TECNOMAGNETE ST100 Series, ST100F, ST200 Series, ST100R, ST200F Instruction And Maintenance Manual

Sistema elettronico di controllo per piani magnetici

Electronic control system for magnetic chucks

Système électronique de commande pour des plateaux magnétiques

Elektronisches Steuersystem für Magnetplatten

Sistema electrónico de control para planos magnéticos

ST100

Manuale uso e manutenzione

Instruction and maintenance manual

Manuel d’utilisation et d’entretien

Betriebs- und Wartungsanleitung

Manual de uso y mantenimiento

ITALIANO

ENGLISHFRANÇAISDEUTSCHESPAÑOL

ST200

Nr. 50 100 7816

INDEX

1

GENERAL NOTES .................................32

1.1

Overview of the company...........................32

1.2

Importance of the manual ..........................33

1.3

Storing the manual .....................................33

1.4

Conventions ...............................................33

1.5

Denition of symbols .................................33

1.6

Personnel responsible for operations ........33

1.7

Trained personal .........................................34

1.8

Individual protection means .......................34

1.9

General safety precautions.........................34

1.10

Behavior during emergency situations ......34

1.11

Limitations ..................................................34

1.12

Improper or non permitted use ..................35

1.13

Nameplate data ..........................................35

2

TRANSPORTATION AND

HANDLING .............................................. 36

2.1

Receipt .......................................................36

2.2

Handling .....................................................36

2.3

Transportation ............................................36

2.4

Storage ......................................................36

3

DESCRIPTION OF THE SYSTEM ......37

3.1

Description of the controllers ..................... 37

3.2

Model ST100X ............................................37

3.3

Model ST200X ............................................38

3.4

Control push-buttons for ST controllers ....39

Page

8

CONNECTION TO

TECNOMAGNETE MODULE

8.1

Installation of miller ST100 .........................48

8.2

Installation of grinder ST100 ......................48

8.3

Installation of miller ST200 .........................49

8.4

Installation of grinder ST200 ......................50

9

ORDINARY USE .....................................51

9.1

ST100 .........................................................51

9.2

ST200 ........................................................51

10

ANALYSIS OF RESIDUAL RISKS ......52

11

MAINTENANCE .....................................52

11.1

Premise ......................................................52

11.2

Maintenance safety instructions.................52

11.3

Weekly maintenance ..................................53

11.4

Monthly maintenance ................................53

11.5

Maintenance to be carried out every

six months ..................................................53

11.6

Extraordinary maintenance.........................53

11.7

Information on extraordinary reparation

and maintenance ........................................ 53

12

TROUBLESHOOTING AND

CORRECTIVE ACTIONS ......................54

Page

.............48

ENGLISH

4

INSTALLATION ......................................43

4.1

General .......................................................43

4.2

Connecting ST100 controllers to the

power supply .............................................44

4.3

Connecting ST200 controllers to the

power supply ..............................................44

5

ENABLING ..............................................45

5.1

ST100 .........................................................45

5.2

ST200 .........................................................45

6

OPTIONAL COMPONENTS ...............46

6.1

Starting the ST100 controller .....................46

6.2

Push-button panels of models ST100

and ST200 ..................................................46

6.3

QE version ..................................................46

7

PLC ...........................................................46

Instruction and maintenance manual

13

DECOMMISSIONING AND

DISPOSAL ...............................................54

13.1

Decommissioning ......................................54

13.2

Dismantling ................................................54

14

WARRANTY AND TECHNICAL

SUPPORT ................................................55

14.1

Warranty terms and conditions ..................55

14.2

Invalidity of warranty ..................................55

15

TECHNICAL SUPPORT SERVICE ....56

DELARATION OF

CONFORMITY .......................................57

Edition: 07-12

Replaces: 03-09

31

1

GENERAL NOTES &

1.1 Overview of the company

Thank you for purchasing one of the many products

manufactured by TECNOMAGNETE S.p.A.

This manual is designed to help you become familiar

with your new product and must therefore be carefully read and followed.

For further information on the system, you can contact TECNOMAGNETE’s technical support at any

time.

The descriptions and illustrations provided in this

manual are for reference only.

While conrming the general characteristics

ENGLISH

of the controllers described in the manual,

TECNOMAGNETE S.p.A. reserves the right, at its

discretion, to change at any time some of the characteristics in order to improve the product or due to

manufacturing and commercial reasons. The necessary updates, if required, shall be supplied as attachments.

This manual is property of TECNOMAGNETE S.p.A.

and cannot be copied in whole or in part or made

available to third parties without the written authorization of the manufacturer. Should the products be

amended and/or updated, upon authorization of

TECNOMAGNETE S.p.A., the manufacturer shall

integrate the existing manual by providing the text

explaining the use of the modied/integrated component along with a description of potential residual

risks.

TECNOMAGNETE started its activities in 1972 as

manufacturer of permanent-electro magnetic systems designed to ensure power, exibility and maximum safety. Its state-of-the-art technologies and the

patents developed over the years have enabled the

company to become a leading supplier in several

international markets.

The permanent-electro magnetic systems manufactured by TECNOMAGNETE are able to produce all

the magnetic force required both to clamp and lift

work pieces, thus eliminating the need of using electric power during machining.

Its main elds of activity include:

CLAMPING SECTION FOR LIFTING

•

MTE permanent-electro lifters designed to ena-

ble the handling of ferrous loads of any shape and

dimension.

•

BAT-GRIP permanent-electro lifters with incor-

porated battery.

•

MaxX manual lifters.

WORK HOLDING LINE

•

QUADSYSTEM chucks for millers and machining

centers of all sizes.

•

TFP0 and TFP1 for high precision grinding.

•

RADIAL-POLE chucks for nishing or roughing

operations on boring mills.

•

QUAD-RAIL modules to clamp rails of varying

lengths.

•

MDS chucks for EDM machines.

32

STAMPING and MOLDING LINE

•

QUAD-PRESS systems to clamp molds.

TECNOMAGNETE has installed approximately

50,000 units in over twenty years, thanks mainly to

its wide-ranging offer, its exibility to meet customers’ requirements and its efcient post-sales service.

Instruction and maintenance manual

1.2 Importance of the manual

1.5 Definition of symbols

A copy of this manual must always be made available to the operators responsible for the installation,

operation and maintenance of the controller in order

to allow them to carry out all the required operations

in compliance with the instructions provided in the

manual.

A full compliance with the instructions provided in

this manual is an essential requirement to be able to

correctly use the equipment and ensure the safety of

operators and other people.

The manual forms integral part of the controller.

Therefore, all reproduction and divulgation rights related to the manual or its exhibits are reserved.

The manual must always be transferred to the new

owner of the machine if the latter is sold.

1.3 Storing the manual

It is severely forbidden to remove parts, tear pages

or alter this manual.

The manual should always be carefully preserved so

that it is not damaged.

Always protect the manual from excessive humidity

and heat and store it in a location where it can be

easily accessed by operators in case of need.

1.4 Conventions

To simplify consultation, the manual has been divided into the following hierarchical order so that each

phase is described in detail:

1 Section 1 of the manual.

1.1 Chapter 1 of Section 1 of the manual.

1.1.1 Paragraph 1 of Chapter 1 of Section 1 of

1.1.1.1 Subparagraph 1 of paragraph 1 of Chap-

Some chapters and/or sections contain bulleted lists

to allow operators to follow the operation described

step by step.

Parts that require specic attention are highlighted

with symbols.

Instruction and maintenance manual

the manual.

ter 1 of Section 1 of the manual.

All information related to safety is highlighted in bold.

