 U.P.S. STORAGE..........................................................................................................................................9

2.2.1 U.P.S..................................................................................................................................................................9

2.2.2 BATTERY CABINETS ....................................................................................................................................9

2.3 POSITIONING............................................................................................................................................10

2.3.1 CHOOSING THE ROOM........................................................................................................................10

3 GENERAL DESCRIPTION.................................................................................11

3.1 OPERATING PRINCIPAL........................................................................................................................11

3.2 DESCRIPTION AND PARTS....................................................................................................................11

3.1.1 RECTIFIER.....................................................................................................................................................12

3.1.2 INVERTER......................................................................................................................................................12

3.1.2 STATIC COMMUTATOR..............................................................................................................................12

3.1.4 MANUAL BY-PASS......................................................................................................................................13

3.1.5 PART LAYOUT..............................................................................................................................................13

3.1.6 BREAKERS ....................................................................................................................................................16

3.1.7 FUSES.............................................................................................................................................................16

3.1.8 TERMINAL CONNECTORS.................................................................................................................. 17

POWER UP TO 150 KVA.....................................................................................................................................................................................17

POWER OVER 150 KVA...................................................................................................................................................................................... 17

4 CONNECTING THE U.P.S. TO THE MAINS SUPPLY.............................................. 18

4.1 COMPATIBILITY WITH THE POWER SUPPLY.......................................................................................... 18

4.2 INDIRECT POWER SUPPLY............................................................................................................................18

4.2.1 TRANSFORMER............................................................................................................................................18

4.2.2 GENERATOR.................................................................................................................................................18

4.3 INPUT WIRE SIZING .........................................................................................................................................18

4.4 PROTECTION OF THE U.P.S. OUTPUT LINE...............................................................................................19

4.5 CONNECTING THE SYSTEM...........................................................................................................................19

4.5.1 CONNECTION WITHOUT BACK-UP LINE ...............................................................................................20

4.5.2 CONNECTION WITH BACK-UP LINE........................................................................................................21

4.6 CONNECTING THE BATTERIES TO THE U.P.S..........................................................................................22

4.6.1 CONNECTION TO A BATTERY CABINET................................................................................................22

4.6.2 CONNECTION TO A 180cm HEIGHT BATTERY CABINET....................................................................22

4.7 MECANICAL OPERATIONS............................................................................................................................23

4.7.1 OPEN FRONT PANEL................................................................................................................................... 23

4.7.3 REMOVE SECONDARY DOOR...................................................................................................................23

4.7.4 REMOVE ROOF.............................................................................................................................................23

4.7.1 REMOVE SIDE DOORS.......................................................................................................................23

5 STARTING-UP AND SHUTTING DOWN THE MACHINE........................................24

5.1 STARTING-UP THE MACHINE.......................................................................................................................24

5.1.1U.P.S with independent reserve line.................................................................................................................24

5.1.2 First time starting-up........................................................................................................................................24

5.2 SHUTTING DOWN..............................................................................................................................................25

________________________________________________________________________________

EVO STAR 60-800

3

5.2.1 EMERGENCY POWER OFF SWITCH ( optional) .......................................................................................

25

5.2.2 RESTORING FROM EPO..............................................................................................................................25

RESTORING FROM PARTIAL SHUTDOWN:............................................................................................................................................. 25

RESTORING FROM TOTAL SHUTDOWN:................................................................................................................................................. 25

6 ACTIVATING THE MANUAL BY-PASS ................................................................ 26

6.1 ACTIVATING THE BY-PASS SHUTTING DOWN THE U.P.S............................................................ 26

RESTORING NORMAL FUNCTIONING FROM THE PREVIOUS CONDITION: ................................................................................. 26

6.2 ACTIVATING THE BY-PASS KEEPING THE U.P.S SWITCHED ON AND BATTERY CHARGING....26

RESTORING NORMAL FUNCTIONING FROM THE PREVIOUS CONDITION: ................................................................................. 27

7 CONTROL PANNEL........................................................................................ 28

7.1 THE CONTROL PANEL AND ITS FUNCTIONS...................................................................................28

7.1.1 MONITORING.........................................................................................................................................29

7.1.2 DIAGNOSTIC TOOLS............................................................................................................................29

7.1.2.1 LED..................................................................................................................................................................................................30

7.1.2.2 EVENT AND HISTORY MENUS ....................................................................................................................................................30

7.1.2.3 BATTERY TEST............................................................................................................................................................................... 31

7.1.3 FUNCTIONING MODE CONFIGURATION.........................................................................................32

7.1.3.1 BATTERY CHARGE MODE ...........................................................................................................................................................32

7.1.3.2 FORCING ON INVERTER MODE ................................................................................................................................................. 32

7.1.4 SYSTEM AUTONOMY .................................................................................................................................32

7.1.5 BUZZER..........................................................................................................................................................32

7.1.6 STRUCTURE MENU..................................................................................................................................... 33

..................................................................................................................................................................................33

7.2 OTHER INFORMATION....................................................................................................................................35

Clear history without reset: ..........................................................................................................................................................................35

Relay programming: .......................................................................................................................................................................................35

Other measure.................................................................................................................................................................................................. 35

Working time..................................................................................................................................................................................................... 35

8 OTHER BOARD................................................................................................ 36

8.1 INVERTER...........................................................................................................................................................36

LED ..........................................................................................................................................................................36

8.2 RECTIFIER..........................................................................................................................................................36

LED ..........................................................................................................................................................................36

8.3 POWER SUPPLY.................................................................................................................................................37

LED E FUSES..........................................................................................................................................................37

8.4 DRIVER IGBT......................................................................................................................................................37

LED ..........................................................................................................................................................................37

8.5 FUSES BOARD.....................................................................................................................................................37

REPLACING THE FUSES...................................................................................................................................... 37

8.6 STATIC DRIVER.................................................................................................................................................37

8.7 TRANSFORMER BOARD..................................................................................................................................38

8.8 RECTIFIER DRIVER..........................................................................................................................................39

8.9 HALL BOARD......................................................................................................................................................39

8.10 RELAY BOARD..........................................................................................................................................40

8.11 RECTIFIER FILTER.........................................................................................................................................41

8.12 BATTERY FUSE................................................................................................................................................41

9 BACK-UP LINE ................................................................................................ 42

10 REMOTE PANEL (OPTIONAL) ..........................................................................42

INSTALLATION OF REMOTE PANEL WITHOUT E.P.O.................................................................................43

INSTALLING THE REMOTE PANEL WITH E.P.O............................................................................................45

11 EMERGENCY POWER OFF ............................................................................... 46

11.1 EPO TYPE...........................................................................................................................................................46

11.1.1 EPO ON CONTROL PANEL .......................................................................................................................46

11.1.2 EPO ON REMOTE PANEL.......................................................................................................................... 46

11.2 PROGRAM EPO ................................................................................................................................................46

________________________________________________________________________________

EVO STAR 60-800

4

11.3

RECOVERY FROM EPO.................................................................................................................................. 46

12 RS232 SERIAL CONNETCION .........................................................................47

13 SNMP ...........................................................................................................48

13.1 SNMP...................................................................................................................................................................48

13.2 ISTALLATION...................................................................................................................................................48

14 OUTPUT FREQUENCY ....................................................................................48

15 BATTERIES....................................................................................................49

15.1 EXTERNAL BATTERY CABINETS........................................................................................................50

15.1.1 DESCRIPTION OF THE MAX 32 BATTERIES CABINET UP TO 44Ah............................................51

15.1.2 DESCRIPTION OF THE MAX 32 BATTERIES CABINET UP TO 120 Ah......................................... 52

16 TECHNICAL CHARTS ..................................................................................53

A BREAKER BOX ............................................................................................

56

B INPUT TWELVE PULSES AND FILTERS..............................................................57

B.1 INPUT TWELVE PULSES.........................................................................................................................57

C GREEN MODE.............................................................................................58

________________________________________________________________________________

EVO STAR 60-800

5

INTRODUCTION

The Uninterruptible Power Supply provides critical loads with continuous computer grad e power. Reliability and

performance are the key design considerations. The UPS design also maximizes isolation of the load from disturbances

and interruptions, minimizes maintenance and repair time with its slide out modular system, and provides monitoring of

significant system operating characteristics.

Proper installation and operation of the UPS are equally important factors in system reliability. This manual provides

complete information on installation, operating and preventative maintenance of the UPS and Battery Cabinet.

Illustrations showing the function of all operator controls, instruments, alarms and indicating lights are also given.

The UPS series is available in different power ratings from 10 to 800KVA.

This manual is from 60 to 800 Kva.

WARNING

The equipment manufacturer supplies this handbook to the companies that will actually use the

equipment.

Reprinting part or whole of this handbook is forbidden.

All the information in this handbook is of exclusive right of the manufacturer.

All rights are reserved.

This handbook is to be used only inside the works in order to find all necessary information to

prevent injuries and to install and use the U.P.S.

Not right use of this information is very danger for device an people

________________________________________________________________________________

EVO STAR 60-800

6

WARNING

PLEASE READ THIS TECHNICAL HANDBOOK VERY CAREFULLY BEFORE

CARRYING OUT INSTALLATION PROCEDURES

PLEASE KEEP THIS HANDBOOK IN A WELL-KNOWN PLACE WITHIN REACH

OF ALL UPS USERS

In this handbook you will find explanations on how to install, set-up, and use the uninterrupted static power supply.

All technicians and users who are about to use these UPS must have previously read this handbook.

Technicians trained only must carry out installation and maintenance.

Inside this machine there are continuously working fans, therefore do not insert any type of

object in the ventilation grids.

Please use protective rubber gloves when working on damaged batteries.

Never remove the doors and protection covers while the equipment is operative.

When working on the UPS you must remove any metallic o bjects you may be wearing, such

as rings, watches, pens and any other type of object which could provoke a short circuit when

operating inside the machine.

There are dangerous voltages in the uninterruptible static power supply even when it’s turned off

with all the switches switched off and with the access covers removed!

There is a dangerous voltage at the ends of the batteries even when the switches are disconnected.

Please operate very carefully on the batteries; a short circuit can cause great damage to people or

things.

Do not smoke and do not use a naked flame when working on the equipment.

If the uninterruptible power supply system or the room where this is installed should catch fire

never use water to put out the flames.

________________________________________________________________________________

EVO STAR 60-800

7

CAUTION!

EMERGENCY PROCEDURES

If there is an emergency it is possible to disconnect the power supply charge by switching off all the switches on the

control panel. On the machines that are equipped you may press the E.P.O. button.

PEOPLE HIT BY ELECTRICAL DISCHARGE

Ask immediately for the help of a qualified and trained person.

When a rather high voltage and high intensity electric hit a body current this can provoke burns. The burns appear in

and around the areas where the current enters and exits the body. Even if only small burns are visible on the skin, the

tissues beneath could be seriously damaged. In any case, and however serious the burn may be, NEVER TOUCH the

injured person with bare hands until you are sure that the electricity has been cut off.

SYMPTOMS AND SIGNS

Redness, edema, skin burns or skins carbonisation in the areas where the electricity entered and exited the body.

The person may loose consciousness.

The person may stop breathing or his/her heart may stop beating .

Shock symptoms.

FIRST AID

Cut off the power supply and move the injured person away from the source of contact. Call immediately for an

ambulance and, if necessary, for the help of a technician specialised in electrical equipment.

PEOPLE WHO HAVE COME INTO CONTACT WITH CORROSIVE LIQUIDS

Ask immediately for qualified expert help.

All batteries installed in this system are completely dry and no corrosive liquids leak out of their cases if the

batteries are in perfect condition. If the storage batteries get damaged in any way, this could provoke the leakage of the

electrolyte or a short circuit of the internal cells; the electrolyte is corrosive and causes burns.

