Page 1

Cod. 71503647/0 - Rev.002 - 02/2008

INSTRUCTIONS FOR USE

CONSERVATION CABINETS

HIGHCONTROL

ALL OUR SYSTEMS COMPLY WITH DIRECTIVE 2006/95/CE

HC20 NTV

NTB

BTV

BTV/2

C

HC40 BTV

NTB

NTV

HC20 BT

BT/2

NT

NT/2

Page 2

TABLE OF CONTENTS

1. GENERAL DOCUMENTATION

1.1 General information page 4

1.2 Installation page 4

1.3 Transport and handling page 4

1.4 Unpacking – disposal of the packaging page 4

1.5 General safety standards page 5

2. INSTALLATION

2.1 Rating plate data page 5

2.2 Positioning page 5

2.3 Room temperature and air change page 6

2.4 Connection to the electricity mains page 6

2.5 Notes for the installation engineer page 7

2.6 Safety and checking systems page 7

2.7 Disposal of the machine page 7

3. TECHNICAL CHARACTERISTICS page 9

4. PROGRAMMING INSTRUCTIONS

4.1 Turning on the machine page 10

4.2 Setting the language page 10

4.3 Setting the date and time page 11

4.4 Displaying and setting the setpoint page 11

4.5 Humidity adjustment page 11

4.6 Door microswitch function page 11

4.7 Recirculation fan page 11

4.8 Restore menu page 11

2

GB3GB

Page 3

5. DEFROSTING MANAGEMENT

5.1 Manual Defrosting page 12

5.2 Periodic Defrosting page 12

5.3 Timed defrosting page 12

6. MANAGEMENT OF THE ALARMS DETECTED AND TURNING THEM OFF

6.1 Alarm logging page 13

6.2 Silencing the alarms page 13

6.3 Alarm list page 13

6.4 Serious alarm log page 14

6.5 List of other malfunctions that cannot be signalled page 15

7. CLEANING AND SERVICING

7.1 Elementary safety norms page 16

7.2 Condenser cleaning page 16

7.3 Cell cleaning page 17

7.4 Defrosting water discharge page 17

Page 4

4

GB

1. GENERAL DOCUMENTATION

1.1. General information

• This manual is an integral part of the product

and it gives all the information necessary for

the correct installation, use and maintenance

of the machine.

• It is essential for the user to read the manual

and to always refer to it when for the use of

the machine. Furthermore it must be conserved in a well-known place that is accessible to all the authorised operators (installation engineer, user and maintenance engineer).

The machine conforms with the low voltage

directive 2006/95/CE, electromagnetic compatibility directive 89/336/EEC and machines

directive 98/37/EC (only for some models).

• The machine is designed for professional

use and therefore only qualified persons may

use it.

• The machine is only intended for the uses it

has been designed for and that is the conservation of foodstuffs.

Products requiring constant temperature

checking and recording are excluded such as:

- thermoreacting chemical products.

- medical products

- haemoderivatives

• The manufacturer declines all liability for any

damage caused by improper or unreasonable use such as for example:

• improper use by untrained personnel

• technical modifications or interventions that

are not model specific

• use of non-genuine spare parts or parts that

are not model specific.

• failure to comply, even partially, with the

instructions in this manual

This appliance is not intended for use by persons

-including children- with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been fiven

superfision or instruction concerning use of the

appliance by a person responsible for their safeti.

Children should be supervised to ensure that they

do not play with appliance.

1.2 Installation

Installation only by people who are authorised

and have the specific skill, respecting the

instructions in this manual.

If the machine has a remote condenser unit,

the installation engineer must check all the connections in accordance with the instructions

given by Castelmac for system and machine

installation.

