Page 1

3"/"24"

"

"

User Manual

Thank"you"for"purchasing"TECJET"printers."Hope"you"have"a"good"operating"experience."

"

In"order"to"safely"and"correctly"use"printers,"please"read"this"manual"carefully"and"operate"as"it"

informs."If"not,"it"may"cause"so me"bad"damages."

"

All"Rights"Reserved"by"printers."

"

"

Contents"

1 Safety"Instructions".................................................................................................................."3"

1.1 Power"

1.2 Printing"Cautions"

1.3 Installing"Environment"

1.4 Ink"Placement"

"

2 Installation"Requirements ........................................................................................................ 4"

2.1-2.7"Body"installations"

2.8 Operating"Panel"

2.9 Media"In st alla t ion "

2.10 Distance"between"Printhead"and"Media"

2.11 Ink"Installation"

2.12 Single"Printhead"Installation"and"Connecting"

2.13 Ink"Color"Order"

2.14 Carriage"Board"and"Cable"Connecting"

"

3 About"Printing"Operation… ................................................................................................... 13"

3.1 Start"to"Use"

3.2 How"to"Calibrate"

3.3 Set"Calibration"IP"Address"

3.4 How"to"Use"Calibration"Software"

"

4 How"to"Install"Software ....................................................................................................... 19"

4.1 Step"One:"Decompress"the"Software"

4.2 Step"Two:"Select"Installation"Fo lder"

4.3 Step"Three:""

4.4 Step"Four:"Select"”Restart"later”"and"Press”Close”"

4.5 Step"Five:"

Page 2

3"/"24"

"

"

"

"

4.6 Step"Six:"

4.7"Step"Seven:"

4.8"Step"Eight:"

4.9"Step"Nine:"Choose"Custom"Printer"

4.10"Step"Ten:""Select"the"Color"Curve"

4.11"Step"Eleven:"Set"As"Default"Printer"

5 Common"Questions"and"Answers ........................................................................................ 23"

Page 3

3"/"24"

"

"

1."Safety"Instructions"

"

1.1 Power"

1) Requirements:"50Hz,"220V,"AC"(±10%),"the"printing"power"consumption"is"120W,"

Maximum"machi n e"power"cons u mp t i o n" is"1920W," p r e -heating"300W,"post-hea ting"

300w,"outside"heating"1200W."In"different"countries"and"regions,"it"may"use"110V"or"

220V"AC."

2) All"devices"should"be"connected"to"a"properly"grounded"outlet,"please"avoid"socket"with"

photocopiers"or"air"conditioning"system."

3) Avoid"using"wall"switches"or"automatic"timers"controlled"outlet."

4) Keep"your"computer"system"away"from"potential"sources"of"EMI,"such"as"speakers"or"

cordless"telephone."

5) Do"not"use"the"damaged"or"worn"Power"cable."

6) If"please"use"the"attached"power"cable,"make"sure"that"insert"the"extra"total"amps"of"power"

line"devices."Use"an"earth"wire"to"be"safe."

7) Do"not"try"to"fix"the"printer"yourselves."Any"problems"please"consult"the"senior"technician"

first."

8) All"the"cables"are"not"allowed"to"be"pulled"out"when"the"power"is"on,"or"will"cause"the"

damages"of"the"main"board."

"

"

1.2 Printing"Cautions"

1) When"turn"on"the"printer,"do"not"move"the"print"head,"or"the"printer"may"be"

damaged."

2) Always"use"the"power"switch"to"turn"off"the"printing,"but"when"the"button"is"

pressed,"the"power"supply"will"be"cut"off."Before"the"power"is"cut"off,"do"not"

unplug"the"printerʹs"plug"or"cable."

3) Before"moving"the"printer,"ensure"that"the"print"head"in"the"initial"position,"and"

fixed."

4) Do"not"attempt"to"remove"the"dryer"or"electric"control"cabinet."

5) Do"not"remove"any"other"closed"or"open"cover"or"plugs."

6) Do"not"insert"any"objects"in"the"slot"of"the"printer."

7) Do"not"touch"the"printer"drying"systemʹs"interior"cover."Even"after"power"is"

disconnected"interior"surface"may"still"be"very"hot."

8) When"contact"material"drying"channel,"special"care"should"be"taken."

9) Keep"clothes"and"all"parts"of"the"body"away"from"the"moving"parts"of"the"

printer."

10) Do"not"wear"necklaces,"bracelets"and"other"hanging"articles."

11) Be"careful"and"not"to"let"your"sleeve"or"glove"is"entangled"by"moving"parts"of"the"

printer."

12) During"printing,"do"not"touch"the"gears"or"the"reel."

"

1.3 Installing"Environment"

To"keep"Tecjet"printers"keep"smooth"operation"in"a"long"time,"Tecjet"printers"should"be"kept"in"

Page 4

3"/"24"

"

"

the"place"where"air"flows"well,"room"is"big"enough "w ith"sm o oth "floo r,"and "the"tem p era ture"

should"be"better"between"18-26℃."

"

1.4 Ink"PlacementKeep"the"ink"bottles"out"of"the"childrenʹs"reach,"don't"let"the"

kid"drink"or"touch"ink"bottles."

1) If"the"ink"sticks"to"skin,"clean"with"soap"and"water;"if"ink"splashes"in"eyes,"

immediately"flush"with"water."

