TECNOMOTOR TPM-02 Operating Instructions Manual

How to use the TPM-02

CONTROL, DIAGNOSIS AND CODING TOOL

FOR TPMS SYSTEMS

Operating Instructions

(ENGLISH)

Produced by TECNOMOTOR S.p.A

All rights reserved. This publication may not be reproduced, in full or in part, without

the express written consent of TECNOMOTOR S.p.A. TECNOMOTOR S.p.A

reserves the right to revise or make changes to this publication without prior notice.

Copyright information

All other product and firm names within this manual may be trademarks of other

entities.

3

TABLE OF CONTENTS

1. Symbols used in the manual .............................................................................................5

2. Safety rules........................................................................................................................5

3. Upon receipt......................................................................................................................7

4. Package contents...............................................................................................................7

4.1 OBD Option ..................................................................................................................7

5. Maintenance and care .......................................................................................................7

6. How to power on/off the equipment .................................................................................8

7. Recharging the equipment (par.7) ....................................................................................8

8. Settings..............................................................................................................................8

9. What is a TPMS system? ..................................................................................................9

10. TPMS indicator lights ...................................................................................................9

11. Type of sensors............................................................................................................10

12. How to position the equipment ...................................................................................11

13. Functions .....................................................................................................................12

13.1. Keypad .......................................................................................................................12

13.2. Sensor Test................................................................................................................. 12

13.3. Tightening Torques .................................................................................................... 14

13.4. Part Number ...............................................................................................................15

13.5. Tire Rotation and Sensor Replacement...................................................................... 16

13.6. Car Test ......................................................................................................................17

14. Test database ...............................................................................................................18

14.1. Vehicle Data Log: ......................................................................................................19

14.2. Sensors Data Log: ......................................................................................................19

14.3. Upload to PC:............................................................................................................. 19

15. Vehicle remote control test .........................................................................................19

16. Sensor installation/removal procedure ........................................................................20

16.1. Maintenance equipment required for TPMS-equipped tires...................................... 20

16.2. Sensor replacement ....................................................................................................21

16.3. Servicing the sensor with the tire installed. ...............................................................22

17. Tire removal ................................................................................................................23

17.1. Breaking the bead.......................................................................................................23

17.2. Breaking the upper bead ............................................................................................24

17.3. Breaking the lower bead ............................................................................................24

17.4. Tire installation ..........................................................................................................25

17.5. Seating the lower bead ...............................................................................................25

17.6. Seating the external bead ...........................................................................................25

18. Hardware and software requirements for update/data upload PC...............................26

19. UP DATING THE TOOL (PRENDERE PARTE AGGIO TPM1)................................27

4

Foreword

Dear Customer,

Thanks for choosing our product. This product has been designed to give you years of

satisfactory service. To ensure this, please read this User Manual thoroughly before

using the product and keep the manual in a safe place for future reference.

Our exhaustive range of products sets a new standard in TPMS (Tire Pressure

Monitoring System) diagnostics while offering an aesthetically pleasing design.

All of our products are designed and manufactured to the highest quality standards.

TPM-02 will prove an indispensable tool for:

• Checking sensor operation before servicing the tires (when vehicle is brought

in for service or repair).

• Establishing proper operation of the TPMS system when the customer picks up

the vehicle.

• Determining why the “Tire Pressure” (TPMS) light turns on.

• Ensuring that sensor provides accurate pressure and temperature readings.

• Measuring the pressure of wireless tires (with no need to unscrew valve cap

and connect a compressed air line with pressure gauge).

• Enabling time-saving, safe repair procedures with reference information (such

as torque figures or part numbers) always handy to avoid damage due to

improper procedures.

• Ensuring that sensors are refitted in their original positions after service

(positioning tool)

• Perform a TPMS coding operation after a sensor replacement.

5

1. Symbols used in the manual

This symbol calls attention to important information concerning

operation and safety.

This symbol calls attention to important information and tips aimed

at ensuring proper operation of the equipment.

This symbol calls attention to important instructions concerning

maintenance of electrical parts.

This symbol calls attention to important service instructions.

2. Safety rules

To recharge the equipment, it is mandatory to use the power

supply unit supplied by Tecnomotor S.p.A. Item No. 1800155.

Tecnomotor shall not be liable for damage to equipment in the

event other power supply units are used.

This appliance has been designed and tested to ensure safe

operation.

The user is required to observe the information and warnings

p

rovided in this manual to ensure safe operation and preserve the

safety features of the appliance.

