TEC.LA Ergus WIG 160 DCi, Ergus WIG 201 DCi, Ergus WIG 160 CDI, Ergus WIG 201 CDI User Manual

MANU.115.M.TIG.00

INDUSTRIE LINE

WIG 160 DCi/CDI

WIG 201 DCi/CDI

USER MANUAL

2

TEC.LA S.r.l. thanks you for having chosen its welding machine, built with the principles of

safety and reliability.

The quality materials used in building the machines ensure total reliability and ease of

maintenance.

We recommend reading the manual before connecting the system to the mains.

DECLARATION OF CE CONFORMITY

MANUFACTURER TEC.LA. S.r.l.

Via Castel Morrone n. 15/c

16161 GENOVA – ITALIA

DECLARES

UNDER ITS SOLE RESPONSIBILITY THAT THE PRODUCTS LISTED BELOW, HAVING THE

TRADE MARK:

MODEL: WIG 160 DCi - WIG 201 DCi – WIG 160 DCI – WIG 201 CDI

SERIAL NUMBER:

REFERRING TO DELIVERIES STARTING JANUARY THE 1ST 2005, IS

IN CONFORMITY

WITH THE PROTECTION REQUIREMENTS SET BY DIRECTIVES 89/336 EEC, 92/31 EEC

AND 93/68 EEC REGARDING ELECTRO MAGNETIC COMPATIBILITY (EMC). IN

PARTICULAR IT CONFORMS WITH THE TECHNICAL REQUIREMENTS OF THE EN 50199,

EN 60974-1 STANDARDS AND IS TO BE USED IN ALL INDUSTRIAL BUILDINGS, NOT FOR

HOUSEHOLD USE.

GENOVA, JANUARY THE 1ST, 2005

MANAGING DIRECTOR

CARLO CURLETTO

3

Valued Customer,

Hoping you will find our product to your satisfaction, we welcome you to our family,

informing you that the ERGUS marked machines have been ISO 9000:2001 certified, thus

guaranteeing greater product reliability and quality.

TABLE OF CONTENTS

GENERAL SAFETY INFORMATION .......................................................................................... 5

DESCRIPTION OF POWER SOURCE ........................................................................................ 7

1. Placing the equipment .............................................................................................................. 7

2. Receipt of materials ................................................................................................................. 7

3. Front panel controls ................................................................................................................. 8

INSTALLATION AND USE ........................................................................................................ 10

INSTALLATION OF ELECTRODE MACHINE .......................................................................... 11

1. Electrode welding ................................................................................................................... 12

2. Electrode welding defects–troubleshooting ............................................................................ 13

INSTALLATION OF MACHINE IN TIG HF ................................................................................ 14

1. TIG welding ............................................................................................................................ 15

2.TIG welding defects – troubleshooting .................................................................................... 18

USING THE DIGITAL PANEL ................................................................................................... 19

1. Setting welding parameters .................................................................................................... 19

2. Pulse ................................ ................................ ................................ ................................ ...... 19

3. Choice of welding procedure .................................................................................................. 19

4. Program memories................................................................................................................. 19

5. Remote and Foot control ........................................................................................................ 19

6. Overheating ........................................................................................................................... 19

4

7. Antisticking ............................................................................................................................. 20

WHAT IF THE INVERTER DOESN’T WORK? ......................................................................... 20

AVAILABLE ACCESSORIES ................................................................................................... 21

1. Pulse unit (built-in the CDi versions) ...................................................................................... 21

2. Foot control ............................................................................................................................ 21

3. Remote control ....................................................................................................................... 21

4. Other accessories .................................................................................................................. 21

TECHNICAL DATA ................................................................................................................... 22

FEATURES ................................................................................................................................ 22

BLOCK DIAGRAM .................................................................................................................... 23

REMOTE CONTROL CONNECTION DIAGRAM ...................................................................... 27

SPARE PARTS LIST ................................................................................................................. 28

5

GENERAL SAFETY INFORMATION

Electric shock

ELECTRIC SHOCK CAN KILL.

Do not touch the parts under high voltage;

Disconnect the power supply from mains before any intervention;

Operator must be insulated from the weld piece and from the ground, using insulated gloves

and clothing;

Do not work with damaged or poorly connected cables or with slack cable clamps;

Keep work clothing and your body, dry;

Do not work in moist or wet areas;

Do not lean against the weld pieces;

Protect the power source with a suitable circuit breaker, placed near the welder if possible;

Do not use the machine if any of its protection parts have been removed;

Make sure that the mains in use is earthed.

Explosions

Do not weld above or near containers under high pressure;

Do not weld recipients that contain fuel or inflammables;

Do not weld in areas containing explosive dusts, gases or vapours;

Always use a pressure gauge to connect the machine gas hose to the bottle;

Do not use damaged or leaking bottles;

Do not use bottles that do not show what kind of gas they contain;

Do not expose bottles to sources of excessive heat;

Never mix the gas inside bottles;

Have always refilled bottles by specialized companies;

Avoid accidental contact between bottles and the electrode or other parts under voltage;

Replace gas hoses that show damage;

Keep pressure reducer efficient;

Use only pressure reducers manufactured for the specific gas.

Fire

Avoid flames being generated by sparks, slag and incandescent materials;

Make sure that fire extinguishing devices are available near the work area;

Remove inflammable and combustible materials from the area.

Burns

Protect the body from burns and ultraviolet radiations by wearing protective flameproof clothing (gloves –

headwear – shoes – helmets, etc.);

Wear a welding helmet;

Keep the electrode or torch tip away from your body and other people’s bodies;

Make sure that there is first aid equipment near the work area;

Do not wear contact lenses, the intense heat of the arc could glue them to the cornea;

Replace mask glass if it is damaged or not suited to the specific welding job;

Wait for the welded parts to cool completely before touching them with your hands.

Fumes

Welding produces fumes and harmful metallic dusts, therefore;

If working in closed areas, use exhaust fans;

Clean the weld piece if solvents or other materials that can release toxic gases are present on its surface;

Do not weld metals covered with or containing lead, cadmium, graphite, zinc, chrome, mercury, if there is not

an adequate exhaust fan;

WARNING: do not use oxygen for ventilation!!!

Radiation

The welding arc produces radiation that can damage eyes and burn the skin. The welding arc is considered

dangerous up to a distance of 15m (50 ft). Use suitable protection.

6

Noise

The welding arc respects current legislation on noise levels (not exceeding 80 db); Protective ear

plugs or muffs must be worn to avoid damage when working overhead or in small areas.

Electromagnetic disturbance

The power source respects legislation regarding electromagnetic disturbances and is suitable for

work in industrial surroundings.

However, it is necessary to remember and take necessary provisions if there are disturbances to:

Data transmission systems;

Communication devices;

Switch board controls;

Safety equipment;

Calibration and measurement instruments.

