Page 1

INSTRUCTION MANUAL

OUR SYSTEMS COMPLY WITH DIRECTIVES 73/23 EEC - 89/336 EEC

ISO 9001

Cert. N° 0412/2

Cod. 71503560/0 - 12/2003

PRESERVATION CABINETS

TECNOCONTROL

TC 60-N

-10 / -22 °C

TC 60-P

+8 / -2 °C

TC 60-C

+15 / +2 °C

HR 40% / 90%

Page 2

CONTENTS

1. GENERAL DOCUMENTATION

1.1 General information page 4

1.2 Installation page 4

1.3 Transport and handling page 4

1.4 Unpacking - disposal of packing page 4

1.5 General safety regulations page 5

2. INSTALLATION

2.1 Dataplate information page 5

2.2 Positioning page 5

2.3 Ambient temperature and air circulation page 6

2.4 Electrical connections page 6

2.5 Connection of refrigerator - remote units page 6

2.6 Condensate drainage connection page 6

2.7 Notes for the installer page 6

2.8 Safety and control systems page 7

2.9 Appliance disposal page 7

3. TECHNICAL CHARACTERISTICS page 8

4. PROGRAMMING INSTRUCTIONS

4.1 Starting up the appliance page 9

4.2 Language setting page 9

4.3 Date and time setting page 10

4.4 Set-point setting and display page 10

4.5 Cell loading function page 10

4.6 Continuous cooling function page 10

4.7 Door microswitch function page 10

2

GB

Page 3

5. DEFROST MANAGEMENT

5.1 Manual defrost page 11

5.2 Periodic defrosting page 11

5.3 Timed defrosting page 11

6. MANAGING AND SILENCING DETECTED ALARMS

6.1 Storing alarms page 12

6.2 Silencing alarms page 12

6.3 Alarms list page 12

6.4 Serious alarms list page 13

6.5 List of other operating faults not indicated page 14

7. MAINTENANCE AND CLEANING

7.1 Basic safety regulations page 15

7.2 Cleaning the condenser page 15

7.3 Cell cleaning page 16

7.4 Defrost water drainage page 16

3

GB

Page 4

4

GB

1. GENERAL DOCUMENTATION

1.1. General information

• This manual is an integral part of the product and provides all the information

necessary for ensuring correct appliance installation, operation and maintenance.

• Read the manual carefully, and always

consult it for appliance operation. Keep

the manual in a well-known place accessible to all authorised operators (installers, users and maintenance personnel)

The appliance complies with Directives

73/23/EEC (low-voltage), 89/336/EEC

(electromagnetic compatibility) and

machines 98/37/EC (for some models

only).

• The appliance is designed for professional use and therefore must only be operated by qualified personnel.

• The appliance must only be used for its

designed purpose, i.e. for preserving

food products.

The appliance must not be used for products requiring constant temperature

control and recording, such as

- heat-sensitive chemicals,

- medicines

- blood derivatives.

• The manufacturer declines all responsibility for any damage caused by incorrect

or unreasonable use, such as:

• improper use by untrained persons

• technical modifications or operations

that are not specific to the models

• use of non-original or non-specific

spare parts

• failure to follow the instructions given

in this manual

1.2 Installation

The appliance must only be installed by

specialised personnel authorised by

Tecnomac, according to the instructions

given in this manual.

If the appliance is fitted with a remote condenser unit, the installer is responsible for

checking all connections in compliance

with the instructions given by Castelmac

for plant and appliance installation.

1.3 Transport and handling

• Loading or unloading the appliance

and/or subsystems from/onto the means

of transport can be done with a lift truck

or fork lift equipped with forks at least

half the length of the cabinet; or a crane

if the appliance is fitted with eyebolts.

Choose lifting equipment suitable for the

weight and overall dimensions of the

packed appliance/components.

• When handling the appliance/subsystems, take all necessary precautions to

prevent damage, complying with the

indications given on the packing (fig. 1)

1.4 Unpacking

• Remove all packing in cardboard, wood

or boxes from the wood base on which

they are placed. Lift the

appliance/subassemblies with suitable

means (e.g. lift truck), remove the wood

base, then position the appliance/subassemblies in the required place.

