Page 1

Blast Chillers

Instruction manual

EasyChill

ChillRapid

E5 E10 E15 E15.2 E20 T20 T24 T30 T40 T50

SurRapid

Page 2

Gentile Cliente,

La ringraziamo per aver preferito uno dei

nostri prodotti, frutto di lunga esperienza

e di una continua ricerca per un prodotto

superiore in termini di affidabilità,

prestazioni e sicurezza.

In questo manuale troverà tutte le

informazioni ed i consigli per poter

utilizzare il suo prodotto nel massimo

della sicurezza ed efficienza.

Dear Customer,

We would like to thank you for having

chosen our products, the result of long

experience and continuous research for a

superior product in terms of reliability,

performance and safety.

This manual will supply all of the

information and advice for the efficient

use of your product in complete safety.

Cher Client,

Nous vous remercions d’avoir choisi notre

produit, fruit d’une longue expérience et

d’une recherche permanente d’un produit

supérieur en termes de fiabilité, de

prestations et de sécurité.

Dans ce manuel vous trouverez toutes les

informations et les conseils pour pouvoir

utiliser votre produit avec une sécurité et

une efficacité optimales.

Sehr geehrter Kunde!

Wir danken Ihnen für Ihre Wahl eines

unserer Produkte, welches das Ergebnis

einer langen Erfahrung und stetiger

Forschungsarbeit ist. Dank dieser konnte

ein Produkt entwickelt werden, das ein

hohes Maß an Verlässlichkeit,

Leistungsfähigkeit und Sicherheit bietet.

In diesem Handbuch finden Sie sämtliche

Informationen und Ratschläge, damit Sie

das Produkt mit maximaler Sicherheit und

Effizienz nutzen können.

Estimado cliente:

Le agradecemos por elegir nuestros

productos, fruto de la gran experiencia y

de la investigación constante para

obtener un producto superior en

términos de fiabilidad, rendimientos y

seguridad.

En este manual, encontrará todos los

datos y consejos para poder utilizar el

producto en sus máximos niveles de

seguridad y eficiencia.

Page 3

+

3

°

+

3

°

C

°

HACCP UV PROGRAM AIR

HARD

-

18

°

START

STOP

PUSH-BUTTONS

CONTROL PANEL

q

w

e

r

t

t

tB

y

u

i

ON /OFF STAND BY

Soft blast chilling cycle +3 °C

Hard blast chilling cycle +3°C

Blast freezing cycle 18°C

nd cycle by time / probe temperature

E

A

Probe chilling indicator led

Timed chilling indicator led

Cycle start / stop

Increase value

Decrease value

o

a

s

d

f

g

h

j

Specifications for some models:

Recipe programs chilling cycles

HACCP and printer optional

Sterilization by UVC lamp optional

Defrosting / forced ventilation

Chilling / freezing cycle indicator led

Storage indicator led

Time display

Temperature display

(MOD.

(MOD.w) Models E5 - E10 - E15 - E15.2

(MOD.r) Models E10 - E15 - E15.2 - E20 - T20 - T20-C

(MOD.t) Models T20 - T20-C - T20-R- T30 - T24-C

) Model E5/14

q

T20-R- T30 - T24-C - T40 - T40-C - T40-R - T50

T40 - T40-C - T40-R - T50

BLAST CHILLER ISTRUCTION C-200371503788/0 - REV.03 - 06/2011

Page 4

CAUTIONPREFACE

i

• This manual is an integral part of the product, providing all the information required to ensure correct installation,

operation and maintenance of the machine.

• Read the manual carefully, making reference to it for machine operation. Keep

the manual in a safe place where it can be

accessed by all authorised operators (installers, operators and service personnel).

• The machine has been constructed in

compliance with the directives 73/23/CEE

(low-voltage), 89/336/CEE (electromagnetic compatibility) and 98/37/CE (machines;

for certain models only).

• Installation must be performed in compliance with National and Local Standards,

by professionally qualified sta and according to the manufacturer's instructions.

• Any contractual and extra-contractual liability of the manufacturer is excluded due

to damage caused by errors during installation and use and, however, failure to

comply with the National and Local Standards in force and the instructions supplied by the manufacturer.

• Make sure that the supplied or specified

components are used.

• Before performing any cleaning or maintenance operation, disconnect the appliance from the electric power supply

mains by operating on the system switch

and/or the product switch.

• In the event of faults and/or bad functioning, deactivate the appliance and do not

attempt any repairs or direct intervention.

THE FOLLOWING OPERATIONS

AND THOSE HIGHLIGHTED

BY THIS SYMBOL MUST NOT BE

ERFORMED BY THE APPLIANCE USER

English

P

In particular:

Electrical connections

•

• Water connections

• Installation

• Testing

• Repairing machine components

• Disassembly of the appliance

and/or its components

• Adjustments and calibration

• Cleaning the appliance and maintenance of:

- Electrical parts,

- Electronic parts,

- Mechanical parts,

- Refrigeration system parts

THE TEXT WITH THIS SYMBOL

IS OF PARTICULAR IMPORTANCE

OR POTENTIAL DANGER SIGNALS

NOTA claries the current operations

BLAST CHILLER ISTRUCTION C-2003

71503788/0 - REV.03 - 06/2011

Page 5

INDEX

Description Pag. Description Pag.

1. GENERAL DOCUMENTATION

1.1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

.3 TRANSPORT AND HANDLING . . . . . . . . . . . . . . . . . . . . . 2

1

1.4 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 GENERAL SAFETY REGULATIONS . . . . . . . . . . . . . . . . . 2

2. INSTALLATION

2.1 DATA PLATE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 REMARKS / MALFUNCTION’S CLAIMS . . . . . . . . . . . . . .3

2.3 POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 AMBIENT TEMPERATURE AND AIR CIRCULATION . . 3

2.5 ELEC TRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . 3

2.5.1 Connecting the appliance to the power supply

2.6 REFRIGERATION COMPONENT CONNECTIONS

REMOTE ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.7 CONDENSATE DRAINAGE CONNECTION . . . . . . . . . . 4

2.8 INFORMATION FOR INSTALLATION TECHNICIAN . . 4

2.9 SAFETY AND CONTROL SYSTEMS . . . . . . . . . . . . . . . . . 4

2.10 DISPOSAL OF WASTE ELECTRONIC

AND ELECTRICAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . 4

. . . . .

5 APPLIANCE FUNCTIONS

5.1 DATE AND TIME SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 ICE CREAM SURFACE HARDENING . . . . . . . . . . . . . . . . . 9

.3 MUTING THE BEEPER AND ALARM RESET . . . . . . . . . . 9

5

5.4 PROGRAM STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.5 DISPLAYING THE THREE LATEST HACCP ALARMS . . . 9

5.6 PRINTING OUT STORED DATA . . . . . . . . . . . . . . . . . . . . . . 9

5.7 FORCED VENTILATION FUNCTION . . . . . . . . . . . . . . . . . . 9

5.8 MANUAL DEFROSTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.9 AUTOMATIC DEFROST CYCLES . . . . . . . . . . . . . . . . . . . . 10

5.10 UV-C LAMP FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.11 USER ENTRY TO PROGRAMMING DATA . . . . . . . . . . . . 10

5.11.1 User parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3

5.12 PRINTER (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6. ALARM MANAGEMENT, BUZZER

6.1 STORAGE OF DATA/ERRORS . . . . . . . . . . . . . . . . . . . . . . 12

6.2 THE SOFTWARE CONTROLS THE FOLLOWING

ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2.1 Information on alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2.2 List of other operating faults not indicated . . . . . . . . 14

English

3. ADVICE TO ENSURE EFFICIENT APPLIANCE OPERATION

3.1 SHUTDOWN PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 OPERATING TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.1 Pre-cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.2 Loading the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. PROGRAMMING AND OPERATING INSTRUCTIONS