Pacemaker wearers

The magnetic fields coming from high votage or frequency can interfere with pacemakers.

Pacemaker wearers must consult their doctor before using this type of equipment or working in the area where it is

present.

Moving parts

Keep all protective doors and coverings in place;

Keep hands, hair and clothing away from moving parts (fan, rotator, wire feeder for MIG machines).

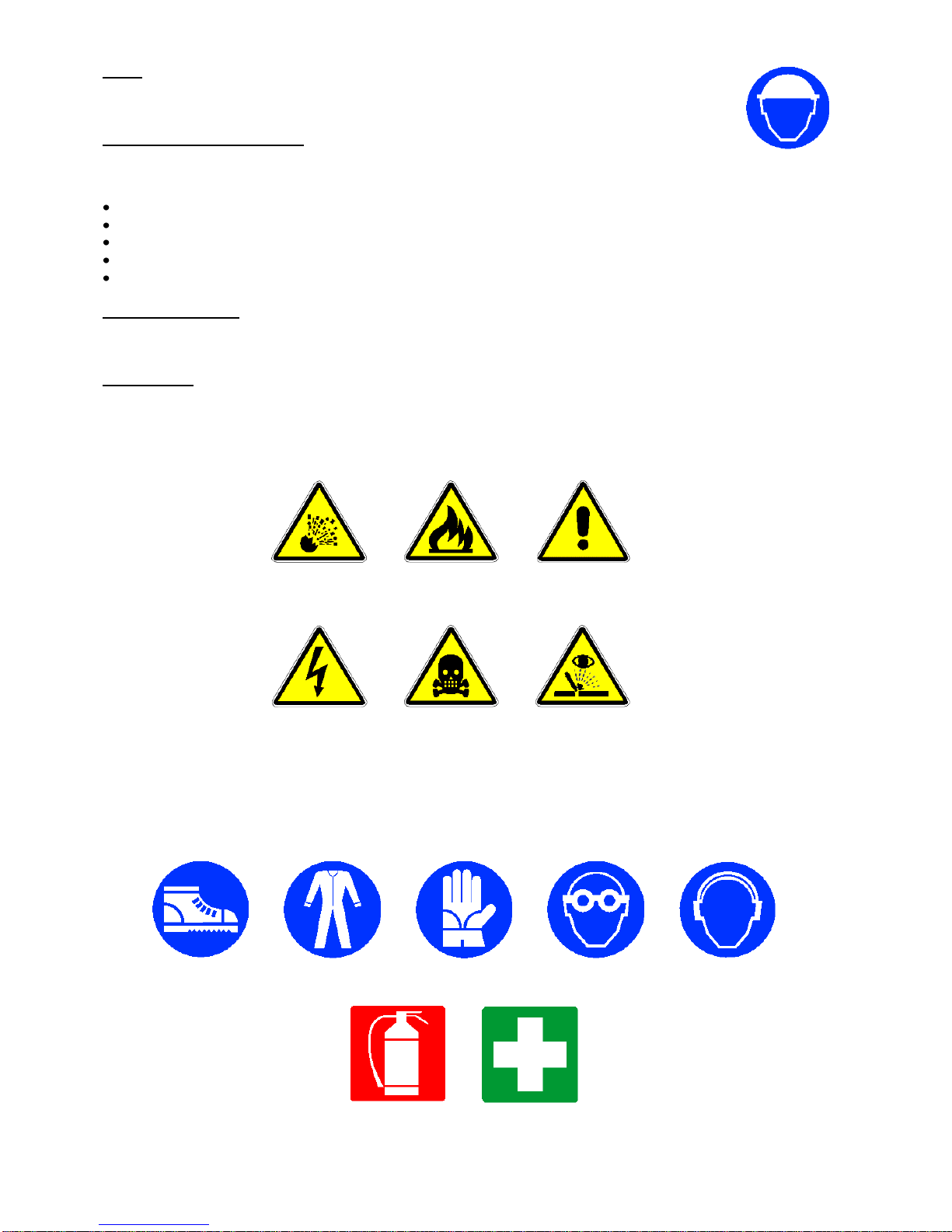

DANGER SIGNS

ACCIDENT PREVENTION SIGNS

GENERIC DANGER

EXPLOSIVE MATERIAL

INFLAMMABLE MATERIAL

DANGEROUS ELECTRICAL

TENSION

POISONOUS SUBSTANCES

BLINDING

SAFETY FOOTWEAR

REQUIRED

BODY PROTECTION

REQUIRED

PROTECTIVE GLOVES

REQUIRED

EYE PROTECTION

REQUIRED

HEARING PROTECTION

REQUIRED

EXTINGUISHER

FIRST AID

7

DESCRIPTION OF POWER SOURCE

The INDUSTRIE WIG 160 DCi/CDI and WIG 201 DCi/CDI power source are designed for coated electrodes

welding and TIG welding with HF ignition. Their basic parts are:

1. Control electronics

2. Power electronics

3. HF generator.

Reduced size and weight make these welders ideal for operators having frequent moving jobs.

The inverter frequency eliminates the characteristic noise of old generation electronic power sources. The welding

bead is more effectively controlled due to the progress of electronic research.

The quality of materials used for manufacturing the ERGUS machines guarantees high performance, long life and

low maintenance.

BEFORE PLUGING AND USE, READ THIS INSTRUCTION MANUAL CAREFULLY.

By following the instructions you can avoid incorrect machine installation.

Damage due to incorrect use invalidates the guarantee.

FOR SPECIAL MAINTENANCE, CONTACT THE DEALER. REPAIRS MADE BY UNAUTHORISED SERVICE

CENTRES INVALIDATE THE GUARANTEE.

Welding power sources are designed for professional use and must be used exclusively by qualified personnel.

This equipment can work under particularly heavy duty and with temperatures between –10°C (14°F) and +40°C

(104°F).

1. Placing the equipment

Avoid placing the equipment in areas that limit the air flow from the fan and from the ventilation grids (do not cover

the power source).

Make sure that the environment temperature does not exceed of 40°C (104°F), that there is no wet air containing

dusts, acids, salts, concentrations of ferrous or metallic dust.

Check that the mains voltage is the same as the power source voltage.

Make sure that the power available from the mains is adequate for the power required by the generator (see

technical data).

Make sure that the working conditions conform with the IP 21 S protection degree.

Casings ensure protection of the electrical components against external agents and against direct contact. They

have various degrees of protection against solids and water, depending on the conditions they are used in.

The degree of protection is shown by the letters IP followed by two digits: the first digit shows the degree of

protection against solid objects and the second the degree of protection against water.

I

Digit

Description

II

Digit

Description

Additional

field

Description

2

Protected against solid objects larger

than 12 mm (for example: a finger).

