Tecnosicurezza DigiTech Series, T9510/BR, T9510/DL Installation Instructions Manual

DigiTech

Installation instructions

Installation instructions

DigiTech

Company

Founded in 1983 with the aim of providing a complete range of professional products,

Tecnosicurezza is now a consolidated reality in the field of locks and security systems for safes.

The experience gained in over 35 years of activity in the security sector has allowed the

designing and manufacturing of high technology and reliability systems, which continue to

receive the approval of an increasingly demanding clientele.

TECNOSICUREZZA is present directly on the Italian, Spanish and US markets and, through a

extensive distribution network, in many European and extra-European countries.

TECNOSICUREZZA is aimed at national and international customers of primary importance, such

as banks, safe manufacturers, cash in transit companies, mass market retailers and post offices.

Today TECNOSICUREZZA is a leading company focused on the customers’ needs and

constantly in step with technology.

2 of 20 II_ DigiTech_01_eng

Installation instructions

DigiTech

Table of contents

COMPANY 2

TABLE OF CONTENTS 3

MODELS AND CHARACTERISTICS 4

ACCESSORIES 4

AUDIT AND PROGRAMMING ACCESSORIES 4

CERTIFICAZIONS 5

IMPORTANT NOTES! 6

KEYPAD DIMENSIONS 7

ROTOBOLT LOCK DIMENSIONS 8

STRAIGHTBOLT LOCK DIMENSIONS 8

SPRINGBOLT LOCK DIMENSIONS 9

MOTORLOCK DIMENSIONS 9

MOTORSPRINGBOLT LOCK DIMENSIONS 9

FIXED KEYPAD INSTALLATION INSTRUCTIONS 10

ROTOBOLT LOCK INSTALLATION INSTRUCTIONS 10

STRAIGHTBOLT AND SPRINGBOLT LOCKS INSTALLATION INSTRUCTIONS 11

MOTORLOCK AND MOTOR SPRINGBOLT LOCKS INSTALLATION INSTRUCTIONS 12

FUNCTIONAL TEST 14

CE DECLARATIONS 15

NOTES 17

CONTACTS 20

II_DigiTech_01_eng 3 of 20

Installation instructions

DigiTech

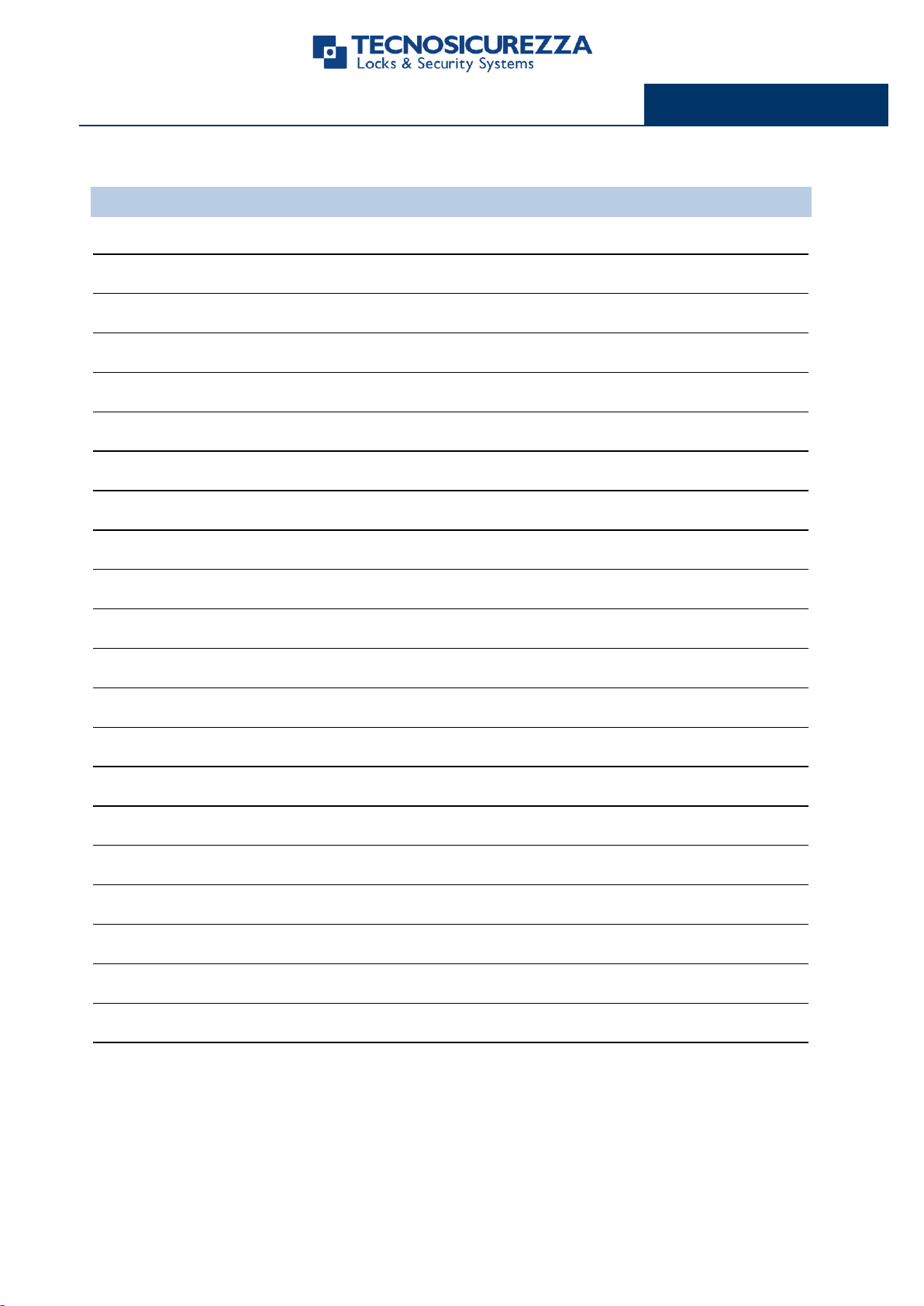

Models and characteristics

Model

Variant

T9510/BR – Keypad in metal. Black colour

with rubber membrane foil keypad in black

colour.

/DL with Dallas key reader.

Code

Description

N077/A

Battery box with alarm interface.

L4001

Large battery box for 6 size C 1.5V batteries.

T6005/W

Power supply interface (12Vdc).

T6005

Power supply interface (12Vdc) with alarm

interface.

L2666

Knob with 6 mm square spindle.

N1982

User Dallas key.

Code

Description

N42180/T

Interfaccia USB.

N42170/D

Dallas key reader with molex connector.

N42170/J

Dallas key reader with jack connector.

N42170/M

Magnetic Dallas key connection cable.

N1996RM

Magnetic Dallas key for audit.

T42146/J

Setup and audit cable.