2) Do"not"shake"ink"bottles,"which"will"cause"the"ink"leaking."

3) After"using"the"ink"bottles"for"a"certain"period"(usually"three"months),"

immediately"removed"for"thorough"cleaning"and"drying;"pay"attention"to"

cleaning"when"replaced"a"new"ink"bottle"to"ensure"print"quality."

4) Dispose"the"waste"ink"according"to"relevant"local"laws."

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

Page 5

3"/"24"

"

"

"

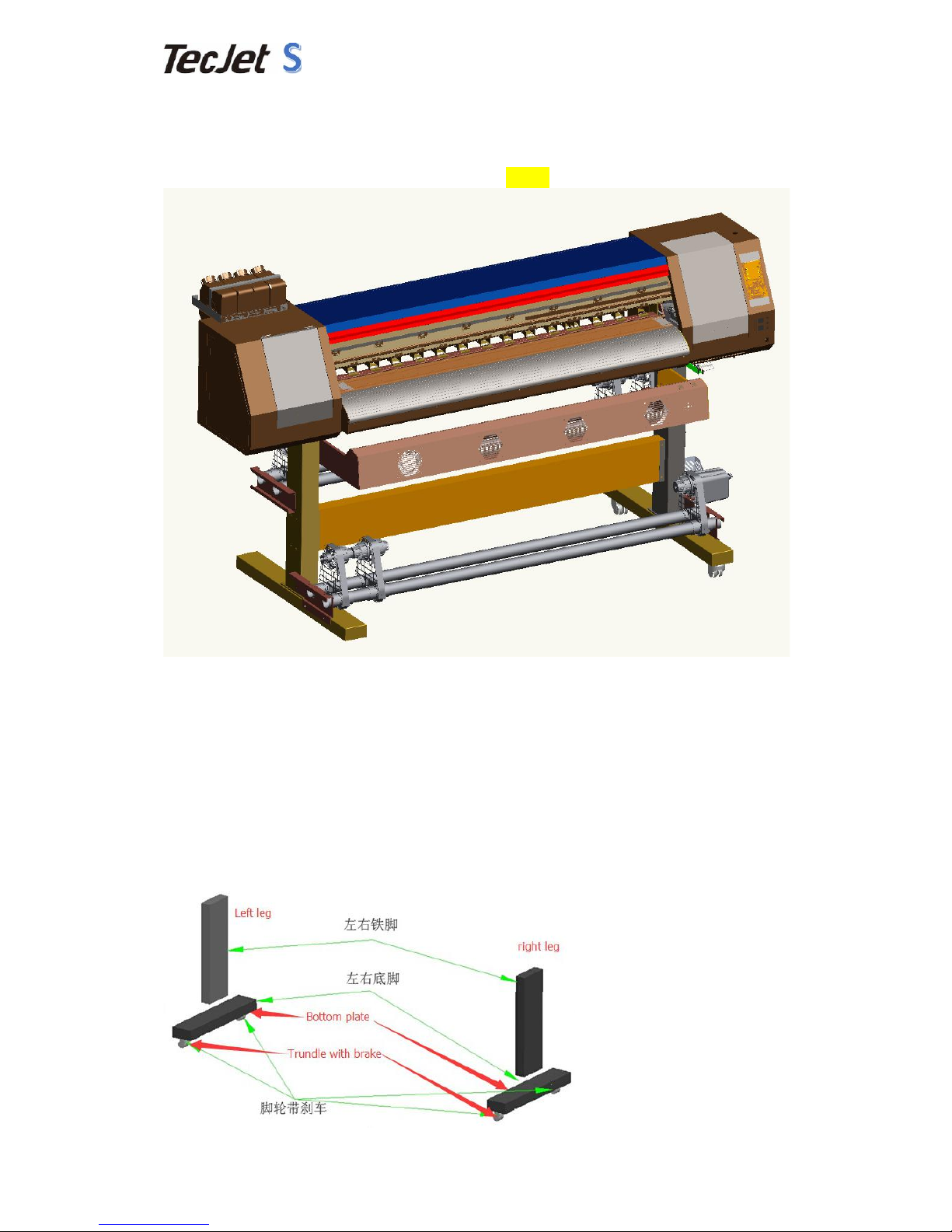

2 Installation"Requirements"

"

After"open"the"wooden"package,"please"install"Tecjet"printer"as"below."

"

Name"of"parts:

(1)Main"body(2)Feeding"system(3)Drying"system(4)Steel"leg"

(5)Horizontal"bar(6)Up"Fixing"plate(7)Fan"Fixing"Plate""""""""""""""""""""""""""""""""""

(8)Tube"Fixing"Plate(9)Legs(10)Take"up"system"

"

Leg"installation"

Install"the"legs"as"image"shows."Fasten"legs"with"8-M6X20"bolt."Leg"brakes"should"be"

installed"under"its"legs"and"fastened"by"16-"M6X20"Bolt."

