TECNOMAGNETE MaxX 125, MaxX 300E, MaxX 250, MaxX Series, MaxX 1500 Use And Maintenance Manual

...

PERMANENT – ELECTRO MAGNETIC SYSTEMS

USSEE

U

LLiigghhtt DDuuttyy LLiiffttiinngg DDiivviissiioonn

hhaanndd ccoonnttrroolllleedd lliifftteerrss -- M

Lainate (MI) - Italy

Edition: May 2019

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

according to LEGISLATION 2006/42/EC concerning machinery

A

A

N

N

D

D

M

M

M

M

A

A

AII

A

N

N

NTTEE

N

U

ALL

U

A

N

N

A

N

N

CEE

C

A

MaaxxXX

code 09MAXX001

version EN

revisione 01

2

CONTENTS

1 GENERAL NOTES ..................................................................................................................................................... 4

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10 E

1.11 U

1.12 N

2 TRANSPORT AND HANDLING.................................................................................................................................. 7

2.1

2.2

2.3

2.4

P

RESENTATION

IMPORTANCE OF THE MANUAL .................................................................................................................. 4

ETENTION OF THE MANUAL

R

ONVENTIONS

C

D

EFINITION OF SYMBOLS

ERSONNEL ASSIGNED TO OPERATIONS

P

RAINED PERSONNEL

T

ERSONAL PROTECTIVE EQUIPMENT

P

ENERAL SAFETY WARNINGS

G

MERGENCY DRILL

NINTENDED OR IMPROPER USE

AMEPLATE DATA

R

ECEIPT

ANDLING

H

RANSPORT

T

NACTIVITY

I

...................................................................................................................................... 4

.................................................................................................................... 4

....................................................................................................................................... 4

......................................................................................................................... 5

....................................................................................................... 5

.............................................................................................................................. 5

(PPE) ................................................................................................. 6

.................................................................................................................... 6

.................................................................................................................................. 6

............................................................................................................... 6

.................................................................................................................................. 7

............................................................................................................................................... 7

............................................................................................................................................ 7

.......................................................................................................................................... 8

............................................................................................................................................ 8

3 DESCRITPION OF THE SYSTEM ................................................................................................................................ 8

3.1 A

3.2

3.2.1. A

3.2.2 C

3.2.3 T

3.2.4 M

3.3

4 MODELS AVAILABLE ............................................................................................................................................. 11

4.1

5 TECHNICAL CHARACTERISTICS .............................................................................................................................. 12

5.1

5.2

6 GENERAL DESCRIPTION OF THE SUPPLY ............................................................................................................... 14

6.1

7 INSTALLATION ...................................................................................................................................................... 14

7.1

8.1 RISKS RELATED TO MAXX LIFTERS ............................................................................................................ 16

8.2 P

8.3 E

8.4 A

DVANTAGES

ASIC PRINCIPLES OF MAGNETIC CLAMPING WITH MAX

B

IR GAP AND ROUGHNESS

ONTACT SURFACE

YPE OF MATERIAL

ATERIAL THICKNESS

AGNETIC FORCE

M

MAXX ........................................................................................... E

MAXX TECHNICAL CHARACTERISTICS .............................................................................................. 12

MAXX

MAXX

G

ENERIC INSTALLATION

ERSONAL PROTECTIVE EQUIPMENT

XPOSURE TO MAGNETIC FIELD

CTION LEVELS

........................................................................................................................................ 8

X ............................................................................... 9

..................................................................................................................... 10

............................................................................................................................... 10

............................................................................................................................... 10

........................................................................................................................... 10

................................................................................................................................ 11

RRORE. IL SEGNALIBRO NON È DEFINITO

DIMENSIONS AND WEIGHTS

DESCRIPTION OF THE SUPPLY

......................................................................................................................... 14

(LA)

OF THE STATIC MAGNETIC FIELD

.......................................................................................................... 13

........................................................................................................ 14

......................................................................................................... 16

............................................................................................................... 16

.................................................................................. 17

.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

3

THE FOLLOWING IS THE BASIC OPERATING PROCEDURE FOR USING THE MAXX .......................................................... 18

9.1

9.2

10 CHECKS AND MAINTENANCE ................................................................................................................................ 19

10.1 C

10.2 C

10.3 D

10.4 F

10.5 P

10.6 M

10.7 D

10.8 F

10.9 P

10.10 S

11 PROBLEMS AND RELATED SOLUTION ................................................................................................................... 22

11.1 P

12.1 D

12.2 D

O

PERATING PROCEDURE - MAGNETIZING AND HANDLING

O

PERATING PROCEDURE - DEMAGNETISATION

ONTROLS – STANDARDS

HECKS - METHOD

AILY CHECK

REQUENT CHECK

ERIODICAL CHECK

AINTENACE - WARNINGS

AILY MAINTENACE

REQUENT MAINTENANCE

ERIODICAL MAINTENANCE

UMMARY TABLE MAINTENANCE/CHECKS

ROBLEMS

ECOMMISSIONING

ISPOSAL

....................................................................................................................................... 20

......................................................................................................................................... 22

........................................................................................................................................... 22

...................................................................................................................... 19

............................................................................................................................... 19

................................................................................................................................ 20

............................................................................................................................... 20

.................................................................................................................... 20

............................................................................................................................. 20

..................................................................................................................... 20

.................................................................................................................... 20

............................................................................................................................. 22

............................................................................ 18

........................................................................................... 19

................................................................................................ 21

13 SPARE PARTS ........................................................................................................................................................ 22

13.1 S

14 WARRANTY AND SERVICE .................................................................................................................................... 23

14.1 WARRANTY CONDITIONS ................................................................................................................ 23

14.2 WARRANTY EXPIRATION ................................................................................................................. 23

15 TECNOMAGNETE SERVICE NETWORK ................................................................................................................... 24

16 ANNEXES .............................................................................................................................................................. 24

16.1 D

PARE PARTS

ECLARATION OF CONFORMITY

....................................................................................................................................... 22

.............................................................................................................. 24

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

1 GENERAL NOTES

Congratulations on choosing a TECNOMAGNETE product.

This publication will help you find out more about your new

product and we recommend that you carefully read these

pages and always follow the instructions. The descriptions

and illustrations contained in this publication are not

difficult, given the basic features of the product described.

TECNOMAGNETE reserves the right to make changes at any

time to components and accessories in order to improve

the product or due to manufacturing or commercial

requirements. Updates of this manual will be provided as

required as Annexes or on the website

ww.tecnomagnete.com

of this manual and its reproduction, even partial, is

prohibited, as is disclosure to third parties, without its

written permission. In the event of changes and/or updates

to the product, which will be agreed exclusively with

TECNOMAGNETE, additional content concerning the use

and any residual risks arising from the changes shall be

provided to supplement the manual.

1.1

Presentation

TECNOMAGNETE was founded in 1974 and has attained a

position of leadership position in world markets as a

manufacturer of powerful, flexible permanent-electro

magnetic systems that operate in total safety, due to its

innovative technology and numerous patents filed over the

years. Permanent-electro magnetic systems produced by

TECNOMAGNETE are able to generate sufficient magnetic

force both for clamping and lifting workpieces, only

consuming electricity when turned on and off.

