Tecnologic TLV 38 Operating Instructions Manual

TLV 38

MICROPROCESSOR-BASED

DIGITAL ELECTRONIC

INDICATOR

OPERATING INSTRUCTIONS

Vr. 01 (ENG) - cod.: ISTR 06612

TECNOLOGIC S.p.A.

VIA INDIPENDENZA 56

27029 VIGEVANO (PV) ITALY

TEL.: +39 0381 69871

FAX: +39 0381 698730

internet : http:\\www.tecnologic.it

e-mail: info@tecnologic.it

FOREWORD

This manual contains the information necessary for the product to

be installed correctly and also instructions for its maintenance and

use; we therefore recommend that the utmost attention is paid to

the following instructions.

Though this manual has been issued with the greatest care,

TECNOLOGIC S.p.A. will not take any responsibility deriving from

its use.

The same applies to each person or Company involved in the

issuing of this manual.

This document is the exclusive property of TECNOLOGIC S.p.A.

which forbids any reproduction and divulgation , even in part, of the

document, unless expressly authorized.

TECNOLOGIC S.p.A. reserves the right to make any formal or

functional changes at any moment and without any notice.

INDEX

INSTRUMENT ORDERING COD

E

7.6

MEASUREMENT RANGE TABLE7.5

FUNCTIONAL DAT

A

7.4

MECHANICAL DIMENSIONS, PANEL CUT-OUT AND

MOUNTING

7.3

MECHANICAL DATA7.2

ELECTRICAL DAT

A

7.1

TECHNICAL DAT

A

7

GUARANTEE AND REPAIRS6.3

CLEANING6.2

ERROR SIGNALLING6.1

PROBLEMS , MAINTENANCE AND GUARANTEE6

PROGRAMMABLE PARAMETERS TABLE5

PARAMETERS CONFIGURATION BY KEY014.5

FUNCTION OF KEY “U”4.4

A

LARMS OUTPUTS FUNCTION

S

4.3

PEAK VALUES MEMORIZATION AND HOLD FUNCTION4.2

MEASURING AND VISUALIZATIO

N

4.1

FUNCTIONS4

ELECTRICAL WIRING DIAGRAM3.4

ELECTRICAL CONNECTION

S

3.3

MECHANICAL MOUNTING3.2

PERMITTED US

E

3.1

INFORMATION ON INSTALLATION AND USE 3

FAST PROGRAMMING OF ALARM THRESHOLDS2.3

PARAMETER PROGRAMMING LEVELS2.2

PARAMETER PROGRAMMING 2.1

PROGRAMMING2

FRONT PANEL DESCRIPTION1.2

GENERAL DESCRIPTION1.1

INSTRUMENT DESCRIPTION1

1 - INSTRUMENT DESCRIPTION

1.1 - GENERAL DESCRIPTION

TLV 38 is a digital microprocessor-based indicator.

Depending on the model required the input accept:

C: Thermocouples temperature probes (J,K,S and TECNOLOGIC

IRS Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermoresistances PT100.

E : Thermocouples temperature probes (J,K,S and TECNOLOGIC

IRS Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermistors PTC and NTC.

I : normalized analogue signals 0/4..20 mA

V : normalized analogue signals 0..1 V, 0/1..5 V, 0/2..10 V

The instrument can have up to 2 outputs: relay type or can drive

solid state relays type (SSR).

The process value is visualized on 4 red displays, while the output

status is indicated by 2 LED displays.

Other important available functions are:

maximum end minimum peak memory, Hold function, zero

calibration (resetting) function and/or auto-ranging for normalized

signals, parameters protection on different levels.

1.2 - FRONT PANEL DESCRIPTION

OUT1

TLV 38

1

7

2

3

4

5

6

OUT2

1 - Key P : This is used to access the programming parameters

and to confirm selection.

2 - Key DOWN : This is used to decrease the values to be set and

to select the parameters. If the key is held down, the user returns to

the previous programming level until he exits the programming

mode. Outside the programming mode it permits visualisation of

the minimum peak measure.