• After removing the packing, check the

integrity of the appliance.

• Remove the protective PVC film on the

panels, from all internal and external

Page 5

2.1 Data plate information

• Check that the data specified on the

plate correspond to the characteristics of

the power supply (V,

kW, Hz, no. phases

and power available)

• The data plate

with appliance specifi-

cations is located at the

rear exterior of the machine and/or on the

electrical control boxes. Any preparation

of individual appliances for the positioning

of condensing units must comply with the

current fire-prevention regulations in the

country of installation (see the local fire

department for the necessary details).

Bear in mind that any intervention of safety valves or fuse plugs in the refrigerating

circuit will lead to the immediate discharge of refrigerant into the environment.

2.2 Positioning

• The appliance must be installed and

commissioned in full compliance with

safety regulations, procedures and current laws

• The installer must ensure compliance

with any fire-prevention provisions (see

the local fire department for the necessary details).

• Position the appliance in the allocated

site

• Adjust the feet until the appliance is perfectly level. For levelling heavy appliances, use appropriate lifting means

WWWWAAAARRRRNNNNIIIINNNNGGGG !!!!!!!!!!!!

THESE OPERATIONS MUST BE ONLY

PERFORMED BY A

LICENSED INSTALLER

2. INSTALLATION

5

surfaces (fig. 2)

•

Always wear protective gloves when

handling packing material and the

wood base.

• NB: Dispose of packing materials in compliance with current regulations in the

country where the appliance is installed.

Do not disperse materials in the environment.

1.5 General safety regulations

The user is fully responsible in case of any

operations carried out on the appliance

and not in compliance with the instructions

given in this manual. The main safety regulations are as follows:

-

do not touch the appliance with moist

or wet hands or feet - do not operate

on the appliance when barefoot;

- do not insert screwdrivers, kitchen

utensils or any other object between

the guards and moving parts

- before performing cleaning or routine

maintenance operations, disconnect

the machine from the power supply by

operating the main switch, also

disconnecting the main knife switch

(if present)