The main fields of operation include:

MACHINE TOOLS CLAMPING SECTOR

Grinding series

Milling series

Turning series

Rail machining series

MOULDING SECTOR

Systems for clamping press molds

LIGHT LIFTING SECTOR

Manually-controlled lifters

Battery-powered lifters

HEAVY LIFTING SECTOR

Magnetic lifters

Fixed beam magnetic module beam

. TECNOMAGNETE retains ownership

4

Telescopic beam magnetic module beam

Importance of the manual

1.2

A copy of this manual must be distributed and kept

available to operators assigned to the installation,

operation and maintenance of MaxX, enabling them to

operate in accableance with the instructions given in this

document. A careful reading of the manual will enable

MaxX to be used in the correct way and safeguard the

security and safety and operators and others. This manual

is an integral part of the MaxX, and all reproduction and

dissemination rights of the manual and its attachments are

reserved. Pass this manual on to any other user or

subsequent owner.

1.3

Retention of the manual

Making changes to and removing parts of this manual are

prohibited. When using the manual, take care not to

damage it. Keep the CD-R or USB key away from impact,

heat and magnetic sources and make it easily accessible to

operators for further reference.

Conventions

1.4

For ease of consultation, the manual is divided into the

following hierarchical order so that each phase is described

in detail:

1. Chapter 1 of the manual

1.1. section 1 of Chapter 1 of the manual

1.1.1. sub-section 1 of section 1 of Chapter 1 of the

manual

Some sections and/or chapters are presented with

numbered sequences in order to illustrate the operation

step by step.

Symbols are given in sections requiring greater attention.

Units of measurement, including the decimal point, are

displayed with the international system (SI).

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

5

Definition of symbols

1.5

All parts concerning safety are highlighted in bold.

All warning notes that alert the personnel concerned that

the described operation involves exposure to residual risk,

with possible damage to health or injury, if not carried out

in compliance with the instructions, are shown in bold and

identified with the following symbol :

All warning notes that indicate that the described

operation must be performed by trained and qualified

personnel are shown in bold and indicated with the

following symbol:

In turn, the trained / specialized personnel, depending on

the specific tasks, can be indicated by the following

symbols: (see details in paragraph 1.7)

Personnel assigned to

1.6

operations

As indicated in this manual, certain procedures must be

carried out only by qualified or trained personnel.

The level of qualification is described using standard terms:

1. qualified personnel have technical knowledge and/or

sufficient experience to enable them to avoid thepotential

dangers from electricity and/or mechanical movements

(operation and maintenance personnel) trained personnel

are appropriately advised and/or supervised by qualified

persons to enable them to avoid the potential dangers from

electricity and/or mechanical movements (operation and

maintenance personnel)

2. the User is obliged to obtain confirmation of

the following from all designated persons, before they are

allowed to work to work with MaxX the personnel have

received the instruction

2.1. the personnel have received the instruction manual, and

have read and understood it

2.2. the personnel shall work in the manner described..

Trained personnel

1.7

The qualifications are given below of the personnel

allowed to use the MaxX:

OPERATOR: a person or persons who,

following appropriate and indispensable training, is/are

assignedand authorized by the owner of the MaxX to run

operations. The occupier of this post must be completely

aware of and understand the contents of this manual

HANDLER: this post requires specific skill

(possibly acquired by attending mandatory courses, if

required by law, in hoists the methods and features of

harnesses handling and safe handling procedures. This

position also requires complete awareness and

understanding of the contents of this manual, in particular

paragraph 2.2

MECHANICAL MAINTENANCE OPERATOR:

this post requires specific skills in the installation, adjustment,

maintenance, cleaning and/or repair of systems. The occupier of

this post must be completely aware of and understand the

contents of this manual.

requires specific skills in carrying out installation, adjustments,

maintenance cleaning and/or repair. For his preparation and

experience he has skills and knowledge in the lifting sector as

well as a sufficient familiarity with the main regulations in order

to be able to determine any deviations from the expected

conditions.

The occupier of this post must be completely aware of and

understand the contents of this manual.

SPECIALIZED TECHNICIAN:

this post

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

6

1.8

Personal protective

equipment (PPE)

The staff referred to in the previous paragraph must wear an

adequate safety distance from the parts clamped on the

magnetic equipment, with special attention when in vertical or

suspended (this distance must be suggested by the plant

operator in accordance with the regulations). The staff must

also wear appropriate safety clothing. Protective footwear is

mandatory, while the need for

headsets, helmets and goggles must be assessed by the

User. Loose fitting clothes or articles that could be trapped by

moving parts are prohibited.

(see chapter 8)

General safety warnings

1.9

The rules and recommendations below are in compliance

with the current safety regulations, on which they are

based. TECNOMAGNETE S.p.A. declines all responsibility for any

damage caused to persons or things deriving from failure to

observe the safety regulations in force and the instructions given

below.

Machine safety systems must be selected and installed on

the basis of the following requirements:

be under the technical responsibility of qualified

personnel

be integrated with technical compliance and with

appropriate control systems

installations must be made in such a way that they can

not be neutralized or tampered with

All designated operators must respect and implement the

following and scrupulously adhere to the regulations on

accident prevention in force in the country of installation and

on the use of the MaxX. All ordinary and extraordinary

maintenance must be performed with stationary system and

with structure not hooked to the crane etc.

To avoid the danger of accidental connections during

maintenance operations, attach a warning sign on the control

panel with the words:

MAINTENANCE IS UNDERWAY

All operations of transport, installation, use, ordinary and

extraordinary maintenance on the MaxX must only be carried

out by the personnel identified in section 6 of chapter 1.

The permanent-electro magnetic system can only be used for

the applications indicated in the manual and only in

combination with devices and components recommended and

authorized by TECNOMAGNETE S.p.A.

1.10

In an emergency, it is recommended to follow the procedures

given in the operation and maintenance manual of the machine

on which the MaxX is installed. In the event of fire, use the

devices provided to extinguish the fire, taking care never to use

water on electrical parts (considering however that MaxX is not

made up of electrical parts).

1.11 Unintended or improper use

Emergency drill

MaxX is not designed or constructed for operation in explosive

atmospheres.

Unintended use may:

cause injury to personnel

damage the system or other equipment

diminish reliability and performance.

MaxX cannot be used for purposes other than those

recommended and in compliance with the intended use,

avoiding the following in particular:

unsuitable parameters of use

defective or lack of maintenance

use of inappropriate materials

failure to follow instructions

uncertain or insecure clamping of MaxX system or parts

thereof

In the events of doubts over the appropriate usage,

contact TECNOMAGNETE S.p.A. to determine whether it is use

for which the system was intended or otherwise.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

7

1.12

Two plates are applied on the MaxX:

1) Logo and data referring to the identification of the

2) Load / force curves, data referring to the performances and

3) The plates are indelible and must not be removed for any

Example of a nameplate on MaxX500:

Fig.1.12A

Nameplate data

manufacturer, serial number, production date, weight of the

MaxX, symbology in compliance with the laws in force

(example Fig.1.12A).

dimensions and types of load to be magnetically anchored

(example Fig.1.12B).

reason even should the MaxX be sold. In the event the plate

has been damaged or lost after coming away from its

housing, contact TECNOMAGNETE S.p.A. to obtain a

replacement. When communicating with TECNOMAGNETE

S.p.A., always quote the model on the plate. Failure to

comply with these provisions exempts

TECNOMAGNETE S.p.A. from any liability for damage or

injury to persons or property that may arise, which shall

remain the sole responsibility of the user with regard to the

competent bodies.