Page 6

3"/"24"

"

"

"

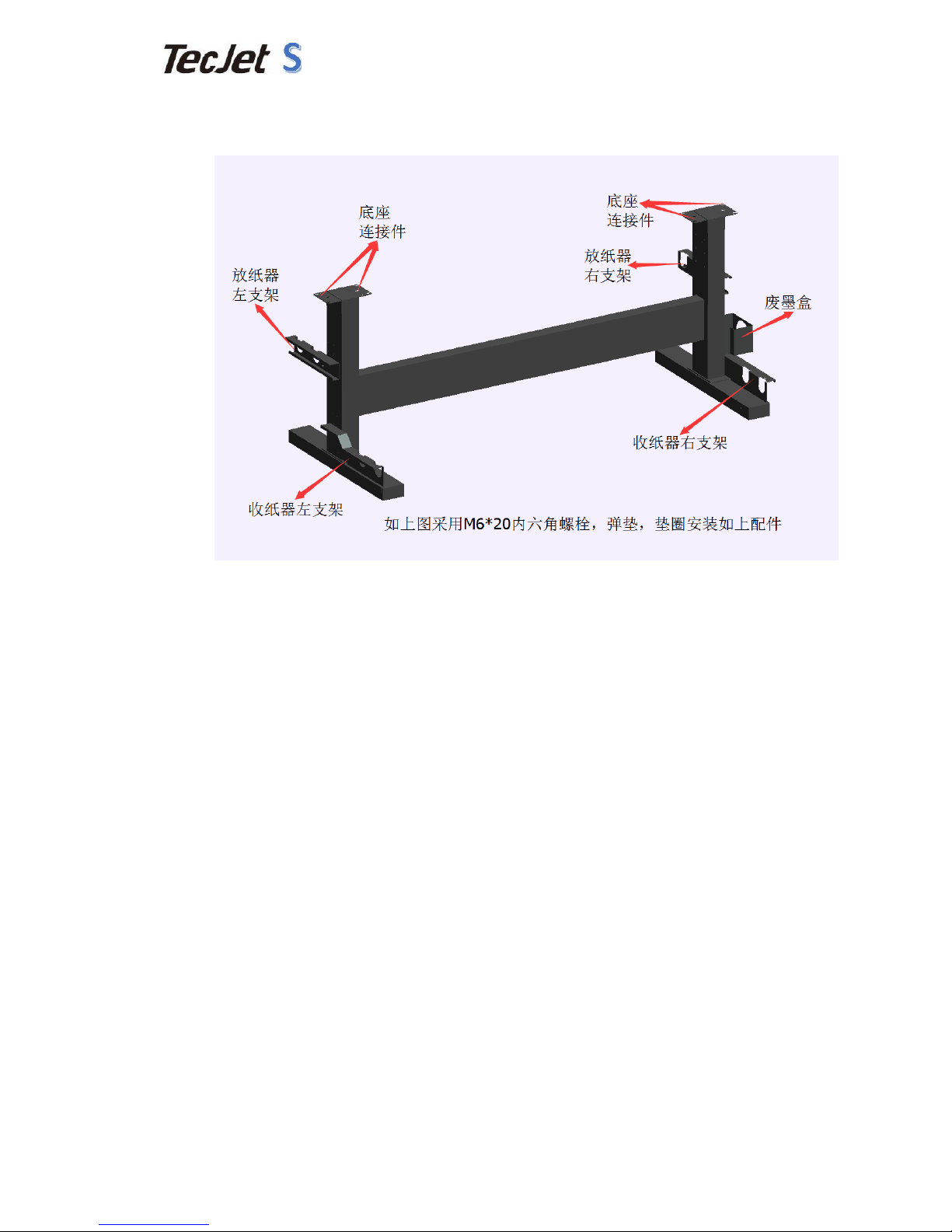

2.1 Install"and"fasten"the"horizontal"bar"with"12-"M6X20"and"Install"the"

Tube"Fixing"Plate"with"16-"M6X20"as"the"image"below.

"

"