4.1 DELAYED START OF COMPRESSOR

DURING FIRST STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4.2 STARTING UP THE APPLIANCE . . . . . . . . . . . . . . . . . . . . . . 6

4.3 SOFT BLAST CHILLING BY TEMPERATURE . . . . . . . . . . . 6

4.4 SOFT TIMED BLAST CHILLING . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 HARD BLAST CHILLING FEATURES . . . . . . . . . . . . . . . . . . 7

4.6 HARD BLAST CHILLING BY TEMPERATURE . . . . . . . . . . . 7

4.7 HARD TIMED BLAST CHILLING . . . . . . . . . . . . . . . . . . . . . . 8

4.8 BLAST FREEZING BY TEMPERATURE . . . . . . . . . . . . . . . . . 8

4.9 TIMED BLAST FREEZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7. MAINTENANCE AND CLEANING

7.1 GENERAL SAFETY REGULATIONS . . . . . . . . . . . . . . . . . . 15

7.2 LEANING THE CONDENSER . . . . . . . . . . . . . . . . . . . . . . . . 15

7.3 CLEANING THE CELL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.4 EXTERNAL CLEANING AND MAINTENANCE . . . . . . . . 16

7.5 DEFROST WATER DRAINAGE . . . . . . . . . . . . . . . . . . . . . . .16

7.6 PERIODIC CLEANING OF THE

AIR CONDENSER FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

BLAST CHILLER ISTRUCTION C-200306/2011

1

Page 6

1. GENERAL DOCUMENTATION

i

1.1 GENERAL INFORMATION

• This manual is an integral part of the product, providing all

he information required to ensure correct installation, ope-

t

ration and maintenance of the machine.

• Read the manual carefully, making reference to it for machine

operation. Keep the manual in a safe place where it can be

English

accessed by all authorised operators (installers, operators and

ervice personnel).

s

The machine has been constructed in compliance with the

directives 73/23/CEE (low-voltage), 89/336/CEE (electromagnetic compatibility) and 98/37/CE (machines; for certain

models only).

• The machine has been designed for professional applications

only and should only be operated by qualified personnel.

• The machine must only be used for the purposes for which

it was designed, i.e. for chilling and freezing food products.

The machine must not be used for products requiring constant temperature control and recording, such as:

- heat-sensitive chemicals,

- medicines or

- blood products.

• The manufacturer declines all responsibility for any damage

caused by incorrect or unreasonable machine use, such as:

- improper use by untrained persons;

- technical modifications or operations not suited to specific

models;

- use of non-original or non-specific spare parts;

- failure to follow the instructions given in this manual.

• This appliance is not intended for use by persons -including

children- with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been fiven superfision or instruction concerning use of the

appliance by a person responsible for their safeti. Children

should be supervised to ensure that they do not play with

appliance.

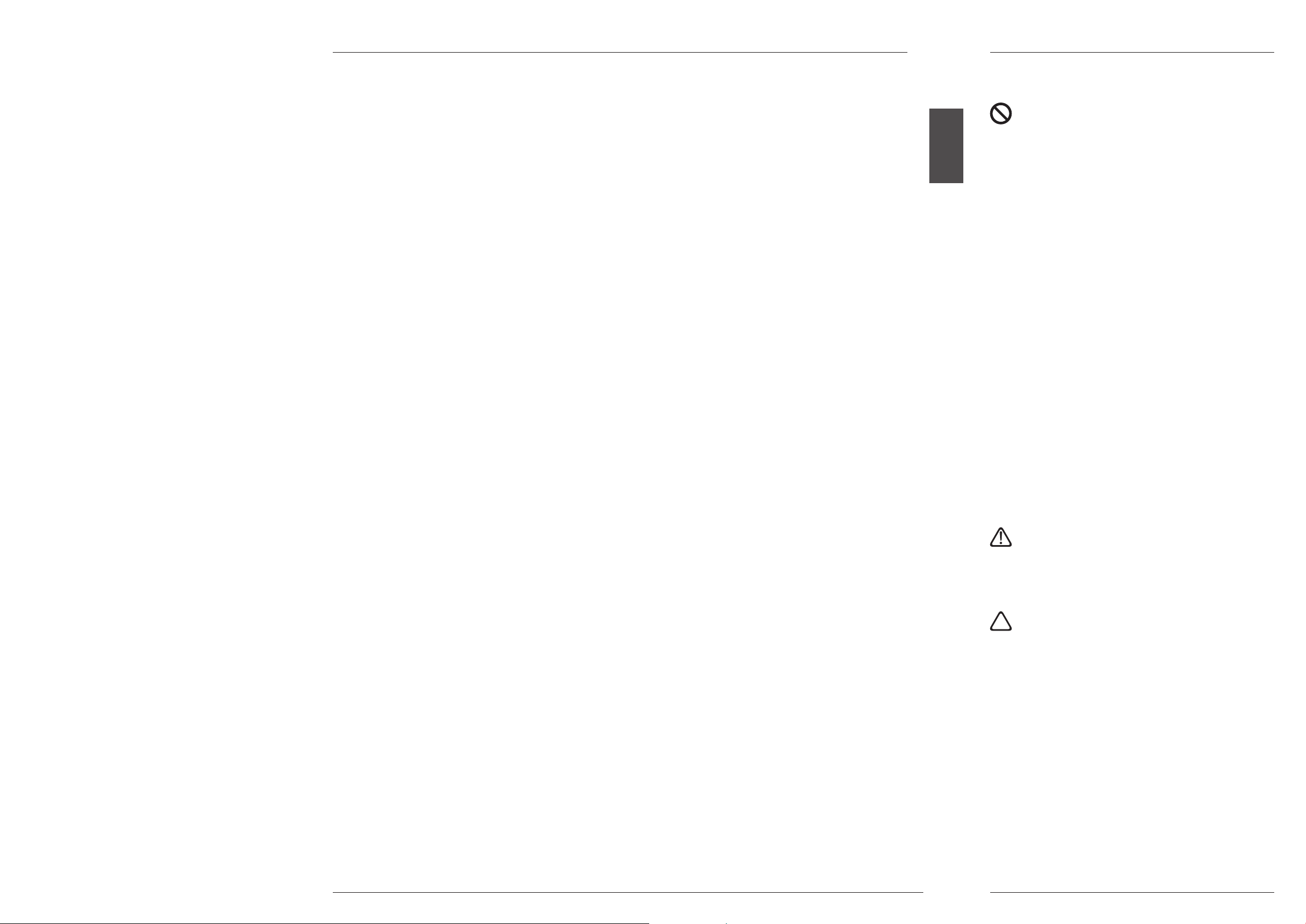

1.4 UNPACKING

• Remove all cardboard, wood or other materials from the

wood base on which the machine is set. Lift the machine/components with suitable means (e.g. lift truck), remove the wood base, then position the machine /

components in the allocated site.

• Once all packing material has been removed, check that the

machine has not been damaged in any way.

• Remove the protective PVC film on the stainless steel panels

from all internal and external surfaces.

Always wear protective gloves when handling packing

material and the wood base.

1.2 INSTALLATION

• The machine must be installed by a specialised technician

authorised by and in compliance with the instructions given

in this manual.

In the event that the machine is fitted with a remote condenser unit, the installation technician is responsible for

checking allconnections in compliance with the instructions

given by for plant and machine installation.

1.3 TRANSPORT AND HANDLING

• To load or unload the machine and/or components

from/onto the means of transport, use a lift truck or fork lift

equipped with forks that are at least half the length of the

machine housing; use a crane if the machine is fitted with

eye bolts. Select the lifting equipment suited to the weight

and overall dimensions of the packaged machine/components.

• When handling the machine/ components, apply all precautions to prevent damage, in compliance with the information given on the packaging material

Nota: Dispose of packing materials in compliance with disposal regulations applied in the country where the machine is to

be installed. Never dispose of materials in the environment. (see

section 2.9).