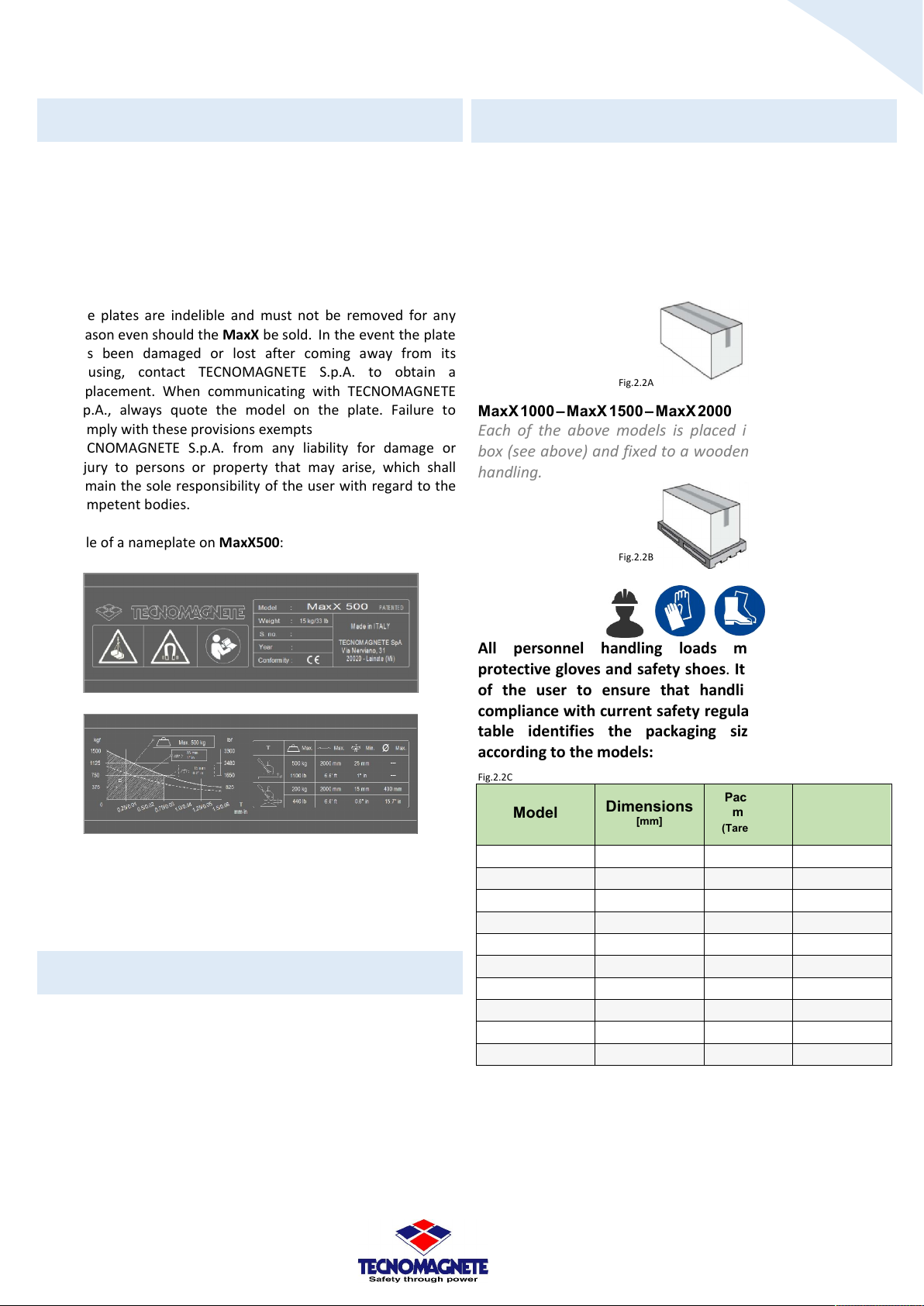

2.2

MaxX 125 – MaxX 250 – MaxX 300E – MaxX 500 – MaxX 600E

MaxX TG 150 – MaxX TG 300

Handling

Each of the above models is placed inside cardboard boxes,

protected by a sheet and wrapped in a layer of

polyurethane foam that guarantees the absolute

mechanical integrity in case of shocks or incidents of the

packaging.

Fig.2.2A

MaxX 1000 – MaxX 1500 – MaxX 2000

Each of the above models is placed inside the cardboard

box (see above) and fixed to a wooden pallet to allow easy

handling.

Fig.2.2B

Fig.1.12B

2 TRANSPORT AND

HANDLING

2.1

Receipt

MaxX are thoroughly checked before shipment. On receipt, the

integrity of the package and the material contained therein must

be checked (unless other instructions are issued by

TECNOMAGNETE S.p.A.), in order to confirm that no damage

occurred during transport and that the consignment complies

with the order specifications. Otherwise, report any irregularities

to TECNOMAGNETE S.p.A. and the Carrier responsible for any

damage during transport.

Notification of damage or defects must be given within ten days

from receipt of the supply. After that period, TECNOMAGNETE

S.p.A. will consider the provision free of defects.

All personnel handling loads must operate with

protective gloves and safety shoes. It is the responsibility

of the user to ensure that handling is conducted in

compliance with current safety regulations. The following

table identifies the packaging size and its weight

according to the models:

Fig.2.2C

Model

MaxX 125

MaxX 250

MaxX 300E

MaxX 500

MaxX 600E

MaxX 1000

MaxX 1500

MaxX 2000

MaxX TG150

MaxX TG300

Dimensions

[mm]

130x130x200 0.3 4

195x145x200 0.5 7

195x145x200 0.5 7

255x190x245 1 16

255x190x245 1 16

350x230x250 3.5 36

400x300x300 5 66

460x300x300 6 82

195x145x200 0.5 7

255x190x245 1 16

Packing

mass

(Tare) [kg]

Complete

packing

(Gross) [kg]

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

8

Inactivity

2.4

When hoisting or handling MaxX, clear the operations

area of obstructions and keep it clear, also consider

providing a sufficient safety zone to prevent harm to

persons, animals or objects that might be in maneuvering

range. MaxX are designed to be hoisted and handled

with suitable hoisting devices, the type and scope of

which must be selected in accableance with the weight.

(see table Fig.2.2C). It must be handled with extreme

care, avoiding impacts that could damage delicate parts,

compromising normal operation When moved with

forklift trucks, comply with the permitted speed and

inclination. Never leave load suspended on hoists. (also

refer to paragraph 1.8).

The permanent-electro magnetic system must be

disconnected from power sources and its moving parts

appropriately locked during transport, handling and

storage.

The instructions on the package must be read and

digested before opening.

Keep the original packaging for later handling.

2.3

Transport

Some parts may have to be dismantled for transport, to be

reassembled and reconnected during installation by

TECNOMAGNETE S.p.A. technicians, or by the User on

TECNOMAGNETE S.p.A.’s recommendations. The system must be

transported in observance of the following environmental limits:

a temperature range of -5 °C to +55 °C, rising to a maximum of

+70 °C for a period no longer than 24 hours. Should it be

necessary to transport the MaxX by sea or by air, suitable

packaging and protection systems must be provided to avoid

any damage caused by impact. To protect against weathering,

use anti-rust lubricants and bags of hygroscopic salts inside the

packages. All moving parts must be properly anchored and

removed from their housing, where possible.

In the event of long-term storage or inactivity, the MaxX must be

thoroughly cleaned of any residues and its uncovered metallic

parts must be protected with oil or grease in order to avoid

oxidation. It is recommended to cover the MaxX with a tarpaulin

and keep them in a dry, sheltered place The room temperature

should be between -5 ° C (23 ° F) and + 55 ° C (131 ° F). The

relative non-ondensing humidity should be between 30% and

90%, The atmosphere should be clean, free of acids, corrosive

gases, salts, etc. If restoring to operation, follow the instructions

contained in this manual.

