Tecnam P92 ECHO, P92-S ECHO User Manual

Maintenance

Manual

Doc. n° 92/115

2nd Issue, September 10th, 2004

1st Revision, October 25th, 2004

Ed

.2

efore flying the aircraft we recommend reading carefully this manual, the flight

B

P92 Echo & P92-S Echo

Maintenance Manual

INTRODUCTION

manual and the engine’s manuals. A thorough knowledge of the aircraft, of its

qualities and of its limitations will allow you to operate with greater safety.

The P92 Echo and P92-S Echo are uncomplicated and sturdy machines whose

features include simple servicing and superior flying qualities. This manual

describes time and modes for correct servicing procedures. Scrupulously following

instructions will insure that your P92 Echo or P92-S Echo will accompany you

dependably for a long time with optimal performance in absolute safety.

This manual consists of 5 sections; a table of contents at the beginning of each

section will allow you to reach quickly any selection.

Information contained in this manual is based on available data at publication time,

possible variations shall be presented with servicing bulletins.

This manual describes correct servicing of parts manufactured by TECNAM and, in

subordinate measure, of the list of components purchased from external suppliers;

for more complete information on individual components it is necessary to refer to

the component’s manufacturer’s manual.

For further information or explanations contact:

COSTRUZIONI AERONAUTICHE

a

1

Traversa via G.Pascoli

TECNAM

s.r.l.

