Page 1

Thank you for purchasing the Pulama 3D Indoor flyer.

The Pulama 3D is engineered to be as adept at slow-speed 3D as it is precision aerobatics. The biplane

design not only provides crisp roll response, but also it gives the Pulama 3D superb slow flight stability

so you can fly high-alpha 3D with authority. Its carbon fiber reinforced Depron foam construction provides the

solid, precise in-flight feel of a balsa profile plane but without the weight.

The Pulama's biplane design increases the wing area and dramatically reduces wing loadin g so h ov er in g

and slow flight 3D can be performed with more precision. Plus, the shorter wingspan makes for crisper roll

rates at all speeds.

These assembly instructions are designed to guide you through the entire assembly process of your new

airplane in the least amount of time possible. Along the way you'll learn how to properly assemble your new

airplane and also learn tips that will help you in the future. We have listed some of our recommendations

below. Please read through them before beginning assembly.

-EPP

-EPP

-EPP

ELECTRIC 3D FLYER ARF

Instruction Manual

Specifications

865mm (34.1 in.)

800mm (31.5 in.)

400 sq in (25.8 sq dm)

Fuselage length:

Wingspan:

Wing Area:

Flying Weight: 260g- 285g (with battery)

Additional Required Equipment

C20 or 2205 brushless motor

18Amp brushless ESC

8040 slow flyer prop

5- 8

11.1V 500-800mAh Li-po

Motor:

ESC:

Propeller:

Servo: g

Radio:4/ more channel

Receiver:4/more channel

Battery charger

Battery:

Www.techonehobby. com

Warning

1. -EPP is not a toy and is not suitable for the flyer under 14 years.

2.Do not fly near houses or buildings children's play areas road traffic railways airports, overhead power

lines and pylons. Do not fly over people.

3.

4. .

5.Do not fly in the strong winds.

6.Do not try to catch the plane by hand when it is flying.

7.The children who are younger than 14 years old should be assisted by an experienced adult when the plane

is being flown.

The Pulama 3D If misused, it can cause

serious bodily harm and damage to property.

, , ,

Fly only in open areas, preferably AMA (Academy of Model Aeronautics) approved flying sites, following all

instructions included with your radio.