SYMPTOMS AND SIGNS

A piercing sensation on the skin

The skin will appear reddened sometimes with small blisters and exfoliation.

FIRST AID

Place the injured area under a strong jet of cold running water for at least 10 minutes so as to avoid further damage

to the tissues. N.B. Make sure that the water can flow away freely as the substance that caused the burn contaminates it.

While swilling the injured area be careful not to splash yourself with contaminated water. Call for an ambulance

immediately.

.

If the electrolyte comes into contact with eyes you must intervene immediately by washing them with running water

until expert medical help arrives.

If the battery electrolyte is swallowed it is advisable to make the injured person drink plenty of milk or water.

IN ALL CASES ASK FOR EXPERT MEDICAL HELP

________________________________________________________________________________

EVO STAR 60-800

8

1 IDENTIFYING PACKAGED U.P.S.

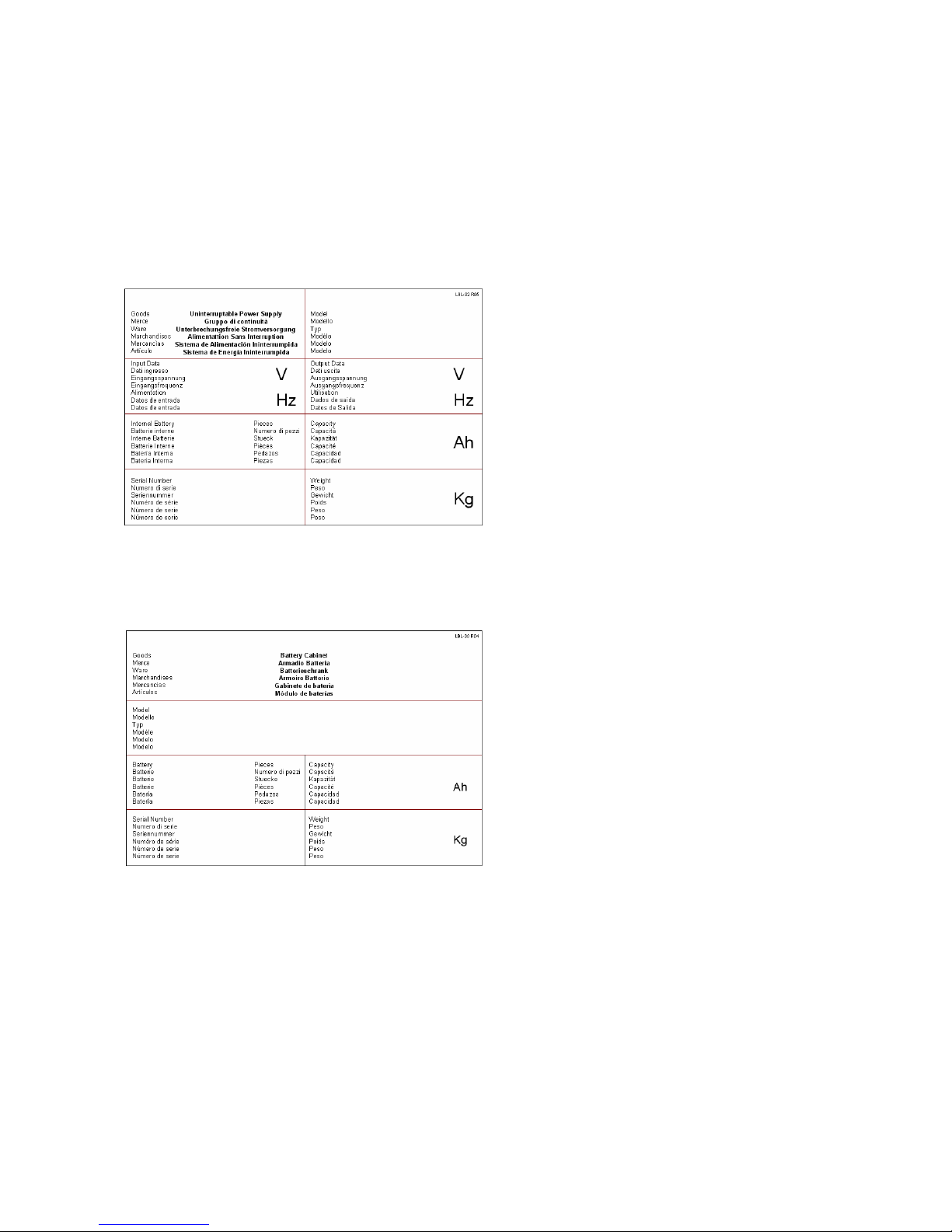

On receiving the goods you should verify the contents. On the front of the package you will find the sticker which

will allow you to identify the contents.

In the picture you can see the identity sticker which is placed on the packaging of the equipment:

1. Ups type

2. Specifies voltage and frequency input admittance

3. Specifies voltage and frequency output admittance

4. Specifies the number of batteries which may be

inside the machine

5. Specifies internal battery capacity

6. Specifies the serial number of the product

7. Specifies weight

In the picture you can see the identity sticker placed on the packaging of the battery:

1. Specifies the battery cabinet model

2. Specifies the number of batteries contained

3. Specifies battery capacity

4. Specifies the serial number of the product

5. Specifies weight

1.1 VERIFYING THE GOODS

After making sure that the goods are those required, please check that the equipment has not been damaged. In order

to do this you must verify the integrity of the p ackaging. After having removed the packaging check that the metal

panels have not been damaged during transport. If the goods are not compliant in any way please put them back in their

original packaging and send them back to the manufacturer.

Picture 1.1

Picture 1.2

1

2 3

4 5

1

3

5

7

2

4

6

________________________________________________________________________________

EVO STAR 60-800

9

2 HANDLIND, STORING AND POSITIONING

2.1 HANDLING

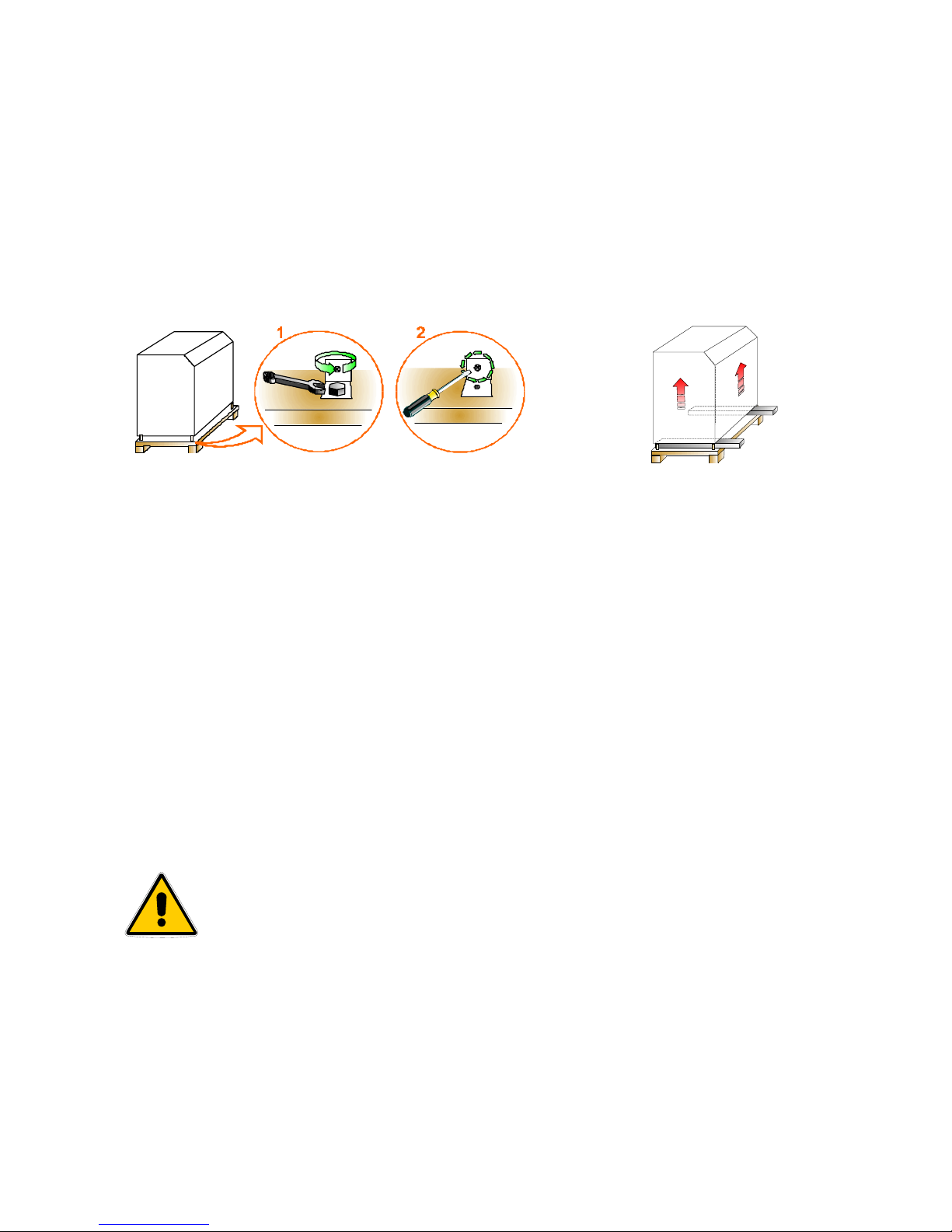

1. Remove the screws which fasten the machine to the pallet (Picture 2.1)

2. Remove the wooden pallet by using a lift truck and carefully place it on the floor (Picture 2.2)

3. For floor handling you will only need a transpallet with a suitable loading capacity

2.2 U.P.S. STORAGE

2.2.1 U.P.S.

If you need to store the UPS this must be protected from dust and dirt (even if it is well packaged). It must not be

exposed to the inclemency of the weather and the room shouldn’t be too humid (humidity below 90% noncondensing), nor should the UPS be exposed to sources of heat; room temperature should be between +1 e +40°C.

2.2.2 BATTERY CABINETS

If you need to store a complete battery cabinet, you should respect all the conditions mentioned in the previous

paragraph. You should also remember that battery discharge over time, even when not in use, therefore it is necessary

to recharge them every 4 months.

In any case, you must follow the manufacturers’ indications to store the batteries.

Non-compliance with these indications can cause an efficiency decrease and a

shorter life of the storage batteries.