3 DESCRITPION OF THE

SYSTEM

Advantages

3.1

MaxX consists of a very small number of details. Rotor and

stator, in steel with high magnetic permeability, are obtained by

machining from solid, using CNC machines; this grants uniformity

and robleness of the product and the quality control necessary

for a magnetic hoist built in large series.

The material used (steel, aluminum, plastic) is easily disposable

and recyclable when the tool is dismantled.

The magnetic material used, with a high specific energy, made it

possible to reduce to the maximum weight and volume.

To allow a high uniformity of performance, given the large series,

the MaxX lifter is magnetized in a single stroke after assembly,

using the largest magnetizer built in Europe.

MaxX is able to handle the load, which is always anchored and

lifted from above, without any deformation or damage with an

optimal use of the available work areas.

Some of the most recognized areas with the use of MaxX are the

following:

- servicing of machine tools

- wholesalers of ferrous material

- cutting plants

- carpentry

- shipyards

- foundries

- steel industries

- mold handling

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

Static magneto-permanent core

Magneto-permanent nucleus invertible

Poles (North - South)

Ferromagnetic crown

Load to anchor

Basic principles of magnetic

3.2

clamping with MaxX

MaxX is born from TECNOMAGNETE experience in the

development of solutions for the handling of ferrous loads.

The MaxX described in this manual is a hand controlled magnetic

lifter able to move (lift, translate and deposit) ferromagnetic

material

(ex. Steel sheets, plates, rounds, common ferrous material).

MaxX is equipped with a ring-locking bracket and therefore can

only be used as a lifter when hung on a hook of the lifting and

translation means.

MaxX exploits the properties of permanent magnets to create a

magnetic field able to penetrate ferrous materials.

The activation is carried out by means of a lever which rotates a

core in which the permanent magnets are incorporated, so as to

obtain a magnetic flux which in the working phase passes

through the load to be manipulated and in the release phase is

short-circuited inside the lift itself.

The patented magnetic circuit of MaxX lifts conveys the flow

exclusively in the polar area, ie only where it is needed, without

dispersions and without affecting other adjacent loads.

4

1

2

3

5

Fig.3.2A Magnetization phase (MAG)

Fig.3.2B Demagnetization phase (DEMAG)

Fig.3.2C

Fig.3.2A Fig.3.2B

N

S

S

S N

S

N

N

Description

N

S

①

②

③

④

⑤

S

S

N

N

The operating cycles of the MaxX are therefore:

- Fig.3.2A in MAG phase the invertible nucleus② is in

parallel to the static one ①. This generates a magnetic

field which, through the poles ③, is completed through

the piece to be anchored⑤.

- Fig.3.2B in the DEMAG phase, the two cores ① and

② are placed in series (rotation of 180 ° of the

invertible core②), constituting a magnetic field which

is short-circuited inside the frame.

Even if the magnetic field acts the same through nonmagnetic bodies (air-dust, non-ferrous materials in

general), maximum efficiency is obtained when the

poles of the same are in good contact with the surface

of the load.

The force curves (see paragraph 3.3), highlight the "fall"

of the anchorage force F (daN) of the lifter with the

increase of the air gap T (in mm), generated by any

"improper presences" between the aforementioned

poles and the load (calamine, foreign bodies,

depressions, protuberances, straps, etc.).

Therefore:

WE RECOMMEND NOT to place MaxX in very dirty or

highly deformed areas of the load. If this is not possible,

follow the performance indications given by the forceair gap curve according to the characteristics of the load

to be lifted.

4

WE RECOMMENDED to clean the surfaces of the load

and the poles before placing the lift. If this is not

1

2

possible, follow the performance indications given by

the force-air gap curve according to the characteristics

of the load to be lifted.

WE RECOMMENDED, to periodically check the

3

mechanical condition of the poles ③ to ascertain the

5

good condition of flatness and the non-damage due to

possible mechanical accidents.

9

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

10

rectified fine milled medium milled rough

Fig.3.2.1A

Fig.3.2.1B

3.2.1. Air gap and roughness

The condition that guarantees the most efficient magnetic

attraction is obtained when the air gaps are reduced to a

minimum and there is a consistent surface of continuous

contact.

The worst results occur when there is a high air gap and a

minimum contact. A very important aspect is therefore the

degree of superficial roughness. A good contact surface

considerably decreases the air gaps thus obtaining an optimal

magnetic attraction force.

100% = rettificata

90 ÷ 80% = light milling

80 ÷ 70% = milling

contact

surface

70 ÷ 60% = rough

T

=Air gap

3.2.2 Contact surface

The magnetic attraction force is directly proportional to the

useful contact surface.

The superficial heat treatments of the material of which the load

is composed influences the physical structure as well as the

capacity of the load to absorb the magnetic flux.

The load made of annealed material is the best.

The load produced with hardened material does not

satisfactorily absorb the flow of time and the tendency to retain

a certain amount of magnetism when the MaxX has been

deactivated (DEMAG).

This amount of magnetism that remains on the load is defined as

magnetic residue and can create difficulties in detaching the

MaxX when it is deactivated (DEMAG). The magnetic residue

can be removed from the load by using a demagnetizer.

3.2.3 Type of material

Check the type of material to which the load is made to be

anchored magnetically. The technical characteristic

required by the material is its magnetic conductivity

(magnetic permeability). The technical characteristic

required by the material is its magnetic conductivity

(magnetic permeability).

1,0 mild steel

0,7 ÷ 0,8 alloy steel

0,5 cast iron

0,2 nichel

0 amagnetic stainless steel, brass, aluminium

3.2.4 Material thickness

It can be hypothesised that the path of the magnetic flux,

inside a load to be anchored magnetically, consists of a

semicircle that starts from the center of a Pole (north) and

arrives at the center of the next one (south). If the load

fails to contain all the generated magnetic flux, the leaking

part is dispersed and does not contribute to the anchorage.

L’attrazione risulta dunque minore di quella che si potrà

avere quando tutto il flusso è assorbito da un carico di

spessore adeguato a contenerlo.

CHECK THE MINIMUM THICKNESS OF THE LOAD

TO BE LIFTED AS IN THE FOLLOWING TABLES

Fig.3.2.4A

LOAD

CONDITIONS

Fig.3.2.4B

LOAD

CONDITIONS

MIN.

MODEL

MaxX 125 20

MaxX 250 20

MaxX 300E 20

MaxX 500 25

MaxX 600E 25

MaxX 1000 40

MaxX 1500 45

MaxX 2000 55

MaxX 125 10

MaxX 250 10

MaxX 300E 10

MaxX 500 15

MaxX 600E 15

MaxX 1000 25

MaxX 1500 30

MaxX 2000 35

MODEL

MaxX TG150 8

MaxX TG300 10

MaxX TG150 8

MaxX TG300 10

THICKNES

S [mm]

MIN.

THICKNES

S [mm]

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

Magnetic force

3.3

Each pole (North/south) is an independent magnetic

island, consisting of a conductive steel core of magnetic

flux, able to generate a high value of magnetic force

concentrated and constant over time. The total magnetic

attraction force available is directly proportional to the

magnetic operating surface, the type of material of which

the load to be lifted and the conditions of its surface are

composed; i.e. from:

Load to be lifted

Load surface conditions (roughness, flatness...)

Contact surface between load and MaxX

Fig.3.3A Fig.3.3B

MaxX

N

S

S

LOAD

(mild steel, alloy steel, cast iron ...)

S

N

N

LOAD

T

=Air gap

Anchorage force

The following graphs/curves are exhaustive of further

information concerning the magnetic force and the load in

function of the air gap.