Assemble the kit according to the sequence provided in the instruction manual

Page 2

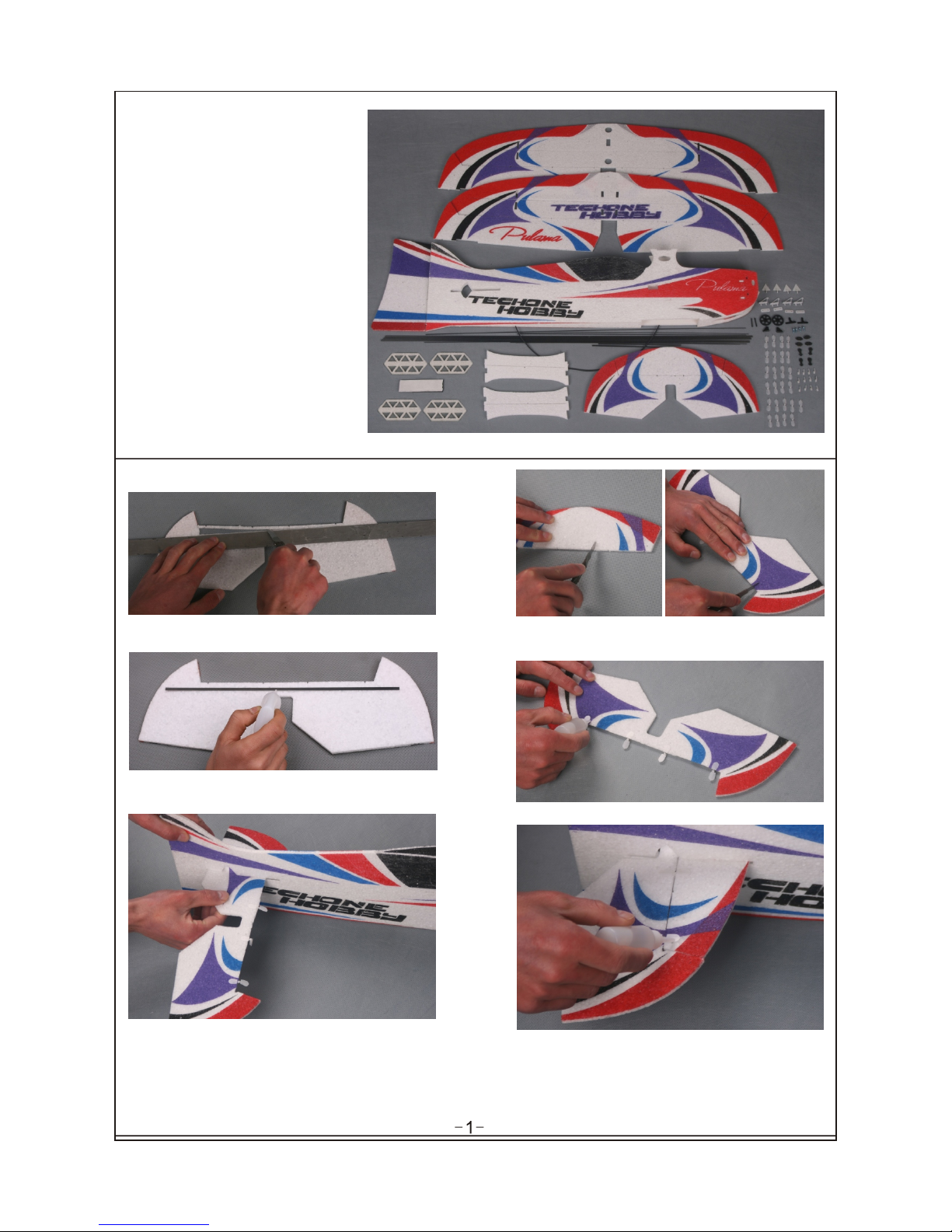

1. Horizontal Stabilizer

Fuselage - 1

Bottom Wing with Ailerons - 1

Top Wing with Ailerons - 1

Horizontal Stabilizer - 1

Elevator - 1

Rudder - 1

Outer Wing Struts - 2

- 4

Wheel Covers - 2

Main Gear Wheels - 2

Landing Gear Struts - 2

Pushrod Supports - 4

Plain Wires 0. 8*360 - 1

Control Horns - 4

Carbon Fiber Strips 1* 4*800 - 3

Carbon Fiber Strips 1* 4*400 - 1

Carbon Fiber Rods 1. 3*700 - 7

Heat-Shrink Tubing 1. 5*400 - 1

Wood Screws - 4

Velcro 100mm - 1

Clevis - 12

Hinges - 25

Spoiling Flap

Kit Contents

Sand a 45º bevel into the b ot to m leading edge of

the elevator.

Cut four slots where the hinges will be installed

.

,

make sure the distance is symmetrical

Insert the hinges into the , then glue the cutslots .

Insert the elevator into the fuselage and center

it.

Insert the stabilizer into the fuselage, against

the elevator, glue the hinges on it.

Glue the carbon strips on the elevator.