80026 Casoria (NA) - ITALY

081-7583210 081-7584528

Date: Sept. 2004

Page . i

Ed

.2

P92 Echo & P92-S Echo

Maintenance Manual

INTRODUCTION

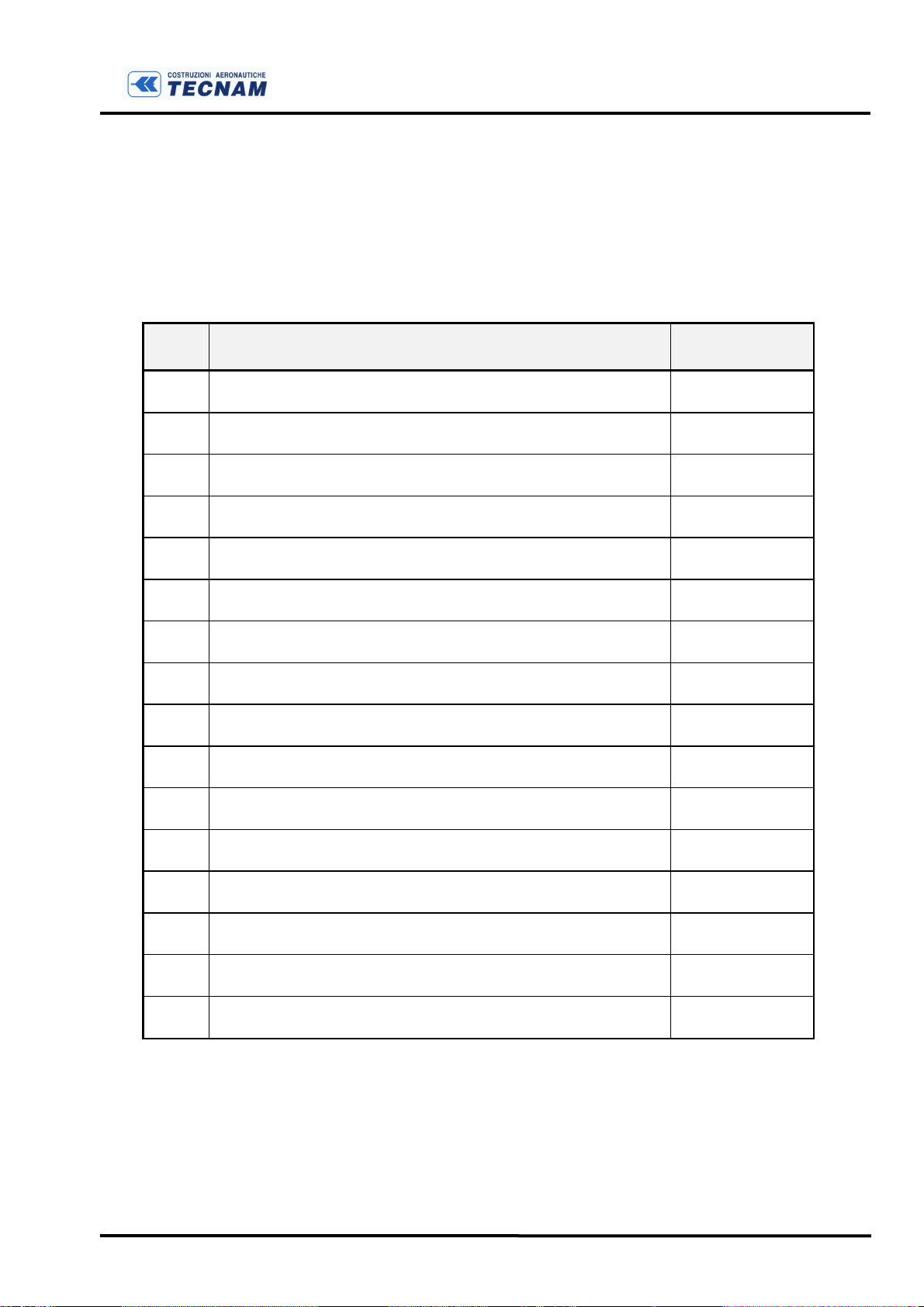

SECTIONS

General Section A

Inspections and Servicing Section B

Airframe Section C

Powerplant and Propeller Section D

Systems Section E

Date: Sept. 2004

Page . ii

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

SECTION A

GENERAL

TABLE OF CONTENTS

1 - DESCRIPTION AND GENERAL CHARACTERISTICS-------------------------------------------- 4

Ed. 2

Page A-1 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

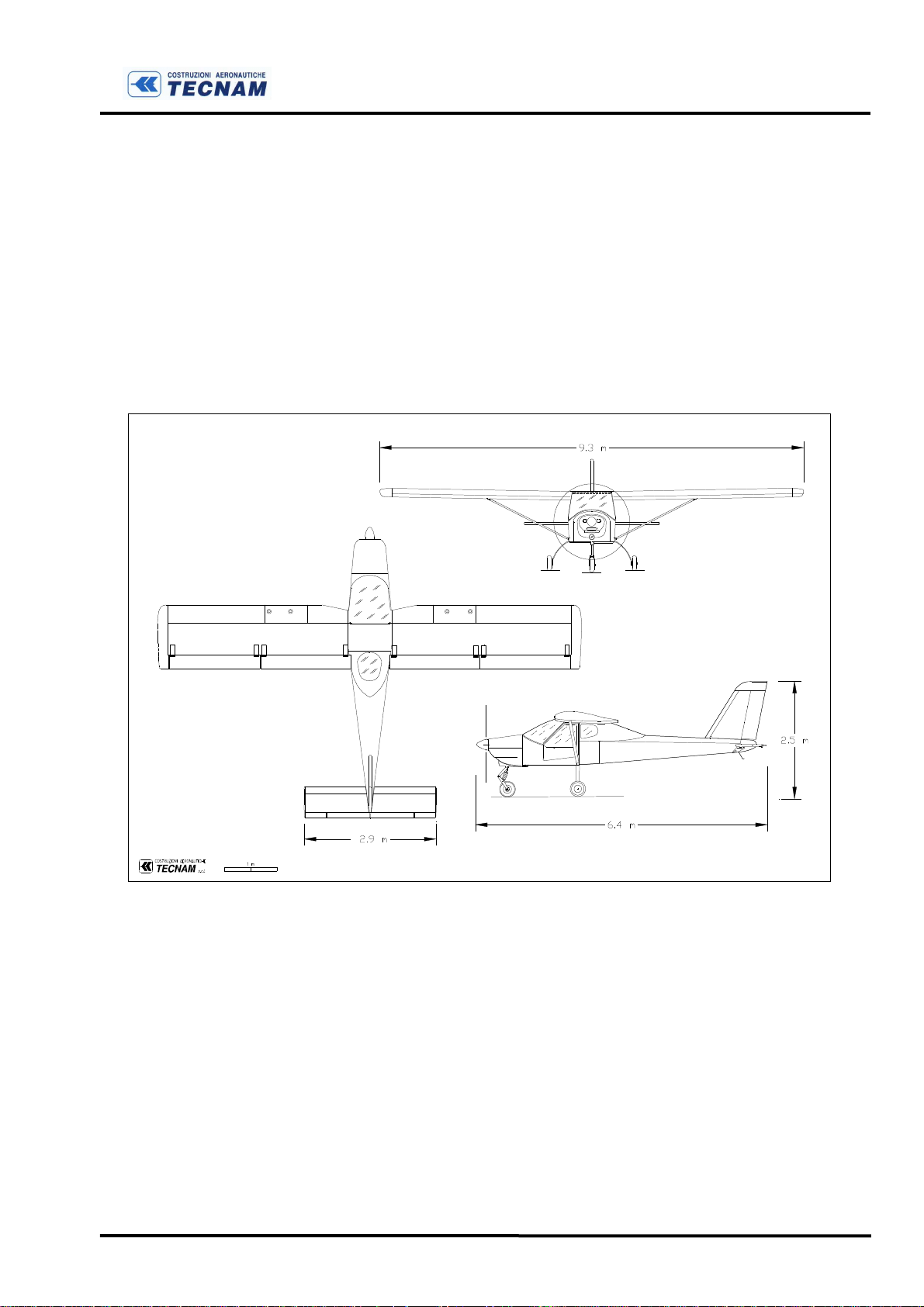

TABLE I

WING

Wing Span 9.3 m

Wing Area 13 m2

Aspect Ratio 6.6

Taper ratio 1.0

Chord 1.4 m

Flap span 1.97 m

Flap chord 0.385 m

Aileron span 1.97 m

Aileron chord 0.385 m

FUSELAGE

Length (overall) 6.4 m

Width max. 1.06 m

Height max. (vertical tail end) 2.5 m

EMPENNAGES

Stabilator Span 2.90 m

Stabilator Area 1.972 m2

Stabilator chord 0.680 m

Vertical Tail Span 1.230 m

Vertical Stabilizer Area 0.720 m2

Rudder Area 0.350 m2

LANDING GEAR

Wheel Track 1.8 m

Wheel Base 1.6 m

Nose Wheel Tire Sava 4.00-6

Main Wheel Tires

WEIGHTS

Maximum Take Off Weight 450 kg

Empty Weight 281 kg

Payload 169 kg

Wing Loading 34.1 kg/m2

Power Loading (Rotax 912 UL) 5.6 kg/hp

Power Loading (Rotax 912 ULS) 4.6 kg/hp

AirTrac A-A1D4

5.00-5

Ed. 2

Page A-2 Date: Sept. 2004

POWERPLANT:

ROTAX 912 UL

Four stroke, four cylinder

Maximum Power 59.6 kW @ 5800 rpm (max. 5 minutes)

Maximum Continuous Power 58 kW @ 5500 rpm

Reduction Gear 1 : 2.27

ROTAX 912 ULS

Four stroke, four cylinder

Maximum Power 73.5 kW @ 5800 rpm (max. 5 minutes)

Maximum Continuous Power 69 kW @ 5500 rpm

Reduction Gear 1 : 2,43

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

PROPELLER:

For 912UL: TONINI GT ECHO 92/166/145

Twin blade all-wood ∅ 166 cm, fixed pitch.

For 912ULS: TONINI GT ECHO 92/172/164

Twin blade all-wood ∅ 172 cm, fixed pitch.

Ed. 2

Page A-3 Date: Sept. 2004

1st revision, October 25

th

2004

FUEL

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

Fuel grade

Rotax 912 UL

• Min RON 90

• EN 228 Regular

• EN 228 Premium

• EN 228 Premium plus

• AVGAS 100 LL (*)

Rotax 912 UL

• Min RON 90

• EN 228 Premium

• EN 228 Premium plus

• AVGAS 100 LL (*)

Fuel tanks 2 wing tanks integrated within the wing's leading

edge with fuel strainer located in engine cowling

Capacity of each wing tank 35 litres (45 litres – Optional)

Total capacity 70 litres (90 litres – Optional)

(*) Please refer to “Rotax Operator’s Manual”

Oil System

Oil system type Forced, with external oil reservoir

Oil Lubricant specifications and grade are detailed into

the “Rotax Operator’s Manual” and in its related

documents

Oil Capacity: max. 3.0 litres – min 2.0 litres

COOLING

Cooling system: Mixed air and liquid pressurized closed circuit

system

Coolant: Coolant type and specifications are detailed into

the “Rotax Operator’s Manual” and in its related

documents.

Ed. 2

Page A-4 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

1 - DESCRIPTION AND GENERAL CHARACTERISTICS

The

P92 Echo

structure monoplane with tricycle landing gear and steerable nose gear.