C

= Load F= Force T=Airgap

11

C

[Kg]

300

225

150

75

Fig.3.3E

0

0 0,25 0,5 0,75 1,00

F

[

]

daN

900

675

450

225

T [mm]

The ones presented are indicative values, obtained with

loads in common steel S275JR, at a temperature of 20 °c.

4 MODELS AVAILABLE

4.1

MaxX

The MaxX lifting system is a product of Tecnomagnete and

is available in the models:

MaxX 125

MaxX 1000

MaxX 250

–

–

MaxX 1500 – MaxX 2000

Fig.4.1A

MaxX 300E

–

MaxX 500

–

:

MaxX 600E

–

Fig.3.3C

C

[Kg]

2000

1500

1000

600E

500

300E

250

0 0,25 0,5 0,75 1,00 1,25 1,50

0

C

[Kg]

Fig.3.3D

daN

[

F

]

F

[

]

daN

6000

4500

3000

1500

750

T [mm]

MaxX TG 150 – MaxX TG 300

Fig.4.1B

:

EXAMPLE

EXAMPL

E

0 0,25 0,5 0,75 1,00

Use and Maintenance Manual

MaxX

T [mm]

codice 09MAXX001

versione EN

revisione 01

5 TECHNICAL

CHARACTERISTICS

5.1 MaxX

In This manual the operating conditions of the MaxX are as

follows:

Operating temperature from -5°C (23°F) to +55°C (104°F)

Load temperature max 80°C (176°F)

The temperature of the load must not exceed + 80 ° C.

For higher temperatures of the load consult Tecnomagnete

S.p.A.

Instead, the following two tables describe the load

characteristics that MaxX can raise:

Fig.5.1A

CONDITION

Fig.5.1B

CONDIZIONI

DI CARICO

LOAD

TECHNICAL CHARACTERISTICS

MaxX

- CARATTERISTICHE DEL CARICO

MODEL

MaxX 125 125 20 1000 ---

MaxX 250 250 20 1500 ---

MaxX 300E 300 20 1500 ---

MaxX 500 500 25 2000 ---

MaxX 600E 600 25 2000 ---

MaxX 1000 1000 40 3000 ---

MaxX 1500 1500 45 3000 ---

MaxX 2000 2000 55 3000 ---

MaxX 125 50 10 1000 300

MaxX 250 100 10 1500 300

MaxX 300E 120 10 1500 300

MaxX 500 200 15 2000 400

MaxX 600E 240 15 2000 400

MaxX 1000 400 25 3000 450

MaxX 1500 600 30 3000 500

MaxX 2000 800 35 3000 600

MaxX TG

MODELLO

MaxX

TG150

MaxX

TG300

MaxX

TG150

MaxX

TG300

MAX LOAD

[kg]

- CARATTERISTICHE DEL CARICO

CARICO

MASSIMO

[kg]

150 8 1500 ---

300 10 2000 ---

60 8 1500 240

120 10 2000 290

MIN.

THICKNESS

[mm]

SPESSORE

MINIMO

[mm]

MAX.

LENGTH

[mm]

LUNGHEZZA

MASSIMA

[mm]

DIAMETER

DIAMETRO

MASSIMO

MAX.

[mm]

[mm]

12

Nickel treatment on all steel parts prevents oxidation/rust

formation, improves the life of the components and allows

a greater surface hardness of the poles to allow an

excellent contact condition between the MaxX and the

Load.

Each MaxX lifter is checked to ensure that all the expected

operating parameters are guaranteed and certified, in

compliance with the strictest international standards.

All models of MaxX products are subjected to a test that

ensures their performance. This test is carried out by

placing MaxX, and Activan-Dolo, on the plate made of mild

steel 80 mm thick with rectified super ¬ surface, of a

dynamometric machine as from the following

photographs. A force equal to 3 times the maximum

operating load is applied to the lift, in order to verify the

lifting capacity and the mechanical resistance.

The thickness of the load conditions the capacity of the lift;

For thicknesses smaller than the width of the pole there is

a reduction in the flow proportional to the ratio between

the thickness (S) of the load to be anchored and the width

(L) of the pole.

Flow reduction factor = S/L

Fig.5.1C Fig.5.1D

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

MaxX

5.2

Fig.5.2A

ON

Fig.5.2B

L

Model

MaxX 125

MaxX 250

MaxX 500

MaxX 1000

MaxX 1500

MaxX 2000

MaxX 300E

MaxX 600E

MaxX TG150

MaxX TG300

13

dimensions and weights

M

E

1

2

5

°

°

50

C

H

D

OFF

FI

G

B

A

Weig

ht

[kg]

A B C D E F G H I L M

3,7 121 76 79 79 66 30 44 145 132 137

6 189 143 79 79 63 35 43 142 130 137

15 250 199 106 101 88 52 60 189 165 170

36 342 284 133 131 88 52 60 219 225 240

66 383 316 166 171 122 64 87 293 330 377

80 457 390 166 171 122 64 87 293 330 377

6 189 143 79 79 63 35 43 142 130 137

15 250 199 106 101 88 52 60 189 165 170

6 189 170 79 87 63 35 43 150 130 137

16 250 230 106 101 88 52 60 189 165 170

I

ON

L

ON

L

0

5

I

0

5

Dimensions [mm]

M

E

H

1

2

5

°

°

C

1

2

5

°

°

C

D

E

H

D

G

OFF

M

G

OFF

F

B

A

F

B

A

10

10

14

14

19

19

10

14

10

14

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

14

Grain

Lever

Tool

6 GENERAL DESCRIPTION

OF THE SUPPLY

MaxX

6.1

Tecnomagnete's products and methods conform to the

European Union directive governing the reduction of

harmful substances (RoHS). MaxX is composed by:

Eyebolt (only for MaxX125) or Load ringmade of

galvanized steel

Structure/body in nickel-plated steel

Side covers made of aluminium with polyurethane

enamel varnish (see paragraph 4.1 with yellow colour

RAL1003 for the models shown in Fig. 4.1 A or red

RAL3000 for the models shown in Fig. 4.1 b)

Aluminium plates with laser serigraphy

Galvanized steel lever with plastic handle

amagnetic steel lever locking pin

fixing screws and grain for fastening the lever made of

galvanized steel

Fig.6.1A

I

Fig.6.1B

Customized Eyebolt to design TECNOMAGNETE

Customized Load ring to design TECNOMAGNETE

Structure / body

Side covers

Label

Lever and handle

Pin lever (for lever lock)

Grain (for lever fixing)

Fixing screws

description of the supply

A

C

D D

E

B

C

D D

E

Description

Made in ITAL Y

TE CNOMA GNET E Sp A

Via Ner viano, 31

200 20 - Laina te (Mi)

F

II

F

G

H

G

H

I

Ⓐ

Ⓑ

Ⓒ

Ⓓ

Ⓔ

Ⓕ

Ⓖ

Ⓗ

Ⓘ

7 INSTALLATION

7.1

Generic installation

The models MaxX125, MaxX250, MaxX300E, MaxX500,

MaxX600E, MaxXTG150 and MaxXTG300 are pre-

assembled manual lifters which do not require any further

installation by the user, for which they mean "ready to

use" products. Only for the above models you can proceed

first with phase a) and then with phase H).

For the models MaxX1000, MaxX1500 and MaxX2000 the

commissioning is extremely easy as long as the following

procedure is carefully followed:

a) pay attention to the weight of the MaxX model

(see paragraph 5.2 table Fig. 5.2B) and then lift it

up (see paragraph 2.2) by means of an appropriate

lifting body and move it by hooking it up from the

eyebolt / load ring:

Fig.7.1B

Fig.7.1A

EXAMPLE

b) Lay MaxX on an iron plate lying on the ground or

on a support suitable for the weights of both the

plate and MaxX.

