TECNOMAGNETE MaxX 125, MaxX 300E, MaxX 250, MaxX Series, MaxX 1500 Use And Maintenance Manual

...

PERMANENT – ELECTRO MAGNETIC SYSTEMS

USSEE

U

LLiigghhtt DDuuttyy LLiiffttiinngg DDiivviissiioonn

hhaanndd ccoonnttrroolllleedd lliifftteerrss -- M

Lainate (MI) - Italy

Edition: May 2019

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

according to LEGISLATION 2006/42/EC concerning machinery

A

A

N

N

D

D

M

M

M

M

A

A

AII

A

N

N

NTTEE

N

U

ALL

U

A

N

N

A

N

N

CEE

C

A

MaaxxXX

code 09MAXX001

version EN

revisione 01

2

CONTENTS

1 GENERAL NOTES ..................................................................................................................................................... 4

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10 E

1.11 U

1.12 N

2 TRANSPORT AND HANDLING.................................................................................................................................. 7

2.1

2.2

2.3

2.4

P

RESENTATION

IMPORTANCE OF THE MANUAL .................................................................................................................. 4

ETENTION OF THE MANUAL

R

ONVENTIONS

C

D

EFINITION OF SYMBOLS

ERSONNEL ASSIGNED TO OPERATIONS

P

RAINED PERSONNEL

T

ERSONAL PROTECTIVE EQUIPMENT

P

ENERAL SAFETY WARNINGS

G

MERGENCY DRILL

NINTENDED OR IMPROPER USE

AMEPLATE DATA

R

ECEIPT

ANDLING

H

RANSPORT

T

NACTIVITY

I

...................................................................................................................................... 4

.................................................................................................................... 4

....................................................................................................................................... 4

......................................................................................................................... 5

....................................................................................................... 5

.............................................................................................................................. 5

(PPE) ................................................................................................. 6

.................................................................................................................... 6

.................................................................................................................................. 6

............................................................................................................... 6

.................................................................................................................................. 7

............................................................................................................................................... 7

............................................................................................................................................ 7

.......................................................................................................................................... 8

............................................................................................................................................ 8

3 DESCRITPION OF THE SYSTEM ................................................................................................................................ 8

3.1 A

3.2

3.2.1. A

3.2.2 C

3.2.3 T

3.2.4 M

3.3

4 MODELS AVAILABLE ............................................................................................................................................. 11

4.1

5 TECHNICAL CHARACTERISTICS .............................................................................................................................. 12

5.1

5.2

6 GENERAL DESCRIPTION OF THE SUPPLY ............................................................................................................... 14

6.1

7 INSTALLATION ...................................................................................................................................................... 14

7.1

8.1 RISKS RELATED TO MAXX LIFTERS ............................................................................................................ 16

8.2 P

8.3 E

8.4 A

DVANTAGES

ASIC PRINCIPLES OF MAGNETIC CLAMPING WITH MAX

B

IR GAP AND ROUGHNESS

ONTACT SURFACE

YPE OF MATERIAL

ATERIAL THICKNESS

AGNETIC FORCE

M

MAXX ........................................................................................... E

MAXX TECHNICAL CHARACTERISTICS .............................................................................................. 12

MAXX

MAXX

G

ENERIC INSTALLATION

ERSONAL PROTECTIVE EQUIPMENT

XPOSURE TO MAGNETIC FIELD

CTION LEVELS

........................................................................................................................................ 8

X ............................................................................... 9

..................................................................................................................... 10

............................................................................................................................... 10

............................................................................................................................... 10

........................................................................................................................... 10

................................................................................................................................ 11

RRORE. IL SEGNALIBRO NON È DEFINITO

DIMENSIONS AND WEIGHTS

DESCRIPTION OF THE SUPPLY

......................................................................................................................... 14

(LA)

OF THE STATIC MAGNETIC FIELD

.......................................................................................................... 13

........................................................................................................ 14

......................................................................................................... 16

............................................................................................................... 16

.................................................................................. 17