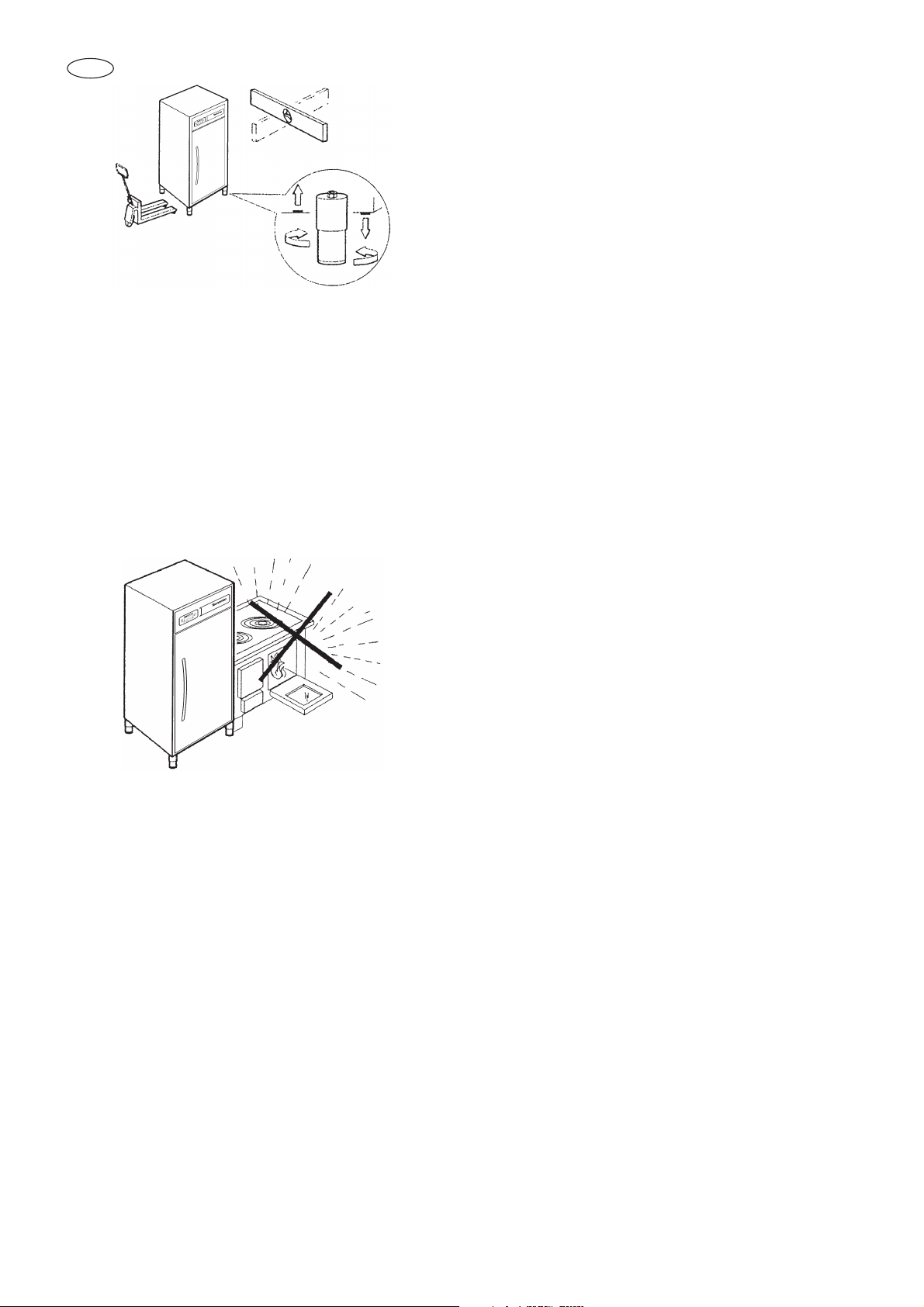

1.3 Transport and handling

• The loading and unloading of subsystems

from vehicles must be done with a forklift

truck or pallet trolley with forks that are

longer than half the object to be moved.

The lifting device must be chosen on the

basis of the dimensions of the packaged

components and have an adequate capacity.

• When moving the equipment/subsystems

you must adopt all the precautions necessary so as not damage them, observing the

instructions on the packaging (fig.1).

1.4 Unpacking

• Remove the cardboard or wooden packaging

or crates from the wooden base on which

they are resting. Then lift the sub-assemblies

with a suitable device (forklift truck), remove

the wooden base and position the subassemblies where they are required.

• After removing the packaging, make sure

that the machine is undamaged.

• Remove the protective PVC film on the panels from all the sides both inside and

out

(fig.2) (for the stainless steel versions.

•

Wear protective gloves when handling the packaging and the wooden

base.

Page 5

GB

2.1 Rating plate data

• Check that the rating plate data and the

electrical line characteristics correspond

(V, kW, Hz, n° of phases and power available ).

• The rating plate with the equipment’s

characteristics is applied to the outside

rear of the machine

and/or the electric panels.

Any preparation

of just machines for the

deployment of con-

densing units must follow the fire regulations in force in the country of installation

(contact the local fire brigade for the due

instructions).

It must also be remembered that any cutin of the safety valves or fuse caps in the

refrigeration circuit involves the immediate dispersal of all the refrigerant into the

atmosphere.

2.2 Positioning

• The machine must be installed and tested in full compliance with safety regulations, traditional instructions and current

law.

• The installation engineer is required to

verify any fire-related prescriptions (contact the local fire brigade for the due

instructions).

• Position the machine where it is required

• Level the equipment by means of the

adjustment feet. For the levelling of heavier machines, use relevant lifting devices.

CCAAUUTTIIOONN !!!!!

!

THIS OPERATION MUST ONLY BE

CARRIED OUT BY A

LICENSED INSTALLATION ENGINEER.

2. INSTALLATION

N.B.: all the various

packaging components must be disposed of according to

the regulations in

force in the Country

where the equipment

is to be used. Under

no circumstances

must anything be dumped where it is not

authorised.

1.5 Safety regulations

The responsibility for operations on the

machine, not taking due care to comply with

the instructions shown in this manual ,lies

with the user. Here below, you will find the

main safety regulations:

- do not touch the machine with damp

or wet hands or feet

- do not operate on the cell with bare

feet

- do not insert screwdrivers, kitchen

utensils or anything else between the

guards and the moving parts

- before carrying out cleaning or ordinary maintenance operations, disconnect the machine from the power supply at the ON/OFF switch (if there is

one also disconnect the machineʼs

general knife switch)

- do not pull the power lead to disconnect the machine from the mains.

