Page 1

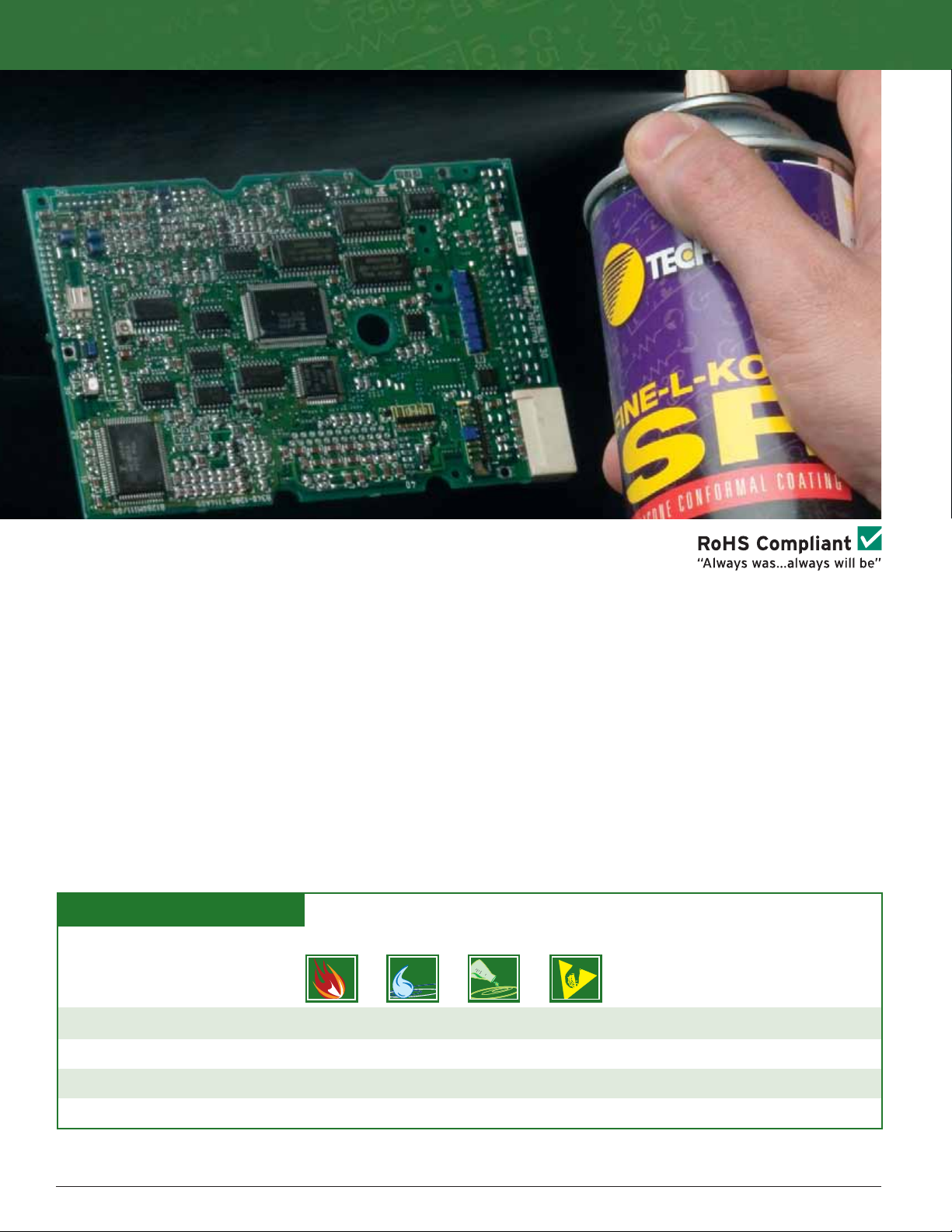

Protect printed circuit boards (PCB) with Fine-L-Kote

™

conformal coatings. Coating can either be sprayed or brushed,

or boards can be dipped directly into the conformal coating for

a thick layer of protection.

Techspray offers a variety of coating formulas to match field

and engineering requirements. Specifications generally depend

on the type of protection needed: e.g. thermal, moisture, and

static resistance.