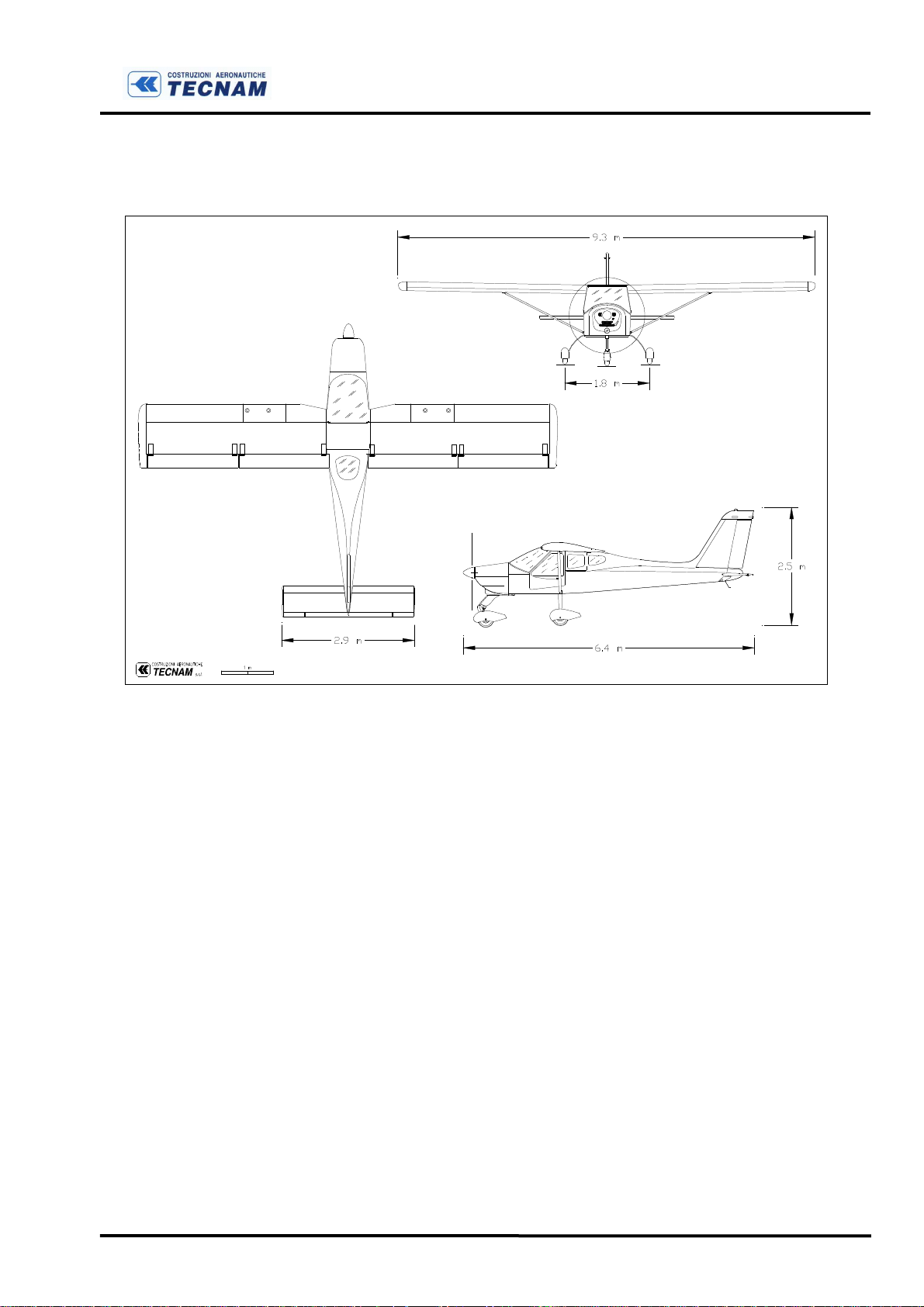

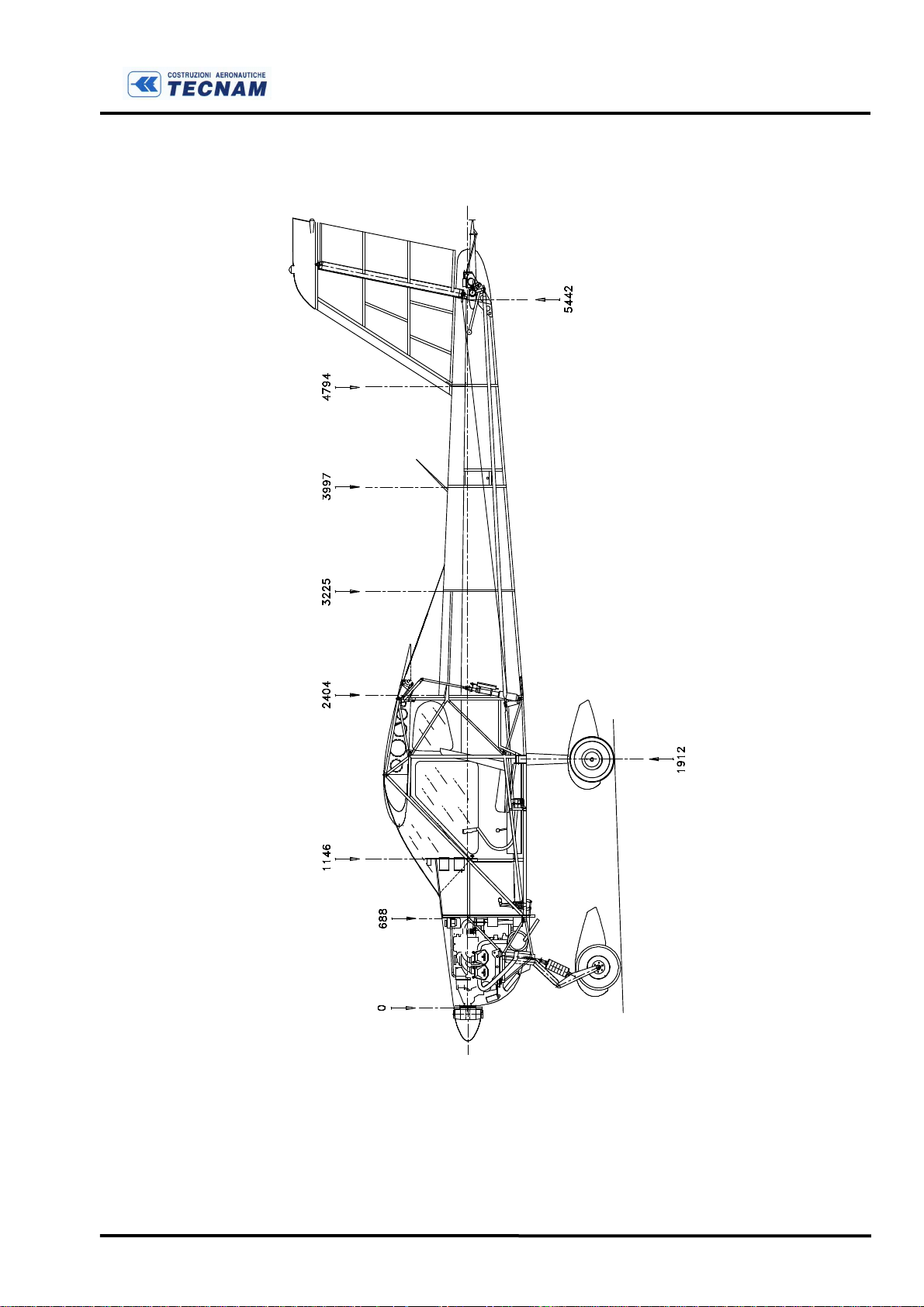

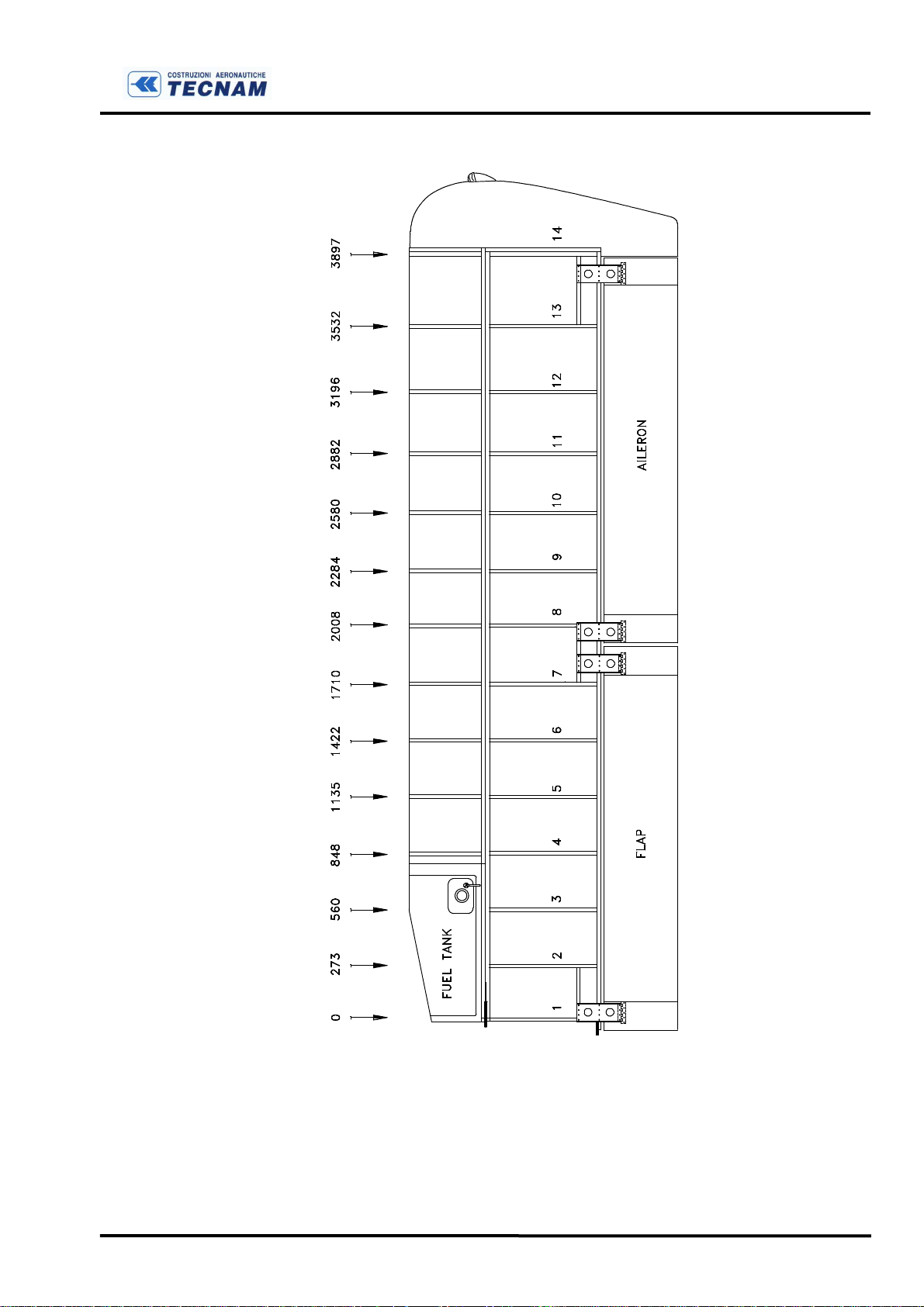