- do not pull the power cable to disconnect the appliance from the power

supply

GB

Page 6

6

GB

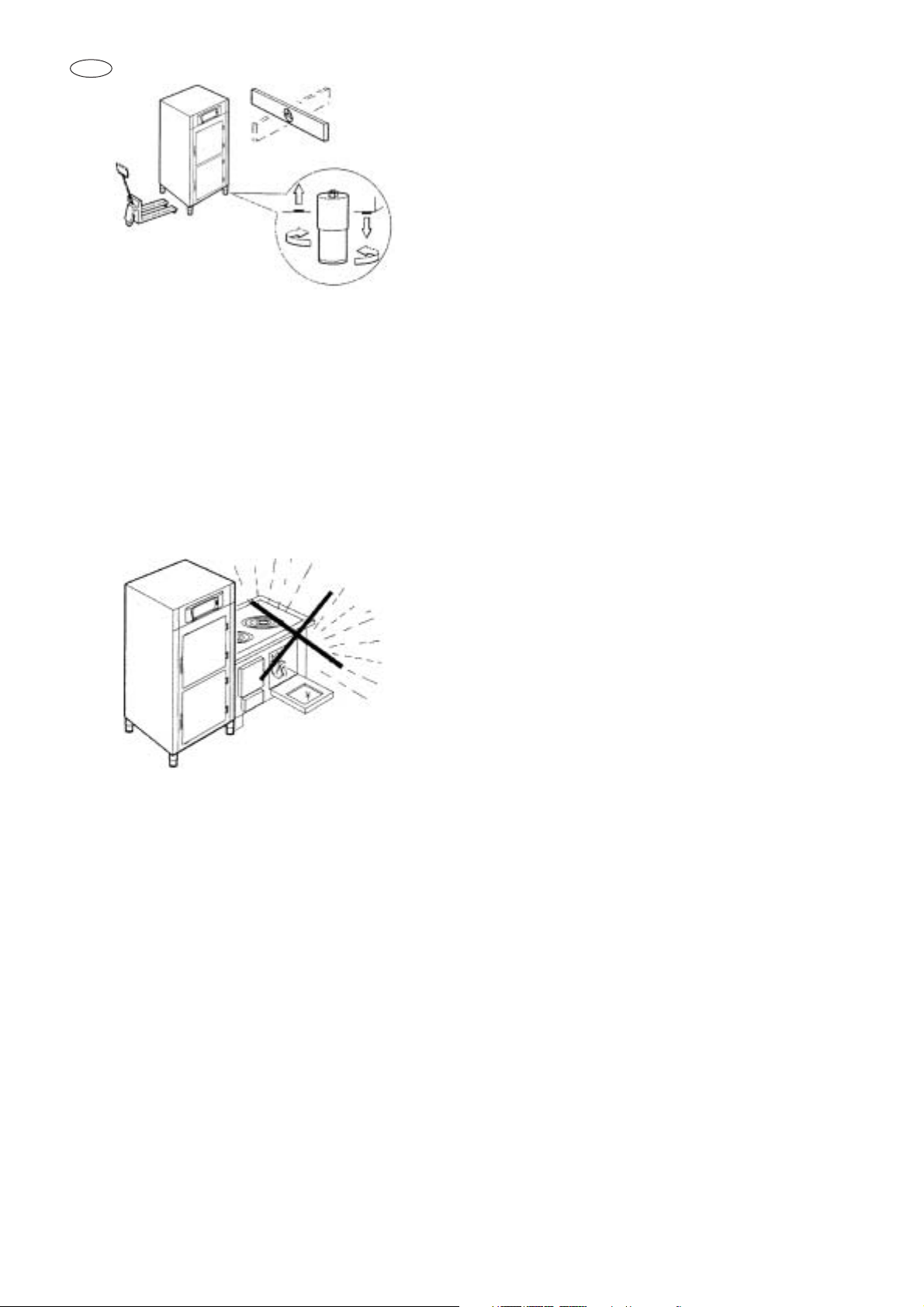

(fig. 1)

• If the appliances are not perfectly level,

their correct operation and condensate

run-off may be compromised.

AVOID

• direct exposure to sunlight

• closed sites with high temperatures and

poor air circulation

• Do not install the appliance near any heat

sources (fig. 4).

2.3 Ambient temperature and

air circulation

For air-cooled refrigerating units, the

maximum ambient temperature for operation is 32°C. Correct operation cannot

be guaranteed at higher temperatures.

The appliance can operate safely up to

38°C.

Remote condensing units must be installed in special rooms or outdoors, in a

place protected against direct sunlight; if

necessary the installer must evaluate the

use of a covering or roof structure (the

costs are borne by the purchaser).

In any case, sufficient air interchange

must be guaranteed.

2.4 Electrical connections

A differential thermal-magnetic circuit

breaker complete with disconnecting

switch must be installed ahead of every

appliance, in accordance with current

regulations in the country of installation.

• Electrical connection cables must comply with the characteristics given in the

technical data (see appliance wiring diagrams, the installer’s responsibility)

The earth wire must be correctly connected to an efficient earthing system.

THE MANUFACTURER DECLINES ALL

LIABILITY AND WARRANTY OBLIGATIONS IN THE EVENT OF INJURY TO

PERSONS OR DAMAGE TO EQUIPMENT AND THINGS, DUE TO INCORRECT INSTALLATION AND/OR FAILURE TO COMPLY WITH CURRENT

LAWS.

2.5 Connection of refrigerator-remote

units

Appliance feed lines are sized for installation distances of up to 10 metres. For

greater distances, contact Castelmac.

2.6 Condensate drainage connection

For all models, fit a condensate/wash

water drainage hose with a minimum diameter of 1” (“geberit” type or similar).

2.7 Information for the installer

Before starting up the machine, check

that it has been correctly installed and

commissioned (test report)

1. Make sure there are no gas leaks from

welds or joints made during the installation phase.

2. Check that the pipes connecting the condenser to the remote condensing unit

have been well insulated.

Page 7

7

3. Check all wiring connections.

4. Check electrical input.

5. Check the standard pressure of the refrigerating system.

6. Check the water connection with adjustment of the pressure switch valve during

operation and the correct flow of condensing water (in water-cooled units).

