Tecnoclima BESST 22, BESST 31, 3TRITFR006, BESST 32, BESST 11 Technical Information Assembly, Use And Maintenance Instructions

...

TECHNICAL INFORMATION ASSEMBLY, USE AND

MAINTENANCE INSTRUCTIONS

Reversible heat pumps

BESST - BESST/R SERIES

Dear Customer,

We thank you for preferring one of our machines, an innovative, modern and high-quality product which will ensure you

wellness, noiselessness and safety for a long time, especially if you rely on TECHNOCLIMA Technical Support Service

which is specifically instructed and trained to maintain your unit at the maximum efficiency level with lower operating costs

and which has

original spare parts available in case of need.

This instruction manual contains important indications and suggestions which must be followed for a simpler installation and

the best possible use of the unit.

Thank you once again,

Tecnoclima S.p.A

CONFORMITY

Reversible heat pumps:

• Machinery Directive

• Low Voltage Directive 73/23/CEE;

• Pressure Equipment Directive 97/23/EEC. Module A1

• Electromagnetic Compatibility Directive 89/336/EEC.

98/37/CEE;

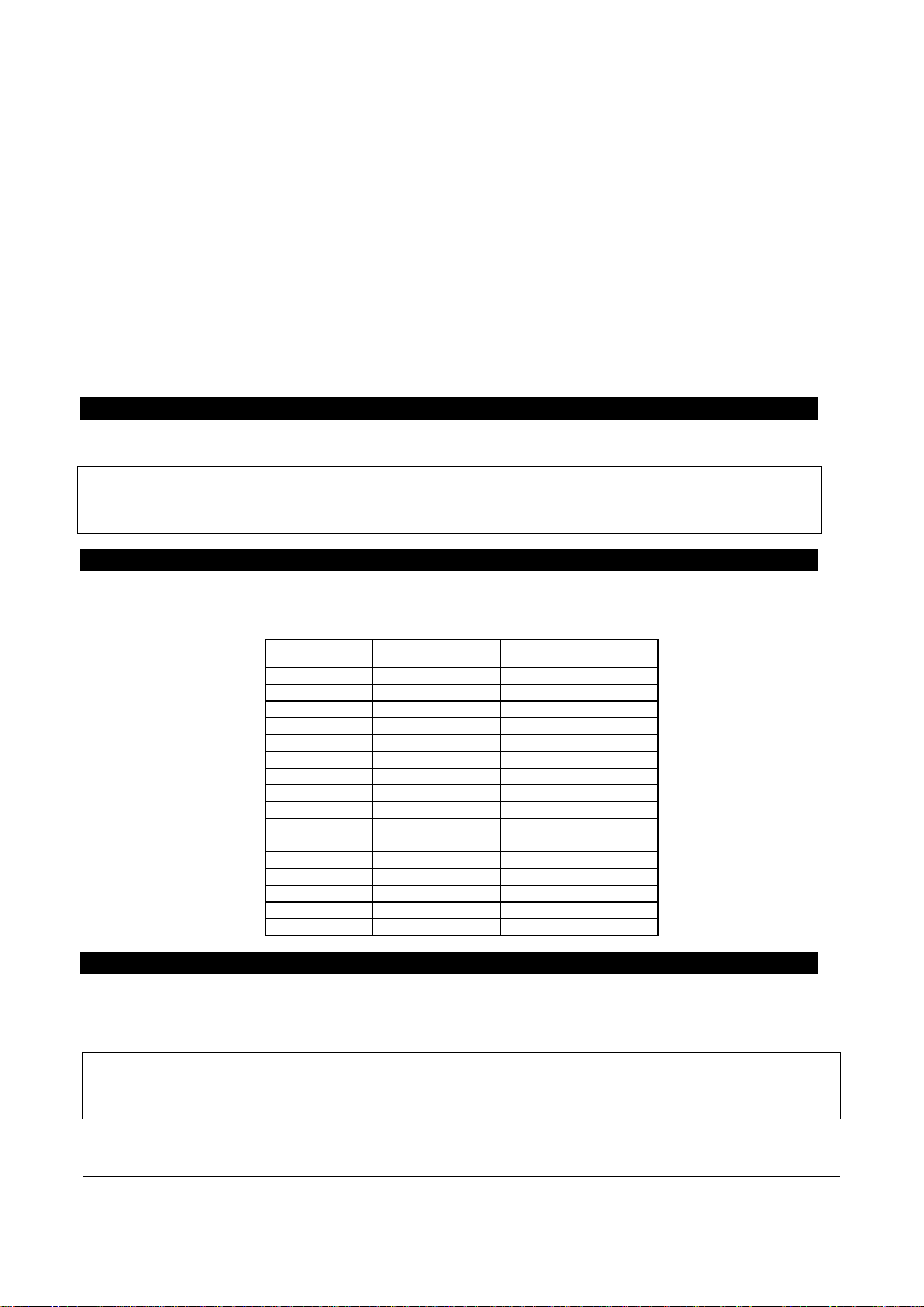

RANGE

This manual makes reference to the TYPES of module. The following table shows the TYPES and their matching

COMMERCIAL NAMES.

TYPE MODEL CODE

1 BESST 11 3TRITFR006

2 BESST 12 3TRITFR008

3 BESST 21 3TRITFR009

4 BESST 22 3TRITFS015

5 BESST 31 3TRITFS018

6 BESST 32 3TRITFS020

7 BESST 41 3TRITFS027

8 BESST 42 3TRITFS036

9 BESST/R 11 3TRITFL006

10 BESST/R 12 3TRITFL008

11 BESST/R 21 3TRITFL009

12 BESST/R 22 3TRITFM015

13 BESST/R 31 3TRITFM018

14 BESST/R 32 3TRITFM020

15 BESST/R 41 3TRITFM027

16 BESST/R 42 3TRITFM036

WARRANTY

The unit is covered by a SPECIFIC WARRANTY, taking effect from the purchase date which must be proved by the user.

Should he not be able to prove it, the warranty will take effect from the appliance manufacture date. The warranty conditions

are detailed in the WARRANTY CERTIFICATE provided with the equipment.

MAKE SURE this instruction manual IS ALWAYS KEPT TOGETHER WITH THE APPLIANCE, so that the user, installer

and maintenance qualified personnel can refer to it.

If you sell or transfer the appliance to another proprietor or if you move and leave the appliance, make sure that the

instruction manual always accompanies the unit, so that the new proprietor and/or installer can refer to it.

This manual comprises 40 pages.

2

TABLE OF CONTENTS

GENERAL

CONFORMITY................................................................................................................................................................... 2

RANGE...............................................................................................................................................................................2

WARRANTY.......................................................................................................................................................................2

GENERAL DIRECTIONS...................................................................................................................................................4

FUNDAMENTAL SAFETY RULES..................................................................................................................................... 5

EQUIPMENT DESCRIPTION............................................................................................................................................. 6

TECHNICAL DATA - WEIGHTS.........................................................................................................................................7

ELECTRIC BOARD AND MULTIFILAR WIRING DIAGRAM.............................................................................................. 9

COOLING CIRCUIT......................................................................................................................................................... 14

ACCESSORIES............................................................................................................................................................... 15

CONTROL PANEL...........................................................................................................................................................15

FAULT INDICATIONS...................................................................................................................................................... 17

SYSTEM MANAGER

SWITCHING ON AND OFF.............................................................................................................................................. 17

INACTIVITY FOR A LONG PERIOD INACTIVITY FOR A LONG PERIOD...................................................................... 19

CL CLE CLEANING ......................................................................................................................................................... 19

MAINTENANCE............................................................................................................................................................... 19

USEFUL INFORMATION.................................................................................................................................................19

INSTALLER

UPON RECEIVING THE PRODUCT ............................................................................................................................... 20

HANDLING AND TRANSPORT....................................................................................................................................... 20

LOCATION....................................................................................................................................................................... 21

HYDRAULIC CONNECTIONS......................................................................................................................................... 22

DIMENSIONS................................................................................................................................................................... 23

ELECTRICAL CONNECTIONS ........................................................................................................................................ 25

ENABLING THE “SO” AND “SEI” CONTROLS”............................................................................................................... 29

FILLING AND EMPTYING THE SYSTEM........................................................................................................................ 29

RECOMMENDED WORKING CONDITION S........... ........................................................................................................ 30

WORKING LIMITS....................................................................................................... ....................................................30

PREPARETION

PREPARATION FOR FIRST COMMISSIONING............................................................................................................. 31

FIRST COMMISSIONING................................................................................................................................................31

SWITCHING THE EQUIPMENT ON AND OFF............................................................................................................... 32

DEFROSTING CONTROL...............................................................................................................................................35

CHECKS DURING AND AFTER THE FIRST COMMISSIONING.................................................................................... 35

INACTIVITY FOR A LONG PERIOD................................................................................................................................35

ORDINARY MAINTENANCE...........................................................................................................................................35

EXTRAORDINARY MAINTENANCE ............................................................................................................................... 36

COMPRESSOR ............................................................................................................................................................... 36

CONTROL AND DISPLAY PARAMETERS......................................................................................................................36

TROUBLESHOOTING..................................................................................................................................................... 38

Symbols with the following meanings are used in some parts of the manual:

CAUTION = For actions requiring special care and adequate training.

FORBIDDEN = For actions which SHOULD NEVER be done.

3

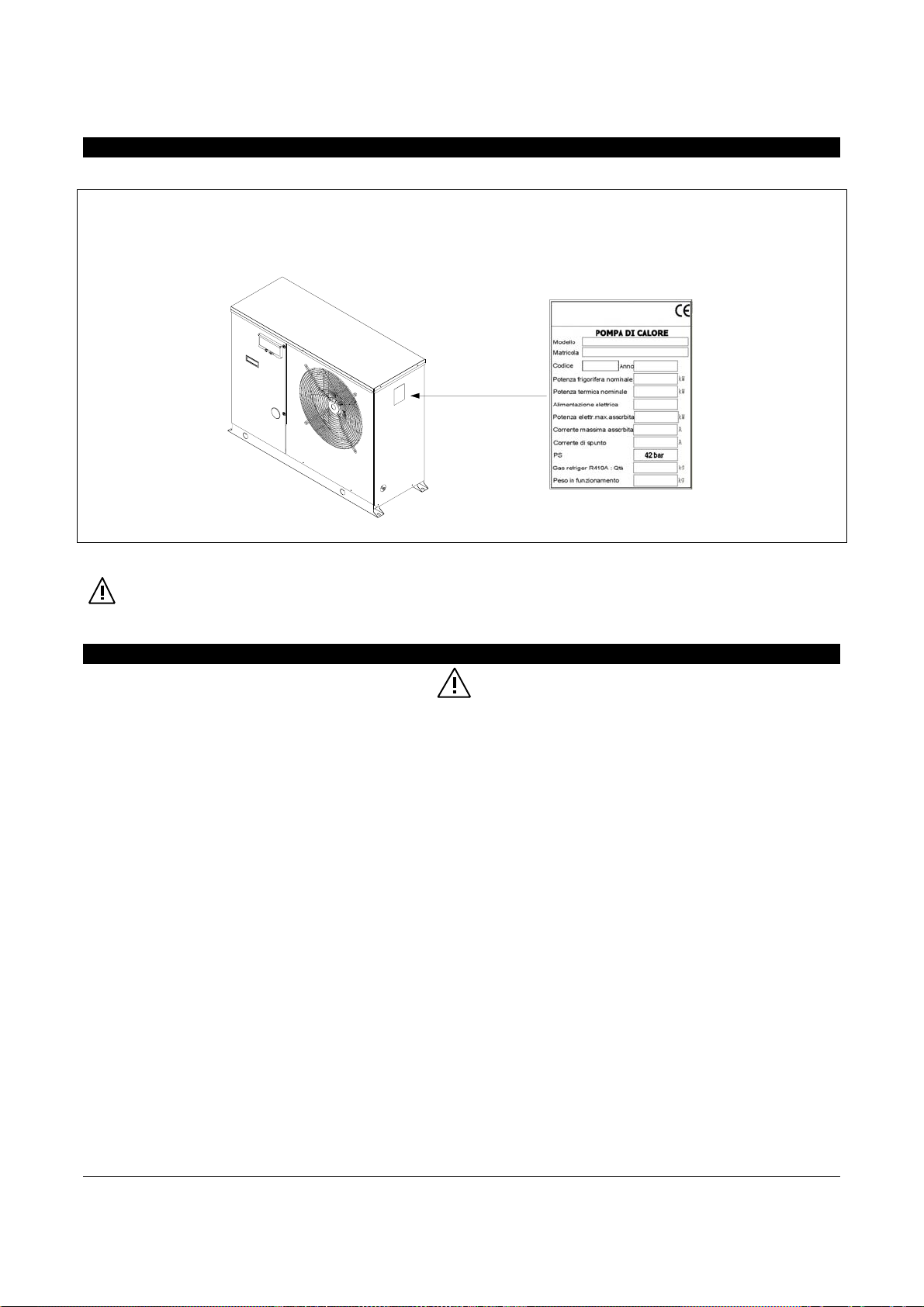

IDENTIFICATION

The unit can be identified through:

- - Rating plate

It bears the technical and performance data of the equipment.