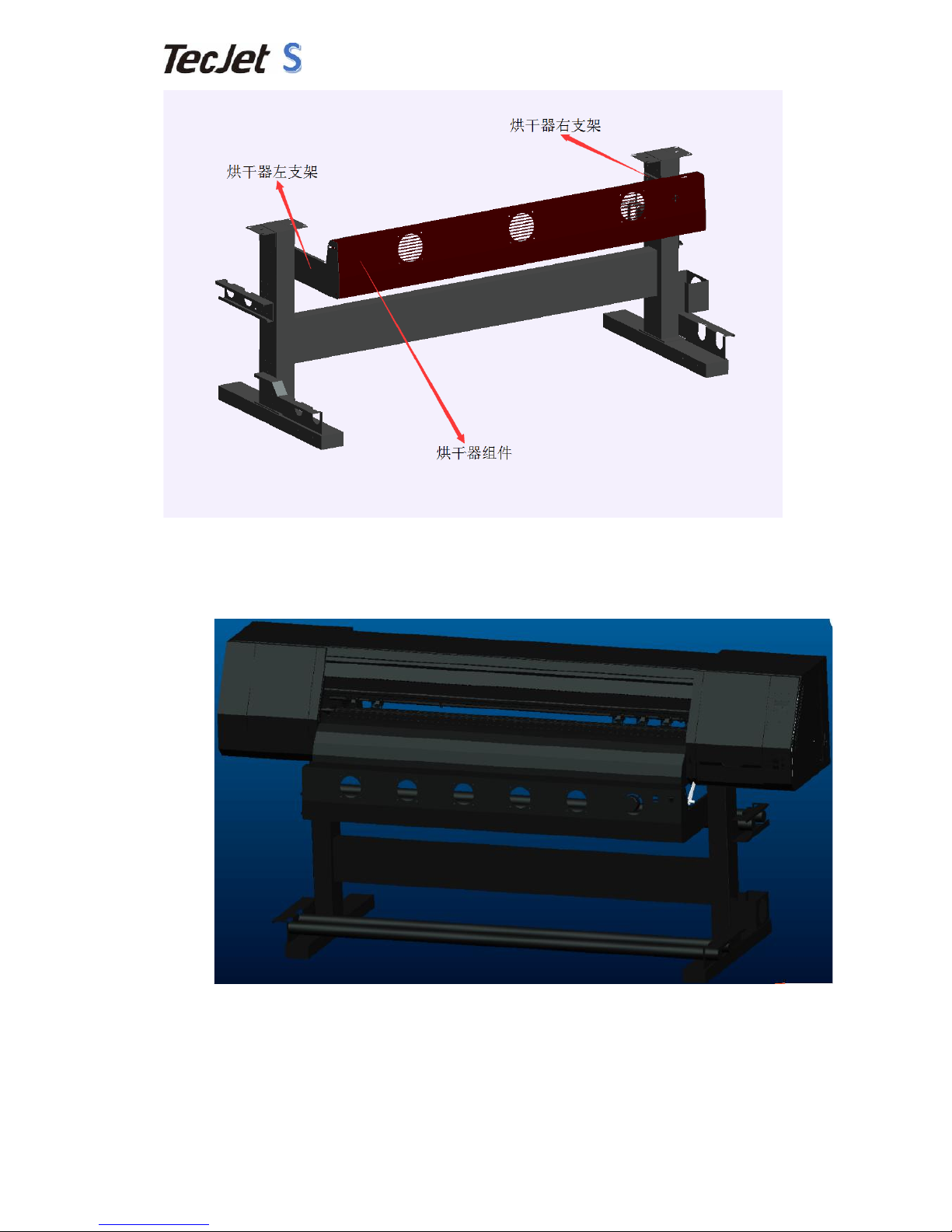

2.2 Install"the"Fan"Fixing"Plate"and"Steel"Legs"with"8-M6X20"bolts."

After"fastening"them,"fasten"the"Up"Fixing"Plates"of"Main"body"and"Steel"

Legs"with"12-M6X20"bolts."Install"dry"fans"on"the"fixing"plate"with"4-

M6X15"bolts(Black"Plastic"Cover).

Page 7

4"/"24"

"

"

"

"

"

"

2.3 Install"and"fastened"the"Steel"Tubes"with"8-M4X25(Black"Plastic"Cover)"on"

the"Tube"Fixing"Plate."

"

Page 8

5"/"24"

"

"

"

"

