Maintenance

Manual

Doc. n° 92/115

2nd Issue, September 10th, 2004

1st Revision, October 25th, 2004

Ed

.2

efore flying the aircraft we recommend reading carefully this manual, the flight

B

P92 Echo & P92-S Echo

Maintenance Manual

INTRODUCTION

manual and the engine’s manuals. A thorough knowledge of the aircraft, of its

qualities and of its limitations will allow you to operate with greater safety.

The P92 Echo and P92-S Echo are uncomplicated and sturdy machines whose

features include simple servicing and superior flying qualities. This manual

describes time and modes for correct servicing procedures. Scrupulously following

instructions will insure that your P92 Echo or P92-S Echo will accompany you

dependably for a long time with optimal performance in absolute safety.

This manual consists of 5 sections; a table of contents at the beginning of each

section will allow you to reach quickly any selection.

Information contained in this manual is based on available data at publication time,

possible variations shall be presented with servicing bulletins.

This manual describes correct servicing of parts manufactured by TECNAM and, in

subordinate measure, of the list of components purchased from external suppliers;

for more complete information on individual components it is necessary to refer to

the component’s manufacturer’s manual.

For further information or explanations contact:

COSTRUZIONI AERONAUTICHE

a

1

Traversa via G.Pascoli

TECNAM

s.r.l.

80026 Casoria (NA) - ITALY

081-7583210 081-7584528

Date: Sept. 2004

Page . i

Ed

.2

P92 Echo & P92-S Echo

Maintenance Manual

INTRODUCTION

SECTIONS

General Section A

Inspections and Servicing Section B

Airframe Section C

Powerplant and Propeller Section D

Systems Section E

Date: Sept. 2004

Page . ii

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

SECTION A

GENERAL

TABLE OF CONTENTS

1 - DESCRIPTION AND GENERAL CHARACTERISTICS-------------------------------------------- 4

Ed. 2

Page A-1 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

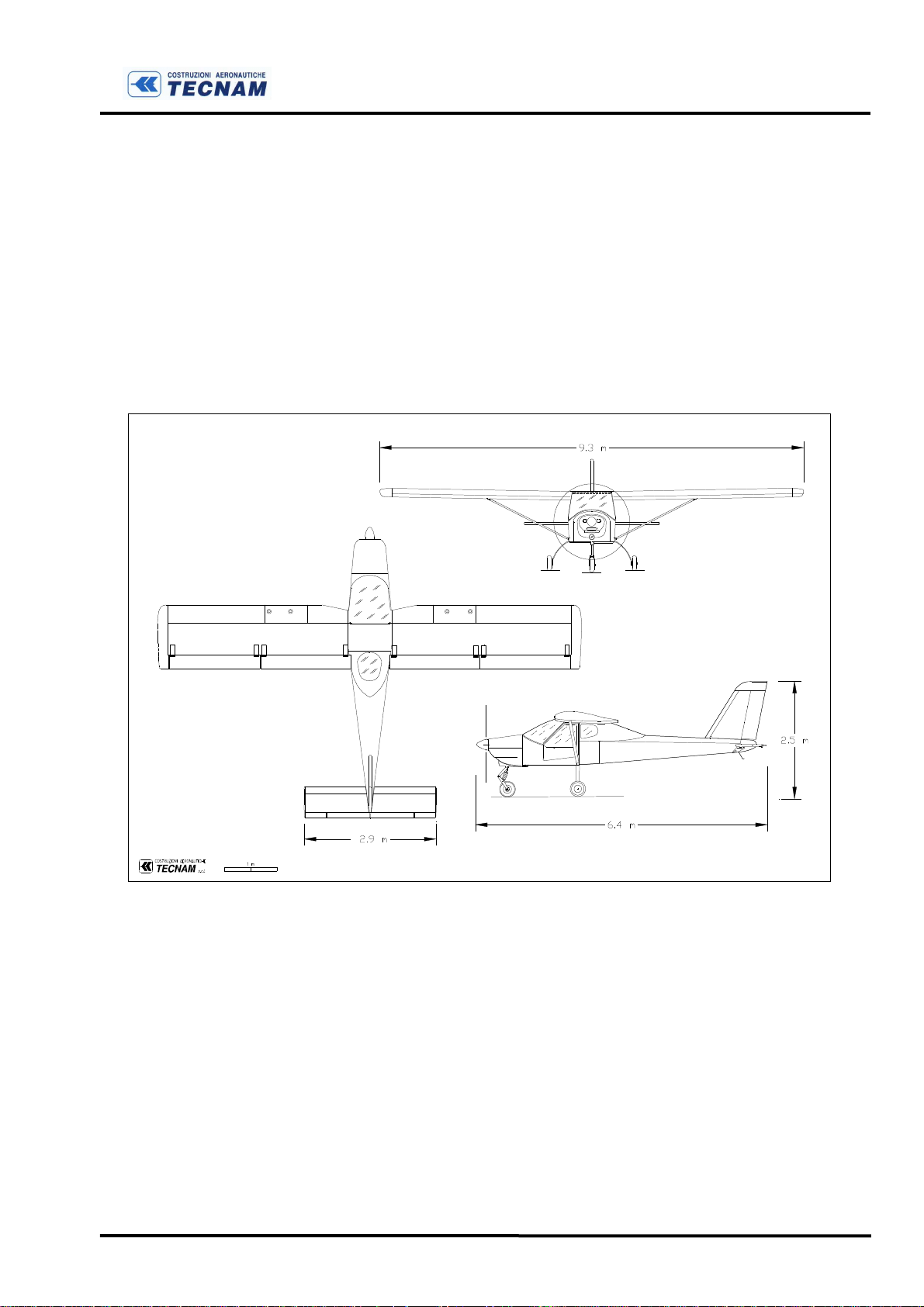

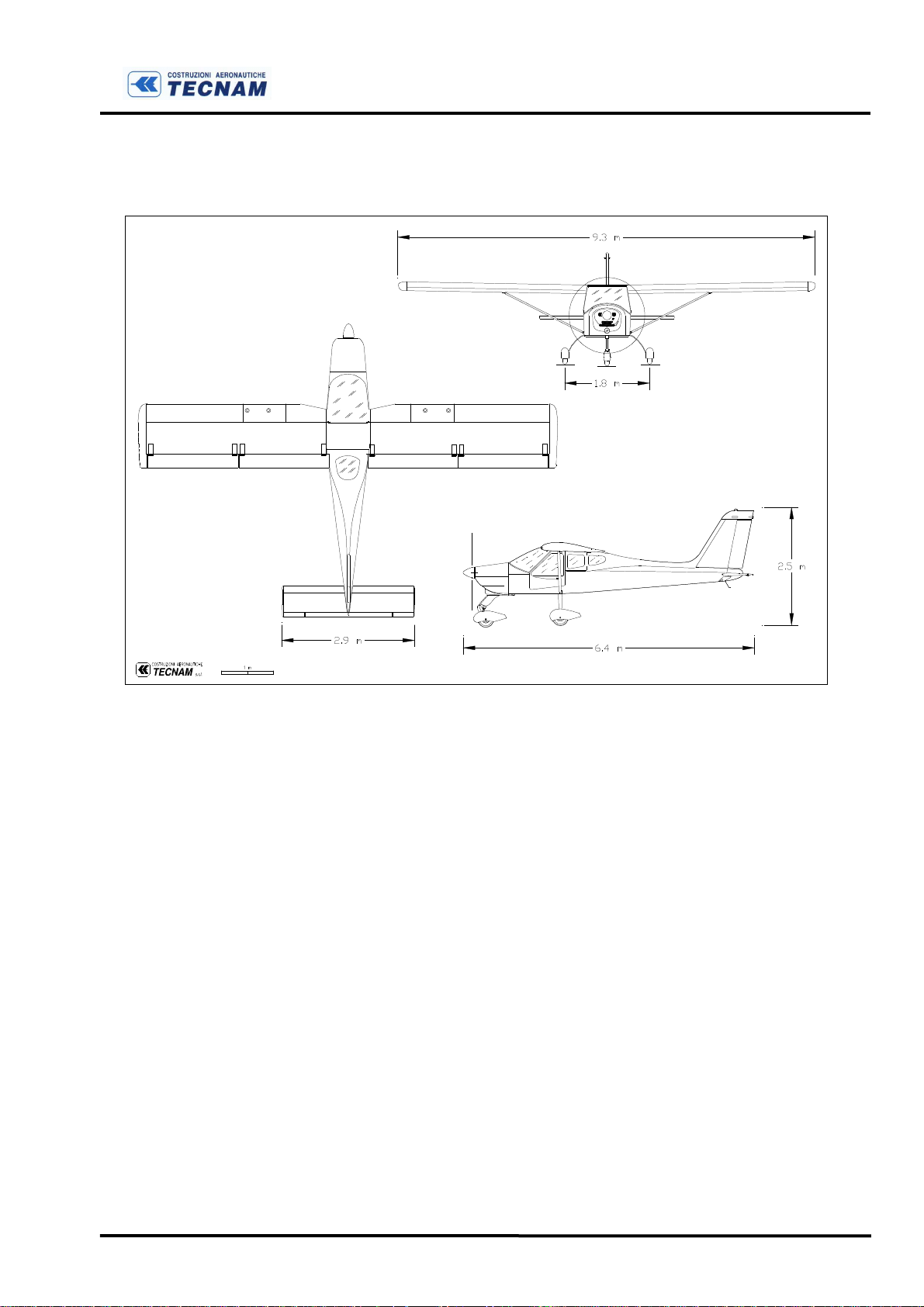

TABLE I

WING

Wing Span 9.3 m

Wing Area 13 m2

Aspect Ratio 6.6

Taper ratio 1.0

Chord 1.4 m

Flap span 1.97 m

Flap chord 0.385 m

Aileron span 1.97 m

Aileron chord 0.385 m

FUSELAGE

Length (overall) 6.4 m

Width max. 1.06 m

Height max. (vertical tail end) 2.5 m

EMPENNAGES

Stabilator Span 2.90 m

Stabilator Area 1.972 m2

Stabilator chord 0.680 m

Vertical Tail Span 1.230 m

Vertical Stabilizer Area 0.720 m2

Rudder Area 0.350 m2

LANDING GEAR

Wheel Track 1.8 m

Wheel Base 1.6 m

Nose Wheel Tire Sava 4.00-6

Main Wheel Tires

WEIGHTS

Maximum Take Off Weight 450 kg

Empty Weight 281 kg

Payload 169 kg

Wing Loading 34.1 kg/m2

Power Loading (Rotax 912 UL) 5.6 kg/hp

Power Loading (Rotax 912 ULS) 4.6 kg/hp

AirTrac A-A1D4

5.00-5

Ed. 2

Page A-2 Date: Sept. 2004

POWERPLANT:

ROTAX 912 UL

Four stroke, four cylinder

Maximum Power 59.6 kW @ 5800 rpm (max. 5 minutes)

Maximum Continuous Power 58 kW @ 5500 rpm

Reduction Gear 1 : 2.27

ROTAX 912 ULS

Four stroke, four cylinder

Maximum Power 73.5 kW @ 5800 rpm (max. 5 minutes)

Maximum Continuous Power 69 kW @ 5500 rpm

Reduction Gear 1 : 2,43

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

PROPELLER:

For 912UL: TONINI GT ECHO 92/166/145

Twin blade all-wood ∅ 166 cm, fixed pitch.

For 912ULS: TONINI GT ECHO 92/172/164

Twin blade all-wood ∅ 172 cm, fixed pitch.