All warnings that draw the attention of operators on

operations that may be hazardous in terms of safety

or health or that may cause physical injuries, if the

applicable instructions are not followed, are highlighted in red and marked with the following symbol:

All warnings related to operations that have to be

carried out by skilled and qualied personnel are

highlighted in bold and marked with the following

symbol:

1.6 Personnel responsible for operations

Some operations, as stated in this manual, can only

be performed by qualied and skilled personnel. The

qualication level is described by means of the following standard denitions:

•

Qualied personnel is personnel with specic

technical knowledge and/or the experience necessary to avoid potential risks originating from

power supply (engineers and technicians).

•

Trained staff is personnel that operates following

the instructions and/or under the supervision of

qualied personnel, who is responsible for verifying that they are not exposed to potential hazards

resulting from the contact with power (personnel

responsible for operation and maintenance). This

personnel must have the following qualications:

1. All personnel must be trained and authorized to

disconnect the machine from the power supply, to

connect it to the grounding system and to mark

circuits and equipment following standard safety

procedures.

2. All personnel must have been specically trained

to follow correct maintenance procedures and

use the protective equipment in accordance with

standard safety procedures.

•

Before using the unit, users shall always have to

verify with authorized personnel that:

1. All personnel has received a copy, has read and

understood the content of the instruction manual.

2. All personnel has agreed to follow the instructions

provided.

33

ENGLISH

1.7 Trained personal

•

OPERATORS: workers who, after receiving the

necessary instructions, have been authorized by

the owner to operate the controller and the equipment connected to it. Workers with this qualication must be thoroughly familiar with the content

of this manual.

•

ELECTRIC MAINTENANCE TECHNICIAN (ref.

EN60204 paragraph 3.45): this qualication is assigned to all personnel specically trained to perform operation on electric components, which include connections, adjustments, maintenance

and/or reparations, and to personnel who is qualied to perform operations inside electric cubicles

ENGLISH

and boards. This qualication implies having a

perfect knowledge and full familiarity with the

content of this manual.

All operators are therefore expected to follow the

instructions below and to thoroughly comply with

the safety procedures concerning the installation

and use of the equipment applicable in the country in which the unit is used.

All ordinary and extraordinary maintenance operations shall have to be carried only after the

unit has been disconnected from the power supply.

Before connecting the power cable, it is essential

to verify that the line voltage complies with the

one shown on the nameplate of the controller.

All transportation, installation, ordinary and extraordinary maintenance operations performed

on the controller must be carried out only by personnel with the qualifications stated in Chapter

1.6 and 1.7.

1.8 Individual protection means

The personnel referred to in the paragraph above

must always wear suitable protective clothing

and use the protection means generally required

to operate the tool machine on which the Tecnomagnete module and controller are installed.

In particular, personnel shall always have to wear

industrial shoes along with ear protection, helmets and goggles, if required.

All personnel should refrain from wearing loose

clothing that could get tangled with moving components.

1.9 General safety precautions

The instructions and recommendations provided

below comply with current safety regulations and

imply the obligation of complying with applicable

provisions.

TECNOMAGNETE S.p.A. shall not be responsible

for damages caused to people or equipment

originating from the failure to follow applicable

safety provisions and to comply with the instructions given below.

1.10 Behavior during emergency situations

In the event of emergency, it is always advisable

to follow the procedures outlined in the operation

and maintenance manual of the machine on

which the controller is installed.

In the event of fire, always use the extinguishing

means provided being careful not to use water to

extinguish fires on electric parts.

1.11 Limitations

The unit can be used only for the applications

specified in operating instructions and only in

combination with the equipment and components recommended by TECNOMAGNETE S.p.A.

34

Instruction and maintenance manual

1.12 Improper or non permitted use

The controller is not designed and has not been

manufactured to be used in explosive environments.

An improper use may:

•

Cause injuries to personnel.

•

Damage the controller or any other equipment

connected to it.

•

Affect the reliability and performance of the

controller.

In particular, it is essential to adhere to the following instructions:

•

Always use suitable working parameters.

•

Carry out the required maintenance in accord-

ance with the instructions provided.

•

Use suitable equipment.

•

Comply with all the instructions provided.

•

Fix the unit onto a stable surface.

•

Contact TECNOMAGNETE S.p.A. in case of

doubt to determine whether a specific operation is permitted.

1.13 Nameplate data

ENGLISH

The controller is tted with an identication label in

compliance with current laws.

ATTENTION

The nameplate should never be removed even if

the unit is resold.

If the nameplate is damaged or has been

removed, it is necessary to contact

TECNOMAGNETE S.p.A. to order a duplicate.

Always quote the model printed on the

nameplate in all communications with

TECNOMAGNETE S.p.A.

Failure to comply with the above instructions

shall entitle TECNOMAGNETE S.p.A. to disclaim

any responsibility for injuries to personnel and

damage to equipment, making the user fully responsible before competent authorities.

Instruction and maintenance manual

35

2

TRANSPORTATION AND

HANDLING

The unit is shipped in a cardboard box, covered with

a plastic sheet and enveloped by polyurethane foam

to protect it from damage in the event of impacts or

accidents.

2.1 Receipt

All units are carefully inspected before shipping.

Upon receipt, customers should verify that the

packaging and the material inside it has not

been damaged (unless otherwise instructed by

ENGLISH

TECNOMAGNETE S.p.A.) in order to ensure that the

unit has not been damaged during transport and that

the material supplied complies with order specications. Visible transport damages should be immediately reported to TECNOMAGNETE S.p.A. and the

forwarding agent.

ATTENTION

All damages and anomalies must be reported within

ten days from receiving the goods.

2.2 Handling

Weight of model ST100: 0,4 kg.

Weight of model ST200: 2,0 kg.

Always keep the original packaging so that it can

be used to transport the unit if needed.

2.3 Transportation

The unit should always be transported within the following environmental limits: temperature ranging

from –10°C to +55°C, with temperature increase up

to 70°C for a maximum of 24 hours.

If the unit requires the use of specic transportation

means (by sea or air), special provisions shall have to

be adopted in order to protect it from damages

caused by potential impacts. The box should also

contain hygroscopic salts to protect the unit from

atmospheric agents.

2.4 Storage

The unit should always be throughly cleaned and

adequately protected when stored for long periods

of time.

Disconnect the controller from the magnetic chuck

and from the power supply.

It is generally advisable to cover the unit with a waterproof bag and store it in dry and safe place.

The temperature of the storage area should range

between 0°C (32°F) and 55°C (131°F).

Relativy humidity should be between 30% and 90%,

non condensing.

The atmosphere should be clean, free from acids,

corrosive gases, salts, etc

When restarting the machine, always follow the instructions provided in Chapter 4.

36

Instruction and maintenance manual

3

DESCRIPTION

OF THE SYSTEM

3.1 Description of the controllers

ST is an innovative electronic controller for

networked chucks designed for milling and grin-

ding operations.