Page 6

6

GB

(fig.1)

• If the equipment are not level, it is possible that their functioning and the flow of

condensate will be compromised.

AVOID

• Places exposed to direct sunlight

• Closed, hot places with little air change

• Do not install the machine near any heat

source (fig.4).

2.3 Room temperature and air change

For air-cooled refrigeration groups, the

air temperature in the operating environment must not exceed 32°C.

The declared performance ratings are

not guaranteed over this temperature.

The machine can function safely up to

38°C.

Remote condensing units must be

installed in special rooms or outside in a

place not exposed to direct sunlight; if the

circumstances make it necessary, the

installer must assess whether to use a

cover or special roofing (the costs will be

met by the purchaser).

In any case, a sufficient air change must

be guaranteed.

2.4 Connection to the electricity mains.

Upline from every piece of equipment it is

essential to install a thermomagnetic differential switch in accordance with the

regulations currently in force in the country or installation, complete with knife

switch.

• The electrical cables for connection must

comply with the characteristics shown in

the technical data (see the machine’s

wiring diagrams, to be done by the installation engineer)

The grounding wire must be correctly

connected to an efficient grounding system.

THE MANUFACTURER DECLINES ALL

LIABILITY AND ALL WARRANTY

OBLIGATIONS IF DAMAGE TO THE

EQUIPMENT, INJURY TO PERSONS

OR DAMAGE TO PROPERTY

RESULTS FROM INCORRECT INSTALLATION AND/OR INSTALLATION THAT

DOES NOT COMPLY WITH LOCAL

REGULATIONS.

CONNECTING THE APPLIANCE

TO THE POWER SUPPLY.

In the event of damage to the power supply cable on the appliance, have the cable

replaced only by a qualified electrician to

avoid any risk of personal injury.

Page 7

7

GB

2.5 Notes for the installation engineer

Check the proper installation and system

testing before commissioning the

machine (test report).

1.Check any gas leaks from the welding or

joints made during the installation phase.

2.Check the good insulation of the connection pipes linking the condenser and the

remote condensing units.

3.Check the electrical connection.

4.Check the electrical input values.

5.Check the standard pressure of the

refrigeration plant.

6.Verify the plumbing connection with the

regulation of the pressure switch valve

during operation and the good circulation

of the condensate water (water-cooled

assemblies).

7.Check that the conservator reaches the

set temperature and perform a manual

defrosting.

If the equipment or the remote condensing unit are not moved into position vertically (e.g. on their backs) or they have

been overturned during installation, do

not turn on immediately but wait at least

four hours before operating.

• Inform the customer how the equipment

should be used exactly with specific reference to the use and the requirements

of the said customer. The installation

and the commissioning must be done

by persons authorised by Castelmac.

2.6 Safety and control systems

• Door microswitch:

this shuts down fan operation in the cell

when the door is open.

• General protection fuses :

these protect the full power circuit from

short circuits and any overloads.

• Safety thermostat:

This cuts in in the case of overtemperature due to long operating times of the

evaporator defrosting heating elements.

• Safety pressure switch:

this cuts in in the case overpressure in

the refrigerating circuit

• Door opening from inside if it accidentally shuts

• Chamber temperature check:

this is managed by the electronic card

through the sensor inside the cell•

Temperature check at the end of defrosting:

this is managed by the electronic card

through the sensor on the evaporator.

2.7 WEEE Notice

The Directive on Waste Electrical and

Electronic Equipment (WEEE), which entered

into force as European law on 13th February

2003, resulted in a major change in the treatment of electrical equipment at end-of-life.

The purpose of this Directive is, as a first priority, the prevention of WEEE, and in addition, to promote the reuse, recycling and

other forms of recovery of such wastes so as

to reduce disposal.

The WEEE logo on the product or

on its box indicates that this product

must not be disposed of or dumped

with your other household waste.

You are liable to dispose of ali your

electronic or electrical waste equipment by relocating over to the specified collection point for recycling of

such hazardous waste. Isolated collection and proper recovery of your

electronic and electrical waste

equipment at the time of disposal

will allow us to help conserving natural resources. Moreover, proper

recycling of the electronic and electrical waste equipment will ensure

safety of human health and environment. For more information about

electronic and electrical waste

equipment disposal, recovery, and

collection points, please contact

your local city centre, household

waste disposal service, shop from

where you purchased the equipment, or manufacturer of the equipment.

Page 8

8

GB

ACCESSORIES

The equipment can be fitted out

– with power voltages that are different from the stan-

dard;

(if requested)

POSITIONING

The equipment is designed for indoor installation.

– Check that the surface the equipment stands on is

suitable for bearing its weight and that it is flat.

– Observe the operating spaces.

OPERATING SPACES

The choice of how to arrange the equipment is fundamentally important for its good operation.

The parts of the equipment need minimum spaces for

functioning and maintenance.

Make sure that the equipment is installed as far as

possible from heat sources.

Make sure that between the ceiling or other cover and

the top of the equipment there is a gap of at least 50

cm to guarantee satisfactory air circulation.

N.B.:

the measurements in the figures are expressed

in mm.