Picture2.1

Picture 2.2

________________________________________________________________________________

EVO STAR 60-800

10

2.3 POSITIONING

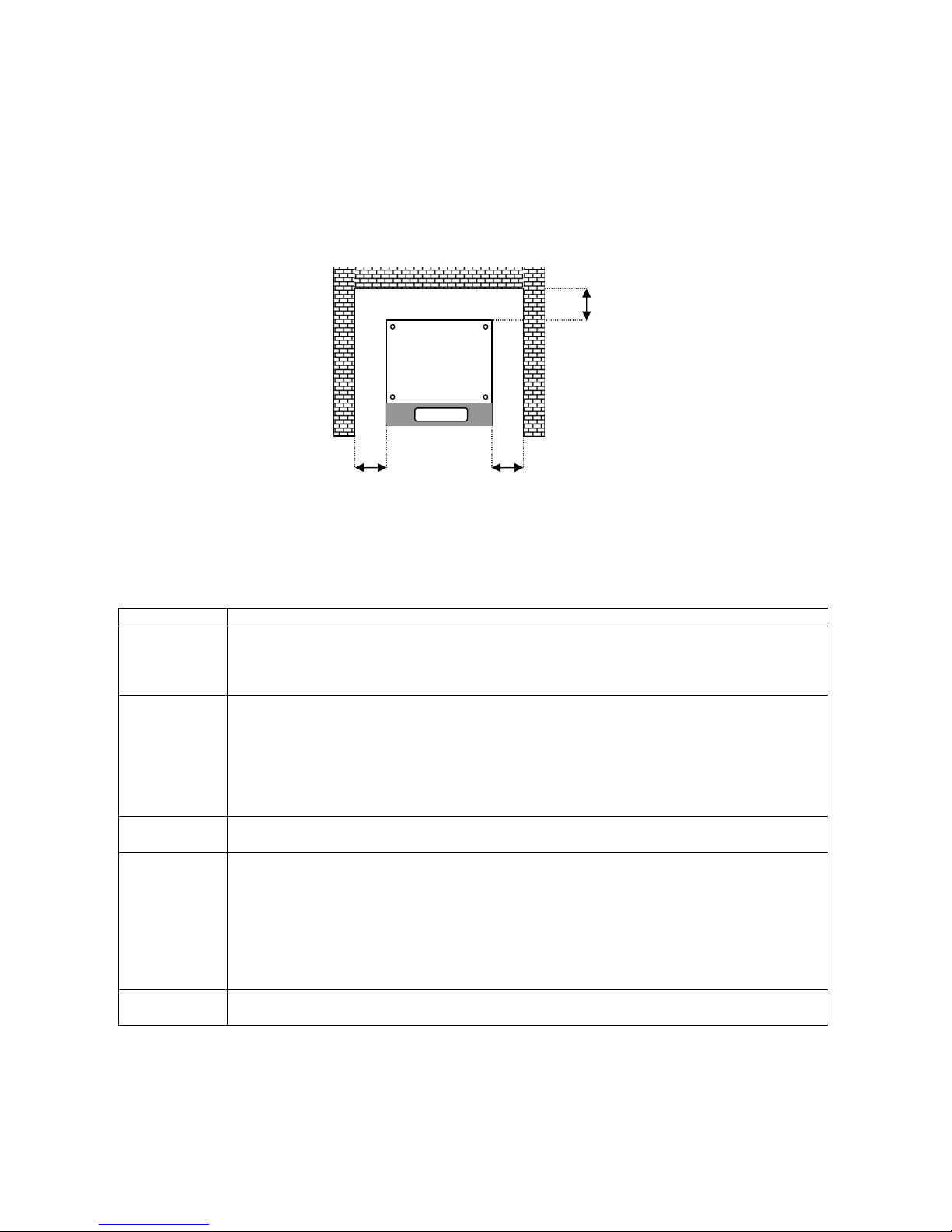

Installation space varies according to the size of the U.P.S and to the battery cabinet. A distance margin from the

walls of the room where the U.P.S. is positioned is also necessary for air circulation and ordinary/extraordinary

maintenance. Please refer to picture 2.3 for minimum margin distances. All models need a distance margin of at least

40cm either side or at least a metre from the ceiling.

2.3.1 CHOOSING THE ROOM

Element Requirements

Room access

• All the doors which the equipment has to go through in order to reach the chosen room have to

be large enough to allow the passage of the U.P.S (c harts 8) and its handling equipment. We

advise you to forbid access to the place where the U.P.S. and its battery cabinets are placed to

all non authorized users.

Room size

• Room space must be suitable to allow installation of the equipment and periodical and

extraordinary maintenance.

• When choosing the rooms please remember that the equipment must not be exposed to the

inclemency of the weather, to corrosive substances, to excessive humidity (humidity below 90%

non-condensing) or to very high sources of heat.

• The environment should not be very dusty. Please be very careful if you decide to carry out any

building work after setting up the machine.

Floor load

• According to the data in charts 8 you must check that the floors of the chosen rooms can support

the equipment’s weight.

Ventilation

• Room temperature should be preferably between 15° and 25°C

• Ventilators expel the heat dissipated by the U.P.S. into the air, therefore the room structure must

be suitable to guarantee sufficient aeration to eliminate the heat produced by the U.P.S.

• If room temperature does not comply with the recommended parameters or if air circulation in

the room is not adequate, you must supply the room with a ventilation system or, if this should

not be sufficient, install an air conditioning system.

Safety rules

• The rooms where the U.P.S. is installed must be equipped according to fire and safety

regulations.

Picture 2.3

40 cm

40 cm 40 cm

U.P.S. from 60 to 800 KVA

________________________________________________________________________________

EVO STAR 60-800

11

3 GENERAL DESCRIPTION

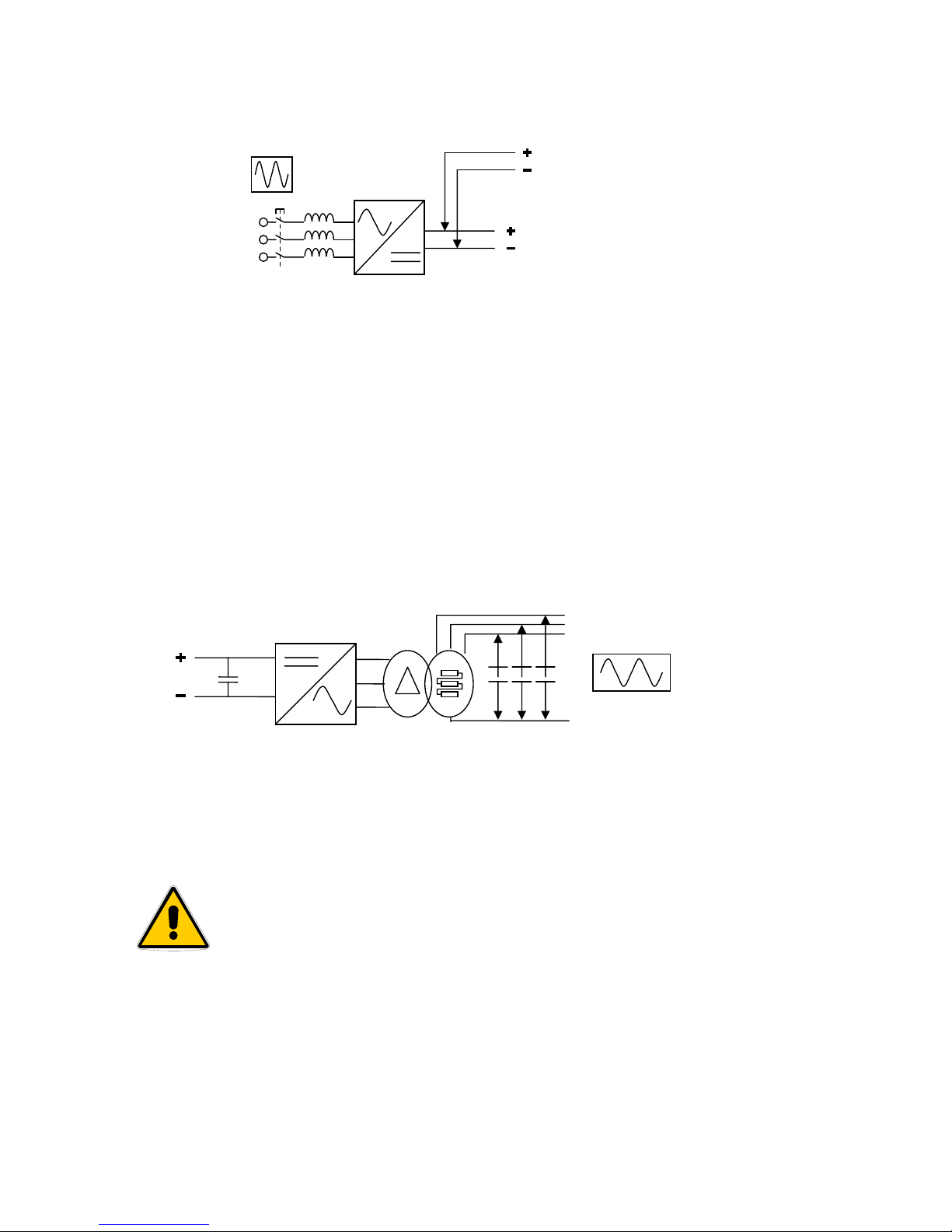

3.1 OPERATING PRINCIPAL

The U.P.S. is a continuous double conversion system with an output transformer. It works by carrying out a

continuous double conversion of the main supply, guaranteeing a constant stabilized supply of both voltage and

frequency, maintaining charge and control of the batteries (On-line functioning). In order to guarantee continuous

supply when the voltage of the electric system are no longer correct, power is drawn from the batteries. The system is

supplied complete with an automatic static commutator that connects the output to the back-up power supply, or if there

are special alarms such as the E.P.O. (Emergency Power Off) it shuts down completely output voltage.

3.2 DESCRIPTION AND PARTS

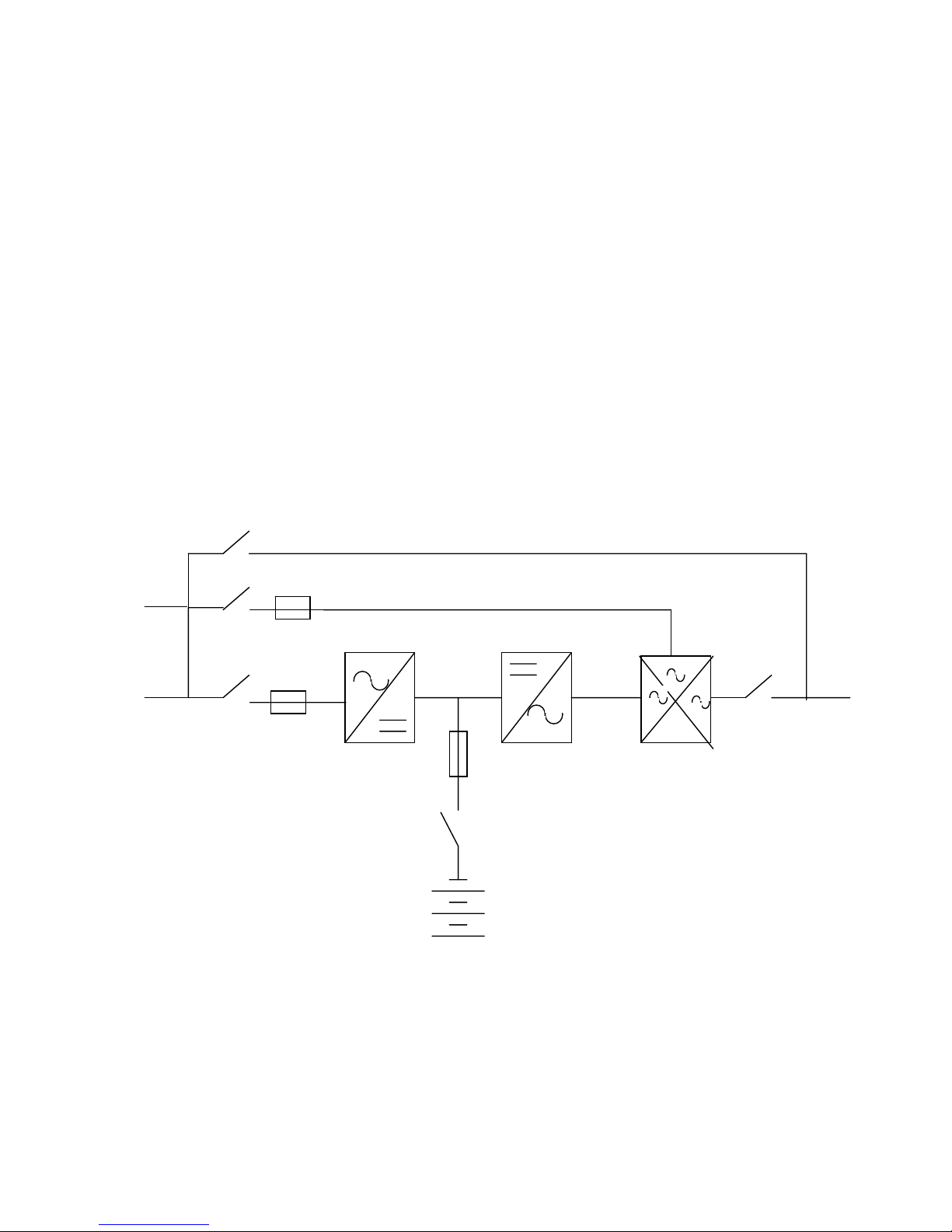

During normal functioning (figura 3.1) the system takes power from the mains by means of the input terminal (1).