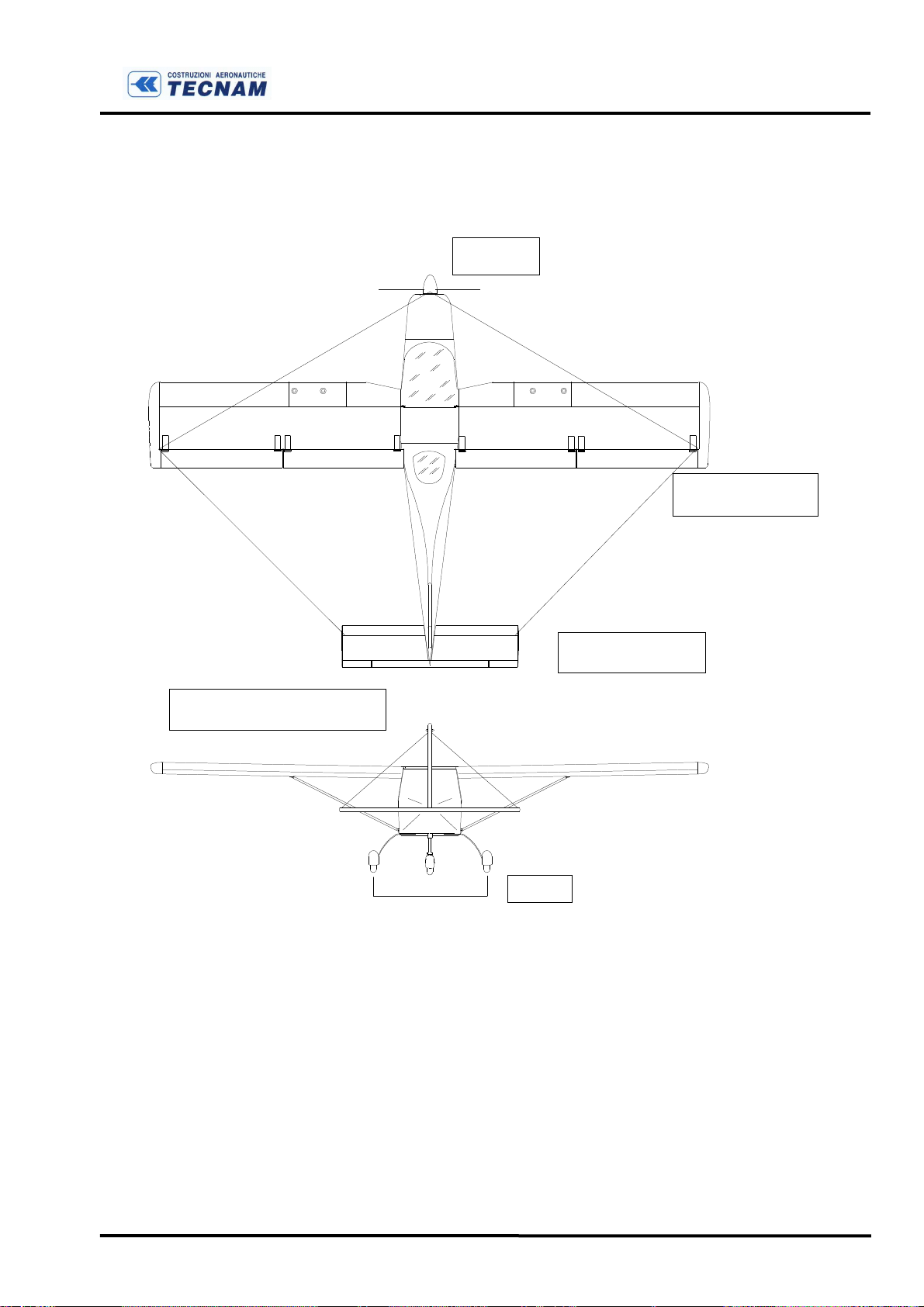

Figure A-1 below shows a Three View drawing of the aircraft (P92-S Echo) while table I