HC 40 BTV - NTB - NTV

HC 20 NT/2 - BT/2 - BTV/2

HC 20 C - NT - NTV - NTB - BTV - FX

890

710

1975 - 2035

953

890

710

1975 - 2035

890

1420

1975 - 2035

Page 9

9

GB

3. TECHNICAL CHARACTERISTICS

Capacity in litres

Temperature °C

Single phase electric power supply

R404a refrigerant

Refrigerating capacity (*)

Input power (*)

Net weight, kg

Width

Depth

Height

Width

Depth

Height

Extractable rack, pitch mm.

Runners supplied, no. of couples

Gastronorm shelves nr.

Shelf sizes mm.

Anti-tipping guides, no. of couples

Humidity HR%

Outer

dimensions

mm.

Internal

dimensions

mm.

(*) Evaporation temperature -10 °C ∅ mm. 120x165x360

(**) Evaporation temperature -28 °C

Capacity in litres

Temperature °C

Single phase electric power supply

R404a refrigerant

Refrigerating capacity (*)

Input power (*)

Net weight, kg

Width

Depth

Height

Width

Depth

Height

Extractable rack, pitch mm.

Runners supplied, no. of couples

Gastronorm shelves nr.

Shelf sizes mm.

Anti-tipping guides, no. of couples

Ice cream tub capacity. No.

Outer

dimensions

mm.

Internal

dimensions

mm.

HC20 BTV

HC20 BTV/2

620

-10/-24

220-230V/50HZ

R404a

450 W

620 W

148

710

890

1975÷2035

590

720

1300

35

—

5

530x650

5

—

HC40 BTV

1350

-10/-24

220-230V/50HZ

R404a

1100 W

1200 W

260

1440

890

1975÷2035

1320

720

1300

35

—

10

530x650

10

—

HC20 NT

HC NT/2

620 (600 NT/2)

+8/-8 (+8/-4 NT/2)

220-230V/50HZ

R134a

350 W (*)

310 W

145 (150 NT/2)

710

890

1975÷2035

590

720

1450 (1300 NT/2)

35

—

5 (6 NT/2)

530x650

5 (6 NT/2)

—

HC20 BT

HC20 BT/2

620

-15/-28

220-230V/50HZ

R404a

450 W (**)

600 W

155

710

890

1975÷2035

590

720

1450

35

—

5

530x650

5

50∅ (58∅ BT/2)