.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

3

THE FOLLOWING IS THE BASIC OPERATING PROCEDURE FOR USING THE MAXX .......................................................... 18

9.1

9.2

10 CHECKS AND MAINTENANCE ................................................................................................................................ 19

10.1 C

10.2 C

10.3 D

10.4 F

10.5 P

10.6 M

10.7 D

10.8 F

10.9 P

10.10 S

11 PROBLEMS AND RELATED SOLUTION ................................................................................................................... 22

11.1 P

12.1 D

12.2 D

O

PERATING PROCEDURE - MAGNETIZING AND HANDLING

O

PERATING PROCEDURE - DEMAGNETISATION

ONTROLS – STANDARDS

HECKS - METHOD

AILY CHECK

REQUENT CHECK

ERIODICAL CHECK

AINTENACE - WARNINGS

AILY MAINTENACE

REQUENT MAINTENANCE

ERIODICAL MAINTENANCE

UMMARY TABLE MAINTENANCE/CHECKS

ROBLEMS

ECOMMISSIONING

ISPOSAL

....................................................................................................................................... 20

......................................................................................................................................... 22

........................................................................................................................................... 22

...................................................................................................................... 19

............................................................................................................................... 19

................................................................................................................................ 20

............................................................................................................................... 20

.................................................................................................................... 20

............................................................................................................................. 20

..................................................................................................................... 20

.................................................................................................................... 20

............................................................................................................................. 22

............................................................................ 18

........................................................................................... 19

................................................................................................ 21

13 SPARE PARTS ........................................................................................................................................................ 22

13.1 S

14 WARRANTY AND SERVICE .................................................................................................................................... 23

14.1 WARRANTY CONDITIONS ................................................................................................................ 23

14.2 WARRANTY EXPIRATION ................................................................................................................. 23

15 TECNOMAGNETE SERVICE NETWORK ................................................................................................................... 24

16 ANNEXES .............................................................................................................................................................. 24

16.1 D

PARE PARTS

ECLARATION OF CONFORMITY

....................................................................................................................................... 22

.............................................................................................................. 24

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

1 GENERAL NOTES

Congratulations on choosing a TECNOMAGNETE product.

This publication will help you find out more about your new

product and we recommend that you carefully read these

pages and always follow the instructions. The descriptions

and illustrations contained in this publication are not

difficult, given the basic features of the product described.

TECNOMAGNETE reserves the right to make changes at any

time to components and accessories in order to improve

the product or due to manufacturing or commercial

requirements. Updates of this manual will be provided as

required as Annexes or on the website

ww.tecnomagnete.com

of this manual and its reproduction, even partial, is

prohibited, as is disclosure to third parties, without its

written permission. In the event of changes and/or updates

to the product, which will be agreed exclusively with

TECNOMAGNETE, additional content concerning the use

and any residual risks arising from the changes shall be

provided to supplement the manual.

1.1

Presentation

TECNOMAGNETE was founded in 1974 and has attained a

position of leadership position in world markets as a

manufacturer of powerful, flexible permanent-electro

magnetic systems that operate in total safety, due to its

innovative technology and numerous patents filed over the

years. Permanent-electro magnetic systems produced by

TECNOMAGNETE are able to generate sufficient magnetic

force both for clamping and lifting workpieces, only

consuming electricity when turned on and off.

The main fields of operation include:

MACHINE TOOLS CLAMPING SECTOR

Grinding series

Milling series

Turning series

Rail machining series

MOULDING SECTOR

Systems for clamping press molds

LIGHT LIFTING SECTOR

Manually-controlled lifters

Battery-powered lifters

HEAVY LIFTING SECTOR

Magnetic lifters

Fixed beam magnetic module beam

. TECNOMAGNETE retains ownership

4

Telescopic beam magnetic module beam

Importance of the manual

1.2

A copy of this manual must be distributed and kept

available to operators assigned to the installation,

operation and maintenance of MaxX, enabling them to

operate in accableance with the instructions given in this

document. A careful reading of the manual will enable

MaxX to be used in the correct way and safeguard the

security and safety and operators and others. This manual

is an integral part of the MaxX, and all reproduction and

dissemination rights of the manual and its attachments are

reserved. Pass this manual on to any other user or

subsequent owner.