1.5 GENERAL SAFETY REGULATIONS

Failure to observe the recommendations made by the present manual will be at the entire responsibility of the machine user. The main safety regulations are as follows:

• do not touch the machine with moist or wet hands or feet;

• never operate the machine while barefoot;

• do not insert screwdrivers, cooking utensils or any other

object between the guards and moving parts;

• before performing cleaning or routine maintenance operations, disconnect the machine from the power supply at

the master switch and the main knife switch (if present);

• never pull on the power cable to disconnect the machine

from the power supply.

2

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 7

2. INSTALLATION

S

erial

~ Hz AW

k

g

WW

W

38Ø-4ØØ/3N 5Ø 1Ø 3ØØØ

Machine model AX8 ØØØ 1Ø3 Ø3213

R4Ø4 A 2.2 CLASS T

1

1

IP 21

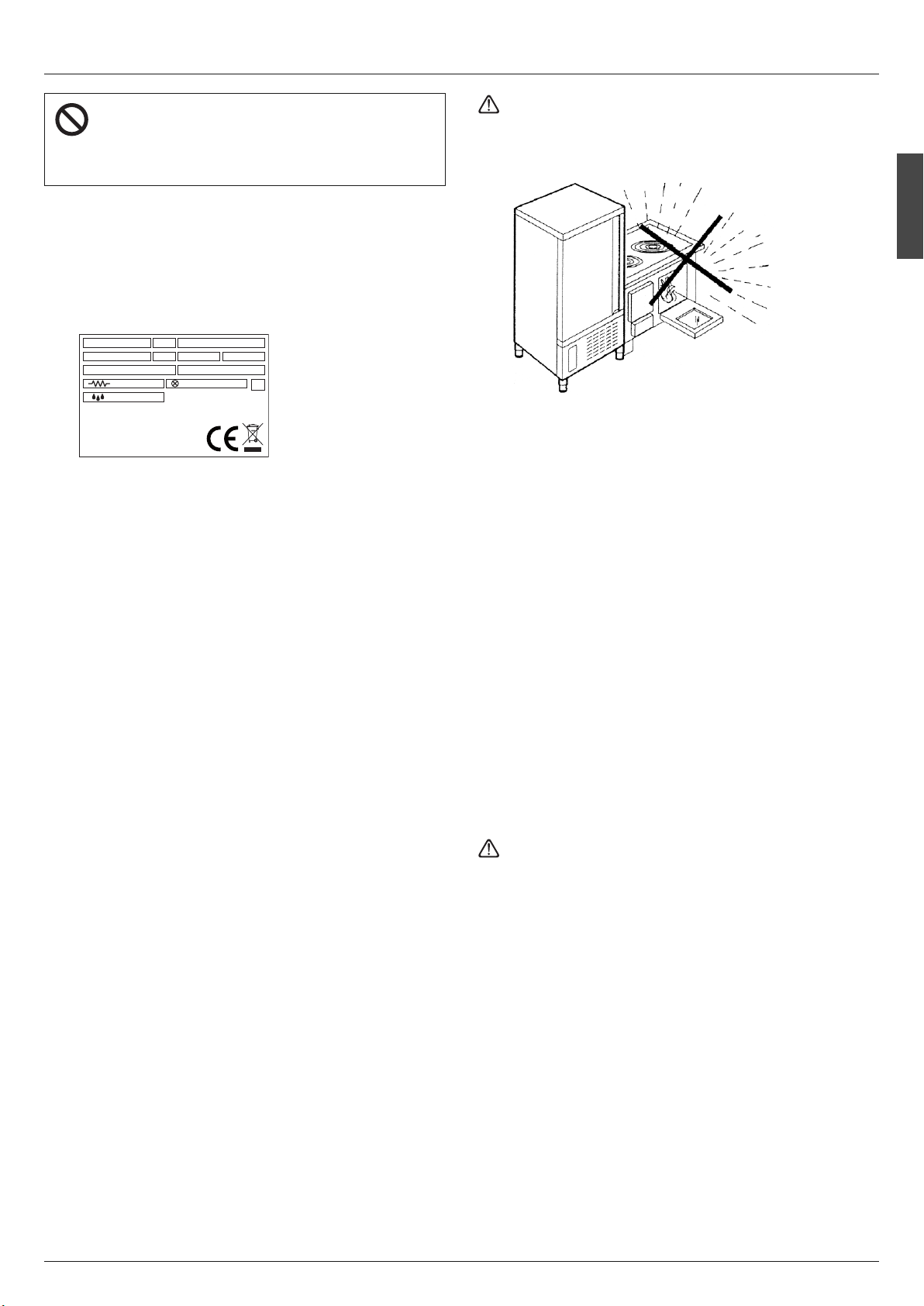

THESE OPERATIONS MUST BE

PERFORMED BY A CERTIFIED

INSTALLATION TECHNICIAN ONLY

2.1 DATA PLATE INFORMATION

Check that the data specified on the plate correspond to the

•

characteristics of the power supply (V, kW, Hz, no. phases and

power available).

• The dataplate with appliance specifications is located at the

rear exterior of the machine and/or on the electrical boards.

The set-up of individual

units and the installation of

condensers are subject to

the fire-safety regulations of

the country in which the

machine isinstalled; seek all

necessary advice from the

local fire-fighting authorities.

Bear in mind that the intervention of safety valves or plug

fuses in the refrigerating circuit will lead to the immediate

discharge of refrigerant into the environment.

2.2 REMARKS / MALFUNCTION’S CLAIMS

In case of machine malfunctioning and claim on Blast Chillers delivered in the following way :

• Assembled MOD.

We ask you to indicate to the dealer / service: machine

model, machine code number and apparatus serial number.

These information are written on the registration label, installed on the back of machine and inside the door.

• Disassembled MOD. t

We ask you to indicate to the dealer / service: machine

model, machine code number and apparatus serial number.

These information are written on the registration label, installed on top of the control panel.

w

Avoid

• direct exposure to sunlight;

closed sites with high temperatures and poor air circulation;

•

• installing the machine near sources of heat.

2.4 AMBIENT TEMPERATURE AND AIR CIRCULATION

For air-cooled appliances, the maximum ambient temperature for operation is 32°C. Correct operation cannot be guaranteed at higher temperatures.

The machine may operate safely to a maximum temperature

of 38°C.

Remote condensing units must be installed in special rooms

or outdoors, protected against direct sunlight by a shelter or

roof structure (at the cost of the purchaser).

Sufficient air circulation must be guaranteed at all times.

2.5 ELECTRICAL CONNECTIONS

A dedicated thermal-magnetic circuit breaker compliant

with established regulations must be installed on the appliance power line.

• Connected electrical cables must correspond to the technical data (as specified on electrical drawings provided by the

installation technician).

Connect the earthing conductor to an efficient earthing system.

English

2.3 POSITIONING

• The machine must be installed and commissioned in complete compliance with safety regulations, procedures and

standing laws.

• The installation technician bears the responsibility of ensuring compliance with fire safety requirements; seek all necessary advice from the local fire-fighting authorities.

• Position the machine in the allocated site.

• Adjust the machine feet until the appliance is perfectly level.

In the case of particularly heavy equipment, use appropriate

lifting means (fig. A - Cap. 1.3).

• If the appliance is not perfectly level, correct operation and

condensate flow-off will not be assured.

The manufacturer declines all liability and guarantee obligations in the event of injury to persons or damage to

equipmentand objects due to incorrect installation and/or

failure to comply with standing installation regulations.

2.5.1 Connecting the appliance to the power supply

In the event of damage to the powersupply cable on the appliance, have the cable replaced only by a qualied electrician to avoid any risk of personal injury

BLAST CHILLER ISTRUCTION C-200306/2011

3

Page 8

.6 REFRIGERATION COMPONENT CONNECTIONS

2

REMOTE ASSEMBLIES

Appliance power lines are sized for installation distances of

up to 10 metres. For greater distances, seek advice from.

2.7 CONDENSATE DRAINAGE CONNECTION MOD.

Fit a condensate/wash water drainage hose with a minimum

diameter of 1” (“Geberit” or similar type).