The iron plate shall have a minimum thickness as

indicated in sub-paragraph 3.2.4 Fig. 3.2.4A and

Fig. 3.2.4B.

c) Arrange the lever, the fastening grain and the tool

for assembly

Fig.7.1C

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

15

Tool

hub

Tool

Lever

Tool

Grain

d) Insert the tool into the special hole and turn the

central hub until the threaded hole in which the

lever is to be screwed.

Fig.7.1D

e) While keeping the hub in the position required in

phase d), tighten the lever in its threaded seat and

fasten it completely (Fig. 7.1E2 The lever tightening

values are shown).

Fig.7.1E1

Fig.7.1E2

Torque values for clamping the lever

MaxX 125/250/300E = 25 Nm

MaxX 500/600E = 48 Nm

MaxX 1000 = 85 Nm

MaxX 1500/2000 = 210 Nm

MaxX TG 150 = 25 Nm

MaxX TG 300 = 48 Nm

f) Insert the grub screw into the housing and tighten

it with the tool until the end of stroke to ensure

the locking of the Lever

Fig.7.1F

g) Handle MaxX with the same procedure described

in phase a)

Fig.7.1G

h) Place MaxX on the load to be handled and follow

the procedure described in chapter 9 as regards

the normal use of the equipment.

Fig.7.1H

MaxX is designed to be lifted and handled with suitable

lifting means (as described in paragraph 2.2), the type and

scope of which must be chosen in relation to the weights

of both the MaxX (see paragraph 5.2 table Fig. 5.2B) and

the addition of the load. It is important to periodically

check the structure of the MaxX with particular attention

to the eyebolt / load ring(see paragraph 10.12).

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

16

8 ANALYSIS OF RESIDUAL

RISKS

Permanent magnetic systems manufactured by

Tecnomagnete are made paying close attention to the

construction criteria and to the regulations in force

regarding safety: in any case, possible dangerous

conditions can remain. This chapter is intended to warn of

risks that may arise in particular situations.

8.1 Risks related to MaxX lifters

Since MaxX is by its nature intended for installation in

various applications it is necessary that the user has

understood and assimilated both the instructions of this

manual and the instructions contained in the Manual of

the installation on which it is installed/ hooked.

The user must therefore be informed of any residual risks

that may arise during the coupling and release phases,

magnetization and demagnetization, handling and laying of

the MaxX and its load. Please note that to correctly carry

out the MaxX lifting must be placed on the centre of

gravity of the load; In fact an unbalanced load can

compromise the magnetic anchorage. Below are

two examples of STABLEpositioning (correctly laid on the

centre of gravity of the load) and UNSTABLE positioning.

Fig.8.1A

UNSTABLE

Fig.8.1B

STABLE

Also, avoid placing the MaxX "cut" with the anchored load.

Fig.8.1C

UNSTABLE

8.2 Personal protective

equipment

The Personal Protective Equipment (PPE) required for the

use of the MaxX are the same as those required for the use

of the system on which it is installed/hooked (see also

paragraph 1.8).

8.3Exposure to magnetic field

For possible risks related to exposure to magnetic fields, a

careful evaluation of the possible effects against pregnant

women, subjects with special pathologies and persons with

pacemaker or other patients, is recommended. Prostheses

equipped with electronic circuits such as hearing aids,

intracranial metallic preparations (or in any case near vital

anatomical structures), vascular clips or splinters in

ferromagnetic material.

It is therefore known that:

1. The permanent magnetic systems produced by

Tecnomagnete are stationary magnetic systems and, as

such, do not emit electric fields.

2. The magnetic field emission does not exceed 100

Gauss at a distance of 100 mm from the magnetic

system

It is therefore specified that the values of the magnetic

fields are lower than the action values indicated in table 2

of annex XXXVI to Legislative Decree 81/2008. MaxX is

therefore a product suitable for the wearers of pacemakers

or other prostheses equipped with electronic circuits. For

further details see section 8.4.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

17

8.4 Action levels (LA) of the

static magnetic field

The European Union Directive on Electromagnetic Fields

(Directive 2013/35/EU, also known as the EMF Directive)

contains general provisions to ensure the safety and health

of workers. Essentially, the EMF Directive provides further

details on how to achieve the objectives of the Framework

Directive (Directive 89/391/EEC), in the specific case of

work in the presence of electromagnetic fields. An action

level (LA) quantified as 0.5 mT (milli-Tesla) is specified to

limit interference with the function of active implantable

medical devices.

The Electromagnetic Fields Directive also provides for an

LA of 3 mT to limit the propulsive risk in the peripheral

field from high intensity sources (> 100 Mt).

The following table shows the LA values of the stationary

fields of the various MaxX models in active state (MAG) or

in deactivated state (DEMAG).

Fig.8.4A

MODELLO Lifter status LA : 0,5 [mT] LA : 3 [mT]

MaxX 125

MaxX

TG150

MaxX 250

MaxX 300E

MaxX

TG300

MaxX 500

MaxX 600E

MaxX 1000

MaxX 1500

MaxX 2000

DEMAG

MAG

DEMAG

MAG

DEMAG

MAG

DEMAG

MAG

DEMAG

MAG

DEMAG

MAG

Distance [cm]

11 5

6 2

12 1

3 1,5

8 1

4,5 2,5

12 1

6 2,5

19 1

7 3

21 1

8 3

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

PROPER USE OF

The following is the basic operating procedure for

Operating procedure

Magnetizing and handling

, check that the poles and the contact

) are clean so that

there is no residue of heavy dust and/or chips.

Also clean and check the correct function

) in order to guarantee its functioning

in optimal conditions (check of the spring return).

Fig.9.

on the load to be handled paying attention

to its characteristics, with attention to the thickness, as

must be in perfect and total contact

MaxX

reater attention to the

by turning the lever to the MAG

Turn the lever until it locks into the mechanical

Pay attention to the weight of the

(see paragraph 5.2 in the table Fig.5.2B) plus the

addition of the weight of the load, after which lift,

by means of a suitable lifting device, and move by

from the eyebolt/

the conditions suggested in paragraphs 2.2 a

CAUTION: DO NOT ACIDENTALLY MOVE THE STOP

WITH THE SUSPENSION LOAD, especially for loads with a

high air gap (e.g.: rounds, tubes) because it could cause

off and fall accidentally (with the load

anchored NOT in optimal conditions if you move the lever

stop device, bringing it to the OUT service position

, it could cause the sudden rotation of the lever

from the MAG position to the DEMAG position).

Place the load perfectly on the ground or on a

support suitable for supporting the weights of both

MaxX

Pin lever

(for lever lock)

18

MAG

Position

Position

Fig.9.1C3

Fig.9.1C4

9

MAXX

using the MaxX

9.1

Before using MaxX

surface of the load to be lifted (Fig.9.1.1

stop lever (Fig.9.1.2

Fig.9.1.1

-

ing of the pin-

1.2

b)

lever lock.

Fig.9.1B

c)

hooking MaxX

MaxX model

load ring (observe

nd

5.1).

Fig.9.1C1

Fig.9.1C2

Position MaxX

indicated in paragraph 5.1.

The poles of the MaxX

with the load to be handled.

Make sure that the poles of the

centered on the load with g

anchoring of a round or a pipe.

Now proceed with the following steps:

are perfectly

a) Activate MaxX

position.