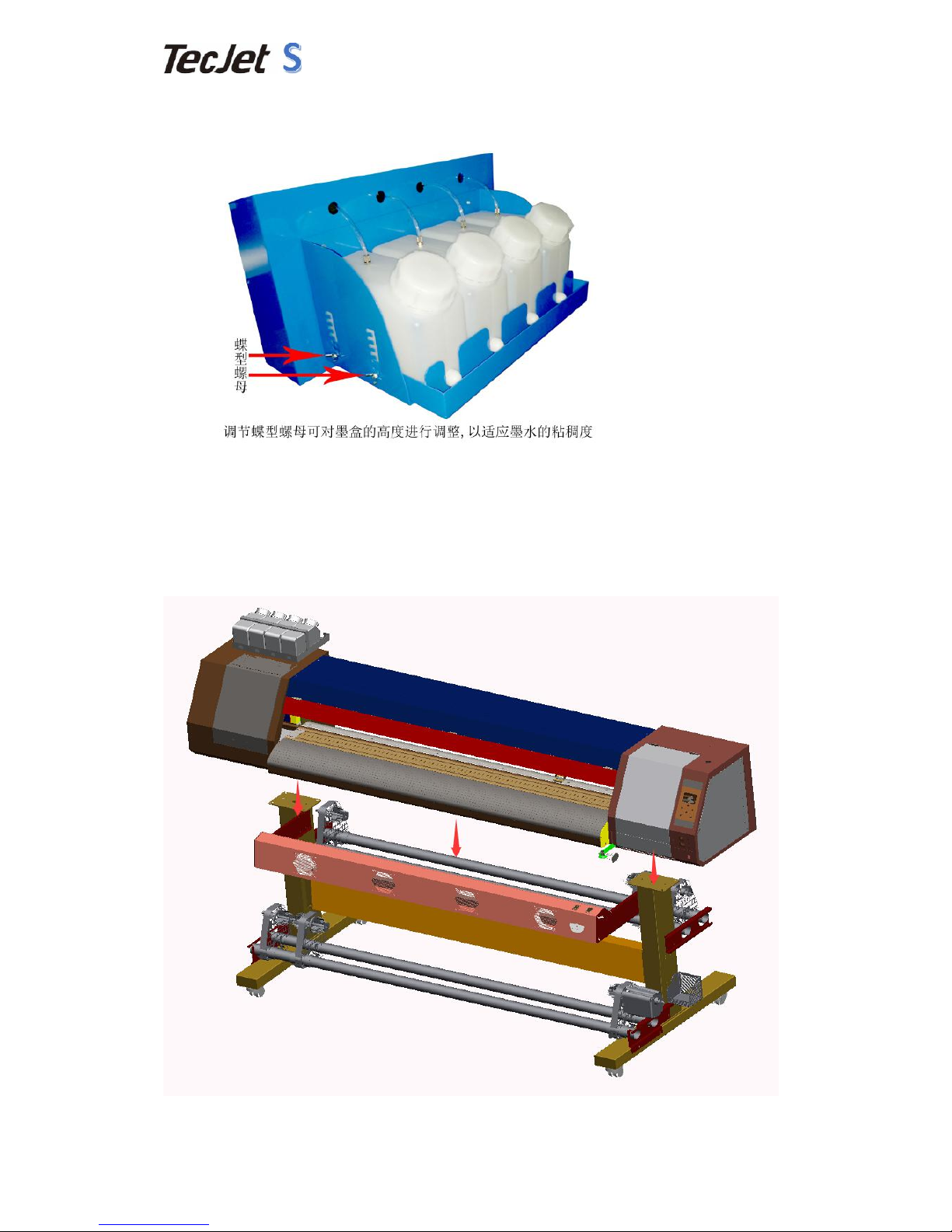

2.4 Install"the"first"Ink"Cartridge"as"the"image"shows."

"

"

2.5 Install"the"Feeding"System"and"Take"Up"System"on"the"Steel"Tubes"with"4-

M6X15"bolts(Black"Plastic"Cover)"and"put"on"the"Main"body"frame"as"image"

shows"and"fix"it"with"8-M6X20"bolts."

"

"

2.6 Operating"Panel

Page 9

6"/"24"

"

"

"

"

1) Press"right"or"left"button"to"control"the"carriage"movement."Press"right"long,"

carriage"moves"to"right;"press"left"long,"carriage"moves"to"left."Release"button,"

carriage"stops."

2) Press"Up"and"down"to"make"forward"or"back"after"entering"the"menu."Control"

media"to"feed"or"not."

3) Return:"Back"or"cancel"what"you"do."

4) Enter:"Confirm"your"order."

5) When"printers"go"on"standby,"press"right"to"enter"cleaning"menu."

2.7 Media"Installation"

Scroll"media"is"better."Keep"media"direct"and"keep"media"parallel"with"platform."

Media"should"be"smooth"and"complete."

Before"install"media,"lift"up"the"pressing"handle."After"installing"media,"you"need"to"

lift"down"the"pressing"handle."

Page 10

7"/"24"

"

"

"

"

2.8 Distance"between"Printhead"and"Media"

Printhead"base"can"be"adjusted"according"to"Media"thickness."The"best"distance"

between"printhead"and"media"is"1.5mm,"not"more"than"2mm."Media"should"be"

smooth."Adjust"the"M4X8"bolts"as"image"shows,"the"distance"will"be"changed"

accordingly.(Example"at"DX5"Head)"

"

