Tecnocontrol Beta SE330K, Beta SE333K Series, Beta SE330KM, Beta SE330KG, Beta SE333KM Series Manual

...Page 1

GAS LEAK DETECTOR FOR DOMESTIC USE WITH

INTERCHANGEABLE SENSOR

at a maximum distance of 30 cm from the ceiling; in the case of Beta

SE330KG and Beta SE333KG LPG gas detectors, at a maximum height of

30 cm above the floor.

- At a distance of between 1 and 4 metres from the gas appliance (cooker,

boiler, etc.). If possible, in every room where there is a gas appliance and,

in the case of multi-storey buildings, at least one on each floor.

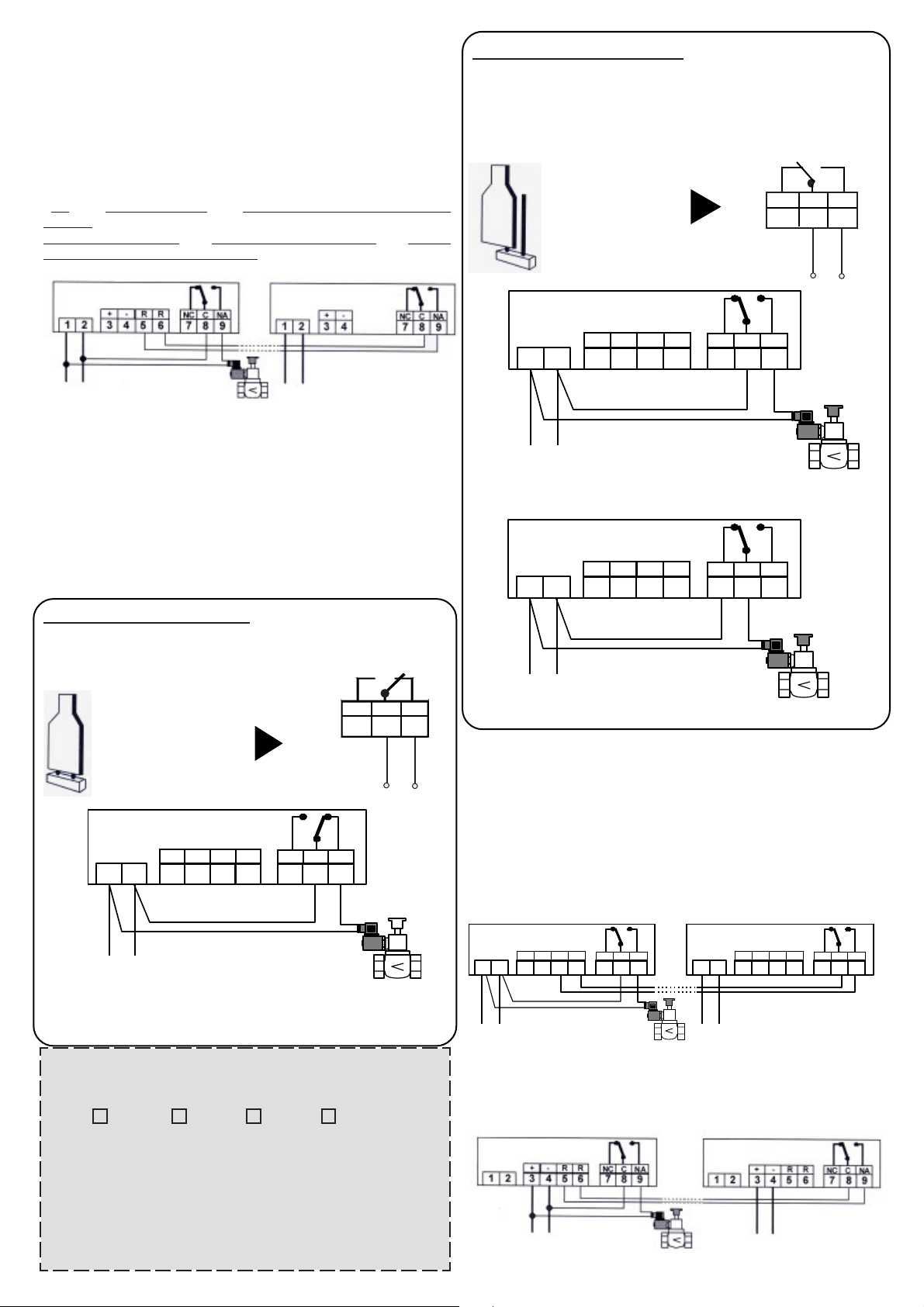

series Beta model SE330K

series Beta model SE333K

Model Detected gas Logic Power supply

SE330KM Methane Neg.

