Page 1

Powered Air

Purifying Respirator

Read all instructions and warnings before use. Users must understand this booklet prior to

use. Keep these User Instructions for future reference. If you have questions regarding

these products, just feel free to let Tecmen know.

Produced by

Freflow V3

Page 2

WARNING

USE FOR

This product with respiratory purifies certain airborne contaminants, including dust, pollutants,

fine particles as well as other contaminants, welding dust and metal dust. Gas filter option

suits welders with specific working conditions. Supplying clean air to the user's facial.

DO NOT USE FOR

• Oxygen deficient atmospheres.

• Contaminant generated in workplace and concentrations that are unknown or immediately

dangerous to life or health (IDLH).

• Oxygen concentration of the air in workplace is 19.5% or lower.

• Without complete assembling of the whole product, never use, which may cause danger for

human life.

• Do not use in sealed place, in place with danger as fire, explosion.

• Do not use the product with its power turned off since carbon dioxide concentration may

increase and oxygen level inside the face guard may decrease.

• Do not use if the product does not supply enough air.(MIN - 165 lpm)

• Do not use at workplace with strong wind. (as negative pressure generated inside the hood,

outside-air comes into the hood)

NOTICE

If bleeping alarmed, immediately get away from the contaminated area and check the

device. The hose may get blocked; Battery low power; Filter is dirty and need get changed

with new one.

Please EXIT that contaminated place in any cases below:

• IF some problem is shown in any part of the product, for example, the air supply is

stopped or its amount is decreased.

• IF it gets hard to breathe, feeling dizzy or headache, feeling the smell or taste of the

contaminants and its stimulus occurred.

• Never use in place with too high level of contamination.

• Make sure the connecting hosepipe smooth and is not entangled or is in the way of other

items in the area.

• Don’t remove the respirator until you are in a safe area.

• Operating temperature range between -5°C and +55°C.

• The TECMEN Freflow PAPR system is not intrinsically safe. Keep away from flammable,

or explosive atmosphere.

• At very high work rates the pressure in the device may become negative at peak inhalation

flow.

• Do not confuse the European standard EN12941 with other standards.

MARKINGS ON THE EQUIPMENT

Read the instruction before use.

Shall be disposed of as electronic waste.