Accessories

Audit and programming accessories

4 of 20 II_ DigiTech_01_eng

Installation instructions

DigiTech

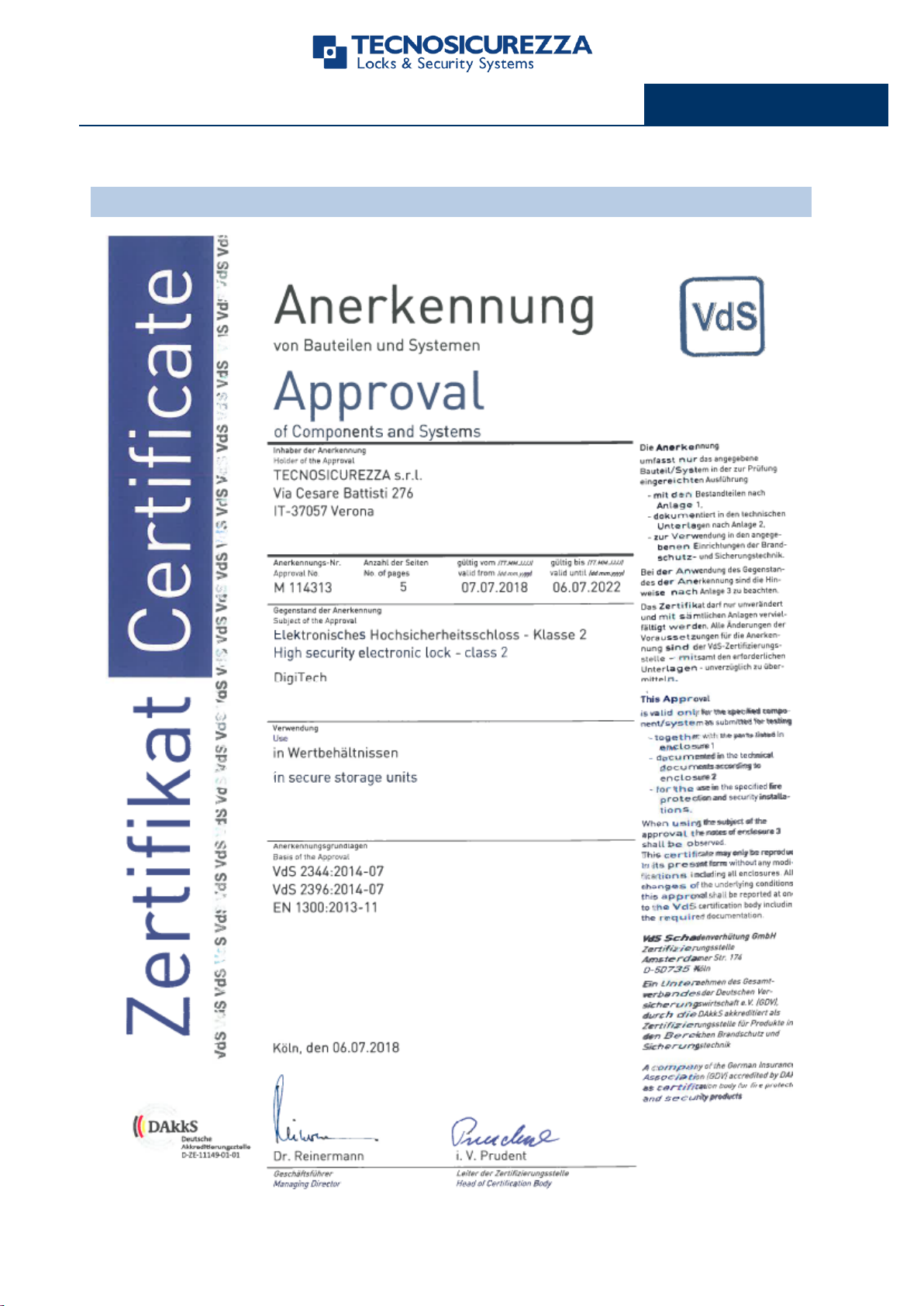

Certificazions

II_DigiTech_01_eng 5 of 20

Installation instructions

DigiTech

Important notes!

Before installing this product, please read carefully the installation and operating

instructions.

Locks can be installed in all traditional safes.

Lock has to be mounted on secure storage metal (preferred steel) units only.

Locks must be protected against external attacks, for this reason it is recommended to

install them on the door away from any through holes.

Any electronic part must be properly protected and not easily accessible even when

the door is open.

Locks have been developed to work correctly in a temperature range from -5 ° C to + 50

° C and in an environment with non-condensing humidity between 25% and 90%.

The mounting dimensions are standard (magic module).

For the installation of the keypad and lock, use only the screws provided by

Tecnosicurezza. Any other screw must be approved in advance.

Locks are supplied with metric (M6) mounting screws. Upon request, Imperial 1/4-20 UNC

format mounting screws are available.

The type of material and the length of the screws must, in any case, be selected so as to

guarantee long life and reliability.

Tighten the screws so that the lock is firmly fixed to the mounting surface

(recommended torque between 2.5 and 5.5 Nm).

The mounting surface must be perfectly flat.

In order to prevent loosening of the screws it is recommended the use of LOCTITE®

threadlocker and/or specific washers positioned under the head of the fixing screw.

The diameter of the passage hole for the connection cable or the spindle must not

exceed 11 mm.

The hole must be completely cleaned of drill dust and no edge should be sharp.

6 of 20 II_ DigiTech_01_eng

Loading...

Loading...