TECNOLOGIC spa - TLV 38 - OPERATING INSTRUCTIONS - Vr. 01 - ISTR 06612 - PAG. 1

3 - Key UP : This is used to increase the values to be set and to

select the parameters. If the key is held down, the user returns to

the previous programming level until he exits the programming

mode. Outside the programming mode it permits visualisation of

the maximum peak measure.

4 - Key U : This is a key with a function programmable by par.

“USrb” (see par. 4.4). It permits to modify the visibility of the

parameters in “ConF” menu (see par. 2.3).

5 - Led OUT1 : indicates the state of output OUT1

6 - Led OUT2 : indicates the state of output OUT2

7 - Led SET :It indicates access to the programming mode and

parameter programming level.

2 - PROGRAMMING

2.1 - PARAMETERS PROGRAMMING

By pushing key "P" and holding it down for approx. 2 sec. it is

possible to enter into the main selection menu.

Using the "UP" or DOWN” keys, it is then possible to roll over the

selections:

to exit from the selection and come back to normal

functioning

"rEt"

to enter into the configuration parameters menu

"ConF"

to enter into the operating parameters menu

"OPEr"

Once the desired item has been selected, push key “P” to confirm.

Selecting "OPEr" and "ConF" gives the possibility of accessing

other menus containing additional parameters and more precisely :

"OPEr" – Operating parameters Menu: it’s accessible without

password, and can contain all the desired parameters (see par.

2.2).

"ConF" – Configuration parameters Menu: this contains all the

operating parameters and the functioning configuration parameters.

2 sec.

H o ld fo r

To enter the menu "ConF", select the option “ConF” and press the

key “P”, the display will now show “0”.

At this request, enter, using keys “UP” and “DOWN”, the number

reported on the last page of this manual and push key “P”.

If an incorrect password is entered, the instrument returns to the

previous state.

If the password is correct, the display will visualise the code

identifying the first group of parameters (“

]

InP“) and with keys “UP”

and “DOWN” it will be possible to select the desired group of

parameters (see parameters table).

Once the desired group of parameters has been selected, the code

identifying the first parameter of the selected group will be

visualised by pushing the “P” key.

Again using the “UP” and “DOWN” keys, it is possible to select the

desired parameter and, if the key “P” is pressed, the display will

alternatively show the parameter’s code and its programming value,

which can be modified by using the “UP” or “DOWN” keys.

Once the desired value has been programmed, push key “P” once

more: the new value will be memorised and the display will show

only the code of the selected parameter.

By using the “UP” or “DOWN” keys, it is then possible to select a

new parameter (if present) and modify it as described above.

To select another group of parameters, keep the “UP” or “DOWN”

key pressed for approx. 2 sec., afterwards the display will return to

visualise the code of the group of parameters.

Release the key and by using the “UP” and “DOWN” keys, it will be

possible to select a new group.

To exit the programming mode, no key should be pressed for

approx. 20 seconds, or keep the “UP” or “DOWN” pressed until exit

from the programming mode is obtained.

Longer

Hold

2 sec.

Hold f or

2 sec.

Hold for

ATTENTION: The instrument is programmed in factory with all the

parameters, to exception of the Alarm thresholds AL1, AL2 (if

available) programmable in the menù "ConF" to the purpose to

prevent wrong accidental programming from non experienced

consumers.

2.2 - PARAMETERS PROGRAMMING LEVELS

The menu “ConF” (protected by password) contains all the

parameters, however it is possible to program all desired

parameters in the menu “OPEr” (without protection by password)

by following this procedure:

Enter the menu “ConF” and select the parameter to be made

programmable or not programmable in the menu “OPEr”.

Once the parameter has been selected, if t he LED SET is switched

off, this means that the parameter is programmable only in the

menu “ConF”, if instead the LED SET is on, this means that the

parameter is also programmable in the menu “OPEr”.

To modify the visibility of the parameter, push key “U” : the LED

SET will change its state indicating the parameter accessibility level

(on = menu ”OPEr” and “ConF”; off = menu “ConF” only).