7. Check that the preservation unit reaches

the set temperature and do a manual

defrost.

If the appliance or the remote condensing unit have not been transported in an

upright position (e.g. horizontally) or

have been overturned during installation,

wait at least 4 hours before starting up

the equipment.

• Inform the customer of the exact use of

the appliance, with specific reference to

the use and requirements of the customer.

Installation and commissioning

must be carried out by authorised

Castelmac personnel.

2.8 Safety and control systems

• Door microswitch:

shuts off fans in the cell when the door is

opened.

• Main fuses:

protect the power circuit against short circuiting and overloads

• Safety thermostat:

intervenes when the appliance overheats

due to extended operation of evaporator

defrosting elements

• Safety pressure switch:

intervenes in the event of overpressure in

the refrigerant circuit

• Mechanism to open door from inside

should the door accidentally close

• Chamber temperature control:

controlled by the electronic board by

means of the sensor located inside the cell

• End of defrost temperature control: controlled by the electronic board by means of

the sensors on the evaporator.

• Internal humidity control (for TC 60-C only)

This is controlled by the electronic board by

means of the sensor located inside the cell.

2.9 Appliance disposal

The appliance must be demolished and

disposed of in compliance with current

regulations in the country of installation,

above all with regard to the refrigerant

gas and compressor lubricant oil.

GB

Page 8

8

GB

(*) Evaporation temperature -10 °C ∆ 120x165x360 mm.