HC20 NTV

620

+8/-2

220-230V/50HZ

R134a

350 W

380 W

141

710

890

1975÷2035

590

720

1450

35

—

5

530x650

5

HC20 C

620

+4/+15

220-230V/50HZ

R404a

475 W

450 W

148

710

890

1975÷2035

590

720

1300

35

—

—

650x450

5

40% / 90%

HC40 NTV

1350

+8/-2

220-230V/50HZ

R134a

660 W

600 W

250

1440

890

1975÷2035

1320

720

1450

35

—

10

530x650

10

HC20 NTB

620

+10/-2

220-230V/50HZ

R404a

475 W

450 W

142

710

890

1975÷2035

590

720

1300

35

—

5

530x650

5

HC40 NTB

1350

+10/-2

220-230V/50HZ

R134a

660 W

620 W

250

1440

890

1975÷2035

1320

720

1450

35

—

10

530x650

10

Page 10

10

GB

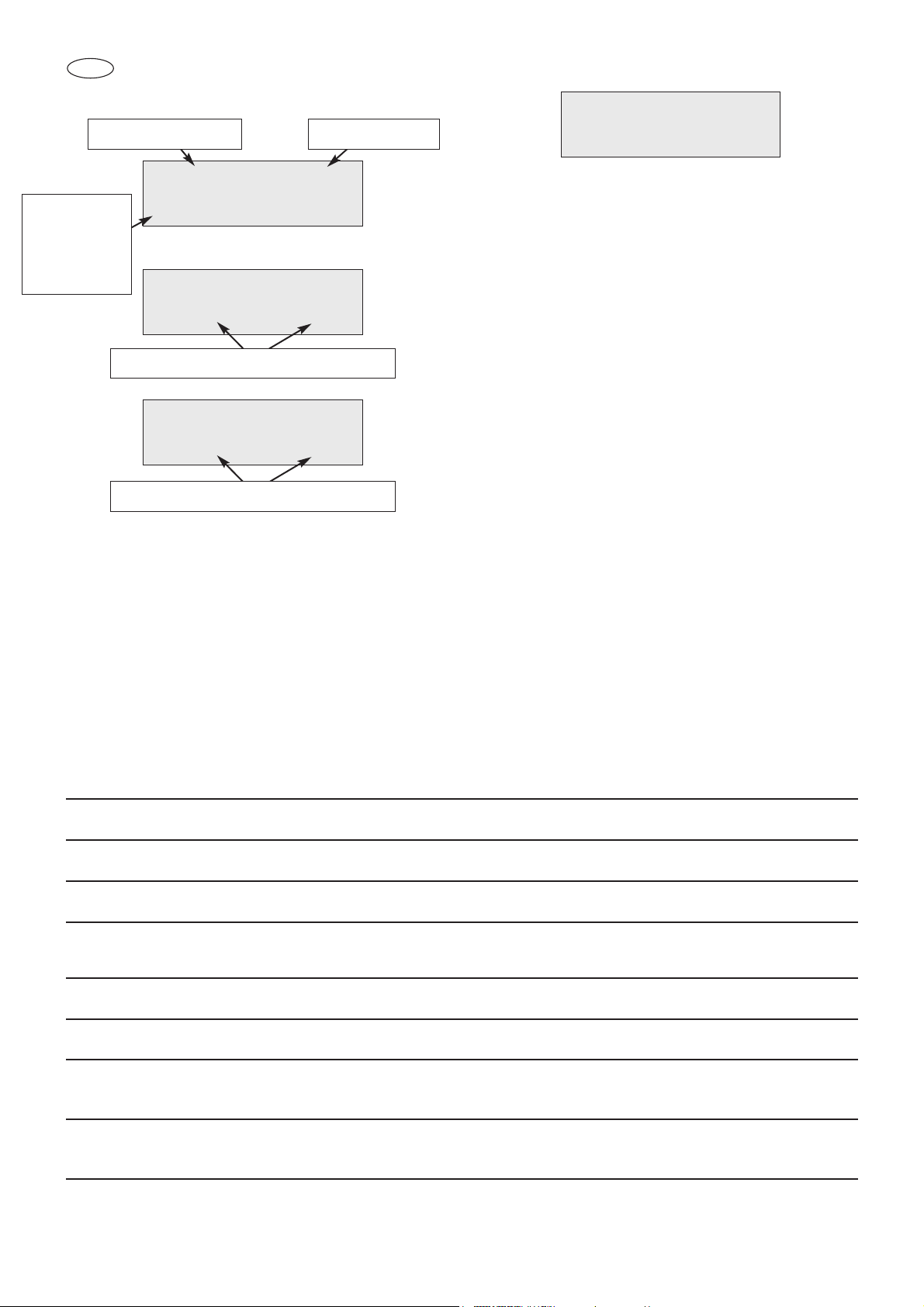

4.1 Turning the machine on

Provide the conservator with voltage by turning the main mains switch on.

Turn on the controller while keeping the

ON/OFF switch pressed , the controller

shows the welcome message, the version of

the software installed, the cabinet model and

then goes on to the following mask.

Message with compressor off and display of

inside cell temperature.

The cabinet has been prepared for functioning at the preset temperature.

Message with compressor on and display of

inside cell temperature.

The temperature on the display is the temperature detected by the sensor inside the cell.

To turn off the controller, keep the ON/OFF

button pressed for five consecutive sec-

onds after which the controller enters low volt-

age stand-by function mode and will display

the following mask

The message displayed on the LCD screen in

the turning off phase is STAND-BY with blinking cursor.

CAUTION to remove the voltage from the

controller switch the main mains switch.

4.2 Setting the language

Press the MENU button and with buttons or

go to MENU 7 LANGUAGE; the first lan-

guage is displayed when the ENTER but-

ton is pressed. The next time the button or

is pressed selects the languages available.

Menu 7

LANGUAGE

COOLING >>OK

CELL -12,5°C

PAUSE >>OK

CELL -14,5°C

AWAITED _

TURNING OFF

ON/OFF

Activation of continuous

operation recirculation

ventilation

Infrared

data receiver

Select the

menu

Decrease the

value

Confirm the entrance to the menu selected

or the value selected

Increase the value

Page 11

11

GB

When the language required is displayed, press

the

ENTER

BUTTON; the controller requests

a second confirmation by displaying EXIT or

CONFIRM.

Press the button to confirm or the

ENTER

button to exit and return to the initial mask.

4.3 Date and time setting

Press the MENU button and with buttons

or

go to MENU 8 SET CLOCK; press

ENTER

and the date and time will be displayed with

the first digit of the day blinking. Modify the digit

with buttons

or and confirm the value

with the

ENTER

button, the new value is

acquired and the month digit blinks next. Repeat

in succession the procedure until the seconds

value is reached , and press the

ENTER

button. The successful acquisition of the values will

be signalled by the flashing date and time.

4.4 Display and setting of the set point

Press the MENU button and with buttons

or

go to the MENU 2 CHANGE mask

SET POINT; press the

ENTER

button; the

temperature set and the temperature to modify is

displayed. Modify the NEW SET temperature

using the button to increase the value by N

degrees and button to decrease the value by

N degrees To memorise the new temperature set,

press the

ENTER

button. The new value will

flash to confirm that it has been memorised.

4.5 Humidity adjustment

(on HC20C only)

Press the MENU and use the

or

buttons

to open the MENU 3 - CHANGE HUMIDITY window; press ENTER; the current humidity level and

the new one to be set will be shown. Use the

or

buttons to change the humidity NEW RH%

and press ENTER to confirm. The value will blink

to confirm it has been accepted.

Humidity values can be varied within an accepted

range of 40% to 90%.

4.6 Door microswitch function

The controller signals the opening of the door and

shows the following mask on the display.