1.3

Retention of the manual

Making changes to and removing parts of this manual are

prohibited. When using the manual, take care not to

damage it. Keep the CD-R or USB key away from impact,

heat and magnetic sources and make it easily accessible to

operators for further reference.

Conventions

1.4

For ease of consultation, the manual is divided into the

following hierarchical order so that each phase is described

in detail:

1. Chapter 1 of the manual

1.1. section 1 of Chapter 1 of the manual

1.1.1. sub-section 1 of section 1 of Chapter 1 of the

manual

Some sections and/or chapters are presented with

numbered sequences in order to illustrate the operation

step by step.

Symbols are given in sections requiring greater attention.

Units of measurement, including the decimal point, are

displayed with the international system (SI).

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

5

Definition of symbols

1.5

All parts concerning safety are highlighted in bold.

All warning notes that alert the personnel concerned that

the described operation involves exposure to residual risk,

with possible damage to health or injury, if not carried out

in compliance with the instructions, are shown in bold and

identified with the following symbol :

All warning notes that indicate that the described

operation must be performed by trained and qualified

personnel are shown in bold and indicated with the

following symbol:

In turn, the trained / specialized personnel, depending on

the specific tasks, can be indicated by the following

symbols: (see details in paragraph 1.7)

Personnel assigned to

1.6

operations

As indicated in this manual, certain procedures must be

carried out only by qualified or trained personnel.

The level of qualification is described using standard terms:

1. qualified personnel have technical knowledge and/or

sufficient experience to enable them to avoid thepotential

dangers from electricity and/or mechanical movements

(operation and maintenance personnel) trained personnel

are appropriately advised and/or supervised by qualified

persons to enable them to avoid the potential dangers from

electricity and/or mechanical movements (operation and

maintenance personnel)

2. the User is obliged to obtain confirmation of

the following from all designated persons, before they are

allowed to work to work with MaxX the personnel have

received the instruction

2.1. the personnel have received the instruction manual, and

have read and understood it

2.2. the personnel shall work in the manner described..

Trained personnel

1.7

The qualifications are given below of the personnel

allowed to use the MaxX:

OPERATOR: a person or persons who,

following appropriate and indispensable training, is/are

assignedand authorized by the owner of the MaxX to run

operations. The occupier of this post must be completely

aware of and understand the contents of this manual

HANDLER: this post requires specific skill

(possibly acquired by attending mandatory courses, if

required by law, in hoists the methods and features of

harnesses handling and safe handling procedures. This

position also requires complete awareness and

understanding of the contents of this manual, in particular

paragraph 2.2

MECHANICAL MAINTENANCE OPERATOR:

this post requires specific skills in the installation, adjustment,

maintenance, cleaning and/or repair of systems. The occupier of

this post must be completely aware of and understand the

contents of this manual.

requires specific skills in carrying out installation, adjustments,

maintenance cleaning and/or repair. For his preparation and

experience he has skills and knowledge in the lifting sector as

well as a sufficient familiarity with the main regulations in order

to be able to determine any deviations from the expected

conditions.

The occupier of this post must be completely aware of and

understand the contents of this manual.

SPECIALIZED TECHNICIAN:

this post

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

6

1.8

Personal protective

equipment (PPE)

The staff referred to in the previous paragraph must wear an

adequate safety distance from the parts clamped on the

magnetic equipment, with special attention when in vertical or

suspended (this distance must be suggested by the plant

operator in accordance with the regulations). The staff must

also wear appropriate safety clothing. Protective footwear is

mandatory, while the need for

headsets, helmets and goggles must be assessed by the

User. Loose fitting clothes or articles that could be trapped by

moving parts are prohibited.

(see chapter 8)

General safety warnings

1.9

The rules and recommendations below are in compliance

with the current safety regulations, on which they are

based. TECNOMAGNETE S.p.A. declines all responsibility for any

damage caused to persons or things deriving from failure to

observe the safety regulations in force and the instructions given

below.