Recycle

Expiry date year/month

1

Page 3

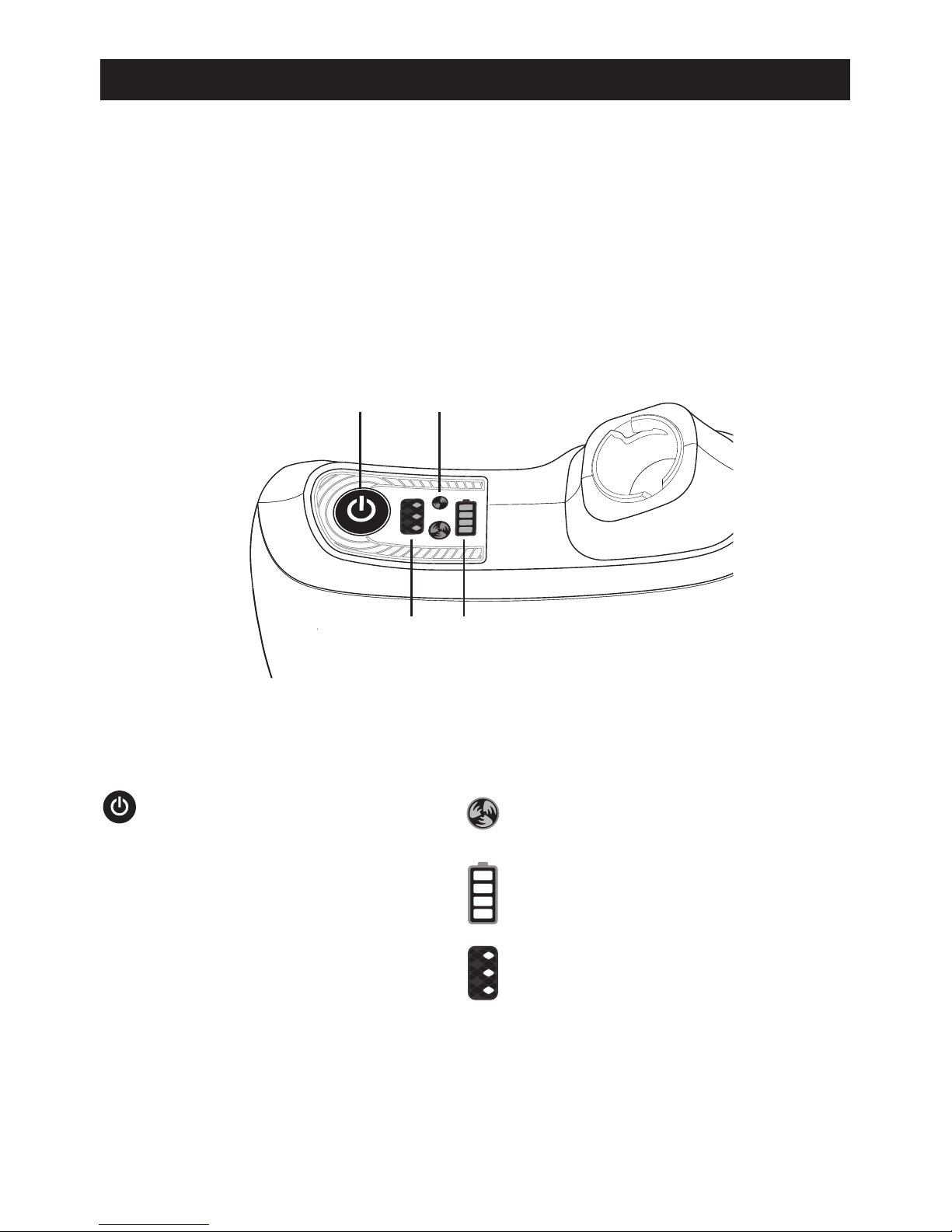

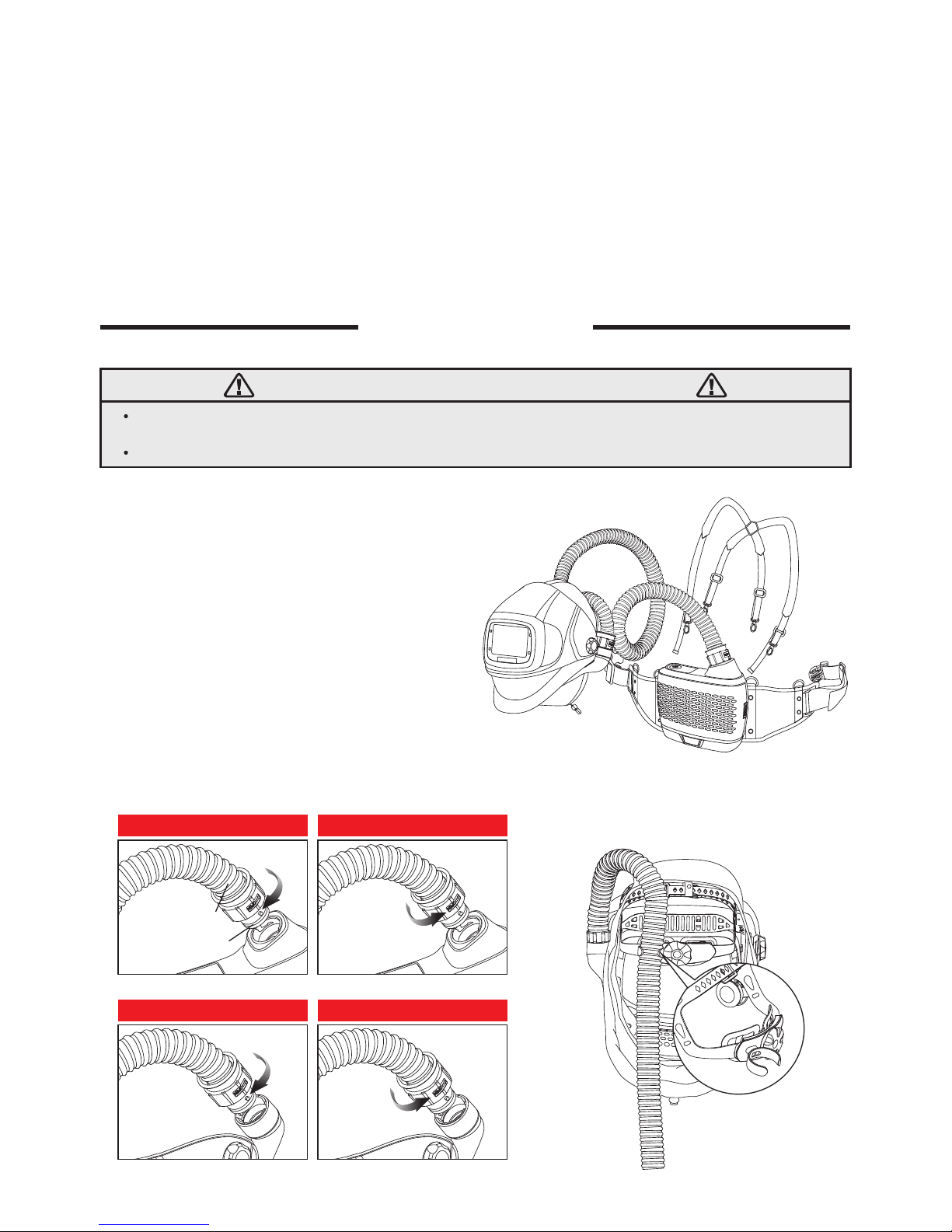

A complete Tecmen PAPR System includes a blower, filtration unit, breathing tube assembly,

battery, and a welding helmet with auto darkening filter.

The blower assembly draws surrounding air through its filter and supplies purified air to the

facial via a breathing tube. There are two levels airflow rate choice: Low speed—170+lpm;

High speed—210+lpm. Switch the airflow by short press Button. Warning lights allow you to

check the filter status. More warning lights turn on, more dirty it means. When warning lights

flash, please replace the filter.

DESCRIPTION & SPECIFICATION

BUTTON

FILTER

WARNING

BATTERY

INDICATOR

AIRFLOW

Indicator light refers to the airflow state. Two

different levels: Low Speed—170+lpm, High

Speed—210+lpm

Warning lights help to check the filter status.

More light spots turn on,more dirty it means.

When warning lights flash, pls. replace the

filter.

Display screen indicates the battery capacity.

Only Button controlling both Power

On/Off and Airflow switch

1.Power On/Off

On—Press and hold for 3 seconds.

Off—Press and hold for few seconds until

bleeping sounds finish.

2.Airflow switch

Press the Button to switch between

170+lpm and 210+lpm

2

Page 4

RESPIRATOR SPECIFICATIONS

Manufacturer’s minimum design flow rate: 165+lpm (5.8+cfm)

Low speed: 170+lpm (6+cfm)

High speed: 210+lpm(7.4+cfm)

Battery type: Rechargeable Li-ion Battery

Battery duration: 9h-low speed(170+lpm); 5h-high speed(210+lpm)

Battery charge time: 3 hours

Battery life: 550 charges

Filter efficiency: 99.97%

Alarms: Visible, Audible and Vibrate

Operating temperature: 23°F to 131°F (-5°C to 55°C)

Storage temperature: 14°F to 131°F (-10°C to 55°C)

Operating R.H.: < 90%

Storage R.H.: < 85%

1027g (Blower Unit + Standard Battery)

EN12941 TH3 —— Highest level of respirator protection

Airflow Rate

Standard Battery

Filter

Temperature

Relative Humidity (R.H.)

Weight

Respirator Approval

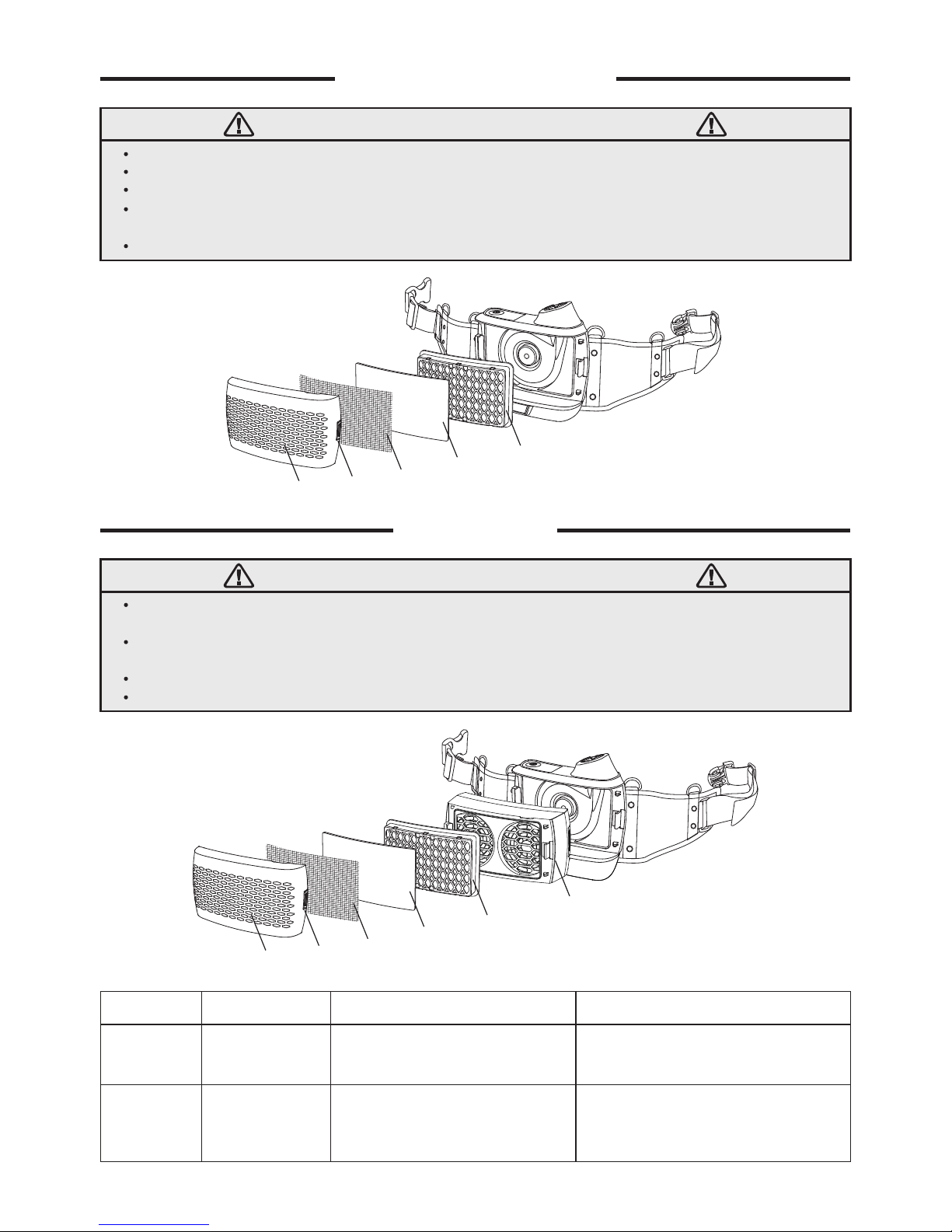

The power must be turned off when replacing the filters. Install the spark screen, pre-filter,

and particulate filter (gas filter if any) in filter cover.