The voltage goes through the disconnecting switch (4) and the fuse board (6/a ) in order to reach the rectifier module

(7), exiting which is a continuous controlled voltage available to charge or maintain battery efficiency (cross fuse (6/b)

and battery switch (8)) and to the inverter input (10). This step is to generate a three-phase voltage, stabilized and

synchronized with the back-up voltage. The static commutator (11) selects the power source to power the load, usually

on inverter (10). If there is an increase of output current or with specific alarms, the device (11) will commutate to the

emergency supply maintaining output continuity. If transferring takes place, output continuity is allowed by the

synchronism of the voltages generated with the emergency voltage. If asynchronous commutation should take place

there will be a power “dip” for maximum 20 ms.

When the power supply is not in the set parameters, the equipment maintains output voltage by taking power fro m

the batteries (9). The system is provided with a current control that keeps the current inside set parameters in the event

of current overloaded.

4

3

2

5

6/a

7

6/b

1

10

8

9

11

12

13

Back-up line

By-pass Line

1. Power supply

2. Manual By-pass

3. Back-up line switch

4. Mains switch

5. Back-up fuses board

6. Fuses board

a) Mains b)Battery

7. Rectifier

8. Battery switch

9. Inverter

10. Static switch

11. Output switch

12. Output

Picture 3.1

1/A

RECT.

INV.

M.B.

I.B.

BATT.

________________________________________________________________________________

EVO STAR 60-800

12

3.1.1 RECTIFIER

Rectifier indicated in picture with the abbreviation RECT, transforms alternating current voltage from main line to

direct current voltage. Its engineering allows, through a six pulse absorption to feed the inverter in its status of

maximum voltage output at the same time as the battery charge. Normally, direct current voltage is constantly set at

436Vdc (sustaining voltage), but when recharging the batteries, this voltage will be automatically limited b y a current

limiter.

In the following description the link from rectifier to inverter is defined as “Dc-link” and the voltage between its

poles is defined as “Dc link voltage”

3.1.2 INVERTER

The inverter, indicated in picture 3.1 with the abbreviation INV, has the role of transforming direct current voltage,

taken from the rectifier output, into sinusoidal voltage, which may be used by the user; This process is carried out by

using power semiconductors, piloted by a PWM signal, which through a transformer and a capacitance filter give us a

very stable three-phase voltage with a harmonic distortion lower than one unit.

The controlling logic of the inverter also controls output current intensity limiting it to a value which corresponds to

150% nominal current voltage.

3.1.2 STATIC COMMUTATOR

The static commutator indicated in picture 5 as B.S., is a commutator made with semiconductors which can select

which power source to connect appliances to. During normal functioning the U.P.S. output is taken at the inverter

output (U.P.S. on-line), but if there is an internal or external event it will commute to the reserve system.

Commutating from one source to another occurs without creating voltage

“dips” only with conditions of synchronism between inverter output and the

reserve system. If there is forced commuting, without synchronism, decided by

the user, this will occur with a voltage dip of max. 20 Sm.

Commuting Conditions on inverter:

1. Inverter switched on and working and synchronized with the

reserve system

2. Loss of system

3. Voluntary forcing through control panel

Commuting Conditions on reserve:

1. Malfunctioning of the inverter

2. Current overcharge

3. U.P.S. switched off

4. Voluntary forcing through control panel

Output voltage

L1 L2 L3

LN

Picture 3.3

Input voltage

To battery

To inverter

U

V

W

Picture 3.2

________________________________________________________________________________

EVO STAR 60-800

13

5. By-manual closing of the breaker

3.1.4 MANUAL BY-PASS

Il by-pass manuale, indicated in picture 3.1 as M.B., consists in a breaker which powers the critical load directly

from the main system. This device is particularly useful during ordinary/extraordinary maintenance, as it allows the

operator to deal with the internal circuits with a minimum risk of contact with voltaged elements.

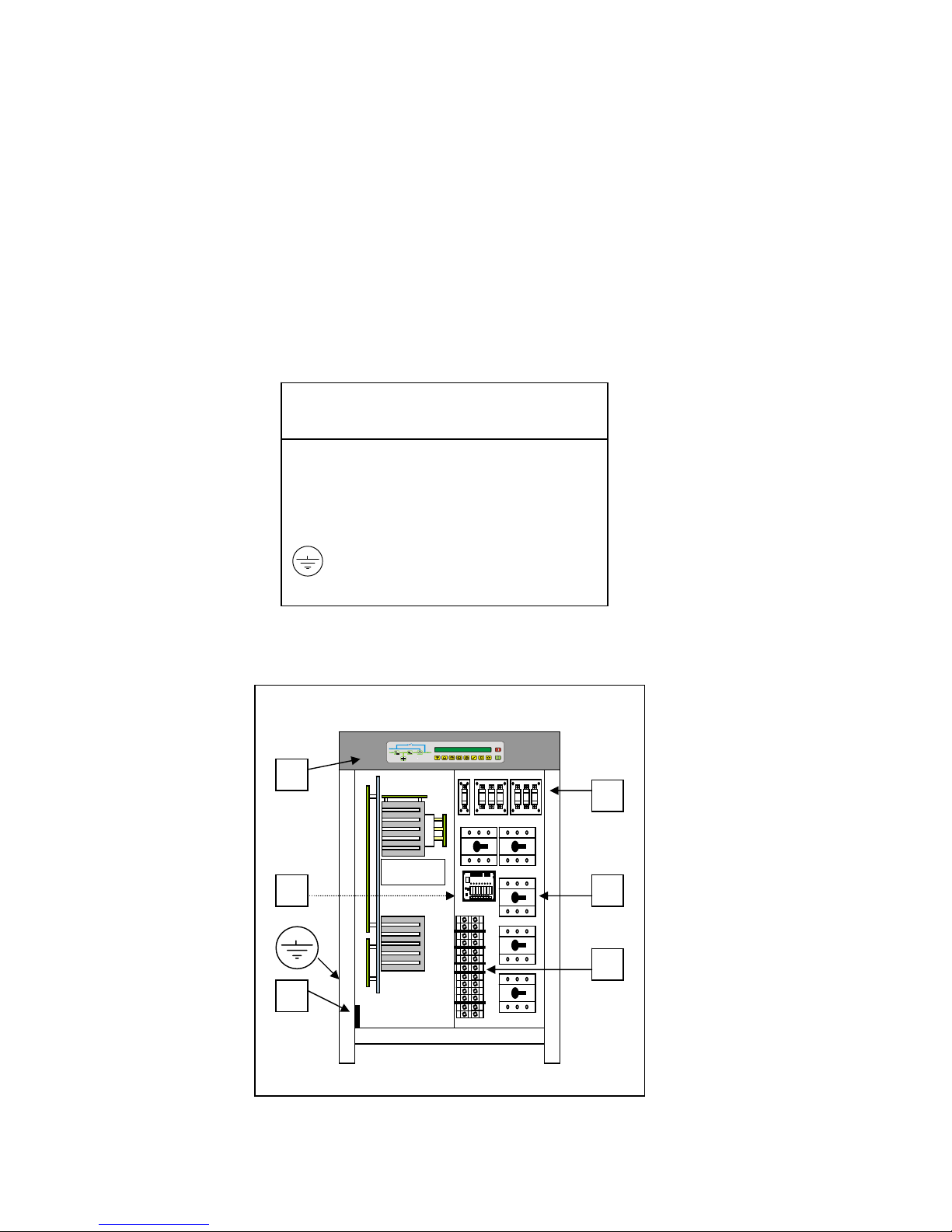

3.1.5 PART LAYOUT

It is important to be familiar with the parts that are necessary during the connection procedures before connecting

the equipment. In order to access the parts which will be described you must remove the “second access”, which is the

metal panel used to protect the inside parts of the U.P.S. and also to protect the user from accidental contacts with live

parts.