(**) Evaporation temperature -28 °C

890 mm

2350 mm

1990 mm

1200 mm

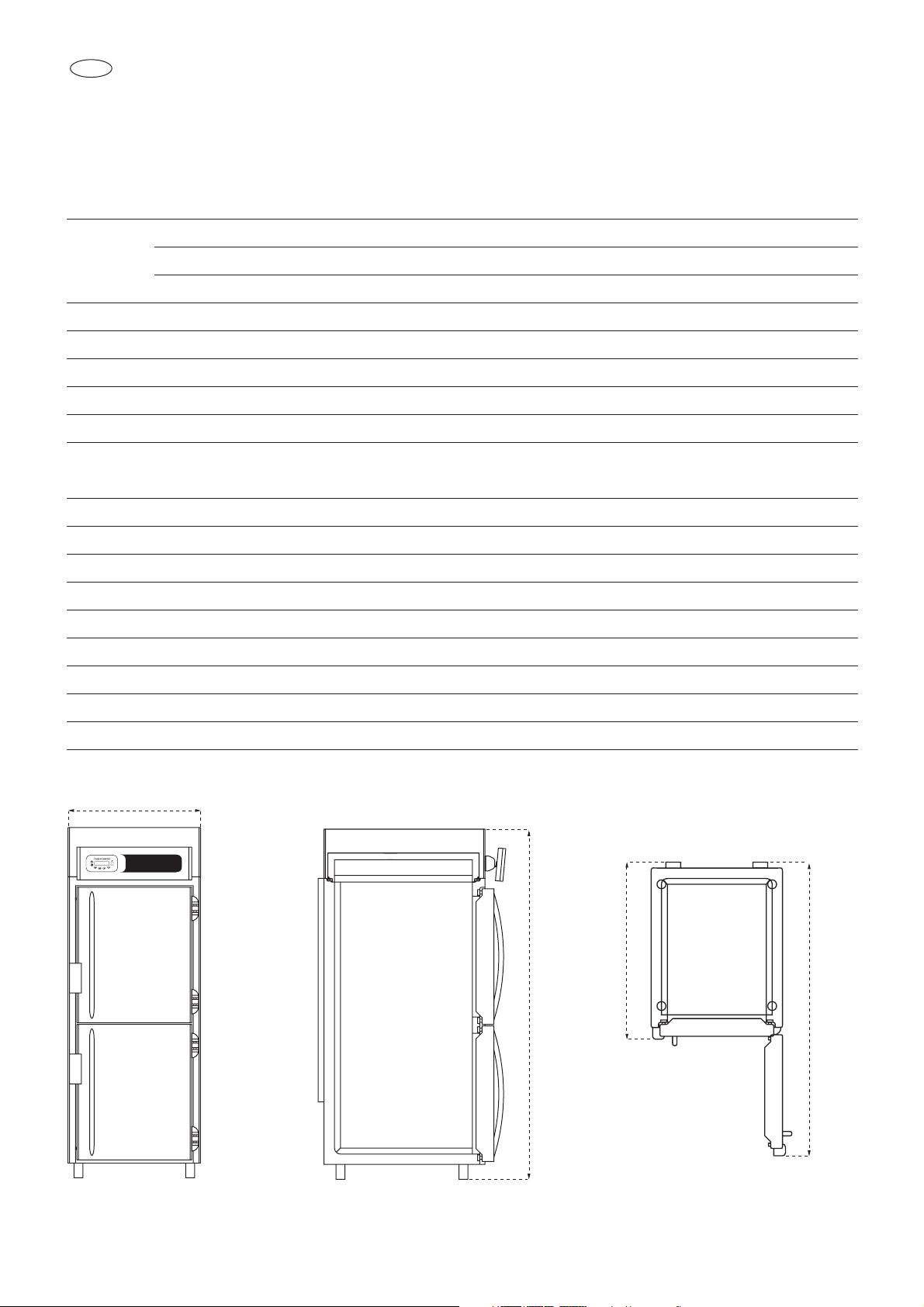

3. THECNICAL CHARACTERISTICS

TC60-N TC60-P TC60-C

Width 890 890 890

Depth 1200 1200 1200

Height 2350 2350 2350

Thickness of insulation 70 mm

Tray size 600 x 800 mm (not supplied)

Max. no trays (distance between trays 50mm): 30 (600 x 800 mm); 60 (600 x 400 mm)

Distance setting between trays 10mm

20 pairs of guides for 600 x 800 mm trays provided.

TECHNICAL SPECIFICATIONS

Temperature °C -10 / -22 +8 / -2 +15 / +2

Power supply 220-230V/50HZ 220-230V/50HZ 220-230V/50HZ

Refrigerant R404a R404a R404a R404a

Current absorbed 7.5 A 4.2 A 5 A

Input power 886 W 700 W 860 W

Defrosting Hot gas

Dehumidification control

Can be programmed from 40% to 90% (available with TC60-C version only)

HACCP 24/7 internal temperature control with alarm registration

Built-in condensation unit (remote-controlled on request)

Outside

dimensions

mm.

Page 9

9

4.1 Starting up the appliance

Power up the preservation unit using the

main switch.

Switch on the controller, holding down the

ON/OFF pushbutton. The controller will dis-

play the welcome message and show the

installed software and go to the following

box:

Message with compressor switched off and

display of temperature inside cell.

The cabinet prepares for operation at the

preset temperature.

Message with compressor switched on and

display of temperature inside cell.

The display shows the temperature detected

by the sensor inside the cell.

To switch off the controller, hold down the

ON/OFF pushbutton for 5 seconds; after

this the controller will go on a low voltage

stand-by operation mode and will display the

following boxes:

The message displayed on the LCD screen

in OFF is WAITING with cursor flashing.

IMPORTANT: to turn off the power to the

controller use the main switch.

4.2 Language setting

Press the MENU button and with the or

buttons go to

MENU 7 LANGUAGE;

press the ENTER button to display the first

language. When the or button is

pressed again the available languages are

selected.

Menu 7

LANGUAGE

WAITING _

OFF

COOLING >>OK

CELL -14,5°C

PAUSE >>OK

CELL -14,5°C

4. PROGRAMMING INSTRUCTION

ON/OFF

Continuous

cooling

function

Infrared

data

receiver

Selects the

menus

Decreases

the value

Confirms entering

the selected

menu or

the selected value

Increases

the value

GB

Page 10

10

GB

When the desired language is displayed,

press the

ENTER button; the controller

requests a second confirmation, displaying

EXIT or CONFIRM.

Press the button to confirm or the

ENTER

button to exit and return to the first box.