Should this plate be damaged or mislaid, ask your local Technical Support Service for a duplicate.

Tampering with the rating plate, removing it or whatever else does not allow a sure identification of the product hinder

any installation or maintenance interventions.

GENERAL DIRECTIONS

After unpacking the appliance, check it for integrity and completeness. Should the content not match your order, please contact the retailer

who sold the equipment.

The equipment must be installed by a qualified company which, at the end of the work, must provide the proprietor with a declaration of

conformity stating that the installation complies with the best practice and the applicable national and local regulations, as well as the

indications of this instruction manual.

These appliances were made for room air heating and/or conditioning and must be destined for this use consistently with their performance

characteristics.

The manufacturer does not assume any contractual or extra-contractual liability for damages caused to people, animals or things by

installation, adjustment and maintenance errors or improper use.

In case of water leakage, turn OFF the main system circuit breaker and close the water taps.

Immediately call the Technical Support Service or professionally qualified personnel and do not personally intervene on the equipment.

The appliance contains refrigerant gas R 410A; act carefully in order not to damage the gas circuit and the finned coil. In case of refrigerant

leakage, turn OFF the main system circuit breaker. Immediately call the Technical Support Service or professionally qualified personnel and

do not personally intervene on the equipment.

The appliances must be exclusively equipped with original accessories. The manufacturer is not responsible for any damages resulting from

the improper use of the appliance and the use of non-original accessories and materials.

The references to laws, regulations, directives and technical standards mentioned in this manual have a mere informational purpose and are

valid at the printing date of the same. The manufacturer cannot be bound towards third parties on account of new regulations or

amendments to those already in force.

The installations to be made (gas piping, electric power supply, etc.) must be adequately fixed and avoid the risk of stumbling.

The manufacturer is responsible for the conformity of his product to the laws, directives and standards which were in force at the time of

marketing.

The knowledge and observance of regulations and standards about the system designing, installation, operation and maintenance are at the

exclusive charge of the designer, installer and user according to their spheres of competence.

4

The manufacture is not held responsible for the non-observance of the instructions contained in this manual, for the consequences of an y

unexpected operation or for any translations from which wrong interpretations may arise.

This appliance must be installed in accordance with the applicable national and local regulations and must be only used in a sufficiently

ventilated environment. Carefully read the instructions before installing and operating this equipment.

Should the unit be connected in parallel to a boiler, close the chiller cocks during the boiler operation.

The temperature of the circulating water inside the chiller should never exceed 60°C.

If you are not going to use the equipment for a long time, please do the following:

– Turn OFF the main system circuit breaker

– Close the water taps

– If there is danger of freezing, make sure an antifreeze liquid has been added to the system, otherwise empty the system

This instruction manual is an integral part of the appliance, therefore it must be kept with care and ALWAYS accompany the appliance if it is

transferred to another proprietor or user or moved to another system.. Should this manual be damaged or mislaid, ask your local Technical

Support Service for a new copy.

The repair or maintenance work must be carried out by the Technical Support Service or qualified personnel according to the prescriptions of

this manual. Do not alter or tamper with the appliance as this may lead to dangerous situations, and the manufacturer of the ap pliance will

not be held responsible for any damages caused.

.

Under adverse visibility conditions, use lighting devices enabling a perfect vision of all parts and components.

The refrigerant fluid contained in the refrigerating circuit is R-410A and it is not classified as dangerous in accordance with directive

1999/45/EC and relevant amendments.

Avoid high steam concentrations which may cause headache, vertigo, somnolence, nausea and other troubles.

In case of skin contact with the liquid, there is a residual risk of freezing through fast evaporation. Seek medical advice.

In case of inhalation, breath fresh air. Administer oxygen if breathing is difficult. Seek medical advice.

In case of eye contact, immediately flush with running water for at least 15 minutes. Seek medical advice.

The refrigerant fluid must be disposed of through authorized waste-disposal companies. In any case, the fluid must be recovered in proper

storage tanks.

FUNDAMENTAL SAFETY RULES

We remind you that the use of products using electric power, gas or gas oil entails the observance of some fundamental safety

rules, like the following:

The use of the appliance by children and unattended disabled people is prohibited.

Do not touch the appliance while barefoot and with wet or humid body parts

Do not perform any cleaning or maintenance before disconnecting the appliance from the mains (by turning OFF the main system circuit

breaker).

The safety and setting devices should not be altered without the appliance manufacturer’s consent and indications

Do not pull, tear or twist the electrical cables on the appliance, although this is disconnected from the mains.

Do not insert sharp objects through the air intake and supply grilles.

Do not open the equipment’s internal part access doors without first turning off the main system circuit breaker.

Do not abandon or leave to the children’s reach the packing material (cardboard, iron bands, plastic bags, etc.) as this is a potential source

of danger.

Do not install the appliance in environments with an aggressive atmosphere

Do not place any objects onto the equipment, nor slide them through the grille.

Do not use any adapters, multiple-outlet sockets or extensions for the electrical connection of the appliance.

Do not distribute this product in different countries, since it must be modified as to technical documentation and layout.

Do not perform any maintenance before disconnecting the appliance from the mains (by turning OFF the main all-pole system circuit

breaker).

.

.

.

5

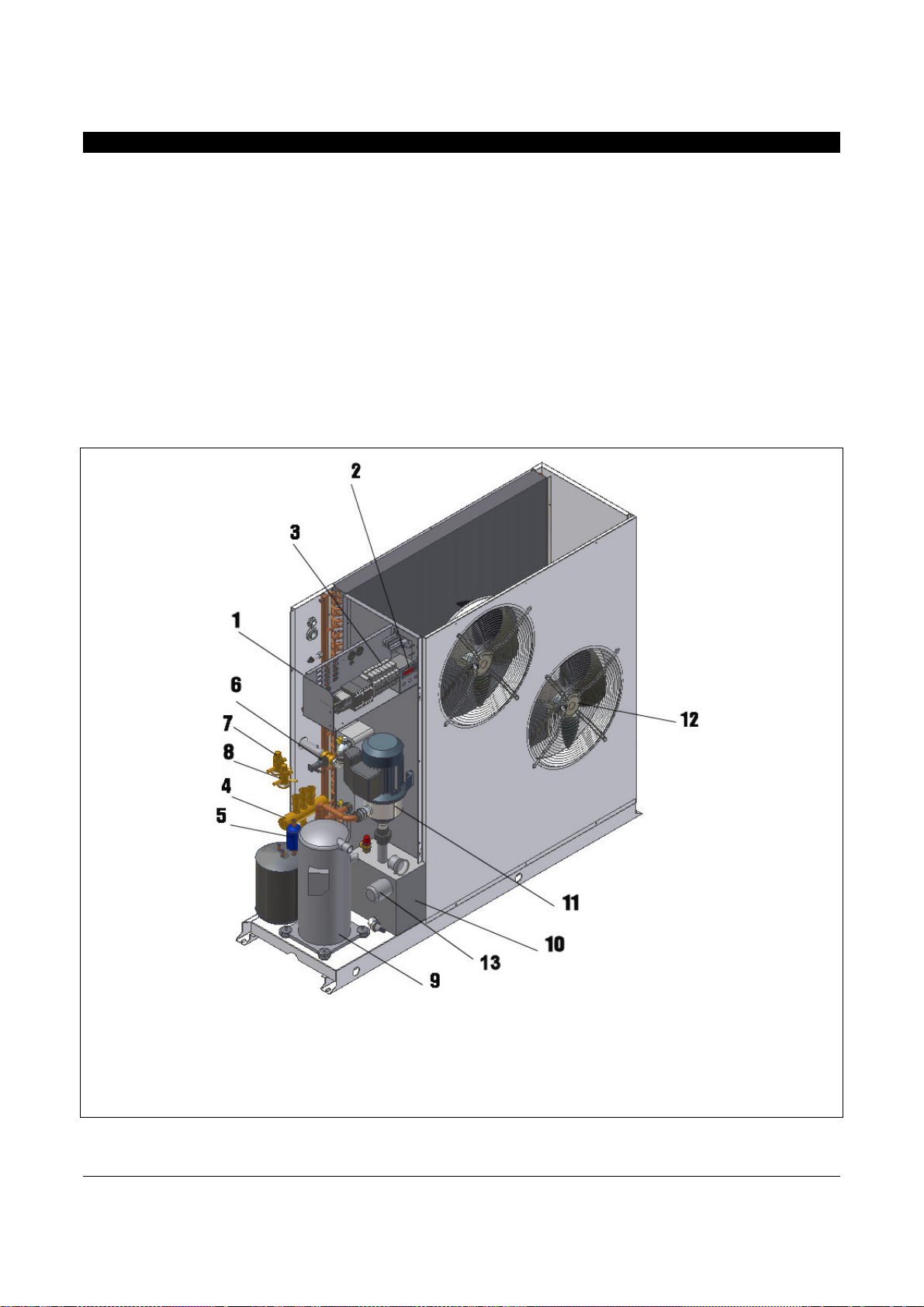

EQUIPMENT DESCRIPTION

The units are divided into two families:

– HEAT PUMPS, BESST series: some available with single-

phase power supply, others with three-phase power

supply, capable of producing both hot water for heating

and cold water for cooling household, residential and

industrial environments.

– HEAT PUMPS, BESST/R series: also av ailable with three-

and single-phase power supply, capable of producing both

hot water for heating and cold water for cooling household,

residential and industrial environments and provided with

supplementary electrical resistor for correct operation

even under very critical weather conditions.

They are used in combination with terminal or fan-coil units in small

and medium-large systems.

They are designed for outdoor installation and the used materials

have been selected to meet this special requirement.

They use a scroll-type rotating compressor, mounted on

antivibration supports inside an adequate compartment, and

electronically-controlled variable-speed helical fans, which

ensure particularly noiseless operation. For three-phase

versions, a phase monitor is standard supplied to check the

proper compressor rotation.

The AISI 318 stainless steel plate heat exchanger, on utility end,

is insulated with an anti-condensation coating and complete with

a flow controller.

The units are equipped with various safety devices, such as

pressure-switches, hydrometer, sensors, specific automatic

switches and phase monitor (only for three-phase units). An

electronic, microprocessor-controlled equipment supervises the

operation. They are also provided with an inertial storage tank

which is integrated into the unit as a standard.