1

Protected against drops

of water falling vertically.

S

Equipment not in

operation.

2. Receipt of materials

The package contains:

1 power source;

1 user manual;

1 male, 4-pole, torch connector;

1 male, quick gas disconnector.

Make sure that all the materials listed above are in the package. If anything is missing, contact your dealer.

Make sure that the generator has not been damaged during transport. If damage is found, promptly contact your

dealer.

8

3. Front panel controls

WIG 201 DCi

1. ON-OFF SWITCH

2. OVERHEATING LED

3. OUTPUT CURRENT KNOB

4. POSITIVE CONNECTOR

5. NEGATIVE CONNECTOR

6. PULSER, REMOTE, FOOT CONTROL

SOCKET

7. WELDING MODE SELECTOR - ELECTRODE , TIG 24 step, with/without HF.

8. TIG TORCH CONNECTION SOCKET

9. GAS TIG TORCH QUICK CONNECTOR

10. HOT START KNOB (MMA ONLY)

11. POST GAS SETTING

12. SLOPE DOWN SETTING

9

WIG 201 CDI

1. ON-OFF SWITCH (on the back panel)

2. FUNCTION SELECTOR

3. OUTPUT CURRENT KNOB

4. POSITIVE CONNECTOR

5. NEGATIVE CONNECTOR

6. REMOTE, FOOT CONTROL SOCKET

7. DISPLAY

8. TIG TORCH CONNECTION SOCKET

9. GAS TIG TORCH QUICK CONNECTOR

1 on the back panel

10

INSTALLATION AND USE

Machine installation must be done by qualified personnel. All connections must be done in conformity with current

specifications and with respect for industrial accident prevention regulations.

Before connecting the power source to the mains, check that it is between 210 V and 250 V. Mains receptacle

must be earthed.

Tables of lengths and sections

Mains used must always supply the required power.

In some applications extension cables are necessary to reach the work area. To ensure maximum power source

output, abide by the following tables showing the section of the extention cables vs. length.

WELDING STICK OF 3,25 MM (1/8”) (140A-160 A) and TIG WELDING OF 200 A

10 mt (33 ft)

2,5 mmq (12 AWG)

20 mt (66 ft)

4 mmq (10 AWG)

30 mt (99 ft)

6 mmq (9 AWG)

NOTE: For different lengths, use a proportional section size.

11

INSTALLATION OF ELECTRODE MACHINE

All welding parameter controls are placed on the welding machine front panel.

Plug the power cord into a 230V single phase mains socket, making sure that it is earthed.

Ref. 4 Ref. 5 Connect positive (+) and negative (-) connectors to the electrode holder and the earth cable.

Rutile electrodes need the electrode holder be connected to negative pole (-) while basic electrodes need the

electrode holder connected to positive pole (+). In any case, for each type of electrode consult the instructions

printed on the electrode box.

Ref. 1 Switch-on for the inverter ignition.

Ref. 2 LED indicating inverter blockage due to overheating (only DCi models).

Ref. 3 Power knob for welding current output.

Electrodes 1,60 mm (1/16”): minimum current 30A maximum current 50A

Electrodes 2,00 mm (5/64”): minimum current 40A maximum current 70A

Electrodes 2,50 mm (3/32”): minimum current 70A maximum current 110A

Electrodes 3,25 mm (1/8”): minimum current 110A maximum current 140A

Electrodes 4,00 mm (5/32”): minimum current 140A maximum current 180A

Ref. 6 Remote control socket.

Ref. 7 Select the desired electrode position;

(only DCi models; for CDI models see page 19).

Ref.10 HOT START SETTING: at spark starting higher current aids sparking, avoiding electrode sticking.

Insert the un-coated end of the electrode into the holder. Connect the earth terminal to the weld piece. Scratch the

electrode on the piece. To end welding, move the electrode away and the arc will extinguish.

12

1. Electrode welding

Arc welding with coated electrodes is a fusion procedure that uses an electric arc as a source of heat. This is

formed between the extremities of a coated electrode and a base material.

The heat developed by the arc melts the base material, the rod and part of the coating. The remaining part of it

burns into smoke, creating an atmosphere that protects the welding bead from the oxidising action of the air.

The part of the coating that enters the weldong bath separates from the metal, moving to the surface where it forms

the slag which contributes in protecting against air.

The procedure can be done in all welding positions.

WELDING POSITIONS

There are four basic positions:

Surface: the electrode is applied from above and the parts to weld are in a horizontal position.

Frontal: the electrode is applied horizontally with the parts to weld in a vertical position.

Vertical: the electrode acts vertically and the parts to weld are in the same position. They are

distinguished in two positions: Vertical ascending: the electrode moves upwards; Vertical descending:

the electrode moves downwards.

ASCENDING

DESCENDING

13

NB: Descending welding needs a quick movement, while ascending welding needs a slow movement which heats

the material to be welded.

Overhead: the electrode works upwards, while the parts to weld are in a horizontal position.

FOR OPTIMAL WELDING ON MATERIALS OF CONSISTENT THICKNESS, THE EDGES TO BE JOINED

SHOULD BE PREPARED FOR WELDING BEFORE PROCEEDING.

2. Electrode welding defects–troubleshooting

DEFECT

POSSIBLE CAUSES

REMEDIES

1. Air bubbles in the bead

(porosity).

A. Wet electrodes.

B. Welding current to high.

C. Greasy or painted Surfaces

A. Dry electrodes before use.

B. Reduce welding current.

C. Clean joints before welding them.

2. Visible cracks in the bead

immediately after

solidification.

A. Joints too rigid.

B. Welding throat too thin.

C. Cooling too quick.

A. Eliminate tension problems due to the

shape of joints.

B. Reduce welding speed to allow for a

thicker deposit.

C. Pre-heat the piece and cool it more

slowly.

3. Fissure due to slight filling of

the split.

A. Welding current too low.

B. Electrode too big for the joint.

C. Insufficient split.

D. Incorrect welding sequence.

A. Increase welding current.

B. Use electrodes of a smaller diameter.

C. Enlarge split.

D. Place the pieces in a correct sequence.

4. Portions of the welded piece

not melted with the sheet

metal or with the joint.

A. Electrodes too thin for the

piece to be welded.

B. Welding current too low.

C. Electrode used with incorrect

slope.

D. Weldingf speed too fast.

E. Slag or dirt on the surface of

the piece.

A. Use electrodes of a larger diameter and

pre-heat the piece.

B. Increase welding current.

C. Correct the welding angle towards the

base plate.

D. Reduce the welding speed.

E. Clean the surface before welding.

5. Non metallic material

trapped in the weld bead

(slag included).

A. Particles trapped in the lower

layers of the preceding

passages.

B. Joint prepared too tight.

C. An irregular deposit helps the

slag to stay trapped.