Machine safety systems must be selected and installed on

the basis of the following requirements:

be under the technical responsibility of qualified

personnel

be integrated with technical compliance and with

appropriate control systems

installations must be made in such a way that they can

not be neutralized or tampered with

All designated operators must respect and implement the

following and scrupulously adhere to the regulations on

accident prevention in force in the country of installation and

on the use of the MaxX. All ordinary and extraordinary

maintenance must be performed with stationary system and

with structure not hooked to the crane etc.

To avoid the danger of accidental connections during

maintenance operations, attach a warning sign on the control

panel with the words:

MAINTENANCE IS UNDERWAY

All operations of transport, installation, use, ordinary and

extraordinary maintenance on the MaxX must only be carried

out by the personnel identified in section 6 of chapter 1.

The permanent-electro magnetic system can only be used for

the applications indicated in the manual and only in

combination with devices and components recommended and

authorized by TECNOMAGNETE S.p.A.

1.10

In an emergency, it is recommended to follow the procedures

given in the operation and maintenance manual of the machine

on which the MaxX is installed. In the event of fire, use the

devices provided to extinguish the fire, taking care never to use

water on electrical parts (considering however that MaxX is not

made up of electrical parts).

1.11 Unintended or improper use

Emergency drill

MaxX is not designed or constructed for operation in explosive

atmospheres.

Unintended use may:

cause injury to personnel

damage the system or other equipment

diminish reliability and performance.

MaxX cannot be used for purposes other than those

recommended and in compliance with the intended use,

avoiding the following in particular:

unsuitable parameters of use

defective or lack of maintenance

use of inappropriate materials

failure to follow instructions

uncertain or insecure clamping of MaxX system or parts

thereof

In the events of doubts over the appropriate usage,

contact TECNOMAGNETE S.p.A. to determine whether it is use

for which the system was intended or otherwise.

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

7

1.12

Two plates are applied on the MaxX:

1) Logo and data referring to the identification of the

2) Load / force curves, data referring to the performances and

3) The plates are indelible and must not be removed for any

Example of a nameplate on MaxX500:

Fig.1.12A

Nameplate data

manufacturer, serial number, production date, weight of the

MaxX, symbology in compliance with the laws in force

(example Fig.1.12A).

dimensions and types of load to be magnetically anchored

(example Fig.1.12B).

reason even should the MaxX be sold. In the event the plate

has been damaged or lost after coming away from its

housing, contact TECNOMAGNETE S.p.A. to obtain a

replacement. When communicating with TECNOMAGNETE

S.p.A., always quote the model on the plate. Failure to

comply with these provisions exempts

TECNOMAGNETE S.p.A. from any liability for damage or

injury to persons or property that may arise, which shall

remain the sole responsibility of the user with regard to the

competent bodies.