The sections that follow provide information on the

size and the basic characteristics of the available

models:

•

ST100F (milling)

•

ST100R (grinding)

•

ST200F (milling)

•

ST200R (grinding)

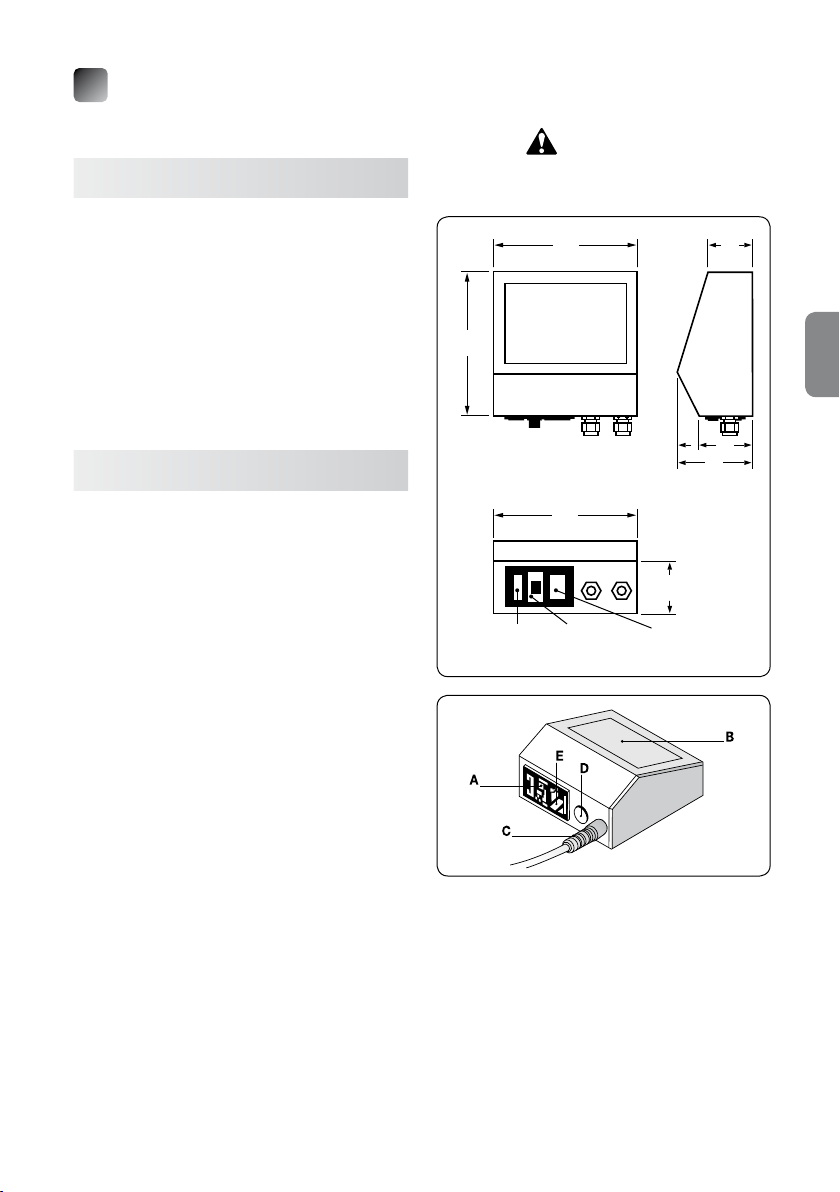

3.2 Model ST100X

The rated operating voltage is 230V.

The control push-button panel is integrated in to the

controller.

The control electronics are situated under the control

push-button panel and enclosed in a plastic housing.

To simplify installation and facilitate the reading of

the push-button panel, it is also possible to install

the controller on a workbench or mount it on the wall

by simply rotating the control panel.

The plastic material of the housing ensures a high

level of insulation and the utmost safety during use.

The rear part of the controller has a block with a male

pin (designed to be connected to the power cable),

an ON–OFF (0-1) switch and a fuse-holder with two

12.5A protection fuses (type 5x20 mm). Two or more

cable ties for the output of the discharge cables of

the chucks to be magnetized may be present next to

these components.

The maximum useful current that ows into the

ST100X controller is approximately 12.5A; the current supplied to the module is impulsive with a cycle

time around a few hundreds of milliseconds (app. 1

second per discharge).

ST100X controllers are suitable to control small

chucks with a single phase voltage of 230V and a

maximum absorption of rated current of 3kW.

For different rated voltages, use a transformer with a

suitable transformation ratio and a rating suitable to

handle the maximum power of the chuck or at any

Instruction and maintenance manual

rate a maximum power of 4kVA. For example, if the

available voltage is 400V, a transformer with a

400/230 transformation ratio is required.

ATTENTION!

Control units can be moved only

when controls are not powered.

135

135

Rear

135

Fuse-holder Main Power supply

switch input

40

50

75

40

MAIN PARTS

A ➜ Main switch

B ➜ Push-button panel

C ➜ Discharge cable output

D ➜ Start contact

E ➜ Power supply input

37

ENGLISH

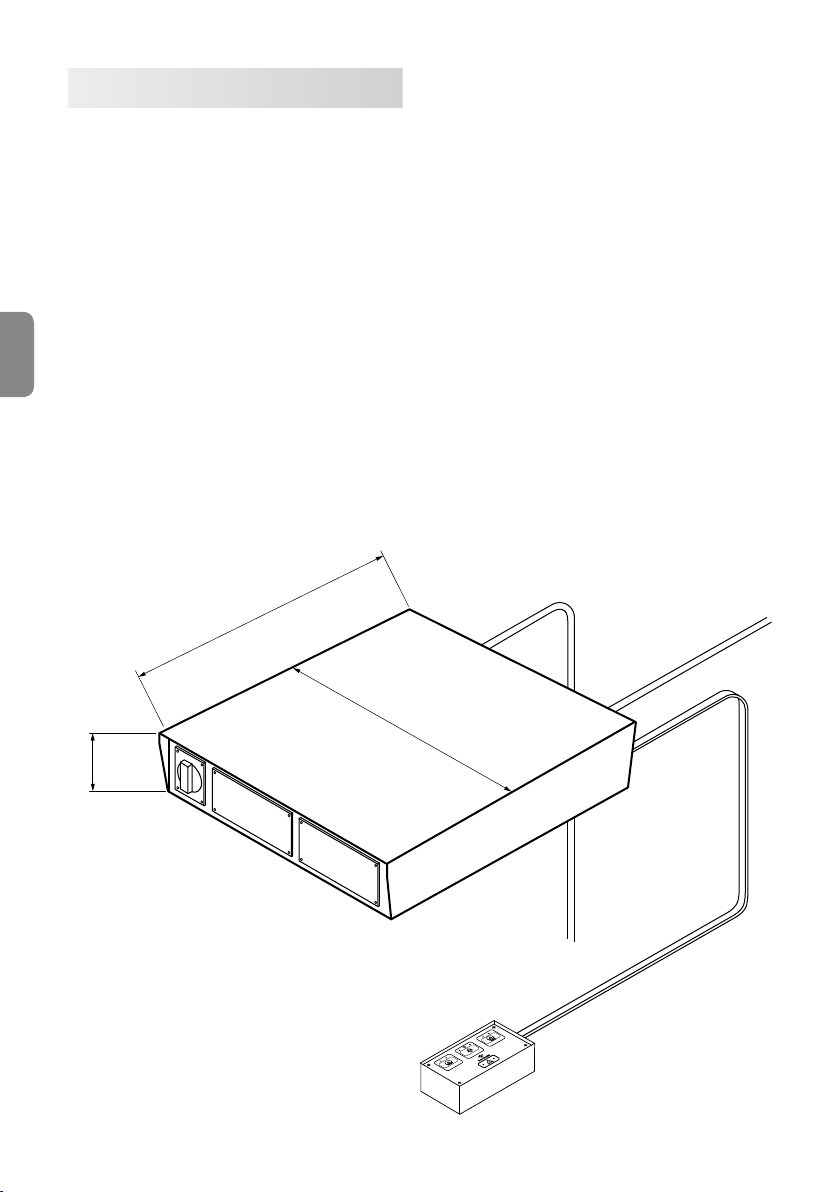

3.3 Model ST200X

The rated operating voltage of this controller varies

according to the type of magnetic chuck to which it

is connected.