1 Electric board

2 Control panel

3 Magnetothermal switch

4 Cycle reversing valve

5 Dehydration filter

6 Flow controller

7 Summer thermostatic valve

6

8 Winter thermostatic valve

9 Scroll compressor

19 Hydraulic kit

11 Pump

12 Helical fan

13 Electrical resistor (only BESST/R)

TECHNICAL DATA - WEIGHTS

BESST - BESST/R SERIES

Ref. UNI-EN 14511:2004 standard

TIPO

Heating capacity

Power input

Heating capacity

Power input

Heating capacity

Power input

Heating capacity

Power input

Heating capacity

Power input

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

1/9 2/10 3/11 4/12 5/13 6/14 7/15 8/16

6,8 8,3 11,0 15,0 19,9 22,2 28,0 37,2

1,74 2,11 2,81 3,61 4,28 4,83 6,48 8,44

5,9 7,2 9,5 13,0 16,6 18,9 23,8 31,7

1,78 2,20 2,90 3,67 4,33 4,86 6,55 8,52

5,0 6,2 8,0 10,8 13,5 15,4 19,2 25,8

1,79 2,26 2,97 3,73 4,36 4,88 6,66 8,63

6,6 8,1 10,6 14,4 18,4 21,0 26,4 34,8

2,14 2,68 3,50 4,49 5,23 5,96 7,84 10,18

5,6 7,1 9,3 12,6 15,9 18,1 22,6 30,0

2,16 2,77 3,60 4,60 5,26 5,99 8,00 10,33

Cooling capacity

Power input

Cooling capacity

Power input

Cooling capacity

Power input

Cooling capacity

Power input

(6)

(7)

(8)

(9)

(6)

(7)

(8)

(9)

kW

kW

kW

kW

kW

kW

kW

kW

7,5 10,3 13,0 17,8 23,6 27,2 33,9 45,1

1,80 2,28 2,93 3,89 4,96 5,67 7,04 9,05

6,9 9,3 11,8 17,0 21,3 24,6 31,0 40,4

2,00 2,72 3,46 4,56 5,78 6,60 8,13 10,51

6,0 8,2 10,2 14,1 17,9 21,0 26,9 34,9

1.76 2,34 3,01 3,93 5,03 5,69 7,05 9,19

5,3 7,1 9,3 13,0 17,0 19,5 24,7 32,2

2,04 2,81 3,58 4,65 5,85 6,66 8,22 10,71

Nominal water flow-rate

(10)

Water fitting diameter inches

Tank capacity - liters

Supporting resistor *

Supply voltage

Protection degree

Helical fan

Nominal air flow-rate

Sound level

(11)

R410A refrigerant charge

Loadless weight

(1) outdoor air +7°C, water 35 – 30°C.

(2) outdoor air +0°C, water 35 – 30°C.

(3) outdoor air -7°C, water 35 – 30°C.

(4) outdoor air +7°C, water 45 – 40°C.

(5) outdoor air +0°C, water 45 – 40°C.

(6) outdoor air +30°C, water 18 – 23°C.

(7) outdoor air +35°C, water 18 – 23°C.

(8) outdoor air +30°C, water 7 – 12°C.

(9) outdoor air +35°C, water 7 – 12°C.

(10) ref. outdoor air 0°C, water 35-30°C

(11) Sound level measure d under free-field conditio ns at 1.5 meters from fan front and 1.5 meters from the ground .

(*)only BESST/R version

m3/h

inches

litres

kW

V/50Hz

IP

N°

m3/h

dB(A)

kg

kg

1,0 1,2 1,6 2,2 2,8 3,2 4,1 5,4

3/4 3/4 1 1 1 1 1-1/4 1-1/4

16 16 36 36 57 57 70 70

3,0 3,0 6,0 6,0 8,0 8,0 10,0 10,0

230 ∼ 230

∼

230

∼

400 3N ∼ 400 3N ∼ 400 3N ∼ 400 3N ∼ 400 3N ∼

44 44 44 44 44 44 44 44

1 1 2 2 2 2 4 4

3.300 3.250 6.500 6.500 8.000 8.000 14.000 13.600

58,0 58,0 62,8 62,8 61,5 61,5 63,0 63,0

1,7 1,9 2,7 3,1 4,9 5,5 8,2 9,6

110 112 164 175 224 230 390 394

7

HYDRAULIC DATA

The following diagram shows the residual lifts with nominal water flow-rate ± 20%.

WATER FLOW RATE – LIFT DIAGRAM

Type 7-15

Type 5-13

Type 8-16

Type 1-9

AVAILABLE LIFT kPa

Do not work outside these curves

Type 3-11

Type 2-10

Type 6-14

Type 4-12

WATER FLOW RATE m3/h

8

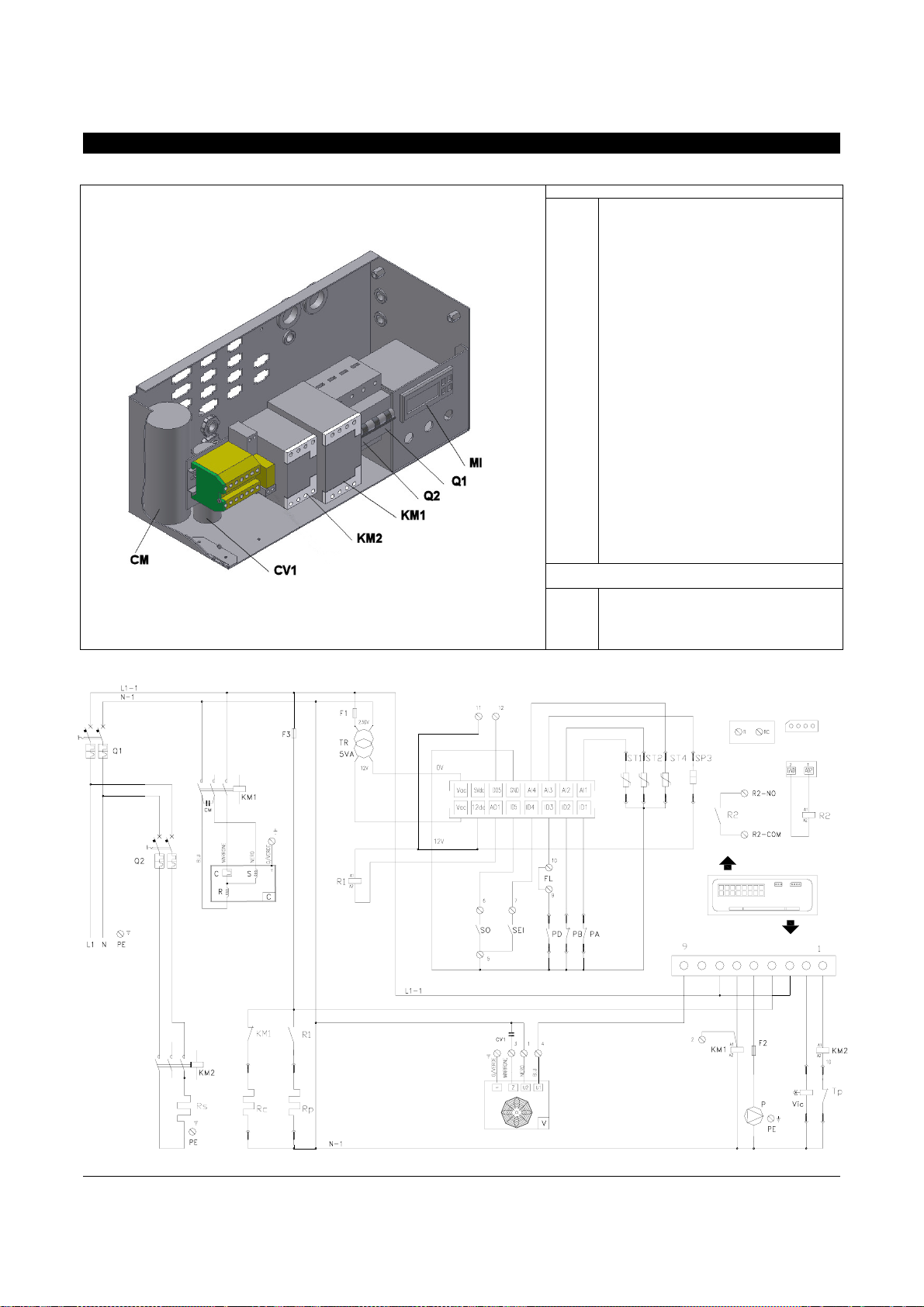

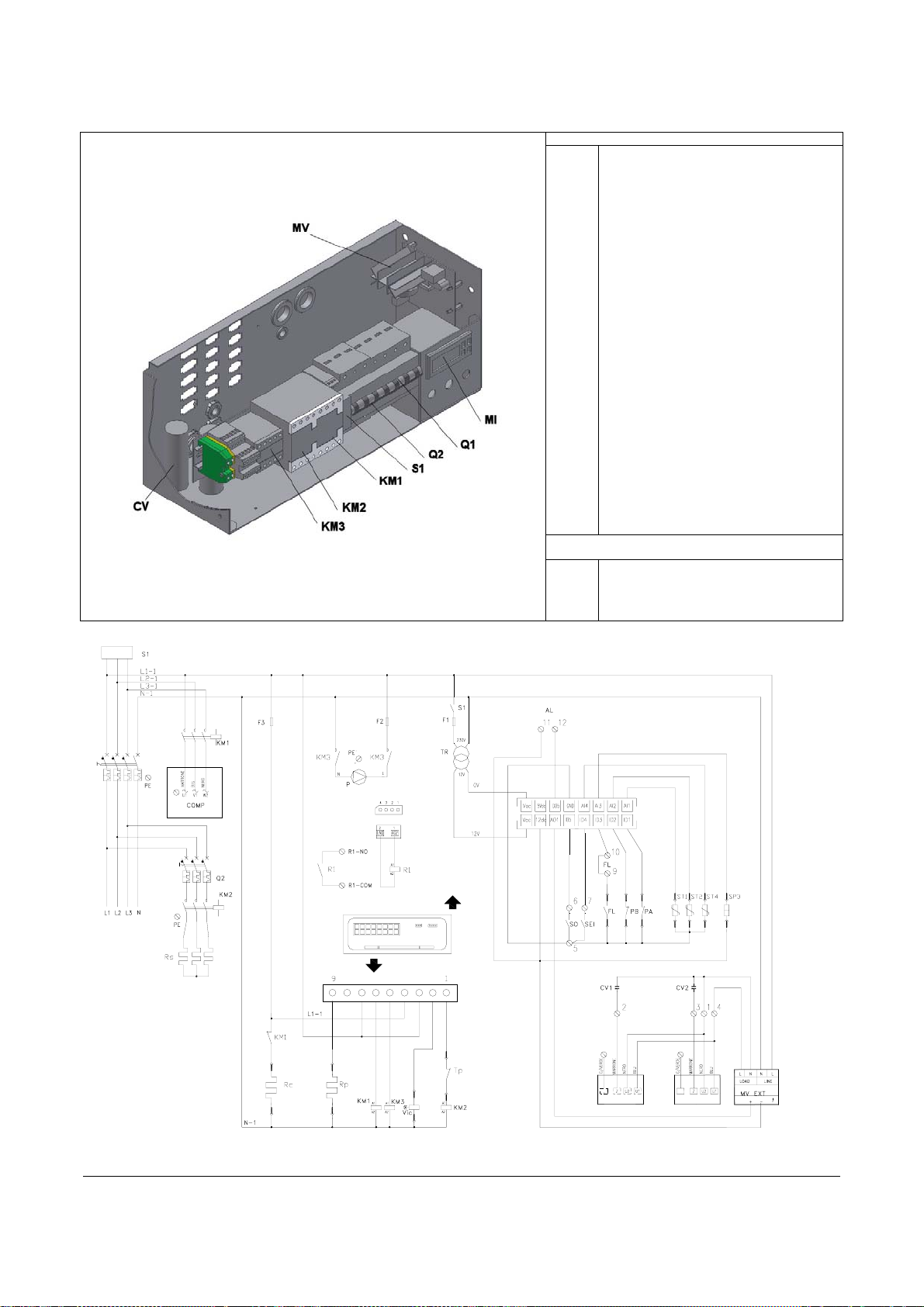

ELECTRIC BOARD AND MULTIFILAR WIRING DIAGRAM

The units are provided with an electric board consisting of the following components.