WARNING : For equipment package maintenance and handling

after equipment installation, the provisions of Legislative Decrees

DDLL 626 of 19/9/94 and 242 of 19/3/96 apply. Use appropriate

tools to open package.

CAUTION : USE UTMOST CARE !!!

Do not allow operation of this equipment by unqualified

persons. It is the owner's responsibility to keep warning labels

and rating plates clean and legible.

This manual is subject to changes and updates.

Be sure to read the update and customization instructions included

in this manual.

The manual is divided into sections for ease of reference. Manual

instructions - especially those concerning maintenance - are

intended for use by specialized technical personnel with good

knowledge of mechanics, electromechanics or of the operation of

computerized unit-based systems. The system has been designed

to facilitate operation and troubleshooting, with a wide

range of display messages providing detailed indications to help

locate problems.

Please read these instructions carefully before operating the

equipment.

Collect this manual and all literature supplied with the equipment

in a file folder and keep it with the machine where operators can

easily access it.

Make sure installation has been performed in compliance with all

applicable regulations and standards.

Read this manual carefully and learn how to use the equipment

properly and safely.

Be sure to observe applicable accident prevention rules when

operating and servicing the equipment.

In the event of unauthorized changes to the equipment, the

manufacturer shall not be liable for any resulting damage

or incident. Please note that bypassing or removing safety devices

is in violation of workplace safety rules in force in the user's

country.

CAUTION

Changes or modifications not expressly approved by the party

responsible for compliance with the FCC Rules could avoid the

users’ authority to operate this equipment.

6

7

3. Upon receipt

Upon receipt, check packing and product components for damage in the presence of

the carrier. Liability for transport damage attaches to the forwarding agent or carrier.

Report any damage, giving details of the nature and severity of the damage, in the

shipping document and file a claim against forwarding agent or carrier.

4. Package contents

Package contains:

• 1 TPM-02 sensor tester

• 1 USB connection cable for PC connection

• 1 CD-ROM with product update utility

• 1 externatl Power Supply.

4.1 OBD Option

Through this optional it is possible to connect the tool to the ECU of the vehicle in

order to carry out the following procedures:

Flashing the ECU when the sensor is replaced

Flashing the ECU when rotating the tires

Adjust when possible the alarm threshold, set the winter tires etc.

Read and delete the malfunctions

The optional kit includes a SD card and intelligent OBD cable

5. Maintenance and care

Please follow these instructions to avoid malfunction or unexpected failures:

- Do not drop or knock the equipment.

- Avoid spilling fluids on the equipment.

- Do not use batteries other than those specified in this manual.

- Do not service the equipment when it is in operation.

- Do not clean the equipment when it is in operation.

- Keep the package for safe handling

8

6. How to power on/off the equipment

Touch the key to power on the equipment.

Touch key

to power off the equipment. The equipment will power off

automatically when no buttons have been pressed for 10 minutes to save battery life.

7. Recharging the equipment (par.7)

The batteries placed inside the equipment are charged. The equipment may only be

recharged using power supply . In the event the equipment should run fully flat, it

will take about 3 hours to fully recharge it.