A = Display board

B = Relay board

C = Interface connector

D = Terminal

E = Breakers

F = Fuse cards

= Earthing

KEY

U.P.S. from 60 to 100 KVA

A

C

F

D

E B

Picture 3.4

________________________________________________________________________________

EVO STAR 60-800

14

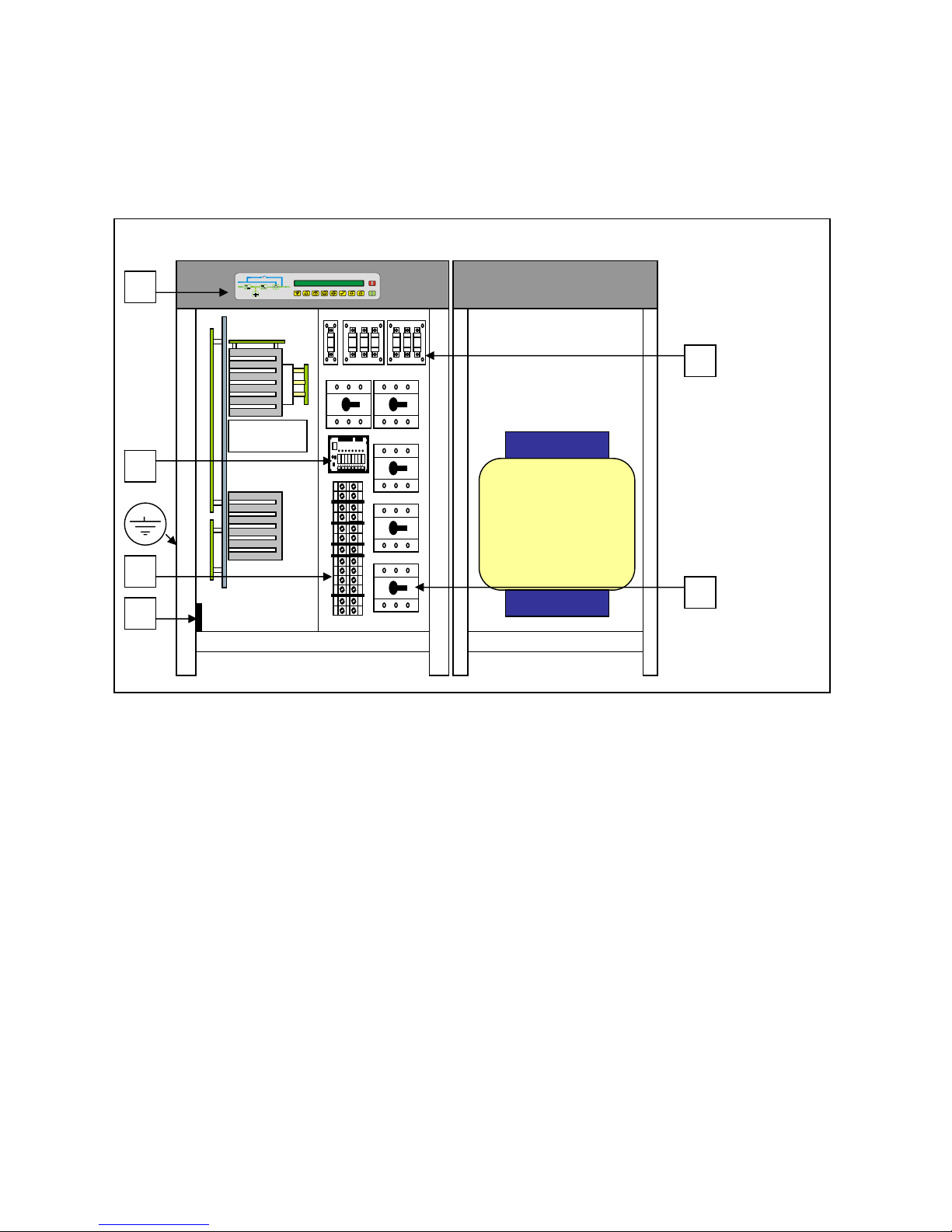

U.P.S. from 120 to 150 KVA

A

B

C

D

E

F

Picture 3.5

________________________________________________________________________________

EVO STAR 60-800

15

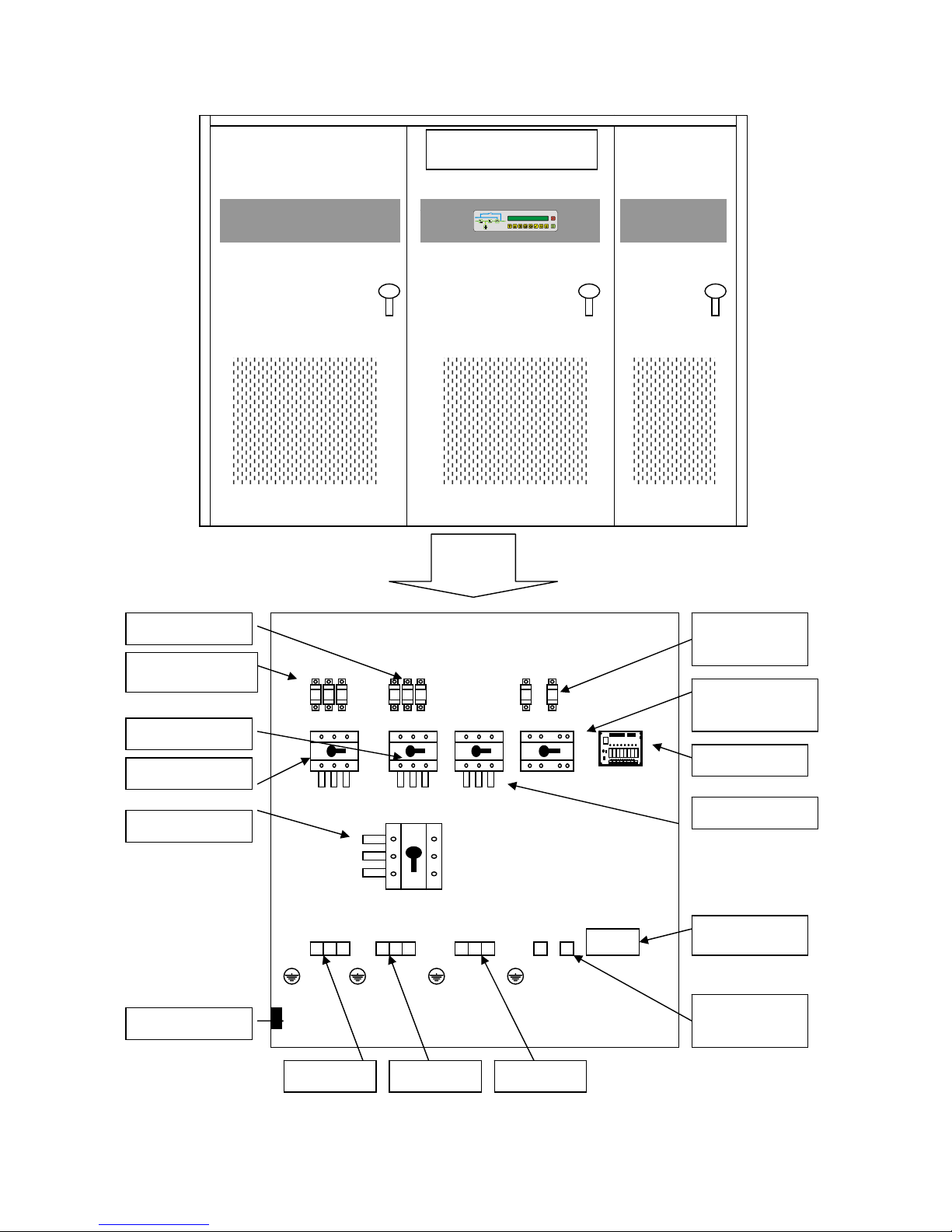

Battery

connection

Mains switch

Reserve switch

Output switch

Battery fuses

Battery switch

Spare fuses

Neutral bar

Rectifier fuses

Relay board

RS 232

By-pass switch

Reserve Input Output

Picture 3.6

U.P.S from 200 to 800

________________________________________________________________________________

EVO STAR 60-800

16

3.1.6 BREAKERS

The U.P.S. has a system of breakers, which allows the user to carry out the necessary operations in order to use and

carry out maintenance on the equipment and to shut down the power supply if there is an emergency. A sticker placed

on the second access specifies the name of each switch near the switch itself. The by-pass switch contains a protection

device so, as it cannot be disconnected inadvertently. The user can remove this protection device if he/she decides to

carry out a manual by-pass.

1. MAINS SWITCH Break the mains supply, as specified in point 1 picture 3.1

2. RESERVE SWITCH Break the secondary power supply, as specified in point 7 picture 3.1

3. MANUAL BY-PASS Short-circuits the secondary input with the output

4. OUTPUT SWITCH Break the loading power supply.

5. BATTERY SWITCH Break, according to the model, one or both battery polarities.

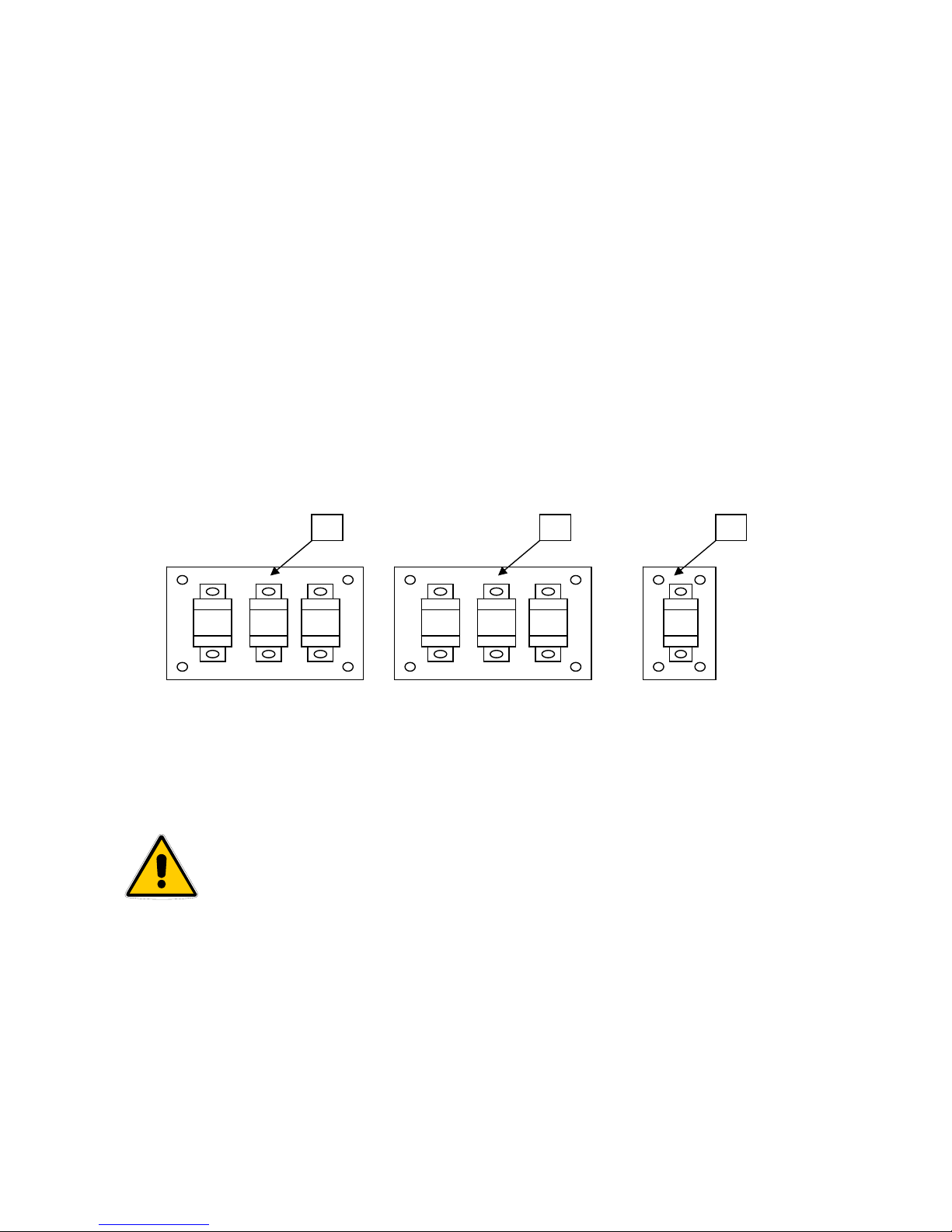

3.1.7 FUSES

The U.P.S. includes a system with two fuse groups, both counting three fuses each which are able to disconnect

electrical power input (points 1 and 7 picture 3.1), when the electrical power is not within the set parameters. The type

of fuse, which is used, guarantee quick intervention and therefore are a guarantee also for optimum protection of the

internal devices. Furthermore, there is also a fuse on the line, which connects the U.P.S. to the batteries (point 6 picture

3.1), both for internal and external batteries.

Board A, (picture 12), to the user’s left, protects the state of the rectifier input, board B , to the user’s right, protects

the reserve line. Whereas the single-fuse board C protects the battery line. In UPS over 150 KVA fuses are on

connection bars without board, for battery there are two fuses.

REPLACING THE FUSES

CAUTION! : ALL CONNECTING PROCEDURES DESCRIBED IN THIS CHAPTER

MUST BE CARRIED OUT BY AUTHORIZED ELECTRICIANS OR BY QUALIFIED

TECHNICIANS.

CAUTION! : BEFORE REPLACING THE FUSES YOU MUST CARRY OUT THE

MANUAL BY-PASS PROCEDURE WITH THE U.P.S. DISCONNECTED (CHAPTER 5)

A nut screw fastens each fuse. When replacing a fuse you must unscrew the two knurled nuts corresponding to the

fuse, which must be replaced, remove the washers, replace the fuse and put back the washers and the knurled nut in this

order. IMPORTANT spare fuses are supplied together with the U.P.S. If they have to be purchased please make sure

that they are extra-fast fuses for the current same as on machine so as to guarantee total protection.

