Page 1

Product Information

Fine-L-Kote™ UR

Urethane Conformal Coating

2104

Introduction

Chemical Components

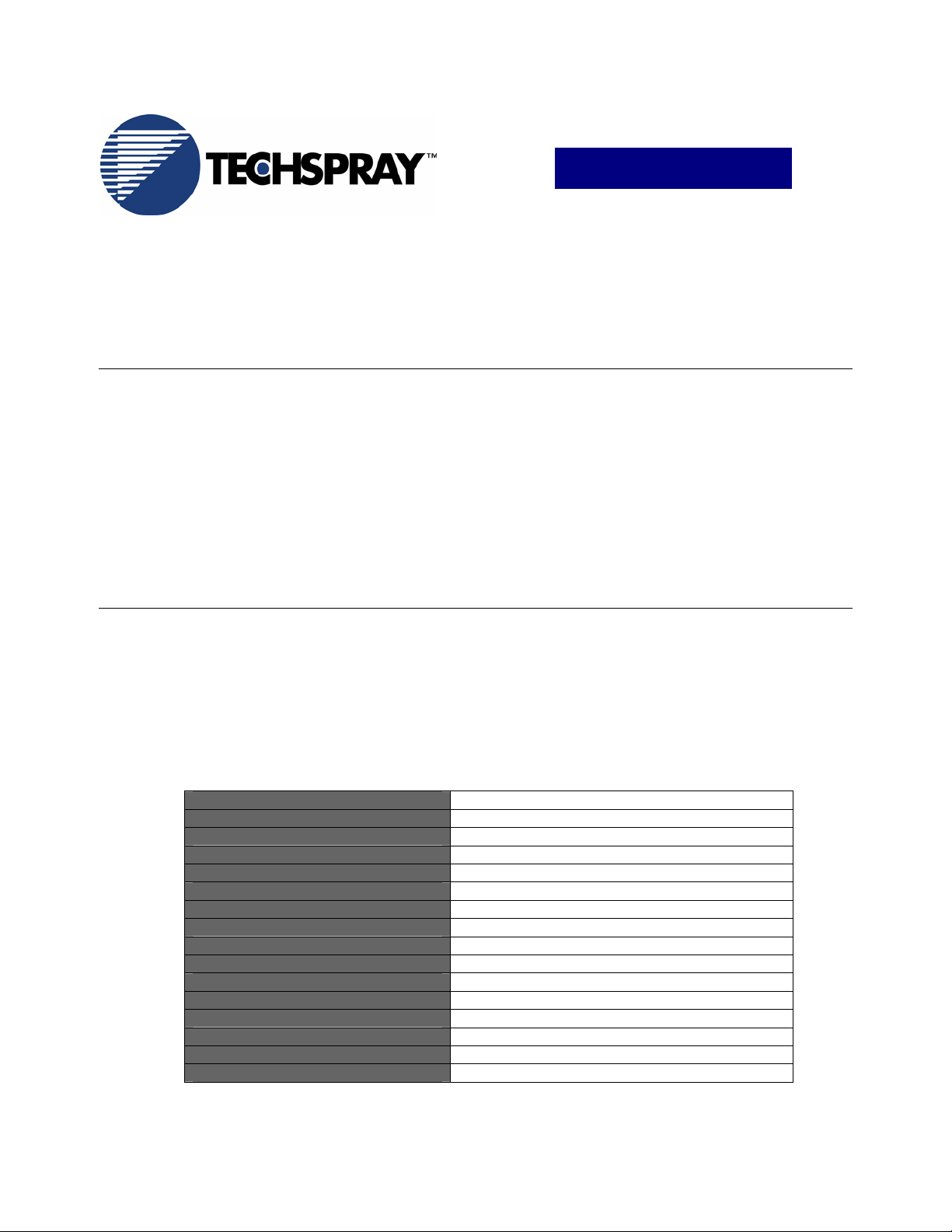

Cure Type Thermal

Meets/Exceeds IPC-CC-830 MIL-I-46058C UR Urethane

Thermal Shock 3

Dielectric Constant (@ 106 Hz) 4.36

Dielectric Strength (Volts/Mill) 315

Volume Resistivity 2x10

Moisture Resistance 4

Resistant to Fungus Yes

Ease of Repair 3

Flexibility 3

Chemical Resistance 4

Dry Time to Touch 15 min.