Fine-L-Kote coatings can be thinned to meet production

requirements using Conformal Coating Remover (2105).

Conformal Coating Remover (2510) is available for rework and

repair, although coating is generally just burnt through in the

soldering process for spot repairs.

For more information: 800-858-4043 - tsales@techspray.com MSDS / Specs: www.techspray.com

16

CONFORMAL COATINGS

All Techspray conformal coatings have the

following advantages:

• Designed to Protect PCB's

• Can Be Removed for Rework

or Repair

• Contain Opti/Scan for UV Inspection

• Non-Ozone Depleting

CONFORMAL COATINGS

Thermal Moisture Chemical Static

Resistant Resistant Resistant Resistant

Full

Cure Dry

Product Type Time To Touch Sale Highlights

2102 SR Silicone }

zz z

72 Hours 1 Hour UL Recognized

2106 HT Silicone

zz

{}24 hours 45 Min. High Temperature

2103 AR Acrylic }}{{24 hours 15 Min. Economical

2104 UR Urethane }}

z

{ 24 hours 15 Min. For Harsh Conditions

Key: z= Best } = Acceptable { = Not applicable / Not recommended

Page 2

17

For more information: 800-858-4043 - tsales@techspray.com MSDS / Specs: www.techspray.com

CONFORMAL COATINGS

BOARD PRODUCTION

AND REWORK

2102

FINE-L-KOTE SR

Silicone Conformal Coating

Silicone Conformal Coating is the most universal coating,

offering protection for a wide variety of environments.

• UL Recognized

• Thermal Resistance — to 392°F (200°C)

• Dielectric Strength — 1100 volts/mil

• Moisture Resistant

• Chemically Resistant

• Vibration Resistant — Flexible

Specifications: Meets or exceeds MIL-I-46058C Type SR and

IPC-CC-830. UL File Number UL746C.

Standard Viscosity — 4-10 CPS

2102-12S 12 oz aerosol

2102-P 1 pint in glass bottle

2102-G 1 gallon in metal pail

2102-5G 5 gallons in metal pail

High Viscosity — 60-90 CPS

2102-GHV 1 gallon in metal pail

2106

FINE-L-KOTE HT

High-Temperature Silicone Conformal Coating

High-Temperature Silicone Coating is designed to prevent

thermal shock with high temperatures. Silicone Conformal

Coating is the most universal coating, offering

protection for a wide variety of environments.

• Designed for High Temperature Environments

• Fast-drying Silicone — 1-Step Process

• Thermal Resistance — to 662°F (350°C)

• Dielectric Strength — 560 volts/mil

• Moisture Resistant

• Vibration Resistant — Flexible

Specifications: Meets or exceeds MIL-I-46058C Type SR and

IPC-CC-830.

2106-12S 12 oz aerosol

2106-G 1 gallon in metal pail

2103

FINE-L-KOTE AR

Acrylic Conformal Coating

Acrylic Conformal Coating is an economical

choice that provides a hard protective surface.

Commonly used on aviation components.

• Thermal Resistance — to 392°F (200°C)

• Dielectric Strength — 640 volts/mil

• Rigid, Hard Coating

Specifications: Meets or exceeds MIL-I-46058C Type AR and

IPC-CC-830.

2103-12S 12 oz aerosol

2103-G 1 gallon in metal pail

2103-5G 5 gallons in metal pail

2104

FINE-L-KOTE UR

Urethane Conformal Coating

Urethane Conformal Coating is widely used in

harsh chemical environments.

• Thermal Resistance — to 248°F (120°C)

• Dielectric Strength — 380 volts/mil

• Moisture Resistant

• Chemically Resistant

• Abrasion Resistant

Specifications: Meets or exceeds MIL-I-46058C Type UR and

IPC-CC-830.