A B C

Picture 3.7

________________________________________________________________________________

EVO STAR 60-800

17

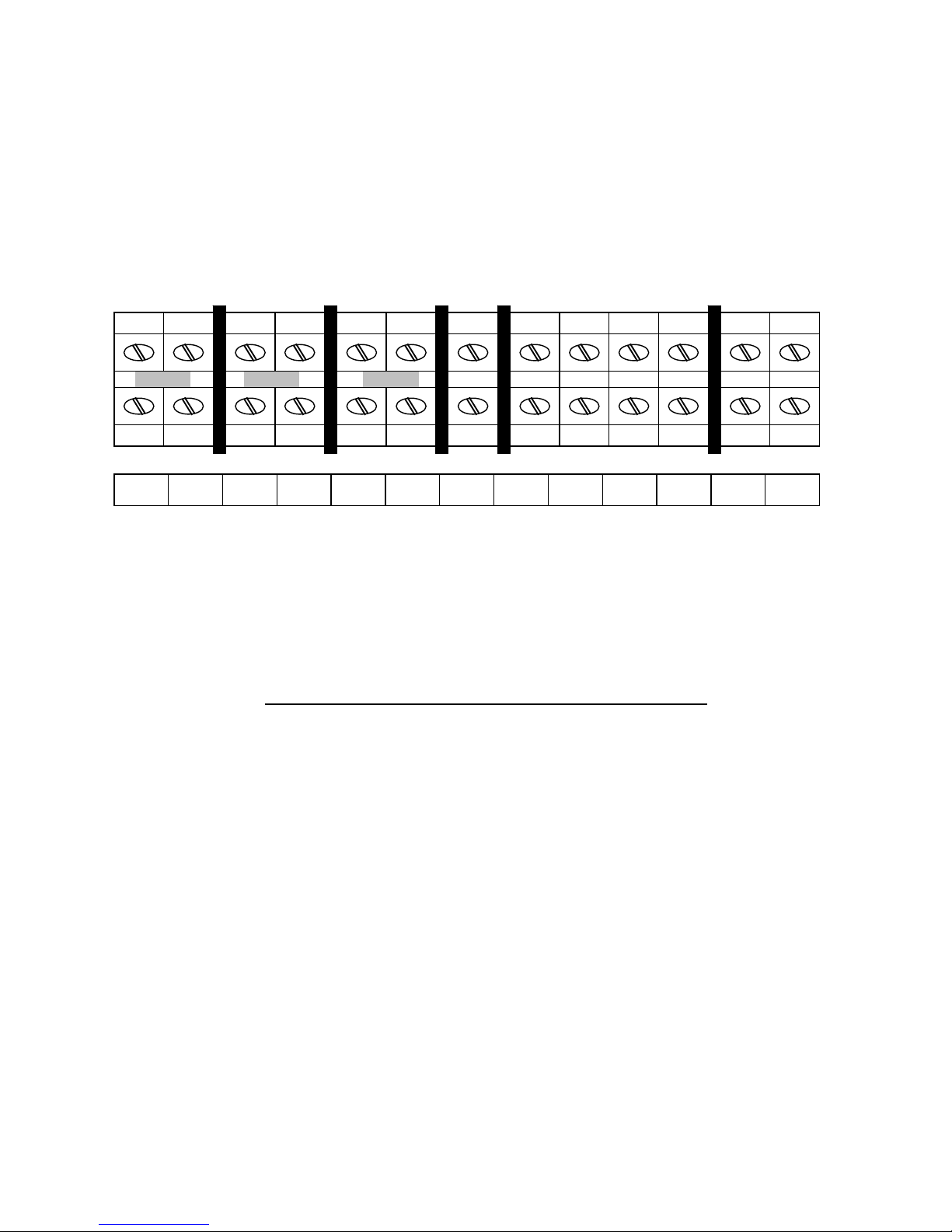

3.1.8 TERMINAL CONNECTORS

POWER UP TO 150 KVA

In all the models the terminal board is on the front of the U.P.S. protected by the second access.

It can be perpendicular or horizontal according to the model.

In any case, please refer to the alphanumeric specifications on the terminal board. The jumpers are arranged as in the

picture (highlighted in grey), and are used to short-circuit the main input and the reserve input. According to the type of

installation, you can remove them to connect the system to an auxiliary power source (back-up supply, generator).

U, V, W = Main input

U1, V1, W1, N1 = Reserve input

U2, V2, W2, N2 = Output

D(-),C(+) = Battery pole input. D(-) negative pole, C(+) positive pole.

In 100KVA device terminal D and C are double, in 120-150KVA also N1 and N2 are double

In this manual fase name U, V, W or R, S, T, or R, Y, B are equivalent.

POWER OVER 150 KVA

In the high power systems instead of using terminal boards for power connections a group of copper bars with

perforated ends are used. Therefore with the help of cable terminals, knurled screws and nuts a suitable connection for

the current values in circulation. As for the connection references please refer to the alphanumeric specifications on the

copper bars which respect the same specifications present on the terminal boards in equipment up to 200KVA.

U U1 V V1 W W1 N1 U2 V2 W2 N2 D(-) C(+)

Picture 3.8

________________________________________________________________________________

EVO STAR 60-800

18

4 CONNECTING THE U.P.S. TO THE MAINS

SUPPLY

CAUTION! : ALL CONNECTING PROCEDURES DESCRIBED IN THIS CHAPTER MUST

BE CARRIED OUT BY AUTHORIZED ELECTRICIANS OR BY QUALIFIED

TECHNICIANS.

CAUTION! : THE U.P.S. NEED A NEUTRAL WIRE. THE SYSTEM CANNOT WORK

WITHOUT IT.

4.1 COMPATIBILITY WITH THE POWER SUPPLY

The parallel connection to the public mains is normally allowed, as the U.P.S. is comparable to a passive charge.

The mains supply must supply a higher power than the U.P.S rated power as it has to take into account several factors,

such as:

1. Power absorbed by the output charge on the uninterruptible power supply

2. System efficiency

3. Power needed to charge the batteries

4. Input harmonic distortion

If you know the amount of power needed by the connected electrical equipment and you can evaluate the probable

expansion margins it is possible to make a first rough estimate of the power required. As for the power absorbed by the

batteries while charging, you can easily work out the power required by multiplying 436 ti mes 1/10 of the total battery

capacity (E.g.: For a 40A/h battery space, the power needed to charge the battery will be: 436 X (40 / 10) = 1,744 kW).

As for input harmonic distortion please remember that for the power supply the uninterruptible power supply is to be

considered as a non-linear load, which generates harmonic frequency currents multiples of the (50/60 Hz). In function

of the line impedance these create a harmonic voltage distortion. This latter value (total harmonic voltage distortion)

must not exceed the specific environment reference parameters. There are several ways of reducing this parameter: by

increasing the power supply, the section of power supplies cables or by choosing an interruptible power supply with

specific features (twelve-phase input, with filter).

4.2 INDIRECT POWER SUPPLY

4.2.1 TRANSFORMER

If you are using a system input isolation transformer this will reduce distortion effects and stop its diffusion in the

system. Therefore, apart from decreasing harmonic disturbance you can also probably avoid oversizing the power

supply line.

4.2.2 GENERATOR

Particular attention must be paid when sizing a possible input power unit; this has high output impedance, which is

defined on the rating plate as subtransient reactance of the alternator. This parameter makes a negligible harmonic

current distortion become a seriously disturbing element for the correct functioning of the U.P.S.

4.3 INPUT WIRE SIZING

When choosing the wir e you mu st b ea r in mind a technical, economical and safety evaluation. Technically speaking,

the main factors that affect wire sizing are voltage, current, overcurrent, temperature and how the wires are laid.

However, it is always a good rule to size the wires so as the voltage drop on each wire is below 3% of the applied

voltage. Particularly important is the sizing of the neutral wire especially when the U.P.S. is used to power unbalanced

________________________________________________________________________________

EVO STAR 60-800

19

loads or loads with strong harmonic distortion. Taking into account these last remarks, the enlargement factor must be

decided according to the size of the phase wire (usually 1,5-2 times).

4.4 PROTECTION OF THE U.P.S. OUTPUT LINE

The main electric distribution systems to which the U.P.S. can be connected are the TN-S and TT systems (pictures

4.1 and 4.2). If you do not have this type of equipment please talk to a specialized technician. The protection devices,

which can be applied to the U.P.S. output line, are against overcurrent and are differential. As for their size, please bear

in mind that if there is a power shortage the U.P.S. works on its own (disconnected from the main line), with a current

restriction equal to 150% of the rated current, therefore in order to protect against overcurrent you must choose a device

that is activated within this threshold. As for differential protections you must use type A differentials (for alternate

current and for switches with continuous components), which are low sensitivity (0,3–0,5-1 A).

4.5 CONNECTING THE SYSTEM

To connect the U.P.S. you must carry out the following procedures:

1. Open the front door, the key is attached to one of the supporting feet

2. Shutdown all breakers.

3. Verify the integrity of the by-pass breaker lock out

4. Make sure there is no voltage on the mains supply

5. Unscrew the second access panel setscrews and remove the panel

6. Connect the earthling wire for the mains to the earth bar

7. Connect the general mains to the U, V and W terminals of the U.P.S. ( in cyclic sense)

8. If the back-up supply mains are available disconnect the jumpers from terminals U1 and U, V1 and V, W1 and W,

then connect the back-up supply to the U1, V1 and W1 terminals

9. Connect the supply mains neutral wire to the N1 terminal

10. Connect the mains that power the connected electric equipment to U2, V2 e W2 terminals at the U.P.S. output

11. Connect the mains neutral wire that powers the connected electric equipment to the N2 terminal at the U.P.S.

output

12. If you need to connect external battery compartments please proceed to the following paragraph.

13. Replace the second access panel and fasten its screws.

14. Lock the front door with its key

Reassemble the side grids on the supporting base

N

PE

TN-S

L1

L2

L3

N

PEN

U.P.S

The TN-S system has the neutral grounded in a

specific point to which the system’s earth is also

connected with a separate protection wire.

TT

L1

L2

L3

N

U.P.S

The TT system has the neutral grounded in a

specific point and the system’s earth is connected

to an earth which is independent from the neutral.

This is the most used device at distribution level.

Picture 4.1

Picture 4.2

________________________________________________________________________________

EVO STAR 60-800

20

4.5.1 CONNECTION WITHOUT BACK-UP LINE

INPUT LINE

L1

L2

L3

LN

U-V-W

Mains

switch

By-pass

switch

Output

switch

N1

C+

D-

U2-V2-W2-N2

USER

L1

L2

L3

LN

Battery

switch

BATTERY

BOX

Picture 4.3

________________________________________________________________________________

EVO STAR 60-800

21

4.5.2 CONNECTION WITH BACK-UP LINE

Picture 4.4

MAINS LINE

L1

L2

L3

U-V-W

Mains

switch

By-pass

switch

Output

switch

N1

C+

D-

U2-V2-W2-N2

USER

L1

L2

L3

LN

Battery

switch

Battery

box

L1 RESERVE

L2 RESERVE

L3 RESERVE

LN RESERVE

BACK-UP LINE

Reserve

switch

U1-V1-W1

________________________________________________________________________________

EVO STAR 60-800

22

4.6 CONNECTING THE BATTERIES TO THE U.P.S.

CAUTION! : ALL CONNECTING PROCEDURES DESCRIBED IN THIS PARAGRAPH

MUST BE CARRIED OUT BY AUTHORIZED ELECTRICIANS OR BY QUALIFIED

TECHNICIANS.

CAUTION! : FOR SECURITY REASONS THE BATTERIES ARE TRANSPORTED WITH

SOME OF THE JUMPERS DISCONNECTED, THEREFORE PLEASE

REMEMBER TO RE-CONNECT THEM. SEE CHAPTER 7

4.6.1 CONNECTION TO A BATTERY CABINET

1. Make sure that the U.P.S. is switched off and that all switches are off

2. Unscrew the setscrew from the second access panel of the U.P.S. and remove it

3. Unscrew the setscrew from the battery cabinet roof and remove it

4. Make sure there is no voltage on the U.P.S. battery terminals and on battery box terminal

5. Connect the earthling wire to the earth bar of the U.P.S

6. Connect the earthling wire to the earth bar of the U.P.S

7. Connect the two wires, supplied to connect the external battery cabinet, to the C and D terminals of the U.P.S. (C=

positive, D= negative)

8. Connect the wires from the U.P.S. to the C and D terminals of the battery cabinet

9. N.B. Check and control all the connections of the jumpers inside the batteries of the battery cabinet

10. Make sure that the corresponding battery breaker placed on the U.P.S is off, then shut down the battery switch on

the cabinet

11. Using a multimeter verify the correct polarity on the U.P.S. battery terminals

12. Close the second access of the U.P.S. by fastening its screws

13. Close the battery cabinet roof by fastening its screws

14. Reassemble the side grids on the supporting base

4.6.2 CONNECTION TO A 180cm HEIGHT BATTERY CABINET

1. Make sure that the U.P.S. is switched off and that all switches are off

2. Unscrew the setscrew from the second access panel of the U.P.S. and remove it

3. Open the front access door of the battery cabinet with its key

4. Make sure there is no voltage on the U.P.S. battery terminals

5. Connect the earthling wire to the earth bar of the U.P.S

6. Connect the earthling wire to the earth bar of the U.P.S

7. Connect the two wires, supplied to connect the external battery cabinet, to the C and D terminals of the U.P.S. (C=

positive, D= negative

8. Connect the wires from the U.P.S. to the C and D terminals of the battery cabinet

9. N.B. Check and control all the connections of the jumpers inside the batteries of the battery cabinet

10. Make sure that the corresponding battery breaker placed on the U.P.S is off, then shut down the battery switch on

the cabinet

11. Using a multimeter verify the correct polarity on the U.P.S. battery terminals

12. Close the second access of the U.P.S. by fastening its screws

13. Reassemble the side grids on the supporting base

________________________________________________________________________________

EVO STAR 60-800

23

CAUTION! : THE U.P.S. AUTONOMY DEPENDS ON THE STATE OF THE BATTERIES; A

CORRECT AND PROGRAMMED MAINTENANCE IS

FUNDAMENTAL TO AVOID A BAD CONDITION OF THE

BATTERIES FROM HAMPERING U.P.S. FUNCTIONING WHEN

NECESSARY.