D. Slight penetration with slag

trapped under the welding

bath.

E. Rust or chips prevent total

melting.

F. Wrong electrode for the

welding position.

A. In situations of slight base welding, clean

slag and pass on the base again with an

electrode of a smaller diameter.

B. Guarantee enough space for slag

cleaning.

C. If necessary, grind the slight or the

irregular part.

D. Remove all slag from corners. Use

smaller electrodes with higher current for

suitable penetration.

E. Clean the joint before welding.

F. Use electrodes suited to the welding

position, otherwise it will be difficult to

remove the slag.

14

INSTALLATION OF MACHINE IN TIG HF

DC - DIRECT CURRENT

Connect the mains power cable to a 230V single phase line, making sure that the socket is earthed.

Place the gas bottle in a safe place and make sure that it is well secured.

Connect the TIG torch gas hose to the pressure gauge following the manufacturer’s instructions which are

included with the gauge. Pure ARGON gas recommended 4-8 lt./min. (1-2 gallon/min).

Ref. 4 Positive connector (+)for the earth cable.

Ref. 5 Negative connector (-) for the TIG torch power cable.

Ref. 8 Connect TIG torch to its socket.

Ref. 9 Insert gas quick disconnector of TIG torch.

Ref. 3 Power knob with potentiometer for welding current output.

Ref. 7 Select 2/4 step position for TIG welding with or without HF (only DCi models; for CDI models see

page 19):

2 T HF Position - 2 step for stud and spot welding, keep the torch trigger pressed

4 T HF Position - 4 step allows working without the torch trigger pressed. Press the trigger;

once the arc is created, the trigger can be released and welding continued; to end the

operation, press and release the trigger again.

2-4 T without HF: use this ignition without HF in high risk areas where disturbances generated

by the HF can create interference (i.e. near computers or electronic equipment). Identical 2/4 T

functions with HF. Ignition without HF is done by scratching the Tungsten electrode tip on the pi

weld piece.

Ref. 12 By setting the slop down time, the current output drops gradually, avoiding the typical defects when

welding ends, such as shrinkage cavities. In the 2-step position this will be obtained by releasing the torch

trigger, while in position 4 -step the trigger must be kept pressed. (only DCi models; for CDI models see page

19).

Ref. 11 Setting the post-gas time, prevents electrode oxidation at the end of welding. Gas should flow for a

few seconds (8/10 recommended). (only DCi models; for CDI models see page 19).

Ref. 6 Connector for: pulser (only DCi models) – remote – foot control.

15

1. TIG welding

TIG welding is a fusion procedure that uses as a source of heat an electric arc created between an infusible

tungsten electrode and the base material to be welded. For TIG welding an inert gas must be used (ARGON) which

protects the welding bead. If filling material is used, it is made up of rods suitable to the material to be welded

(steel, steinless steel, copper, etc).

In TIG mode, welding it is possible in all positions: flat, angle, on the edge, vertical and overhead. Furthermore,

with respect to other types of welding, the welded joint has greater mechanical resistance, greater corrosion

resistance and limited heating in the welded area which limits distortion. Welding can be done even without weld

material, guaranteeing a smooth, shiny weld with no impurities or slag.

Preparation of material

Welding results also depend on the cleanliness of the piece before it is welded. Edges must always be properly

shaped before cleaning operations. The most suitable ones are “V” or “X”.

Preparation of joints must be done so that there is good penetration.

Once these are ready, they must be cleaned, de-greased with solvents, they can be brushed or ground with

attention to chips removal.

Pure ARGON gas should be used. If other blends are used, oxidation may occur.

Electrode selection and preparation

The electrode must withstand as much current as possible without melting, because melted tungsten would

contaminate the welded metal. Tungsten may form hard inclusions that compromise the resistance of the weld.

When welding in alternating current, where polarity changes continually from positive to negative, the current must

be strong enough to slightly melt the electrode tip.

WELDING CURRENT AND RELATIVE ELECTRODE DIAMETER

electrode (mm)

Direct current (A)

Negative pole

1.0 (1/32”)

1.6 (1/16”)

2.4 (3/32”)

3.2 (1/8”)

10-70

60-150

100-250

200-400

ELECTRIC CURRENT

INERT GAS

TUNGSTEN ELECTRODE

DEPOSIT

PENETRATION

MELTED AREA

BASE MATERIAL

PROTECTIVE GAS

TORCH

ROD

16

Electrode preparation for DC welding

The electrode should be pointedaccording to the welding current.

Angle @

[°]

Range of current

[ A ]

30

60-90

90-120

120

0-30

30-120

120-250

>250

TYPES OF ELECTRODES

ELECTRODE

COLOUR

USE

Cerium-Tungsten

Grey

Universal

Thorium Tungsten

Red

Fe-Stailess steel-Copper

Welding Position

Place the tip at 3-4 mm (.12 - .16in) from the weld piece, press the torch trigger, the arc will automatically ignite; as

soon as the bath forms, move slowly and with constant speed so as to produce a bath that is uniform in penetration

and width.

If filling material is used, keep the rod at a slope and about 20 mm (.79in) from the piece; when the weld pool

becomes fluid, move the torch back and add material, touching the rod to the pool. (Filling material is always

necessary for aluminium.)

Pull the rod away and position the torch back near the weld bead.

Repeat this operation quickly and constantly so that the weld remains homogenous.

17

TIG WELDING PARAMETERS

Stainless STEEL

Sheet

metal

thickness

mm.

Type of seam

Welding current (A)

Electrode

mm.

Filling

material

mm.

Welding

speed

mm./min.

Argon

lit./min.

Number

of

passages

Horizontal

position

Vertical

position

1

(.039 in)

Head to head

25 – 60

23 – 55

1.0

1.6

250 – 300

6

1

Overlapping

60

55

1.0

1.6

250 – 300

6

1

External angle

40

35

1.0

1.6

250 – 300

6

1

Internal angle

55

50

1.6

1.6

250 – 300

6

1

2

(.078 in)

Head to head

80 – 110

75 – 100

1.6 – 2.4

1.6 – 2.4

175 – 225

6

1

Overlapping

110

100

1.6 – 2.4

1.6

175 – 225

6

1

External angle

80

75

1.6 – 2.4

1.6

175 – 225

6

1

Internal angle

105

95

1.6 – 2.4

2.4

175 – 225

6

1

3

(.12 in)

Head to head

120 – 200

110 – 185

2.4 – 3.2

2.4

125 – 175

7

1

Overlapping

130

120

2.4 – 3.2

2.4

125 – 175

7

1

External angle

110

100

2.4 – 3.2

2.4

125 – 175

7

1

Internal angle

125

115

2.4 – 3.2

3.2

125 – 175

7

1

4

(.16 in)

Head to head

120 – 200

110 – 185

2.4 – 3.2

3.2

100 – 150

7

1

Overlapping

185

170

2.4 – 3.2

2.4

100 – 150

7

1

Internal angle

180

165

2.4 – 3.2

2.4 – 3.2

100 – 150

7

1

5

(.2 in)

External angle

160

140

3.2 – 4.0

2.4 – 3.2

100 – 150

7

1

6

(.24 in)

Head to head

220-275

190-230

3.2 – 4.0

3.00 – 4.00

150 - 240

7

2

Overlapping

250 - 300

210 - 250

3.2 – 4.0

3.00 – 4.00

150 - 240

7

2

Internal angle

280 – 320

230 - 280

3.2 – 4.0

3.00 – 4.00

150 - 240

7

2

COPPER and its alloys

Sheet

metal

thickness

mm.