2104-12S 12 oz aerosol

2104-G 1 gallon in metal pail

2104-5G 5 gallons in metal pail

2105

CONFORMAL COATING THINNER

2105-G 1 gallon in metal pail

2510

CONFORMAL COATING REMOVER

2510-N 10ml Pen

2510-P 1 pint in metal bottle

2102-12S

2103-12S

2104-12S

2106-12S

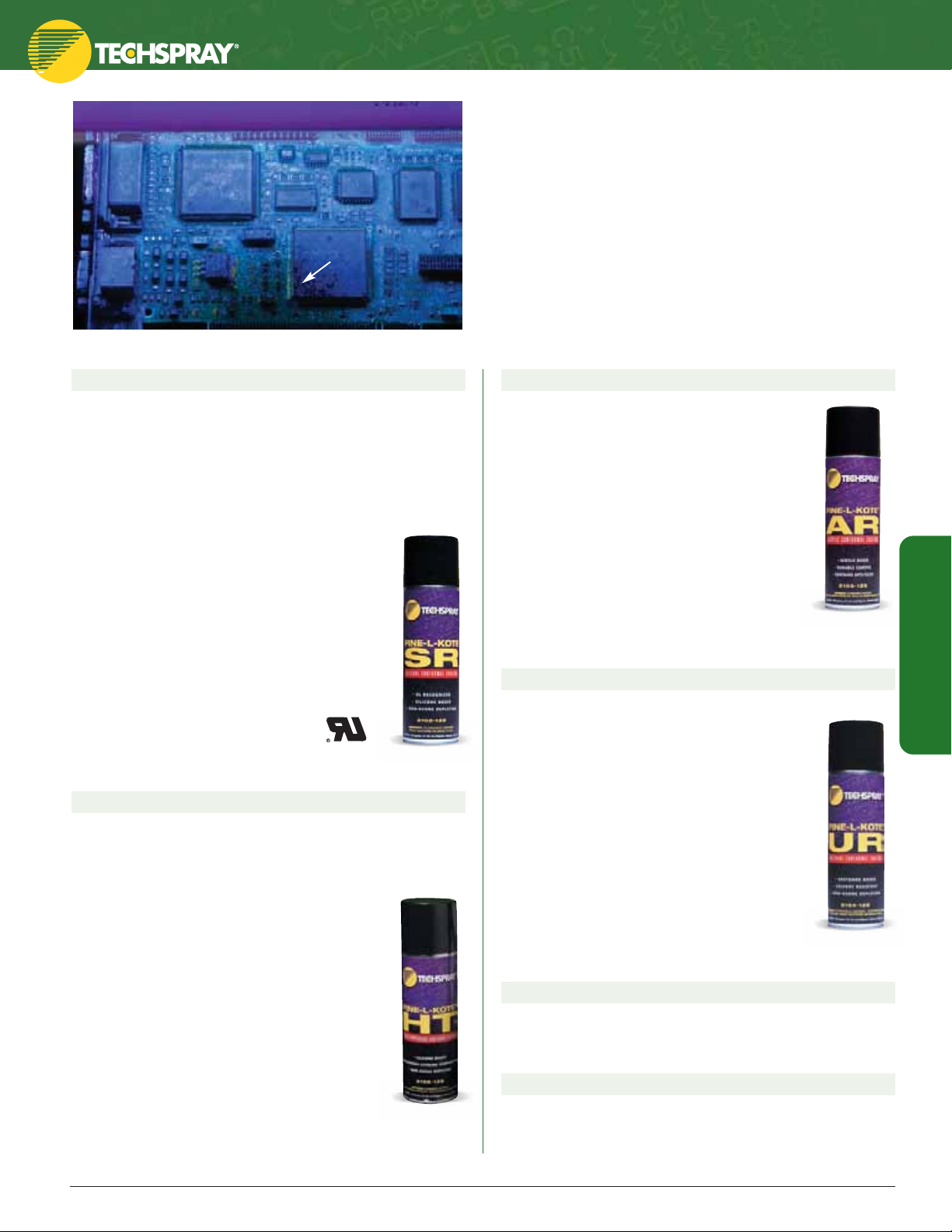

Opti/Scan for UV Inspection

Fine-L-Kote coatings contain Opti/Scan to allow

quality control inspection of coverage and evenness

of the coating on a PCB. A coated board can be

passed under a standard, low-cost UV (black) light,

and the coated areas glow. The brighter the glow,

the thicker the coating.

Poor

Coverage

Loading...

Loading...