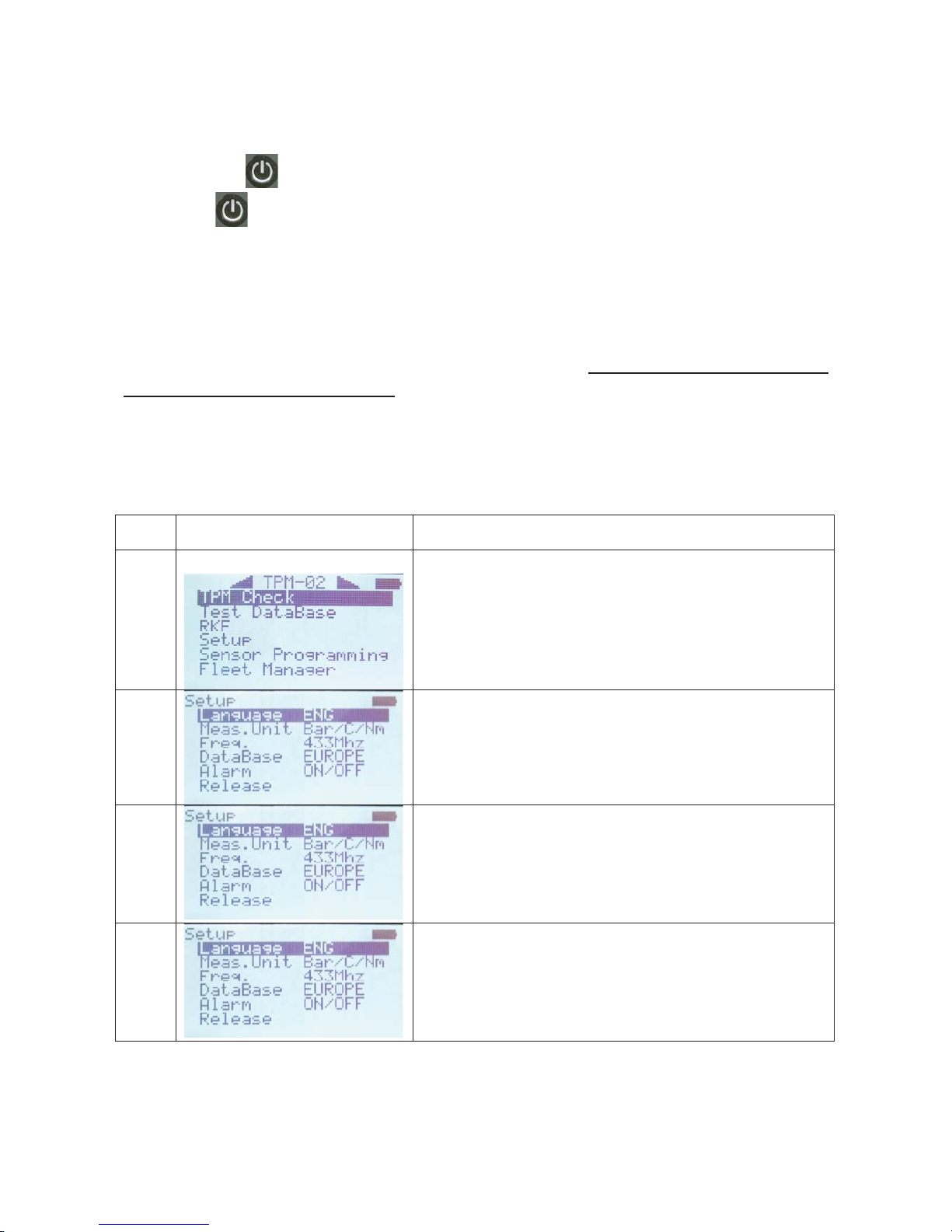

8. Settings

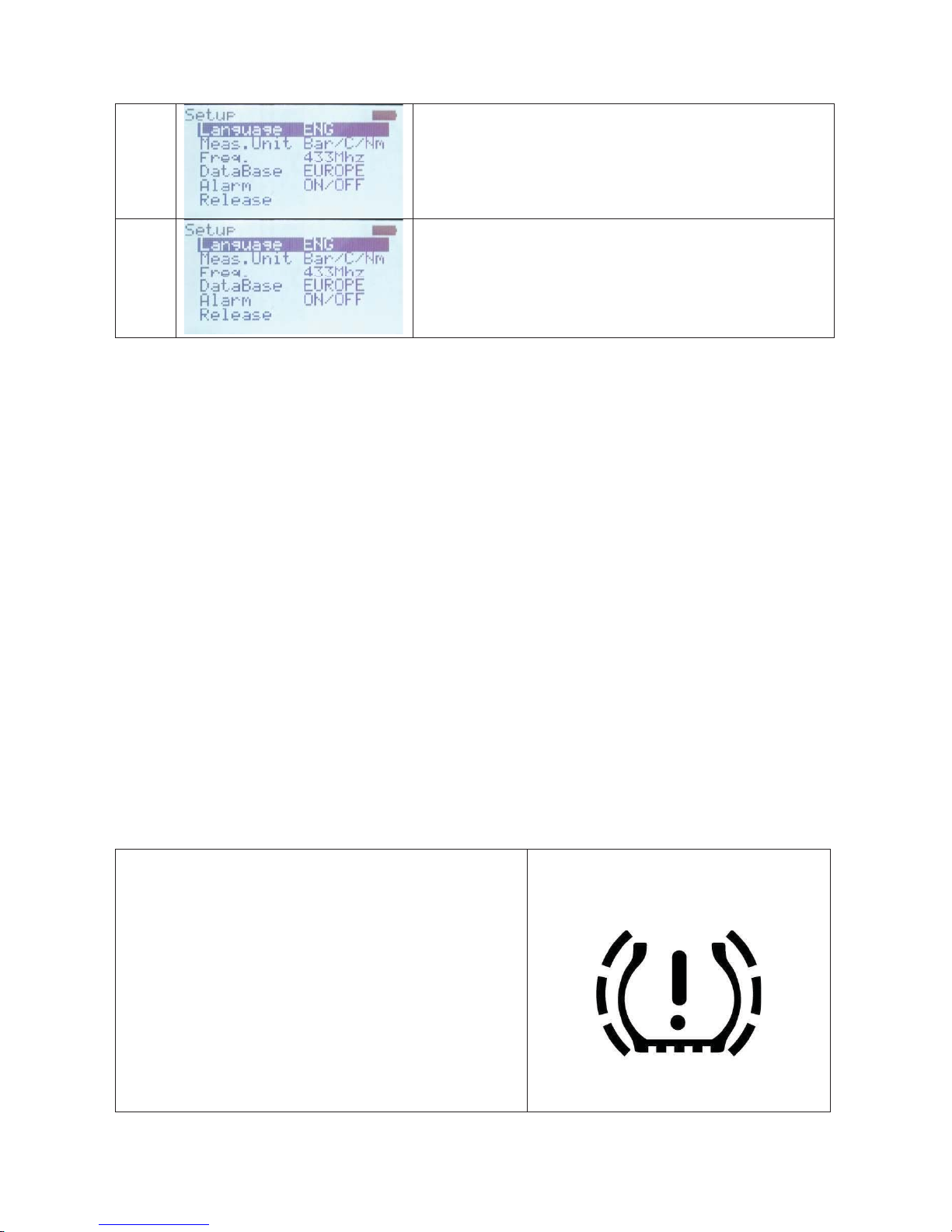

Step Screen page Description

1 Select option SETUP from the main menu page

2 Selecting LANGUAGE user can choose from:

French, Italian, English, Portuguese, Spanish and

German

3 Selecting MEASURMENT UNIT user can select

it for different parameters.

Pressure (bar / psi / KPa)

Temperature (C/F)

Torque (Nm / FtLbs)

4 Selecting COUNTRY it’s possible to setup the

Operating Frequency of the tool.

USA (315Mhz)

EUROPE (433Mhz)

9

5 Selecting ALARM it’s possible to enable or

disable SOUND and VIBRATION

6 Selecting RELEASE the tool will show software

infos:

FW VERSION

DB VERSION

SERIAL: XXXXXX

9. What is a TPMS system?

The TPMS or Tire Pressure Monitoring System continually monitors tire pressures

and temperatures and sends the information to the body computer to have it displayed

on the instrument panel. The system is made up of an ECU placed inside the cab that

receives radio frequency pressure and temperature signals from four sensors installed

inside the tires.

When the vehicle is running, the sensors transmit their signals every 20-30 seconds

approximately. In the event of a significant pressure variation, transmission interval is

shortened to 8-10 seconds.

When the vehicle is at standstill, transmission interval may vary between 10 and 40

minutes, depending on the type of sensor installed.

10. TPMS indicator lights