NOTE: WHEN BATTERIES ARE CONNECTED DON’T CLOSE BATTERY SWITCH IF UPS

IS OFF

4.7 MECANICAL OPERATIONS

4.7.1 OPEN FRONT PANEL

• Open the lock with supplied key

In model of power 120KVA -800KVA open door where the control panel is mounted

4.7.3 REMOVE SECONDARY DOOR

• Open front panel

• Remove screws on sides

• Remove ground wire fix on secondary door (remember to connect it before closing secondary door)

4.7.4 REMOVE ROOF

• Remove the four screws on roof

• Lift roof

• Remove ground wire fix under roof (remember to connect it before closing roof)

4.7.1 REMOVE SIDE DOORS

• Remove the four screws on side door

• Lift door

• Remove the four screws on roof

• Remove ground wire fix on door (remember to connect it before closing door)

________________________________________________________________________________

EVO STAR 60-800

24

5 STARTING-UP AND SHUTTING DOWN THE

MACHINE

5.1 STARTING-UP THE MACHINE

CAUTION! : IF THE BATTERY BREAKER IS CLOSED, BEFORE STARTING UP T2000,

THIS CAN CAUSE U.P.S DAMAGE.

5.1.1U.P.S with independent reserve line

1. Make sure that the wires are correctly connected respecting the cyclic sense of the phases U,V,W

2. Make sure that the “Manual By-pass” switch is turned off and blocked by its blocking device

3. Give power to the mains

4. Close the “Reserve switch” breaker, the display will turn on and the message “UPS STOPPED” will appear, all the

synoptic led’s will be red except led “H ” which remain green; wait till led “A” start flashing, if this does not

happen the supply voltage is not adequate or the cyclic sense of the phases is incorrect, therefore you must

disconnect the equipment, verify the connections and start this procedure again from the beginning.

5. Close the “Mains switch” and “Output switch” breakers, led’s “G and B” will turn green

6. Press the

button for about two seconds, on the display the message “switch on proced ure started” will appear,

if the steps of procedure have been followed correctly led “C” and led “E” will become green and the message

“UPS in alarm mode” will appear

7. Once you have carried out the turning on procedure and led’s “C” and “E” are green, it is possible to close the

“Battery switch” breaker and led “D” will be green.

8. If installation has been correctly carried out and the turning on procedure done successfully, the message “UPS in

normal operation operation” will appear and all the synoptic led’s will be green

9. Go to paragraph 5.1.2

5.1.2 First time starting-up

If the turning on procedure has been carried out for the first time we advise you to continue this procedure to verify the

real efficiency and to get familiar with the system

1. Select the language you wish to use by following the indications in the menu (diagram 1a/b)

2. Carry out the battery test (see 6.1.2.2) and verify the outcome

3. Carry out the complete by-pass procedure with the U.P.S. switched on (paragraph 5.1) and all operations to restore

the by-pass

4. Carry out a power shortage test by turning off the “Mains switch” and make sure that the U.P.S. goes into alarm

mode and that led D starts flashing and led F stays green (picture 1and 7) then turn on the “Mains switch” and

check that normal functioning has been restored.

________________________________________________________________________________

EVO STAR 60-800

25

5.2 SHUTTING DOWN

CAUTION! : THE FOLLOWING PROCEDURE WILL DISCONNECT THE LOAD!

In order to turn off you must:

1. Press for about 5 seconds the

button. On the display the message “TURN OFF UPS” will appear and leds

“C”,”E” and “F” (picture 17) will be red and the message “UPS STOPPED” will appear on display

2. Open “Output switch” and led “G” will be red

3. Open “Battery switch” and led “D” will be red

4. Open “Reserve switch” and led “A” will be red

5. Open “Mains switch” and the U.P.S. will be off completely

5.2.1 EMERGENCY POWER OFF SWITCH ( optional)

The Emergency Power Off switch (E.P.O.) allows, after pre-setting the function, U.P.S. shutdown totally or partially

in emergencies. Standard setting only has the totally turned off feature. If you want to modify this set up please ask for

a specialized technician to do. It is installed on the machine or on the remote control panel.

Specialised technicians can carry out After-sales installation only.

The switch on board the machine is on the right-hand side of the control panel; for the switch on the remote control

panel, please see picture 19.

Partial shutdown results in deactivating the static and the inverter, which in consequence will turn off all the electric

equipment connected to the system’s output, whereas the rectifier and battery will continue receiving charge current.

Total shutdown deactivates all functions (including the rectifier). During the emergency the message “WARNING

emergency shutdown” will appear on the control panel. There are two ways to restore normal functioning:

5.2.2 RESTORING FROM EPO

RESTORING FROM PARTIAL SHUTDOWN

:

RESTORING FROM TOTAL SHUTDOWN

:

Press switch off button

for about three

seconds then press the switch on button

for

about five seconds and wait till the end of the

shutdown procedure.

Press the switch on button

for about five

seconds and wait till the end of the shutdown

procedure.

________________________________________________________________________________

EVO STAR 60-800

26

6 ACTIVATING THE MANUAL BY-PASS

CAUTION! : IF YOU CARRY OUT THIS PROCEDURE INCORRECTLY YOU COULD

DAMAGE THE U.P.S.

THE MANUFACTURER DECLINES ALL RESPONSABILITIES FOR

DAMAGE DUE TO INCORRECT MANOUEVRING.

CAUTION! : DURING THE ENTIRE PERIOD OF FUNCTIONING IN BY-PASS MODE, THE

ELECTRIC EQUIPMENT CONNECTED TO THE OUTPUT OF THE

DEVICE WILL BE SUBJECT TO THE FLUCTUATIONS MAINS

VOLTAGE.

This manual operation transfers the load directly to the mains during maintenance or if the equipment breakdown.

6.1 ACTIVATING THE BY-PASS SHUTTING DOWN THE U.P.S

1. Verify that led “A” is green .

2. Press the

button for about 5 seconds; the message “ Turn off U.P.S ” will appear on the display and leds

“C”,”E” and “F” will turn red and the message “UPS stopped” will appear on the display

3. Turn on the “by-pass switch” breaker and led “D” will be red

4. Turn off the “Output switch” breaker and led “G” will be red

5. Turn off the “Reserve switch” breaker

6. Turn off the “Mains switch” breaker

7. Turn off the “Battery switch” breaker

RESTORING NORMAL FUNCTIONING FROM THE PREVIOUS CONDITION

:

1. Turn on the “Reserve switch” breaker, the message “UPS Stopped” will appear on the display, all the synoptic leds

will be red except led “H” remain green; wait till led “A” starts flashing, if this does not happen the supply voltage

is not adequate or the cyclic sense of the phases is incorrect, therefore you must disconnect the equipment, verify

the connections and start this procedure again from the beginning.

2. Turn on the “Main switch” e “Output switch” breakers, led “B” and led “G” will be green

3. Turn off the “Manual by-pass” breaker.

4. Press the

button for about 2 seconds; the message “Switch on procedure started” will appear on the display, if

the procedure has been carried out correctly led “C” and led “E” will be green and the message “UPS in alarm

mode” will appear

5. Once you have carried out the turning on procedure and that led “C” and “E” are green, it is possible to close the

“Battery switch” breaker and led “D” will be green

6.2 ACTIVATING THE BY-PASS KEEPING THE U.P.S SWITCHED

ON AND BATTERY CHARGING

1. Verify that led “A” is green

2. Press keys F6 and F2 at the same time, using the scroll keys select “On reserve” and confirm your choice by

pressing F6; make sure that led “F” become yellow

3. Turn on the “Manual by-pass” breaker

4. Turn off the “Output switch” breaker

________________________________________________________________________________

EVO STAR 60-800

27

RESTORING NORMAL FUNCTIONING FROM THE PREVIOUS CONDITION

:

1. Make sure the led “F” is yellow

2. Turn on the “Output switch” breaker

3. Turn off the “Manual by-pass” breaker

4. Press keys F6 and F2, at the same time and wait until led “F” turns green

Picture 6.1

By-pass line

6/A

7

Auxiliary

________________________________________________________________________________

EVO STAR 60-800

28

7 CONTROL PANNEL

The user can communicate with the U.P.S. in the following ways:

1. Using the control panel on the front of the control board

2. Using relay interface

3. Using a Personal Computer connected to the U.P.S.

4. Using the remote control panel (Optional)

You can connect all these check tools described above to the same machine without creating interference or

incompatibility among the components. The use of photocouplers on all interfaces (except for relay interface)

guarantees galvanic separation of the interfaces remote controlled from the U.P.S. assuring all connected equipment

total protection from disturbance and interference.

7.1 THE CONTROL PANEL AND ITS FUNCTIONS

Panel check functions can be split into three main categories:

1. Monitoring

2. Diagnostic tools

3. Functioning mode configuration

In the interface system we refer to “elements”. For element we mean a group of components which concur to the

same function.

ELEMENTS DESCRIPTION

SYSTEM Includes the U.P.S. as a whole

RECTIFIER Includes devices for conversion from alternating to direct voltage

BATTERY Includes the device for energy storage

INVERTER Includes devices for conversion from alternating to direct voltage

BACK-UP This is the emergency mains supply

BREAKERS Includes all the breakers in the U.P.S.

Picture 7.1

________________________________________________________________________________

EVO STAR 60-800

29

7.1.1 MONITORING

Monitoring allows checking that all specific functions are within the set limits

ELEMENTS AVAILABLE MEASUREMENTS

U.P.S. System

Phase-phase output voltage

Phase-neutral output voltage

Output current

Inside temperature

Load percentage

Inverter

Phase-phase output voltage

Link DC voltage

Link DC current

Frequency

Rectifier

Input Voltage

Link DC voltage

Link DC current

Battery

Voltage

Current

Back-up

Voltage

Frequency

Chart 1

7.1.2 DIAGNOSTIC TOOLS

The diagnostic tools allow checking the U.P.S. functioning state, by checking for the presence of alarms in progress or

already activated and Battery State.