Type of seam

Welding current

Horizontal position

(A)

Electrode

mm.

Filling

material

mm.

Welding

speed

mm./min.

Argon

lit./min.

Number

of

passages

1

(.04 in)

Head to head

70 – 90

1.6

1 – 1.6

300

6 – 8

1

Overlapping

70 – 100

1.6

1 – 1.6

300

7 – 8

1

Head 2 L

60 – 100

1.6

1 – 1.6

300

7 – 8

1

2

(.078 in)

Head to head

130 – 150

1.6

1.6

250

7 – 8

1

3

(.12 in)

Head to head

170 – 200

2.4 – 3.2

2.4 – 3.2

260

7 – 10

1 - 2

Internal angle

200 – 250

2.4 – 3.2

2.4 – 3.2

225 7 1

Overlapping

200 – 250

2.4 – 3.2

2.4 – 3.2

225

7 – 10

1

TIG welding parameters in direct current (DC).

Filling material

Filling material can be wire or rods; metal strips cut from the same weld piece metal can be used, in that case the

filling material must always be well cleaned.

The composition of the weld material must not generate porosity; it must be selected according to the basic

material to be worked on.

If suitable material is used, with uniform movement, the seam must be smooth, no porosities and look good.

18

2.TIG welding defects – troubleshooting

DEFECT

POSSIBLE CAUSES

REMEDIES

1. The electrode melts

when the arc

strikes.

A. Electrode connected to the “+” pole.

A. Connect the electrode to the “-“ pole.

2. Dirty welding bath.

A. Electrode contaminated from contact

with the welding bath or rod.

B. Gas contaminated with air.

A. Remake the electrode tip.

B. Check the gas hoses or change bottle.

3. The electrode melts

or oxidises when

the arc strikes.

A. No gas available on the welding bath.

B. Torch clogged by impurities.

C. Gas hose cut.

D. Gas pathway contains impurities.

E. Gas valve closed.

F. Torch valve closed.

G. Electrode too small for current being

used.

A. Check for obstacles in the gas lines and

check the bottle.

B. Clean the torch.

C. Replace the gas hoses.

D. Detach the gas feed from the torch and

increase pressure to blow away

impurities.

E. Open.

F. Open.

G. Lower welding current or replace the

electrode with a larger one.

4. Welding visibly

slight.

A. Inadequate protective gas.

A. Increase the gas flow or check the gas

feed line.

5. Arc unstable during

TIG welding.

A. Tungsten electrode too big for the

welding current.

A. Select the right size electrode.

(Reference table 3).

6. The welding arc

doesn’t stabilize.

A. Earth clamp not connected to the

piece, or connectors not connected to

the right poles.

B. Torch cables disconnected.

C. Incorrect gas flow, empty bottle or

closed valve.

A. Connect the earth clamp to the weld

piece or connect torch cables and earth

to the right connectors.

B. Connect the torch cable to the “-“ pole.

C. Correct the gas flow, change bottle or

open the valve.

7. The arc doesn’t

strike smoothly.

A. Tungsten electrode too big for the

welding current.

B. Tungsten electrode not adequate for

the job.

C. Gas flow too high.

D. Wrong gas being used.

E. Poor contact between earth clamp

and weld piece.

A. Select the right size electrode.

(Reference table 3).

B. Select the right type of electrode.

(Reference table 4).

C. Select the right gas flow for the job.

D. Select the right type of gas. (Reference

table 6).

E. Ensure good contact between earth

clamp and weld piece.

19

USING THE DIGITAL PANEL

1. Setting welding parameters

Set welding parameters using the “FUNCTION” (2) keys. For each function selected, the present value appears on

the DISPLAY (7) and the LED of the corresponding icon turns on.

Press “ENTER”: the measurement symbol flashes. Set the new value with the “+” and “-“ touch buttons.

Press “ENTER” to confirm and move on to the next function with the “+” button.

The KNOB (3) rules over the maximum current output.

2. Pulse

With the PULSE function selected, the display prompts for ON/OFF; select the desired mode with the “ENTER”

button. In the ON mode, the pulsing DUTY CYCLE can be varied between 30% and 80%, and the frequency

between 1 and 175Hz. Maximum current output is set with the Knob (3), meanwhile the minimum is the “BASE”.

3. Choice of welding procedure

Once programming is ended, 6 different procedures can be selected:

STICK (ELECTRODE)

STICK + ARC FORCE (ELECTRODE WITH OVERCURRENT)

TIG 2T HF (TIG WELDING IN 2 STEP WITH HF)

TIG 4T HF (TIG WELDING IN 4 STEP WITH HF)

TIG 2T NO HF (TIG WELDING IN 2 STEP WITHOUT HF)

TIG 4T NO HF (TIG WELDING IN 4 STEP WITHOUT HF).

The procedure selected appears on the display and the LED of the corresponding icon turns on.

Begin welding. The “PREVIEW” display changes to “WELDING” and the current shown is what is actually output*.

* In TIG PULSE, the display shows “PREVIEW” and the ammeter shows the maximum current set.

4. Program memories

When there are several, repetitive welding jobs to be done, or different operators are doing jobs with the same

machine, the group of parameters used can be saved in the memory, then called up at any time.

ENTERING DATA IN THE MEMORY:

Set the welding parameters as shown in (1) above.

Press the “MEM, R” (READ MEMORY) button; select a number from 2 to 18 with the + and – buttons.

Press the “MEM, W” (WRITE MEMORY) button.

READING THE MEMORY

Welding programs that are memorised can easily be called up.

Press the “MEM, R” (READ MEMORY) button; the display will show a number from 1 to 18.

Change the number, if necessary, with the + and – buttons.

Press the “MEM, R” button again, to confirm the selection.

If any of the parameters value is changed while a memory is being used, by the next welding session these will

automatically replace the preceding ones.

5. Remote and Foot control

Once the REMOTE CONTROL (or Foot Control) is connected to the socket (6), output current regulation will be

automatically transferred from the KNOB (3) to these controls.