SE330KG L.P.G. Neg.

SE333KM Methane Pos.

SE333KG L.P.G. Pos.

Sensor module

Code

ZSDM1 METHANE SE330KM/SE333KM

ZSDG1

Detected gas

L.P.G. SE330KG/SE333KG

GENERAL DESCRIPTION

The Beta SE330K and SE333K gas detectors are methane or LPG control

units with LEDs and a buzzer that warn of the presence of gas in the

room. They are designed to be operated either directly or in remote mode.

The Beta detectors are calibrated to detect gas at 10% of the LEL (Lower

Explosive Limit); this threshold can vary according to environmental

conditions but will not exceed 15% of the LEL within the first five years of

use. The Sensor module must be replaced at the end of these five years or

if the “FAULT” LED turns on.

There is a label on the cover that should state the expiry date (5 years

after the date of installation); this label must be compiled by the person

who installs the detector, at the time of installation.

LEDS AND BUZZER

There are three LEDs on the front of each detector:

230Vac 50Hz /

12Vdc

Beta

30cm

max

1-4m

Methane gas

detector

The instrument MUST NOT BE INSTALLED:

- Directly above the sink or gas appliance.

- In small rooms where alcohol, ammonia, spray cylinders or other

substances based on volatile solvents might be used.

- In closed environments or corners where there is no free circulation of

air.

- Near walls or other obstacles that could prevent the flow of gas from the

appliance to the detector, or extractors and fans that could divert the flow

of air.

- In environments where the temperature could exceed 40°C or fall below

– 5°C.

1-4m

30cm

max

L.P.G. gas

detector.

INSTALLATION INSTRUCTIONS

Use a screwdriver to undo the screw on the right-hand side of the

instrument and lift the cover (Fig 1).

Fig.1

Position the base correctly and fasten it on the built-in 3-module box or on

the wall, using the screws and dowels provided.

ELECTRICAL CONNECTION: POWER SUPPLY

Attention: undertrack cables are required to connect the instrument to the

mains.

The gas detector must be powered at 230 Vac using terminals 1 and 2, or

at 12Vdc using terminals 3 (+) and 4 (-). (Fig. 2).

- GREEN LED (ON): indicates the instrument is powered.

- YELLOW LED (FAULT) + BUZZER: Indicates the sensor is broken.

- YELLOW LED (FAULT) blinking only: indicates the CO sensor

needs to be replaced.

- RED LED (ALARM): indicates the concentration of gas in the

air is above the alarm threshold.

If the gas sensor is defective, the buzzer will make a noise at a rate of

every two seconds, turning on the yellow LED and relay output.

In the event of an alarm, the red LED turns on and the buzzer and relay are

activated twenty seconds later.

LIGHTING DELAYS

After the detector is turned on, the catalytic sensor in the detector takes

about a minute to warm up, during which time the green LED blinks to

indicate the alarm is disabled.

INSTALLATION

Attention: the instrument must be installed and put out of service by a

specialized technician.

Your gas supply and any shut-off devices must be installed in conformity

with the domestic laws in force.

INSTALLING THE INSTRUMENT

The instrument MUST BE INSTALLED:

- In the case of Beta SE330KM and Beta SE333KM methane gas detectors,

1 2

3

4

+ -

Fig.2

A circuit breaker must be fitted that is able to disconnect the detector from

the power supply, with a contact distance of at least 3 mm, in accordance

with the European standard IEC EN 60335-1.

230Vac

CHARACTERISTICS OF THE OUTPUT SIGNAL

The Beta SE330K and SE333K control units have an output relay with

voltage-free contacts; the rating of the contacts is 8A 250Vac/30Vdc.