4.3 Date and time setting

Press the MENU button and with the or

buttons go to

MENU 8 SET CLOCK;

press

ENTER and the date and time will be

displayed with the first figure of the day flashing. Change the figure with the or buttons

and confirm the value with the

ENTER but-

ton; the new value is stored and the month

figure will flash.

Repeat the procedure until arriving at the

seconds value, then press the

ENTER but-

ton. When the values have been stored, the

date and time will flash.

4.4 Set-point display and setting

Press the MENU button and with the or

buttons go to

MENU 2 CHANGE SET

POINT

; press the ENTER button; the set

temperature and the temperature to be modified will be displayed. Modify the

NEW SET

temperature using the button to increase

the value by N degrees and the button to

decrease the value by N degrees. To store

the new set temperature press the

ENTER

button.

The new value will flash to confirm it has

been stored.

4.5 HUMIDITY ADJUSTMENT

(on TC60C only)

Press the MENU and use the

or

but-

tons to open the

MENU 3 - CHANGE HUMID-

ITY window; press ENTER; the current

humidity level and the new one to be set will

be shown. Use the

or

buttons to

change the humidity

NEW RH% and press

ENTER to confirm. The value will blink to

confirm it has been accepted.

Humidity values can be varied within an

accepted range of 40% to 90%.

4.6 CONTINUOUS COOLING FUNCTION

Hold the button for a few seconds to turn

on the continuous cooling function.

CONTINUOUS COOLING will appear on the

display; press

or

to set the continuous running time limit of the compressor

(MAX 6 HOURS). With this function,

HIGH/LOW temperature alarms are inhibited.

At the end of Continuous Cooling the preservation unit returns to normal working conditions.

4.7 Door microswitch function

The controller signals door opening, showing

the following box on the display:

The evaporator fans will stop each time one

of the doors is opened and will restart when

the door is closed. If the door stays open for

more than 5 minutes, the warning buzzer is

activated and the evaporator fans will restart

as though the door were closed.

DOOR OPEN >>OK

Cell -21°C

NEW SET: -15°C

PRESENT: -15°C

Menu 2

CHANGE SETPOINT

Date: 12/04/03

Time: 11:54:23

Page 11

11

5.1 Manual defrost

A manual defrost can be activated: press the

MENU button, with the or buttons go

to MENU 4 DEFROST and press the ENTER

button.

The controller requests a further confirmation, displaying

EXIT or CONFIRM. Press the

button to confirm or the

ENTER button to

exit and return to the first box.

Message with defrost active:

At the end of defrosting the compressor will

restart and the display will show the word

REGENERATION until the set-point temperature is reached.

Defrosting is completed when the set-point is

reached (detected by the two sensors located on the evaporator) or when the maximum

defrost time is reached.

In the case of maximum time being reached

the controller signals the anomaly with the

following intermittent alarm message and the

buzzer:

The controller memorises the type of alarm,

date and time.

To cancel the alarm message press the

ENTER button.

In any case, the alarm is stored in the controller’s alarms memory.

5.2 Periodic defrosting

For all models, defrosting can be repeated

automatically at regular intervals, beginning

immediately after the appliance is switched

on.

The time between automatic defrosts is factory-set at 6 hours.

Also in this case, defrosting is completed on

reaching the set-point (detected by the two

sensors on the evaporator) or when the maximum defrost time is reached.

The anomaly is signalled as in the case of

manual defrosting.

5.3 Timed defrosting

It is possible to set the starting time for 4 daily

automatic defrosts that will always be repeated in a 24-hour time period. In this mode,

automatic periodic defrosts are disabled.

Defrosting is completed as described above.

F18 DEFROST TIME

S 19/02/02 06:09

DEFROST TIME

—> Call SERVICE

REGENERATION >>OK

CELL -10,5°C

DEFROST >>OK

CELL -18°C

Menu 4

DEFROST

5. DEFROST MANAGEMENT

GBGB

Page 12

12

GB

6.1 Storing alarms

The controller is equipped with visual and

acoustic signalling of alarms caused by

appliance operation anomalies.

A maximum of 16 alarm events are stored;

further alarms will overwrite those already

recorded. The alarms are signalled by a

buzzer and the display will show the type of

alarm.