The available diagnostic tools are:

1. Event menu

2. History menu

3. Battery test

________________________________________________________________________________

EVO STAR 60-800

30

7.1.2.1 LED

Led Associated element Colour Meaning

green Back-up mains OK

Breaker is off (where is foreseen)

red

Incorrect input voltage

Incorrect frequency

A Back-up mains supply

flashing

Not synchronised

green Rectifier mains OK

red Rectifier mains alarmed

B Rectifier mains supply

flashing Incorrect cyclical sense

green Rectifier OK

Rectifier alarmed

C

Rectifier

red

Rectifier off

green battery OK

red Battery alarmed

D Battery

flashing Battery discharging

green inverter OK

Inverter alarmed

red

inverter off

E Inverter

flashing inverter current over 125%

green Static commutator on inverter

yellow Static commutator on back-up

F Static commutator

red Static commutator off or blocked

green Output voltage OK

Incorrect output voltage

red

Opened breaker

G Output voltage

flashing

Output current over the nominal

value

green Manual by-pass open

H By-pass

red Manual by-pass closed

Chart 2

7.1.2.2 EVENT AND HISTORY MENUS

The “EVENT” menu allows viewing of all the alarms in progress, whereas the “HISTORICAL” menu allows viewing

alarms which were active but which have already been restored. They are used when the alarm of the machine goes off

to locate the origin and the cause of the alarm and also to establish how serious the problem is. Both have an error code

and a short message. The historical menu also shows the date and the time the alarm went off.

1. The “error code” is the code which identifies the type of error shown by the system

2. La “ display message” shows the message that can be seen in the “EVENT” or “HISTORICAL” menu, that is, a

brief explanation of the reason for the alarm

3. The “seriousness” defines how serious the problem is:

Anomaly

: If the alarm is caused by a temporary event

User

: If incorrect or intentional manoeuvring by the user

causes the alarm

Failure

: If the alarm is caused by a system failure that can

be restored only by the user

________________________________________________________________________________

EVO STAR 60-800

31

SYSTEM

Error code Display message Description Seriousness

SY1 Inverter w/o load Inverter without load Anomaly

SY2 Load on back-up Load on mains Anomaly

SY3 Error out voltage Error in output voltage User /failure

SY4 High Temperature Temperature block Anomaly

SY5 Pretemp. alarm Critical temperature Anomaly

SY6 Error direct voltage. DC Link voltage error Anomaly

SY7 Mains error Power supply in alarm Anomaly

RECTIFIER

Error code Display message Description Seriousness

RC1 High Temperature High Temperature Anomaly

RC2 Cyclic sense error. Cyclic sense error. User

RC3 Rectifier Error Rectifier alarmed Failure

RC4 Boost charge Boost charge activity User

RC5 Voltage Error Error in mains voltage Anomaly

INVERTER

Error code Display message Description Seriousness

IV1 Inverter off Inverter off User / Anomaly

IV2 Desaturation IGBT Desaturation IGBT failure / User

IV3 Voltage Error Error in inverter voltage Anomaly / failure

IV5 Inv. Not synchronised Error in frequency synchronism Anomaly

IV6 Frequency error Frequency error Anomaly

IV7 Current > 125% Output Current > 125 % Anomaly

IV8 Current > 150% Output Current > 150 % Anomaly

IV9 High current Output Current outside parameters Anomaly

BACK-UP

Error code Display message Description Seriousness

RS1 Cyclic sense error. Cyclic sense error. User

RS2 Voltage Error Voltage Error Anomaly

RS3 Frequency error Frequency error Anomaly

BREAKERS

Error code Display message Description Seriousness

SZ1 Rectifier Error Rectifier breaker User

SZ2 Back-up error Back-up breaker User

SZ3 Output error Output breaker User

SZ4 By-Pass Manual By-pass User

SZ5 Battery error Battery breaker User

OP1 User mode Jumper in the relay board User

Chart 3

7.1.2.3 BATTERY TEST

CAUTION! : CARRY OUT THE BATTERY TEST ONLY WHEN THE MACHINE IS IN

NORMAL MODE OPERATION

The battery test allows the user to check battery connection quality and fuse condition. To carry out the test press the F6

and the F3 keys together then press F6 to confirm, as specified in diagram 1. The test lasts for a minute, during which

the U.P.S. takes the necessary energy to maintain its load from the battery. At the end of the test the result will appear

under the form of “Good Battery” or “Bad battery”.

________________________________________________________________________________

EVO STAR 60-800

32

CAUTION! : PLEASE NOTE THAT SPECIALIZED TECHNICIANS MUST CARRY OUT

THE PROCEDURES DESCRIBED BELOW ONLY

In the second case, that is to say “Bad batteries”, you must check the fuses on the connecting line between the U.P.S

and the battery cabinet. To do so you must measure the direct voltage on the battery fuse ends which are placed in the

U.P.S and in the battery cabinet with a multimeter. If the fuses are not damaged, voltage measurement is next to zero.

If the fuse check is positive, it means that the connected batteries are no longer suitable to maintain the load if there is a

power shortage.

7.1.3 FUNCTIONING MODE CONFIGURATION

This product gives you the possibility of configuring the functioning mode in order to modify its use.

7.1.3.1 BATTERY CHARGE MODE

Press the F6 key and the starting key as specified in diagram 1a/b. These keys activate the starting procedure which

consists of the starting of the rectifier only. This makes it possible to charge the batteries through the terminal contacts

C and D. This function is very useful if the U.P.S. is not used for a long time and therefore needs complete battery

charge.

7.1.3.2 FORCING ON INVERTER MODE

To activate this function press the F6 key and the F2 key together as specified in diagram 1a/b. This will mean that the

system output will constantly be connected to the inverter, thus excluding the emergency mains supply. While the

system is starting up it provides output energy only when the voltage level has reached set parameters. With this type of

forcing it is possible to start up the U.P.S. without the emergency mains supply.

7.1.4 SYSTEM AUTONOMY

During a black-out on display will appear autonomy of the system.

This time is a function of battery voltage, and load percentage.

7.1.5 BUZZER

Internal buzzer is associated to summary alarm, you can turn on or turn off it press F2 key. If you turn of f buzzer it

will be off as long as all alarms off and other alarm start.

________________________________________________________________________________

EVO STAR 60-800

33

7.1.6 STRUCTURE MENU

________________________________________________________________________________

EVO STAR 60-800

34

________________________________________________________________________________

EVO STAR 60-800

35

7.2 OTHER INFORMATION

Button

PR1 STOP

PR2 HELP F1

PR3 BUZZER F2

PR4 MEASURE F3

PR5 HISTORY F4

PR6 DATE TIME F5

PR7 CONFERMATION F6

PR8 UP F7

PR9 DOWN F8

PR10 START

PR11 Reset of board

Clear history without reset:

This operation is possible only if U.P.S. is in normal mode

Press F4 key to enter historical menu

In this menu F7,F8 can select undermenu

Press F6 key to enter menu and press F4 to escape

Enter into menu “Clear History”, is possible erase every message in history buffer. If you wont this press F6 key to

confirm erase, or press F3 to escape without erase.

Relay programming:

This operation require A11 board on machine

Press F3+F6 keys, change with F7, F8 program menu keys and select with F6 key “Relay programming” or press F3

key to escape

In the secondary menus you can select a relay (F7,F8, keys) press F6 key to confirm or F3 to escape.

In relay menu there are all the alarms possible for relay, selected alarm are marked by “*”, select desiderate alarm

and press F6 to confirm or F3 to escape without modify. Is possible to select more alarm for one relay. The complete

default relay configuration is in chapter 11. Note: the leds on A11 turn on when one alarm associated to relay is in

progress.

Other measure

From version software 3.01 on are available on measure menu indication about output power, active power, power

factor.

Working time

It is possible to read information about working time of machine and are available calcs of the hours in the

following mode

On inverter: total time in which load was supplied by UPS

On reserve: total time in which load was supplied by back-up line

On battery: total time in which load was supplied by UPS and UPS supply by batteries

Summary time: UPS on time.

________________________________________________________________________________

EVO STAR 60-800

36

8 OTHER BOARD

8.1 INVERTER

Board control: AC voltage generate to UPS, output voltage, static switch, internal temperature and syncro.

LED

LED

Number Name Description Colour

DL1 SIOK

Syncro between back-up voltage and inverter voltage. When this occours

UPS can transfer supply of load from one line to other without discontinuity.

If there is forced commuting, without synchronism, decided by the user, this

will occur with a voltage dip of max. 20 ms.

green

DL2 FIOK

Back-up frequency in tolerance range.

greem

DL3 RPSKO

Cyclic sense error on back-up line

red

DL4 VRKO

Back-up voltage out of tolerance

red

DL5 VROK

Back-up voltage OK

green

DL6 PRTEM

Inside the UPS there are two temperature probes, these are mounted on

heatsink with power modules, one is front of air input, secondi is on back

near air output. The first is temperature alarm, the second is prealarm, hair

flow go from front to back. Probe turns on at 70°C.

yellow

DL7 HITEM

If air flow is too hot probe turn on and temperature alarm is set. Probe turns

on at 90°C. Temperature alarm will turn off UPS and load supply is

transferred to back-up line.

red

DL8 DESAT

One or more module IGBT have desaturation

red

DL9 START

Inverter on

green

DL10 VDCKO

DClink voltage out of range

red

DL11 F0OK

Phase zero ok

green

DL12 FRAL

Problem on control of frequency generate by device

yellow

DL13 VIOK

Inverter voltage ok

green

DL14 I125%

Output current overload, over 25% of nominal value

red

DL15 II150%

Output current overload, over 50% of nominal value

red

DL16 LMAINS

Load supply by back-up line

green

DL17 VUKO

Output voltage low, under 20% of nominal value

red

DL18 LINV

Load supply by inverter voltage

green

DL19 IUMAX

Output voltage over max value

red

8.2 RECTIFIER

Logic rectifier board controls: DC voltage generate by AC/DC conversion, driver of rectifier’s SCR, input current and

battery current.

LED

LED

Number Name Description Colour

DL1

SUPP Input voltage board OK

green

DL2

PHMKO Input order phases wrong

red

DL3

BTEST Battery test in progress

yellow

DL4

RDON Rectifier on

green

DL5

BOOST Battery boost (not used)

yellow

DL6

HTEMP Temperature high

red

DL7

VMKO Mains voltage out of range

red

________________________________________________________________________________

EVO STAR 60-800

37

8.3 POWER SUPPLY

This board supplies all other boards taking energy from A08 board and from DC voltage when rectifier is on. So it can

supply the boards in case of input line black out.

LED E FUSES

LED

Number Name Description Colour

DL1

VAL Input board voltage ok

green

DL2

+12v Output board voltage ok

green

DL3

-12v Output board voltage ok

green

DL4

+5v Output board voltage ok

green

FUSES

FU1 = + DC fuse on connection with positive pole of DC voltage

FU2 = - DC fuse on connection with negative pole of DC voltage

Fuses are 6,3*32 2A

8.4 DRIVER IGBT

This board supply driver signal for IGBT modules.

LED

LED

Number Description Colour

DL1

Isolated A -8V supply voltage

Verde

DL2

Isolated A -15V supply voltage

Verde

DL3

Isolated B -8V supply voltage

Verde

DL4

Isolated B +15V supply voltage

Verde

8.5 FUSES BOARD

REPLACING THE FUSES

CAUTION! : ALL CONNECTING PROCEDURES DESCRIBED IN THIS CHAPTER MUST

BE CARRIED OUT BY AUTHORIZED ELECTRICIANS OR BY QUALIFIED

TECHNICIANS.

CAUTION! : BEFORE REPLACING THE FUSES YOU MUST CARRY OUT THE MANUAL

BY-PASS PROCEDURE WITH THE U.P.S. DISCONNECTED (CHAPTER 5)

A nut screw fastens each fuse. When replacing a fuse you must unscrew the two knurled nuts corresponding to the

fuse, which must be replaced, remove the washers, replace the fuse and put back the washers and the knurled nut in this

order. The fuses used are extra-fast fuses for the current specified in charts 9a and 9b.

If you replace fuses with models different to the above described the guarantee will no longer be valid.

8.6 STATIC DRIVER

Static switch is made by SCR, this board drives them.

________________________________________________________________________________

EVO STAR 60-800

38

8.7 TRANSFORMER BOARD