English

Provide a waste pipe with a

trap with a diameter of at least 1

1/2” at floor level.

t

.9 SAFETY AND CONTROL SYSTEMS

2

• Door microswitch:

shuts down fan operation in the cell when the door is opened.

• General fuses:

rotect the power circuit against short circuiting and over-

p

loads.

• Compressor heat relay:

intervenes in the event of overloads or operating faults.

• Safety pressure switch:

ntervenes in the event of excessive pressure in the refrige-

i

rant circuit.

• Plug fuses:

intervene in the event of overpressure or operating fault in

the safety pressure switch (see above).

• Chamber temperature control:

operated by the electronic board by means of aprobe inside

the cell.

• Temperature control end defrost cycle:

controlled by the electronic board by means of the probe in

the evaporator.

2.8 INFORMATION FOR THE INSTALLATION TECHNICIAN

Before starting up the machine, check that it has been correctly installed and commissioned (test report).

1. Check that there are no gas leaks from weldings or joints

made during installation works.

2. Check that the pipes connecting the condenser to the remote condensing unit have been well insulated.

3. Check all wiring connections.

4. Check electrical input.

5. Check the standard pressure in the refrigerant system.

6. Check the water connections and efficiency of the pressure

switch valve during operation, as well as the flow of condensing water (in water-cooled units).

7. Perform at least one blast freezing cycle (to the SET temperature) and one manual defrosting cycle.

In the event that the appliance or the remote condensing

unit have not been transported in a vertical position (e.g. on

the back) or have been overturned during installation works,

allow at least 4 hours before starting up the equipment.

• Inform the customer of the exact purpose of the appliance,

with specific reference to the use and requirements of the

customer.

The appliance must be installed and put into service by a

technician authorised.

2.10 DISPOSAL OF WASTE ELECTRONIC AND ELECTRICAL

EQUIPMENT WEEE (only Mod.

Fulfilling Directives 2002/95/CE, 2002/96/CE and

2003/108/CE on the disposal of waste electronic and electrical equipment.

The crossed out wheeled bin symbol indicates the

product must be collected separately from other

waste when it has become redundant. Differentiated collection of this equipment is arranged and

handled by themanufacturer.

Consequently, the user who is wanting to dispose of this

equipment must contact the manufacturer and follow the

method the latter has adopted to allow separate collection

of the redundant equipment.

Appropriate differentiated collection for the subsequent recycling, treatment and eco-friendly disposal of the dismantled equipment prevents possible negative effects on the

environment and health and facilitates the recycling of materials used in manufacturing the equipment.

Administrative sanctions foreseen by the regulations in force

shall be applied for any abusive disposal of the product by

the holder.

w

)

4

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 9

3. ADVICE TO ENSURE EFFICIENT APPLIANCE OPERATION

0.5 - 2cm.

3.1 SHUTDOWN PROCEDURES

In the event of emergency, shut down the appliance by swit-

hing o power at the main panel, by means of the knife

c

switch or by removing the plug from the power socket.

3.2 OPERATING TIPS

efore starting up the appliance, clean the inside of the cell

B

thoroughly.

3.2.1 Pre-cooling

Before using the appliance for the first time, or after a prolonged period of disuse, pre-cool the cell by running an

empty cycle until the set operating temperature has been

reached.

To ensure optimal performance without any alteration to

food quality:

• arrange food products in such a way as to favour the circulation of cold air throughout the cell;

• open the door as little as possible.

3.2.2 Loading the appliance

a) Ensure that foods to be chilled and/or frozen are separate

and do not have a thickness greater than 50-80 mm. Do not

load the appliance beyond the quantity recommended by

the manufacturer.

d) Position the core probe at the centre of the largest product

or food item; make sure that the tip of the probe does not

rotrude or touch the tray.

p

The probe must be cleaned and sanitised before each new

cycle (operation) to prevent inadvertent contamination.

e) Avoid covering the trays and/or containers with insulating

covers or film. The more the product is insulated, the more

time is required for chilling or freezing.

Trays must be packaged when the product has been chilled,

before being placed in storage.

English

b) Ensure thatthere issucient clearance between trays to ena-

ble free air circulation.

If the appliance is not completely full, distribute the trays and

foods evenly throughout the available space.

c) Position trays inside the tray compartment as far as they will

go, as close as possible to the evaporator.

BLAST CHILLER ISTRUCTION C-200306/2011

5

Page 10

4. PROGRAMMING AND OPERATING INSTRUCTIONS

i

IN THE EVENT OF MALFUNCTION,

SEEK THE ASSISTANCE OF A

CERTIFIED TECHNICIAN

4.1 DELAYED START OF COMPRESSOR DURING FIRST

English

TARTING (only for MOD.

S

Pre-heating function of compressor sump.

When the board is reached by mins tension, a 2-hour preheating phase starts and the display shows some blinking

dashes“---”. During this phase the machine cannot be started.

Nota: The delayed start takes place only if the machine is given

power by its dedicated magnetothermic switch.

• It is therefore advisable that, after first starting, the machineis

started or stopped by using the control panel pushbutton.

This way, the compressor pre-heating function is guaranteed,

and the machine starting takes place in a direct way.

• Initial pre-heating is necessary in order to safeguard the com-

pressor’s life. Only if strictly necessary (and under the customer’s responsability) it is possible to by-pass countdown

by pressing the pushbutton“printer/HACCP”for about 5 seconds.

r

• Hard blast chilling (+3°c)

This process is designed to cool food products with a thick-

ess greater than 2-3 cm. Variable air temperatures are used

n

to accelerate penetration of cold into the product.

• Blast freezing (-18°c)

This function freezes the product completely to a tempera-

ure of -18°C in less than 4 hours. The rapidity of the process

t

prevents formation of macrocrystals essential to ensure that

the product retains its original consistency and quality when

thawed for consumption.

• Automatic conservation

At the end of each cycle (chilling or freezing), the appliance

will automatically switch to the required storage temperature.

Two different end-cycle modes are available for each cycle:

• By temperature - the cycle ends when the probe reaches

the required temperature.

• Timed - cycle length is pre-set.

work cycles and modes can only be selected when the appliance is ON (LED on push -button

y

off).

This function is not activated if machine stops/starts operating due to lack of power during working cicle.

4.2 STARTING UP THE APPLIANCE

When the appliance is powered up, it can be:

• ON displays1%andjand left LEDtA on push-button

on, LEDqoff.

t

• OFF-STAND-BY LED on push-buttonqon.

To switch from one status to another, press push-buttonq.

Whenever the appliance switches from STAND-BY status to

ON, a self-test is carried out: all LEDs and displays are

switched on, push-buttons are checked, then the installed

software version is displayed.

Operation

The main work cycles (chilling/freezing) performed by the

appliance:

• Soft blast chilling (+3°c)

Pre-cooked food is rapidly chilled (90’) to a temperature of

+3°C, thus preventing proliferation of bacteria and preventing dehydration of the cooked food due to evaporation.

Food can thus be stored perfectly for 5 to 7 days without altering its original qualities.

4.3 SOFT BLAST CHILLING BYTEMPERATURE

(pre-cooked, hot foods).

• To select this cycle, press push-buttonw(relative LED lights

up), then press push-buttontto select the temperature

mode (LED

• Insert the core probe into the core of the product to be

chilled.

• Start up the cycle by pressing push-buttony. LEDtA and

those relative to the push-buttons pressed illuminate

throughout the cycle, while LEDs1#flash.

• Displayhindicates the maximum blast chilling time (starting temperature to end of the blast chilling temperature factory setting - 90 minutes).

• The temperature measured by the core probe is shown by

displayj.

• The instrument timer starts the countdown of the maximum

blast chilling time as soon as the temperature measured by

the core probe falls below the temperature of +65°C (the dot

at the bottom right of displayhflashes).

• During the blast chilling cycle, the air temperature is around

0° C.