reports main technical characteristics and dimensions; figure A-2 shows a longitudinal

section of the aircraft and figure A-3 shows the wing’s planform view.

P92 Echo

GENERAL VIEW

and

P92-S Echo

are a twin seat, single engine, strutted high wing, metal

F

IGURE

A-1 P92 E

CHO - THREE VIEWS

Ed. 2

Page A-5 Date: Sept. 2004

P92-S Echo

GENERAL VIEW

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

F

IGURE

A-1

BIS

P92-S E

CHO - THREE VIEWS

Ed. 2

Page A-6 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

F

IGURE

Ed. 2

A-2 L

ONGITUDINAL SECTION

Page A-7 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

F

IGURE

A-3 W

ING’S PLANFORM VIEW

Ed. 2

Page A-8 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

SECTION B

INSPECTIONS AND SERVICING

TABLE OF CONTENTS

1. GROUND HANDLING..........................................................................................................2

2. PARKING AND TIE DOWN................................................................................................2

3. JACKING................................................................................................................................2

4. LEVELING.............................................................................................................................3

5. CONTROL SETTINGS......................................................................................................... 4

6. TRIM-TAB ADJUSTMENT .................................................................................................4

7. AIRCRAFT ALIGNMENT...................................................................................................5

8. WEIGHING AND DETERMINATION OF THE C.G. VERTICAL ................................6

TABLE OF WEIGHTS AND DETERMINATION OF C.G..............................................................7

9. CORROSION PREVENTION..............................................................................................8

10.

SERVICE BULLETINS....................................................................................................9

11.

SERVICING.....................................................................................................................10

12.

LUBRICATION...............................................................................................................11

INTRODUCTION ........................................................................................................................... 11

LUBRICATION POINTS (SEE

FIG.

B-5)........................................................................................12

13.

Ed.2

INSPECTION’S POINT .................................................................................................15

14.

INSPECTIONS................................................................................................................16

FOREWORD...................................................................................................................................16

PERIODIC INSPECTIONS............................................................................................................. 17

Page B-1 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

1. GROUND HANDLING

Moving the aircraft on ground is accomplished by pushing on the wing struts close to

wing attachments or by pulling on the propeller blades close to hub. Aircraft can be

steered using the rudder or, for sharp turns, by lowering the tail to raise nose wheel off the

ground. In this case, owing to the favourable CG location, a gentle push on the tail cone

just ahead of empennage surfaces is all that’s needed. Avoid dragging nose wheel

sideways and do not attempt to counter any movement of the aircraft by handling it by its

wing tips.

2. PARKING AND TIE DOWN

As a general precaution for outdoor parking, it is wise to position aircraft into the wind

and to set the parking brakes or chock the wheels if chocks are available.

In severe weather and high wind conditions, aircraft tie-down is recommended. Tie ropes

should be secured to the wing tie-down fittings located at the upper end of each wing

strut. Secure opposite end of ropes to ground anchors. Nose gear fork may be used as

fixing for forward tie-down.

Aircraft control stick should be locked using safety belts to prevent possible wind action

from causing control surfaces to hit end travel.