Before installed, always make sure filter material is intact and dry with no tears or other

damages. Install the filter cover assembly to the blower unit by engaging tabs on filter cover

into bracket on blower unit and rotate assembly to close. Push filter cover assembly down

until latch clicks into position securing filter cover assembly. Inspect both sides of cover to

see that the filter cover is properly installed. To replace filter, push latch into release filter

cover and replace filter as fig.1 shown.

When to replace the filter: If the filter gets blocked by contaminants, all the three points of

warning lights will flash, accompanied with vibrate and bleeping sound. Please immediately

exit contaminated environment and check the status.

ASSEMBLING & SPARE PARTS

fig.1

3

Page 5

WARNING

PARTICULATE FILTER

Never use the respirator without the spark screen, pre-filter, and the HE particulate filter (HEPA) installed.

Always replace filter when damaged or blocked. Do not try to wash, clean or reuse dirty ones.

Stored at a temperature between 14°F to 131°F (-10°C to 55°C),in a clean environment without direct light.

Remember not confuse the markings on a filter relating to any standard other than EN 12941 with the classification

of this device when used with this filter.

Please install the particle filter according to fig.2a.

GAS FILTER

fig.2a

fig.2b

WARNING

This gas filter must be always used together with FreFlow particle filter. The gas filter give additional protection

against certain gaseous environment. (See the table below)

The particle filter and gas filter cannot be cleaned. Stop using it immediately when smelling peculiar smell and

replace it until you are in a safe area.

Stored at a temperature between 14°F to 131°F (-10°C to 55°C),in a clean environment without direct light.

Please install the particle filter and gas filter according to fig.2b.

Filter

Cover

Spark

Screen

Pre-Filter

Particulate

Filter

Latch

Filter

Cover

Spark

Screen

Pre-Filter

Particulate

Filter

Gas Filter

Latch

Marking Part No. Color Code Protection Against

P (R SL)

A1B1E1K1

V1P3 TM3 00

V1GF TM3 00

White

Brown / Grey / Yellow / Green

Particulates (R=replaceable,

SL=test against sodium chloride

and paraffin oil)

Organic gases / Inorganic gases /

Sulfur dioxide, acidic gases /

Ammonia and organic ammonia

derivatives

4

Page 6

BATTERY

WARNING

The battery should be charged in a place that is electrically safe.

The charging time of different types of battery is different. Actual charging time depends on the remaining

battery capacity.

Please check out the voltage of the charger (AC 110V~220V).

Please separate the battery from the body before charging.

Upon using-condition, the battery’s life may be slightly different.

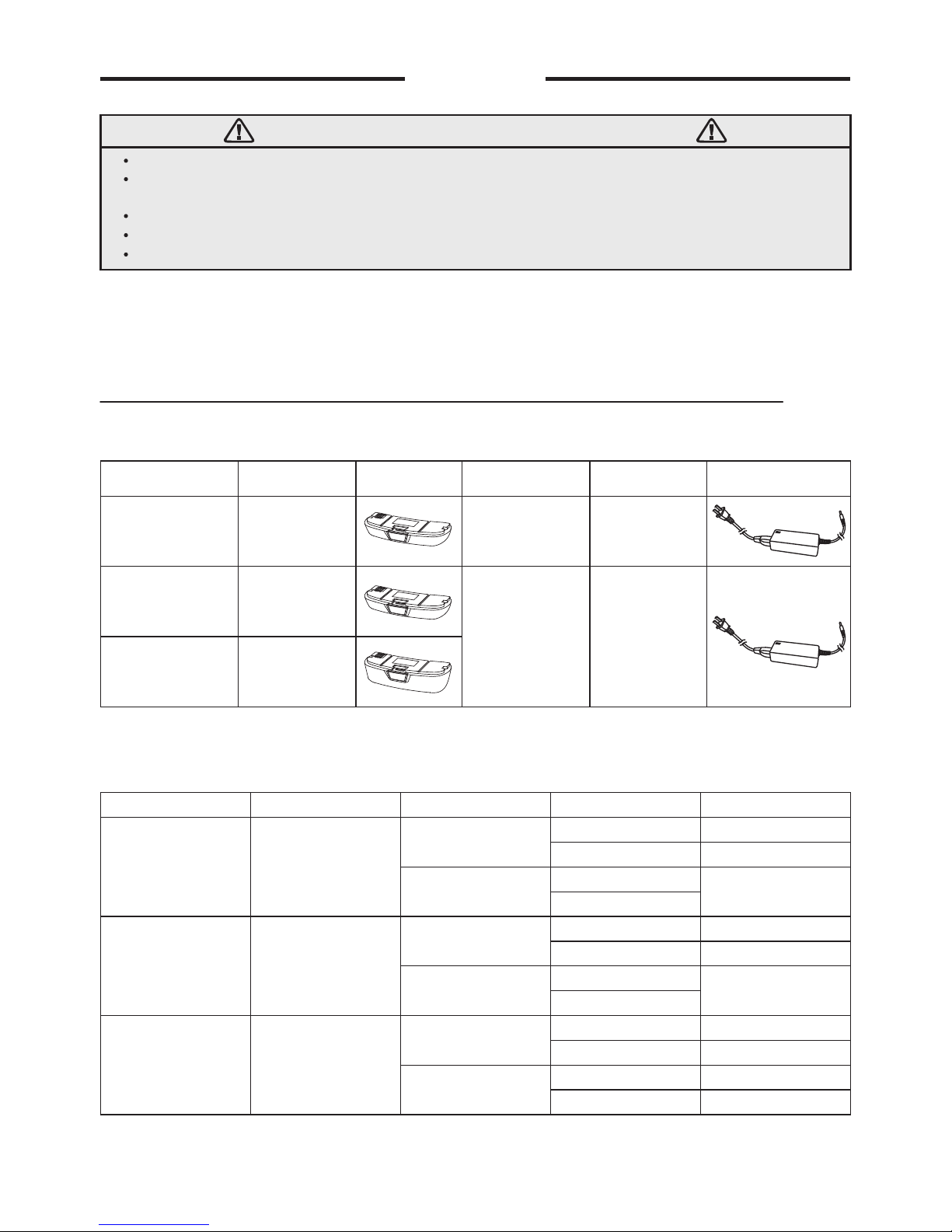

Battery is divided into standard battery, fast-charging standard battery and fast-charging

extended battery. When these three types of battery are used with different filter

components, the battery duration is different. Please choose the appropriate battery

according to actual situation.