To enter the menu “OPEr”, select the option “OPEr” and press the

key “P”.

The display will now show the code identifying the first group of

parameters present and by pressing the “UP” and “DOWN” keys it

will be possible to select the group of parameters to be modified.

The programming and exit modes for the “OPEr” menu are the

same as those described for menu “ConF”.

2.3 - FAST PROGRAMMING OF THE ALARM THRESHOLDS

If the alarm outputs are used this procedure permits rapid

programming of the the alarm thresholds.

This procedure is possible only if the relative parameters of alarm

threshold are present in "OPEr" menu.

The possible modification of these value, with the procedure

described, is instead subordinate to what is programmed in par.

“Edit” (contained in the group “

]

PAn “).

This parameter can be programmed as :

= AE : The alarm thresholds can be modified

= AnE : The alarm thresholds can be visualized on the dispay but

cannot be modified

Once you have configure the alarm thresholds as “OPEr”

parameters to visualize or visualize and program the value push

key “P” then release it during the normal state of the instrument.

The display will visualise “AL 1” alternatively to the programmed

value.

To modify the value, press “UP” key to increase it or the “DOWN”

key to decrease it (this is possible only if “Edit”=AE).

These keys change the value one digit at a time but if they are

pressed for more than one second, the value increases or

decreases rapidly and, after two seconds in the same condition, the

changing speed increases in order to allow the desired value to be

reached rapidly.

Once the desired value has been reached, by pushing key P it is

possible to exit by the fast programming mode or it is possible to

visualise the other alarm thresholds.

To exit the fast alarm thresholds programming it is necessary to

push key P, after the visualisation of the last threshold, or

TECNOLOGIC spa - TLV 38 - OPERATING INSTRUCTIONS - Vr. 01 - ISTR 06612 - PAG. 2

alternatively, if no key is pressed for approx. 15 seconds, the

display will return to normal functioning automatically.

3 - INFORMATION ON INSTALLATION AND US

E

3.1 - PERMITTED USE

The instrument has been projected and

manufactured as a measuring and control device to

be used according to EN61010-1 for the altitudes

operation until 2000 ms.The use of the instrument

for applications not expressly permitted by the

above mentioned rule must adopt all the necessary protective

measures. The instrument CANNOT be used in dangerous

environments (flammable or explosive) without adequate

protection. The installer must ensure that EMC rules are respected,

also after the instrument installation, if necessary using proper

filters. Whenever a failure or a malfunction of the device may cause

dangerous situations for persons, thing or animals, please

remember that the plant has to be equipped with additional devices

which will guarantee safety.

3.2 - MECHANICAL MOUNTING

The instrument, in case 33 x 75 mm, is designed for flush-in panel

mounting. Make a hole 29 x 71 mm and insert the instrument, fixing

it with the provided special bracket. We recommend that the gasket

is mounted in order to obtain the front protection degree as

declared. Avoid placing the instrument in environments with very

high humidity levels or dirt that may create condensation or

introduction of conductive substances into the instrument. Ensure

adequate ventilation to the instrument and avoid installation in

containers that house devices which may overheat or which may

cause the instrument to function at a higher temperature than the

one permitted and declared. Connect the instrument as far away as

possible from sources of electromagnetic disturbances such as

motors, power relays, relays, solenoid valves, etc.

3.3 - ELECTRICAL CONNECTION

Carry out the electrical wiring by connecting only one wire to each

terminal, according to the following diagram, checking that the

power supply is the same as that indicated on the instrument and

that the load current absorption is no higher than the maximum

electricity current permitted. As the instrument is built-in equipment

with permanent connection inside housing, it is not equipped with

either switches or internal devices to protect against overload of

current: the installation will include an overload protection and a

two-phase circuit-breaker, placed as near as possible to the

instrument, and located in a position that can easily be reached by

the user and marked as instrument disconnecting device which

interrupts the power supply to the equipment. It is also

recommended that the supply of all the electrical circuits connected

to the instrument must be protect properly, using devices (ex.

fuses) proportionate to the circulating currents. It is strongly

recommended that cables with proper insulation, according to the

working voltages and temperatures, be used. Furthermore, the

input cable of the probe has to be kept separate from line voltage

wiring. If the input cable of the probe is screened, it has to be

connected to the ground with only one side. Whether the

instrument is 12 V version it’s recommended to use an external

transformer TCTR, or with equivalent features, and to use only one

transformer for each instrument because there is no insulation

between supply and input. We recommend that a check should be

made that the parameters are those desired and that the

application functions correctly before connecting the outputs to the

actuators so as to avoid malfunctioning that may cause

irregularities in the plant that could cause damage to people, things

or animals.