Type 1, 2, 9, 10

Factory-installed c om ponents

C

CM

CV1

F1

F2

F3

KM1

KM2

MI

Conn.A

Conn.B

P

PD

Tp

TR

Q1

Q2

SP3

ST1

ST2

ST4

PA

PB

VIC

Rp

Rc

Rs

R1 / R2

V1

(*)

Components to be assembled upon installation

(not supplied with the appliance)

AL

FL

SEI

SO

Compressor

Run capacitor

Fan capacitor

Control protection fuse

Pump protection fuse

Resistor protection fuse

Compressor remote switch

Resistor remote switch

Control panel

Input terminal block

Load output terminal block

Circulating pump

Flow controller

Protection thermostat

Auxiliary circuit transformer

Automatic main breaker

Supporting resistor automatic switch

Pressure transducer

Exchanger inlet temperature probe

Exchanger outlet temperature probe

Outdoor air temperature probe

High pressure switch

Low pressure switch

Cycle reversing valve

Plate heat exchanger resistor

Compressor crankcase resistor

Supporting resistor

RP relay / Boiler contact auxiliary relay

Fan

(*) only for BESST/R version

Remote alarm signaling system (12V DC output,

max 20 mA)

External flow switch

Remote SUMMER-WINTER switch

Remote ON-OFF switch

230V 50Hz

AL-12V DC

CONN C

CONN C

CONN A

CONN A

CONN C

CONN B

CONN B

9

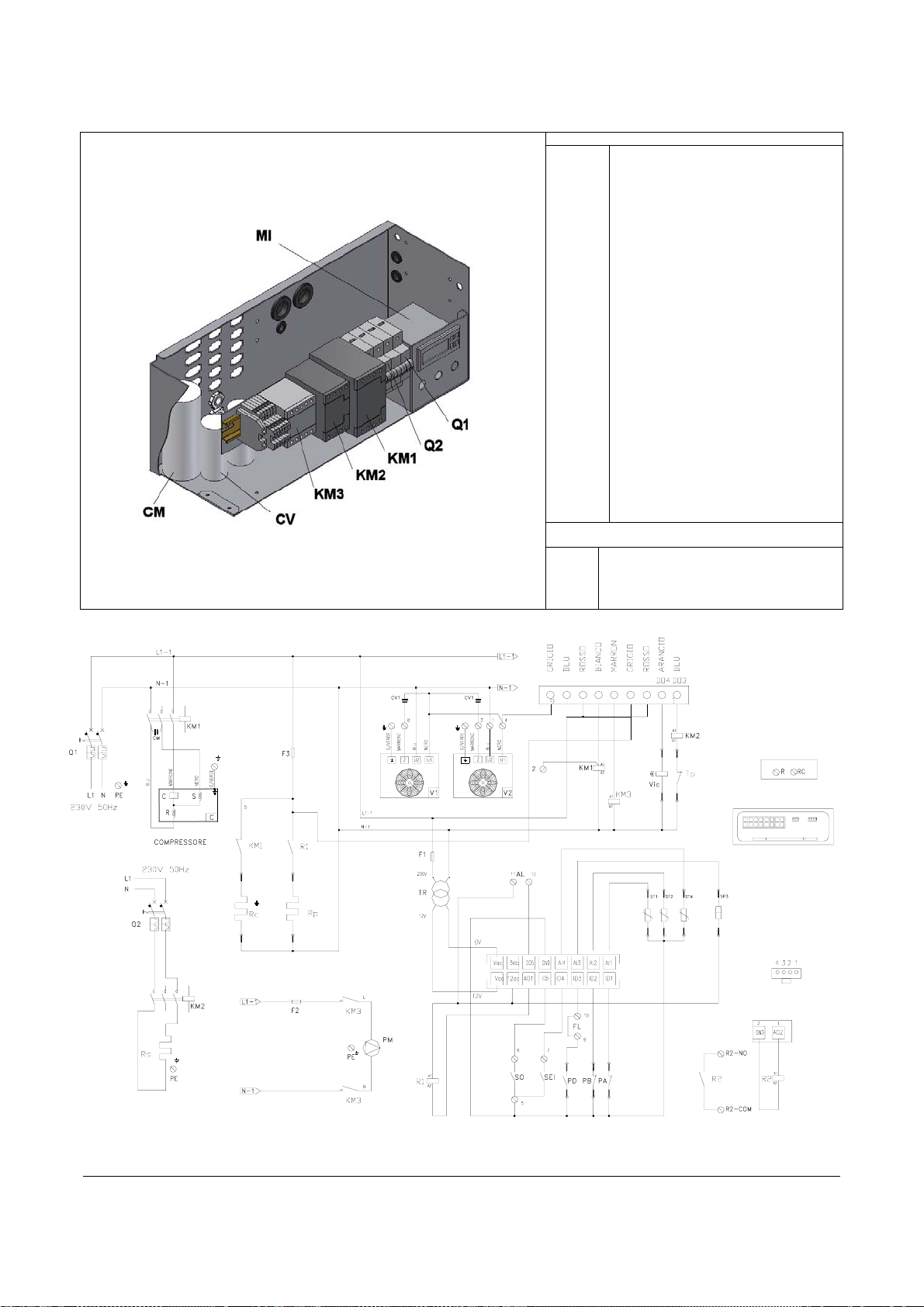

Type 3 and 11

Factory-installed c om ponents

C

CM

CV1/2

F1

F2

F3

KM1

KM2

KM3

MI

Conn.A

Conn.B

P

PD

Tp

TR

Q1

Q2

SP3

ST1

ST2

ST4

PA

PB

VIC

Rp

Rc

Rs

R1 / R2

V1/2

(*)

Components to be assembled upon installation

(not supplied with the appliance)

AL

FL

SEI

SO

Compressor

Run capacitor

Fan 1/2 capacitor

Control protection fuse

Pump protection fuse

Resistor protection fuse

Compressor remote switch

Resistor remote switch

Pump remote switch

Control panel

Input terminal block

Load output terminal block

Pump/ Circulating pump

Flow controll er

Protection thermostat

Auxiliary circuit transformer

Automatic main breaker

Supporting resistor automatic switch

Pressure transducer

Exchanger inlet temperature probe

Exchanger outlet temperature probe

Outdoor air temperature probe

High pressure switch

Low pressure switch

Cycle reversing valve

Plate heat exchanger electrical resistor

Compressor crankcase resistor

Supporting resistor

RP relay / Boiler contact auxiliary relay

Fan 1/2

Only for BESST/R series

Remote alarm signaling system ((12V DC output,

max 20 mA)

External flow switch

Remote SUMMER-WINTER switch

Remote ON-OFF switch

CONN B

CONN A

CONN C

CONN B

CONN A

CONN C

CONN C

10

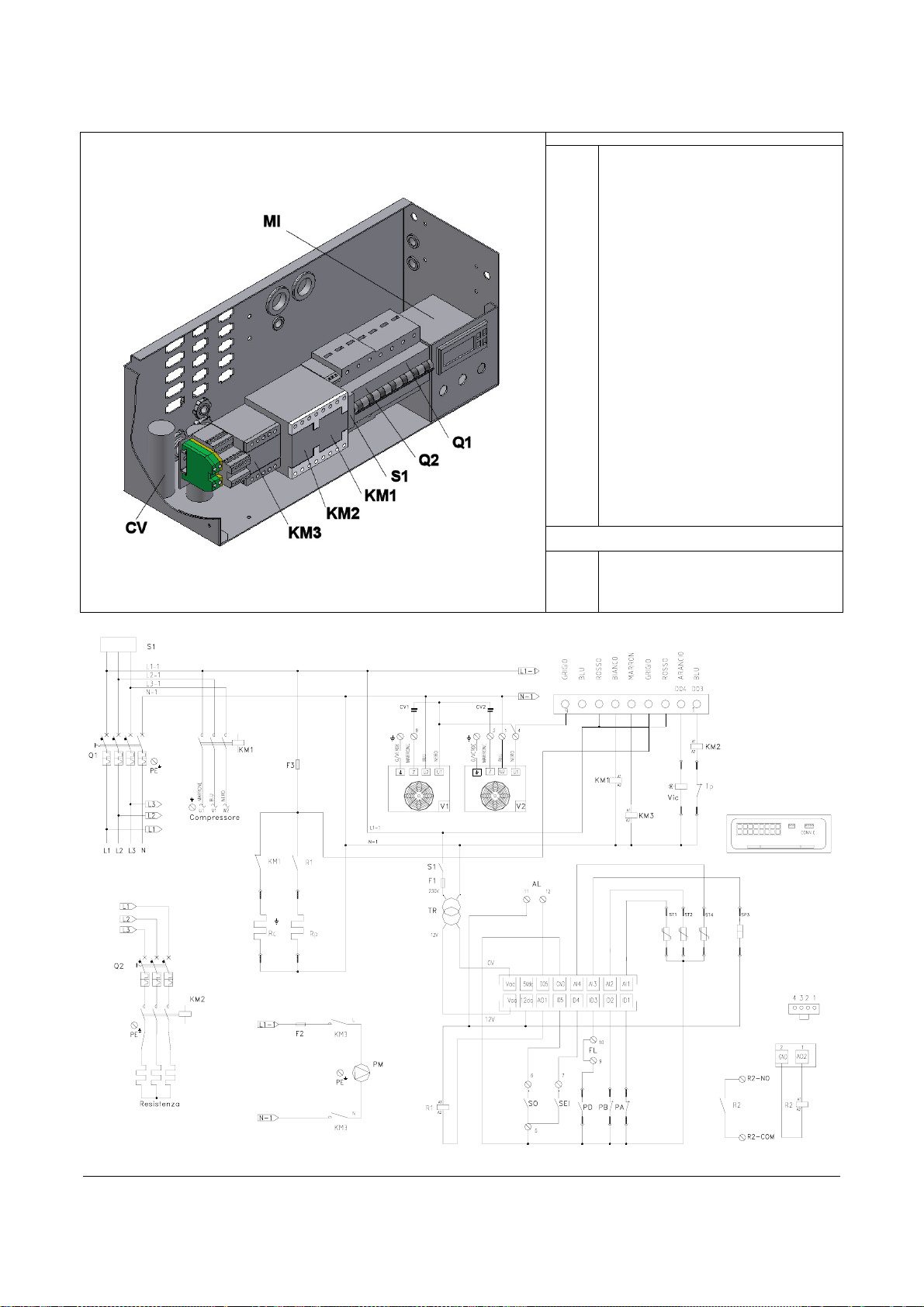

Type 4 and 12

Factory-installed c om ponents

C

CV1/2

F1

F2

F3

KM1

KM2

KM3

MI

Conn.A

Conn.B

P

PD

Tp

TR

Q1

Q2

S1

SP3

ST1

ST2

ST4

PA

PB

VIC

Rp

Rc

Rs

R1 / R2

V1/2

(*)

Components to be assembled upon installation

(not supplied with the appliance))