The control push-button is external, but can also be

integrated into the controller.

The control electronics are enclosed in a metal housing. The metal material of the housing is grounded in

order to guarantee maximum safety during the enabling cycles.

It is important to verify that the grounding system is

always in good working order.

The controller does not have a socket for the connection to the power supply. The controller has an

ENGLISH

ON–OFF (0-1) switch, thus to adequately protect it

against short circuits, it is necessary to install a suitable protection system upstream from the controller.

It is generally advisable to use a magneto thermal

switch (curve C) with an In value compliant with the

rating specied on the magnetic chuck nameplate

that will be connected to the controller.

275

The maximum power of controller ST200X is approximately 25kW per discharge if the single phase

power supply is 400V, 15kW for power supplies of

230V and 30kW for power supplies of 480V. The absorbed current is impulsive with a cycle time around

a few hundreds of milliseconds (approximately 1

second per discharge).

ST200X controllers are suitable to power single

chucks or chucks that are part of large magnetic

banks

When using chucks with a different rated voltage,

install a transformer with a suitable transformation

ratio and a rated power that matches the maximum

power of the chuck.

It is also possible to order a compact version for

ST200-QE electric cabinets with supporting terminal

board, to power the controller and magnetic chuck,

with interface connector and push-button panel.

38

331

85

Instruction and maintenance manual

3.4 Control push-buttons for ST controllers

ST controllers can be connected to the push-button

panels described below.

3.4.1 ST100 (basic version),

ST200 (basic version)

This push-button panel is the base model used to

control milling chucks.

It is tted with the following three-buttons:

•

Magnetization FULL-MAG,

•

Demagnetization DEMAG,

•

Enabling ENABLE.

The ENABLE button is used together with the magnetization and demagnetization button, depending

on the cycle that needs to be performed.

There are also 4 indicator lights placed next to the

FULL-MAG and DEMAG buttons and the CYCLE

and ALARM symbols.

These indicator lights provide information on the status of the controller. When the controller is started,

the corresponding LED indicator switches on.

If a cycle is active, the only LED that is on is the one

related to the cycle, while all the others are off.

At the end of the cycle, the only visual indication that

is on is the one related to the new system status.

D

A C

B

PUSH-BUTTON PANEL

A

➜ FULL-MAG button

B

➜ ENABLE button

C

➜ DEMAG button

D

➜ MAG led

E

➜ Cycle led

F

➜ DEMAG led

G

➜ Alarm status led

E

G

F

ENGLISH

System status MAG Led DEMAG Led Cycle Led Alarm Led

Full-Mag Permanently on Off Off Off

Demag Off Permanently on Off Off

Cycle Off Off Permanently on Off

Current alarm Off Off Off Permanently on

Communication

*

alarm

*

For version ST200 only

Instruction and maintenance manual

Off Off Off On ashing

39

3.4.2 ST100 (version with 2 levels),

ST200 (version with 2 levels)

To be able to use different levels of magnetization, it

is possible to replace the push-button panel described above with a 2-level model that enables to

control milling and grinding chucks.

This push-button panel has the following ve buttons:

•

Magnetization FULL-MAG,

•

Partial magnetization MAG-1L

•

Partial magnetization MAG-2L

•

Demagnetization DEMAG,

•

Enabling ENABLE.

ENGLISH

The magnetization buttons MAG-1L, MAG-2L and

FULL-MAG enable to select three different levels of

magnetization.

The ENABLE button is used together with the magnetization and demagnetization buttons, depending

on the cycle that needs to be performed.

There are also 4 indicator lights placed next to the

FULL-MAG and DEMAG buttons and the CYCLE

and ALARM symbols.

These indicator lights provide information on the status of the controller. When the controller is started,

the corresponding LED indicator switches on.

If a cycle is active, the only LED that is on is the one

related to the cycle, while all the others are off.

At the end of the cycle, the only visual indication that

is on is the one related to the new system status.

FULL-MAG and DEMAG indicator lights are always

on; MAG-1L and MAG-2L ash only during partial

magnetization cycles.

D

E

A

H

G

B

F

C

PUSH-BUTTON PANEL

A

➜ FULL-MAG button

B

➜ ENABLE button

C

➜ DEMAG button

D

➜ FULL-MAG led (xed) of MAG led for partial

magnetization (ashing)

E

➜ Cycle Led

F

➜ DEMAG Led

G

➜ 2nd level MAG button

H

➜ Alarm status Led

I

➜ 2nd level MAG button

System status MAG Led DEMAG Led Cycle Led Alarm Led

Full-Mag Permanently on Off Off Off

Demag Off Permanently on Off Off

Mag Level 1 On ashing Off Off Off

Mag Level 2 On ashing Off Off Off

Cycle Off Off Permanently on Off

Current alarm Off Off Off Permanently on

Communication

*

alarm

*

For version ST200 only

40

Off Off Off On ashing

Instruction and maintenance manual

3.4.3 ST200 (model with 7 levels)

To be able to use several levels of magnetization, it is

possible to replace the basic push-button panel with

a 7-level model that enables to control milling and

grinding chucks.

This push-button panel has the following ve buttons:

•

Magnetization MAG,

•

Increase of magnetization

level +

•

Reduction of magnetization

level –

•

Demagnetization DEMAG,

•

Enabling ENABLE.

The ENABLE button is used together with the magnetization and demagnetization buttons, depending

on the cycle that needs to be performed.

There are also ve indicator lights placed next to the

full FULL-MAG, DEMAG, + and – buttons and the

CYCLE and ALARM buttons.

These indicator lights are used to provide information on the status of the system, which is automatically reset to the last operating cycle.

Once the start sequence has been successfully

completed, the indicator light corresponding to the

total/partial magnetization or demagnetization

switches on, depending on the option selected. A

failure in the start sequence switches on the central

alarm indicator light.

If a cycle is active, the only LED that is on is the one

related to the cycle, while all the others are off.

The FULL-MAG and DEMAG indicator lights are always on and ash during partial magnetization cycles only.

F

A

H

C

G

D

J

E

B

I

PUSH-BUTTON PANEL

A

➜ MAG button

B

➜ ENABLE button

C

➜ DEMAG button

D

➜ Button +

E

➜ Button -

6

➜ FULL-MAG Led (xed) of MAG Led for

partial magnetization (ashing)

G

➜ Cycle Led

H

➜ DEMAG Led

I

➜ Alarm status Led

J

➜ Level selection LED (levels from 1 to 7) and

FULL-MAG 8

ENGLISH

System status MAG Led DEMAG Led Cycle Led Alarm Led

Full magnetization

Level 8

Permanently on Off Off Off

Demag Off Permanently on Off Off

Partial magnetization

Levels 1-7

On ashing Off Off Off

Cycle Off Off Permanently on Off

Current alarm Off Off Off Permanently on

Communication

alarm

*

*

For version ST200 only

Instruction and maintenance manual

Off Off Off On ashing

41

3.4.4 ST200 CH-ENABLE

This push-button panel can be used when you need

to select different discharge levels for the magnetic

chucks, i.e. enable or disable the desired discharge.

The push-button panel can be used in combination

with a push-button and LED to manage selections.

It has four buttons that enable to select/deselect the

desired discharge channel. The status of the channel

is shown by the corresponding LED.

After you have selected the discharge sequence,

you can also specify which discharges have to be

carried out with a full or partial magnetization and/or

select them with the appropriate buttons (CH1, CH2,

CH3 and CH4).