Cure Time 24 Hours

Accelerated Cure Time 20 min. @ 120°F 30 min. @ 180°F Two Step Process

Removal (2510-P or 2510-N) 1-5 min.

Burn Through Yes

As a urethane conformal coating, Fine-L-Kote™ UR is highly resistant to most

solvents, moisture, fungus and molds. A clear, repairable coating, Fine-L-Kote™ UR

is formulated with a black light indicator, Opti/Scan™, to provide checks for

conformity in quality control. Coated boards can be reworked by applyi ng soldering

iron directly to coating, or complete removal can be achieved by using Trace

Technologies™ Conformal Coating Remover (2510-N, 2510-P).

Features / Benefits

Solvent Resistant

Recommended for Harsh Environments

Flexible

Contains Opti/Scan™

Propyl acetate…………………………………. (109-60-4) 25-30%-Aerosol

49-53%-Bulk

Urethane Prepolymer <10%-Aerosol

19-23%-Bulk

Cyclotetramethylene oxide…………………… (109-99-9) 15-20%

Aerosol-Tetrafluoroethane……………………. (811-97-2) 30-35%

Xylene…………………………………………... (1330-20-7) 9.28%-Aerosol

<20-24%-Bulk

Bulk-Ethyl Benzene…………………………… (100-41-4) <5-8%

Bulk-Optical Brightener <.1%

Ratings: 5 (Excellent), 4 (Very Good), 3 (Good), 2 (Fair), 1 (Poor)