Outlined below are the most significant TPMS indicator lights.

Depending on the type of vehicle, this light may

indicate one of the following conditions:

• Turns on to indicate that the pressure of

one or more tires is above or below the

specified rated pressure.

• Turns on to indicate a TPMS malfunction

(for instance, when one of the sensors is

malfunctioning).

•

Light operation may vary to differentiate

indications when tire pressure has

crossed the warning or alert thresholds.

10

Tire location indicator

This light indicates the location of the under- or

overinflated tire.

The light may be associated with a display

message.

Display messages “Check tire pressure

”

Audio Alarms

Audio alarm for wrong tire pressure or TPMS

malfunction

11. Type of sensors

Sensors may be grouped into two broad categories, depending on whether they are

incorporated into valve body or not as shown in the table below.

Design 1

The valve shown in the figure is made up two elements:

- pressure sensor

- valve body

Valve body is made up of four elements: retaining screw, valve,

nut and valve cap.

Design 2

The valve shown in the figure is a single component that

incorporates both pressure sensor and tire valve. This valve

design also features a grommet/O-ring (to keep air from escaping

past the hole in the rim), a nut and the valve cap.

In design 1, valve and sensor may be replaced separately when

needed; in design 2, valve and sensor are replaced as a set.

Loading...

Loading...