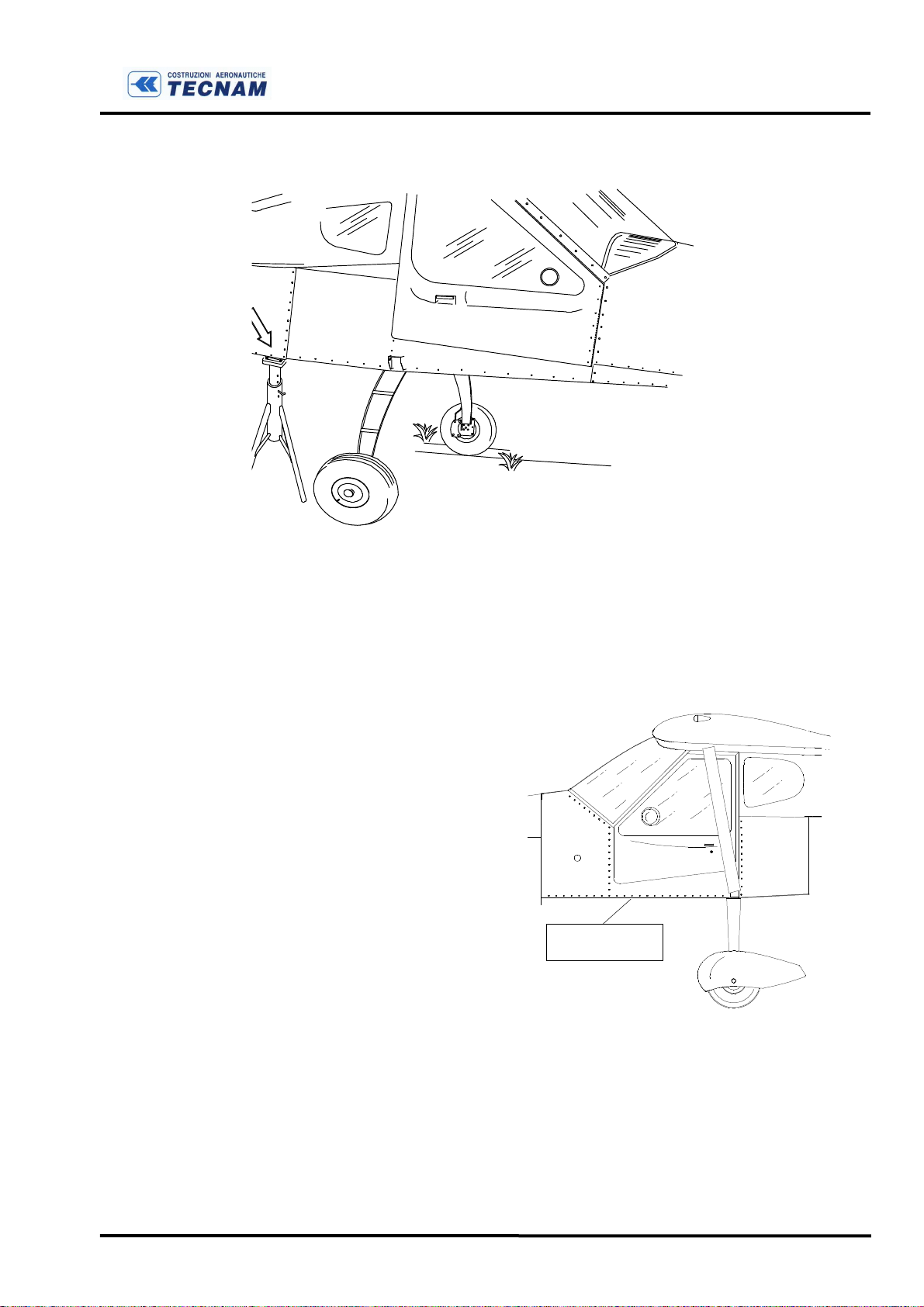

3. JACKING

Given the low empty weight, jacking one of the main gear wheels can be accomplished

even without hydraulic jack. In fact, it is sufficient that one person lifts the wing tip in

proximity of the spar area before the tip, while another person positions a suitably high

support, like a wooden stand or block, under the leaf spring attachment. To avoid

scratching the paint, cover the stand or block with rubber or other suitable material.

In the event the leaf spring must be removed, the stand should be positioned under the

cabin, just ahead of the leaf spring as shown in figure B-1.

CAUTION

As general rule, apply force to aircraft structure only on main structural

elements such as frames, ribs or spars.

Ed.2

Page B-2 Date: Sept 2004

N THE LEVEL

ON THE INSIDE OF THE

CABIN

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

F

IGURE

B-1 J

ACKING

4. LEVELING

Occasional levelling of aircraft may be necessary to insure proper wing incidence and/or

dihedral or for exact CG location.

The aircraft is levelled when the

lower cabin door sill is horizontal

(see fig. B-2) and the main gear

support girder is horizontal in a

transversal direction. Level the

aircraft using a simple level and

adjust the aircraft’s tilt through

shims placed under wheels or by

regulating tire pressure.

POSITIO

Ed.2

F

IGURE

B-2 L

EVELLING

Page B-3 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

5. CONTROL SETTINGS

Adjustment of control surfaces must not exceed travel limits reported in table below. Zero

reference mark for stabilator is on left side of aircraft (see figure below).

AILERONS

STABILATOR Up 16o Down 3o

TRIM (

RUDDER RH 25o LH 25o

FLAPS (

(starting from tip line-up

Stab. at 0o , see fig. below

maximum travel

)

)

)

Up 20o Down 15o

2o 12o

0o 35o

Cable tension should be as follows:

CONTROL CABLE TENSION: 20 daN ± 2 for all

REFERENCE RIVET

± 2o

± 1o

± 1o

± 2o

± 2o

F

IGURE

B-3 S

TABILATOR ZERO REFERENCE

6. TRIM-TAB ADJUSTMENT

Travel adjustment of trim tab on tail plane should be carried out as follows:

• Move stabilator to neutral (0 degrees) and lock in position; (this is accomplished by

aligning the stabilator’s leading edge with the reference rivet located on the left side of

tail cone);

• Turn Master-Switch ON;

• Trim to maximum pitch-up;

• Adjust thread of hinged control rod until tab is deflected downwards 12° (use a

protractor or measure downward displacement of trailing edge - 12° relates to roughly

24mm -);

• Tighten adjustment thread lock-nut and fasten connecting pin of control rod to trim-

tab.

Ed.2

Page B-4 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

7. AIRCRAFT ALIGNMENT

Section B

INSPECTIONS

AND SERVICING

A

UPPER/REAR RIVET ON ALUMINIUM SKIN.

i.e. The rivet in common between the fin's rear

spar and the upper rib.

C

B

G

SPINNER BACK

PLATE UPPER

POINT

FIRST RIVET BETWEEN THE

TUBULAR SPAR AND THE

C'

OUTERMOST RIB

A'

LAST RIVET ON THE LOWER

SIDE OF THE REAR WING

SPAR

Ed.2

C

C'

Main Wheels

F

Axle Line

F'