AL

FL

SEI

SO

Compressor

Fan 1/2 capacitor

Control protection fuse

Pump protection fuse

Resistor protection fuse

Compressor remote switch

Resistor remote switch

Pump remote switch

Control panel

Input terminal block

Load output terminal block

Pump/Circulating pump

Flow controller

Protection thermostat

Auxiliary circuit transformer

Automatic main breaker

Supporting resistor automatic switch

Phase sequence relay

Pressure transducer

Exchanger inlet temperature probe

Exchanger outlet temperature probe

High pressure switch

Low pressure switch

Cycle reversing valve

Plate heat exchanger electrical resistor

Compressor crankcase resistor

Supporting resistor

RP relay / Boiler contact auxiliary relay

Condensation fans 1/2

Only for BESST/R series

Remote alarm signaling system (12V DC output,

max 20 mA)

Secondary flow switch

Remote SUMMER-WINTER switch

Remote ON-OFF switch

400V 50HZ 3N

Rs

CONN B

CONN A

CONN B

CONN A

CONN C

CONN C

11

Type 5, 6, and 13, 14

Factory-installed c om ponents

C

CV1/2

F1

F2

F3

KM1

KM2

KM3

MI

MV

Conn.A

Conn.B

P

PD

Tp

TR

Q1

Q2

S1

SP3

ST1

ST2

ST4

PA

PB

VIC

Rp

Rc

Rs

R1

V1/2

(*)

Components to be assembled upon installation

(not supplied with the appliance)

AL

FL

SEI

SO

Compressor

Fan 1/2 capacitor

Control protection fuse

Pump protection fuse

Resistor protection fuse

Compressor remote switch

Resistor remote switch

Pump remote switch

Control panel

Fan modulation board

Input terminal block

Load output terminal block

Pump

Flow controller

Protection thermostat

Auxiliary circuit transformer

Automatic main breaker

Supporting resistor automatic switch

Phase sequence relay

Pressure transducer

Exchanger inlet temperature probe

Exchanger outlet temperature probe

Outdoor air temperature probe

High pressure switch

Low pressure switch

Cycle reversing valve

Plate heat exchanger electrical resistor

Compressor crankcase resistor

Supporting resistor

Boiler contact au xiliary relay

Condensation fans 1/2

Only for BESST/R series

Remote alarm signaling system (12V DC output,

max 20 mA)

Secondary flow switch

Remote SUMMER-WINTER switch

Remote ON-OFF switch

400V 3N - 50HZ

12

CONN B

CONN C

CONN C

CONN A

CONN A

CONN C

Type 7, 8 and 15, 16

Factory-installed c om ponents

C

CV1/2/3/4

F1

F2

F3

KM1

KM2

KM3

MI

MV

Conn.A

Conn.B

P

PD

Tp

TR

Q1

Q2

S1

SP3

ST1

ST2

ST4

PA

PB

VIC

Rp

Rc

Rs

R1

V1/2/3/4

(*)

Components to be assembled upon installation

(not supplied with the appliance)

AL

FL

SEI

SO

Compressor

Fan 1/2/3/4 capacitor

Control protection fuse

Pump protection fuse

Resistor protection fuse

Compressor remote switch

Resistor remote switch

Pump remote switch

Control panel

Fan modulation board

Input terminal block

Load output terminal block

Pump

Flow controller

Protection thermostat

Auxiliary circuit transformer

Automatic main breaker

Supporting resistor automatic switch

Phase sequence relay

Pressure transducer

Exchanger inlet temperature probe

Exchanger outlet temperature probe

Outdoor air temperature probe

High pressure switch

Low pressure switch

Cycle reversing valve

Plate heat exchanger electrical resistor

Compressor crankcase resistor

Supporting resistor

Boiler contact auxiliary relay

Condensation fans 1/2/3/4

Only for BESST/R series

Remote alarm signaling system (12V DC output,

max 20 mA)

Secondary flow switch

Remote SUMMER-WINTER switch

Remote ON-OFF switch

400V 3N - 50HZ

CONN A

CONN A

CONN C

CONN B

CONN B

CONN C

CONN C

13

HEAT PUMP

In Winter cycle

COOLING CIRCUIT

1

8

In Summer cycle

8

9

12

16

10

15

1114

2

54

7

33

136

1

12

7

16

10

15

5 4

136

9

1114

2

3 3

COMPONENTS:

1

Fan

2

Finned coil (condenser)

3

Check valve

4

Thermostatic valve (Summer cycle)

5

Thermostatic valve (Winter cycle)

6

Filter

7

Liquid indicator

8

Flow controller

14

9

10

11

12

13

14

15

16

Plate heat exchanger

Cycle reversing valve

High pressure safety switch

Compressor

Liquid receiver

Low pressure safety switch

Pressure transducer

Safety valve

ACCESSORIES

Below is a list of available accessories to be separately ordered.

ACCESSORY CODE

Remote control kit 4TRRT02

Antivibration mount kit 4TRAV01

Soft start kit 4TRRS01

Enclosure kit 4TRKP01 - 4TRKP02 - 4TRKP03 - 4TRKP04

SUPPORTING RESISTOR.

The control panel enables all necessary settings for the heat pump operation and displaying of main

parameters and alarms.

It is located on the electric board front, inside the equipment, and can be accessed through a small door on the inspection panel.

CONTROL PANEL

The control panel enables all necessary settings for the heat pump operation and displaying of main

parameters and alarms.

It is located on the electric board front, inside the equipment, and can be accessed through a small door on the inspection panel.

Alarm icon Mode (Heat; Cool…) icons

Economy icon

(configurable)

Clock icon

Resource (compressor, fans…) icon Menu navigation icon

Display:

During normal operation, it shows the return water temperature from the system.

It can also show the values of all set parameters and the codes of any alarms.

Displayed quantity measure

unit

15

Keys Press and immediately release

Symbol printed on

front frame

Press and hold (if key is

properly configured)

Scroll menu items, increase parameter

values

Scroll menu items, decreases

parameter values

Manual alarm reset

Acces to machine status menu (set

point, AI,DI,DO, compl.hours,pump

hours,etc.)access to menu subfolders,

access to parameter value, confirmation

of parameter value

Exit from menu, parameter list,

parameter value and return to upper

Access to programming menu

Request for manual

defrosting

Device switch on/off (and

vice-versa)

Access to essential

display configuration

folder

Access to operation mode

(Heat/Cool/Std-by)

SET used for:

• access to machine status menu

• access to menu subfolders

• access to parameter value

• confirmation of parameter value and/or exit

• pressing and holding the key gives access to the essential display selection menu (if the key is

• configured for this function); the available options can be displayed with the up and down keys (depending on the machine configuration)

UP

• scrolling up the displayed folders and parameters

• increase of parameter value (if in parameter value change mode)

• pressing and holding the key gives access to the manual defrosting feature (if the key is configured for this feature), from essential display

only.

DOWN

• scrolling down the displayed folders and parameters

• decrease of parameter value (if in parameter value change mode).

• Pressing and holding the key switches on/off the essential display device (if the key is configured for this feature)

ESC

Exit from menu, parameter list, parameter value without saving it, and return to previous level. Pressing and holding the key from the

essential display (if the key is configured for this feature) gives access to the operating mode change folder; the available modes can be

displayed with the UP and DOWN keys (depending on the machine configuration), while pressing the SET button confirms the selection

made.

and pressing the SET key confirms the selection made.

used for:

used for:

used for:

Simultaneously pressing SET

Simultaneously pressing UP

16

+ESC gives access to the Parameters, Functions, Password folders, etc.

+DOWN resets any alarms

FAULT INDICATIONS

In case of abnormal operation of the equipment, alphanumerical

codes alternating with the system

return temperature are displayed on the control panel display.

Some alarms are automatically reset, whereas others can only be

reset by the manufacturer’s Technical Support

MANUAL FAULT RESET

To reset a fault alarm after removing the cause which triggered it:

Service.

DESCRIPTION INDICATION RESET

High pressure

Low pressure

Flow controller

Water circuit antifreeze

High water temperature (over 60° C)

Faulty-clock error

Not-set clock error

Inlet temperature probe

Outlet temperature probe Er61 automatic

Outside temperature probe fault

Condensation pressure probe

Configuration error

Compressor work hours exceeded

Pump work hours exceeded

Alarm history records exceeded

Er01

Er05

Er20

Er30

Er35

Er45

Er46

Er60

Er68

Er75

Er80

Er81

Er85

Er90

manual

manual

manual

automatic

automatic

automatic

automatic

automatic

automatic

manual

manual

manual

Simultaneously press UP

alarms

and DOWN to reset the

SWITCHING ON AND OFF

After the first commissioning by the manufacturer’s Technical Support Service, the unit is set for “automatic” operation and no further

interventions are required.

Therefore, the system manager must SWITCH ON or OFF the unit from the control panel or the

remote switch (if present).

To access the control panel, open the relevant door and do the

following

- Remove the lock screw

- Simultaneously press the (A) points and lift the door

After operating the control panel:

- Close the door and replace the lock screw.

:

After powering on the unit, the OFF indication is displayed. Press the key to bring the machine to stand-by mode, from this

moment the pump should activate and the system return water temperature appear on the display. At this point, act as follows:

Switching on

To select the operating mode, press and hold the key

“HEAT”,“COOL” or “STBY” ” is displayed, depending on the

controller’s current operation status.

Select with UP

confirm with the SET

or DOWN the HEAT mode and

key.

until

17

Heating (WINTER CYCLE))

Selecting HEAT the

Cooling (SUMMER CYCLE)

Selecting COOL the

symbol lights up

symbol lights up.

Switching off the heating/cooling modes

Hold for some seconds

; the symbol lights up.

The switching between Heating and Cooling modes, on

heat pump models, should be made by the

manufacturer’s Technical Support Service.

until COOL” or HEAT (cycle on) is displayed. Select with the key STBY and confirm with SET

OPERATIONS MADE BY THE ON-OFF AND “SEI” SUMMERWINTER REMOTE SWITCHES (IF PRESENT)

Switching on the cooling mode

- Turn OFF the “SEI” SUMMER-WINTER remote switch

- Turn ON the “SO” ON-OFF remote switch

The indicator LED

lights up on the control panel.

It is recommended to switch the operating mode only once

a day.

Switching off the cooling mode

- Turn OFF the “SO” ON-OFF remote switch.

The OFF indication starts flashing on the CONTROL

PANEL.

Switching on the heating mode

- Turn ON the “SEI” SUMMER-WINTER remote switch

- Turn ON the “SO” ON-OFF remote switch”.

The indicator LED

Switching off the heating mode

Turn OFF the “SO” ON-OFF remote switch

The OFF indication starts flashing on the CONTROL

PANEL.

In case of power failure for more than four hours, after

restoring the unit, keep it powered but switched off for at

least eight hours..

lights up on the control panel..

18

In case of power failure for less than four hours, after

restoring the unit, keep it powered but switched off for the

same number of hours the power failed

INACTIVITY FOR A LONG PERIOD INACTIVITY FOR A LONG PERIOD

If you are not going to use the equipment for a long time, please

do the following:

– Switch off the equipment, whatever its operating mode, using

the control panel

– Turn OFF the remote switch (if present)

After switching off the equipment:

– Switch off the internal terminal units by turning off the switch

of each appliance

– Turn OFF the main system circuit breaker

– Close the water taps

If the outside temperature can drop below zero, there is a

danger of freezing.

The hydraulic system MUST BE DRAINED or an

antifreeze liquid (such as ethylene glycol) must be added

to it according to the doses recommended by the liquid’s

manufacturer. Please, contact the manufacturer’s

Technical Support Service on the matter.

CL CLE CLEANING

The only cleaning operation which the user must perform

concerns the chiller external panels which must be only cleaned

using a cloth dampened with water and soap. In the event of

resisting stains, dampen the cloth with a 50% mix of water and

denaturated alcohol or with specific products. After the cleaning,

carefully dry the surfaces.