The evaporator fans will stop every time one of

the doors opens and will start again when it closes again. If the door remains open for more than

five minutes, the signalling buzzer is activated

and the fan of the evaporator will start up again as

if it were closed.

4.7 Recirculation fan in continuous opera-

tion (Function not available for model

HC20NT/2 HC20NTV HC20BTV HC20BTV/2

HC40NTV HC40BTV)

Keep the button pressed on ON to activate

the recirculation fan. In this mode the internal fan

remains on in continuous mode independently of

the compressor function.

Press the same button again to deactivate it.

4.8 Restore menu

If the electronic card crashes or because of peaks

or losses of voltage the programming data is lost,

it is possible for the user to load the factoring settings.

Press the MENU button, use buttons

or

to go to the restore menu and press the

ENTER

button; in this way the cabinet model and the

programming number loaded is shown.

Press

ENTER

again and confirm with the but-

ton ; the card turns off and the factory settings

are restored.

DOOR OPEN >>OK

Cell -21°C

NEW SET: -15°C

CURRENT: -15°C

Menu 2

CHANGE SETPOINT

Date: 12/04/03

Time: 11:54:23

Page 12

12

GB

5.1 Manual defrosting

(not available for HC20 BT - BT/2 - NT - NT/2)

It is possible to activate manual defrosting:

press the MENU button move to MENU4

DEFROSTING with buttons

or and

press the

ENTER

button.

The controller requests a further confirmation, displaying EXIT or CONFIRM.

Press the button to confirm or the

ENTER

button to exit and return to the initial mask.

Message with active defrosting:

At the end of the defrosting the compressor starts

again and the display will show the

wording RECOVERY until the set-point temperature is reached.

The defrosting can terminate on reaching the

defrosting setpoint detected by the two sensors

on the evaporator or because a maximum defrosting time has been reached. If the maximum temperature is reached, the controller signals the fault

with the following flashing alarm message and

buzzer:

The controller memorises the type of alarm, date

and time.

To cancel the alarm message, press the

ENTER

button.

The alarm is anyway registered in the controller’s

alarm log.

5.2 Periodic defrosting

(not available for HC20 BT - BT/2 - NT - NT/2)

For all models, the defrosting must be repeated

automatically and at regular intervals starting

immediately after the instrument comes on.

The time elapsing between one automatic defrosting and the next is set in the factory at six hours.

In this case too, the defrosting can terminate

when the end of defrosting temperature detected

by the two sensors on the evaporator is reached

or because a maximum defrosting time has been

reached.

The fault is shown as in the case of manual

defrosting.

5.3 Timed defrosting

(not available for HC20 BT - BT/2 - NT - NT/2)

It is possible to set the start time of four automatic defrostings a day that are always repeated over

the twenty-four hour period. In this way, the automatic periodic defrostings are inhibited.

The defrosting term occurs in the way described

previously.

F18 DEFR. TIME

S 19/02/02 06:09

DEFR. TIME

—> Call SERVICE

RECOVERY >>OK

CELL -10,5°C

DEFROS >>OK

CELL -18°C

Menu 4

DEFROSTING

5. DEFROSTING MANAGEMENT

Page 13

13

GB

6.1 ALARM LOGGING

The controller is fitted with visual and acoustic

alarm signalling determined by machine malfunctions.

The alarms are recorded up to a maximum of sixteen events; further alarms a written over those

already detected.

The alarm is signalled by a buzzer and the type of

alarm is shown on the display.Only the

HIGH/LOW cell temperature alarms have an

alarm signalling delay from the moment they are

detected. It is sixty minutes.

The controller will show the HIGH or LOW temperature prealarm on the display and, at the

end of the time it will log it in the alarm list.

High cell temperature prealarm message

Low cell temperature prealarm message

At the end of the prealarm time the controller will

show the following mask:

To cancel the alarm access MENU1 ALARM LOG

6.2 Silencing alarms

To silence the signalling buzzer during an alarm,

press the

ENTER

button.

6.3 Alarm list

It is possible to see the alarms the controller has

logged while operating.

To enter the display mode press MENU, go to

MENU1 ALARM LOG using buttons

or

and press

ENTER

.

Using buttons

or scroll through all the

alarms logged by the controller. The controller

logs the type of alarm, the date the alarm began

and the time it lasted.

When you press buttons

or together, the

last alarm reset date is shown. The maximum and

minimum temperature alarm also shows the minimum and maximum temperatures achieved.

In the blackout alarm, the date and time of the

beginning of the blackout and the date and time of

end. If no alarms are logged, the controller shows

the message NO EVENTS IN THE LOG.

Example of a high temperature alarm:

AL 27: HIGH TEMP.

Duration 015’

AL 27: HIGH TEMP.

S.=18/03/02 12:29

AL 27: HIGH TEMP.