WARNING: For remote or foot control operation, the SLOPE-UP and SLOPE-DOWN times must be set to zero (0)

6. Overheating

Particularly high environment temperatures, when combined with heavy-duty machine jobs, may cause the word

“OVERLOAD” appearing on the display; this means that the generator has been overheated.

At the end of the cooling cycle, the indicator automatically returns to “PREVIEW”.

20

7. Antisticking

If during STICK or STICK + ARC FORCE welding procedure the electrode sticks for a few seconds,

“ANTISTICKING” will appear on the display and the output current drops to lmin, avoiding electrode overheating.

WHAT IF THE INVERTER DOESN’T WORK?

The welder doesn’t switch-on: check the mains connection and the switch position (1).

Irregular electrode welding:

Check correct connection of the cable holder and earth clamp according to the electrode being used.

Check that the welding current is appropriate for the electrode and the piece to be welded.

Check that the electrodes are not wet or damaged.

Check that the weld piece is not excessively dirty, greasy, etc.

Check that the earth clamp is well connected to the weld piece.

The welder doesn’t generate the power required:

Check that the mains voltage is between 210V-250V (even during welding)

If extension cables are used, make sure that they conform to the table on page 10.

In TIG welding:

The torch spatters during welding:

Check that the torch and earth are correctly connected.

Check that gas is present and that the flow is sufficient.

Check that the weld piece is not greasy or dirty.

Check that the weld piece isn’t composed of alloys incompatible with the power source used.

Check that the electrode is the right colour for the material to be welded.

Check if too high a current setting is being used.

Duty Cycle too short:

Check that the fan is turning.

Check if the fan is blocked and that air circulates from the air grids.

Check if the working environment is too hot.

21

AVAILABLE ACCESSORIES

1. Pulse unit (built-in the CDi versions)

Using pulsed current allows greater control in certain operating situations.

I MIN basic current (MIN/MAX adjustable) Low frequency adjustable from 0.6 to 6 Hz

I MAX peak current (MIN/MAX adjustable) Medium frequency adjustable from 6 to 60 Hz

High frequency adjustable from 60 to 600 Hz

Base/peak percentage time (30/70%).

The welding bead is formed by the surge impulses, while the base current keeps the arc ignited. This solution aids

welding small thicknesses and, compared to a traditional TIG weld made with equal values of average current,

creates a heat affected zone (HAZ) that is much narrower and has less destortions.

2. Foot control

The foot control allows for the arc ignition and extinguishing, independently of the torch trigger; furthermore, the

operator can adapt to different requirements during welding, such as current increase or decrease by varying the

pressure on the pedal.

3. Remote control

The remote control can set welding current in both electrode and TIG modes, at a distance from the power source.

The standard extension cable is 5 mt. (16.4 ft); longer ones can be supplied upon request.

4. Other accessories

CODE: DESCRIPTION:

0000KIT25G Welding set with clamps and 25 sqmm cables

0000KIT50G Welding set with clamps and 50 sqmm cables (200 A)

0000KIT264 TIG 26.4 torch, 4 m (160 A) Tx25

0000KIT268 TIG 26.8 torch, 8 m (160 A) Tx25

0050KIT264 TIG 26.4 torch, 4 m (200 A) Tx50

0050KIT268 TIG 26.8 torch, 8 m (200 A) Tx50

0123410004 Pulse box

0123410002 Remote control

0123410003 Foot control

0123420001 G BOX (adaptor for operating with power generators)

0000090390 Welding helmet

0123410110 Trolley

0123410100 Cooling unit

0123411111 Trolley with circuit breaker switch

00008018-L Pressure gauge with two manometers

000080RB-F Pressure gauge with flowmeter

000RID1MAN Pressure gauge with one manometer

0000019011 Disposable ARGON bottle (110 lt)

22

TECHNICAL DATA

WIG 160 DCi/CDI

WIG 201 DCi/CDI

Mains voltage

230V + 10%

230V + 10%

Frequency

50/60 HZ

50/60 HZ

Power factor

0,85

0,85

Nominal current

27A

27A

ProtectiveFuses

16A t-lag

16A t-lag

OCV

85V

85V

Electrode Nominal Power

5,3 KW

5,3 KW

TIG DC Nominal Power

3,3 KW

4,5 KW

Electrode arc voltage

20,2 – 26,4V

20,2 – 26,4V

TIG arc voltage

10,2 – 16,4V

10,2 – 18V

Electrode duty cycle

160 A@60%

160 A@60%

Electrode output at 100% duty cycle

120 A

130 A

TIG DC duty cycle

160 A@70%

200 A@40%

TIG DC output at 100% duty cycle

130 A

140 A

Degree of protection

IP 21 S

IP 21 S

Insulation Class F F

Working temperature

–10°C+40°C

–10°C+40°C

Size (mm)

385x180x220

385x180x220

Size (in)

15.15x7.08x8.66

15.15x7.08x8.66

Weight

10,25 Kg (22.59 lbs.)

10,25 Kg (22.59 lbs.)

FEATURES

WIG 160 DCi

WIG 201 DCi

WIG 160 CDI

WIG 201 CDI

Electrode output range

TIG DC output range

Hot start

Arc force

Antisticking

Type of TIG arc ignition

TIG DC control

Base current

Slope up

Slope down

Post gas

End current

Program memory

Pulser

Pulser frequency

Pulser duty cycle

5-160A

5-160 A

SELECTABLE

AUTOMATIC

AUTOMATIC

HF/LIFT

2 - 4 Step

30 %

0-10S

0-20S

5-160 A

5-200 A

SELECTABLE

AUTOMATIC

AUTOMATIC

HF/LIFT

2 - 4 Step

30%

0-10S

0-20S

5-160A

5-160 A

AUTOMATIC

ADJUSTABLE

AUTOMATIC

HF/LIFT

2 - 4 Step

30%-80%

0-20S

0-20S

0-20S

min. 80%

18

YES

1-150Hz

30-80%

5-160A

5-200A

AUTOMATIC

ADJUSTABLE

AUTOMATIC

HF/LIFT

2 - 4 Step

30%-80%

0-20S

0-20S

0-20S

min. 80%

18

YES

1-150Hz

30-80%

N.B: The manufacturer reserves the right to make changes to product specifications at any time and without notice.

The manufacturer is relieved of all liability for improper or incorrect use of its products that could harm persons or

things.

23

BLOCK DIAGRAM

WIG 160 DCi

24

WIG 160 CDI

25

WIG 201 DCi

26

WIG 201 CDI

27

REMOTE CONTROL CONNECTION DIAGRAM

WIRING OF CONNECTORS

28

SPARE PARTS LIST

WIG 160 DCi

Nr.