Ed. 2

Page A-3 Date: Sept. 2004

1st revision, October 25

th

2004

FUEL

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

Fuel grade

Rotax 912 UL

• Min RON 90

• EN 228 Regular

• EN 228 Premium

• EN 228 Premium plus

• AVGAS 100 LL (*)

Rotax 912 UL

• Min RON 90

• EN 228 Premium

• EN 228 Premium plus

• AVGAS 100 LL (*)

Fuel tanks 2 wing tanks integrated within the wing's leading

edge with fuel strainer located in engine cowling

Capacity of each wing tank 35 litres (45 litres – Optional)

Total capacity 70 litres (90 litres – Optional)

(*) Please refer to “Rotax Operator’s Manual”

Oil System

Oil system type Forced, with external oil reservoir

Oil Lubricant specifications and grade are detailed into

the “Rotax Operator’s Manual” and in its related

documents

Oil Capacity: max. 3.0 litres – min 2.0 litres

COOLING

Cooling system: Mixed air and liquid pressurized closed circuit

system

Coolant: Coolant type and specifications are detailed into

the “Rotax Operator’s Manual” and in its related

documents.

Ed. 2

Page A-4 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

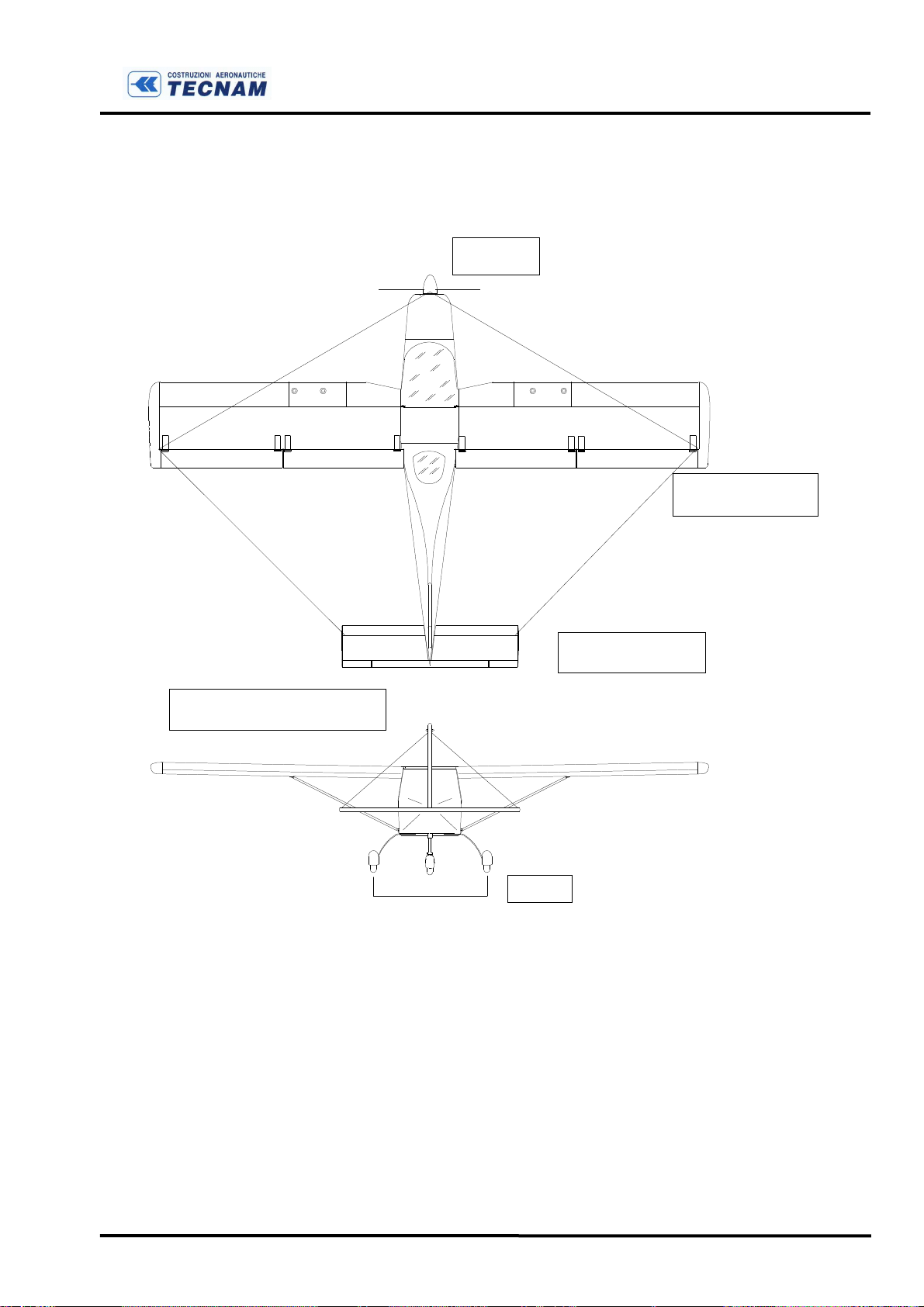

1 - DESCRIPTION AND GENERAL CHARACTERISTICS

The

P92 Echo

structure monoplane with tricycle landing gear and steerable nose gear.

Figure A-1 below shows a Three View drawing of the aircraft (P92-S Echo) while table I

reports main technical characteristics and dimensions; figure A-2 shows a longitudinal

section of the aircraft and figure A-3 shows the wing’s planform view.

P92 Echo

GENERAL VIEW

and

P92-S Echo

are a twin seat, single engine, strutted high wing, metal

F

IGURE

A-1 P92 E

CHO - THREE VIEWS

Ed. 2

Page A-5 Date: Sept. 2004

P92-S Echo

GENERAL VIEW

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

F

IGURE

A-1

BIS

P92-S E

CHO - THREE VIEWS

Ed. 2

Page A-6 Date: Sept. 2004

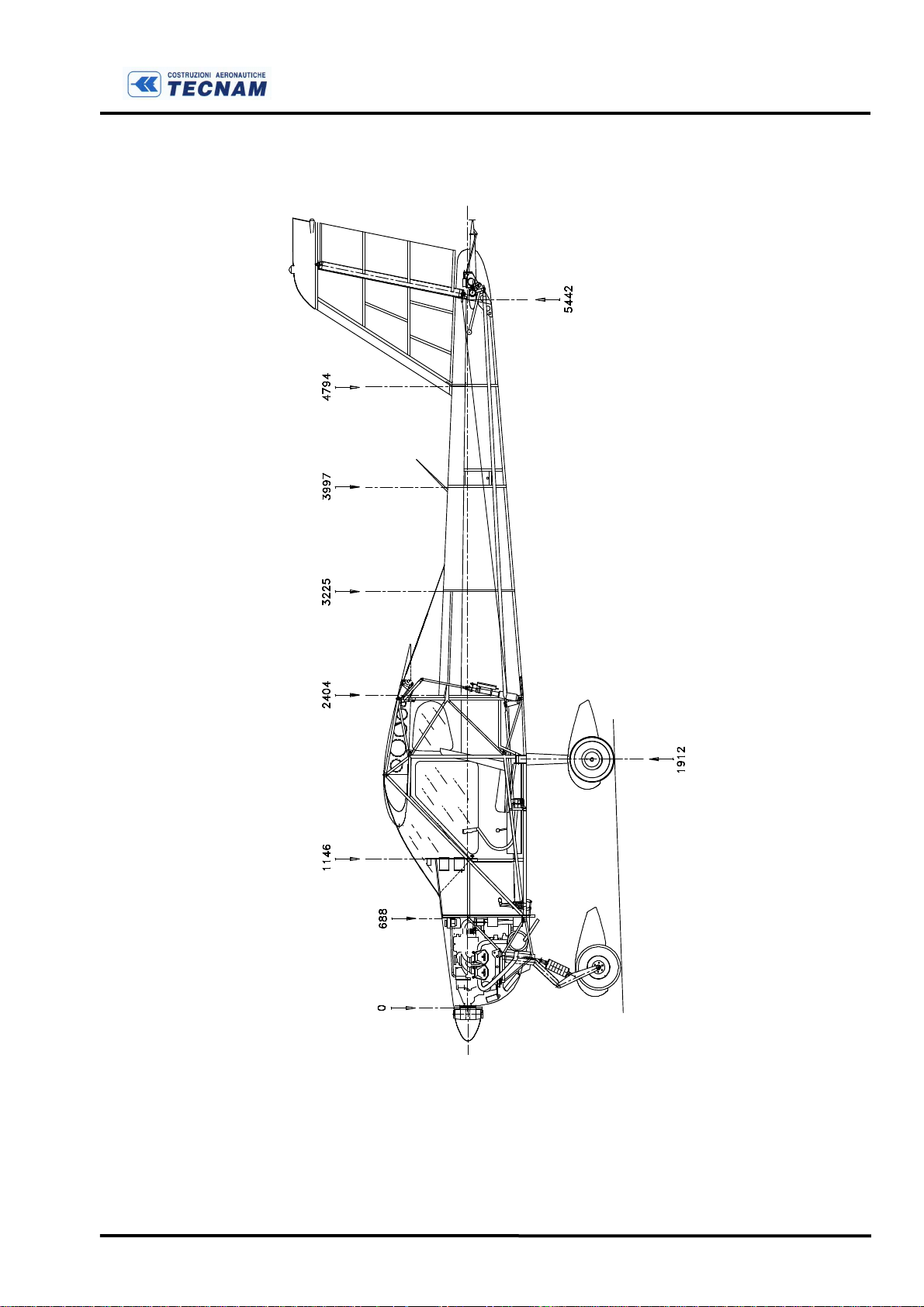

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

F

IGURE

Ed. 2

A-2 L

ONGITUDINAL SECTION

Page A-7 Date: Sept. 2004

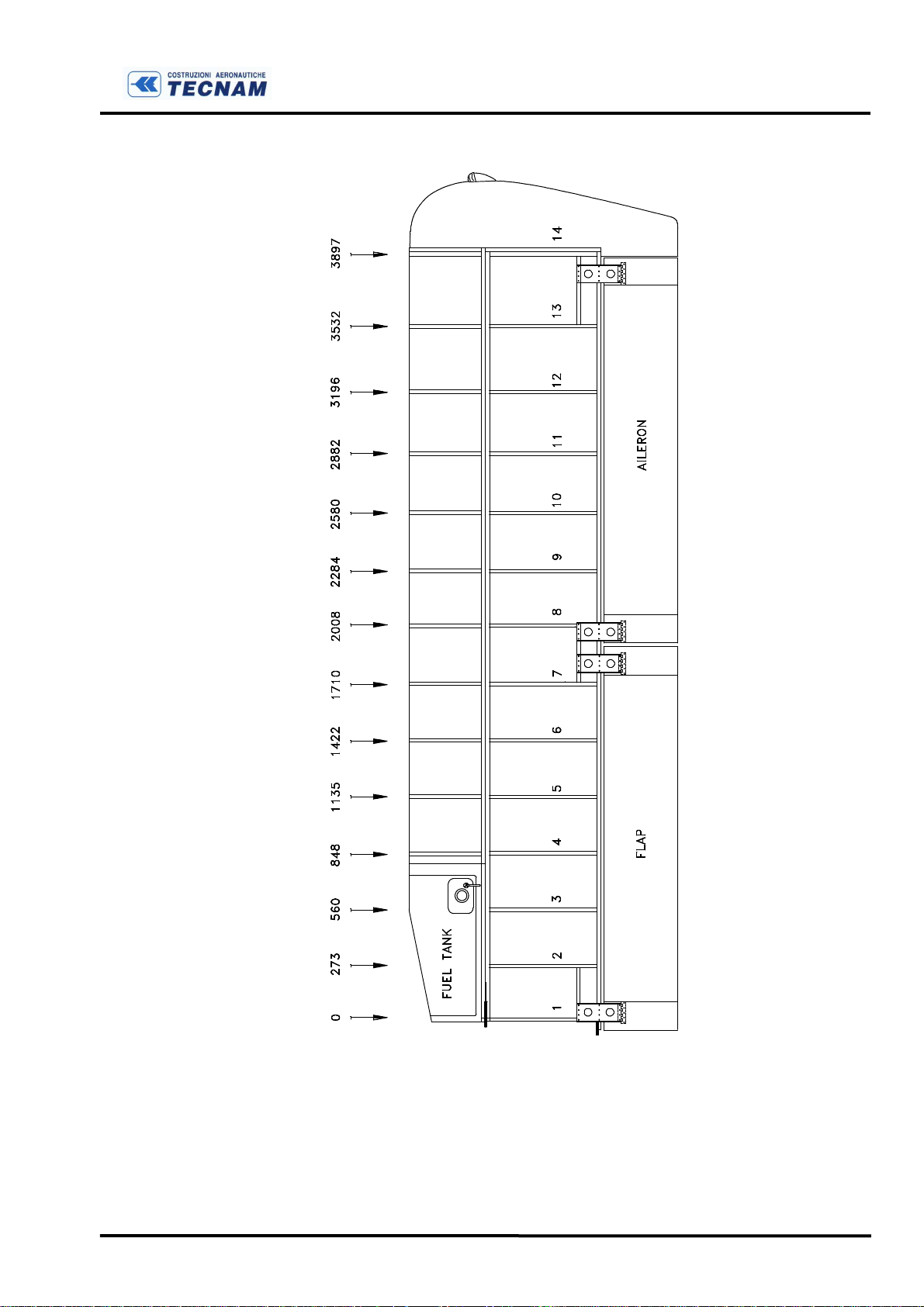

P92 Echo & P92-S Echo

Maintenance Manual

Section A

GENERAL

F

IGURE

A-3 W

ING’S PLANFORM VIEW

Ed. 2

Page A-8 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

SECTION B

INSPECTIONS AND SERVICING

TABLE OF CONTENTS

1. GROUND HANDLING..........................................................................................................2