Max Temp.= +25°C

ALARM DETECTED

CELL -24,0 °C

PAUSE >>Lt

CELL -24°C

COOLING >>Ht

Cell -18°C

6. MANAGEMENT OF THE ALARMS DETECTED

AND TURNING THEM OFF

Page 14

14

GB

6.4 MALFUNCTIONING MESSAGE (they jeopardise machine operation – CALL THE SERVICE

MESSAGE DISPLAY CAUSE CANCELLATION

ERR. SENSOR S1 Flashing Temperature sensor failure Automatic when failure rectified

ERR. SENSOR S2 Flashing Evaporator sensor failure Automatic when failure rectified

ERR. SENSOR S3 Flashing 2ndtemperature sensor failure Automatic when failure rectified

PROBE L1 ERR. Flashing Humidity probe fault Automatic when fault reset

(HC20C only)

DEFR TIME Flashing Long defrosting time Press ENTER

COMP. USE Flashing Operating time Press ENTER long compressor

LOW EVAP T Flashing Evaporator temperature Press ENTER when failure rectified

less than set point

PROTECTION Flashing Max pressure switch cut-in Rearm high pressure pressure switch

or max thermostat Turn off and restart the control

Example of a blackout alarm:

In the case of HIGH/LOW temperature

alarms, before being registered a prealarm

time of sixty minutes is calculated; at the end

of this time the controller logs the alarm in the

alarm log and shows the following mask on

the display:

To eliminate the indication go into the alarm

log as shown in the paragraph above.

6.4 Serious alarm list

SERIOUS alarms can determine the incorrect

functioning of the conservator.

The display is the same as that described for

the alarms and the signalling buzzer is activated. To silence the buzzer, press the

ENTER

button.

The cancellation is automatic when the malfunction is rectified, the alarm is however

logged in the ALARM MENU.

IMPORTANT!

CONTACT AN AUTHORISED

TECNOMAC CENTRE

IN THE CASE OF A SERIOUS ALARM.

ALARM DETECTED

CELL -24,0 °C

AL 26: BLACK OUT

S 15/03/02 10:01

AL 26: BLACK OUT

B 15/03/02 10:22

AL 26: BLACK OUT

Max Temp.= +12°C

Maximum

temperature

reached

during the

blackout

Number of alarms Alarm type

Date and time the blackout finished

Date and time the blackout started

Page 15

15

GB

SIGNALLING MESSAGES (they do not jeopardise the functioning of the machine)

MESSAGE DISPLAY CAUSE CANCELLATION

>>HT FIXED high temp prealarm Automatic rectification

>>LT FIXED low temp prealarm Automatic rectification

ALARM DETECTED FIXED logging of a Remove the cause of the

alarm

alarm in the log and enter into MENU 1 alarm

log to reset the controller

SET CLOCK loss of clock data Set clock data

6.5 List of any other malfunctions that cannot be signalled:

PROBLEM CAUSE SOLUTION

The compressor does not function 1 – Loss of power 1 – Check the connection with the electricity line

The fans do not turn 1 – Loss of power 1 – Check the connection with the electricity line

2 – Fan failure 2 – Intervention of technician for replacement

3 – Condenser in operation failure 3 – Intervention of technician for replacement

4 – Protection fuse broken 4 – Intervention of technician for replacement

The electronic card does 1 – Loss of power 1 – Check the connection with the electricity line

not come on 2 – Protection fuses broken 2 – Intervention of technician for replacement

The compressor works but 1 – No refrigerating gas 1 - Intervention of technician

does not cool the cell 2 – Condenser dirty 2 – Clean the condenser

Page 16

16

GB

The information and instructions in this chapter are for those who work on the machine:

the user, the maintenance engineer and also

non-specialised personnel.

All cleaning and maintenance operations

must be done after disconnecting the

power supply from the system.