TEC.LA Code

Descrizione

Description

1

DDF115.160.T-E.02.00

WIG 160 DCi

WIG 160 DCi

2

Y.DD.COPE.115.06.00

COPERCHIO CON MANIGLIA

COVER WITH HANDLE

3

Y.DD.MANO.438.02.00

MANOPOLA 15 COMPLETA

KNOB 15

4

Y.DD.MANO.438.01.00

MANOPOLA 22 COMPLETA

KNOB 22

5

MMCD00200

DINSE 25

CONNECTOR DINSE 25

6

PFON.002.002.00

PIASTRA DI FONDO

BOTTOM PLATE

7

CABL.014.020.00

ATTACCO TORCIA

TORCH CONNECTOR SOCKET

8

CABL.014.021.00

ATTACCO COMANDO A DISTANZA

REMOTE CONTROL SOCKET

9

MMGA00100

ATTACCO RAPIDO GAS

GAS QUICK CONNECTOR

10

MMVV00200

VENTILATORE

FAN

11

MMTGV00250

PROTEGGIDITA

FAN GRID

12

CAVO.001.003.00

CAVO ALIMENTAZIONE

MAINS POWER CABLE W/PLUG

13

MEER00400

FILTRO EMI

EMI FILTER

14

SC.INV8.03.00.00

INVERTER – GRUPPO DI POTENZA

POWER INVERTER

15

SC.CONTWIG6.00.00.00

SCHEDA CONTROLLO

LOGICS PCB

16

MEYB00600

INTERRUTTORE

ON/OFF SWITCH

17

MEYB01000

COPRI-INTERRUTTORE

SWITCH COVER

18

Y.DD.ELEV.115.01.00

GRUPPO ELETTROVALVOLA

SOLENOID VALVE ASSEMBLY

19

MMGA01500

ATTACCO GAS

GAS CONNECTOR - REAR

20

GR.GHF3.00.00.00

SCHEDA HF C/GENERATORE

HF PCB ASSEMBLY

21

MVCC00200

TRACOLLA C/FIBIE

BELT

22

MMAG00100

CORNICE PLASTICA

PLASTIC FRAME

23

MISS00750

SCATOLA CARTONE

CARDBOARD BOX

24

MMCH00560

CONNETTORE VOLANTE PER TORCIA

MALE TORCH CONNECTOR

25

MMGA00130

ATTACCO RAPIDO GAS - MASCHIO

MALE GAS CONNECTOR (ON TORCH)

26

MERPB100K

POTENZIOMETRO

POTENTIOMETRE

27

MEYC00200

COMMUTATORE 6 POSIZIONI

6 POSITION SWITCH*

28

SC.HF3.00.00.00

SCHEDA HF C/GENERATORE

HF PCB ASSEMBLY

6

PFON.002.002.00

Dettaglio piastra di fondo

Bottom plate details

62

MSMD00500

DISSIPATORE DIODI

HEAT DISSIPATOR W/DIODES

63 DIODI DI USCITA

OUTPUT DIODES

64

INDU.001.003.00

INDUTTANZA

CHOKE

65

MEDP00500

PONTE DIODI

RECTIFIER BRIDGE

66

MEEV00300

VARISTOR

VARISTOR

67

Y.DD.TRAS.438.01.00

TRASFORMATORE

TRANSFORMER

68

TRA.001.006.00

TRASFORMATORE AUSILIARE

AUXILIARY TRANSFORMER

*Please always mention the type of machine.

29

WIG 160 DCi

30

WIG 160 CDI

Nr.

TEC.LA Code

Descrizione

Description

1

DDD115.160.T-E.02.01

WIG 160 CDi

WIG 160 CDi

2

Y.DD.COPE.115.07.00

COPERCHIO CON MANIGLIA

COVER WITH HANDLE

3

Y.DD.MANO.115.01.00

MANOPOLA 15 COMPLETA

KNOB 15

4

AVVO.002.002.00

AVVOLG. HF DC DOPPIA FERRITE

DOUBLE CORE HF FERRITE WINDING

5

MMCD00200

DINSE 25

CONNECTOR DINSE 25

6

PFON.002.002.00

PIASTRA DI FONDO

BOTTOM PLATE

7

CABL.014.029.00

ATTACCO TORCIA

TORCH CONNECTOR SOCKET

8

CABL.014.030.00

ATTACCO COMANDO A DISTANZA

REMOTE CONTROL SOCKET

9

MMGA00100

ATTACCO RAPIDO GAS

GAS QUICK CONNECTOR

10

MMVV00200

VENTILATORE

FAN

11

MMTGV00250

PROTEGGIDITA

FAN GRID

12

CAVO.001.003.00

CAVO ALIMENTAZIONE

MAINS POWER CABLE W/PLUG

13

MEER00400

FILTRO EMI

EMI FILTER

14

SC.INV8.03.00.00

INVERTER – GRUPPO DI POTENZA

POWER INVERTER

15

SC.MTIG.01.03.00

SCHEDA CONTROLLO

LOGICS PCB

16

MEYB00300

INTERRUTTORE

ON/OFF SWITCH

17

MEYB01000

COPRI-INTERRUTTORE

SWITCH COVER

18

Y.DD.ELEV.115.01.00

GRUPPO ELETTROVALVOLA

SOLENOID VALVE ASSEMBLY

19

MMGA01500

ATTACCO GAS

GAS CONNECTOR - REAR

20

SC.HF3.00.00.00

SCHEDA HF

HF PCB

21

MVCC00200

TRACOLLA C/FIBIE

BELT

22

MMAG00100

CORNICE PLASTICA

PLASTIC FRAME

23

MISS00750

SCATOLA CARTONE

CARDBOARD BOX

24

MMCH00560

CONNETTORE VOLANTE PER TORCIA

MALE TORCH CONNECTOR

25

MMGA00130

ATTACCO RAPIDO GAS - MASCHIO

MALE GAS CONNECTOR (ON TORCH)

26

MERPB100K

POTENZIOMETRO

POTENTIOMETRE

6

PFON.002.002.00

Dettaglio piastra di fondo

Bottom plate details

62

MSMD00500

DISSIPATORE DIODI

HEAT DISSIPATOR W/DIODES

63 DIODI DI USCITA

OUTPUT DIODES

64

INDU.001.003.00

INDUTTANZA

CHOKE

65

MEDP00500

PONTE DIODI

RECTIFIER BRIDGE

66

MEEV00300

VARISTOR

VARISTOR

67

Y.DD.TRAS.438.01.00

TRASFORMATORE

TRANSFORMER

68

TRA.001.006.00

TRASFORMATORE AUSILIARE

AUXILIARY TRANSFORMER

31

WIG 160 CDI

32

WIG 201 DCi

Nr.