It is recommended to choose fast-charging extended battery to match the gas filter.

Standard Battery

Fast-charging

extended battery

Fast-charging

standard battery

Standard Battery

Fast-charging

extended battery

Fast-charging

standard battery

Battery charger

Fast-charging

battery charger

V1BA TM3 00

V1FBA TM3 00

V1FEB TM3 00

V1BC TM3 00

V1FBC TM3 00

Type Part No. Picture Picture Type Part No.

5

Battery type Filter type Airflow rate Battery duration

Particle

Particle + Gas

Particle

Particle + Gas

Particle

Particle + Gas

3 h

1 h

2 h

9 h

5 h

9 h

5 - 6 h

15 h

9 h

11 h

7.5 h

Battery performance for different combinations of filter assembly

Battery charge time

170+lpm

210+lpm

170+lpm

210+lpm

170+lpm

210+lpm

170+lpm

210+lpm

170+lpm

210+lpm

170+lpm

210+lpm

Not recommended

Not recommended

Page 7

Indicator Light

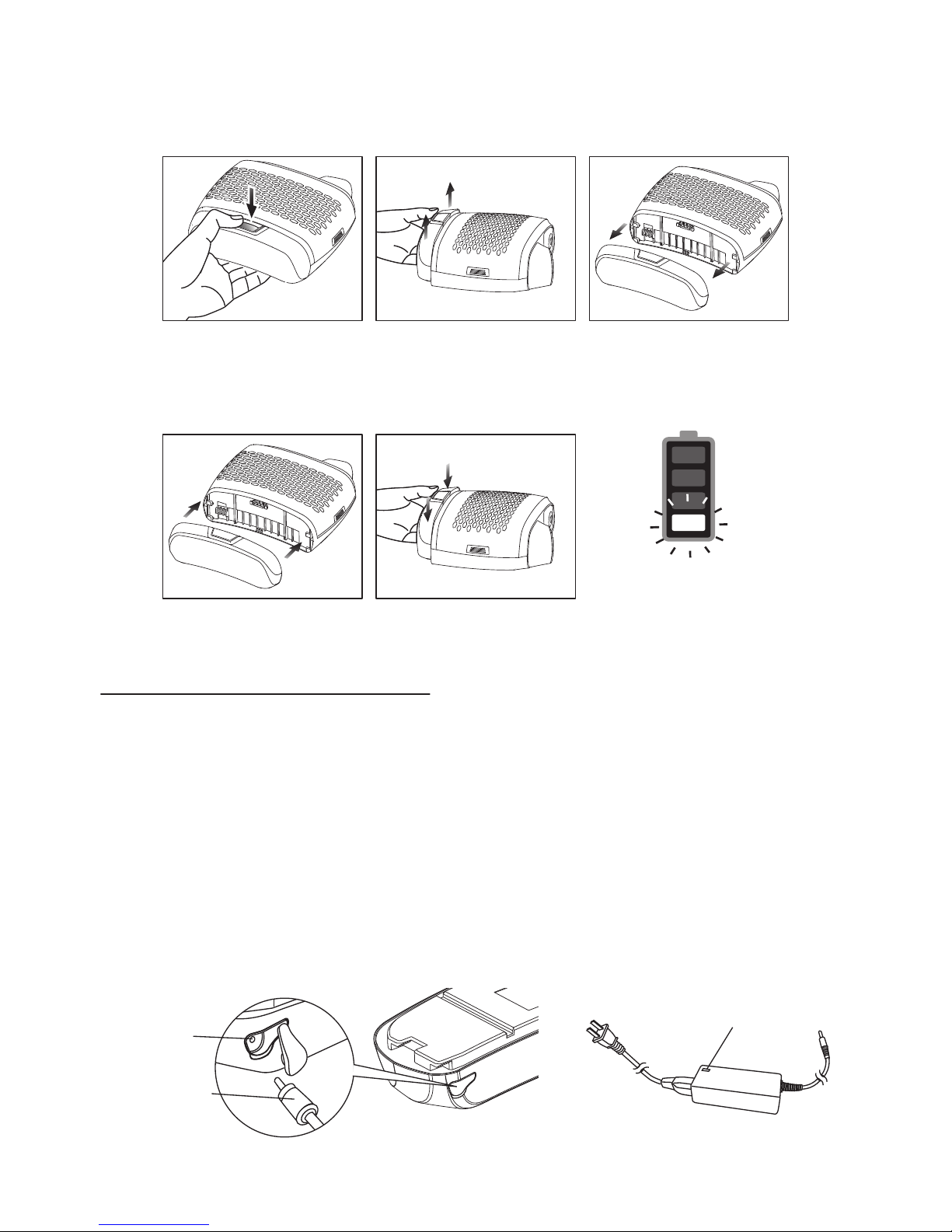

Disassembling the Battery

Push the button, take the battery out as fig.3a / 3b / 3c shown direction. Separate it from the

body.

fig.5a

Push

Pull

fig.3a fig.3b fig.3c

Push

Push

fig.4a fig.4b

Battery-charging

This indicator show the battery capacity.

When four sections show up, the battery is fully charged.

When just one section left (See fig.5a), bleeping sounds on, accompanied by vibration to

remind users to stop work and get battery charged. The frequency is bleeping sounds occur

every 30 seconds and vibration occurs every 2 minutes. After the warnings occur around 15

minutes, the battery indicator gets flashing, which shows there should be at most 15 minutes

left before the blower off (Airflow low speed 170+lpm).

Remove battery pack from blower assembly. Connect charger cord to battery terminal (See

fig.5b).

When the indicator light on charger turns from red to green (See fig.5c) , never stop it

immediately and please keep charging for another 0.5h.

Battery

Charging

Terminal

Charger

Cord

Battery

fig.5b fig.5c

Assembling the Battery

Fitting the battery to the blower body, push until hearing ‘Click’ sound. (see fig.4a / 4b)

6

Page 8

Notice of battery use

• Do not put PAPR unit with power-on in the package. It’s better to remove the battery from

the body when put in the package.

• Do not keep PAPR unit inside the car in hot summer season.

• Do not throw or give the high impact to PAPR unit.

• Do not put PAPR unit on the electric heat generating equipment.

• Do not use any other battery charger.

• Standard battery operation time:

9 hours at low speed (170+lpm), 5 hours at high speed (210+lpm).

• Battery storage temperature: 14°F to 115°F (-10°C - 45°C), R.H.< 85%

Breathing tube

O-ring

fig.7a fig.7b

fig.7dfig.7c

BREATHING TUBE

Assembling

Insert the two prongs on the breathing tube

into the blower unit and helmet air duct (See

fig.6), twist 1/4 to the anti- “open” direction

(See fig.7a / 7c), then clip the breathing tube

into holder on the back cover of the headgear

to lock into place (See fig.8).

Disassembling

Twist 1/4 to the “open” direction and then take

the prongs out from the blower unit and

helmet air duct (See fig.7b / 7d).

WARNING

Always inspect the PAPR end of the breathing tube to confirm the rubber O-ring is in place, see fig.7a. Replace if

missing or damaged.

Be sure tube is properly installed and non-filtered air cannot enter the facial.

fig.6

fig.8

7

Assembling from blower Disassembling from blower

Assembling from helmet Disassembling from helmet

Page 9

1. Blower Assembly

Make sure the spark screen, pre-filter and particulate filter (gas filter if any) are properly

installed and securely latched.