13

Page 2

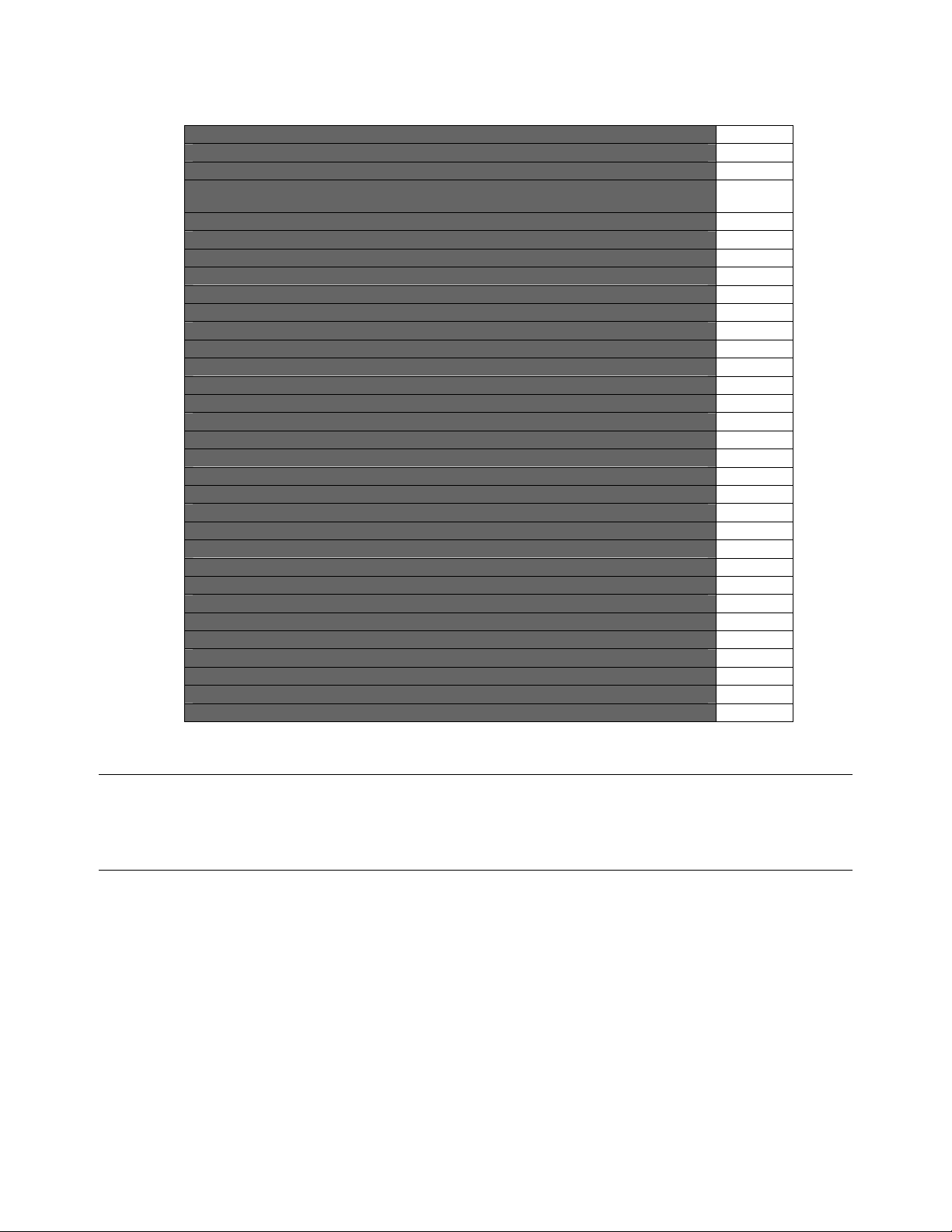

Uncured Liquid Bulk Gardener Color 1 Solids (%) 40 Viscosity (cps) Bulk / HV 10-20 /

NCO Content (%) 2.9

Pounds/Gallon 8.1

Flash Point (°F) 81

Wet Film (40% solids, 3 mil thickness)* *All conditions of test at 50% R.H. and 72°F

Set to Touch (minutes) 10

Surface Dry (minutes 45

Hard Dry (hours) 4

Full Cure (hours) 12

Sward Hardness (1 day) 2

Cured Film

Mechanical Properties

Color of Film Clear

Sward Hardness 38

Taber Abrasion Loss (mg) (1000g load, 1000 cycles)

cs 10 wheel 18

cs 17 wheel 28

Tensile Strength (psi) 5,000

Elongation (%) (20 in/min. Instron) 85

Impact Resistance (pounds)

Direct 160

Reverse 140

Thermal Shock (Mil –I-46058C, UR) Passes

(-65°C - + 125°C for appearance – doesn’t crack)

Electrical Properties

Dielectric Strength (volts/mil) 380

Dielectric Constant (60 hz) 4.1

(10

Insulation Resistance (ohms) 1.5 x 10

Environmental Policy

Packaging and Availability

Typical Properties for 2104

150-250

6

hz) 3.8

12

Techspray® is committed to developing products to ensure a safer and cleaner

environment. We will continue to meet and sustain the regulations of all federal,

state and local government agencies.

Fine-L-Kote™ UR may be ordered in the following container sizes:

2104-12S 12 Ounce Aerosol

2104-P 1 Pint in Glass

2104-PHV 1 Pint in Glass

2104-G 1 Gallon in Metal

2104-GHV 1 Gallon in Metal

2104-5G 5 Gallons in Metal Pail

Page 3

Resources

Techspray® products are supported by a global sales, technical and customer

services resources.

For additional technical information on this product or other Techspray® products in

the United States, call the technical sales department at 800-858-4043, email

tsales@techspray.com or visit our web site at:

North America Europe Countries Outside US

Tech Spray L.P. Techspray International Call to locate a distributor

P.O. Box 949 UNIT 4, 44/46 Bunyan Road, Kempston in your country.

Amarillo, TX 79105 Bedford MK42 8HL United Kingdom

800-858-4043 +44 (0) 1234 855443

email: tsales@techspray.com email: tseurope@techspray.com

Important Notice to Purchaser/User: The information in this publication is based on tests that we believe are reliable. The results may

vary due to differences in tests type and conditions. We recommend that each user evaluate the product to determine its suitability for

the intended application. Conditions of use are outside our control and vary widely. Techspray’s only obligation and your only solution

is replacement of product that is shown to be defective when you receive it. In no case will Techspray® be liable for any special,

incidental, or consequential damages based on breach of warranty, negligence or any other theory.

www.techspray.com.

Tech Spray, L.P.

P.O. Box 949

Amarillo, TX 79105

www.techspray.com

Page 4

Copyright 2006 Tech Spray, L. P.

For Commercial Use Only

Loading...

Loading...