This function is designed to guarantee uniform cooling of

the product, preventing frost formation on thesurfaces. During the blast chilling cycle, the compressor may therefore

stop and restart, depending on the reading of the cell temperature probe.

• The blast chilling phase ends only when the core probe (inserted in the product core) indicates that the set blast chilling temperature (+3°C) has been reached as signalled by an

intermittent beep for a minute. During the beep, LEDs

andgflash.

Displayjindicates the temperature inside the cell, while

display1%shows blast chilling time reset to zero.

t

A on).

f

6

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 11

If at the end of the maximum blast chilling interval the core

iii

•

probe continues to display a temperature higher than the

value for the end of blast chilling, the displays will indicate

an alarm for excessively long chilling (ALL 14) alternating with

the temperature and time; at the same time, the alarm beep

ill be activated.

w

The blast chilling cycle continues until the end chilling temperature has been reached; display

utes remaining until the end of the cycle.

ota: press push-button

N

ton again to clear the alarm display.

• At the end of the chilling cycle, the appliance automatically

switches to the set storage temperature for an indefinite interval (like a standard storage appliance).

Nota: LEDs

• The cell temperature is constantly shown on displayj; during this cycle, defrost cycles are performed at regular intervals with duration set as required (parameter programming

reserved for installation technician). The factory setting for

positive storage temperature is +2°C.

• Press push-buttonyto set the appliance to STOP status

(relative LED switches off ), ready for a new cycle.

• To modify the final blast chilling temperature, consult the

user programming instructions.

switch off while LEDsglight up.

f

o mute the alarm; press push-but-

t

i

counts back the min-

h

.5 HARD BLAST CHILLING FEATURES

4

When the HARD function is used, chilling takes place in two

stages:

• an initial “Hard” stage when the air temperature is brought

down to below 0°C in order to accelerate chilling;

a second“Soft” stage, involving air temperatures around 0°C.

•

4.6 HARD BLAST CHILLING BYTEMPERATURE

• Press push-button

ush-button

p

on). Insert the core probe into the core of the product to be

chilled.

• Start up the cycle bypressing push-buttony. LEDtA and

those relative to the push-buttons pressed illuminate

throughout the cycle, while LEDsfflash.

• Displayhindicates the maximum blast chilling time (starting temperature to end of the blast chilling temperature factory setting - 90 minutes).

• The temperature measured by the core probe is shown by

displayj.

• The instrument timer starts the countdown of the maximum

blast chilling time as soon as the temperature measured by

the core probe falls below the temperature of +65°C (the dot

at the bottom right of displayhflashes).

• Once the cycle has been started, the appliance operates initially with an air temperature below 0°C (LED on push-button

flashes), then with temperatures around 0°C (LED on

e

push-buttoneon).

t

(relative LED lights up), then press

e

o select the temperature mode (LED

t

t

English

A

4.4 SOFT TIMED BLAST CHILLING

• Press push-buttonw(relative LED lights up), then press

push-buttontto select the timer mode (LEDtB on). Displayhshows the maximum chilling time (set by default to

90 minutes).

To modify this time, press push-buttonsuandi(time in

minutes).

• Press push-buttonyto start the appliance. LEDtB and

push-button LEDs remain on and LEDsfflash throughout

the cycle.

• Internal cell temperature is shown on displayj.

• When the maximum chilling time has counted back to 0, the

chilling cycle is completed and the appliance automatically

switches to the set positive storage temperature for an indefinite interval.

• LEDs illuminate and the beep is activated when the cycle is

finished (as in the chilling cycle by temperature). The same

applies for the positive storage function.

Press push-buttonyto set the appliance to STOP status

(relative LED switches off ), ready for a new cycle.

Use the storage function sparingly. After chilling, food

products should be placed in storage cabinets.

Nota: the first stage of the cycle is completed when the core

probe detects a temperature of +20°C in the product core.

• The blast chilling phase ends only when the core probe (inserted in the product core) indicates that the set blast chilling temperature (+3°C) has been reached as signalled by an

intermittent beep for a minute. During the beep, LEDs

andgflash.

Displayjindicates the temperature inside the cell, while

displayhshows blast chilling time reset to zero.

• The alarm (ALL 14) and conservation functions cut in with

relative indicators in the same way as for timed Soft blast

chilling.

• Press push-buttonyto set the appliance to STOP status

(relative LED switches off ), ready for a new cycle.

f

BLAST CHILLER ISTRUCTION C-200306/2011

7

Page 12

ARD blast chilling affords a considerable reduction in

H

working time, and is particularly suited to foodstuffs with a

high fat content, for large pieces or for packaged products.

•

SOFT chilling is recommended for delicate and finely chopped

roducts, such as vegetables, mousses, etc..

p

4.7 HARD TIMED BLAST CHILLING

• To select this cycle, press push-buttone(relative LED lights

English

up), then press push-buttontto select the “timed” mode

LED

(

(set by default to 90 minutes).

To modify this time, press push-buttons

minutes).

• To set the time of the first negative temperature stage, press

push-buttonefor five seconds, then wait for displayhto

show the flashing value.

The time setting (in minutes) can be modified by means of

push-buttonsuandi.

Press push-buttoneagain to return to standard display.

• Start up the cycle by pressing push-buttony. LEDtB and

push-button LEDs remain on and LEDsfflash throughout

the cycle.

• Internal cell temperature is shown on displayj.

• Once the cycle has been started, the appliance operates initially with an air temperature

below 0°C (LED on push-buttoneflashes), then with temperatures around 0°C (LED on push-buttoneon). For example: HARD timed chilling cycle 90 minutes. First stage of

40 minutes with negative air temperature. Second cycle

stage of 50 minutes with air temperature around 0°C.

• When the maximum chilling time has counted back to 0, the

chilling cycle is completed and the appliance automatically

switches to the set positive storage temperature for an indefinite interval.

• LEDs illuminate and the beep is activated when the cycle is

finished (as in the temperature chilling cycle). The same applies for the storage function.

• Press push-button

(relative LED switches off ), ready for a new cycle.

t

B

on). Display

y

hows the maximum chilling time

s

h

andi(time in

u

to set the appliance to STOP status

.8 BLAST FREEZING BY TEMPERATURE

4

• To select this cycle, press push-button

up), then press push-buttontto select the temperature

mode (LEDtA on). Insert the core probe into the core of

the product to be chilled.

Start up thecycle by pressing push-button

•

those relative to the push-buttons pressed illuminate

throughout the cycle, while LEDs

• The appliance proceeds to operate in the same way as that

described for the positive chilling cycle. During this cycle the

ompressor operates in continuous mode to enable the ap-

c

pliance to reach the cycle end temperature in the shortest

time possible (default temperature at product core is set at 18°C). Maximum freezing time is 240 minutes.

• The alarm (ALL 14) for excessively-long freezing and conservation functions cut in with relative indicators in the same

way as for timed Soft blast chilling. The factory setting for

negative storage temperature is -25°C.

• LEDs illuminate and the beep is activated when the cycle is

finished (as in the soft chilling cycle by temperature). The

same applies for the storage function.

Press push-button

(relative LED switches off ), ready for a new cycle.

4.9 TIMED BLAST FREEZING

• Press push-buttonr(relative LED lights up), then press

push-buttontto select the timer mode (LEDtB on). Displayhshows the maximum chilling time (set by default to

240 minutes).

To modify this time, press push-buttonsuandi(time in

minutes).

• Start up the cycle by pressing push-buttony. LEDtB and

push-button LEDs remain on and LEDsfflash throughout

the cycle.

Internal cell temperature is shown on displayj.

• When the maximum chilling time has counted back to 0, the

cycle is completed and the appliance automatically switches

to the set negative storage temperature for an indefinite interval.

LEDs illuminate and the beep is activated when the cycle is

finished (as in the freezing cycle by temperature). The same

applies for the storage function. The factory setting for negative storage temperature is -25°C.