2. Breathing Tube

Make sure tube is not damaged and connected locked to the blower unit and helmet.

3. Battery

Check connection to blower unit is secure and battery is fully charged.

4. Airflow rate test / Alarm sound check

It’s necessary to do both airflow rate test and alarm sound check before use. Testing

method refers to page 9.

5. Face seal

Inspect face seal for damage and replace if necessary. Make sure the air is supplied to

helmet.

ENTER AND EXIT CONTAMINATED AREA

Before using Respirator - Check the following items.

AIR FLOW CONTROL

SHOULDER STRAP & BELT CUSHION

Two indicator lights on display (See fig.10a). Low Speed-170+lpm; High Speed-210+lpm.

When turn on the PAPR, default setting is low speed airflow; Switch the airflow by short

press the Button (See fig.10b).

Hook

fig.9a fig.9b

Low Speed — 170+lpm

High Speed — 210+lpm

fig.10a fig.10b

Connect hooks to belt (See fig.9a).

Connect with the blower by screw locking (See fig.9b).

8

Page 10

After turning on the product, check the alarm sound warning function by blocking the air

outlet as fig.11 shown in the picture above. The warning signal on the panel should flash with

a sound and blower vibrate (approximately 15 to 30 seconds after the outlet is blocked). The

product is working correctly if the warning functions follow the process above.

(Please make sure the filter is equipped and the battery is fully charged before doing this

test.)

SELF CHECK BEFORE EACH TIME USE

ALL THE TESTS MUST ALWAYS BE DONE IN A SAFE ENVIRONMENT.

Alarm sound check

fig.11

BLOCK AIR FLOW

WITH HAND

Steps

• Take off helmet and disconnect tube from helmet.

• Turn off the blower by long press button.

• Release belt. Remove straps from shoulders and remove blower off of your lower back.

• IF some problem is shown in any part of the product, for example, the air supply is stopped

or its amount is decreased;

• IF it gets hard to breathe, feeling dizzy or headache, feeling the smell or taste of the

contaminants and its stimulus occurred;

• NEVER use in place with too high level of contamination. If you suspect the levels reach a

level which this respirator may no longer provide enough protection.

WARNING

Never remove the respirator in areas where the air is contaminated.

Always take off the PAPR after you step out of the workplace.

Respirator removal

Always exit the contaminated area immediately if any of the following

conditions occur:

9

Page 11

Airflow rate test

Take airflow test always before using this product.

Make sure all the components are fully assembled before testing.

Connect the end of hose to the bottom of airflow indicator and then start the Button. Keep

the Flow Indicator vertical.(see fig.12)

If the ball inside the pipe floating above the limited line in low speed mode, it proves normal

function.

If the ball cannot float up to limited line, please refer to Trouble-shooting Guide on page11.

MAINTENANCE

The respirator components must be cleaned, inspected and prepared for next use

after each use. Use soft cloth dipped in mild soap water for wiping. Be careful for the

water NOT to get inside the body.

CLEANING

The face seal can be used to facilitate cleaning after disassembling from the shell, but it must

be replaced if it is damaged.

Blower unit and battery pack: Clean the outer surfaces of the PAPR and battery pack

with a soft cloth dampened in a solution of water and mild, pH neutral detergent. Be

careful for the water NOT to get inside the body. Do not use solvents or abrasive

cleaners. Ensure the electrical contacts of the motor/blower and battery pack are dry

before assembling well.

Breathing tube: Wiping the exterior is insufficient. Clean the outer hose and connection

on the breathing tube with the soft cloth dipped in water and detergent solution.

Optional breathing tube covers can also be used to facilitate cleaning. Ensure the

breathing tube is completely dry before using or storing. They cannot be immersed in

liquids for cleaning and must be replaced if wet.

Filter: Open the filter cover and inspect all the filters and spark screens. The Particle,

gas and pre-filters cannot be cleaned. The spark screen can be cleaned using a clean,

soft cloth dipped in a solution of water and a mild pH neutral detergent. Completely dry

the spark screen with a clean cloth. Replace the pre-filter and Particle filter if

excessively dirty, wet or damaged. Do not attempt to remove contamination using a

compressed air line as this will automatically invalidate the warranty. If the spark screen

cannot be cleaned or is damaged, replace with a new spark screen.

1.

2.

3.

Limited Line

Keep Vertical

fig.12

10

Page 12

TROUBLE-SHOOTING GUIDE

Blower not ON

No airflow from blower

Problems Trouble-shootingCauses

Airflow test failed

Battery time is too short

even fully charged

Increased sound level

Warning indicator ON,

blower vibrate and alarm

sound bleeping

Feeling smell of incoming air

Long press ON button.

Charge the battery.

Check and reassemble the

battery.

Check and clear the

obstruction.

Check the tube status.

Replace new filter.

Replace new battery.

Fully charge battery.

Replace filter.

Replace a new charger.

Replace filter and pre-filter

as required.

Check if tube/anywhere gets

blocked before use.

Check if the package is

removed.

Check the filter status and

replace new one if needed.

Check how the tube

assemble as well as status.

Check and equip both filters.

Battery no power

Battery not installed properly

Tube blocked/air leakage

Dirty filter needs replacement

Battery faulty

Incorrect charging

Blocked filter

Damaged charger

Filter is getting clogged

Damaged Filter

Hose with leakage problem

Filter component not

complete

Tube gets blocked/air

leakage

Filter assembled without

removing the package

The hose may get blocked/

air leakage

STORAGE

The TECMEN Freflow PAPR system is not intrinsically safe. Keep away from flammable, or

explosive atmosphere. Storage should be in a clean, dry, cool place with filter.

Blower storage

Stored at a temperature between 14°F to 131°F (-10°C to 55°C),in a clean environment

without direct light.

Battery storage

To help maximize battery service life:

• Disconnect the charger after a full charge has been received.

• Battery should be removed from blower if long time storage.

• Store the battery at 14°F to 115°F (-10°C to 45°C), R.H. <85%, to get maximize battery

service life.

11

Page 13

WELDING HELMET OPERATING INSTRUCTION

WARNING

Auto-Darkening welding helmets are designed to protect the eye and face from sparks,

spatter and harmful radiation under normal welding conditions. This auto darkening filter will

automatically turn on when pick it up. The filter automatically changes from a light state to a

dark state when an arc is struck, and it returns to the light state when welding stops.

The Auto-Darkening welding helmet comes assembled. But before it can be used, it

must be adjusted to fit the user properly. Check battery surfaces and contacts and

clean it if necessary. Verify if the battery is in good condition and installed properly.

Set up for delay time, sensitivity and shade number for your application.

The helmet should be stored in dry, cool and dark area and remove the battery, when

not using it for a long time.

WARNING

The user must stop using the auto-darkening welding helmet immediately

if the above-mentioned problems cannot be corrected. Contact the dealer.

• Irregular Darkening Dimming

Headband has been set unevenly and there is an uneven distance from the eyes to the filter

lens. (Reset the headband to reduce the difference to the filter).

• Auto-Darkening filter does not darken or flickers

① Front cover lens is soiled or damaged (Change the cover lens).

② Sensors are soiled (Clean the sensors surface).

③ Welding current is too low (Adjust the sensitivity level to higher).