GENERAL TERMS OF THE GUARANTEE

THIS CERTIFICATE IS THE ONLY DOCUMENT THAT ENTITLES

YOU TO REPAIR OF THE PRODUCT UNDER THE TERMS OF

- The product is GUARANTEED for a period of 24 months from the date

of purchase.

- The GUARANTEE does not cover damage caused by tampering,

incorrect or improper use and installation.

- The GUARANTEE is valid only if it is duly compiled.

- In the event of defects covered by the GUARANTEE, the manufacturer

will repair or substitute the product free of charge.

SERVICING AFTER THE GUARANTEE PERIOD:

Any repairs after the period of the GUARANTEE will be charged on the

basis of the parts substituted and the cost of labour.

12Vdc

THE GUARANTEE.

Page 2

CONNECTION OF THE ELECTRIC VALVE AND

NA C NC

R R

+ -

1 2 3

5 4 6 7 8 9

N

A C N

C

R R + -

1 2 3

5 4 6 7 8 9

N

A C N

C

R R

+ -

1 2 3

5 4 6 7 8 9

NA C NC R R + -

1 2 3 5 4 6 7 8 9

NA C NC R R + -

1 2 3 5 4 6 7 8 9

REMOTE SENSORS

The Beta SE330K and SE333K control units each have two terminals (5-

6) active when closed, for connecting the following remote detectors (Fig. 3):

for METHANE gas: model SE195KM or model SE396KM.

for LPG gas: model SE195KG or model SE306KG.

If the remote sensors are not connected to terminals 5 and 6, these must

not be modified, and therefore kept disconnected at all times.

Do not forget that the electric valve must be installed on the gas pipe

outside the room to be controlled as it cannot protect against leaks upstream.

The Beta SE330/SE333 + Beta SE330/SE333 configuration is IMQ

certified.

The other configurations, Beta SE330/SE333 + SE195 K and Beta SE330/

SE333 + SE396K are not IMQ certified.

SE330K SE396K

N.O. manual

230Vac - 50Hz 230Vac - 50Hz

Fig. 3 Example of connection of a remote sensor.

The Beta SE396K detector is not IMQ certified but complies fully with

standard IEC UNI EN 50194.

reset valve

POSITIVE LOGIC – NEGATIVE LOGIC

The Beta SE330K and SE333K gas detector can control an electric valve

using two different logics:

1 – POSITIVE LOGIC (SE333K)

2 – NEGATIVE LOGIC (SE330K)

The J2 JUMPER allows you to select the one required.

N.B. The J2 JUMPER is set by default to NEGATIVE LOGIC (SE330K).

NEGATIVE LOGIC (SE330K): in this case, the coil of the relay is

kept deactivated (Fig. 6).

It is perfect for N.O. (normally open) electric valves (Fig. 7) or N.C.

(normally closed) electric valves (Fig. 8).

In the event of an alarm, contacts 8 and 9 remain closed until the

alarm stops.

230Vac/50Hz

Fig.7

J2 JUMPER IN

“NEGATIVE LOGIC”

POSITION

SE330K

Normally open

SE330K

NC C NA

7 8 9

Fig.6

EV

POSITIVE LOGIC (SE333K): in this case, the coil of the relay is

always live (Fig. 4) to ensure the inherent safety of the relay.

It is perfect for N.C. (normally closed) electric valves (Fig. 5).

In the event of an alarm, contacts 7 and 8 remain closed until the

alarm stops.

NA C NC

J2 JUMPER IN

“POSITIVE LOGIC”

POSITION

EXAMPLE OF APPLICATION WITH N.C. ELECTRIC VALVE SE333

SE333K

EV

Fig.5

230Vac/50Hz

ATTENTION: If there is a temporary loss of power during operation with

positive logic, the N.C. valve closes automatically and will need to be reset

manually when power is restored.

Normally close

7 8 9

Fig.4

EV

Normally close

230Vac/50Hz

Fig.8

ELECTRICAL CONNECTION WITH SEVERAL

DETECTORS:

Connection of two detectors with a single electric valve is shown in the

diagrams below. It is possible to connect more than two detectors, repeating

the same connections.