2. PARKING AND TIE DOWN................................................................................................2

3. JACKING................................................................................................................................2

4. LEVELING.............................................................................................................................3

5. CONTROL SETTINGS......................................................................................................... 4

6. TRIM-TAB ADJUSTMENT .................................................................................................4

7. AIRCRAFT ALIGNMENT...................................................................................................5

8. WEIGHING AND DETERMINATION OF THE C.G. VERTICAL ................................6

TABLE OF WEIGHTS AND DETERMINATION OF C.G..............................................................7

9. CORROSION PREVENTION..............................................................................................8

10.

SERVICE BULLETINS....................................................................................................9

11.

SERVICING.....................................................................................................................10

12.

LUBRICATION...............................................................................................................11

INTRODUCTION ........................................................................................................................... 11

LUBRICATION POINTS (SEE

FIG.

B-5)........................................................................................12

13.

Ed.2

INSPECTION’S POINT .................................................................................................15

14.

INSPECTIONS................................................................................................................16

FOREWORD...................................................................................................................................16

PERIODIC INSPECTIONS............................................................................................................. 17

Page B-1 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

1. GROUND HANDLING

Moving the aircraft on ground is accomplished by pushing on the wing struts close to

wing attachments or by pulling on the propeller blades close to hub. Aircraft can be

steered using the rudder or, for sharp turns, by lowering the tail to raise nose wheel off the

ground. In this case, owing to the favourable CG location, a gentle push on the tail cone

just ahead of empennage surfaces is all that’s needed. Avoid dragging nose wheel

sideways and do not attempt to counter any movement of the aircraft by handling it by its

wing tips.

2. PARKING AND TIE DOWN

As a general precaution for outdoor parking, it is wise to position aircraft into the wind

and to set the parking brakes or chock the wheels if chocks are available.

In severe weather and high wind conditions, aircraft tie-down is recommended. Tie ropes

should be secured to the wing tie-down fittings located at the upper end of each wing

strut. Secure opposite end of ropes to ground anchors. Nose gear fork may be used as

fixing for forward tie-down.

Aircraft control stick should be locked using safety belts to prevent possible wind action

from causing control surfaces to hit end travel.

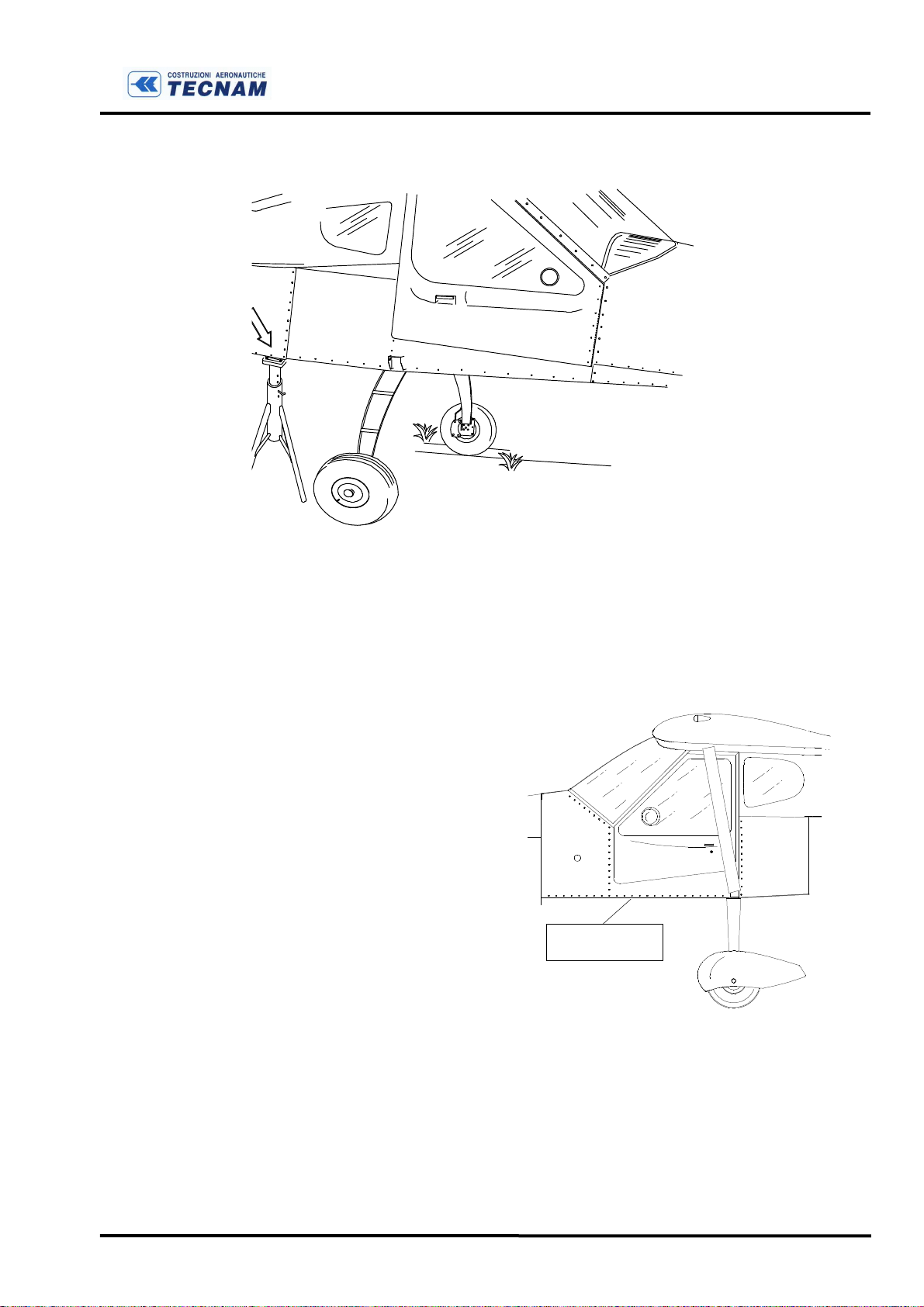

3. JACKING

Given the low empty weight, jacking one of the main gear wheels can be accomplished

even without hydraulic jack. In fact, it is sufficient that one person lifts the wing tip in

proximity of the spar area before the tip, while another person positions a suitably high

support, like a wooden stand or block, under the leaf spring attachment. To avoid

scratching the paint, cover the stand or block with rubber or other suitable material.

In the event the leaf spring must be removed, the stand should be positioned under the

cabin, just ahead of the leaf spring as shown in figure B-1.

CAUTION

As general rule, apply force to aircraft structure only on main structural

elements such as frames, ribs or spars.

Ed.2

Page B-2 Date: Sept 2004

N THE LEVEL

ON THE INSIDE OF THE

CABIN

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

F

IGURE

B-1 J

ACKING

4. LEVELING

Occasional levelling of aircraft may be necessary to insure proper wing incidence and/or

dihedral or for exact CG location.

The aircraft is levelled when the

lower cabin door sill is horizontal

(see fig. B-2) and the main gear

support girder is horizontal in a

transversal direction. Level the

aircraft using a simple level and

adjust the aircraft’s tilt through

shims placed under wheels or by

regulating tire pressure.

POSITIO

Ed.2

F

IGURE

B-2 L

EVELLING

Page B-3 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

5. CONTROL SETTINGS

Adjustment of control surfaces must not exceed travel limits reported in table below. Zero

reference mark for stabilator is on left side of aircraft (see figure below).

AILERONS

STABILATOR Up 16o Down 3o

TRIM (

RUDDER RH 25o LH 25o

FLAPS (

(starting from tip line-up

Stab. at 0o , see fig. below

maximum travel

)

)

)

Up 20o Down 15o

2o 12o

0o 35o

Cable tension should be as follows:

CONTROL CABLE TENSION: 20 daN ± 2 for all

REFERENCE RIVET

± 2o

± 1o

± 1o

± 2o

± 2o

F

IGURE

B-3 S

TABILATOR ZERO REFERENCE

6. TRIM-TAB ADJUSTMENT

Travel adjustment of trim tab on tail plane should be carried out as follows:

• Move stabilator to neutral (0 degrees) and lock in position; (this is accomplished by

aligning the stabilator’s leading edge with the reference rivet located on the left side of

tail cone);

• Turn Master-Switch ON;

• Trim to maximum pitch-up;

• Adjust thread of hinged control rod until tab is deflected downwards 12° (use a

protractor or measure downward displacement of trailing edge - 12° relates to roughly

24mm -);

• Tighten adjustment thread lock-nut and fasten connecting pin of control rod to trim-

tab.

Ed.2

Page B-4 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

7. AIRCRAFT ALIGNMENT

Section B

INSPECTIONS

AND SERVICING

A

UPPER/REAR RIVET ON ALUMINIUM SKIN.

i.e. The rivet in common between the fin's rear

spar and the upper rib.

C

B

G

SPINNER BACK

PLATE UPPER

POINT

FIRST RIVET BETWEEN THE

TUBULAR SPAR AND THE

C'

OUTERMOST RIB

A'

LAST RIVET ON THE LOWER

SIDE OF THE REAR WING

SPAR

Ed.2

C

C'

Main Wheels

F

Axle Line

F'