④ Check battery and verify they are in good condition and installed properly. Also, check

battery surfaces and contacts and clean if necessary.

• Slow response

Operating temperature is too low (Do not use at temperatures below -5°C or 23°F).

• Poor vision

① Front/inside cover lens and/or the filter is soiled (Change lens).

② There is insufficient ambient light.

③ Shade number is incorrectly set (Reset the shade number).

④ Check if removing the film on the front cover lens.

• Welding helmet slips

Headband is not properly adjusted (Readjust the headband).

COMMON PROBLEMS AND REMEDIES

12

Page 14

CARTRIDGE OPERATION

• BATTERY INSTALLATION

Slide the battery holder out of the auto darkening filter,

(remove the used battery when replacing battery), put

new CR2450 batteries inside the battery holder, and put

the battery holder back into the auto darkening filter.

Please make sure the anode and cathode of the battery

are installed correctly (See fig.13).

• POWER ON / OFF

This auto darkening filter will automatically turn on when

pick it up.

Sensitivity level setting 0 - 9: The welding helmet will be

automatically off after 15 minutes not being used.

Sensitivity level setting =10: The filter will be darkening all

the time to meet some specially welding application under

both WELD MODE and CUTTING MODE. With this

setting, the welding helmet will not automatically turn off after 15 minutes of not being used.

To save power, remember to set the sensitivity value between 0 - 9 and keep the filter

in dark place when not being used.

• DIGITAL SCREEN ACTIVATION

Press any of four button to activate the digital screen (See fig.14a). After 6 seconds, digital

screen will automatically turn to standby mode. Short press the button again will active the

screen once more and previous settings will remain.

• MODE CONTROL

Short Press “ON / MODE” button to select the mode appropriate for the work activity

(See fig.14a):

Weld Mode − used for most welding applications. Push “FUNC” button to adjust shade

number, sensitivity, and delay settings properly before welding. In this mode the lens turns to

dark immediately when you start welding.

Cutting Mode − used for cutting applications. Push “FUNC” button to adjust shade number,

sensitivity, and delay settings properly before cutting. In this mode the lens turns to dark

immediately when you start cutting.

Grind Mode − used for grinding applications. In this mode the lens shade is fixed shade No.

4. Can not adjust shade number, sensitivity, and delay settings.

• BATTERY INDICATOR

The symbol “ ” show the current state of the battery (See fig.14b). The volume of batteries

has four levels symbol to appear (See fig.14c). The symbol “ ” appears on the display

screen before 1−2 days of battery life remains, the CR2450 lithium batteries should be

replaced in time. The symbol of the Battery Indicator is not real-time, should be updated

after pressing “ON / MODE” button shortly.

Be sure Positive (+) side of

battery faces up.

fig.14a fig.14b fig.14c

fig.13

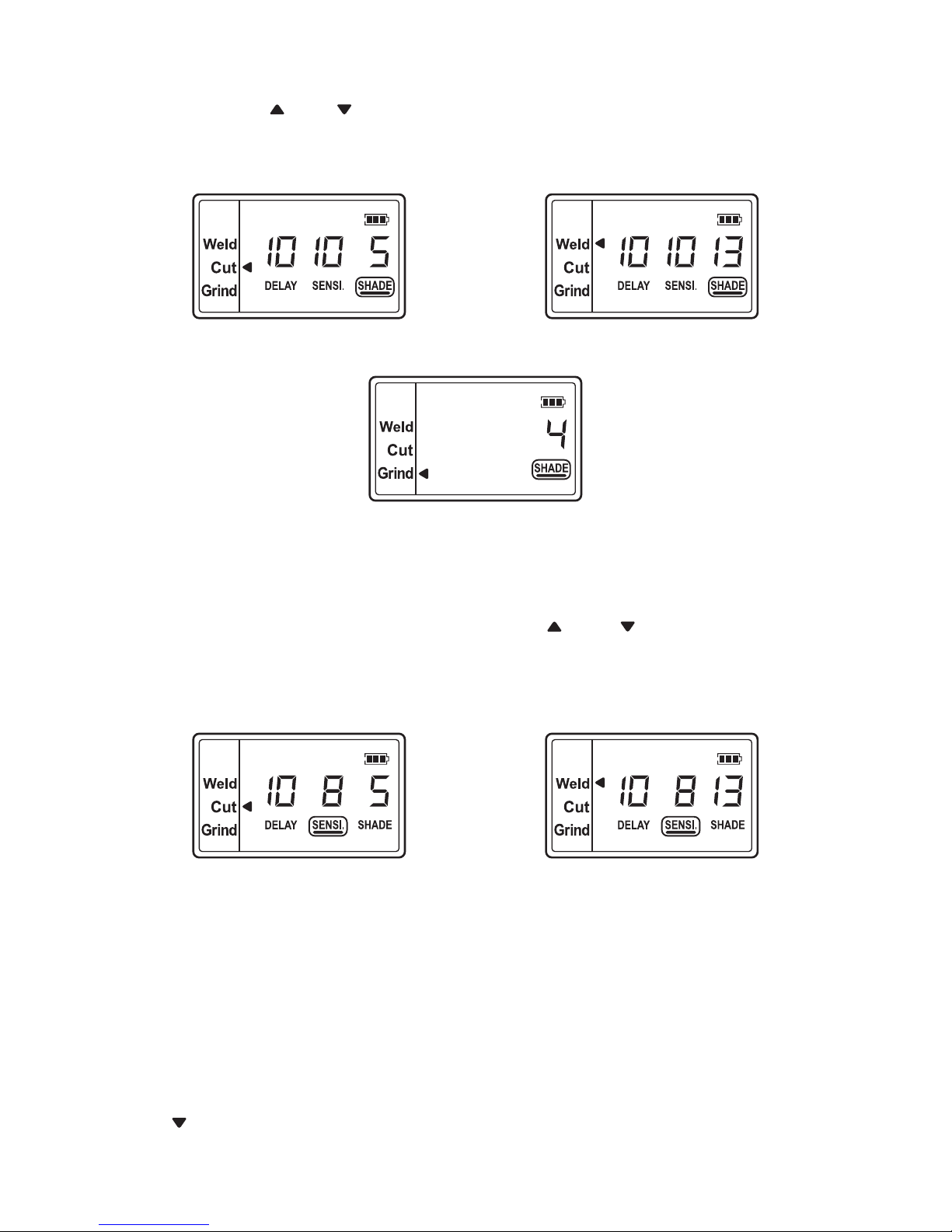

• VARIABLE SHADE CONTROL

After turn on the lens, short press “FUNC” button to choose “SHADE”, and adjust the lens

shade number. Use “ ” and “ ” buttons to select the lens shade in the dark state. The shade

range for each mode are as follows:

Cutting Mode − Shade 5 ~ 8 (See fig.15a) Weld Mode − Shade 9 ~ 13 (See fig.15b)

Grind Mode − No. 4 only (See fig.15c)

Select the proper shade number for your welding / cutting process, by referring to the “Shade

Guide Table” on page 19.