SE330K

Connection with Normally Open manual reset electric valve (with relay

normally deactivated) and a second SE330K detector.

SE330K SE330K

230Vac 50Hz 230Vac 50HzNO GAS GAS EV

GUARANTEE CERTIFICATE

TO COMPILE AND SEND IN CASE OF DAMAGE

DEVICE: SE330KM SE330KG SE333KM SE333KG

Serial number (s.n.)_________________________________________

DEALER

Stamp: Date of purchase:

USER

Surname and name _________________________________________

Address _____________________________________ n°__________

Postcode ________________ Town/city ________________________

Telephone_________________________________________________

_____/_____/_____

Connection with 12 Vdc Normally Open manual reset electric valve (with

relay normally deactivated) and a second SE330K detector.

SE330K

12Vdc 12Vdc

NO GAS GAS EV 12Vdc

SE330K

Page 3

N

A C N

C R R + -

1 2 3 5 4 6 7 8 9

N

A C N

C R R + -

1 2 3 5 4 6 7 8 9

Connection with Normally Closed manual reset electric valve (with relay

SE333K

normally activated) and a second SE333K detector.

LOWER EXPLOSIVE LEVEL (L.E.L.)

You need to use a calibration cylinder with sample gas to test correct

operation of the sensor.

SE333K SE333K

230Vac 50Hz 230Vac 50HzNCGAS GAS EV

Connection with 12 Vdc Normally Closed manual reset electric valve (with

relay normally activated) and a second SE333K detector.

SE333K SE333K

12Vdc 12Vdc

NC GAS GAS EV 12Vdc N.C.

OPERATION TEST

In the case of the Beta SE330K and SE333K models, before carrying out

the operation test, open the cover under the three LED lights (Fig. 9) with

a flat-headed screwdriver.

If you wish to recreate the dangerous conditions the gas sensor is meant

to protect against, do not use the gas of normal domestic appliances. Our

detectors are calibrated at 10% of the LEL (lower explosive level).

Here is a simple explanation: as an example, a kitchen measures 3 metres

in width, 4 metres in length and 3 metres in height.

- The volume of the kitchen is equivalent to 4 x 3 x 3, and therefore 36 m³

or 36,000 litres.

There is a dangerous mix when methane accounts for 5% of the volume of

the kitchen.

- This 5% is called the LEL (lower explosive limit).

- In this case, 5% of 36,000 litres is 1800 litres (LEL).

- Our detectors, being IMQ certified, are activated at 10% of the LEL and

therefore at 10% of 1800 litres which, in this case, is 180 litres, AT ONE

TENTH OF THE LOWER EXPLOSIVE LIMIT (LEL).

Taking into account the fact that a domestic hob has a nozzle a few tenths

of a millimetre in length and that the pressure is just a few millibars, it would

take several hours to produce 180 litres of methane (and trigger the sensor).

Even if the nozzle is larger, the very particular and strong odour of methane

would make it impossible for anyone in the room not to notice and realise

the serious danger, even when the amount of methane in the room is too

little to cause an explosion.

REPLACING THE SENSOR

N.B. The Sensor module must be replaced by a specialized

technician.

The sensor module should be replaced no more than TWICE, for a

total product life-span of 15 years.

Fig.9

When this is done, it is possible to test operation of the instrument by

pressing and holding the little TEST button on the Sensor module (Fig.

10) of the Beta SE330K and SE333K control unit for at least 2 seconds,

or the button on the card of the Beta SE396K remote detector, if connected,

for at least 30 seconds.

All the LEDs turn on and the buzzer and relay output are activated for 5

seconds.

Fig.10

Replace the Sensor module if the “FAULT” LED starts blinking, or by the

expiry date on the label on the cover.

Replace the label on the cover stating the expiry date (5 years after the

date of installing the new sensor module); this label must be compiled by

the person who installs the detector at the time of replacing the sensor

module.

SENSOR MODULE

Code

ZSDM1 Methane SE330/SE333KM

ZSDG1 L.P.G. SE330/SE333KG

N.B. Make sure the code of the new Sensor module

matches the code on the Sensor module to be replaced.