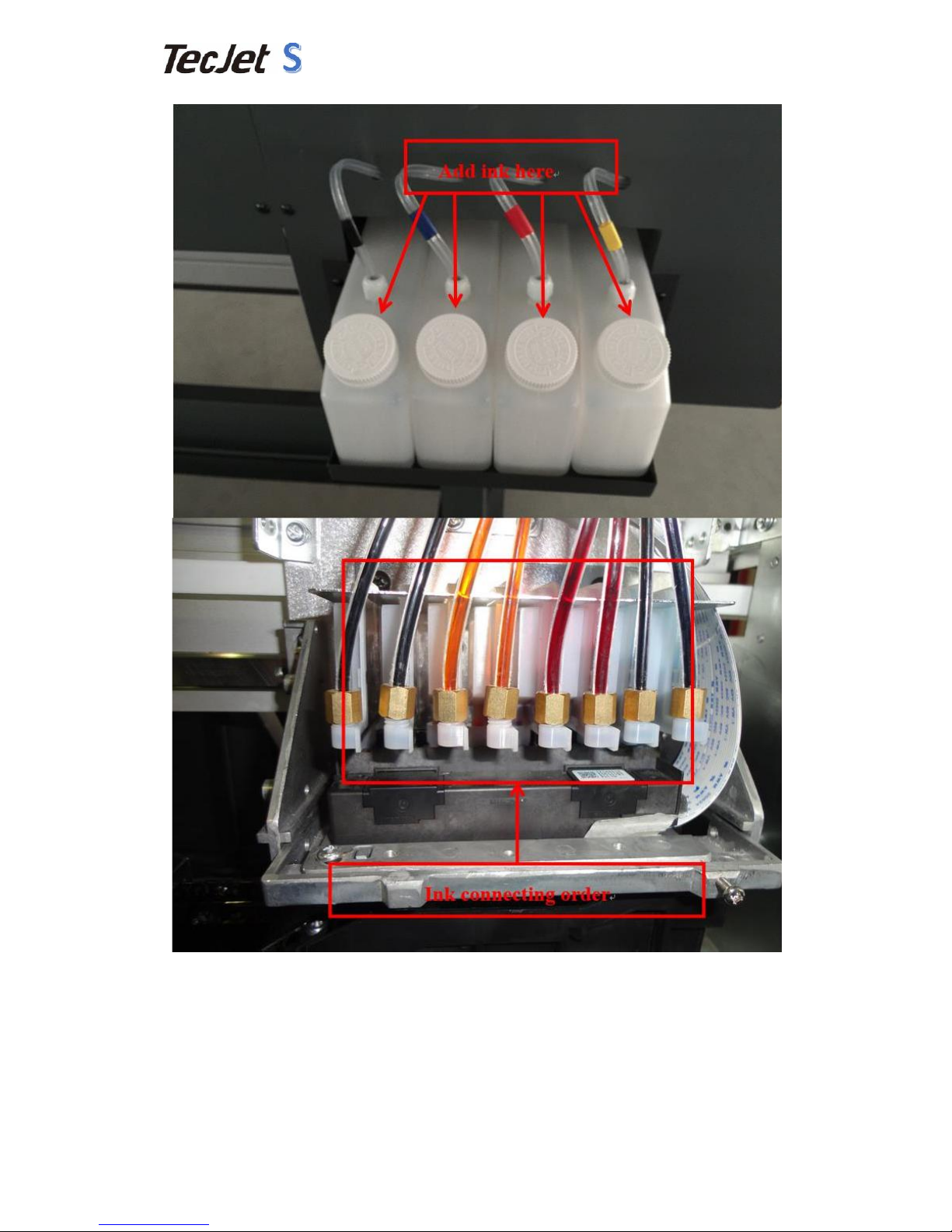

2.9 Ink"Installation"

1) Keep"ink"out"of"the"reach"of"Children."If"it"enters"your"eyes"or"splash"on"your"

clothes,"please"flush"with"plenty"of"water."

2) Clean"ink"tube"with"our"clean"flush."

3) The"temperature"of"ink"should"be"better"kept"between"18℃—28℃."

4) After"open"the"inks,"it"should"not"be"kept"for"a"long"time."Please"use"it"ASAP."

5) Don’t"shake"the"ink"bottles."Don’t"pollute"environment"by"throwing"ink,"ink"

bottle"at"your"will."

6) Add"ink"as"image"below"shows."Connect"ink"tube"as"the"image"shows.

M4X8 Bolt

Page 11

8"/"24"

"

"

"

"

"

"

Attention:"Ink"bottle"cap"cannot"be"too"tight"so"that"there’s"no"air"left."

2.10 XP600&DX5&DX 7&5113"Single"Printhead"Installation"and"

Connecting.

Page 12

9"/"24"

"

"

"

"

" "

"

DX5-1"

DX5-2"

"

""""""""""""" "

"

""""""""""""""""""""""""DX7-1""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""DX7-2"

"

""""""""""" "

"

"""""""""""""""""""""XP600-1"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""XP600-2"

"

Page 13

10"/"

"

"

""""""""""" "

"

""""""""""""""""""""""5113-1""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""5113-2"

"

Cables"should"be"connected"as"images"below."(IMPORTANT!!!)"

For"DX5"printhead,"connection"should"be"as"below:"

"

"

For"DX7"printhead,"connection"should"be"as"below:"

"

For"XP600"printhead,"connection"should"be"as"below:"

Page 14

11"/"

"

"

"

For"5113"printhead,"connection"should"be"as"below:"

"

"

2.11 Ink"Color"Order"

For"DX5"printhead,"it’s"the"order"as"below."

"

"

For"DX7"printhead,"it’s"the"order"as"below."

"

For"XP600"printhead,"it’s"the"order"as"below"

Page 15

12"/"

"

"

"

"

For"5113"printhead,"it’s"the"order"as"below"

"

Page 16

11"/"24"

"

"

"

"

2.12 Carriage"Board"and"Cable"Connecting"

For"DX5"printhead,"it"should"be"connected"as"below."

"

"

For"DX7"printhead,"it"should"be"connected"as"below."

"

"

For"XP600"printhead,"it"should"be"connected"as"below."

"

Page 17

11"/"24"

"

"

"

"

For"5113"printhead,"it"should"be"connected"as"below."

"

Page 18

11"/"24"

"

"

"

"

3. About"Printing"Operation"

"

3.1 Start"to"Use"

(1)Press"the"power"button"like"the"image"below."

(2)Close"the"printer"by"press"the"power"button"to"“O”"situation."

3.2 How"to"Calibrate"

1)"How"to"set"the"IP"of"your"computer(Here"run"at"Windows10"Enterprise"64-bit"

System)"

Please"check"the"cable"and"machine"make"sure"the"machine"is"power"on"and"

network"cable"connected"with"the"machine"and"computer"successfully."

Step"one:Find"Wifi"Icon"at"the"right"down"corner"of"the"desktop"and"press"it."

"

Step"two:Find”Network"Settings”"and"press"it.

开关

Page 19

16"/"24"

"

"

"

"

Step"three:"Go"down"by"the"mouse"and"find"“Network"and"Sharing"Center”"and"press"it."

"

"

"

Step"four:"Find"“Local"Connection”"icon"and"press"it."

"

Step"five:Find"“Properties”"and"press"it."

Page 20

17"/"24"

"

"

"

Step"six:Find"“Internet4"(TCP/IPv4)”"and"press"the"“Properties”."

"

Step"seven:Select"the"“Use"the"following"IP"address”"and"at"IP"address"enter"“196"12"0"188”"and"

press"ok."