• SENSITIVITY CONTROL

Press “FUNC” button to choose “SENSITIVITY”. Use “ ” and “ ” buttons to make the lens

more or less sensitive to arc light of different welding processes. Sensitivity setting 5-10 is

the normal setting for everyday use. The sensitivity ranges for each mode are as follows:

Cutting Mode (Shade 5 ~ 8) / Weld Mode (Shade 9 ~ 13) − Sensitivity 0 ~ 10 (See fig.16a /

16b)

Grind Mode − No sensitivity adjustment

As a simple rule for optimum performance, it is recommended to set sensitivity to the

maximum at the beginning and then gradually reduce it, until the filter reacts only to the

welding light flash and without annoying spurious triggering due to ambient light conditions

(direct sun, intensive artificial light, neighbouring welder's arcs etc.).

It may be necessary to adjust helmet sensitivity to accommodate different lighting conditions

or if lens is flashing On and Off. Adjust helmet sensitivity as follows: Adjust helmet sensitivity

in lighting conditions helmet will be used in.

• Press “ ” button to lower setting to 0.

13

Page 15

• VARIABLE SHADE CONTROL

After turn on the lens, short press “FUNC” button to choose “SHADE”, and adjust the lens

shade number. Use “ ” and “ ” buttons to select the lens shade in the dark state. The shade

range for each mode are as follows:

Cutting Mode − Shade 5 ~ 8 (See fig.15a) Weld Mode − Shade 9 ~ 13 (See fig.15b)

Grind Mode − No. 4 only (See fig.15c)

Select the proper shade number for your welding / cutting process, by referring to the “Shade

Guide Table” on page 19.

• SENSITIVITY CONTROL

Press “FUNC” button to choose “SENSITIVITY”. Use “ ” and “ ” buttons to make the lens

more or less sensitive to arc light of different welding processes. Sensitivity setting 5-10 is

the normal setting for everyday use. The sensitivity ranges for each mode are as follows:

Cutting Mode (Shade 5 ~ 8) / Weld Mode (Shade 9 ~ 13) − Sensitivity 0 ~ 10 (See fig.16a /

16b)

Grind Mode − No sensitivity adjustment

As a simple rule for optimum performance, it is recommended to set sensitivity to the

maximum at the beginning and then gradually reduce it, until the filter reacts only to the

welding light flash and without annoying spurious triggering due to ambient light conditions

(direct sun, intensive artificial light, neighbouring welder's arcs etc.).

It may be necessary to adjust helmet sensitivity to accommodate different lighting conditions

or if lens is flashing On and Off. Adjust helmet sensitivity as follows: Adjust helmet sensitivity

in lighting conditions helmet will be used in.

• Press “ ” button to lower setting to 0.

fig.15bfig.15a

fig.15c

fig.16a fig.16b

14

Page 16

• Face the helmet in the direction of use, exposing it to the surrounding light conditions.

• Press “ ” button repeatedly until the lens darkens, then press “ ” button until lens clears.

Helmet is ready for use. Slight readjustment may be necessary for certain applications or if

lens is flashing on and off.

• DELAY CONTROL

Press “FUNC” button to choose “DELAY”, begin lens delay adjustments. Use the Lens Delay

Control “ ” and “ ” buttons to adjust the time for the lens to switch to the clear state after

welding or cutting.

Cutting Mode (Shade 5 ~ 8) / Weld Mode (Shade 9 ~ 13) − Delay 0 ~ 10 (See fig.17a / 17b)

Grind Mode − No sensitivity adjustment

The delay is particularly useful in eliminating bright after-rays present in higher amperage

applications where the molten puddle remains bright momentarily after welding. Use the

Lens Delay Control buttons to adjust delay from 0 to 10 (0.1 to 1.0 second). When welding

stopped, the viewing window automatically changes from dark back to light but with a

pre-set delay to compensate for any bright afterglow on the workpiece. The delay time /

response can be set from Level 0 to level 10. It is recommended to use a shorter delay

with spot welding applications and a longer delay with applications using higher currents.

Longer delays can also be used for low current TIG welding, and TIG / MIG / MAG pulse.

• ADJUSTING THE FIT OF THE HELMET

The overall circumference of the headband can be made larger or smaller by rotating the

knob on the back of the headband (See adjustment “Y” in fig.18). This can be done while

wearing the helmet and allows just the right tension to be set to keep the helmet firmly on

the head without it being too tight.

• If the headband is riding too high or too low on your head, adjust the strap which passes

over the top of your head. To do this release the end of the band by pushing the locking pin

out of the hole in the band. Slide the two portions of the band to a greater or lesser width

as required and push the locking pin through the nearest hole (See adjustment “W” in

fig.18).

• Front and back bands will automatically self-adjust according to headform, and soft pads

suit forehead and back of head perfectly, which will bring more comfort (See fig.19a). Test

the fit of the headband by lifting up and closing down the helmet a few times while wearing

it. If the headband moves while tilting, re-adjust it until it is stable.

• ADJUSTING THE DISTANCE BETWEEN THE HELMET AND THE FACE

Step 1: Press down and hold the “LOCK” latch on both sides (See fig.19b) and it can be

slide back and forth.

Step 2: Loosen the “LOCK” latch and keep it snap into slots. Please make sure the

distance between the lens to both eyes are equal, to avoid uneven darkness.

• ADJUSTING VIEW ANGLE POSITION

Tilt adjustment is located on right side of helmet. Loosen the right headgear tension knob

and adjust the lever forward or back to the proper position. Re-tighten the right headgear

tension knob (See fig.19c).

fig.17bfig.17a

15

Page 17

MAINTENANCE

• ADJUSTING VIEW ANGLE POSITION

Tilt adjustment is located on right side of helmet. Loosen the right headgear tension knob

and adjust the lever forward or back to the proper position. Re-tighten the right headgear

tension knob (See fig.19c).

fig.19b

fig.19a

fig.19c

‘W’

‘Y’

‘T’ ‘T’

TOP

fig.18

fig.20a fig.20b fig.20c

fig.21a fig.21b fig.21c

REPLACING THE SHELL COVER

Place fingertips into the gap around the shell cover and flex the shell cover upwards until it

releases from the helmet (See fig.20a / 20b). When installing the new shell cover, put the

side of lug boss of shell cover into the slot and then lock the other side into the helmet. When

hearing “click”,the shell cover is completely fixed (See fig.20c).

REPLACING THE AUTO DARKENING FILTER

Press the thumb on the bottom sides of the auto darkening filter and push it upward (See

fig.21a), remove the auto darkening filter from the shell (See fig.21b). When installing the

new auto darkening filter, clip the lower part of the filter into the bottom of helmet window first,

and then insert the whole filter into the helmet window (See fig.21c).

16

Page 18

fig.22a fig.22b

fig.23a fig.23b fig.23c

REPLACING THE OUTSIDE COVER LENS

Replace the outside cover lens if it is damaged. Place your fingernail in recess above filter

view window and flex lens upwards until it releases from edges of filter view window (See

fig.22a). When installing new outside cover lens, align one side of lens into the slot, and then

insert into the other side.

REPLACING THE INSIDE COVER LENS

Replace the inside cover lens if it is damaged. Place your fingernail in recess above filter

view window and flex lens upwards until it releases from edges of filter view window (See

fig.22b).

REPLACING THE GRINDING LENS AND GRINDING LENS COVER

Place fingertips into the gap around the grinding lens cover (See fig.23a), and flex the cover

upwards until it releases from helmet (See fig.23b). Press the grinding lens lightly and push

inward, remove the lens from slot and take it out carefully (See fig.23c). When installing new

grinding lens, put one side of lens into slot, and then insert into the other side. When

installing new grinding lens cover, put the side of lug boss of lens cover into the slot and then

lock the other side into the helmet. When hearing “click”, the lens cover is completely fixed.