MAINTENANCE

Periodical maintenance is essential to keep the equipment effective,

safe and reliable over time.

It can be done, every six months for some interventions and

every year for others, by the manufacturer’s Technical Support

Service which is technically skilled and trained and provided

with genuine spare parts, if necessary..

USEFUL INFORMATION

Seller:…………………………………………………………..

Street …………………………………………………………………...

Phone.

…………………………………………………………………..

Installer: ………………………………………………………...

Mr. …………………………………………………………………..

Street ……………………………………………………………………

Phone.

……………………………………………………………………

DATE INTERVENTION

It is recommended to switch the operating mode only once a

day.

To put the equipment back into operation after a long

downtime, ask for the intervention of the manufacturer’s

Technical Support Service .

Should the unit be connected in parallel to a boiler, close

the equipment cocks during the boiler operation. The

temperature of the circulating water inside the heat pump

should never exceed 60°C.

Do not use sponges impregnated with abrasive products or

powder detergents

Do not perform any cleaning or maintenance before

disconnecting the appliance from the mains (by turning OFF

the main system circuit breaker)

For equipment installed near the sea, maintenance intervals

must be cut by half.

Do not perform any maintenance before disconnecting the

appliance from the mains (by turning OFF the main all-pole

system circuit breaker).

Technical Support Service: ……………………………………….

Mr.…………………………………………………………………………..

Street…………………………………………………………………………...

Phone.……………………………………………………………………………

19

UPON RECEIVING THE PRODUCT

Check if the received product is intact and whether the packing

list matches the labels on the package. Should the content not

match your order, please contact the retailer who sold the

equipment and the carrier. The units are supplied in a single

package on a wooden pallet, protected by a cardboard

wrapping, and they are accompanied by::

– instruction manual

– warranty certificate

– labels with barcodes

The instruction manual is an integral part of the equipment,

therefore we recommend you to read it and keep it with care.

.

It is recommended to remove the wrapping only when the

equipment has been positioned in the installation site.

Do not abandon the packing material or leave it to the

children’s reach, as this is a potential source of danger

HANDLING AND TRANSPORT

Handling and transport must be always carried out with the

equipment in horizontal position. If a lift truck is used, fork the

appliance on the bottom, opening wide the truck forks to the

maximum extent. If a crane is used, slide the ropes into the

upper part of the wooden base, taking care not to put pressure

on the equipment.

It is recommended to remove the wrapping only when the

equipment has been positioned in the installation site..

Dimension / Type 1, 2, 9, 10 3, 4, 11, 12 5, 6, 13, 14 7, 8, 15, 16

L 1140 1340 1600 1990 mm

H 950 1150 1450 1650 mm

D 480 540 580 670 mm

Once the wrapping has been removed, the units can be

handled by inserting two metal tubes (max. diameter: 33 mm,

min. thickness: 3.2 mm) into the holes provided in the base and

using adequate lifting devices.

The equipment weight is unbalanced toward the

compressor end (electric board end).

During the transport, the unit must be maintained in

vertical position only.

The appliance must be handled by qualified personnel,

adequately equipped with devices sized for the appliance

weight and dimensions

20

LOCATION

The installation site must be determined by the system designer or a

competent person and must take into account technical requirements

and applicable laws and regulations which prescribe special

authorizations, (ex.: city planning, architectural, environmental

regulations, etc.).

It is therefore recommended to request and obtain the necessary

authorizations before installing the equipment.

The equipment must:

– be placed on an even surface which can support its weight.

– be placed on a sufficiently stiff floor slab which does not

transmit any vibration to the premises located under or adjacent

to it.

It is recommended to insert a rubber layer (hardness: 60 shores,

thickness: 10 mm) between floor slab and equipment, or use the antivibration mounts available as an accessory.

POSITION FOR ANTI-VIBRATION MOUNT FIXATION

B

A

Size 1-2-9-10 3-4-11-12 5-6-13-14 7-8-15-16

A 1000 1200 1500 1500 mm

B 500 600 700 700 mm

C 1000 1000 1000 1000 mm

D 600 800 800 800 mm

The area in front of the condensation fans must be totally

free from obstacles

If multiple appliances are installed side by side on the

external coil end, clearances must be summed up .

The unit is destined for outdoor installation and must be located

within a buffer area in accordance with the figure below. The defined

clearances are required to enable a correct air flow and allow for

normal cleaning and maintenance operations.

It is advisable to avoid:

– the installation in skylight shafts and/or basement window wells

– obstacles or barriers causing the recycling of exhaust air

– the installation in sites with an aggressive atmosphere

– the installation in sites where the equipment noise may be

enhanced by reverberation or echoes

the installation in corners with settling of dust, leaves and whatever

-

may reduce the appliance efficiency, obstructing the air path

– the penetration of the equipment exhaust air into lived-in rooms

through doors or windows, causing trouble to people.

TYPE 1-2-9-10

TYPE 3-4-11-12

TYPE 5-6-13-14

TYPE 7-8-15-16

A 1070 mm

B 325 mm

A 1270 mm

B 375 mm

A 1530 mm

B 425 mm

A 1920 mm

B 525 mm

The two appliances should not be installed one with the fan

air supply facing the finned coil of the other

21

HYDRAULIC CONNECTIONS

The choice and installation of the components is the installer’s

responsibility who must work according to the best practice rules and

the regulations in force. Before connecting the pipes, make sure they

do not contain stones, sand, rust, waste or anyway foreign bodies

which might damage the system.

System hydraulic connection diagram

1-2-9-10-type heat pump

A system “calibration” by-pass MUST be made for types 56-7-8 and 13-14-15-16 (see drawing below). The by-pass

enables a better control of water flow-rate and lift, since the

provided pump is pre-equipped for a single speed.

F

DELIVERY TO SYSTEM

RETURN FROM SYSTEM

1 Pressure gauge

2 Antivibration coupling

3 Check valve

4 Mesh filter

5 Flow controller

F

3-4-5-6-7-8 type and 11-12-13-14-15-16 type heat pump

F

RETURN FROM SYSTEM

DELIVERY TO SYSTEM

F

6 Pump

7 Safety valve

8 Air vent

9 Expansion tank

10 Temperature probe

11 Fill/top up

12 Drain cock

13 Calibration by-pass (compulsory on 5-6-7-8 types and 13-14-

15-16 types)

14 Flow switch

22

A

The hydraulic connections must be completed installing:

–

- a 0.5 mm inlet mesh filter (return from system).

- an outlet liquid flow switch (delivery to system) to be sized and set

depending on the system hydraulic characteristics: it must be

installed halfway of a straight horizontal pipe section of at least 1

meter of length

Together with the flow controller onboard the machine, the flow

switch must ensure a correct water flow rate across the

equipment (with a min. temperature of 4°C and a max.

temperature of 6°C);;

Special feeding/top-up waters must be conditioned with

proper treatment systems. The values listed in the table below

can be taken into account as reference values.

REFERENCE VALUES

PH 6÷8

Electrical conductivity lower than 200 mV/cm (25°C)

Chlorine ions lower than 50 ppm

Sulfuric acid ions lower than 50 ppm

Total iron lower than 0,3 ppm

M-alkalinity lower than 50 ppm

Total hardness lower than 50 ppm (5 °F)

Sulfur ions zolfo

mmonia ions

Silica ions lower Than 30 ppm

ppm = parts per million

none

none

– air vent valves in the piping upper points;

- flexible couplings;

- check valves;

- chemical washing check valves.

The calibration by-pass must be installed downstream of the

machine for better regulation of the water flow-rate and lift

within the system.

Provide a system fill/top-up device and a drain device to be

connected in the lower part of the hydraulic circuit.

Systems filled with antifreeze liquid or covered by

special law provisions must be fitted with hydraulic

disconnectors. The manufacturer is not liable for

obstruction, breakage or noise resulting from the

failure to install filters, flow switches or vibration

dampers.

The units are equipped with a pump as a standard.

In addition, the water flow-rate must be maintained

constant during operation.

The system water content must be adequate, in order o

avoid unbalances in the cooling circuit operation (see table

on page 7)

DIMENSIONS

H

L

L1

Dimensions / Type 1 - 2 - 9 - 10 3 – 4 – 11 - 12 5 – 6 – 13 - 14 7 – 8 – 15 - 16

P1

P

L 1040 1240 1500 1890 mm

H 805 1000 1305 1500 mm

P 378 428 478 570 mm

L1 1100 1300 1560 1950 mm

D1 425 472 520 615 mm

Return/Delivery 3 / 4 ” 1 ” 1 ” 1 ¼ “ inch

Top-up

1 / 2 ” 1 / 2 ” 1 / 2 ” 1 / 2 ” inch

For weights, refer to page 7.

23

SIZE AND LOCATION OF CONNECTIONS

Type 1-2 and 9-10

M: delivery to system

R: return from system

r: water top-up

R

r

M

65

330

Type 3-4 and 11-12

M

r

R

40 345

55

120

130 55

255

625

24

SIZE AND LOCATION OF CONNECTIONS

Type 5-6 and 13-14

M

r

R

40

Type 7-8 and 15-16

350

685

130 60

M: delivery to system

R: return from system

r: water top-up

ELECTRICAL CONNECTIONS

Units leave the factory completely wired and ready for

connection to the mains electricity supply and for the flow switch

connection, which must be carried out by qualified personnel in

accordance with current legislation.

For any intervention of electrical nature, please refer to the wiring

diagrams contained in this manual.

It is also recommended to check the following::

– - if the characteristics of the mains power supply are adequate

M

1285

135

r

R

95

425

For electrical connections use double insulation cables.

It is compulsory:

– to use a main magnetothermal, all-pole circuit breaker to

protect the mains line

– to establish an efficient earth connection.

The use of gas and water pipes for the appliance earth

25

for the power input values indicated in the electrical

characteristics table, also considering any other equipment in

parallel operation.

– if the supply voltage matches the rated value ± 10%, with a 3%

maximum unbalance between phases.

connection is prohibited.

Failure to earth the appliance or observe the wiring diagrams

relieves the manufacturer of all liability for damage.

POWER SUPPLY LINE SIZING TABLE FOR BESST VERSION ONLY:

:

TYPE Supply voltage

1 – 9

2 – 10

3 – 11

4 – 12

5 – 13

6 – 14

7 – 15

8 – 16

(V-ph~Hz)

230 ~ 50 2.72 14.6 58

230 ~ 50 3.75 19.0 82

230 ~ 50 4.66 27.8 97

400 - 3N ~ 50 5.95 16.2 64

400 - 3N ~ 50 7.15 17.5 74

400 - 3N ~ 50 8.25 19.0 101

400 - 3N ~ 50 10.00 22.0 111

400 - 3N ~ 50 12.80 27.2 118

Max power input

(kW)

Max current input

(A)

Starting current

(A)

CAUTION:WHEN SIZING THE POWER SUPPLY LINE FOR THE BESST/R VERSION, THE

ELECTRIC RESISTANCE VALUE MENTIONED ON PAGE 7 (TECHNICAL DATA) MUST

ALSO BE CONSIDERED ,TOGETHER WITH THE POWER VALUE SHOWN IN THE

TABLE ABOVE

CABLE GLAND FOR POWER LINE ENTRY AND EXTERNAL

CONNECTIONS

The equipment is provided with proper cable glands for main

power supply cables and other electrical connections.

- Insert the main power supply cable into the larger cable gland

- Slide the cables from the outside guiding them toward the

electric board.

Avoid direct contact with the non-insulated copper pipes

and the compressor.

The power supply cables should not enter the appliance

in positions which are not specifically shown in this

manual.

Cable gland for power line entry and external connections.