Page 3

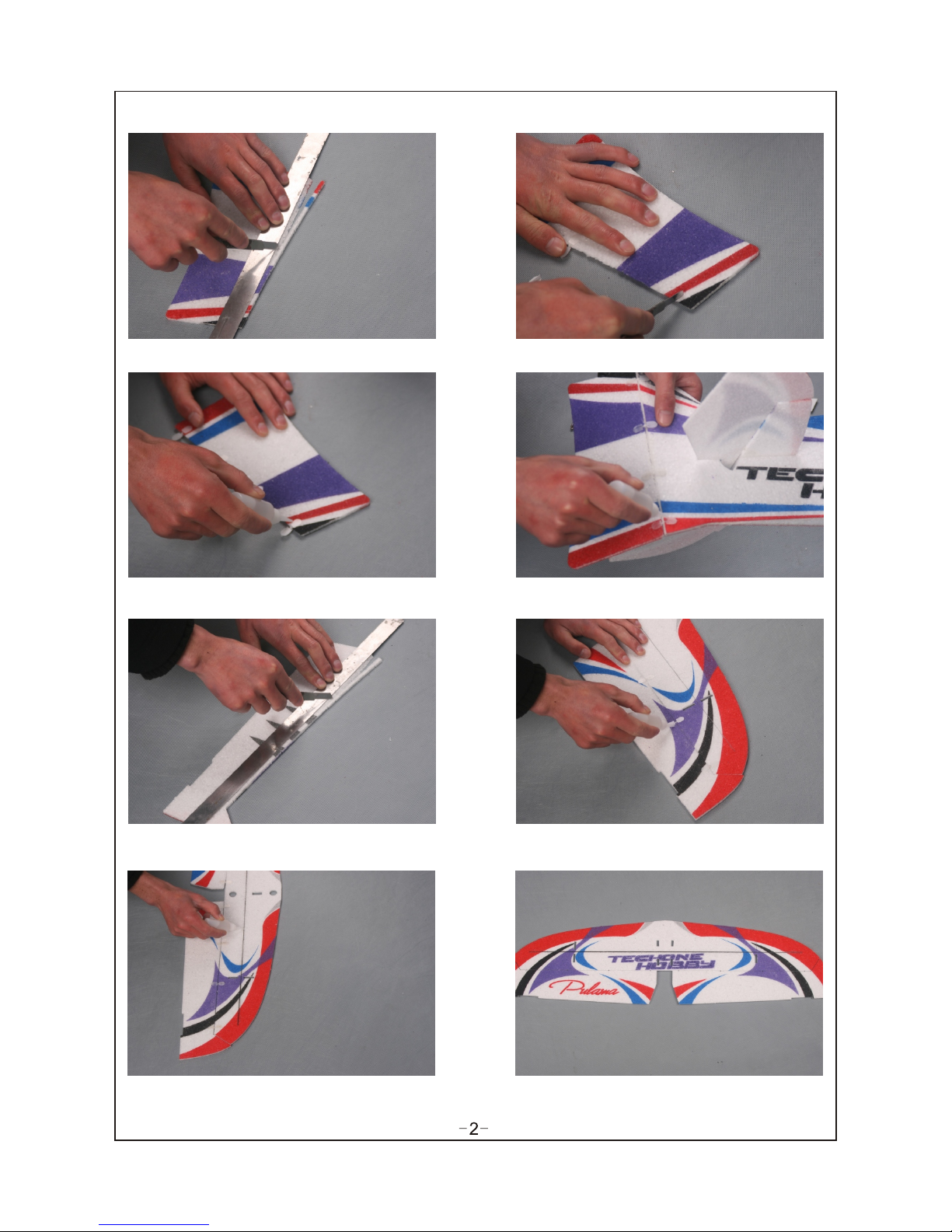

2. Vertical Stabilizer

Sand a 45º bevel into the left side of the leading

edge of the rudder.

Sand a 45º bevel into the bottom of the leading

edge of the four wing ailerons.

Cut sl ot s the

slots .

the same on stabilizer, then insert

the hinges into the , and glue the cut

Insert the hinges into the , then glue the cutslots .

Cut four slots where the hinges will be installed

.

,

make sure the distance is symmetrical

Cut sl ot s the

slots

.

the same on wings and wing

ailerons, then insert the hinges into the ,

and glue the cut

Hinge the ailerons to the top wing, using the

same techniques that you used to hinge the

bottom wing.

Cut a piece of carbon fiber strip as long as the

slot of the wing, then glue it to the slot.

Page 4

3. Wing

Glue the bottom wing to the fuselage, make sure

the slots in the wing are pushed firmly over the

mounting tabs on the fuselage.

Glue the h to orizontal stabilizer the fuselage.

Glue the two outer wing struts to the bottom

wing, make sure the wing struts are

perpendicular to the wing.

A

C

D

B

Make sure A=B, C =D.

Cut two carbon fiber strips as long as the slots of

the outer wing struts, then glue them to the slots.

Glue the top wing to the center wing mount and

the outer wing struts, make sure the wing is

perfectly flat while the glue cures.

Glue the two carbon fiber rods to wings.

Push the carbon fiber rod down through the

outer hole in the top wing (A) and slide it

through the hole in the outer wing strut (B).Push

the end of the carbon fiber rod through the inner

hole in the bottom wing (C).