Fig.9.1A

the load to come

Fig.9.1C4

d)

the load and the

Fig.9.1D

IN service

OUT

service

-LEVE

.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

Operating procedure

Demagnetize with the load perfectly on the

ground or on a support suitable for supporting the

Manually move the mechanical lever stop device

until the lever is released during movement.

Holding with one hand the lever stop device in

the lever, with the other hand, and make it rotate

until it accompanies it to the end stop in DEMAG

with the same procedure described in

CHECKS and

MAINTENANCE

Adequate checks and maintenance are key factors in

will last longer under optimum

operating and performance conditions and that it is

Standards

Work equipment must be subject to periodic

inspections at frequencies determined on the basis of the

information supplied by the manufacturers, or the

standards of good practice, or in the absence thereof,

which can be inferred from the codes of good practice.

For this purpose, the types of contro

UNI ISO 9927

see paragraph 10.3

FREQUENT CONTROL:

PERIODIC CONTROL

Met

Below are the descriptions of

examination conducted with the

aim of identifying any anomalies or deviations

from normal conditions by means of visual checks.

Generally, the visual inspection is conducted

ssembling the equipment, unless there

are particular needs that may arise.

NON DESTRUCTIVE CHECK:

examinations such as penetrating liquids,

ultrasounds, magnetic particles, X

be necessary after the visual examination

TEST

controls, levers, indicator screws, etc. Functional

tests are those that allow to obtain a value or a

OPERATIONAL TEST

without load and/or tests for the functioning of the

s (with greater attention to the limiting

devices and indicators).

DEMAG

19

9.2

-

Demagnetisation

weights of both the load and the MaxX.

a)

b)

position as described in phase a)

position.

Fig.9.2A

Fig.9.2B

proceed holding

10

ensuring that the MaxX

functionally safe over time.

10.1Controls –

technical standards

1:2014 are reported:

DAILY CONTROL:

10.2 Checks -

ls derived from the

-1:2016 and ISO 12482-

see paragraph 10.4

: see paragraph 10.5

hod

c) Move MaxX

paragraph 7.1 in step a).

Fig.9.2C

to the inspection methods:

VISUAL CHECK:

FUNCTIONAL

the control methods, related

without disa

reference is made to

-rays, which may

: concern tests carried out on

measure.

: include tests with and

device

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

20

Resistance class 8.8

Resistance class 12.9

P [N]

M [Nm]

P [N]

M [Nm]

10.3 Daily check

Daily check carried out by the operator and the person in

charge of the handling of the system in which the MaxX is

installed/hanged up, to be carried out before starting the

operations of Normal Use of the MaxX. Refer to chapter 9

of this Manual for further information.

10.4 Frequent check

Control conducted on the basis of the working

environment, frequency and severity of use of the MaxX,

within time intervals not exceeding 3 months (unless there

are periods of inactivity).

TECNOMAGNETE suggests weekly, monthly and quarterly

checks according to the MaxX component.

10.5 Periodical check

Control conducted on the basis of the working

environment, frequency and severity of use of the MaxX,

within time intervals not exceeding 12 months (unless

there are periods of inactivity).

10.6 Maintenace - Warnings

MAINTENANCE OPERATIONS MUST BE CARRIED OUT

ONLY AND EXCLUSIVELY BY PERSONNEL TRAINED IN

ACCORDANCE WITH THE REGULATIONS

The main warnings to be taken during maintenance

operations are:

all maintenance must be carried out when the system is

stationary and with MaxX not connected to the crane,

etc.

repairs must be carried out by qualified personnel who

must scrupulously comply with the accident prevention

regulations in force in the country of destination

Always use the Personal Protective Equipment (PPE)

described in paragraph 1.8.

do not wear rings, watches, chains, bracelets, fluttering

clothes, etc. during maintenance operations

comply with the maintenance deadlines indicated

Replacements of components must only be made with

original spare parts to guarantee perfect operation

during cleaning operations, be careful not to use

grinding wheels, abrasive, corrosive or solvent materials

that could remove and/or make illegible numbers,

acronyms or information inscriptions located on MaxX.

10.7 Daily Maintenace

Maintenance to be performed at the end of the daily work

activity. Depending on the method, it can be carried out by

the operator or by the handler.

For the Operational Test of the MaxX lever, it must be

placed on an iron plate resting on the ground or on a

support suitable for supporting the weights of both the

plate and the MaxX. The iron plate must have a minimum

thickness as indicated in sub-paragraph 3.2.4 (Fig.3.2.4A

and Fig.3.2.4B).

10.8 Frequent maintenance

Maintenance to be performed at the end of the work

activity within intervals of time not exceeding 3 months

(unless periods of inactivity).

The maintenance that requires a monthly frequency is

deducted from the consideration of a work activity usually

carried out on a shift of 8÷10 hours per day.

10.9 Periodical maintenance

Maintenance to be performed at the end of the work

activity within intervals of time not exceeding 12 months

(unless there are periods of inactivity).Annualmente per il

MaxX is mandatory to perform a functional and

operational test using a suitable dynamometric equipment

(this test is defined as a tear-off test).

TECNOMAGNETE is able to provide you with adequate

technical assistance to carry out the tear-off test.

10.10

The table Fig.10.10 gives the values for the axial preload P

and the corresponding values for the tightening moments

M to be applied to the screws. The table applies to

hexagonal head screws type UNI 5737-65 and cylindrical

head screws with hexagonal socket type UNI 5931-67.

The chosen friction coefficient is 0.14 valid for machined

surfaces blackened or oiled. The tightening torque must be

applied slowly with torque wrenches.

Fig.10.10

Thread

M 6x1 9000 10,4 15200 17,5

M 8x1,25 16400 24,6 27700 41,6

M 10x1,5 26000 50,1 43900 84,6

M 12x1,75 37800 84,8 63700 143

M 14x2 51500 135 86900 228

M 16x2 70300 205 119000 346

Tightening of screws

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

21

CHECKS and MAINTENANCE tabel

DAILY

FREQUENT

PERIODICAL

10.11 Summary table

Maintenance/Checks

Fig.10.11

Component

subject to

control

Labels

Pin lever

(for lever lock)

Lever

Body and

lever

Body and

lever

Eyebolt /

Load ring

Poles

Complete

MaxX

verify that the value M indicated in the table Fig.5.2B paragraph 5.2 concerning the eyebolt / load ring does not decrease by

(❋)

more than 10% (the eyebolt and the load ring are subject to wear / dent / consumption)

Legend of competences as per paragraph 1.7 TRAINED PERSONNEL

OPERATOR HANDLER

skill

method objective

Visual check

Operational

test

Operational

test

Visual check

Visual check

Checking integrity and

legibility

Check for slip and spring

return.

Keep the operating area

of the lever lock pin

clean.

Check the smoothness

of the lever rotation

(subject to the

conditions described in

chapter 9). Keep the

lever operating area

clean

Verification of the

absence of deformation

Verification of the

absence of deformation

MECHANICAL MAINTENANCE TECHNICIAN SPECIALIZED TECHNICIAN

skill

method objective skill

Checking of the sliding

and the spring return.

Carefully clean the

operating area of the

lever lock pin.

Monthly

Operational

test

Checking of the sliding

Monthly

Operational

test

and the spring return.

Carefully clean the

operating area of the

lever lock pin

Weekly

Visual

inspection

Weekly

Visual

inspection

Quarterly

Visual

inspection

Quarterly

Visual

inspection

wear and the absence of

roughness, roughness in

Checking the state of

oxidation

Verification of the

absence of oxidation (if

necessary, lubricate

with suitable product

and dose)

Check that there are no

dimensional

deformations beyond

10% of the values

indicated in the table

Fig.5.2B of paragraph

5.2.