26

NOTE FOR FIRST STARTUP:

THE APPLIANCE MUST BE ALWAYS POWERED TO ENABLE CORRECT PRE-HEATING OF THE COMPRESOR OIL. THE

APPLIANCE MUST HAVE BEEN POWERED F OR AT LEAST EIGHT HOURS BEFORE THE FIRST STARTUP IS POSSIBLE.

The electric board with the connection terminal block is located inside the equipment, in the upper part of the circuit component

compartment.

Before starting any operations, turn OFF the

main system circuit breaker

To make the electrical connections:

– Undo the four fixation screws on the inspection panel

– Remove the panel

– Turn OFF the main equipment switch A

A

– Use hole A for the main power supply line and hole B for

the other external connection cables.

A

B

27

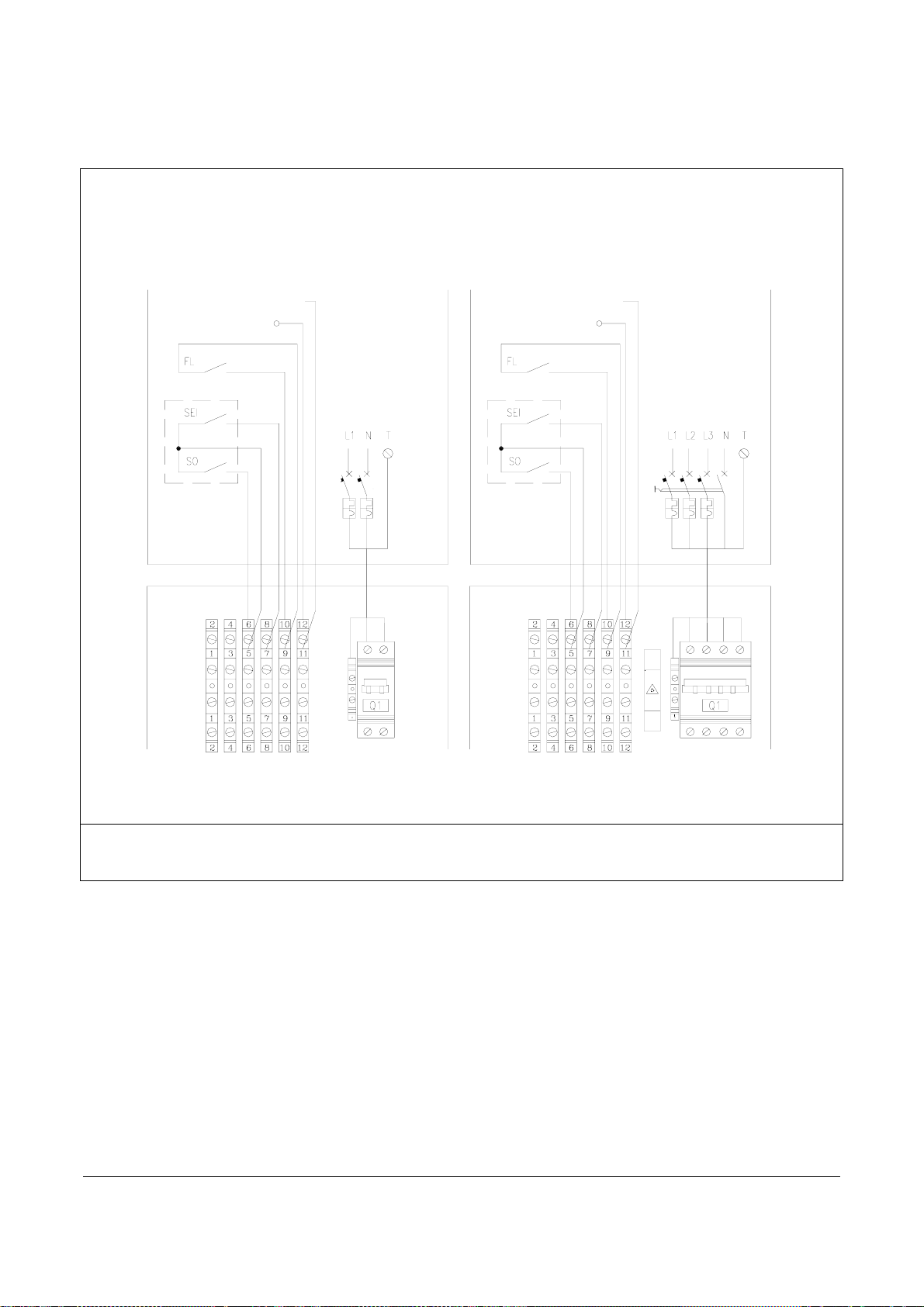

– Make the connections as shown in the figure.

V

ersione Monofase

Versione Monofase Versione Trifase

REMOTE ALARM SIGNAL

AL 12 V DC OUTPUT

COLLEGAMENTI ESTERNI

COLLEGAMENTI ESTERNI

(A CURA DELL'INSTALLATORE)

(A CURA DELL’INSTALLATORE)

REMOTE ALARM SIGNAL

POWER SUPPLY

230 V – 50 HZ

COLLEGAMENTI INTERNI

INTERNAL CONNECTION

ESEGUITI IN FABBRICA

MADE IN FACTORY

POWER SUPPLY

400V 3+N ∼ 50 HZ

S1

FL External flow switch

SEI Remote SUMMER-WINTER switch

SO Remote ON-OFF switch

AL Remote alarm signaling system (12V DC output, max 20 mA)

After making the electrical connections, lock the cables with the cable glands, turn ON the main equipment switch and replace the inspection

panel through the proper fixation screw.

28

ENABLING THE “SO” AND “SEI” CONTROLS”

DO THE FOLLOWING FROM THE CONTROL PANEL:

The operations described below must be carried out with the maximum care so as not to affect the equipment regular operation.

In case of errors or interpretation doubts, please WAIT 15 SECONDS WITHOUST PRESSING ANY KEYS.

To enable the SO and SEI controls, act as follows:

Power on the unit, by turning ON the main system circuit breaker and the main equipment switch”. If this is the first startup, the OFF

indication appears on the display. In this case, press the

temperature value appears on the display.

-

HOW TO SET THE“SO” (ON-OFF) REMOTE CONTROL):

- Now press the

indicating access to user parameters.

- Now press the

and keys simultaneously to access the user parameters. The “Par” indication appears on the display,

key to access the CF menu.

key to bring the machine back to stand-by. At this point, the return

.

- The CF indication appears on the display, indicating the remote control parameter menu.

Pressing the

set the remote SO control, just press

- Press the

- Power off the machine to store the value. - Power on again and check with the key

HOW TO SET THE“SEI” (SUMMER-WINTER CYCLE SWITCHING) REMOTE CONTROL

- Now press the

indicating access to user parameters.

key CF19 is displayed: with the arrow key move to CF20, which indicates the “SO” parameter, that is ON-OFF To

reduce the value from 0 to –13 (minus 13); then confirm with the key.

key, , until the return water temperature value appears on the display.

and keys simultaneously to access the user parameters. The Par indication appears on the display,

- Now press the key to access the CF menu.

- The CF indication appears on the display, indicating the remote control parameter menu.

- Pressing the SET

key CF19 is displayed, which indicates the “SEI” parameter, that is remote summer/winter switching. To enable

the remote control, just press

- Press the

key, until the return water temperature value appears on the display.

and reduce the value from 0 to -14 (minus 14) with the arrow keys; then confirm with the key .

FILLING AND EMPTYING THE SYSTEM

FILLING

– Before starting to fill the system, turn OFF the main system

circuit breaker.

- Check if all the equipment and system drain cocks are closed

- Open all the equipment, system and respective terminals vent

valves

29

– Open the system shut-off devices

– Start the filling by slowly opening the system water fill cock “A”

outside the appliance

– When water begins to come out of the vent valves, close them

and go on filling up to the system set pressure value.

A

Check the connections for tightness.

It is recommended to repeat this operation after some hours of operation and periodically check the

system pressure. Do the topping up after switching off the machine (pump “OFF”)

The system must be filled at a pressure between 1 and 2 bars, which can be checked through the gauge on the unit .

EMPTYING

– Before starting to empty the system, turn OFF the main system

circuit breaker)

– Check if the system water fill/top-up cock is closed

– Open the equipment front inspection panel.

– For 5-6-7-8 types and 13-14-15-16 types, open the by-pass valve (to be installed downstream of the machine), the equipment drain

cock, the system drain cocks and all vent valves.

– For 1-2-3-4 types and 9-10-11-12 types, open the two equipment drain cocks, the system drain cocks and all vent valves.

If antifreeze liquid has been added to the system, it should not be freely drained since it is polluting. It must be collected for possible

reuse.

RECOMMENDED WORKING CONDITIONS

For best operation of the equipment, the following conditions must be met:

WORKING CYCLE OUTLET WATER TEMPERATURE OUTDOOR AIR TEMPERATURE

min. max. min. max.

Cooling +7°C +18°C 15°C +42°C

Heating +35°C +45°C -15°C +25°C

WORKING LIMITS

50

45

40

35

30

25

20

15

10

5

0

- 5

-10

TEMPERATURA ARIA ESTERNA [°C]

OUTDOOR AIR TEMPERATURE (C°)

-10 - 5 0 5 10 15 20 25 30 35

TEMPERATURA ACQUA [°C]

WATER TEMPERATURE (°C)

ABB

For best operation of the equipment, the work must be performed within area “A”

It is possible to work within area “B” by changing the

unit operating parameters.

45

40

35

30

25

20

15

10

5

0

- 5

-10

-15

TEMPERATURA ARIA ESTERNA [°C]

OUTDOOR AIR TEMPERATURE (C°)

It is forbidden to work outside areas “A” and “B”.

B

20 30 40 50 60

TEMPERATURA ACQUA [°C]

AB

°

30

PREPARATION FOR FIRST COMMISSIONING

The appliance first commissioning must be performed by the

manufacturer’s Technical Support Service.

Before commissioning the unit, make sure that:

– All safety conditions have been met

– The equipment has been correctly fixed to the supporting base

– The buffer area around the equipment has been observed

– I The hydraulic connections have been made according to the

instruction manual

– The hydraulic system has been filled and vented

– The hydraulic circuit shut-off valves are open

– All electrical connections have been correctly made

– Voltage is included within a 10% tolerance with respect to the unit

nominal voltage

– The earth connection has been correctly made

– All electrical connections have been properly tightened

FIRST COMMISSIONING

NOTE FOR FIRST STARTUP:

FIRST COMMISSIONING

THE APPLIANCE MUST BE ALWAYS POWERED TO ENABLE CORRECT PRE-HEATING OF THE COMPRESOR OIL. THE

APPLIANCE MUST HAVE BEEN POWERED F OR AT LEAST EIGHT HOURS BEFORE THE FIRST STARTUP IS POSSIBLE.

After switching on the appliance:

- Turn OFF the main system circuit breaker

- Remove the inspection panel by undoing the four fixation screws

– - Turn ON the main equipment switch “A”

A

– Turn ON the main system circuit breaker)

– Make sure the display is on and showing the system return

water temperature

– Keep the unit powered but not working for at least two hours, so

that the compressor crankcase oil is heated

– switch on the appliance..

For the internal component locations, refer to the diagrams on

pages 9, 10, 11, 12, 13.

31

BY-PASS CALIBRATION OPERATIONS FOR 5-6-7-8 TYPES AND 13-14-15-16 TYPES

- - Switch on the appliance.

- Wait for the unit operation to get stabilized

- Check the heat rise between system delivery and return which must be between 4°C and 6°C

- If it is not so, operate the calibration by-pass, opening it to increase the heat rise or closing it to decrease the heat rise

- After adjusting the by-pass, bring the unit back to steady state and check if the heat rise between system delivery and return is between

4°C and 6°C.