The status LEDs are off when the corresponding

ENGLISH

magnetic chuck is in DEMAG mode, are on (though

not ashing) in FULL-MAG mode and ashing when

the partial magnetization mode is selected.

The cycle LEDs shall be on (though not ashing)

when a cycle is in progress and off when no cycle is

in progress.

Alarm LEDs are on (though not ashing) during all

alarm conditions, except for communication alarms.

E

I

F

A

K

G

C

M

J

N

PUSH-BUTTON PANEL

A

➜ CH1 selection button

B

➜ CH2 selection button

C

➜ CH3 selection button

D

➜ CH4 selection button

E

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 1

F

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 2

G

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 3

H

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 4

I

➜ Cycle Led

J

➜ Alarm status Led

K

➜ CH1 selection Led

L

➜ CH2 selection Led

M

➜ CH3 selection Led

N

➜ CH4 selection Led

B

L

H

D

42

Instruction and maintenance manual

4

INSTALLATION

4.1 General

Electric safety can be guaranteed only if the electric

system is correctly connected to a grounding system in good working order, as foreseen by current

laws concerning electric safety. Therefore, it is essential to always verify this safety requirements before starting the unit and have the distribution system carefully inspected by qualied personnel in

case of doubt. TECNOMAGNETE S.p.A. shall not be

responsible for damages originating from the failure

to connect the unit to an appropriate grounding system.

Users shall have to make sure that the unit is protected with a differential magnetothermal switch

suitable to withstand the rated current used by the

system. It is therefore necessary to install a suitable

protection with magnetothermal switch (curve C)

with a In value compliant with nameplate data.

TECNOMAGNETE systems are permanent-electro

systems, which means that they need to be powered

only during the short cycle phases. This conguration is designed to ensure maximum safety in the

event of power failure.

TECNOMAGNETE controllers use the power supply

by means of a sophisticated partializing process,

which means that they can be operated only when

the machine is idle and that they require a rated current that is normally lower than the one required to

operate the machine on which the magnetic system

being controlled is installed.

Check the supply voltage and frequency.

The electrical supply to the controller must be single-phase 230V/400V/480V (phase + neutral) or twophase (phase + phase).

ATTENTION

ST100 controllers are designed to operate with supply voltages of 230V 50/60 Hz and cannot therefore

be used for Tecnomagnete modules with lower or

higher ratings. To use different voltages, install a

transformer with a suitable rating (not above 4 kVA)

or contact TECNOMAGNETE S.p.A. for assistance.

ATTENTION

ST200 controllers are designed to operate with

supply voltages of 200V - 480V at 50/60 Hz and

can therefore be used, after validation, to enable

TECNOMAGNETE modules with different voltage

specications. To use different voltages, install a

transformer with a rating compliant to that of the

magnetic chuck or contact TECNOMAGNETE S.p.A.

for assistance.

ATTENTION

All cables supplied must have a bending radius with

a diameter <10mm and a tension of >15N/mm2. Installation must always be performed by qualied

technicians in accordance with current law requirements.

ENGLISH

ATTENTION

Do not perform repeated MAGNETIZATION/DEMAGNETIZATION CYCLES

TECNOMAGNETE systems are constituted by permanent magnets and use electric power only to enable/disable the area being machined. Therefore,

they can be regarded “COLD” magnetic clamping

systems.

The repetition of MAGNETIZATION/DEMAGNETIZAZION cycles at very close intervals may increase

the temperature of the magnetic chuck, especially

when using controllers with DEMAG NUFLUX cycle.

It is therefore advisable to run cycles only when necessary.

The connection of the magnetic chuck to the power

supply must be carried out by qualied personnel

only.

Instruction and maintenance manual

43

4.2 Connecting ST100 controllers to the power supply

4.2.1 Connecting the controller to the power

supply

The controller must be supplied with a single-phase

voltage. The multi-pole cable supplied with the controller has three leads suitable for the purpose.

The controller cannot be powered from the threephase + neutral distribution network that supplies

the tool machine used. If the voltage required for the

controller is not available, install a power transformer

with a rating suited for the magnetic chuck.

ENGLISH

4.2.2 Power cable

TECNOMAGNETE supplies a suitable multi-pole

power cable with a standard length of two meters,

which prevents overheating problems and a voltage

drop within the rating of the TECNOMAGNETE module, if used in ordinary operating conditions.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

Ordinary operating conditions are intended as intermittent working cycles, with intervals of at least one

minute between two enabling cycles.

Single-phase power supply

F

N

PE

BLACK

BROWN

YELLOW/GREEN

4.2.4 Electric specifications

The fuses of model ST100 model are 12.5A lagged

fuses with a length of 20 mm and a diameter of 5 mm

(20 x 5 mm).

4.3 Connecting ST200 controllers to the power supply

4.3.1 Connecting the controller to the power

supply

The controller must be supplied with a single-phase

voltage. The supplied multi-pole cable has three

leads suitable for the purpose, two for the phase and

neutral terminals (or phase) and one for the earth

(yellow/green).

The controller cannot be powered from the threephase + neutral distribution network that supplies

the tool machine used. If the voltage required for the

controller is not available, install a power transformer

with a rating suited for the magnetic chuck.

Single-phase power supply

F

N

PE

BLACK

BROWN

YELLOW/GREEN

Three-phase power supply

R

S

T

PE

4.2.3 Selecting the correct dimensions for dis

charge cables

The discharge cable tted on ST100 comprises suitable leads, has a standard length of three meters

and is dimensioned to prevent overheating and the

loss of power on the chuck in ordinary operating

conditions.

Ordinary operating conditions are intended as enabling/disabling cycles occurring at an interval above

1 minute.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

44

BLACK

BROWN

YELLOW/GREEN

Instruction and maintenance manual

4.3.2 Power cable

TECNOMAGNETE supplies a suitable multi-pole

power cable with a standard length of four meters,

which prevents overheating problems and a voltage

drop within the rating of the TECNOMAGNETE module, if used in ordinary operating conditions.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

Ordinary operating conditions are intended as intermittent working cycles, with intervals of at least one

minute between two enabling cycles.

4.3.3 Selecting the correct dimensions for discharge cables

The discharge cable tted on ST200 comprises four

leads suitable for the purpose, has a standard length

of six meters and is dimensioned to prevent overheating and the loss of power on the chuck in ordinary operating conditions.

Ordinary operating conditions are intended as enabling/disabling cycles occurring at an interval above

1 minute.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

4.3.4 Electric specifications

All ST200 controllers are available as single and twophase models; the maximum installed power for

each cycle is 25 kVA (cosϕ=0.9) for two-phase 400V

plants, 15kVA for 230V plants and 32 kVA for 480V

plants.

To optimally protect the installation, it is necessary to

install a suitable magnetothermal switch (curve C)

with an In value compliant with the rating specied

on the nameplate.

5

ENABLING

5.1 ST100

ST100 controllers are not tted with a specic enabling device, which may however be ordered as optional (see Chapter 6.1).

5.2 ST200

The ST200 controller has an enabling device tted

on connector DB9 situated on the rear of the controller (PINS 8 and 9).

The technical specications for the contact are:

•

Voltage 30V, current 1A

•

Voltage 110V, current 0.3A

It is always advisable to use an auxiliary relay.

Before using other models of start systems, contact

TECNOMAGNETE S.p.A. for assistance.

When at least one of the magnetic chucks controlled

by ST200 is in magnetization mode, the enabling

contact is closed. PINS 6 and 7 can be connected to

the power of the tool machine and used to run the

enabling cycles through the controller: the controller

can only run the cycles when PINS 6 and 7 are closed. Connect the safety catch to the operating machine on which the TECNOMAGNETE module is installed.