F

IGURE

B-4 R

EFERENCES FOR ALIGNMENTS

Page B-5 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

Datum length in mm

A -B 5030

A’-B 5030

A -C 4365

A’-C’ 4365

C -G 1860

C’-G 1860

F -F’ 1880

± 25

± 25

± 25

± 25

± 20

± 20

± 20

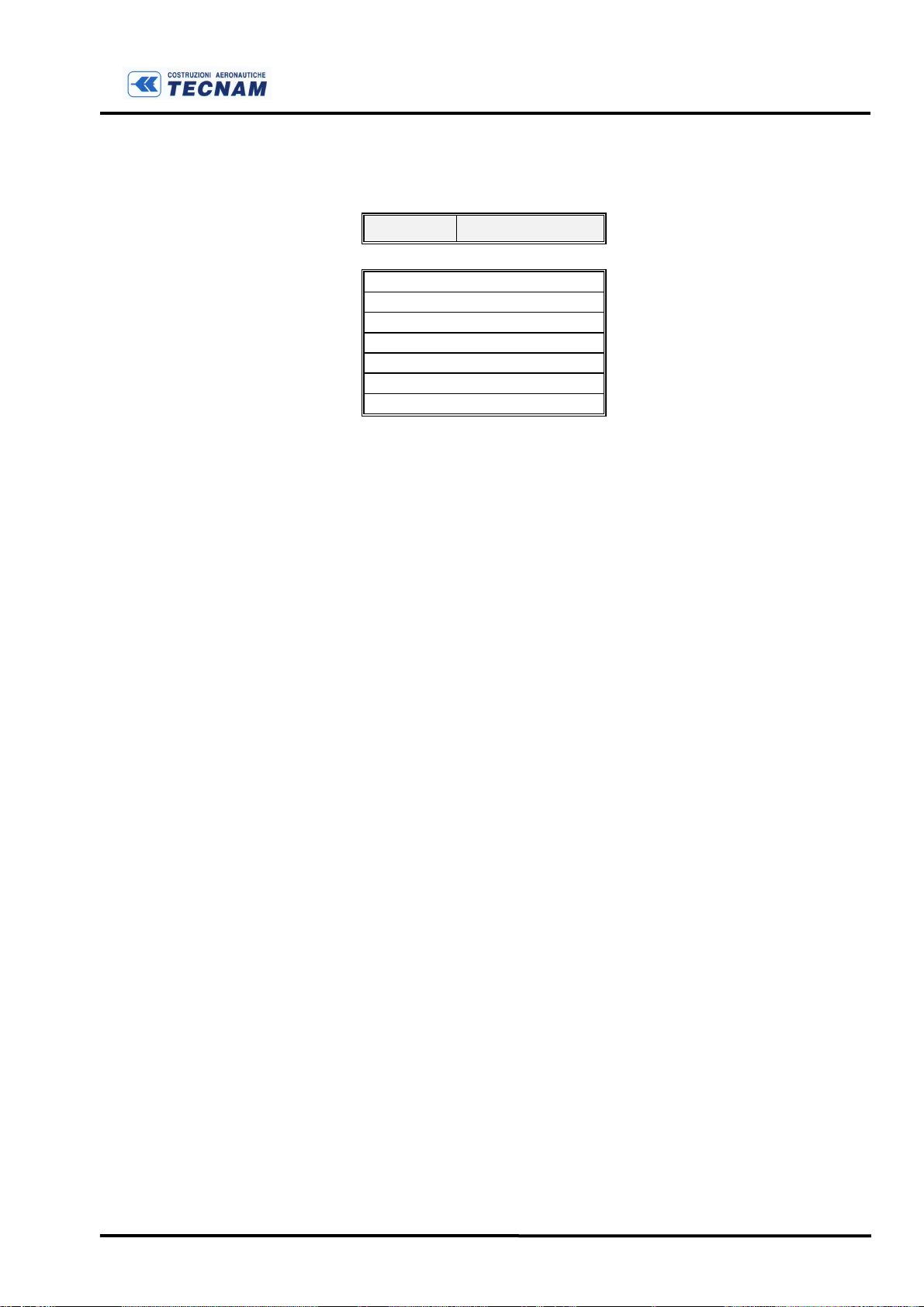

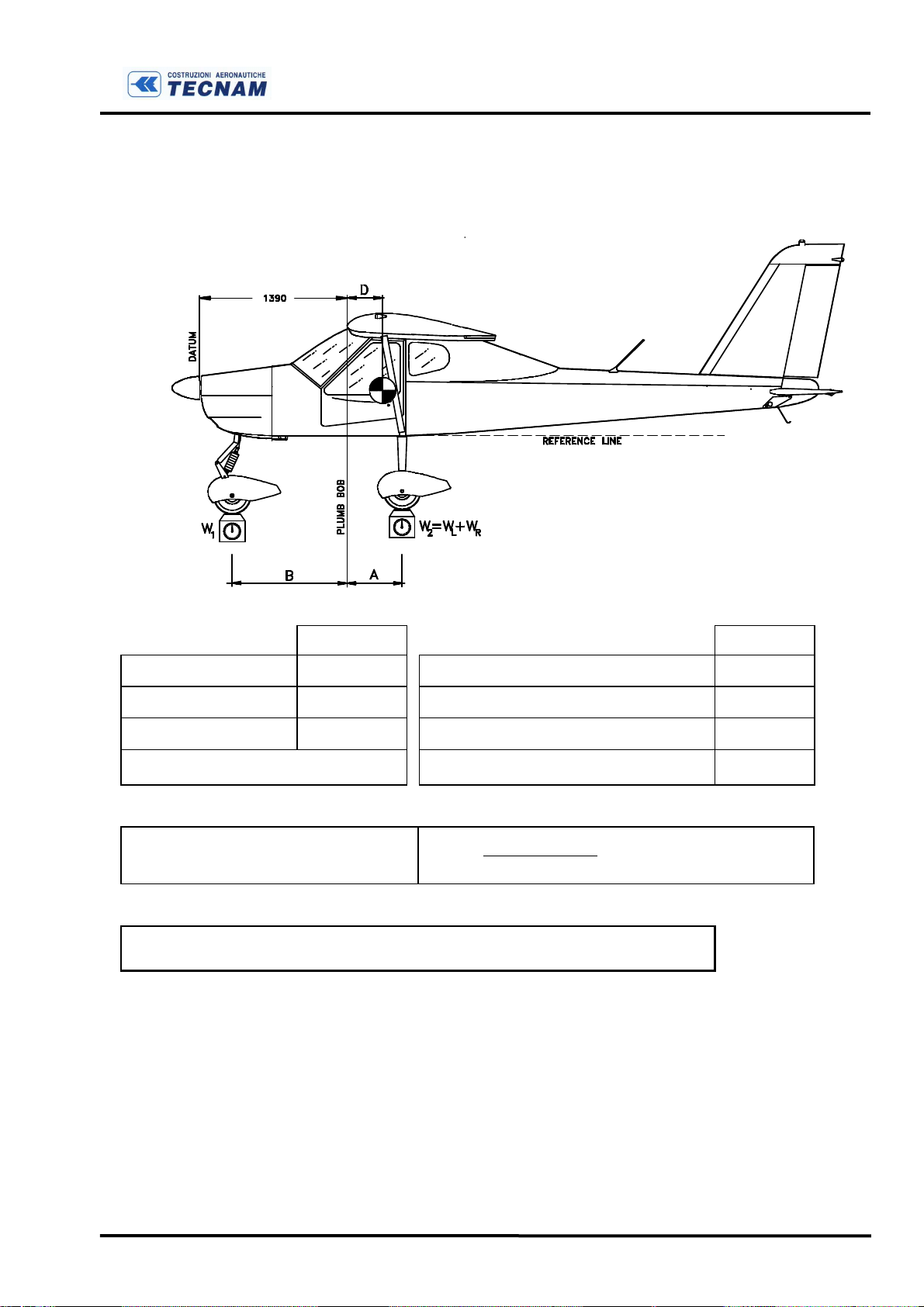

8. WEIGHING AND DETERMINATION OF THE C.G. VERTICAL

U

SE FOLLOWING GUIDELINES

a. Carry out weighing procedure inside hangar

b. Remove any objects inadvertently left on board aircraft

c. Align nose wheel

d. Drain fuel

e. Oil, hydraulic fluids and coolants at operating levels

f. Move seats to most forward position

g. Flaps retracted (0°)

h. Control surfaces in neutral position

i. Position scales (min. capacity. 200 kg) under each tire

:

Ed.2

L

EVELLING

a. Level the aircraft (see paragraph 4)

W

EIGHING

a. Record weights of individual scales

b. Calculate empty weight

D

ETERMINATION OF

C.G.

a. Dropping a plumb bob tangent to the wing’s leading edge, (in the un-

tapered section of the wing, at about one meter from the root), trace a

reference mark on floor.

b. Repeat operation on other wing.

c. Connect the two reference marks with a taut line

d. Measure distances between reference line and landing gear axes

e. Recorded data allows determination of C.G. location and aircraft’s

moment (see following table)

Page B-6 Date: Sept 2004

WAW

B

We

⋅−⋅

P92 Echo & P92-S Echo

Maintenance Manual

TABLE OF WEIGHTS AND DETERMINATION OF C.G.

Section B

INSPECTIONS

AND SERVICING

Kg meters

Wheel weight front

“ “ LH

“ “ RH

W2=WL+WR=

W1 =

WL =

WR =

Distance from bob to nose wheel.

Distance from bob to LH wheel

“ “ RH “

Distance average (AL+ AR)/2

A

=

L

AR =

A =

B =

Empty weight W

e =W1 + W2

=

D

=

2 1

=

___________meters

CG position as wing chord %

De% = De / 1.4 ⋅ 100 =

Ed.2

Page B-7 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

9. CORROSION PREVENTION

It is important to keep the aircraft clean and to remove any collection of corrosive agents

such as oil, grease, dregs and other foreign matter. To avoid damage to finish do not use

polishing detergents.

Original or equivalent corrosion prevention must be re-applied after any alteration or

repair.

If any trace of corrosion is detected it should be removed as soon as possible and part

should be immediately treated to prevent further corrosion.

(a) For steel parts, with the exception of highly stressed components or stainless steel, it is

possible to use abrasives, power brushes, steel brushes if operated manually and steel

wool.

Removing corrosion byproducts from highly stressed steel components (main gear steel

spring) requires particular care.

(b) For aluminium parts, treatment consists in mechanically removing as much as

possible corrosion byproducts, applying corrosion inhibitor and replacing original finish.

Steel wool, emery or steel brushes (unless stainless steel) along with other highly abrasive

material should not be used since steel or emery particles become embedded in the softer

material causing corrosion.

After cleaning surface corrosion, parts must be treated with anti-corrosion finish.

Ed.2

Page B-8 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

10. SERVICE BULLETINS

The following table must report all servicing bulletins pertaining to the aircraft’s

operating life.

NR. TITLE TYPE

Ed.2

Page B-9 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

11. SERVICING

For scheduled servicing on engine Rotax 912, please refer to the Rotax documentations.

The list below includes only primary engine maintenance operations.

D

AILY

1.

Pitot and static ports - Check for obstructions (see section E);

2.

Oil - Check oil level in reservoir located on firewall.

3.

Coolant - Check coolant level in overflow reservoir located on firewall;

4.

Fuel strainer - Drain off any water and sediment by opening tap and

collecting an amount of fuel at least equal to cup’s capacity.

5.

Fuel tank vents - Check for obstructions.(see section E)

EVERY

100

HOURS

6. Flange carburettor - Visually inspect rubber flange connecting carbs to

engine.

7. Battery - Check level of electrolyte.

8. Engine oil - Change engine oil and replace filter element (refer to

Operator’s Manual of ROTAX 912); initially after first 25 hours.

9. Brake fluid - Check level of brake fluid in the master cylinder located below

the left seat. Add fluid as needed using MIL H5606 standard type UNIVIS

J43.

10.Fuel filter – Check and eventually clean the fuel filter of the electric pump

(if installed).

11.Fuel line and carburettor air filter - Visually inspect fuel lines. Remove

filter and clean accurately. Repeat operation more often in dusty conditions.

If aircraft is equipped with carb heat system, scoop filter shall in any case be

replaced (automotive type air filter: Autobianchi Y10).

12.Propeller - Check attachment bolts for integrity, tightening torque (18 Nm)

and safetying, initially after the first 25 hours.

Ed.2

Page B-10 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

13.Gyro instrumentation (if installed)- In case of incorrect readings of vacuum

system, clean or replace central filter and, if needed, adjust vacuum valve.

14.Flap and stabilator - Check visually for condition and for absence of crack,

wear etc. of Dacron covers.

A

S NEEDED

14.

Tires - Check condition and maintain proper tire pressure.

12. LUBRICATION

INTRODUCTION

Section B

INSPECTIONS

AND SERVICING

Periodic lubrication of moving parts insures proper operation and extends parts’ life

considerably.

Lubrication type, points and intervals are indicated below.

Avoid excessive lubrication as this may cause external surfaces of hinges and bearing to

collect dirt and dust.

If part is not lubricated using a grease gun, grease part by hand removing excess.

To grease main gear wheel bearings, first remove thrust bearings from wheel hubs, then

clean surface using solvent, apply grease and re-assemble.

NOTE - Use grease type MIL-G-3278 or equivalent (e.g. ESSO

BEACON 325).