• Press push-buttonyto set the appliance to STOP status

(relative LED switches off ), ready for a new cycle.

to set the appliance to STOP status

y

f

(relative LED lights

r

LED

.

y

flash.

t

and

A

8

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 13

5. APPLIANCE FUNCTIONS

5.1 DATE AND TIME SETTINGS

• Set the machine to ONq.

Press and hold down push-button 5

•

seconds to access the dateand time setting function.Display

indicates in sequence the abbreviations Hr (hours), Mn

j

(minutes), dA (day), Mo (month) and Yr (year), while display

shows their respective settings. To scroll the abbrevia-

h

ions, press push-button 5

t

• To modify the settings, use push-buttonsuandi.

5.2 ICE CREAM SURFACE HARDENING

• Set the machine to ONq.

• Press and hold down push-buttonyfor more than five seconds to access the surface hardening function (push-button

LED flashes). The compressor is switched on; display

shows the default cycle time. Set the cycle time (in minutes)

by means of push-buttonsuandi.

• Open the cell door, place the product inside, then shut the

door to start the cycle. All LEDs remain off, with the exception

of the Start LED. When the cycle time has elapsed, an acoustic signal is given. The appliance remains on, ready for another ice cream hardening cycle. Open the cell door, remove

the hardened product, replace it, then shut the door.The machine will perform another hardening cycle for the time set

for the previous one. Every time the door is opened and closed after a cycle, the time is reset.

• To exit the function, press push-button 6y.

ADDITIONAL FUNCTIONS

t

t

.

or more than five

f

t

y

h

RECALLING A STORED PROGRAM

• When the appliance is ONq, press push-buttonobriefly;

isplay

d

to select the required program. Start up the cycle by pres-

i

sing push-buttony.

.5 DISPLAYING THE THREE LATEST HACCP ALARMS

5

• Set the machine to ONq.

• Press and hold down push-buttonafor more than five seconds (relative LED illuminates) to enter the alarm display

function (date, hour and minute, alarm type and maximum

temperature detected).

• Every time the HACCP push-button is pressed, the stored

data are displayed. EXAMPLE:

ALL 11 Display

ill show program P1. Use push-buttons

w

j

h

--- Str (start)

12 hr hour

29 min minutes

6 day days

8 mon month

03 yr year

End end

13 Hr

21 min

6 day

8 mon

03 yr

24 maximum temperature

Display

detected inside the cell

u

a

j

nd

a

English

5.3 MUTING THE BEEPER AND ALARM RESET

• Press push-buttonito mute the alarm beeper.

• Alarms are reset :

- by pressing push-buttoniwhen the beeper is off;

- automatically if alarm conditions are removed;

• See also section 6 (Alarm Management).

5.4 PROGRAM STORAGE

• The programming function is used for cycles for processing

products with the same characteristics. Up to 99 programs

can be stored. Select the type of chilling process (Soft, Hard,

Timed Freezing or by Temperature), then press and hold

push-buttonountil displayjshows the abbreviation P1

(push-buttonoLED flashes).

• Use push-buttonsuandito set the number of the program on displayj.

• Start up the cycle by pressing push-buttony.

• When the cycle has been completed, the appliance automatically switches to the set storage temperature for an indefinite time.

• Press push-buttonyto set the appliance to STOP status (relative LED switches off ), ready for a new cycle.

o

i

5.6 PRINTING OUT STORED DATA

• With the appliance in STAND-BY status, press and hold down

push-buttonafor more than five seconds to print out the

latest work cycle.

• With the appliance in STAND-BY status, press push-button

once to print out HACCP data). When the appliance is

a

operating and the printer is on, the current cycle will be printed out.

5.7 FORCED VENTILATION FUNCTION

• To activate this function when the appliance is ONq, press

push-buttondfor more than five seconds.The fan will continue to operate even when the cell door is open.

• During forced ventilation, displayjwill show “AIR”.

5.8 MANUAL DEFROSTING

• To activate this function when the appliance is ONqpress

push-buttond(relative LED illuminates).

• If conditions allow it (the temperature detected by the evaporator probe must be lower than the set point in the program parameters), the appliance will perform a defrost cycle.

Displayjwill show “dEF”.

• To immediately stop a defrost cycle, press push-buttond.

a

BLAST CHILLER ISTRUCTION C-200306/2011

9

Page 14

.9 AUTOMATIC DEFROST CYCLES

5

(not available for MOD.

q

• The appliance automatically performs defrost cycles during

storage.Three defrost cycles are performed during a 24-hour

period(once every 8 hours).

The appliance automatically restarts once the defrost cycle

•

has been completed.

.11 USER ENTRY TO PROGRAMMING DATA

5

• Access for programming configuration parameters is only

permitted when the appliance is ON

and thereis no data

q

memory error active.

• Press and hold down push-buttonsuandiat the same

ime for more than five seconds; the computer will give ac-

t

cess to the programming function. Display

j

while displayhwill show the relative value.

• Use push-buttontto select parameter display (LEDtA il-

5.10 UV-C LAMP FUNCTION

English

Use this function to sterilize the interior of the cell.

•

• When the appliance is ON

LED illuminates). The UV-C lamp switches on and sterilizes

the interior for a default time of 30 minutes. To interrupt the

sterilization cycle, press push-buttonsor open the cell

, press push-buttons(relative

q

luminated), or display 16 with settings (LEDtilluminated).

Use push-buttons

•

(if LED

t

B is illuminated).

t

A is illuminated) or to modify the settings (if LED

u

nd

a

o scroll the list of parameters

t

i

• The computer automatically exits the programming function

after approximately 40’.

door.When the door is closed again, the lampwill remain off.

5.11.1 User parameter settings

Parameter Min. Max. Unit/meas. DEF

PA PASSWORD -99 +99 Number -19

/ = PROBE PARAMETERS

/1 Cell probe calibration -10 +10 °C 0

/2 Evaporate probe calibration -10 +10 °C 0

/3 Core probe calibration -10 +10 °C 0

/8 Temperature scale (0=Fahrenheit 1=Celsius) 0 1 Flag 1

c = CHILLING / FREEZING

c0 Cell probe differential 1 15 °C +3

c1 Duration of timed chilling and max. duration for chilling by temperature 0 400 min 90

c2 Chilling end set point (core probe) -55 +99 °C 3

c3 Positive storage set point (cell probe) -55 +99 °C 2

Duration of timed freezing and max. duration of freezing by temperature

c4

(when c4=0, key and freezing function to -18°C are disabled.

For chilling units only.)

c5 Freezing end set point (core probe) -55 +99 °C -18

c6 Negative storage set point (cell probe) -55 +99 °C -25

c8 Positive and negative chilling duration countdown start temperature -55 +99 °C +65

cA Core probe readout (readout only) --- --- °C ---

Set point for SOFT blast chilling (cell probe) and during second stage

cb

of HARD blast chilling

HA RD chilling set point (temperature transition HARD ->SOFT of core probe) -55 +99 °C 2 0

cF Cell set point during first stage of HARD blast chilling (core probe) -55 +99 °C -20

d = DEFROST

d0 Defrosting interval (0 = no defrost) 0 99 hours 8 h

dA Defrost probe readout (readout only) --- --- °C ---

U = INPUTS + VARIOUS

u5 Duration of UV lamp activation (if u5=0, UV key is disabled) 0 99 min 0

uA Print interval (when uA=0, HACCP key is disabled) 0 99 min 20

0 400 min 240

-55 +99 °C

displays PA,

-5

cd

10

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 15

.12 PRINTER (OPTIONAL)

5

• If you have to turn the instrument on/off press

• If you have to feed the paper by hand press

If you have to change the roll of paper:

•

- Turn the instrument off

- Press for opening the panel at the front of the instrument

Slip the roll of paper into the lower side of the roller

-

- Press as long as the roller drags the roll of paper

English

- Put the roll of paper into its box

- Close the panel at the front of the instrument

• If you have to execute the print test

- Switch off the power supply of the instrument

- Press .