DB9 PIN connector

5 4 3 2 1

9 8 7 6

ENGLISH

Instruction and maintenance manual

ENABLE ENABLE

MACHINE CONTROLLER

pin n° 1 ➜ B1

pin n° 2 ➜ A2

pin n° 3 ➜ Vdc

pin n° 4 ➜ Gnd

pin n° 5 ➜ Alarm

pin n° 6 ➜ COM ENABLE Controller

pin n° 7 ➜ ENABLE Controller

pin n° 8 ➜ COM ENABLE machine

pin n° 9 ➜ ENABLE machine

When possible, it is advisable to use both types of

contacts.

45

6

OPTIONALS

7

PLC

6.1 Starting the ST100 controller

ST100 models can be tted with an optional external

start button, connected with means of a male/female

connector.

When the magnetic chuck is controlled by the ST100

controller, it is magnetized, which means that the

controller enabling contact is closed

The technical specications for the contact are:

•

30V voltage, 1A current

•

110V voltage, 0.3A current

ENGLISH

It is generally advisable to use an auxiliary relay.

Before using other models of start systems, contact

TECNOMAGNETE S.p.A. for assistance.

6.2 Push-button panels of models ST100

and ST200

ST100 controllers can be tted with an optional twolevel push-button panel for milling and grinding

chucks.

Model ST200 can instead be tted with an optional

2-level push-button panel for milling and grinding

operations and with a 7-level push-button panel.

It is also possible to remotely connect all models of

push-button panels (basic, 2-level, 7-level).

Model ST100 is not tted with a PLC interface that

can be used for control purposes.

Model ST200 has a PLC interface that is constituted

by an external housing that has to be connected to

the controller by means of the DB9 connector. The

interface is constituted by a DB37 pin connector designed to be interfaced with the control system and

used to receive the magnetization/demagnetization

enabling controls, to increase and reduce the magnetization levels and to provide indications on the

machine status.

The function of available contacts is described below.

6.3 QE version

On models QE it is possible to use an optional external teleruptor with a power rating compliant to the

one printed on the nameplate of the connected magnetic chuck. Said teleruptor must be installed in accordance with the instructions provided on the electric wiring diagram supplied with the equipment.

This device ensures a more efcient control of the

electric commands through the machine.

46

Instruction and maintenance manual

19 1

37 20

Pin Name Direction Description

1 SW Mag

2 SW Demag

3 SW Level +

4 SW Level 5 Abilit PLC

6 Input Enable

7 nc

8 nc

9 nc

10 Level 1

11 Level 2

12 Level 3

12 Level 4

14 Level 5

15 Level 6

16 Level 7

17 Level 8

18 COM

19 NO2

20 Wait

21 Alarm

22 Ld3

23 Ld5

24 Out2

25 Out1

26 nc

27 nc

28 Vext

29 Vext

30 Vext

31 Rif

32 Rif

33 Rif

34 Mag

35 Demag

36 COM

37 NO2

Magnetization button

Demagnetization button

Button that increases the magnetization level

Button that decreases the magnetization level

Enabling input for PLC management

Input-Enable input

Not connected

Not connected

Not connected

1st level magnetization output

2nd level magnetization output

3rd level magnetization output

4th level magnetization output

5th level magnetization output

6th level magnetization output

7th level magnetization output

8th level magnetization output

Normally open common contact Out-Abilit

Normally open contact Out-Abilit

Output, cycle in progress

Alarm output

Not used

Not used

Not used

Not used

Not connected

Not connected

Common contact for buttons Mag, Demag, Level+, Level-

Insulated 24Vdc (power supply provided by customer)

Insulated 24Vdc (power supply provided by customer)

Common contact for output statuses

Insulated 0V (reference to customer power supply)

Insulated 0V (reference to customer power supply)

Magnetization status output

Demagnetization status output

Normally open common contact Out-Abilit

Normally open contact Out-Abilit

ENGLISH

Instruction and maintenance manual

47

8

CONNECTION TO THE

TECNOMAGNETE MODULE

8.1 Installation of miller ST100

Magnetic

module

ENGLISH

8.2 Installation of grinder ST100

Connector

Discharge cable

Controller

Power supply

Magnetic

module

Cable tie

Discharge cable

48

Controller

Power supply

Instruction and maintenance manual

8.3 Installation of miller ST200

Power supply

Push-button panel

CH ENABLE push-button panel

Enabling

Discharge

Discharge

PLC interface

ON/OFF

4 PIN connector

7 PIN connector

Junction box

Installation of Installation of

1 chuck 3 chucks

Controller

ST200

Magnetic chucks

Magnetic chuck

Installation of Installation of

2 chucks 4 chucks

Magnetic chucks

Controller

ST200

Magnetic chucks

Controller

ST200

Controller

ST200

ENGLISH

Instruction and maintenance manual

49

8.4 Installation of grinder ST200

Installation of Installation of

1 chuck 3 chucks

Controller

ST200

Power supply

Push-button panel

CH ENABLE push-button panel (optional)

Enabling

Discharge

Discharge

G

Discharge

Discharge

PLC interface

ON/OFF

ENGLISH

Magnetic chucks

Magnetic chuck

Controller

ST200

Installation of Installation of

2 chucks 4 chucks

Controller

ST200

Magnetic chucks

Magnetic chucks

50

Controller

ST200

Instruction and maintenance manual

9

ORDINARY USE

9.1 ST100

To start the ST100 controller, follow this procedure:

1) Connect the discharge cable to

TECNOMAGNETE’s module.

2) Connect the plug of the power cable to the 230V

electric socket and connect the connector to

the magnetic chuck, where available.

3) Switch the ST100 controller on using the switch

on the rear of the controller.

4) Verify that the LEDs on the push-button panel

turn on.

5) Press the demagnetization button (DEMAG).

Note: for ST100 (base) and ST100 (version with

2 levels) simultaneously press buttons ENABLE

and DEMAG.

6) Verify that the LED above the DEMAG button

turns on.

7) Press the magnetization button (MAG).

Note: for ST100 (base) and ST100 (version with

2 levels) simultaneously press buttons ENABLE

and FULL-MAG.

8) Verify that the LED above the MAG button

switches on.

9) Verify that the module is magnetized.

10) Start working remembering to close the con-

nector and check the status of the chuck after

every magnetization/demagnetization cycle.

7) Press the magnetization button (MAG).

Note: for ST200 (base) and ST200 (version. with

2 levels) simultaneously press buttons ENABLE

and FULL-MAG. For ST200 (version with 7 levels) simultaneously press buttons ENABLE and

MAG.

8) Verify that the LED above the MAG button

switches on.

9) Verify that the module is magnetized.

10) If the discharge cable has been removed, start

the working cycle remembering to close the

connector and check the status of the chuck at

the end of each magnetization and demagnetization cycle.

ENGLISH

WARNING

Do not place the discharge connector near or in

the presence of liquids, flammable material or

any other hazardous material.

9.2 ST200

To start ST200 controllers, follow this procedure:

1) Connect the discharge cable to

TECNOMAGNETE’s module.

2) Connect the plug of the power cable to the electric socket and connect the connector to the

magnetic chuck, where available.

3) Switch the ST200X controller on using the

switch on the front of the controller.

4) Verify that the LEDs on the push-button panel

turn on.

5) Press the demagnetization button (DEMAG).

Note: for ST200 (base), ST200 (version with 2

levels) and ST200 (version with 7 levels) simultaneously press buttons ENABLE and DEMAG.