There is signalling delay only for HIGH/LOW

cell temperature alarms, which are signalled

60 minutes after being detected.

The controller will show the HIGH or LOW

temperature pre-alarm on the display, storing

it in the alarms list when the time has

elapsed.

Cell high temperature pre-alarm message

Cell low temperature pre-alarm message

When the pre-alarm time has elapsed the

controller will show the following message:

To cancel the alarm enter the

MENU 1

ALARMS LIST.

6.2 Silencing alarms

To silence the buzzer during an alarm press

the

ENTER button

6.3 Alarms list

It is possible to display the alarms that the

controller stored during its operation.

To enter the display press

MENU, with the

or buttons go to

MENU 1 ALARMS

LIST and press ENTER.

Using the or buttons scroll the alarms

stored by the controller.

The controller stores the type of alarm, the

start date of the alarm and its duration in

minutes.

If the and buttons are pressed at the

same time the date of the last alarm reset is

displayed. The maximum and minimum temperature alarm also displays the maximum

and minimum temperatures reached.

In the blackout alarm the date/time of power

failure start and finish is recorded. If no

alarms have been stored the controller displays

NO EVENTS IN MEMORY.

Example of high temperature alarm:

AL 27: HIGH TEMP.

Duration 015’

AL 27: HIGH TEMP.

S.=18/03/02 12:29

AL 27: HIGH TEMP.

Max Temp.= +25°C

ALARM DETECTED

CELL -24,0 °C

PAUSE >>Lt

CELL -24°C

COOLING >>Ht

Cell -18°C

6. MANAGING AND SILENCING

DETECTED ALARMS

Page 13

13

FAULT MESSAGES (they compromise appliance operation - CALL THE TECHNICAL ASSISTANCE SERVICE)

MESSAGE DISPLAY CAUSE CANCELLATION

ERR. SENSOR S1 Intermittent Temperature sensor fault Automatic on elimination of fault

ERR. SENSOR S2 Intermittent Evaporator sensor fault Automatic on elimination of fault

ERR. SENSOR S6 Intermittent Evaporator sensor fault Automatic on elimination of fault

ERR. SENSOR IN Intermittent Sensor reading out of range Switch the controller off and on

DEFROST TIME Intermittent Long defrost time Press ENTER

COMP. USE Intermittent Long compressor operation time Press ENTER

LOW EVAP T Intermittent Evaporator temperature Press ENTER on

below the set-point Elimination of fault

PROTECTION Intermittent Intervention of max. pressure switch Reset high pressure switch or

or compressor thermal-magnetic thermal-magnetic circuit breaker

circuit breaker Switch the controller off and on

Example of power failure (blackout) alarm:

In the case of HIGH/LOW temperature

alarms, a pre-alarm time of 60 minutes is

counted before they are stored; when this

time has elapsed the controller records the

alarm in the alarms list and shows the following message on the display:

To cancel this indication, enter the alarms list

as described in the previous paragraph

6.4 Serious alarms list

SERIOUS alarms can cause the preservation

unit to function incorrectly.

They are displayed in the same way as the

other alarms and the buzzer is activated. To

silence the buzzer press

ENTER.

Cancellation occurs automatically when the

fault is eliminated, but the alarm is still stored

in the

ALARMS MENU.

IMPORTANT!

IN THE EVENT OF A SERIOUS ALARM,

CONTACT THE AUTHORISED

TECNOMAC SERVICE CENTRE.

ALARM DETECTED

CELL -24,0 °C

AL 26: BLACK OUT

S.=15/03/02 10:01

AL 26: BLACK OUT

B.=15/03/02 10:22

AL 26: BLACK OUT

Max Temp.= +12°C

Max temp.

reached

during the

power failure

Number of alarms Type of alarm

End of power failure date and time

Start of power failure date and time

GBGB

Page 14

14

GB

WARNING MESSAGES (they do not compromise appliance operation)