Ed.2

Page B-11 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

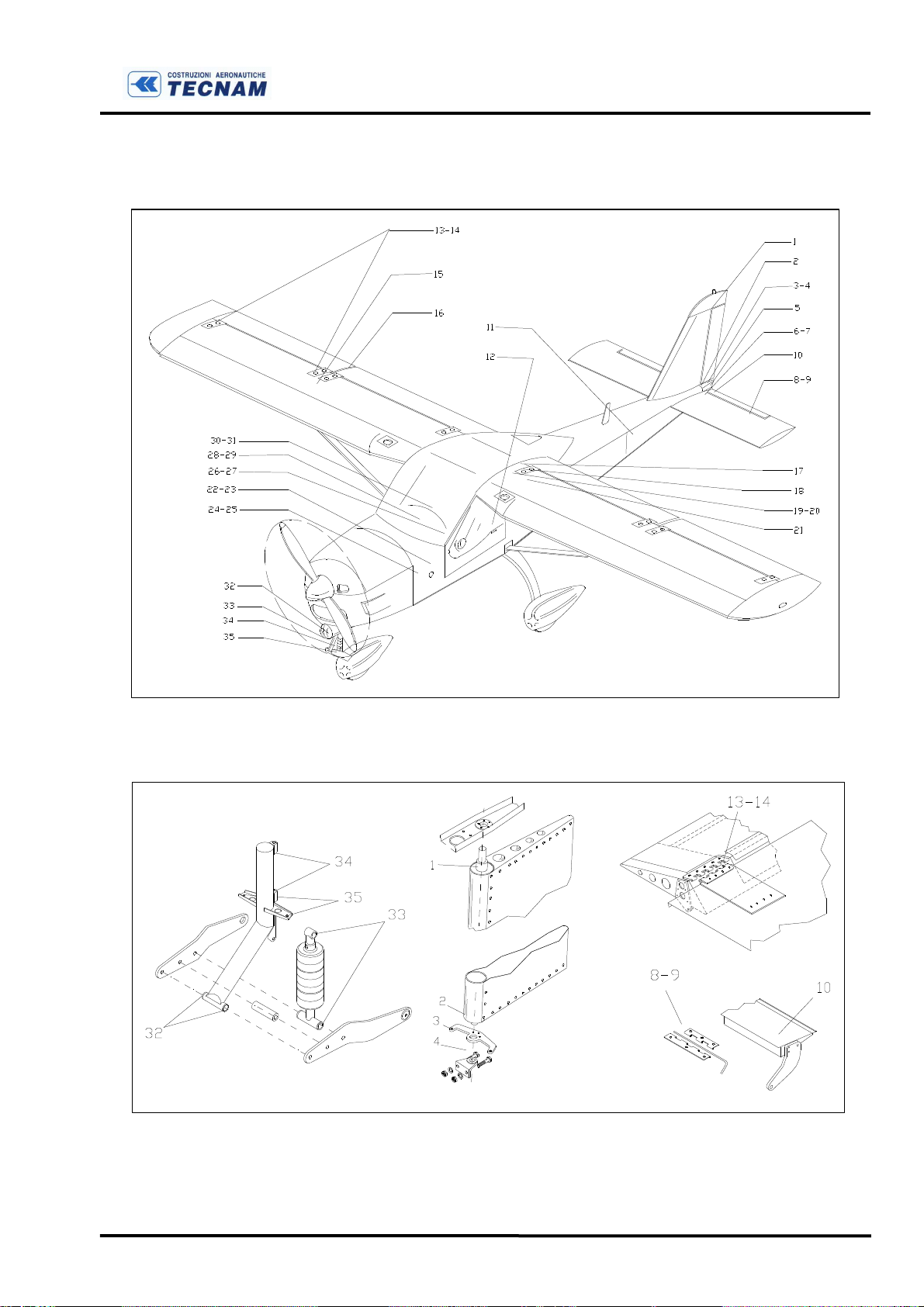

LUBRICATION POINTS (SEE fig. B-5)

1-2 Rudder hinges

3-4 Rudder control cable terminals

5 Stabilator control rod terminals

6-7 Stabilator support bearings

8-9 Trim-tab hinges

10 Tab control push-rod terminals

11 Stabilator pass-through rod

12 Stabilator control rod (inside cabin)

13-14 Aileron hinges

15 Differential ailerons hinges

16 Aileron control pushrods

17 Aileron control rods pass-trough

18 Flaps control pushrods

19-20 Flaps torque-tube support

21 Flap actuator terminals

22-23 Rudder pedals support

24-25 Rudder pushrods and cable terminals

26-27 Brake lever support

28-29 Control stick lever and support

30-31 Aileron control pulleys

32 Nose gear fork attachment hinge

33 Shock absorber attachment hinge

34 Nose gear strut attachment hinge

35 Steering pushrod terminals

Section B

INSPECTIONS

AND SERVICING

Ed.2

Grease door hinges and adjustable seat rails when necessary.

Page B-12 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

F

IGURE

F

IGURE

B-5 L

UBRICATION POINTS

B-6 E

VERY

100

HOURS

Ed.2

Page B-13 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

Ed.2

IGURE

F

B-7 E

VERY

100

HOURS

Page B-14 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

13. INSPECTION’S POINT

Inspection points that are not in plain view may be accessed through specific portholes

and/or removal of panels or fairings as detailed below:

1.

Portholes on wing underside - access to aileron differential

bellcrank.

2.

Upper strut-wing fairing (if present) - inspection of strut

attachment.

3.

Lower strut-wing fairing (if present) - inspection of strut

attachment.

4.

Tail cone underside portholes - access to stabilator control; vertical stabilizer forward attachment; -inspection of structure and

rudder control cables.

5.

Battery porthole - access to battery compartment.

6.

Tail cone end fairing - access to stabilator torque tube and

attachments to control lever; attachment of vertical stabilizer aft

spar; rudder bellcrank; trim actuator and pushrods.

7.

Aft cabin bulkhead and luggage compartment floor - inspection

of aft fuselage section and attachments; inspection of stabilator

control system and of cable pulleys for rudder control; access to flap

actuator; access to aileron control cable turnbuckles.

8.

Forward cabin side panels - access to half-wings’ forward

attachment; access to fuel line tank outflow.

9.

Cabin overhead panel (if present) - access to connection between

cabin’s cable circuit and wing’s pushrod system for aileron control;

10.

Dashboard panel (if present) - access to instrumentation.

11.

Engine cowling - access to engine and related systems; access to

main components of electrical; access to nose gear strut and steering

assembly.

12.

Propeller spinner - access to propeller hub.

Ed.2

Page B-15 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

14. INSPECTIONS

FOREWORD

TECNAM deems inspection schedule outlined below compulsory for the aircraft’s

operational safety over an extended period of time. Described servicing requirements

pertain to operation in non-extreme climatic conditions.

For the Rotax 912 engine, it is compulsory to adhere to maintenance requirements as

reported in the engine’s Operator’s Manual.

Inspections are to be carried out as follows:

A. Inspections for airworthiness before first flight of day as specified in

Flight Manual.

B. Periodic Inspection 100 hours as specified in the previous sections.

C. Special inspections, added to normal periodic.

D. Singular inspection, when aircraft has been exposed to fortuitous events

that may have damaged one or more of its components.

If aircraft is rarely used, inspection at 100 hours must be performed yearly.

Inspections and checks, unless specifically indicated, apply to the following

S

TRUCTURES IN GENERAL

- Condition of panel covers, ribs, frames, stringers

etc., absence of cracks, deformation, rivet slackening, corrosion and any

other apparent sign of damage.

M

OVING PARTS

absence of

- Lubrication, security of attachment, safetying of bolts,

EXCESSIVE

tolerance, proper adjustment, proper travel, condition

of attachments and hinges, absence of corrosion, deformation, rivet

slackening, cleanliness.

F

LUID LINES AND HOSES

- Absence of leaks, cracks, dents, chafing, proper

radius, deterioration.

B

OLTS AND ATTACHMENTS

- Proper tightening and safetying, absence of cracks

or nicks, damage to thread, wear and excessive tolerance.

Ed.2

Page B-16 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

PERIODIC INSPECTIONS

Every porthole, fairing, panel etc. shall be removed to allow for inspection.

Procedures listed in SERVICING are included in the inspections.

Instructions for actions following inspection are detailed in specific sections pertaining to

the aircraft group or system.

N

ATURE OF INSPECTION

ENGINE COMPARTMENT

Remove cowling and check for fuel, oil and coolant leaks; clean

1

engine compartment

Check density of battery electrolyte

2

Visually inspect electric pump connections

3

Visually inspect engine mount and silent-blocks attachments

4

Visually inspect exhaust manifold, muffler and heat exchanger

5

Visually inspect air intake and carburetor feed circuit

6

Visually inspect coolant reservoir, radiator and circuit line

7

Visually inspect oil reservoir, radiator and circuit line

8

INSPECTION

I

NTERVALS

(

HRS

)

Special

100

(a)

Page B-17 Date: Sept 2004

Ed.2

Check wires and electrical connections (low and high tension)

9

Check carburetor control and throttle movement

10

Check idle and carburetor sync. 600

11

Clean electric fuel pump filter

12

(a) Every 100h or more frequently in warm climate.

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

N

ATURE OF INSPECTIONS

FUEL SYSTEM

Check rigid circuit lines for integrity and wetness

1

Check shutoff valves

2

Rinse tanks and clean exit filters 1200

3

Check vent floats 600

4

Check electric fuel pump

5

FLIGHT CONTROLS

Check cables, terminals, pulleys and turnbuckles for integrity and

1

proper condition of aileron and rudder control

Check pushrod terminals, lever hinge bushings, stabilator control

2

pass-through

INSPECTION

INTERVALS

100

(

HRS

Special

)

Check pushrod terminals and aileron control pass-through

3

Check flaps pushrod terminals

4

Check flaps actuator for integrity and play, attachment of

5

terminals and electrical connections

Check torque tube, levers and attachments for flaps control

6

Check resin control lever for trim actuator 600

7

Check trim control levers and pushrods for integrity and play

8

Check rudder pedals for integrity and play

9

Check control stick group for integrity and play

10

General check for proper tension level for control cables 600

11

600

Ed.2

Page B-18 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

N

ATURE OF INSPECTIONS

MOVING SURFACES

Visually inspect integrity of dacron wrap-around for ailerons and

1

stabilator; watch for cracks, chinks, etc.

Visually inspect and check integrity of wrap-around paneling for

2

rudder and flaps.

Check integrity and play of flaps and aileron hinges

3

Check integrity and play of stabilator attachments

4

Check integrity and play of trim-tab hinges

5

Check play and proper fastening of stabilator tubular spar

6

Check integrity of balance weight support

7

ISPEZIONE

INTERVALS

(HR)

Special

100

Check integrity and play of rudder lever and hinges

8

WING

Visually check general condition of wrap-around skin and rivets

1

Disconnect wings from fuselage and check condition of

2

attachments and for possible play

Check condition of spar and wing structure through dedicated

3

openings

1200

600

Ed.2

Page B-19 Date: Sept 2004

5

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

N

ATURE OF INSPECTIONS

FUSELAGE and EMPENNAGE

Visually check general condition of wrap-around skin and rivets

1

Inspect cabin truss for deformations and corrosion 600

2

Check seat rails and stops and safety belt attachments

3

Check internal condition of tailcone structure 600

4

Check attachment between vertical stabilizer and tail beam 600

5

Check integrity and fastening of stabilizer support assy 600

6

Check integrity and general condition of transparent surfaces and

7

doors

Check electric circuit wiring and antennae attachments from

8

inside of tailcone

100

ISPEZIONE

INTERVALS

(HR)

Special

600

MAIN LANDING GEAR

Check brake system (reservoir, master cylinder, lines and

1

calipers)

Replace brake pads 600(a)

2

Visually check steel spring struts, connection clamp and

3

fastening of bolts

Remove legs and check for proper curvature and integrity 1200

4

Inspect main wheels for condition and fastening

Remove wheels, clean and grease wheel bearings 600(b)

6

Check fairing integrity and attachments

7

(a) when brake pad thickness is below 2.4 mm

(b) initially at 100 hours

Ed.2

Page B-20 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section B

INSPECTIONS

AND SERVICING

N

ATURE OF INSPECTIONS

NOSE GEAR

I

Inspect support truss for gear strut and attachment hinges

1

Check proper movement of steering levers and pushrods

2

Check integrity and play of strut-to-fork hinge attachment 600

3

Check shock hinge attachments 600

4

Check shock for general condition and state of rubber disks

5

Inspect wheel for condition and fastening

6

Remove wheel, clean and grease wheel bearings 600(c)

7

Remove nose gear assy for general safety check and inspection 1200

8

INSPECTION

INTERVALS

100

(HR)

Special

Check integrity of fairing and fairing attachments

9

INSTRUMENT PANEL

L

General inspection of operation of flight and engine instruments

1

Check generator charge

2

Check compass alignment 48

3

Check calibration of airspeed indicator and altimeter 1200

4

Check operation of avionic instrumentation (if installed)

5

Check operation of switches and breakers

6

(c) initially at 100 hours.

months

Ed.2

Page B-21 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

SUMMARY OF REFERENCE VALUES

T

ORQUE SETTINGS FOR CONNECTION BOLTS AS A FUNCTION OF THEIR LEG DIAMETER

Bolts resistance category 8.8

= 3.1 Nm

∅ 4

= 10.4 Nm

∅ 6

= 24.6 Nm

∅ 8

Section B

INSPECTIONS

AND SERVICING

Warning: propeller attachment bolts must be

fastened to 18 Nm value even though they have a ∅ 8

diameter.