"

Step"eight:After"that"there"is"an"attention"windows"will"come"out,just"press"ok."

"

Step"nine:The"Subnet"Mask"will"default"to"”255"255"255"0”automatically"and"press"ok"and"finished."

Page 21

18"/"24"

"

"

"

"

3.3 Set"Calibration"IP"Address"

Step"one:Set"the"Calibration"IP"address"as"below."

"

Step"two:Press"the"“Connect”"and"see"if"the"IP"succeed."

"

3.4 How"to"Use"Calibration"Software"

1) Vertical"Calibration,"adjusting"printhead"

Open"the"calibration"software,"after"connecting"the"printer,"press"“More”"first"and"then"press"“Vert."

test”"

Page 22

19"/"24"

"

"

"

"

"

Adjust"printhead"according"to"printing"image."The"result"should"be"as"below."

"

2) Two-way"Calibration"

Page 23

20"/"24"

"

"

"

"

Press"“Hidi.Align”"and"do"two-way"calibration"and"print"images

:

And"see"which"line"is"the"best"and"enter"its"number.For"example,"if"number"3"is"the"

best,"then"enter"30+3=33."

3) Feeding"calibration"

"

"

Page 24

21"/"24"

"

"

"

"

Image"01"

Press"the"“Step"Align”"and"do"the"Feeding"calibration"and"print"the"image."

"

"

"

"

"

"

"

"

Measure"the"distance"of"two"arrows"and"accurate"to"MM."Put"the"“Distance"number”"

into"image"01.And"press"calculate"and"then"press"save."

"

4) Print"setting"

Page 25

22"/"24"

"

"

"

Print"setting"should"be"as"the"image"up."

5) Advanced"setting"

Press"“Entry"advanced"Setup”"and"enter"Password"16753."

"

"

1) Voltage"adjust"should"choose"512,"it’s"default."

2) If"ink"emerge"light"or"spitting,"you"can"use"higher"voltage."If"ink"didn’t"continue,"

and"two"much"ink,"please"use"lower"voltage."The"standard"value"is"512,"and"the"

range"of"value"is"460-580."

3) Color"order"(KCMYCM)"can"be"changed"as"per"your"need."

Page 26

23"/"24"

"

"

"

6) Calibration"values"import"and"export"

Click"“more…”in"maintenance"area"and"you"will"see"the"following"image."

"

After"calibrate"all"values,"please"save"them"in"your"computer."If"you"need"to"change"

carriage"board,"you"should"import"the"files"you"saved"in"this"step.

Page 27

24"/"24"

"

"

7) Control"panel"

8) Carriage"connection"instruction"

Mainboard

Page 28

25"/"24"

"

"

"

"

USB"

"

Internet"

access"

"

"

Feeding"

servo"1"

"

Feeding"

servo"2"

Connect"

carriage"

board"

"

"

"

"

Power"

(3)

Wiper"

motor"

"

"

"

UV"lamp"and" sensors(4)

Ink"

pump"

"

"

"

"

"

"

"

"

"

."

Connect" Led"

panel"

Wipe"sensors(5)

4. How"to"Install"Software

Page 29

26"/"24"

"

"

"

4.1 Install"Maintop"Software"

Step"One:Decompress"the"software"and"open"the"folder"and"double"click"“INSTALL”"to"install"the"

software."

"

"

"

"

4.2 Step"Two:"Select"Installation"Folder"and"press"“OK”."

"

4.3 Step"Three:"After"depressing,"there"is"a"windows"come"out"“MainTop"RIP"Port""

Monitor"installation"is"failed!”"and"press"ok."

"

Page 30

27"/"24"

"

"

Page 31

28"/"24"

"

"

"

4.4 Step"Four:"Select"“Restart"later”"and"press"“Close”."

"

4.5 Step"Five:"Press"“Close”"on"the"READ"MEE."

"

4.6 Step"Six:Select"“MainTop"Print"Manager”"and"“MainTop”"and"Send"to"“Desktop"

creat"shortcut”."

Page 32

29"/"24"

"

"

"

"

4.7 Step"Seven:Open"the"“MainTop”"shortcut"on"the"Desktop,"then"press"“File”"and"

select"“Printer"Setup”"open"it."

Page 33

21"/"24"

"

"

"

4.8 Step"Eight:Select"the"“Microsoft"XPS"Document"Writer,Ne00”"and"press"“Install”."

"

4.9 Step"Nine:Press"“Custom”."

"

4.10 Step"Ten:Copy"the"Color"Curve“DYMK_DYE_SY_XP600_20170423”"from"our"CD"

disk"to"Desktop,"and"select"the"“easyjet”(File"inside"that"folder)"and"press"

Open.(The"Color"Curves"is"different"of"Epson"DX5,DX7,XP600,5113"printhead)."

"

"

Page 34

21"/"24"

"

"

"

4.11 Step"Eleven:Press"“Set"As"Default"Printer”"and"press"OK"then"finish."

"

Page 35

21"/"24"

"

"

"

"

5. Common"Questions"and"Answers"

"

"

Number"

Common"questions"

Question"analysis"

Answer"and"solutions"

"

"

"

"

"

"

1"

"

"

"

"

"

After"power"on,"

printer"has"no"action,"

carriage"doesn’t"move"

a)"Check"power"outlet,"cable"and"

power"box"and"see"if"they"are"in"

good"condition."