MESSAGE DISPLAY CAUSE CANCELLATION

>>HT CONTINUOUS high temperature pre-alarm Automatic cancellation

>>LT CONTINUOUS low temperature pre-alarm Automatic cancellation

ALARM DETECTED CONTINUOUS alarm recorded Eliminate the cause

in the memory of the alarm and enter

MENU 1 to reset the

controller alarms list

SET CLOCK loss of clock data Set clock data

6.5 List of other operating faults not indicated:

FAULT CAUSE CURE

Compressor does not operat 1 - No power 1 - Check connection to power supply

Fans do not rotate 1 - No power 1 - Check connection to power supply

2 - Faulty fan 2 - Contact a technician for replacement

3 - Faulty condenser 3 - Contact a technician for replacement

4 - Protection fuse blown 4 - Contact a technician for replacement

Electronic board 1 - No power supply 1 - Check connection to power

does not switch on 2 - Protection fuse blown 2 - Contact a technician for replacement

Compressor operates but 1 - No refrigerant gas 1 - Contact a technician

does not cool cell 2 - Dirty condenser 2 - Clean the condenser

Page 15

15

The information and instructions given in this

section are intended for all personnel operating on the appliance: the user, the maintenance man and also non-specialised personnel.

Ensure that the electrical power to the

system has been disconnected before

carrying out any cleaning or maintenance

work on the appliance.

7.1 BASIC SAFETY REGULATIONS

To safely carry out all cleaning and routine maintenance operations, follow these

rules:

- do not touch the machine with moist or

wet hands or feet.

- do not operate the machine when

barefoot;

- do not insert screwdrivers, kitchen utensils or any other object between the

guards and moving parts.

- before performing cleaning or routine

maintenance operations, disconnect the

machine from the power supply at the

main switch and pull out the plug.

- do not pull the power cable to disconnect

the appliance from the power supply.

Removal of guards and safety devices

for the purposes of routine maintenance

is strictly prohibited. The manufacturer

declines all responsibility for accidents

caused by non-compliance with the

above obligation.

Before starting up the appliance, carefully clean the inside of the cell.

7.2 CLEANING THE CONDENSER

To ensure correct and efficient air condenser operation, it must be kept clean to

allow free circulation of air. This operation

should be performed at least every 30

days. Use a non-metal brush to remove

all dust and debris from the condenser

fins.

Use a vacuum cleaner to prevent the

dust removed from being dispersed in

the environment. To remove greasy

deposits, use a brush soaked in alcohol.

DO NOT USE SHARP OR ABRASIVE

OBJECTS TO SCRAPE THE SURFACES

PERFORM THIS OPERATION ONLY

WITH THE APPLIANCE SHUT DOWN

IMPORTANT

The condenser has sharp edges. Always

wear protective gloves, glasses and breathing masks when carrying out the above operations.

7. ROUTINE MAINTENANCE

IIIIMMMMPPPPOOOORRRRTTTTAAAANNNNTTTT !!!!!!!! !!!!!!!! !!!!!!!!

THESE OPERATIONS MUST

BE PERFORMED ONLY

BY A LICENSED INSTALLER

GBGB

Page 16

16

GB

7.3 CELL CLEANING

To guarantee hygiene and ensure the

quantity of the preserved foods, clean

the interior of the cell frequently, according to the type of food stored.

-ì Weekly cleaning is recommended.

The cell interior and components can be

cleaned with a soft cloth or sponge.

Clean with water and non-abrasive neutral detergents. Rinse with a cloth or

sponge soaked with water, or with a gentle jet of water (not stronger than mains

pressure). Do not use sharp or abrasive

instruments to scrape the surfaces. DO

NOT USE ABRASIVE FLUIDS, SOLVENTS OR THINNERS.

NB: Always wear protective gloves when

cleaning.

7.4 DEFROST WATER DRAINAGE

The system is arranged for automatic and

manual defrosting, as required.

Make sure that the water from the evaporator

drains correctly into the collection bowl, and

that the drain tube is not clogged.

Page 17

Via del Lavoro, 9 - C.P. 172

I - 31033 Castelfranco Veneto (TV) Italy

Tel. +39.0423.738451

Fax. +39.0423.722811

E-mail: tecnomac@castelmac.it

Web-site: www.castelmac.it

Cod. 71503560/0 - 12/2003

Loading...

Loading...