6) Verify that the LED above the DEMAG button

turns on.

Instruction and maintenance manual

51

10

ANALYSIS OF RESIDUAL

RISKS

11

MAINTENANCE

11.1 Premise

In designing the chuck, the manufacturer has

taken into account specific manufacturing criteria and all applicable and current safety requirements, which do not however eliminate other

potential residual risks.

This chapter provides a description of the potential risks that could arise in specific situations.

•

As the controller is designed to be used to

ENGLISH

control TECNOMAGNETE modules that are

generally installed on tool machines, it is essential to make sure that operators have read

and are familiar with the instructions provided

in this manual, in the manual of the module and

of the tool machine on which the module is installed. Operators must also be made aware of

any other potential residual risk.

•

The individual protection means that have to

be used when working with the chuck are the

same ones required for the use of the tool machine on which the module is installed.

•

As for the potential residual risks originating

from the exposure to electromagnetic fields,

specific precautions should be taken by pregnant women; users suffering from specific

pathologies; users with pacemakers or other

prosthesis with electronic circuits including

hearing aids, intracranial metal implants (or

any other implant situated next to vital anatomic structures), vascular clips or chips in

ferromagnetic material. It is useful to remember that:

1. TECNOMAGNETE magnetic systems are

stationary systems and do not generate

electric fields.

2. The V/m (Volt/meter) value generated during

operation is equivalent to 0 (ZERO).

3. The electromagnetic emissions generated

during the enabling/disabling phase does

not exceed 100 Gauss at a distance of 100

mm from the system.

52

An appropriate maintenance is essential to maintain

the unit in good working order for a long period of

time, to ensure excellent performances and to guarantee its functional safety.

11.2 Maintenance safety instructions

ATTENTION

All maintenance operations must be performed by

qualied personnel only (see Chapter 1.7).

While performing maintenance operations, always

take into account the following:

•

All maintenance operations should be performed

when the unit is idle and disconnected from the

power supply.

•

All reparations on electric systems must be per-

formed after disconnecting the system from the

power supply and enabling the emergency button. All personnel responsible for the operation,

maintenance and cleaning of the unit shall have to

thoroughly follow the safety instructions applicable to the country of installation.

•

Always wear safety gloves and shoes and any

other type of PPE required including overalls that

cover as much of the body as possible.

•

Do not wear rings, watches, chains, bracelets,

loose clothing, etc. during maintenance work.

•

Stand on a rubber insulating mat (if possible)

when doing maintenance work.

•

Avoid working on wet oors or under very damp

conditions.

•

Always perform maintenance operation according

to schedule.

•

Always replace components with original spare

parts in order to guarantee maximum performance.

•

When performing cleaning operations, avoid us-

ing grinders or abrasive, corrosive or solvent material that could cause the removal and/or make

numbers, initials or information printed on the unit

illegible.

•

Never wet the unit.

•

Clean all electric parts with a vacuum system only,

not with compressed air.

Instruction and maintenance manual

11.3 Weekly maintenance

These operations, which have to be carried out by

the operator at the end of the weekly production,

shall include:

•

Inspection of the indicator lights;

•

Inspection of the buttons.

11.4 Monthly maintenance

These operations, which are based on a daily working shift of 8÷10 hours and must be performed by

qualied and skilled personnel only, include:

•

Visual inspection of the terminal boards, the mag-

netic chucks and the controllers;

•

Visual inspection of the cables and plugs.

11.5 Maintenance to be carried out every six months

These operations, which are based on a daily working shift of 8÷10 hours and must be performed by

qualied and skilled personnel, include:

• Disconnection of the discharge cables of the

magnetic chucks from the connection boxes;

• Measurement of the resistance and insulation values at 500V;

• Reconnection of the discharge cables of the magnetic chucks to the connection boxes.

ENGLISH

11.6 Extraordinary maintenance

Maintenance operations not specically described in

this manual are considered extraordinary maintenance and must be carried out by qualied personnel specically authorized by TECNOMAGNETE

S.p.A.

11.7 Information on extraordinary reparation and maintenance

The sections that follow provide a dimensional layout and assembly instructions for each chuck model

to simplify troubleshooting.

TECNOMAGNETE S.p.A. can be contacted at any

time for further information or queries regarding the

operation and maintenance of the controller.

Instruction and maintenance manual

53

12

TROUBLESHOOTING AND

CORRECTIVE ACTIONS

13

DECOMMISSIONING AND

DISPOSAL

This section provides information designed to help

operators to troubleshoot and correct the problems

that may arise during the use of the equipment.

For information on how to solve problems related to

electric issues, see the enclosed diagrams and the

operation and maintenance manuals supplied with

the controller.

All reparation on electric components must be carried out only after disconnecting the unit from the

power supply and enabling the emergency button.

ENGLISH

All personnel responsible for reparation operations

must thoroughly follow the accident prevention procedures in force in the country of installation of the

unit.

Problem Cause

The LEDs

do not turn

on when the

switch is

pressed.

The LEDs

do not turn

on when the

switch is

pressed.

The controller

performs the

required cycle,

but does not

magnetize the

chuck.

Disconnected

power cable

No voltage Verify that

Disconnected

discharge

cable

Corrective

action

Switch the

controller off

and inspect

the connections using the

wiring diagram

as reference.

voltage is

present.

Inspect the

connections.

13.1 Decommissioning

The unit should always be disconnected from the

power supply and disassembled from the tool machine on which it is installed if it is not likely to be

used for extended periods of time.

13.2 Dismantling

The user is responsible for the demolition, dismantling and disposal of the materials/components that

are part of the unit. Said operations shall have to be

carried out in accordance with UE directives or with

the laws in force in the country of use.

Dismantling operations must always be carried out

with utmost care to ensure maximum safety and prevent potential industrial accidents. Specic care

should be taken when performing the following operations:

•

Disassembly of the unit in the installation site.

•

Dismantling of the unit.

•

Separation of the materials/components that are

part of the unit.

Demolition and disposal operations should be carried out in compliance with appropriate regulations

in order to protect the health of workers and the environment. In particular all separation, recycling and

disposal operations must be compliant with the provisions stated in the national or regional laws concerning the disposal of solid industrial and toxic and

dangerous waste. Said provisions apply in particular

to:

•

Sleeves, exible ducts and plastic or non metal

parts must be disposed of as special waste.

•

Electric components such as switches, transform-

ers, sockets, etc. must be disassembled so that

they can be reused, if in good conditions, or inspected and recycled.

54

Instruction and maintenance manual

14

®

WARRANTY AND

TECHNICAL SUPPORT

14.1 Warranty terms and conditions

TECNOMAGNETE products are guaranteed for 36

months from the date of manufacture except where

otherwise indicated in writing. Said warranty covers

all defects of materials and workmanship. Faulty

parts shall be replaced or repaired by the manufacturer in his workshops.

All material to be repaired must be sent CARRIAGE

PAID.

After reparation, the controller shall be sent

CARRIAGE FORWARD to the customer.

The warranty does not cover expenses relating to

our engineers visiting the installation site nor machine dismantling. If on-site assistance is required,

labor cost shall be invoiced at current prices, along

with transfer and travel expenses.

The manufacturer shall not be responsible for direct

or indirect damages caused to people or property by

this controller or by reparations carried out by the

purchaser or third parties.

Reparations under warranty shall not affect the duration of the warranty period.

This warranty does not cover:

•

Malfunctions caused by incorrect use or tting

•

Damages originating from the use of spare parts

other than those recommended

•

Damages caused by oxidation.