A

C

B

Page 5

Glue the two carbon fiber rods to the .stabilizer

Cut two pieces of carbon fiber rod of 160mm.

Install them as above picture.

4. landing Gear

Push the landing gear strut into the precut hole

in the fuselage side, then twist the landing gear

strut so that the axle is straight.When satisfied

with the alignment, glue the landing gear strut to

the fuselage side and the bottom wing.

Inst all the two whe els and wheel c hocks.

Keep 1 mm distance b etween whee l and its

choc k. Apply some foam-friendly thick C/A

to glu e the chocks.

Glue the two wheel covers together.

Slide one wheel cover onto each axle and up

against the wheels. Align the wheel covers, then

glue them securely to the axles.

Cut one piece of carbon fiber rod of 50mm, then

insert it to the fuselage and glue it.

Page 6

Install the aileron control linkage.

Cut two pieces of carbon fiber rod to a length of 150mm, four pieces of heat-shrink tubing to a length of

25mm,four pieces of plain wire to a length of 38mm.Heat the heat-shrink material with a heat gun to shrink it

into place. For extra security, apply some C/A to the end of the pushrod and allow it to "wick" into the joint.

5. Control System

Install the aileron, elevator and rudder servos

into the servo mounting hole in the fuselage.

Use some glue to secure them into place.

Because the size of servos differs, you may

need to cut the servo mounting hole larger to fit

your particular servos.

Install the control horns.

Glue them to the ailerons.

Cut two pieces of carbon fiber rod of 60mm,

then follow the same steps.

Install the rudder control linkage(480mm).

Slide two plywood pushrod supports over the

end of the carbon fiber rod .

Notice: Glue the plywood pushrod supports to

the fuselage after finish the installation of

linkage.

Page 7

6. Final Assembly

Install your battery into the battery compartment,

using a piece of hook and loop material.

Mount your ESC and receiver, using a piece of

hook and loop material.

Install the cabin door with the same way.Glue the spoiling flap to the wing.

Install the elevator control linkage(380mm).

7. Motor

Apply some foam-friendly C/A

into the four motor mount

screw holes in the firewall.

Install the motor assembly onto

the firewall, using the four wood

screws provided.

I nstall the and propeller onto the

motor.

Page 8

Balance Point

The Center of Gravity (C/G or Balance Point) is 72mm from

the leading edge of the TOP wing, measured at the center of

the wing.

WAR NI NG F or t es t fl yi ng a nd g en er al s po rt f ly in g, w e

suggest you balance the airplane at the C/G recommended

above. For 3D flying, you may want to experiment moving

the C/G back in small increments until you're satisfied with

the result.

Control throws

Sport Flying

Ailerons: (28mm)1. 10" Up and Down

Elevator: (32.4mm) 1. 2 8" Up and Down

Rudder: (40mm)1. 57" Right and Left

3D Flying

Ailerons: (70mm)2.76" Up and Down

Elevator: (81mm)3.19" Up and Down

R udder: (100mm)3.94" Right and Left

The control throws are measured from the widest point

of the control surfaces

Exponential

Sport Flying

Ailerons: 20%

Elevator: 20%

Rudder: 20%

3D Flying

Ailerons: 35% - 50%

Elevator: 35% - 50%

R udder: 35% - 50%

Exponential softens the response of the control surfaces

around neutral stick. This makes the airplane easier to

control while using such large control throws. The

Exponential values shown are given as a percent. Please

note that different brands of radio control systems may call

for + or - Expo. Please check your transmitter's owners

manual for more info.

Motor Thrust

To ensur e great fligh t performan ce and

to be ab le to trim your a irplane pro perly,

it is cr itical that y ou adjust the m otor

thru st as describ ed. We suggest that

you ad d 2 degrees of do wn-thrust a nd 1

degr ees of right- thrust. This can be

achi eved by addin g a washer or two

behi nd the top and ri ght side of the

moto r (between th e motor and the

fire wall). When s et properly, the trim for

the el evator and th e rudder shou ld be

neut ral. Fine-t une the down- thrust and

righ t-thrust un til this trim i s achieved.

Loading...

Loading...