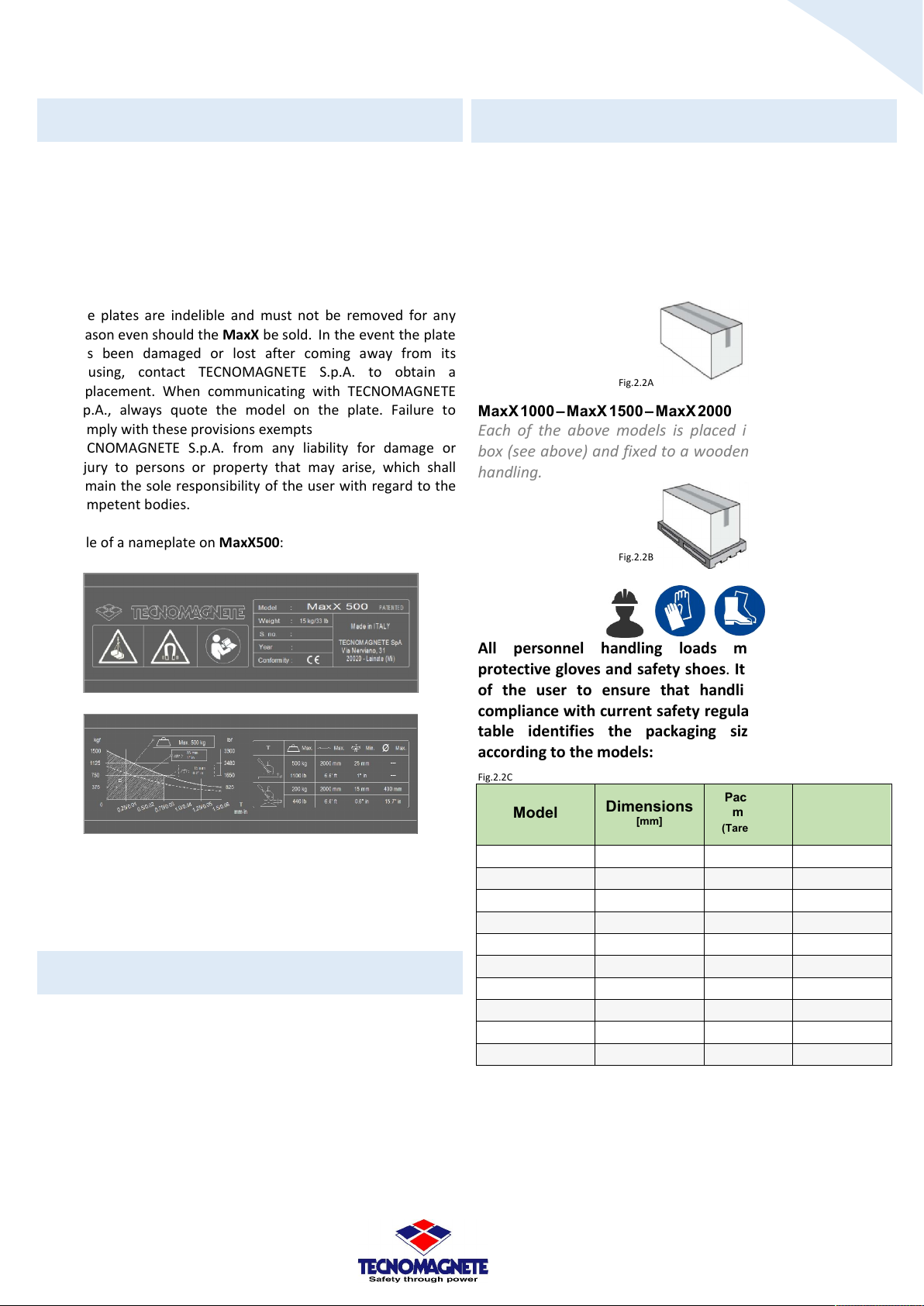

2.2

MaxX 125 – MaxX 250 – MaxX 300E – MaxX 500 – MaxX 600E

MaxX TG 150 – MaxX TG 300

Handling

Each of the above models is placed inside cardboard boxes,

protected by a sheet and wrapped in a layer of

polyurethane foam that guarantees the absolute

mechanical integrity in case of shocks or incidents of the

packaging.

Fig.2.2A

MaxX 1000 – MaxX 1500 – MaxX 2000

Each of the above models is placed inside the cardboard

box (see above) and fixed to a wooden pallet to allow easy

handling.

Fig.2.2B

Fig.1.12B

2 TRANSPORT AND

HANDLING

2.1

Receipt

MaxX are thoroughly checked before shipment. On receipt, the

integrity of the package and the material contained therein must

be checked (unless other instructions are issued by

TECNOMAGNETE S.p.A.), in order to confirm that no damage

occurred during transport and that the consignment complies

with the order specifications. Otherwise, report any irregularities

to TECNOMAGNETE S.p.A. and the Carrier responsible for any

damage during transport.

Notification of damage or defects must be given within ten days

from receipt of the supply. After that period, TECNOMAGNETE

S.p.A. will consider the provision free of defects.