C

ONTROL CABLE TENSION (FOR BOTH AILERON AND RUDDER )

T

IRE PRESSURE

VALUE : 20 dN ± 2 dN

:

NOSE 15 PSI

MAIN 23 PSI

(1.0

BAR

(1.6

BAR

)

)

C

ONTROL SURFACES TRAVEL RANGE

Ailerons

Stabilator

Trim

Up 20° down 15° ±2°

Up 18° down 3° ±1°

2°, 12° ±1°

Rudder

Flaps

RH 25° LH 25° ±2°

0° -35° ±2°

Ed.2

Page B-22 Date: Sept 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

SECTION C

AIRFRAME

TABLE OF CONTENTS

1 - INTRODUCTION ......................................................................................................................1

2 - WING........................................................................................................................................... 2

3 - REMOVAL AND RE-INSTALLATION OF A WINGS.........................................................3

2.1 - F

LAP CONTROL (SEE FIG.

4 - HORIZONTAL TAIL................................................................................................................6

5 - VERTICAL TAIL....................................................................................................................... 9

6 - FUSELAGE...............................................................................................................................11

7 - LANDING GEAR.....................................................................................................................13

7.1 M

AIN GEAR WHEEL REMOVAL (SEE FIG.

7.2 R

EMOVAL OF MAIN GEAR WHEEL BEARING (SEE FIG

7.3 N

OSE GEAR

7.4 R

EMOVAL OF THE NOSE GEAR FAIRING (IF INSTALLED) AND WHEEL (SEE FIG

.................................................................................................................................17

C-3)..................................................................................................... 3

C14)..............................................................................15

.C15)...........................................................16

.C-17).....................17

Ed.2

Page C-1 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

1 - INTRODUCTION

The airframe consists of the following main components as shown in figure C-1:

1) Wings

2) Fuselage

3) Empennage

4) Landing gear

5) Powerplant

Section C

AIRFRAME

F

IGURE

C-1 M

AIN AIRFRAME COMPONENTS

In case it becomes necessary to disassemble the aircraft for transport or other reason, it is

necessary to read section C carefully.

Ed.2

Page C-1 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

2 - WING

Each wing is connected to the fuselage by means of two pin attachments and a single strut

brace per side.

Wings are constructed of a central light alloy torsion box; leading edge is attached to front

spar where metal fuel tank (10) and wing-fuselage plastic union (9) find collocation. Flap

(1) and aileron (2) are attached by two hinges each to rear spar.

The torsion box, as shown in figure C-2 and with reference to numbers in parenthesis,

consists of a main spar (4) and a secondary spar (5) that make up its front and rear walls

respectively and of a series of ribs (6); metal panels cover the entire structure. Front and

aft spars are equipped with wing-to-fuselage attach fittings (7). Wing-to-strut attach fitting is located approximately at the middle of main spar (8). Both aileron and flap hinges

are made of “piano-hinges" type MS 20001-4 for direct attachment to spar of moving surfaces.

F

IGURE

Ed.2

C-2 W

ING STRUCTURE

Page C-2 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

Aileron is constructed of a single light alloy spar to which are joined box type leading

edge and ribs; entire structure is covered with “Dacron” synthetic cloth. Flap has the same

aileron structure and is covered aluminum panels.

Wing tips (3) are molded epoxy resin, fiberglass reinforced.

3 - REMOVAL AND RE-INSTALLATION OF A WINGS

Procedure for removal of a wing and strut is as follows.

A.

Drain fuel tank using drain tank and closing opposite side tank fuel circuit;

B.

Remove access panel located under the wing allowing access to fuel line and disconnect, plug pipe ends on both wings;

C.

Disconnect transparent scavenge small pipe only LH wing;

D.

Disconnect wires for navigation lights (if present);

E.

Disconnect flap control (see fig. C-3) by removing roller bearings (7) linking pushpull rods (6) with flap control plate;

F.

Remove aileron control (see fig. C-4) by disconnecting pins (4) linking small bar (3)

with rods (5).

G.

While supporting the wing’s end, release strut’s upper pin, then release lower pin and

remove strut.

H.

While supporting the wing from below the root area, release the two wing-to-fuselage

attachment pins. To expedite release of aft pin, keep flap lifted, then remove wing.

I.

Replace pins.

Reverse above procedure for reinstallation paying close attention to tighten strut’s bolts to

recommended value (M8 bolt torque 24.6 Nm).

2.1 - Flap control (see fig. C-3)

Flap control system is push-rod type. The torque tube (1), connects the two moving surfaces and hinges to supports (2) rigidly attached to fuselage structure. Rotation is transmitted through a push-rod (3) whose position is controlled by an electric linear actuator

(4) governed by a switch on dashboard. Jack stops are adjusted by moving the switches

locate inside the flap actuator body (4).

Two push-pull rods (6) are connected to the ends of the torque tube (see fig. C-3) (1) allowing quick inspection owing to favorable location between wing and fuselage.

The two push-pull rods controlling flap movement feature an extendible linkage just before the roller bearings allowing trailing edge line-up.

Ed.2

Page C-3 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

F

IGURE

C-3 F

LAP CONTROL

2.2 - Aileron control (see fig. C-4)

Aileron control system uses rigid rods inside wing and steel cables inside cabin.

Flight control system inside cabin includes three pairs of pulleys which transmit movement from the two control sticks (1) linked by a rod (2), to a small bar (3) located cabin

overhead in correspondence to the main rods from the wings. The main rods ends are

joined using two pins (4) to the small bar ends. The two main rods (5), are routed through

the ribs and are attached at bellcrank lever system (6) push-pull rod (7). The push-pull rod

crosses the wing’s secondary spar and features roller bearings and extendible linkage to

regulate length.

Ed.2

Page C-4 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

F

IGURE

C-4 A

ILERON CONTROL

To remove aileron, disconnect one end of push-pull rod and remove pins from hinges.

Reverse above procedure to reinstall aileron insuring that, with stick vertical, the aileron’s

trailing edge is aligned with wing’s trailing edge.

Through access panels located on wing’s bottom, check that the bellcrank lever is in neu-

tral position, i.e. the inside arm at right angle with spar axis. To remove wings, disconnected release short bar (3) that close steel cable system, to main rods (5) by pins (4). The

steel cable system is designed to insure proper cable tension without the need to check

each time the half-wings are removed. It is however recommended that periodic checks

be carried out and proper tension applied by acting on the two turnbuckles (8) located behind the cabin’s rear panel.

Also check periodically that pulleys rotate freely and pins tolerance for entire transmission is within standards (ref. Section B).

Ed.2

Page C-5 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

If control stick should feel unusually hard, reduce cable tension as this may be the primary cause for malfunction (ref. Section B); also check that parts of the link system positioned under seats are properly greased.

If control stiffness persists, check integrity of bellcranks or pulleys and insure that cable

has not come off pulleys.

Alignment of moving surfaces with half-wing must be done using outboard trailing edge

as reference. Further lateral corrections (aircraft leans to one side) may be carried out adjusting trim tab located on left aileron trailing edge.

4 - HORIZONTAL TAIL

Horizontal tail is an all moving type, that is, the stabilizer and elevator form a single, uniform plane called stabilator which rotates about an axis normal to fuselage centre line at

the desired pitch setting.

The stabilator structure (see fig. C-5) is constructed of a light alloy tubular spar (1) to

which a series of ribs (2) and an light alloy leading edge (3) are riveted. Entire structure is

Dacron covered.

A trim tab (4) provides stick force adjustment and longitudinal compensation through an

electric actuator controlled by pilot. Tab is split in two halves interconnected at the support brackets (5) and attached to the stabilator through four external hinges (6) that allow

immediate inspection.

Figure C-5 S

TABILATOR

Ed.2

Page C-6 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

Each half plane engage on steel tubular hub that escape to fuselage, locked in place by

means of pins (7). Taking up possible tolerance make by means of two riveted grains (8).

To remove each stabilator, disconnect the two halves of the tab from each other and from

the control rod, remove pins (7), then remove half-planes. To avoid cover damage during

operation, handle parts by their rigid components.

Reverse operation for reinstallation slightly greasing the inside of the torque tube (1) to

facilitate insertion and gently tapping parts into position being careful not to deform outward ribs.

The stabilator control system is push-rod type (see fig. C-6) and is controlled from the

cabin via the control sticks. Control is transmitted through a push-pull rod (1) linked to a

bellcrank (2) and a shaft (3) that runs through (4) the tail cone, transmit movement to

stabilator’s hub lever (5).

All significant transmission element such as bellcranks, pushrods, supports and hinges

can be easily accessed and inspected.

F

IGURE

C-6 S

TABILATOR CONTROL

If unusual tolerance is found along transmission, replace parts presenting excessive wear.

The stabilator hub (see fig. C-7) consists of, a steel tube (1) with welded horn assembly

(2) and attachment for stabilator control shaft (3). Counterweight (4) is at the end of an

arm joined control lever by means of two bolts. Arm entering tail stock through lightening hole of the last tail cone ordinate.

Longitudinal trim is controlled by a switch located on cabin tunnel or (optional) by two

push-buttons mounted on the stick handle; position is, in any case, monitored via an indicator located on dashboard. Control activates the linear actuator (5) connected to supports

Ed.2

Page C-7 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

(6) and plates (7). Actuator’s motion is transmitted to an adjustable push-pull rod (8)

through a bellcrank (9).

To remove stabilator’s hub disconnect electric actuator frame assembly (7), from support

(6), release aft bellcrank assembly (3) then release plates (2) from brackets(6).

Ed.2

F

IGURE

C-7 H

ORIZONTAL TAIL CONTROL SYSTEM

Page C-8 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

5 - VERTICAL TAIL

The vertical tail is an all-metal light alloy structure (fig. C-8). Rudder tip is fiberglass

with cut-outs for navigation and strobe light.

The vertical stabilizer consists of a twin spar with wrap-around load bearing skin paneling. An attachment plate to the fuselage tail cone (1) secures the stabilizer’s front spar to

the lower tip while the rear spar is extended to attach directly onto the last tail cone ordinate (2).

The rudder consists of an aluminum alloy torque tube (3), formed sheet metal ribs (4) and

sheet metal panel cover (5) held in place by rivets.

F

IGURE

C-8 V

ERTICAL STABILIZER, RUDDER AND SUPPORTS

The hubs (6) and (7) are to the ends of rudder provide by means of bushings (8) hinged

rudder with vertical stabilizer. The lower hinge assembly is attached to a bellcrank controlled by cables from rudder pedals.