14.2 Invalidity of warranty

The warranty shall not apply in the following cases:

•

If the customer fails to make the payments at due

time or fulll contractual obligations

•

If unauthorized reparations or alterations are

made

•

If the serial number has been tampered with or

deleted

•

If the damage originates from improper opera-

tions or use; for example improper maintenance,

impacts and other causes that cannot be attributed to ordinary operating conditions

•

If the controller has been disassembled, tampered

with or repaired without the written authorization

of TECNOMAGNETE S.p.A.

All controversies originating from this warranty

shall be settled by the Court of Milan.

For help or further information, contact our technical

services department at the following address:

TECHNICAL SUPPORT SERVICE

Via Nerviano, 31 - 20020 Lainate (Mi) - ITALY

TECNOMAGNETE S.p.A.

Tel. +39-02.937.59.208 - Fax. +39-02.937.59.212

service@tecnomagnete.it

ENGLISH

Instruction and maintenance manual

55

15

TECNOMAGNETE 1

SUPPORT CENTERS

MAIN OFFICE - ITALY

TECNOMAGNETE SpA

Via Nerviano, 31

20020 Lainate - Italy

Tel. +39 02937591

Fax +39 0293759212

info@tecnomagnete.it

FRANCE - BELGIUM - LUXEMBOURG

TECNOMAGNETE SARL

52 Av. S. Exupéry

01200 Bellegarde Sur Valserine

ENGLISH

Tel. +33.450.560.600 (FRANCE)

Fax +33.450.560.610

contact@tecnomagnete.com

GERMANY - AUSTRIA - HUNGARY

SWITZERLAND - SLOVAKIA THE NETHERLANDS

TECNOMAGNETE GmbH

4 Ohmstraße

63225 Langen (GERMANY)

Tel. +49 6103 750730

Fax +49 6103 7507311

kontakt@tecnomagnete.com

PORTUGAL

SOREP

Rua Nova Da Comeira, 4

2431-903 MARINHA GRANDE (PORTUGAL)

Tel. +351 244572801

Fax +351 244572801

geral@sorep.co.pt

SPAIN

DTC TECNOLOGIA

Poligono Osinalde - Zelai Haundi,1

20170 USURBIL (SPAIN)

Tel. +34 943 376050

Fax +34 943 370509

dtc@dtctecnologia.com

U.S.A. - CANADA - MEXICO

TECNOMAGNETE Inc.

6655 Allar Drive, Sterling Hts, MI 48312

Tel.: +1 586 276 6001

Fax: +1 586 276 6003

infousa@tecnomagnete.com

BRAZIL

COMASE Com. e Prest. de Serv. Ltda

Av. J. Alvez Correa 3608,

Jd. Planalto, Valinhos - SP- CEP 13270-400

Fone/ Fax: +55 (19) 3849-5384

JAPAN

TECNOMAGNETE Ltd.

1-9-7 Shibaura,

Minato - KU

105-0023 Tokyo

Tel. +81 3 5765 9201

Fax +81 3 5765 9203

infojapan@tecnomagnete.com

CHINA

TECNOMAGNETE R.O.

Pudong Lujiazui Dong road 161,

SHANGHAI- Room 2110 - PC: 200120

Tel: +86 21 68882110

Fax + 86 21 58822110

info@tecnomagnete.com.cn

SINGAPORE - SOUTH-EAST ASIA - ASIA PACIFIC

TECNOMAGNETE Singapore R.O.

101 Thomson Road 26 - 02 United Square

Singapore 307591

Tel: +65 6354 1300

Fax +65 6354 0250

infosgp@tecnomagnete.com

SWEDEN - NORWAY - DENMARK

FINLAND - BALTIC REPUBLICS

TECNOMAGNETE AB

16 Gustafsvagen

63346 Eskilstuna (SWEDEN)

Tel. +46 016 132200

Fax +46 016 132210

info@tecnomagnete.se

56

Instruction and maintenance manual

Tecnomagnete S.p.A.

Sede Legale in Milano, P.le Cadorna 10

Sede Operativa ed Amministrativa in Lainate (Mi),

via Nerviano 31 - 20020 Italy

DICHIARAZIONE DI CONFORMITA’

LA SOTTOSCRITTA DITTA:

TECNOMAGNETE SPA

Via Nerviano 31

20020 – LAINATE (MI) ITALY

DICHIARA SOTTO LA PROPRIA RESPONSABILITÀ CHE:

LE UNITA’ DI CONTROLLO

ELETTRONICHE

Modelli/Models

“ST 100 / 200”

AL QUALE QUESTA DICHIARAZIONE SI RIFERISCE È

CONFORME ALLE SEGUENTI NORME O ALTRI DOCUMENTI NORMATIVI:

•

DIRETTIVA 89/336 CEE (COMPATIBILITÀ

ELETTROMAGNETICA) E SUCCESSIVE

MODIFICHE ED INTEGRAZIONE

•

DIRETTIVA BASSA TENSIONE 73/23

SONO STATE UTILIZZATE LE SEGUENTI NORME E

SPECIFICHE TECNICHE:

DELARATION OF CONFORMITY

THE FIRM

DECLARES ON IT’S OWN RESPONSABILITY :

THE ELECTRONIC CONTROL UNITS

TO WHICH THIS DECLARATION REFERS CONFORMS

WITH THE REQUIREMENTS OF THE FOLLOWING

DIRECTIVES:

•

DIRECTIVE 89/336 CEE (ELECTO

MAGNETIC COMPATIBILITY) AND

FOLLOWING AMENDMENTS

•

LOW TENSION DIRECTIVE 73/23

THE GROUP ALSO CONFORMS WITH THE

FOLLOWING STANDARDS AND TECHNICAL

SPECIFICATIONS:

EN 61000-6-4 ; EN 61000-6-2 ; EN 61000-4-3 ; EN 55011

THE LEGAL REPRESENTATIVE

MICHELE CARDONE

....................................

SIGNATURE AND STAMP OF AUTHORIZED PERSON

14.01.2005

•

IT

TECNOMAGNETE S.p.A.

20020 Lainate (MI)

Via Nerviano 31

Tel. +39 02.937.591

Fax +39 02.935.708.57

info@tecnomagnete.com

www.tecnomagnete.com

•

FR

TECNOMAGNETE S.A.R.L.

52 avenue Saint-Exupéry

01200 Bellegarde-sur-Valserine

Tel. +33.450.560.600

Fax +33.450.560.610

•

DE

TECNOMAGNETE GmbH

Ohmstraße 4, D - 63225 Langen

Tel. +49 6103 750 730

Fax +49 6103 750 7311

•

SE

TECNOMAGNETE AB

Gustafsvagen 16

633 46 Eskilstuna

Tel. +46 016 132 200

Fax +46 016 132 210

•

US

TECNOMAGNETE Inc.

6655 Allar Drive,

Sterling Hts, MI 48312

Tel. +1 586 276 6001

Fax +1 586 276 6003

•

JP

TECNOMAGNETE Y.K. Ltd.

Omodaka Building 1F

1-9-7 Shibaura, Minato-ku

105-0023 Tokyo

Tel. +81 (0)3-5765-9201/02

Fax +81 (0)3-5765-9203

•

CN

TECNOMAGNETE Shanghai R.O.

Pudong Lujiazui Dong road 161,

Room 2110 - PC: 200120

Tel. +86 21 68882110

Fax + 86 21 58822110

•

SG

TECNOMAGNETE Singapore R.O.

101 Thomson Road 26 - 02 United Square

Singapore 307591

Tel: +65 6354 1300

Fax +65 6354 0250

09CONTR01

Loading...

Loading...