Tecnologic S.p.A. and its legal representatives do not assume

any responsibility for any damage to people, things or animals

deriving from violation, wrong or improper use or in any case

not in compliance with the instrument’s features.

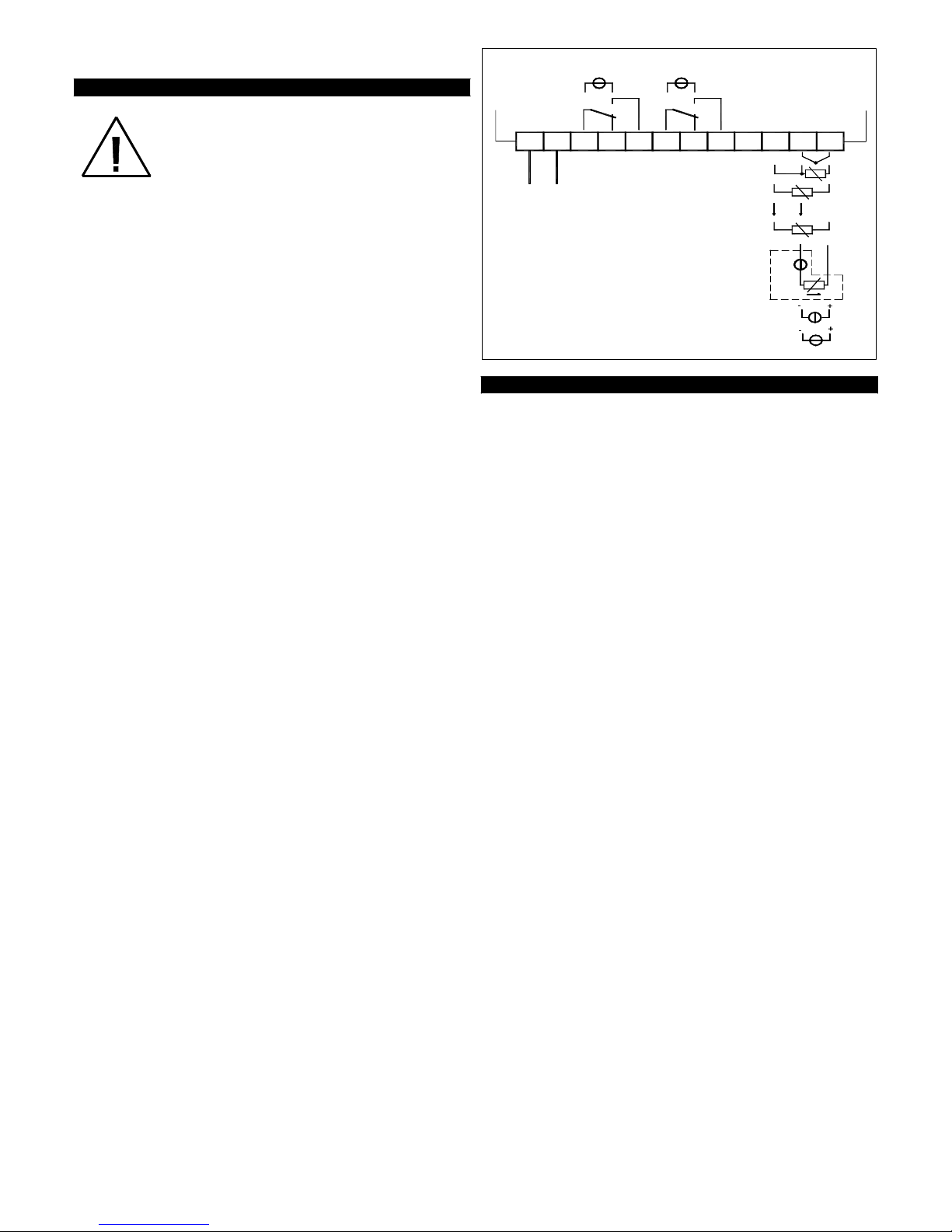

3.4 - ELECTRICAL WIRING DIAGRAM

-

+

+

-

TLV38

INP U T

SUPPL Y

0...1 V

ACTIVE

0/4..20 mA

0..50/60 mV

0/1..5 V

0/2..10 V

ACTIVE

PASSIVE

(2 w ires)

4..20 mA

4..20 mA

OUT 12 VDC

Max 20 mA

gen.

ext.

RELAY

1 23

C

SSR

SSR : 8 m A / 8 V DC

RELAYS: 8A-AC1 (3A-AC3) 250 VAC

7

OUT 1

NC4NO

5 6 98 10

PTC

NTC

I

+

Pt100

11+12

TC

+

-

+

-

+

NONCC

+

-

OUT 2

4 - FUNCTIONS

4.1 - MEASURING AND VISUALIZATION

All the parameters referring measurements are contained in the

group “

]

InP”.

Depending on the model required the input accept:

C: Thermocouples temperature probes (J,K,S and TECNOLOGIC

IRS Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermoresistances PT100.

E : Thermocouples temperature probes (J,K,S and TECNOLOGIC

IRS Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermistors PTC and NTC.

I : normalized analogue signals 0/4..20 mA

V : normalized analogue signals 0..1 V, 0/1..5 V, 0/2..10 V

Depending on the model, using par. “SEnS”, it’s possible to select

the type of input probe, which can be :

- for thermocouples J (J), K (CrAL), S (S) or for infrared sensors

serie TECNOLOGIC IRTC1 with linearization J (Ir.J) or K (Ir.CA)

- for thermoresistances Pt100 IEC (Pt1) or thermistors PTC

KTY81-121 (Ptc) or NTC 103AT-2 (ntc)

- for normalised signals in current 0..20 mA (0.20) or 4..20 mA