- Switch on the power supply of the instrument

• Signals: on/off led

- if it is lighted, the instrument will be in ON mode

BLAST CHILLER ISTRUCTION C-200306/2011

11

Page 16

6 ALARM MANAGEMENT, BUZZER

6.1 STORAGE OF DATA/ERRORS

The applianceelectronic controlleris equipped with a system

f acoustic and visual signals to indicate the intervention of

o

safety devices. The table below gives a list of the alarms

shown on the panel display

English

.2 THE SOFTWARE CONTROLS THE FOLLOWING ALARMS

6

ALL 01 Evaporator probe alarm

Cause: Exit from operating range (-50°C / +100°C) for over

30 seconds.

Probe is defective (REPLACE PROBE).

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 01” with standard display

Reset: Automatically resets only when probe reading has

returned to normal.

ALL 02 Core probe alarm

Cause: Exit from operating range (-50°C / +100°C) for

more than 30 seconds during current chilling cycle

by temperature.

Effect: Interruption of current chilling cycle by tempera-

ture and automatic start-up of timed chilling cycle.

Chilling by temperature push-button disabled.

Probe is defective (REPLACE PROBE).

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 02” with standard display

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 03” with standard display

Reset: Automatically resets only when probe reading has

returned to normal.

ALL 04 Optional probe alarm

(disabled if no probe is connected)

ALL 05 Input SW2 (door microswitch alarm)

Cause: Input active for more than 5 minutes with ap-

pliance in start status.

Door open (close door) Microswitch fault (replace

the microswitch)

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 05” with standard display

Reset: Press the mute push-button (with beeper off ).

Automatically resets if input value returns to normal Alternatively, switch off the panel then turn it

back on (stand-by).

ALL 06 Input SW1 alarm

(Press. max for all models)

(Thermal-magnetic switch for MOD.r)

(Oil diff. pressure switch for MOD.t)

Cause: Input active for more than 5 seconds

Effect: Sets the appliance to STOP.

Reset the max. pressure switch, thermal-magnetic

switch or differential pressure switch.

Alarm relay: Not activated.

Reset: Press the mute push-button (with beeper off ).

Resets automatically if probe value returns to normal, but cycle remains in timed mode. Alternatively, switch off the panel then turn it back on

(stand-by).

ALL 03 Cell probe alarm

Cause: Exit from operating range (-50°C / +100°C) for over

30 seconds.

Probe is defective (REPLACE PROBE).

Effect: Any current chilling cycle is interrupted.

If a storage phase is in progress, the compressor

and the fan set to stand-by status.

When the appliance is in Stop status, press Start to

set the compressor and fan to stand by.

12

BLAST CHILLER ISTRUCTION C-2003 06/2011

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 06” with standard display

Reset: Press the mute push-button (with beeper off ) with

no alarm cause displayed

Page 17

ALL 07 Input SW4 alarm (ALL 07)

(Automatic reset min. idrostat pressure switch

for all water cooled models)

(Automatic reset min. pressure switch only for

OD.

M

t

)

Cause: Input active for more than five seconds when ap-

pliance in start mode

The alarm is disabled for approx. two minutes at

ach compressor start-up. The alarm is disabled

e

during “pump-down”.

If the alarm persists, contact SERVICE.

Effect: Appliance sets to STOP.

Start/Stop and Defrost push-buttons are disabled.

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 07” with standard display

Reset: Press the mute push-button (with beeper off ).

Alternatively, switch off the panel then turn it back

on (stand-by).

ALL 08 Input SW3 alarm

(Kriwan compressor automatic reset only for

MOD.r).

ALL 10 Input Ht2 alarm

(Input in voltage 2 ... fuses only for MOD.r)

In the water-cooled C.U. version, if the hydrostat

should intervene due to the lack of water, the ma-

hine stops and “ALL 10” appears on the display.

c

The machine re-starts automatically when the water

supply returns.

ALL 11 Excessive temperature alarm

Cause: (only during storage) cell probe constantly detects

a temperature greater than the sum of positive or

negative storage set points with relative alarm

delta.

ALL 12 Blackout alarm

Cause: (only during storage) after the return of power the

cell probe detects a temperature greater than the

sum of positive or negative storage set points with

relative alarm delta.

This alarm is disregarded if the storage probe is already in alarm status.

ALL 13 Compressor preventive maintenance alarm

Cause: Compressor operating time is a whole multiple of

hours set under password.

English

Cause: Input active for more than five seconds at least

three times when appliance is in start mode

Effect: Compressor shuts down and resumes operation

when input value returns to normal.

The appliance sets to STOP at third alarm.

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display/Led: Alternates message “ALL 08” with standard display

Reset: Press the mute push-button (with beeper off ).

Alternatively, switch off the panel then turn it back

on (stand-by).

ALL 09 Input Ht1 alarm

(Input in voltage 1 ... fuses only for MOD.t)

ALL 14 Temperature not reached in set time alarm

Cause: Blast chilling by temperature has lasted longer

than the time set for Timeout

Effect: Store the alarm in HACCP memory

Chilling cycle continues.

Beeper: Activated (3 seconds, then a pause of 30 seconds)

until the mute button is pressed.

Display: Alternates message “ALL 14” with standard display

Alarm relay: Not activated.

Reset: Press the mute push-button (with beeper off ).

Alternatively, switch off the panel then turn it back

on (stand-by).

BLAST CHILLER ISTRUCTION C-200306/2011

13

Page 18

LL 15 Keyboard/membrane alarm

A

Cause: A pressed push-button has been detected when

panel is switched on.

ffect: All keys are disabled.

E

All relays are disabled. All inputs are disregarded.

The LED indicator of the pressed button flashes.

Beeper: Activated (3 seconds, then a pause of 30 seconds)

English

ntil the mute button is pressed.

u

Display: Alternates message “ALL 15” with standard display

Reset: Switch off the panel then turn it back on (stand-

by).

Note: The appliance cannot be used until this alarm has

been removed.

6.2.2

List of other operating faults not indicated:

.2.1 Information on alarms:

6

• During alarms, the beeper is activated and the display shows

the message “ALL xx”.

• The alarm message is alternated on the display even when

the beeper has been silenced, until the alarm has been clea-

ed.

r

• Alarm relays remain activated as long as the alarm is displa-

yed.

• In the case that more than one alarm has been activated,

each one is alternately displayed.

When the beeper is activated, the operator can silence it by

•

pressing the relative push-button, after which the alarm can

be cleared, by pressing the beeper reset button again.

• Power failures will not erase current alarms.

FAULT CAUSE SOLUTION

Compressor does not operate 1 - Overload switch has cut in 1 - Seek assistance from a service technician

2 - Power failure 2 - Check connection to power lines

Fans do not rotate 1 - Power failure 1 - Check connection to power lines

2 - Fan fault 2 - Seek assistance from a service technician

to replace fan

3 - Condenser fault 3 - Seek assistance from a service technician

to replace condenser

4 - Protective fuse faulty 4 - Seek assistance from a service technician to

replace fuse

Electronic panel does 1 - Power failure 1 - Check connection to power lines

not switch on 2 - Protective fuses broken 2 - Seek assistance from a service technician to

replace fuses

Compressor operates but 1 - Shortage of refrigerant gas 1 - Seek assistance from a service technician

does not cool cell 2 - Solenoid valve fault 2 - Seek assistance from a service technician

3 - Condenser is soiled 3 - Clean the condenser (see par. 4.2)

14

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 19

7 MAINTENANCE AND CLEANING

i

THESE OPERATIONS MUST BE

PERFORMED BY A CERTIFIED

INSTALLATION TECHNICIAN ONLY

The information and instructions given in this section ad-

ress all persons operating the appliance: the user, the main-

d

tenance technician and non-specialised personnel.

Ensure that the electrical power to the system has been disconnected before carrying out any cleaning or maintenance work on the appliance.