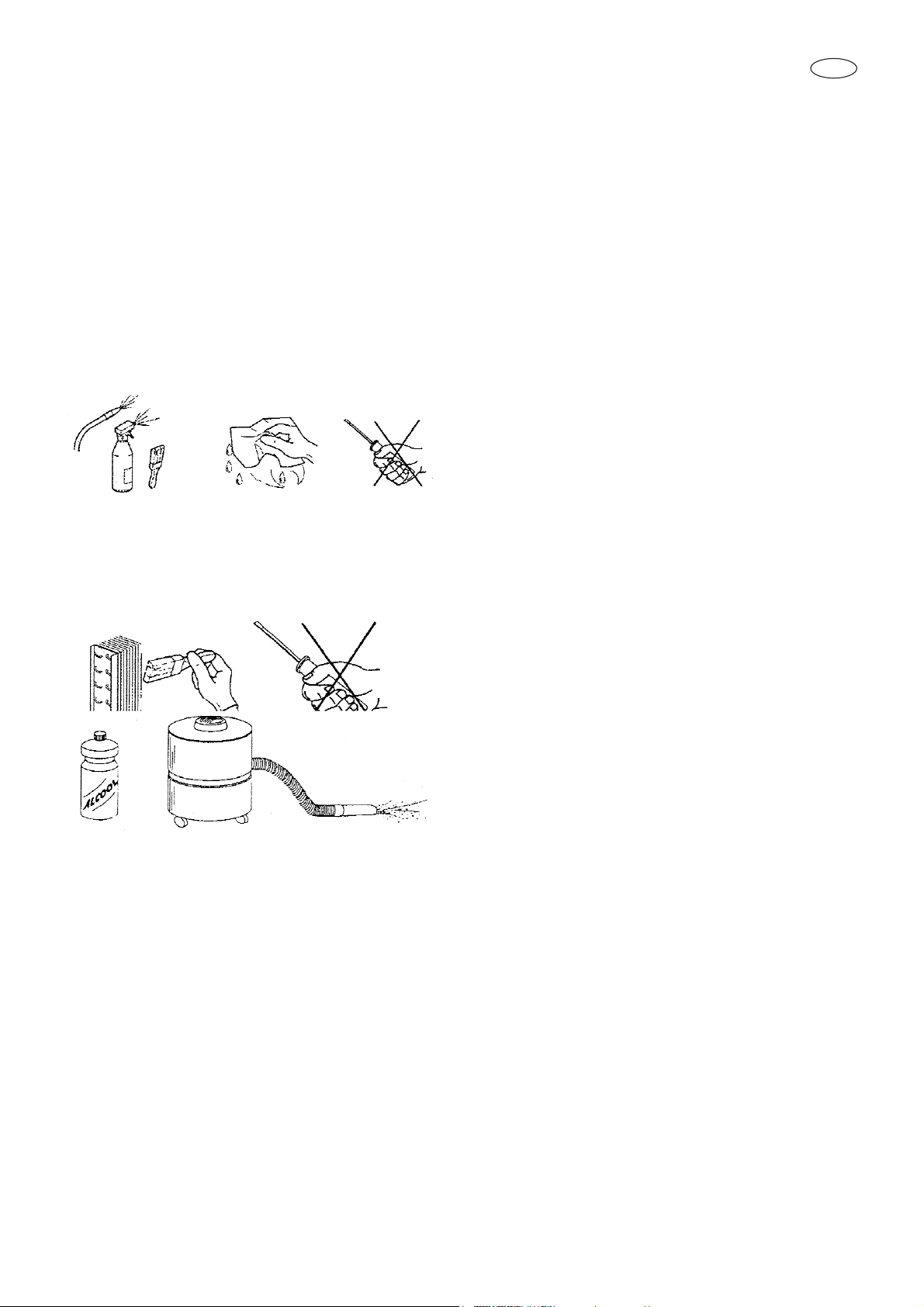

7.1 ELEMENTARY SAFETY STANDARDS

To carry out all the cleaning and servicing

operations in full safety.

we draw your attention to the following

safety standards.

- do not touch the machine with wet or

damp hands or feet.

- do not operate the machine with bare

feet.

- do not insert screwdrivers, kitchen utensils or anything else between the guards

and the moving parts.

- before carrying out cleaning or servicing

operations, disconnect the machine from

the electricity mains, turn off at the

ON/OFF switch and remove the plug.

- do not pull the power lead to disconnect

the machine from the mains.

Removing protective and safety devices

must not be removed under any circumstances to carry out ordinary maintenance operations. The manufacturer

declines all liability for accidents caused

through a failure to comply with this obligation.

Before starting up the machine it is necessary to thoroughly clean the inside of

cell.

7.2 CONDENSER CLEANING

For the correct and efficient functioning of

the condenser, it is necessary for the air

condenser to be kept clean to allow the

free circulation of the air. This operation,

to be undertaken every thirty days at the

most can be performed with non-metallic

brushes in order to remove all the dust

and the down from the fins of the condenser itself.

You are advised to use a vacuum cleaner in order not to spread removed dust

around the environment. If there are

greasy deposits, eliminate them with a

paint brush soaked in alcohol.

DO NOT SCRAPE THE SURFACES WITH

POINTED OR ABRASIVE BODIES.

THIS OPERATION MUST BE CARRIED

OUT WITH THE SYSTEM AT A STANDSTILL.

CAUTION

The condenser has sharp edges.

While undertaking the abovementioned operations, always wear protective gloves, glasses and masks to protect the breathing apparatus.

7. ORDINARY MAINTENANCE

CCAAUUTTIIOONN !!!!!

!

THIS OPERATION MUST ONLY BE

CARRIED OUT BY A

LICENSED INSTALLATION ENGINEER.

Page 17

17

GB

7.3 CELL CLEANING

In order to ensure hygiene and protect

the quality of the foodstuffs treated, the

inside of the cell must be cleaned frequently, depending on the type of foods

conserved.

Weekly cleaning is recommended.

The conformation of the cell and the

internal components permit them to be

washed using a cloth or sponge.

For the cleaning of the unit cabinet use a

soft cloth with a mild detergent solution

specific for Stainless Steel.

N.B. always use protective gloves when

cleaning.

7.4 DRAINAGE OF DEFROSTING

WATER .

The system has a facility for automatic

and manual defrosting when necessary.

Check the correct evaporator water

drainage ensuring there are no obstructions in the drainage pipe.

Page 18

Via del Lavoro, 9 - C.P. 172

I - 31033 Castelfranco Veneto (TV) Italy

Tel. +39.0423.738451

Fax. +39.0423.722811

E-mail: tecnomac@castelmac.it

Web-site: www.castelmac.it

Cod. 71503647/0 - Rev.002 - 02/2008

ISO 9001

Cert. N° 0412/2

Loading...

Loading...