REPLACING THE FACE SEAL

Press the “LOCK” key on cantilevered components and push the headgear in the direction

of arrow to separate headgear from the helmet (See fig.24a). In accordance with the order

of 1-4 in the figure, aligh the face seal with the velcro inside the helmet shell and make sure

the face seal is closely attached to helmet shell (See fig.24b). Then press the “LOCK” key on

cantilevered components to install the headgear to the helmet (See fig.24c), buckle up the

face seal according to 1-5 points (See fig.24d).

17

Page 19

fig.24a fig.24b

fig.24c

fig.24d

CLEANING

Clean helmet by wiping with a soft cloth. Clean the filter surfaces regularly. Do not use strong

cleaning solutions. Clean sensors and solar cells with methylated spirit and a clean cloth and

wipe dry with a lint-free cloth.

18

Page 20

SHADE GUIDE TABLE

(1)

As a rule of thumb, start with a shade that is too dark, then go to a lighter shade which gives sufficient view of the weld zone without going below

the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow

or sodium line the visible light of the (spectrum) operation

(2)

These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the workp

iece.

Data from ANSI Z49.1-2005

Shielded metal arc

welding

Gas metal arc

welding and flux

cored arc welding

Gas tungsten arc

welding

Air carbon

Arc cutting

Plasma arc welding

Plasma arc cutting

Torch brazing

Torch soldering

Carbon arc welding

Gas welding

Light

Medium

Heavy

Oxygen cutting

Light

Medium

Heavy

Less than 3 (2.5)

3-5 (2.5–4)

5-8 (4–6.4)

More than 8 (6.4)

(Light)

(Heavy)

(Light)

(2)

(Medium)

(2)

(Heavy)

(2)

Under 1/8

1/8 to 1/2

Over 1/2

Under 1

1 to 6

Over 6

Less than 60

60-160

160-250

250-550

Less than 60

60-160

160-250

250-500

Less than 50

50-150

150-500

Less than 500

500-1000

Less than 20

20-100

100-400

400-800

Less than 300

300-400

400-800

–

–

–

Under 3.2

3.2 to 12.7

Over 12.7

Under 25

25 to 150

Over 150

—

10

12

14

—

11

12

14

10

12

14

12

14

6 to 8

10

12

14

8

12

14

3 to 4

2

14

4 or 5

5 or 6

6 or 8

3 or 4

4 or 5

5 or 6

7

8

10

11

7

10

10

10

8

8

10

10

11

6

8

10

11

8

9

10

–

–

–

GUIDE FOR SHADE NUMBERS

OPERATION ELECTRODE SIZE ARC MINIMUM SUGGESTED

(1)

1/32 in. (mm) CURRENT (A) PROTECTIVE SHADE NO.

SHADE (COMFORT)

PLATE THICKNESS

in. mm

19

Page 21

TECHNICAL SPECIFICATIONS

Optical Class:

Viewing Area:

Cartridge Size:

Arc Sensor:

Light State:

Grind State:

Cutting Shade:

Welding Shade:

Shade Control:

Power On / Off:

Sensitivity Control:

UV / IR Protection:

Power Supply:

Switching Time:

Grinding:

Delay (Dark to Light):

Low Amperage TIG Rated:

Operating Temp.:

Storing Temp.:

Helmet Material:

ADF Weight:

Application Range:

Approved:

1 / 1 / 1 / 1

107 x 75 mm (4.21" x 2.95")

156 x 123 x 33 mm (6.14" x 4.84" x 1.30")

4

DIN 3.5

DIN 4

Shade No. from 5 to 8

Shade No. from 9 to 13

Internal, Digital Display Control

Automatic On / Off

Low ~ High, Digital Display Control

Up to Shade DIN16 at all times

Solar cell. Battery replaceable,

2 × CR2450 lithium battery

1/25,000 s. from Light to Dark

Yes

0.1 ~ 1.0 s, Digital Display Control

≥ 2 amps (DC); ≥ 2 amps (AC)

-10 °C ~ +55 °C (14 °F ~ 131 °F)

-20 °C ~ +70 °C (- 4 °F ~ 158 °F)

High Impact Resistance Nylon

160 g

Stick Welding (SMAW); TIG DC&AC; TIG Pulse DC;

TIG Pulse AC; MIG/MAG/CO2; MIG/MAG Pulse;

Plasma Arc Cutting (PAC); Plasma Arc Welding (PAW);

Air Carbon Arc Cutting (CAC-A); Oxyfuel Gas Welding

(OFW); Oxygen Cutting (OC); Grinding

DINplus, CE, ANSI Z87.1, CSA Z94.3, AS/NZS 1338.1

20

Page 22

PART LIST

1

1

1

2

3

5

6

7

8

9

10

11

12

4

2

2

2

3

1

2

3

4

5

6

7

9

8

21

The part with * means it is not included in the product, which need to be

purchased seperately.

Page 23

PART LIST

22

Shell cover

Outside cover lens

Auto darkening filter

Inside cover lens

Grinding lens cover

Grinding lens

Helmet shell

Side window

Side window cover

Face seal

Air duct

Headgear (Including Sweatband)

Body

Standard battery

Particle filter (P3 Filter)

Pre-filter

Spark screen

Filter cover

Gas filter

Fast-charging standard battery

Fast-charging extended battery

Shoulder strap

Belt cushion (Include Screws & Washers)

Hose cover

O-ring

Hose

Standard battery charger

Fast-charging battery charger

Airflow indicator

V3SC TM26 00

FC TM26 00

ADF950S IEXP

IC TM950S 00

V3LC TM26 00

V3GL TM26 00

V3PH TM26 00

V3SW TM26 00

V3SWC TM26 00

V3FS TM26 00

V3AD TM26 00

V3HG TM26 00

V1BM TM3 00

V1BA TM3 00

V1P3 TM3 00

V1PF TM3 00

V1SS TM3 00

V1FC TM3 03

V1GF TM3 00

V1FBA TM3 00

V1FEB TM3 00

V1SH TM3 00

V1BE TM3 00

V1HC TM3 00

V1OR TM3 00

V1HO TM3 00

V1BC TM3 00

V1FBC TM3 00

V1AI TM3 00

A.Tecmen PAPR Helmet Assembly

A-1

A-2

A-3

A-4

A-5

A-6

A-7

A-8

A-9

A-10

A-11

A-12

B. Blower Unit

B-1

B-2

B-3

B-4

B-5

B-6

B-7*

B-8*

B-9*

C. Wears

C-1

C-2

D. Hose

D-1

D-2

D-3

E.Battery Charger

E-1

E-2*

F.Airflow Indicator

F

ITEM PART NO. DESCRIPTION

The part with * means it is not included in the product, which need to be

purchased seperately.

Page 24

Tecmen’s only obligation shall be repair, replace or refund the purchase price of such parts

or products material and fabrication defects free of charge within the warranty period.

This warranty does not cover to cause by improper handling abuse or application other than

recommended in the user instruction.

If you come across any problem during warranty period, contact your distributor, send the

defective parts together with the completed defect problem if necessary.

Thank you very much for choosing a TECMEN product!

For future reference, please complete the owner’s record below:

Serial Number:

Purchase Date:

WARRANTY

R

Loading...

Loading...