Ed.2

Page C-9 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

To the upper ends rudder torque tube is joined steel arm with, to the end, counterweight

and rotate freely onto vertical stabilizer tip. In case tip isn’t profile two plastic fairing

(one of this removable) counterweight fitting in slot.

To remove rudder, after disconnected little stern and flying tail (see § 4), disconnect cables from bellcrank, remove lower bearing and release rudder with downward motion.

Control system layout (fig. C-9) is steel cable join rudder control lever with rudder pedals lever.

Rudder pedals (1) direct two transmission connection rod (3) close circuit rudder control

and pass on the movement to the nose wheel leg via two threaded stem ball and socket

joint adjustable push rods connections.

Cable tension must be checked periodically and adjusted to proper value (Tension = 20

daN ± 2) using the turnbuckles (4); condition and smooth operation of pulleys (5) must

also be checked. To access levers and rudder pedals support, remove cabin’s central tunnel; for speedier operation remove seats from railings.

F

IGURE

C-9 R

UDDER CONTROL

Ed.2

Page C-10 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

6 - FUSELAGE

The forward fuselage consist of a steel truss survival cell (fig. C-10) and of a light alloy

semi-monocoque structure attached to the cabin’s aft section.

Rear (fig. C-11) consist in a light alloy semi-monocoque structure. Four longitudinal

structural elements trestlework connection allow. Tail beam rear end are two strut brackets of tail horizontal plane (2) and attachments vertical plane longeron on ordinate.

Framework shown in figure C-10 below, details location of attachment points for halfwing (1), aft structure (2), brace-strut (3), main gear (4), engine mount (5), flap torque

tube (6), stabilator bellcrank (7), throttle (8) and pulleys for cable driven aileron control

(9). Seat supports and safety harness attachment points are also shown.

Ed.2

F

IGURE

C-10 C

ABIN FRAMEWORK

Engine mount is constructed of steel tubing and secured to fuselage with four-point attachment. Bolts travel through bushings welded on mount, cross firewall and exit through

other bushings welded to fuselage framework. Nose wheel truss is integral part of engine

mount.

Page C-11 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

Figure C-11 Fuselage aft section

Cabin access is through two doors constructed of light alloy square tubing. A fiberglass

structure, external, shaped for better comfort is riveted. Both doors feature spring lock

door handles with inside safety latch.

Seats are make up in metal tubing framework with fabric covered padding. Seats can be

adjusted along railings attached to fuselage using release lever positioned just below seat.

Floor matting is light alloy covered by a thin layer of carpeting.

Entire fuselage, wing and other exposed surfaces are finished with a highly resistant

weatherproofing synthetic coating.

Wash using only soapy water and chamois.

NOTE

A

LL PARTS IN PERSPEX MATERIAL MUST NEVER BE DUSTED DRY, BUT WASHED WITH LUKEWARM SOAPY

WATER. IN ANY CASE, NEVER USE, ON THIS KIND OF SURFACE, PRODUCTS SUCH AS GASOLINE, ALCOHOL

OR ANY KIND OF SOLVENT

.

Ed.2

Page C-12 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

7 - LANDING GEAR

The main landing gear (see fig. C-12) consists of two special steel leaf-spring struts (1)

for elastic cushioning of landing loads.

Gear struts are attached to fuselage underside at main framework girder.

Two shims (2,3) are positioned between gear struts and fuselage; struts are held in place

by light alloy tie brackets (4) by means of bolts (5) and bolt (6) to the end.

F

IGURE

C-12 M

AIN GEAR

Wheels are cantilevered on gear struts and feature hydraulically actuated disk brakes (see

fig. C-13) controlled by a lever (1) located on cabin tunnel between seats. Main gear

wheels adopt Air Trac A-A1D4, 5.00-5 tires inflated at 23 psi (1.6 bar). Hydraulic circuit

shut-off valve (2) is positioned between seats and, when off, activates parking brake function obtained pulling lever.

Braking is simultaneous on both wheels. Control lever (1) activates pump (3) that features

built-in brake fluid reservoir (4); check valve (5) secure brake function when activated,

unintentionally, parking brake.

Ed.2

Page C-13 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

F

IGURE

C-13 H

YDRAULIC BRAKE CIRCUIT

Removal of single gear strut is as follows:

A.

Remove cabin seats by pushing them forward and off the railings;

B.

Raise aircraft onto supports;

C.

Close the shut-off valve (ref.2 in fig. C-13) without pull the brake lever (1); Do not

activate brake lever (1) during the operation

D.

Disconnect hydraulic brake circuit by unscrewing upper latch of external line on fuselage underside. Cap lines temporarily to prevent fluid spill;

E.

Loosen bolts (part 5 fig. C-12) holding aluminum bracket (part 4 fig. C-12) at leaf

springs lateral attachment;

F.

Release inboard leaf-spring pin (part 6 fig. C-12) by unscrewing locknut on cabin

girder;

G.

Remove spring-steel strut pulling horizontally.

Reinstall using reverse procedure. It is however necessary to eliminate any trapped air:

once the circuit is closed and fluid in reservoir is at normal level, bleed air through small

valve provided. For best results pump hydraulic fluid through small valve allowing

trapped air to escape through open reservoir.

If verify brake function decrease, provide check and substitution, eventually, main gear

pads.

For this procedure refer to Periodic Inspection Table in Section B pertaining to main

landing gear.

Ed.2

Page C-14 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

7.1 Main gear wheel removal (see fig. C14)

Removal of a single wheel is carried out as follows:

• Landing gear

A.

Lift aircraft (see sect. B).

B.

Disengage parking brake.

C.

Remove fairing (1, if installed) by loosening three rear screws (2) and the frontal

screw (3).

D.

Remove the small screw (4) located on the aluminum support

E.

Remove hub ring nut (5)

F.

Grab tire with both hands and pull.

Section C

AIRFRAME

6

1

2

5

4

3

F

IGURE

C-14 R

EMOVAL OF MAIN GEAR WHEEL

Ed.2

Page C-15 Date: Sept. 2004

7.2 Removal of main gear wheel bearing (see fig.C15)

Removal of a wheel bearing (taper roller bearing) becomes necessary when eccessive resistance occurs during wheel motion. Procedure is as follows:

A.

Remove the fairing (1)

B.

Unscrewing (4), remove the aluminum support use to fix the fairing.

C.

Unscrew the hub ring nut (5).

D.

By the use of a screwdriver, remove the hub washer and the dust-shield ring.

E.

Grab tire (6) with both hands and pull.

F.

Extracting the wheel the taper-roller bearing will be also removed.

Clean bearing accurately using an appropriate solution and wipe wheel rim side. Grease

using FIAT ZETA2. Reverse procedure for mounting. Insert washers and felt by sliding

them perpendicular to hole.

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

3

5

1

6

6

5

4

2

F

IGURE

Ed.2

C-15 R

EMOVAL OF MAIN WHEEL BEARING

Page C-16 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section C

AIRFRAME

7.3 Nose gear

The nose gear (fig. C-16) is attached to the engine mount with two hinges (1) and is

equipped with a Sava 4.00-6 type tire.

Steering motion is transmitted from the pedals through two steering tubes that are attached to the nose gear strut by means of two brackets (2) welded to the strut.

Gear fork is made up of light alloy plates (4) & (5) and a spacer (6); it hinges on the strut

leg and is braced by a rubber-disc shock absorber (3).

F

IGURE

C-16 N

OSE GEAR ASSY

7.4 Removal of the nose gear fairing (if installed) and wheel (see fig.C-17)

To remove the nose gear fairings (if installed) proceed as follows:

A.

To remove front portions of fairing (5 & 6) loosen the screws (2) and (3)

B.

Remove the two fairings (6) and (5).

C.

To remove the rear upper fairing (4) loosen the screws (1)

D.

Unscrew nuts (7) and remove washer from wheel axle

E.

Unscrew bolt (8) in gear lever housing.

F.

Remove the rear fairing (9)

Reverse procedure to reinstall. Avoid damage to fiberglass fairing by not tightening

screws excessively.

Ed.2

Page C-17 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

To remove nose wheel proceed as follows:

A.

Remove the fairings (5) (6) and (9)

B.

Loosen bolts (10), (11) and (13)

C.

Detach the two wheel forks (12) from each other.

D.

Remove wheel axle

E.

Remove the wheel (13)

Section C

AIRFRAME

F

IGURE C - 17 REMOVAL OF NOSEGEAR FAIRING

S

UMMARY OF TIRE INFLATION PRESSURE

Nose tire

Main tire

15 psi 1.0 bar

23 psi 1.6 bar

Ed.2

Page C-18 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section D

POWERPLANT and

PROPELLER

SECTION D

POWERPLANT and PROPELLER

TABLE OF CONTENTS

1 - POWERPLANT..........................................................................................................................2

1.1 C

OWLING

1.2 P

OWERPLANT MAIN FEATURES

2 - GENERAL SERVICING PROCEDURES...............................................................................4

2.1 I

DLE SPEED SYNCHRONIZATION

2.2 O

RDINARY SERVICING

3 - PROPELLER..............................................................................................................................4

3.1 P

ROPELLER REMOVAL

3.2 P

ROPELLER INSTALLATION

3.3 P

ERIODIC INSPECTION

......................................................................................................................................2

......................................................................................................3

.....................................................................................................4

...................................................................................................................4

...................................................................................................................4

............................................................................................................4

...................................................................................................................5

Ed.2

Page D-1 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section D

POWERPLANT and

PROPELLER

1 - POWERPLANT

1.1 Cowling

Powerplant cowling consists of two parts: fiberglass nose section and light alloy panel on

top and all fiberglass bottom.

Top cowling is easily removed by releasing four latches, two on each side.

Removal of lower portion is just as easy by quick release of two side pins and two latches

located on bottom. Figure D-1 below shows cowling version featuring ram intake and

landing light.

Before removing cowling, disconnect landing light wiring and ram intake air hose from

heat exchanger (optional).

If any cracks are detected, immediately drill stop holes at crack ends. Air circulation is

provided by front openings in nose section and by an outflow area on the underside by the

firewall.

Ed.2

IGURE

F

D-1 E

NGINE COWLING

Page D-2 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section D

POWERPLANT and

PROPELLER

1.2 Powerplant main features

The installed powerplant is a Bombardier-Rotax type 912 horizontally-opposed fourcylinder, one central camshaft with pushrods and OHV. Other features include liquid

cooled cylinder heads and ram air-cooled cylinders. Prop drive is via reduction gear.

Electric starter, integrated AC generator and mechanical fuel pump are standard.

Technical data:

912UL 912ULS

- Maximum power 81 hp (59.6 kW) 98.6 hp (73.5 kW)

- rpm @ maximum power 5800 rpm 5800 rpm

- Bore 79.5 mm 84 mm

- Stroke 61 mm 61 mm

- Displacement 1211 cm3 1352 cm3

- Compression ratio 9.0 : 1 10.5 : 1

- Firing order 1-4-2-3 1-4-2-3

- Direction of rotation of

cw from pilot’s perspective cw from pilot’s perspective

propeller’s shaft

- Fuel

Please refer to:

Rotax Operator’s Manual

Please refer to:

Rotax Operator’s Manual

- Reduction ratio 1 : 2.273 1 : 2.4286

F

IGURE

D-2 I

NSTALLED ENGINE WITH CARB HEAT SYSTEM

1st revision, October 25th 2004

Ed.2

Page D-3 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section D

POWERPLANT and

PROPELLER

2 - GENERAL SERVICING PROCEDURES

2.1 Idle speed synchronization

With the exception of idle speed synchronization, no other carburetor regulations are

required. Fuel mixture is controlled and set by manufacturer and requires no further

adjustment.

2.2 Ordinary servicing

For all servicing operations refer to the Engine Operator’s Manual furnished by the

engine’s manufacturer and furnished along with the present manual.

3 - PROPELLER

The GT propeller is manufactured by “Fratelli Tonini” and is all-wood, with composite

reinforced leading edge and blade protective finished with special lacquer coating.

3.1 Propeller removal

To remove propeller use the following procedure:

A.