Check"parts"related"to"power"and"see"if"

there’s"24V"power"output."

b)"Main"board"fused"

Change"fuse"

c)"Led"lamp"in"carriage"board"

does"not"work;"main"board"or"

carriage"board"broken."

Cables"of"26P"need"to"be"connected"

tightly;"Voltage"from"main"board"

abnormal,"then"change"main"board"or"

carriage"board."

d)Carriage"board"servo"driver"

abnormal"

Check"connecting"between"servo"driver"

and"main"board;"change"a"new"servo"

driver."

"

"

2"

"

Carriage"board"moves"

and"can’t"back"ink"

station."

a)"Wrong"signal"from"raster"slip"

Check"raster"slip"and"encoder"

b)"Carriage"moves"left"only"

Cables"of"26P"don’t"connect"well;"change"

new"carriage"board"or"main"board;"

motors"connecting"not"well"or"change"

new"motors."

"

3"

Carriage"board"backs"

ink" station" normally,"

but"hit"the"right"bar."

Original"sensor"broken"

Check"sensor"connecting"

"

"

"

"

4"

"

"

No"ink"from"any"

channel"when"testing"

printhead"

a)"42V"input"abnormal"

Check"if"there’s"42v"voltage"from"power"

box"and"see"if"42v"fuse"in"main"board"has"

been"fused"

b)"printhead"cables"connecting"

Check"printhead"cable"connecting"well"or"

not"

c)"abnormal"carriage"board"or"

printhead"plate"

Change"carriage"board"or"printhead"plate"

"

"

5"

"

Some"channels"no"ink"

output"or"ink"output"

abnormally"

a)"carriage"board"or"printhead"

plate"abnormal"

Change"carriage"board"and"printhead"

plate"

b)"cables"connected"with"

printhead"

Check"the"printhead"cables"

"

6"

Ink"sucking" motor,"

wiper"and"fans"are"

abnormal"

a)"Ink"pump"and"solenoid"valve"

abnormal"

Check"cables,"ink"pump,"solenoid"valve"

and"fans"

b)"main"board"is"broken"

Change"new"main"board"

"

7"

Abnormal"media"

feeding"

a)"motor"connecting"and"motors"

Check"cables"and"feeding"motors"

b)"drive"plate"and"main"board"

Change"new"circuit"board"

"

8"

After"turning"on,"

computer"shows"not"

connecting"or"it"can’t"

a)"printer"IP"and"computer"IP"is"

different"

Set"the"IP"address"again"

b)"internet"cables"can’t"work"

Change"new"internet"cables"

Page 36

21"/"24"

"

"

"

print"

c)"cables"connecting"main"board"

and"carriage"board"are"not"

connected"well"

Check"cables"connecting"

9"

Printing"is"not"finished"

but" data" transmission"

ends"

a)"carriage"board"is"broken"

Change"new"carriage"board"

b)"there"is"not"enough"space"to"

install"maintop"

Clean"installation"disk"or"change"another"

disk"so"that"the"space"is"big"enough"

10"

Empty"or"overlapping"

printing"

a)"feeding"adjustment"is"not"good"

Make"feeding"adjustment"again;"change"

different"media"to"adjust"

b)"media"situation"different"from"

feeding"calibration"and"printing"

Adjust"media"feeding"in"system"and"make"

media"feed"well"

11"

Image"printing"size"is"

too"long"or"short"

a)"calibration"values"are"not"

correct"

Calibrate"feeding"again"or"change"values"

in"maintop"

12"

Bad"resolution"and"ink"

spitting"

a)"distance"between"head"and"

media"is"too"high("normal"

1.8-2.2mm)"

Adjust"the"distance"

b)"lower"than"42V"

Check"42V"power"and"see"if"it’s"OK"

c)"vertical"calibration"and"

two-way"calibration"is"not"good"

Make"vertical"and"two-way"calibration"

again"

d)"carriage"moves"too"fast"

Change"printing"speed"

e)"abnormal"head"drive"plate"

Change"a"new"head"drive"plate"

13"

No"ink"out"when"

printing"

a)"affected"by"interior"

temperature"and"humidity"

Keep"temperature"normal"

b)"bad"ink"quality"

Change"good"quality"ink"

c)"Ink"supply"system"is"not"good"

Keep"ink"supply"pressure"normal"and"no"

air"leakage"in"ink"tubes"and"connecting"

parts"

d)"carriage"moves"too"fast"

Change"printing"speed"

e)"head"drive"plate"is"of"problems"

Change"new"head"drive"plate"

14"

Color"cast"

a)"check"ink"and"head"situation"of"

ink"out"

Ink"is"not"matched"with "maintop"profile"or"

head"block"

b)"less"than"42V"

Check"42V"power"

c)"abnormal"head"drive"plate"

Change"new"head"drive"plate"

15"

Error"reports"from"

carriage"and" print"

ends"

a)"26P"cables"connecting"not"

good"

Connect"them"again"

b)"servo"motor"reports"errors"

Check"servo"motor"connecting"

c)"error"reports"from"raster"slip"

Check"raster"slip"position"and"situation."

Connecting"between"raster"slip"and"

circuit"plate"is"not"good."Check"Encoder"

"

Loading...

Loading...