7.1 GENERAL SAFETY REGULATIONS

• Recall the following regulations to ensure that all cleaning

and routine maintenance operations are conducted safely.

- do not touch the machine with moist or wet hands or feet;

- never operate the machine while barefoot; - do not insert

screwdrivers, cooking utensils or any other object between

the guards and moving parts.

• before performing cleaning or routine maintenance operations, disconnect the machine from the power supply at the

master switch and by pulling out the plug;

• never pull on the power cable to disconnect the machine

from the power supply.

• Removal of guards and safety devices for the purposes of

routine maintenance is strictly prohibited. The manufacturer

declines all responsibility for accidents causedby failure to

observe the above regulation.

• Before starting up the appliance, clean the inside of the cell

thoroughly, as described in par. 7.3.

The condenser has sharp edges. Always

wear protective gloves, goggles and masks

hen carrying out the above operations.

w

7.3 CLEANING THE CELL

• To guarantee hygiene and ensure the quality of processed

oods, clean the interior of the cell frequently, according to

f

the type of food stored.

• Weekly cleaning is recommended.

• The cell interior and components can be cleaned with a soft

cloth or sponge.

• Clean with water and non-abrasive neutral detergents. Rinse

with a damp cloth or sponge, or with a gentle jet of water

(no stronger than mains pressure). Do not use pointed or

abrasive instruments to scrape appliance surfaces.

Never use abrasive fluids, solvents or thinners.

English

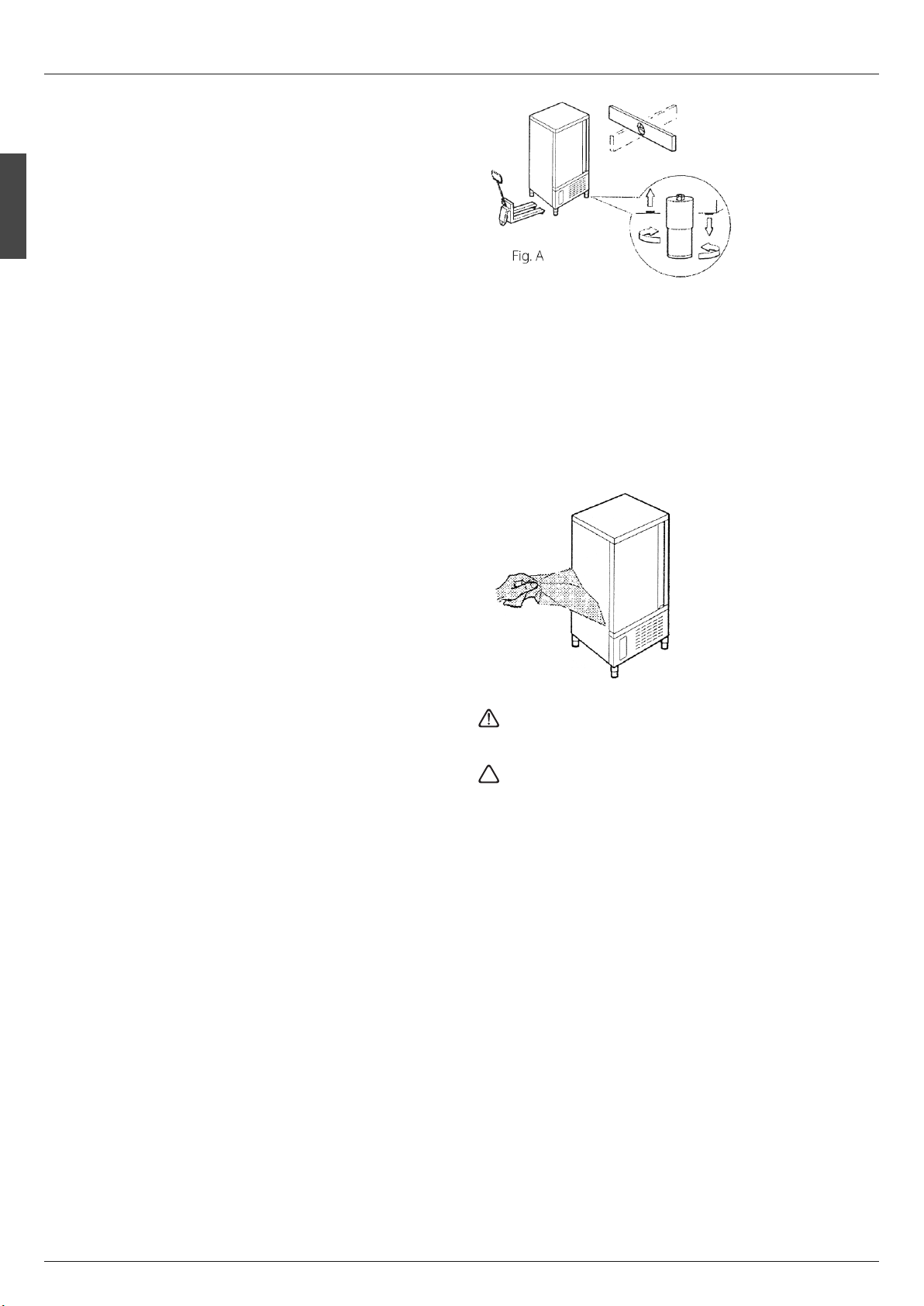

7.2 LEANING THE CONDENSER

• To ensure correct and efficient air condenser operation, it

must be kept clean to allow free circulation of air. This operation should be performed at least once a month. Use a

non-metal brush to remove all dust and debris from the condenser blades.

• Use a vacuum cleaner to prevent the dust removed from

being dispersed in the surrounding area. To remove greasy

deposits, use a brush dipped in alcohol.

Never use pointed

or abrasive

instruments

to scrape

appliance surfaces

Perform this

operation only after the appliance has been shut down

Nota: Always wear protective gloves while cleaning.

7.4 EXTERNAL CLEANING AND MAINTENANCE

• For the cleaning of the unit cabinet use a soft cloth with a

mild detergent solution specific for Stainless Steel.

BLAST CHILLER ISTRUCTION C-200306/2011

15

Page 20

ow to access the evaporator for cleaning

1

1

2

3

H

• It is possible to gain access to the inside part of the evaporator, to perform the cleaning of the same:

Fig. 1 Fig . 2

English

Fig . 3 Fig . 4

.5 DEFROST WATER DRAINAGE

7

• The system is prearranged for automatic and manual defrosting, as necessary.

• Make sure that the water from the evaporator drains out into

the collecting tray, and that the drain tube is not clogged.

7.5 PERIODIC CLEANING OF THE AIR CONDENSER FILTER

(only for MOD.

• Press with a screwdriwer on both sides of front panel (see

rawing). Take and clean the filter.

d

• Put the filter in the original position.

• Push with the hands and close the panel.

e

)

• Removing the screws located on the front fan panel and

opening it to the right side, or removing the panel.

• Periodically, provide to clean the evaporator, using nebulized hot water at low pressure, and addressing the water

throw on the evaporator battery.

• Finished the cleaning, provide to dry the evaporator using

air pressure in order to desiccate and remove the residues of

presence of water . After that refit the fan panel in proper position.

• To carefully clean with a cloth the surfaces adjacent to the

evaporator and provide to reassemble the frontal fans panel.

Before starting the machine pls verify to have removed

the equipments used in precedence for the cleaning.

16

BLAST CHILLER ISTRUCTION C-2003 06/2011

Page 21

Page 22

Via del Lavoro, 9 - C.P. 172 - 31033 Castelfranco Veneto (TV) - ITALY - EU

el. +39 0423 738451 - Fax +39 0423 722811 - tecnomac@castelmac.it - www.tecnomac.eu

T

71503788/0 - REV.03 - 06/2011 - Istruzione Abbattitori

Castel Mac SpA si riserva il diritto di apportare modifiche sia tecniche che estetiche senza preavviso. Castel Mac reserves the right to change models and specifications without prior notice.

Loading...

Loading...