F

IGURE

B-4 R

EFERENCES FOR ALIGNMENTS

Page B-5 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

Datum length in mm

A -B 5030

A’-B 5030

A -C 4365

A’-C’ 4365

C -G 1860

C’-G 1860

F -F’ 1880

± 25

± 25

± 25

± 25

± 20

± 20

± 20

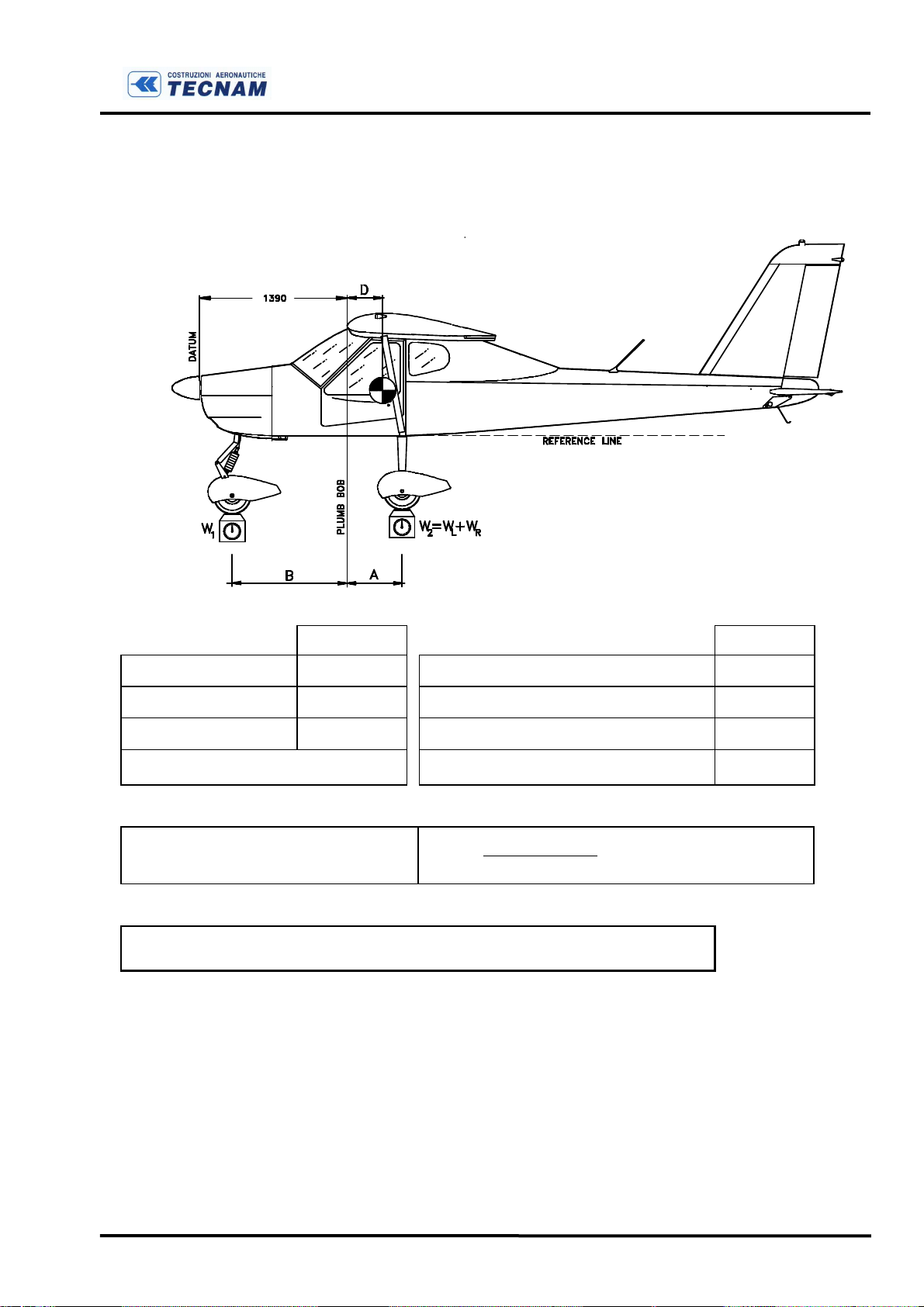

8. WEIGHING AND DETERMINATION OF THE C.G. VERTICAL

U

SE FOLLOWING GUIDELINES

a. Carry out weighing procedure inside hangar

b. Remove any objects inadvertently left on board aircraft

c. Align nose wheel

d. Drain fuel

e. Oil, hydraulic fluids and coolants at operating levels

f. Move seats to most forward position

g. Flaps retracted (0°)

h. Control surfaces in neutral position

i. Position scales (min. capacity. 200 kg) under each tire

:

Ed.2

L

EVELLING

a. Level the aircraft (see paragraph 4)

W

EIGHING

a. Record weights of individual scales

b. Calculate empty weight

D

ETERMINATION OF

C.G.

a. Dropping a plumb bob tangent to the wing’s leading edge, (in the un-

tapered section of the wing, at about one meter from the root), trace a

reference mark on floor.

b. Repeat operation on other wing.

c. Connect the two reference marks with a taut line

d. Measure distances between reference line and landing gear axes

e. Recorded data allows determination of C.G. location and aircraft’s

moment (see following table)

Page B-6 Date: Sept 2004

WAW

B

We

⋅−⋅

P92 Echo & P92-S Echo

Maintenance Manual

TABLE OF WEIGHTS AND DETERMINATION OF C.G.

Section B

INSPECTIONS

AND SERVICING

Kg meters

Wheel weight front

“ “ LH

“ “ RH

W2=WL+WR=

W1 =

WL =

WR =

Distance from bob to nose wheel.

Distance from bob to LH wheel

“ “ RH “

Distance average (AL+ AR)/2

A

=

L

AR =

A =

B =

Empty weight W

e =W1 + W2

=

D

=

2 1

=

___________meters

CG position as wing chord %

De% = De / 1.4 ⋅ 100 =

Ed.2

Page B-7 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

9. CORROSION PREVENTION

It is important to keep the aircraft clean and to remove any collection of corrosive agents

such as oil, grease, dregs and other foreign matter. To avoid damage to finish do not use

polishing detergents.

Original or equivalent corrosion prevention must be re-applied after any alteration or

repair.

If any trace of corrosion is detected it should be removed as soon as possible and part

should be immediately treated to prevent further corrosion.

(a) For steel parts, with the exception of highly stressed components or stainless steel, it is

possible to use abrasives, power brushes, steel brushes if operated manually and steel

wool.

Removing corrosion byproducts from highly stressed steel components (main gear steel

spring) requires particular care.

(b) For aluminium parts, treatment consists in mechanically removing as much as

possible corrosion byproducts, applying corrosion inhibitor and replacing original finish.

Steel wool, emery or steel brushes (unless stainless steel) along with other highly abrasive

material should not be used since steel or emery particles become embedded in the softer

material causing corrosion.

After cleaning surface corrosion, parts must be treated with anti-corrosion finish.