All personnel handling loads must operate with

protective gloves and safety shoes. It is the responsibility

of the user to ensure that handling is conducted in

compliance with current safety regulations. The following

table identifies the packaging size and its weight

according to the models:

Fig.2.2C

Model

MaxX 125

MaxX 250

MaxX 300E

MaxX 500

MaxX 600E

MaxX 1000

MaxX 1500

MaxX 2000

MaxX TG150

MaxX TG300

Dimensions

[mm]

130x130x200 0.3 4

195x145x200 0.5 7

195x145x200 0.5 7

255x190x245 1 16

255x190x245 1 16

350x230x250 3.5 36

400x300x300 5 66

460x300x300 6 82

195x145x200 0.5 7

255x190x245 1 16

Packing

mass

(Tare) [kg]

Complete

packing

(Gross) [kg]

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

8

Inactivity

2.4

When hoisting or handling MaxX, clear the operations

area of obstructions and keep it clear, also consider

providing a sufficient safety zone to prevent harm to

persons, animals or objects that might be in maneuvering

range. MaxX are designed to be hoisted and handled

with suitable hoisting devices, the type and scope of

which must be selected in accableance with the weight.

(see table Fig.2.2C). It must be handled with extreme

care, avoiding impacts that could damage delicate parts,

compromising normal operation When moved with

forklift trucks, comply with the permitted speed and

inclination. Never leave load suspended on hoists. (also

refer to paragraph 1.8).

The permanent-electro magnetic system must be

disconnected from power sources and its moving parts

appropriately locked during transport, handling and

storage.

The instructions on the package must be read and

digested before opening.

Keep the original packaging for later handling.

2.3

Transport

Some parts may have to be dismantled for transport, to be

reassembled and reconnected during installation by

TECNOMAGNETE S.p.A. technicians, or by the User on

TECNOMAGNETE S.p.A.’s recommendations. The system must be

transported in observance of the following environmental limits:

a temperature range of -5 °C to +55 °C, rising to a maximum of

+70 °C for a period no longer than 24 hours. Should it be

necessary to transport the MaxX by sea or by air, suitable

packaging and protection systems must be provided to avoid

any damage caused by impact. To protect against weathering,

use anti-rust lubricants and bags of hygroscopic salts inside the

packages. All moving parts must be properly anchored and

removed from their housing, where possible.

In the event of long-term storage or inactivity, the MaxX must be

thoroughly cleaned of any residues and its uncovered metallic

parts must be protected with oil or grease in order to avoid

oxidation. It is recommended to cover the MaxX with a tarpaulin

and keep them in a dry, sheltered place The room temperature

should be between -5 ° C (23 ° F) and + 55 ° C (131 ° F). The

relative non-ondensing humidity should be between 30% and

90%, The atmosphere should be clean, free of acids, corrosive

gases, salts, etc. If restoring to operation, follow the instructions

contained in this manual.

3 DESCRITPION OF THE

SYSTEM

Advantages

3.1

MaxX consists of a very small number of details. Rotor and

stator, in steel with high magnetic permeability, are obtained by

machining from solid, using CNC machines; this grants uniformity

and robleness of the product and the quality control necessary

for a magnetic hoist built in large series.

The material used (steel, aluminum, plastic) is easily disposable

and recyclable when the tool is dismantled.

The magnetic material used, with a high specific energy, made it

possible to reduce to the maximum weight and volume.

To allow a high uniformity of performance, given the large series,

the MaxX lifter is magnetized in a single stroke after assembly,

using the largest magnetizer built in Europe.

MaxX is able to handle the load, which is always anchored and

lifted from above, without any deformation or damage with an

optimal use of the available work areas.

Some of the most recognized areas with the use of MaxX are the

following:

- servicing of machine tools

- wholesalers of ferrous material

- cutting plants

- carpentry

- shipyards

- foundries

- steel industries

- mold handling

Use and Maintenance Manual

MaxX

codice 09MAXX001

versione EN

revisione 01

Loading...

Loading...