- Replace the inspection panel

After operating the by-pass valve (to be installed downstream of the machine for 5-6-7-8 types and 13-14-15-16 types), wait for the

unit operation to get stabilized and repeat the check .

Should not it be possible to regulate the heat rise between system delivery and return within 4÷6°C, check the system load losses

and compare them with the flow rate-available lift chart of the pump on page 8.

A heat rise over 6°C entails the risk of ice forming in the plate heat exchanger

For the by-pass location, refer to the hydraulic diagram on page 21

It is not allowed to operate the unit with a heat rise over 6°C.

SWITCHING THE EQUIPMENT ON AND OFF

To SWITCH ON and OFF the “COOLING” and “HEATING” functions, use the CONTROL PANEL installed on the machine, or the two “SO”

ON-OFF and “SEI” SUMMER-WINTER REMOTE SWITCHES, if installed..

Mode (Heat, Cool…) Icon

Economy icon

(configurable)

Clock icon

Dysplayed quantity

measure unit

Resource (compressor, fans)icon

Menu navigation icon

If the “Er 20” indication appears on the display in this first phase, please follow the instructions i:

To access the control panel, open the relevant door:

- Remove the lock screw

- Simultaneously press the (A) points and lift the door

After operating the control panel:

- Close the door and replace the lock screw.

- Check the water flow rate and the connection with the flow switch terminals 9 and 10.

32

Switching on

To select the operating mode, press and hold the

“HEAT”, “COOL” or “STBY” is displayed, depending on the

controller’s current operation status.

Select HEAT mode with the UP

confirm with the

key.

or DOWN keys and

key until

Heating (WINTER CYCLE)

Selecting HEAT the

The switching from Heating to Cooling modes must be only

done when the plate heat-exchanger inlet water

temperature is lower than 20°C

The switching from Cooling to Heating modes must be only

done when the plate heat-exchanger inlet water

temperature is higher than 20°C.

. symbol lights up

It is recommended to switch the operating mode only once a

day

.

Cooling (SUMMER CYCLE)

Selecting COOL the

. symbol lights up.

Switching off the heating/cooling modes

Select the STBY option and confirm with the

. symbol lights up.

In case of power failure for more than four hours, after

restoring the unit, keep it powered but switched off for at

least eight hours

In case of power failure for less than four hours, after

restoring the unit, keep it powered but switched off for the

same number of hours the power failed.

key. The

OPERATIONS MADE BY THE ON-OFF AND “SEI” SUMMER-WINTER REMOTE SWITCHES (IF PRESENT).

Funzione Raffreddamento

Switching on

- Turn OFF the “SEI” SUMMER-WINTER remote switch”

- Turn ON the “SO” ON-OFF remote switch

The indicator LED

lights up on the control panel .

33

Switching off

Turn OFF the “SO” ON-OFF remote switch

The “OFF” indication starts flashing on the CONTROL

PANEL

Switching on the heating mode

Switching on

- Turn ON the “SEI” SUMMER-WINTER remote switch

- Turn ON the “SO” ON-OFF remote switch

The indicator LED

Switching off the heating mode

- Turn OFF the “SO” ON-OFF remote switch.

The “OFF” indication starts flashing on the CONTROL PANEL

In case of power failure for more than four hours, after

restoring the unit, keep it powered but switched off for at

least eight hours.

In case of power failure for less than four hours, after

restoring the unit, keep it powered but switched off for the

same number of hours the power failed.

lights up on the control panel.

It is recommended to switch the operating mode only once a

day

34

DEFROSTING CONTROL

To prevent ice from forming on the finned coil, during the winter

heating phase, each machine is equipped with an automatic

defrosting device, controlled by the microprocessor through

pressure probes and timer.

CHECKS DURING AND AFTER THE FIRST COMMISSIONING

Once the startup has occurred, check if:

- On three-phase models, the indicator light on the phase monitor is

on; in this case start the compressor.

- The current absorbed by each compressor phase is lower than the

maximum one indicated in the Technical Data table

- The equipment is working within the recommended operating

conditions (see page 29)

INACTIVITY FOR A LONG PERIOD

To switch off the heat pump, whatever its operating mode, o nly

use the control panel

After switching off the unit:

– Turn OFF the remote switch (if present)

– Deactivate the internal terminal units, by turning off the switch of

each appliance

– Turn OFF the main system circuit breaker

– Close the water taps.

ORDINARY MAINTENANCE

Periodic maintenance is essential to preserve the appliance

efficiency both from the functional and the energy-saving point of

view.

The maintenance plan which the manufacturer’s Support

Technical Service or the refrigeration serviceman must observe,

at least once a year, features the following operations and

checks:

– - Expansion tank pressure check (2 bar)

- Water circuit filling

- Water circuit check for presence of air

- Efficiency of safety devices

- Supply voltage

- Electrical input

It may be necessary to remove the chiller inspection panels during

maintenance operations.

In this case, proceed as follows::

– - Undo the fixation screws and remove the inspection panels.

– At the end of maintenance operations::

– Replace the panels proceeding in reverse order.

The

indicating this status.

- The hydraulic circuit is totally vented

– The equipment performs a stop and a subsequent restart.

– - Tightness of electrical connections

- State of compressor remote switch

- Efficiency of plate heat exchanger resistor

- Efficiency of compressor resistor

- Cleaning of finned coil (*)

- Cleaning of fan grilles

- Cleaning of condensate collection vessel (if installed).

(*) every three months.

symbol flashes on the control panel during defrosting,

It is not allowed to operate the unit with an inverted phase

(only three-phase models

If the outside temperature may drop below zero, there is the

risk of frosting.

The temperature of the circulating water inside the heat pump

should never exceed 60°C.

Should the unit be connected in parallel to a boiler, close the

unit cocks during the boiler operation. The temperature of the

circulating water inside the heat pump should never exceed

60°C.

For equipment installed near the sea, maintenance intervals

must be cut by half

35

EXTRAORDINARY MAINTENANCE

REFRIGERANT GAS CHARGING

Units are pre-charged with refrigerant gas R410a and adequately

tested in factory.

Therefore, under normal conditions, they do not require any

interventions by the manufacturer’s Support Technical Service as to

checking the refrigerant gas. However, small leaks may occur over

time through connections, from which refrigerant gas might come out,

thus discharging the circuit and causing abnormal operation of the

appliance.

In these cases, the refrigerant leaks must be located and

repaired, and the cooling circuit washed with nitrogen or suitable

products and then recharged according to this procedure:

– - Drain and dehydrate the whole cooling circuit with a vacuum

pump until reading about 10 Pa on the vacuum-meter;

Wait at least 5 minutes and make sure this value does not rise

again over 200 Pa..

- Connect the refrigerant gas bottle or a charging cylinder to the

liquid line tap..

– Charge the quantity of refrigerant gas (in liquid state) indicated

on the equipment’s rating plate.

– Always check the overheating and undercooling values which,

under the appliance rated operating conditions, must be included

between 6 and 10°C (OVERHEAT.) and max. 2 °C (UNDERCOOL.),

respectively.

After some hours of operation, make sure the flow indicator

shows “dry circuit” (dry – green).

Operating conditions other than the rated ones mat generate

significantly different values

The refrigerant gas must be only charged in liquid state .

The tightness test or the leak detection must be only

performed using refrigerant gas R410A, mixed with nitrogen if

necessary, checking with an adequate leak detector

Do not charge the cooling circuits with a refrigerant gas

different from R410C. Using a refrigerant gas other than

R410A may cause serious damages to the compressor

Do not use oxygen, acetylene or other flammable or

poisonous gases in the cooling circuit, because they can

cause explosions.

COMPRESSOR

The compressor is installed already filled with oil and sealed.

Therefore, it does not normally need special interventions by the

manufacturer’s Support Technical Service.

In case of failure, if the compressor can be repaired, only use

Mobil EAL ARCTIC 22 CC ester oil.

Do not use oils other than the one indicated. The use of other

oils may cause serious damages to the compressor .

CONTROL AND DISPLAY PARAMETERS

The unit control panel enables direct access to main control parameters and display of some typical system variables.

• MAIN PARAMETERS AND TYPICAL VARIABLES

DESCRIPTION

Summer set point COOL 15

Cooling differential tr10 3

Winter set point HEAT 40

Heating differential tr11 3

Return water temperature Ai01

Delivery water temperature Ai02

Condensation pressure Ai03

Outdoor temperature Ai04

DISPLAY INDICATION FACTORY SETTING

A DISPLAY VALUE

DISPLAY ONLY

Observe the factory settings and do not exceed the

admissible ranges so as to obtain the equipment best

operation .

36

ACCESSING AND CHANGING PARAMETERS (USER-LEVEL))

The equipment must be powered and the system return water temperature or the “OFF” indication must appear on the display.

To access and, if necessary, change the parameters, do the following::

Access to the various parameter menus.

– - Pressing the SET

parameters. Scrolling with the

state), CL (clock and date parameters), SP (variable set point parameters), Sr (real non-variable display-only set

points).

Heat and Cool set point change.

To change the inlet (system return) water temperature, do the following.

– Pressing the SET key

this point, the “COOL” indication appears on the display, showing the Summer set point. To change the Summer set point, press the

key, and increase/decrease the previously set value with the and keys. To confirm press the key. Then press the

key to exit.

To change the Winter set point, do the following: When COOL is displayed, press the

the

- To save the parameters, it is always advisable to power off the equipment and then power it on again. The display will indicate the return

water temperature once again.

Changing the temperature differential in heating and cooling modes.

Modifica dei differenziali di temperatura in heat e cool.

To change the temperature differential of the two cycles, proceed as follows:

key change the parameter with the and keys.

Exit and save

key, the “Ai” indication appears on the display, indicating the temperature and pressure

and keys, the other parameter menus can be accessed: A0 (output

. the first “Ai” menu is displayed; with the key enter the SP menu and press the SET key . At

key to access HEAT (Winter set point); press

- Press the

- Now press the

- Press the

cycle. Press

Key. Then press

- .

- To change the temperature differential of the Winter cycle, move to the tr10 parameter (see previous item).

- Press the

access the parameter, and change the differential value with the arrow keys.

- Press the

Exit and save

- To save the parameters, it is always advisable to power off the equipment and then power it on again.

The display will indicate the return water temperature once again.

and keys simultaneously. The “PAR.” indication appears on the display.

key to access the CF menu.

key to access the tr menu, then press to access tr10, which indicates the temperature differential for the Summer

again to access the parameter, and change the differential value with the arrow keys. To confirm press the .

key to exit

key until the tr10 parameter is displayed; with the key move to the tr11 parameter. Now press the key to

key, until the return water temperature value appears on the display.

37

TROUBLESHOOTING

In case of abnormal operation of the equipment, alphanumeric codes

(ex. Er01) are displayed on the control panel, alternating with the

system return water temperature.

Some alarms are automatically reset, whereas others can only be

manually reset by pressing the UP and DOWN keys (see pages

15 and 36).

AUTOMATIC FAULT RESET

When the alarm cause has been removed, the control panel

automatically returns to normal operating mode..

MANUAL FAULT RESET

When the cause which generated the fault has been removed,

restore operation by simultaneously pressing the “UP” and

“DOWN” keys

FAULT CAUSE SOLUTION

The compressor does

not

start

Remote switch coil fault.

Phase monitor LED off (three-phase version) Invert two phases

The compressor stops

due to protection device

trip

Insufficient efficiency

The compressor is noisy

Supply voltage too low.

Circulating pump faulty or clogged.

Electrical connections not well tightened.

Electronic board failure.

Start capacitor failure (single-phase version)

Compressor failure.

Excessive delivery pressure (Er01).

Low suction pressure (Er05).

Low flow rate (Er020).

Circulating pump faulty or clogged (Er020).

Abnormal flow switch operation.