(4.20)

- for normalised signals in tension 0..1 V (0.1), 0..5 V (0.5), 1..5 V

(1.5), 0..10 V (0.10) or 2..10 V (2.10).

- for normalised signals in tension 0..50 mV (0.50), 0..60 mV (0.60),

12..60 mV (12.60).

We recommend to switch on and off the instrument when these

parameters are modified, in order to obtain a correct measuring.

For the instruments with input for temperature probes (tc, rtd) it’s

possible to select, through par. “Unit”, the unit of measurement

(°C, °F) and, through par. “dP” (Pt100, PTC and NTC only) the

desired resolution (0=1°; 1=0,1°).

Instead, with regards to the instruments with normalised analogue

input signals, it is first necessary to program the desired resolution

on par. “dP” (0=1; 1=0,1; 2=0,01; 3=0,001) and then, on par.

"SSC", the value that the instrument must visualise at the

beginning of the scale (0/4 mA, 0/12 mV, 0/1 V o 0/2 V) and, on

par. "FSC", the value that the inst rument must visualise at the end

of the scale (20 mA, 50 mV, 60 mV, 5 V or 10 V).

Only for the instruments with normalized signals input, the

parameters "SSC" and "FSC" determines the measurement range

and the parameter “0.Pot” determ ines the zero value (inside the

range “SSC” ... “FSC”).

Always for the instruments with normalized signals input it is

possible to effect the input setting through auto-ranging (see

functioning of key “U”) in this case the values of the parameters

"SSC", "FSC" and "0.Pot" are automatically calculated by the

instrument.

TECNOLOGIC spa - TLV 38 - OPERATING INSTRUCTIONS - Vr. 01 - ISTR 06612 - PAG. 3

Loading...

Loading...