TEC.LA Code

Descrizione

Description

1

DDF115.200.T-E.01.00

WIG 201 DCi

WIG 201 DCi

2

Y.DD.COPE.115.06.00

COPERCHIO CON MANIGLIA

COVER WITH HANDLE

3

Y.DD.MANO.438.02.00

MANOPOLA 15 COMPLETA

KNOB 15

4

Y.DD.MANO.438.01.00

MANOPOLA 22 COMPLETA

KNOB 22

5

MMCD00300

DINSE 50

CONNECTOR DINSE 50

6

PFON.002.002.00

PIASTRA DI FONDO

BOTTOM PLATE

7

CABL.014.020.00

ATTACCO TORCIA

TORCH CONNECTOR SOCKET

8

CABL.014.021.00

ATTACCO COMANDO A DISTANZA

REMOTE CONTROL SOCKET

9

MMGA00100

ATTACCO RAPIDO GAS

GAS QUICK CONNECTOR

10

MMVV00200

VENTILATORE

FAN

11

MMTVG00250

PROTEGGIDITA

FAN GRID

12

CAVO.001.003.00

CAVO ALIMENTAZIONE

MAINS POWER CABLE W/PLUG

13

MEER00400

FILTRO EMI

EMI FILTER

14

SC.INV8.03.00.00

INVERTER – GRUPPO POTENZA

POWER INVERTER

15

SC.CONTWIG6.00.00.00

SCHEDA CONTROLLO

LOGIC PCB

16

MEYB00600

INTERRUTTORE

ON/OFF SWITCH

17

MEYB01000

COPRI-INTERRUTTORE

SWITCH COVER

18

Y.DD.ELEV.115.01.00

GRUPPO ELETTROVALVOLA

SOLENOID VALVE ASSEMBLY

19

MMGA01500

ATTACCO GAS

GAS CONNECTOR - REAR

20

GR.GHF3.00.00.00

SCHEDA HF C/GENERATORE

HF PCB ASSEMBLY

21

MVCC00200

TRACOLLA C/FIBIE

BELT

22

MMAG00100

CORNICE PLASTICA

PLASTIC FRAME

23

MISS00750

SCATOLA CARTONE

CARDBOARD BOX

24

MMCH00560

CONNETTORE VOLANTE PER TORCIA

MALE TORCH CONNECTOR

25

MMGA00130

ATTACCO RAPIDO GAS - MASCHIO

MALE GAS CONNECTOR (ON

TORCH)

26

MERPB100K

POTENZIOMETRO

POTENTIOMETRE

27

MEYC00200

COMMUTATORE 6 POSIZIONI

6 POSITION SWITCH*

28

SC.HF3.00.00.00

SCHEDA HF

HF PCB

6

PFON.002.002.00

Dettaglio piastra di fondo

Bottom plate details

62

MSMD00500

DISSIPATORE DIODI

HEAT DISSIPATOR W/DIODES

63 DIODI DI USCITA

OUTPUT DIODES

64

INDU.001.003.00

INDUTTANZA

CHOKE

65

MEDP00500

PONTE DIODI

RECFIFIER BRIDGE

66

MEEV00300

VARISTOR

VARISTOR

67

Y.DD.TRAS.438.01.00

TRASFORMATORE

TRANSFORMER

68

TRA.001.006.00

TRASFORMATORE AUSILIARE

AUXILIARY TRANSFORMER

* Please always mention the type of machine.

33

WIG 201 DCi

34

WIG 201 CDi

Nr.

TEC.LA Code

Descrizione

Description

1

DDD115.200.T-E.01.01

WIG 201 CDi

WIG 201 CDi

2

Y.DD.COPE.115.06.00

COPERCHIO CON MANIGLIA

COVER WITH HANDLE

3

Y.DD.MANO.115.01.00

MANOPOLA 15 COMPLETA

KNOB 15

4

AVVO.002.002.00

AVVOLG. HF DC DOPPIA FERRITE

DOUBLE CORE HF FERRITE WINDING

5

MMCD00300

DINSE 50

CONNECTOR DINSE 50

6

PFON.002.002.00

PIASTRA DI FONDO

BOTTOM PLATE

7

CABL.014.029.00

ATTACCO TORCIA

TORCH CONNECTOR SOCKET

8

CABL.014.030.00

ATTACCO COMANDO A DISTANZA

REMOTE CONTROL SOCKET

9

MMGA00100

ATTACCO RAPIDO GAS

GAS QUICK CONNECTOR

10

MMVV00200

VENTILATORE

FAN

11

MMTVG00250

PROTEGGIDITA

FAN GRID

12

CAVO.001.003.00

CAVO ALIMENTAZIONE

MAINS POWER CABLE W/PLUG

13

MEER00400

FILTRO EMI

EMI FILTER

14

SC.INV8.03.00.00

INVERTER – GRUPPO POTENZA

POWER INVERTER

15

SC.MTIG.02.03.00

SCHEDA CONTROLLO

LOGIC PCB

16

MEYB00300

INTERRUTTORE

ON/OFF SWITCH

17

MEYB01000

COPRI-INTERRUTTORE

SWITCH COVER

18

Y.DD.ELEV.115.01.00

GRUPPO ELETTROVALVOLA

SOLENOID VALVE ASSEMBLY

19

MMGA01500

ATTACCO GAS

GAS CONNECTOR - REAR

20

SC.HF3.00.00.00

SCHEDA HF

HF PCB

21

MVCC00200

TRACOLLA C/FIBIE

BELT

22

MMAG00100

CORNICE PLASTICA

PLASTIC FRAME

23

MISS00750

SCATOLA CARTONE

CARDBOARD BOX

24

MMCH00560

CONNETTORE VOLANTE PER TORCIA

MALE TORCH CONNECTOR

25

MMGA00130

ATTACCO RAPIDO GAS - MASCHIO

MALE GAS CONNECTOR (ON TORCH)

26

MERPB100K

POTENZIOMETRO

POTENTIOMETRE

6

PFON.002.002.00

Dettaglio piastra di fondo

Bottom plate details

62

MSMD00500

DISSIPATORE DIODI

HEAT DISSIPATOR W/DIODES

63 DIODI DI USCITA

OUTPUT DIODES

64

INDU.001.003.00

INDUTTANZA

CHOKE

65

MEDP00500

PONTE DIODI

RECFIFIER BRIDGE

66

MEEV00300

VARISTOR

VARISTOR

67

Y.DD.TRAS.438.01.00

TRASFORMATORE

TRANSFORMER

68

TRA.001.006.00

TRASFORMATORE AUSILIARE

AUXILIARY TRANSFORMER

35

WIG 201 CDI

36

TEC.LA. S.r.l.

Via Castel Morrone 15/C - 16161 Genova – ITALIA

Phone +39 0107 450 222 – 0107 411 034

Fax +39 0107 406 917

e-mail info@teclaitalia.com

Loading...

Loading...