Ed.2

Page B-8 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

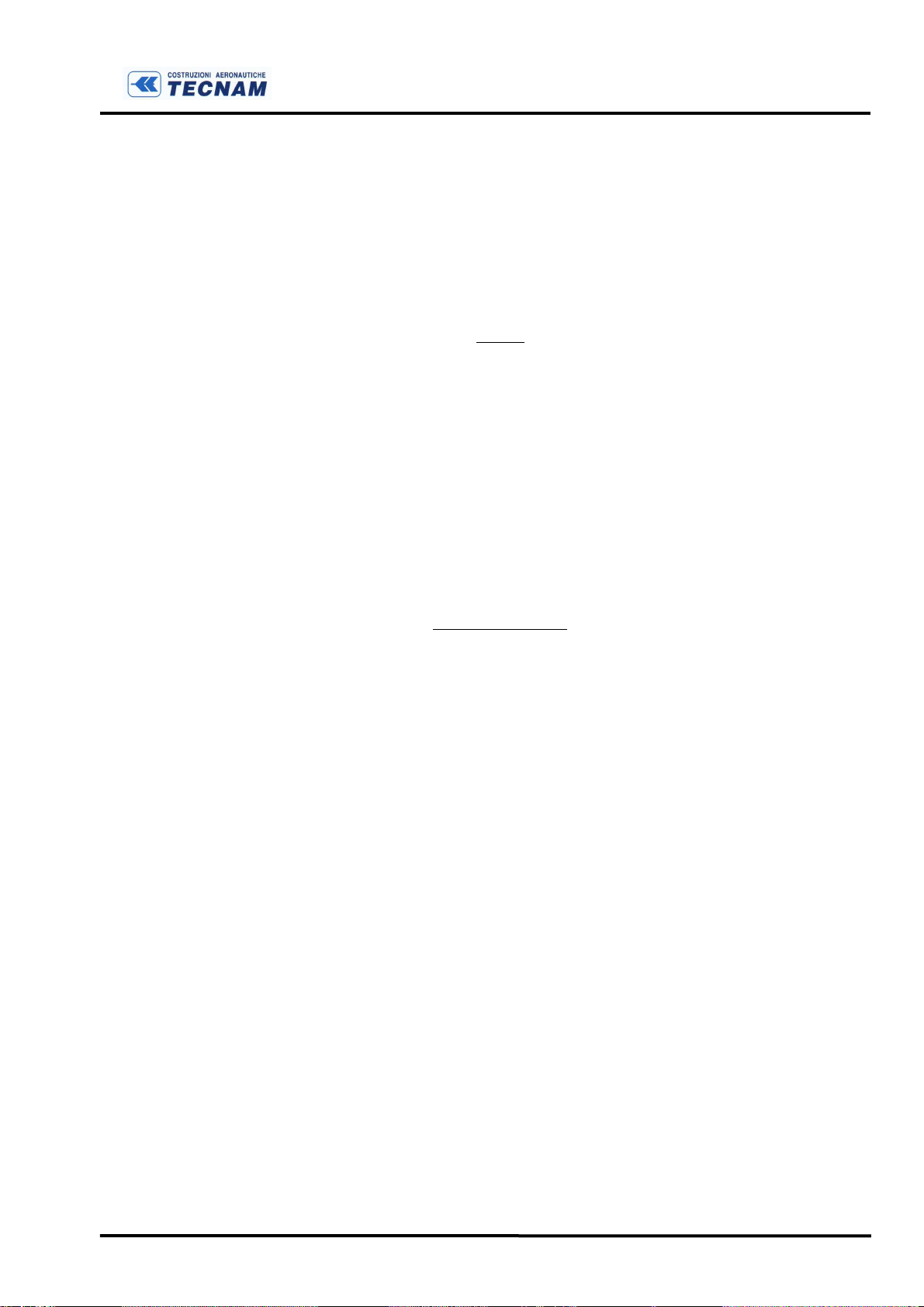

10. SERVICE BULLETINS

The following table must report all servicing bulletins pertaining to the aircraft’s

operating life.

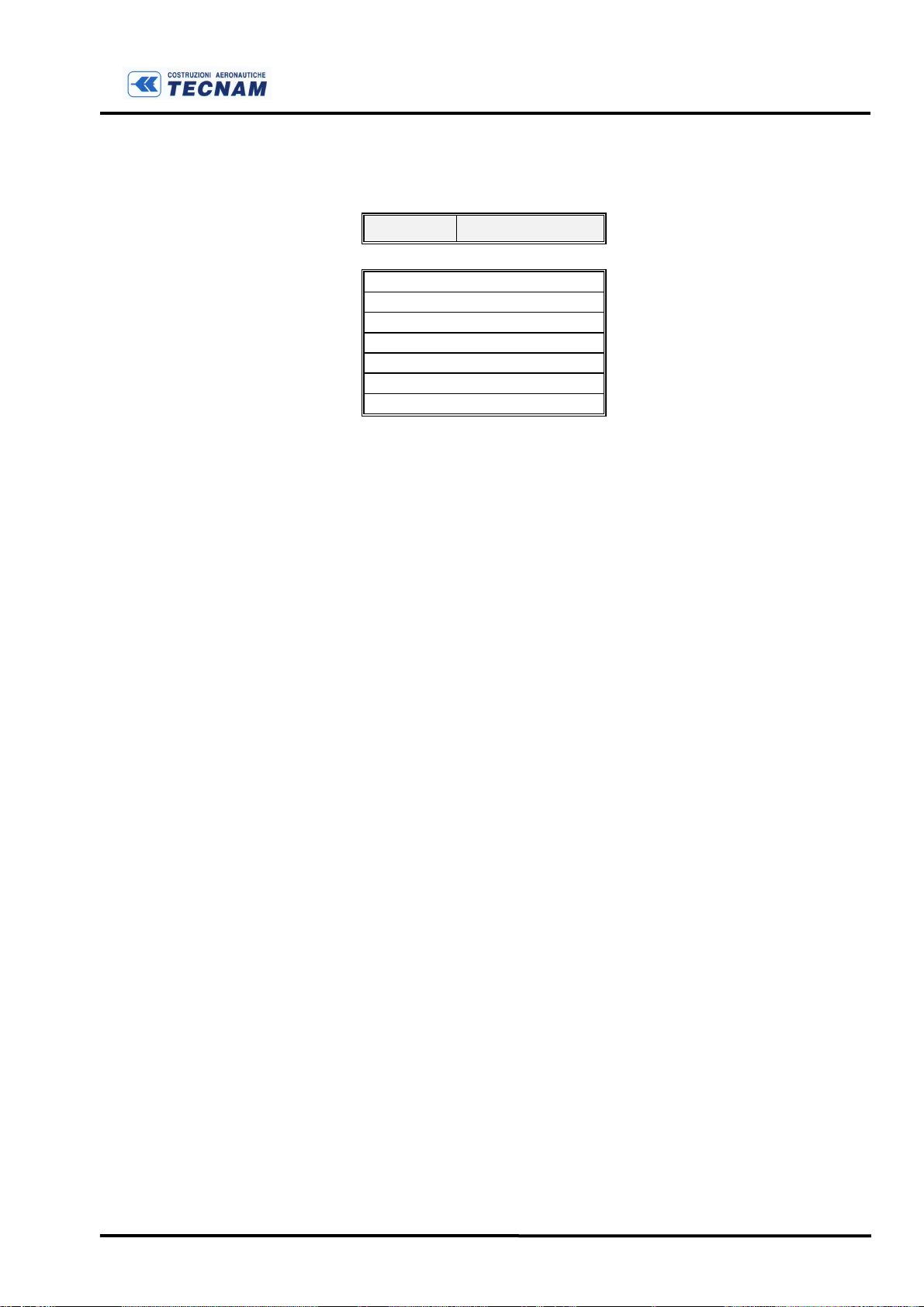

NR. TITLE TYPE

Ed.2

Page B-9 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

11. SERVICING

For scheduled servicing on engine Rotax 912, please refer to the Rotax documentations.

The list below includes only primary engine maintenance operations.

D

AILY

1.

Pitot and static ports - Check for obstructions (see section E);

2.

Oil - Check oil level in reservoir located on firewall.

3.

Coolant - Check coolant level in overflow reservoir located on firewall;

4.

Fuel strainer - Drain off any water and sediment by opening tap and

collecting an amount of fuel at least equal to cup’s capacity.

5.

Fuel tank vents - Check for obstructions.(see section E)

EVERY

100

HOURS

6. Flange carburettor - Visually inspect rubber flange connecting carbs to

engine.

7. Battery - Check level of electrolyte.

8. Engine oil - Change engine oil and replace filter element (refer to

Operator’s Manual of ROTAX 912); initially after first 25 hours.

9. Brake fluid - Check level of brake fluid in the master cylinder located below

the left seat. Add fluid as needed using MIL H5606 standard type UNIVIS

J43.

10.Fuel filter – Check and eventually clean the fuel filter of the electric pump

(if installed).

11.Fuel line and carburettor air filter - Visually inspect fuel lines. Remove

filter and clean accurately. Repeat operation more often in dusty conditions.

If aircraft is equipped with carb heat system, scoop filter shall in any case be

replaced (automotive type air filter: Autobianchi Y10).

12.Propeller - Check attachment bolts for integrity, tightening torque (18 Nm)

and safetying, initially after the first 25 hours.

Ed.2

Page B-10 Date: Sept 2004

Loading...

Loading...