Remove screws holding spinner dome to spinner bulkhead.

B.

Remove safetying.

C.

Remove bolts that secure prop to hub.

After removal, do not lay propeller down on its tip but always lay flat and away from

sources of humidity, heat or, in any case, away from areas subject to excessive

temperature change.

3.2 Propeller installation

To install propeller, follow procedure below insuring propeller is correctly aligned with

hub before tightening bolts:

A.

Carefully clean hub area insuring no oil traces are present;

B.

Check bolts for cracks, rust, proper thread and cleanliness;

C.

Check spinner bulkhead for cracks or deformations;

D.

Check spinner for cracks and deformations;

E.

Install spinner bulkhead and prop;

F.

Insert washers and fasten locknuts (bolt torque = 18 Nm);

G.

Safety all bolts;

H.

Install spinner.

Ed.2

Page D-4 Date: Sept. 2004

P92 Echo & P92-S Echo

Maintenance Manual

Section D

POWERPLANT and

PROPELLER

After correct installation of propeller, let the engine run for a few minutes and, after

turning it off, carry out a further inspection (tightness, overall state, etc.).

F

IGURE

D-3 P

ROPELLER INSTALLATION

3.3 Periodic inspection

Refer to specific subsection in the Periodic Inspection Schedule of Section B.

For further information refer to the “Operator’s and Servicing Manual for GT

Propellers” furnished by the propeller’s manufacturer.

Ed.2

Page D-5 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

SECTION E

SYSTEMS

TABLE OF CONTENTS

1 - FUEL SYSTEM ..........................................................................................................................4

2 - INSTRUMENTATION ..............................................................................................................5

2.1 - E

NGINE INSTRUMENTATION

3 - PITOT AND STATIC SYSTEM ...............................................................................................8

4 - EXHAUST MANIFOLDS..........................................................................................................9

5 - CARBURETOR HEAT AND CABIN HEAT (optional) .........................................................9

6 - BRAKE SYSTEM.....................................................................................................................11

6.1 - D

RAINING AND REPLACING BRAKE FLUID

6.2 - R

EPLACING BRAKE PADS

........................................................................................................7

..................................................................................11

...........................................................................................................12

Ed.2

7 - ELECTRICAL SYSTEM.........................................................................................................13

8 - EMERGENCY PARACHUTE SYSTEM (optional)..............................................................15

Page E-3 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

1 - FUEL SYSTEM

The fuel system (see Fig. E-1) consists of two metallic fuel tanks (1) located in the wing’s

leading edge after wing-fuselage union. Each fuel tank has 35 liters capacity (optional 45

liters). On the upper external is refueling’s cap (2), bay (3) for float (4) chamber and fuel

tank bleed (5). Metal cover plate (6) may be removed for inspection of tank interior that

assembly riveted and puttied with dope gasoline resistant. Return line discharged flange

(7) of fuel system on the left fuel tank rear wall placed. At each fuel tank outlets are present (and serviceable by specific port holes) fuel mesh filters (8).

Ed.2

F

IGURE

E-1 F

UEL SYSTEM

Diaphragm mechanical pump (13), engine connected, stoking provide by means flexible

pipelines come to the fuel tank and across cabin vertical rods, easily accessible, after disassembled plastic structural. On the same cabin vertical rods are circuit on-off valve (9),

one for each fuel tank, easily accessible to the pilot. Circuit link with union tee in correspondence of the firewall, and then to drainage bowl (10), located left upper side in the

engine bay, visible through an upper cowling port.

Page E-4 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

Downstream respect to the gascolator is located a fuel filter (11) built in an electric fuel

pump (12) and then the mechanical (13). Mechanical pump feeds the fuel manifold (14);

its left branch feeds the left carburetor. In derivation a tee connector (16) with restrictor

feed the fuel pressure gauge (15). The rear branch of the ”X” manifold (14) is connected

to the fuel return line (17). In case of mechanical pump failure, electrical pump feed is

available.

Return tube (17) engage in pipe fitting (18) located

on the fire-wall and then by means a thin transparent

tube return at the LH fuel tank.

Disassembled wing is necessary disconnect return

tube by means pipe fitting (19). For release of pipe

fitting’s little tube push in direction to the base

knurled flange. For coupling to the tube insert in

your seat.

Periodically check the fuel tank vent (5) to ensure

that their openings are unobstructed; repeat inspection more frequently if operating in dusty conditions.

It is recommended, for inspection purposes, to use a

small rubber tube to blow through the vent clearing

possible obstructions.

F

IGURE

E-2 G

ASCOLATOR

Drain gascolator daily (see Fig. E-2) using the spring tap (2). Unscrew ring nut (1) for

disconnect bowl and accede at wire mesh filter (4), use particular care at don’t damage

seal (3) and spring (1).

2 - INSTRUMENTATION

The instrument panel, realized in light alloy (see Fig. E-3), is imaginatively divided in

three sections. The left section holds flight control instruments, the right section holds

engine controls and the central section holds eventual communication and navigation instruments.

Ed.2

On lower part of instrument panel are the following:

• Magneto switches and switches for navigation lights, landing light and strobe light if

installed;

Page E-5 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

• flap switch and circuit protection breakers;

• throttle knobs.

Individual instruments may be removed using particular care in disconnecting wiring,

tubing or other linkage as the case applies.

When installing instruments, follow recommendations below:

A.

Do not over-tighten bolts as plastic instrument casing may break.

B.

Insure hoses are free of any foreign matter and that no tight radius turns are present as

this may choke hose or cause malfunction.

C.

Insure proper grounding and tightening of all electrical instruments.

Ed.2

F

IGURE

E-3 I

NSTRUMENT PANEL

Repair, calibration or overhaul of instruments must be carried out only by specialized stations.

Page E-6 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

2.1 - Engine instrumentation

- An electric tachometer is installed;

- An electric oil temperature indicator is installed. The sensor is located on the oil pump

tube and is marked with “TO” on the pump flange.

F

IGURE

E-4 S

ENSORS FOR PRESSURE AND OIL TEMPERATURE

- An oil pressure instrument is installed. See fig. E-4 for sensor location.

- Cylinder head temperature sensors are located on cylinders 2 or 3 and are linked with

relative instrumentation.

- LH and RH fuel level sensors.

Ed.2

Page E-7 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

3 - PITOT AND STATIC SYSTEM

Referring to figure E-5, system consists of a pitot tube (1) mounted on left wing strut and

two static ports (2) connected in parallel (3) and located on left and right side of fuselage

just ahead of door frames. Flexible plastic tubing connect pitot and static ports to pressure

instruments.

Servicing the system is easy and is carried out in accordance with Section B; simply remove tubes from instruments and blow air in tube in port direction and never viceversa,

clearing possible obstructions and checking line condition.

Check visually and more frequently pitot tube on left strut (1) and static ports (2) clearing

possible obstructions.

Ed.2

F

IGURE

E-5 P

ITOT AND STATIC SYSTEM

For safety reasons and to ensure correct airspeed readings, it is important to check the pitot system for leaks adopting the following procedure:

Fasten a piece of rubber hose approximately 30 centimeters long to the pitot tube, close

off the opposite end of the hose and slowly roll it up until the airspeed indicator shows

cruise speed. Constant reading is an indication of no leak in system.

CAUTION

Avoid blowing air through pitot or static ports, as this causes

immediate damage to the airspeed indicator.

Page E-8 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

4 - EXHAUST MANIFOLDS

With reference to figure E-6, exhaust manifolds (1) are flanged to the engine and join the

muffler (2) separately. The muffler also works as a heat exchanger (3) for carb and cabin

heat (optional).

The exhaust system must always be checked for possible cracks. Close attention must be

given to the heat exchanger system which should be totally disassembled for inspection as

cracks would allow noxious fumes to be mixed with cabin air.

F

IGURE

E-6 E

XHAUST MANIFOLDS

5 - CARBURETOR HEAT AND CABIN HEAT (optional)

Two different systems are available:

• C

ABIN HEAT ONLY

This heat system (see Fig. E-7) consists of the above mentioned heat exchanger (3), of

an intercept valve (4) and of an outflow hatch (1) located in rudder bar proximity, and

(optional) two defogging otuflow openings (2).

The intercept valve, located externally on lower part of firewall is controlled by a

round knob located on lower left side of dashboard.

• C

ARBURETOR HEAT AND CABIN HEAT

Carburetor heat is controlled by a valve located in the airbox that switch This system is

designed to direct carb air intake from scoop and manifold located on top portion of

Ed.2

Page E-9 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

firewall. Using a central valve (air valve in fig. E-7) hot air from heat exchanger may

be deviated towards carburetors.

The valve, is controlled by a round knob located centrally on dashboard.

The heating system does not require particular servicing except for periodic check of heat

exchanger and of intercept valve whose faulty closure may cause unwanted heat to enter

cabin.

Ed.2

Figure E-7 C

ARBURETOR HEAT AND CABIN HEAT SYSTEMS

Page E-10 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

Section E

6 - BRAKE SYSTEM

The brake system (see fig. E-8) consists of a brake fluid reservoir (4), a master cylinder

(3) and two disc brakes; an intercept valve activates parking brake (2).

Braking action is through a lever (1) located on cabin tunnel between seats. Hydraulic circuit intercept valve is also located between seats and, when closed with lever pulled,

keeps circuit under pressure and aircraft’s parking brake on. It is also installed a checkvalve (5) that provides braking action even if the parking brake valve (2) is shut.

Ed.2

Figure E-8 B

6.1 - Draining and replacing brake fluid

Service one side first, then other;

A.

Remove reservoir cap;

B.

Unscrew line nipple from disk caliper;

RAKE SYSTEM

Page E-11 Date: Sept. 2004

SYSTEMS

C.

Using a manually operated pump, add brake fluid UNIVIS J43 until level reaches

P92 Echo & P92-S Echo

Maintenance Manual

Section E

bottom of reservoir, reattach line to caliper avoiding fluid spill.

D.

Repeat operations A, B, C on opposite side of aircraft.

E.

Add fluid to reservoir up to 3/4 level and close cap.

To drain system proceed as follows:

F.

Pull brake lever (1) to pressurize circuit;

G.

Loosen small escape valve and release oil spurt;

H.

Close small valve and release brake lever.

I.

Repeat operations F, G and H until oil comes out clean and no longer in spurts proving

absence of air bubbles.

J.

Add oil used for drainage to reservoir;

K.

Close reservoir and repeat operation for other brake.

Hydraulic fluid may also be replaced using gravity after disconnecting

the circuit. This method is however more laborious and less safe.

6.2 - Replacing brake pads

When thickness of lining is less than 2.4 mm, brake pads should be replaced using the following procedure:

A.

Release parking brake;

B.

Remove (optional) fairings to expedite operation

C.

Loosen bolts (2) from caliper (1);

D.

Remove brake pads (3);

E.

Replace brake pads.

Ed.2

F.

Reassemble.

F

IGURE

E-9 B

RAKE CALIPER

Page E-12 Date: Sept. 2004

SYSTEMS

P92 Echo & P92-S Echo

Maintenance Manual

7 - ELECTRICAL SYSTEM

Electrical energy is supplied by a 12-volt direct-current system. Energy is supplied by an engine-driven generator and by a buffer battery.

The 18 Ah capacity battery, is located in a distinct compartment on the right side

of the tail cone. The compartment is suitably drained and vented, and access is

through a small hatch secured by a screw.

Every 50 hours, or more often during summer, add distilled water to keep electrolyte at correct level. Battery elements must be completely submerged.

Before installing battery, accurately clean support removing any trace of electrolyte and insure that drain tube is free from obstructions. Use sodium bicarbonate

solution for cleaning purposes.

Section E

Make sure battery terminals are in proper condition and apply Vaseline. Insure

Master switch is OFF before connecting cables. Also insure that no sulfuric acid

comes into contact with the aircraft’s structure. In case this should occur, rinse

accurately using soap and water.

Generator is permanent magnet type. DC conversion is via an electronic regulator with integrated rectifier. Generator servicing and repair must be carried out