See note below (❋).

If necessary, contact

TECNOMAGNETE

Check that there are no

deformations, dents,

a value >10%. If

necessary, contact

TECNOMAGNETE

Monthly

Operational

test

Check the tightening of

all screws in according

to Fig.10.10 of

paragraph 10.10

method objective

Within 6

months

Visual

inspection

Within 6

months

Visual

inspection +

Operational

test

Within 6

months

Visual

inspection +

Operational

test

Annual

Visual

inspection

Annual

Functional

test and/or

operational

test

Checking the presence of

the labels and their

legibility. Clean or, if

TECNOMAGNETE to

replace it with equivalent

Check for the presence of

dust and dirt that could

obstruct the fluid

movement of the locking

pin. Clean with care or ask

TECNOMAGNETE for an

adequate technical

Check for the presence of

dust and dirt that inhibit

the smooth rotation of the

lever (subject to the

conditions described in

chapter 9). Clean carefully

or ask TECNOMAGNETE for

adequate technical

assistance if necessary.

If the method proves to be

TECNOMAGNETE for

adequate technical

Where possible, carry out a

tear-off test with a

dynamometric machine to

measure the magnetic

clamping force. If possible,

contact TECNOMAGNETE

to request adequate

technical assistance with a

suitable measuring

necessary, ask

labels.

intervention.

inefficient, ask

assistance.

instrument.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

22

11 PROBLEMS AND

RELATED SOLUTION

The operating personnel in charge of maintenance/repair

must scrupulously comply with the accident prevention

regulations in force in the country of destination of the

system.

11.1 Problems

The operating problems and their solutions for the MaxX

are described in detail in chapters 9 and 10.

DECOMMISSIONING

12

AND DISPOSAL

12.1

If you decide not to use MaxX anymore, it is recommended

to make it inoperative by removing it from the

crane/trailer on which it is hooked.

12.2

Decommissioning

Disposal

13 SPARE PARTS

We suggest to contact the TECNOMAGNETE Service

Network to request spare parts according to the MaxX

model.

13.1

The following figures list the spare parts for the MaxX.

Fig.13.1A

5

11

5

Fig.13.1B

Spare parts

1A

1

9 10

1B

1

109

11

8

Description

1

1A

8

7

8

1

1B

7 6

2

3 4

Made in IT ALY

TEC NOMA GNETE S pA

Via Nerv iano , 31

20020 - Lainate (Mi)

9

3

4

5

9 88

5

6

11

11

8

The user, according to the EU Directives or the laws in

force in his country, must take care of the demolition,

disposal and disposal of the various materials that make up

MaxX.

In the case of demolition of MaxX, safety precautions must

be taken to avoid risks associated with the dismantling of

industrial machinery, paying particular attention:

disassembly from the installation area

transport and handling

dismantling

separation of different materials

To carry out demolition and disposal it is necessary to

observe some basic rules to safeguard the health and the

environment in wich we live, paying particular attention to

the operations of separation, recycling or disposal of

materials, always reffering in any case to the National or

Regional Laws in force on the disposal of solid industrial

waste and toxic and harmful waste.

Plastic or non-metallic sheaths and elements in general

must be disassembled and disposed of separately.

1A_Load ring / 1B_Eyebolt

Screw UNI 5931 – 8.8

Pin lever (for lever lock)

Helical spring

(handle)

Lever

Cover

Cover

Screw UNI 5931 – 8.8

Left plate

Right plate

Grain screw UNI 5927 – 8.8

(handle side)

(opposite side of the handle)

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

23

14 WARRANTY AND

SERVICE

14.1

The MaxX are guaranteed for a period of 24 months from

the date of invoice, unless otherwise agreed in writing with

TECNOMAGNETE. The warranty covers all defects in

materials and workmanship and provides for the

replacement of spare parts or repairs of defective parts

exclusively by care and / or at the TECNOMAGNETE.

The MaxX for repair must be sent by the customer in FREE

PORT (freight prepaid).

Once the repair has been completed, it will be returned to

the customer in a FREIGHT COLLECT .

The warranty does not provide for the intervention of

workers or TECNOMAGNTE employees at the installation

site, nor for the dismantling of the MaxX from the plant.

In the event that for practical reasons TECNOMAGNETE

sends an employee, the labor will be invoiced at current

prices plus any travel expenses and travel.

In no case does the warranty entitle you to compensation

for any direct or indirect damage caused to property or

persons or for repairs carried out by the buyer or by third

parties. Repairs carried out under warranty do not change

the warranty period. They are excluded from the warranty:

damage resulting from normal wear and tear resulting

failures caused by incorrect use or assembly

damage caused by the use of spare parts other than

damage caused by fouling.

WARRANTY CONDITIONS

from use

those recommended

14.2

The product warranty is void in the following cases:

default or other breach of contract if, without the

when the serial number has been tampered with or

when the damage is caused by:

if it is disassembled, tampered with or repaired

if it is used in hazardous areas where adequate safety

For any dispute, the competent court is the one in Milan.

For any problem or information please contact the

Technical Assistance Service at the following address:

WARRANTY EXPIRATION

consent of TECNOMAGNETE, any changes are made

deleted

- improper operation or use

- incorrect treatment

- impacts and other causes not attributable to the

normal conditions of operation and/or use

without authorisation from TECNOMAGNETE S.p.A.

systems have not been installed, characterized by

fixed and mobile protections with additional

interconnected signalling devices.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

15 Tecnomagnete

service network

HEADQUARTERS

TECNOMAGNETE SpA

Via Nerviano, 31

20020 Lainate - Italy

Tel. +39 02937591

Fax +39 0293759212

info@tecnomagnete.it

Company with certified quality system

FRANCIA – BENELUX - SVIZZERA FRANCESE

TECNOMAGNETE SARL

52 Av. S. Exupéry

01200 Bellegarde Sur Valserine

Tel. +33.450.560.600 (FRANCIA)

Fax +33.450.560.610

contact@tecnomagnete.com

GERMANIA - AUSTRIA -SVIZZERA TEDESCA

TECNOMAGNETE GmbH

4 Ohmstraße

63225 Langen (GERMANIA)

Tel. +49 6103 750730

Fax +49 6103 7507311

kontakt@tecnomagnete.com

U.S.A. - CANADA - MESSICO

TECNOMAGNETE Inc.

6655 Allar Drive, Sterling Hts, MI 48312

Tel.: +1 586 276 6001

Fax: +1 586 276 6003

infousa@tecnomagnete.com

CINA

TECNOMAGNETE Shanghai Liason Office

Tel. +86 21 6888 2110

info@tecnomagnete.com.cn

24

Information on authorized Technical Assistance Service

can be found by connecting to the site:

www.tecnomagnete.com

and accessing the menu CONTACTS / Sales networks and

locations.

16 ANNEXES

Attachments are generally understood to mean certificates,

technical drawings, spare parts lists, etc. If added to this

User and Maintenance Manual for completeness of

information.

16.1

A copy of the EC declaration of conformity and the TÜV

certificate relating to the technical file and the user manual

are attached below.

It is also possible to download the EC declaration of

conformity in pdf format by visiting the website:

www.tecnomagnete.com/engcecertificate.htm

Declaration of conformity

All MaxX products comply with the Machinery

Directive 2006/42/EC.

In addition, the following technical standards have

been applied during the design and construction of

the products: UNI EN 13155:2009;

UNI EN 13001-3-1:2018;

UNI EN ISO 12100:2010.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

25

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

26

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

Loading...

Loading...