Detected gas

1_Turn off the detector, unplug it

from the mains and use a

screwdriver to lever off the little

cover under the three LEDs (Fig.

11).

Model

You will then need to re-engage the electric valve connected to the output

of the gas detector (if present).

ROUTINE TESTING

You are advised to ask the installer to give the detector a general test at

least once a year.

IMPORTANT: Do not use pure gas, such as that in a lighter,

directly on the sensor since the sensor could be irremediably

damaged.

Fig.11

2_Undo the two screw

fasteners on the Sensor

module to be replaced (Fig. 12).

Fig.12

Page 4

4_Check the new Sensor

module is compatible with

the one to be replaced (if

the sensor module is not

compatible, the YELLOW

LED and BUZZER turn on)

and carefully insert the 4

connectors in the correct

place.

Fig.14

3_Remove the Sensor

module to be replaced (Fig.

13).

Fig.13

5_Fasten the Sensor module with the

two screws and close the cover, first

inserting the two tabs at the bottom

(Fig. 15). The instrument can now be

turned on.

WARNING

Remove any dust on the surface of the instrument with a cloth. Do not

attempt to open or dismount the gas detector since this could result in

electric shock and damage to the product. Bear in mind that the sensor is

also sensitive to commonly used products such as sprays, detergents,

alcohol, glue and paint. These products can contain substances which, in

high quantities, could trigger the sensor and cause false alarms.

It is advisable to ventilate the room when using these products.

Do not forget that the detector cannot detect leaks outside the room in

which it is installed or leaks in the walls or under the floor. The gas (methane

or LPG) contains an additive that gives it an unpleasant odour, to make it

easy to detect by smell. If a ring on a gas hob is left on without being lit,

even for several minutes, the amount of gas will not be sufficient to trigger

the alarm of the detector (even though it can be clearly smelt). In fact, the

amount of gas in the room could be under the alarm threshold.

The detector does not work when there is a power cut.

TECHNICAL CHARACTERISTICS

- Power supply 230Vac, 50 Hz / 12 Vcc 2.5W

- Power consumption 20mA max

- Operation temperature -10°C…. +40°C

- Relative humidity 30%…. 90% RH

- Alarm threshold at 10% of the LEL (lower explosive limit) of the gas.

- Warming up period after the instrument is switched on:

about 1 minute

- Acoustic level of buzzer: 85 dB (A) at 1 metre

- Electronic self-diagnosis with signal to indicate malfunction.

- Rated to IP42

- Remote unit input

- Conforms to standard IEC UNI EN 50194

Fig.15

After the instrument is turned on, the catalytic sensor in the detector takes

about a minute to ‘warm up’, during which time the green LED blinks to

indicate the sensor is warming up and the detector is not operational.

ATTENTION! In the event of an alarm:

1) Put out all naked flames.

2) Close the valve on the gas meter or LPG cylinder.

3) Do not turn any of the lights on or off; do not use any electrical

appliances or devices.

4) Open the doors and windows to increase ventilation in the

room.

If the alarm stops, find the cause and take appropriate action.

If the alarm continues and you cannot find and eliminate the

cause of the leak, vacate the premises and, when you are

outside, contact the gas emergency service.

TO BE COMPILED BY THE INSTALLER:

Date of installation ________________________________________

Date of replacement ______________________________________

Attention: the detector must be replaced 15 years after the

date of installation on this voucher

Site of installation _________________________________________

Serial number (s.n.) _______________________________________

(Written on the inside of the plastic container).

Date of initial replacement of sensor module:____________________

Date of second replacement of sensor module:__________________

Attention: the entire detector must be replaced five years

after second replacement of the sensor module.

Stamp

Signed ________________

Tecnocontrol Srl via Miglioli, n°47 20090 Segrate (Milano) Italy

Tel. +39 02 26922890 Fax +39 02 2133734

www.tecnocontrol.it E-mail: info@tecnocontrol.it

La Tecnocontrol s.r.l. reserves the right to make any aesthetic or functional modification to the without prior notice at any time.

dis.0134152a cod.2.710.2335 Made in Italy

Loading...

Loading...