Page 1

1

The Metis was designed by Filippo Materazzi, F3P, Aeromusical and

F6A Italian Champion. It is the last version of his famous indoor

freestyle airplane which he flew in World Air Games 2009. It has

been totally updated but maintaining its particular style. Now it has

bigger mobile surfaces, a higher top and bottom fuselage and a

completely new milling, paying attention to maintain the strength of

the airframe. Thanks to all these tricks it flies slowly and smoothly

but it can become very agile, reactive and fast if you need it. This

characteristic is fundamental for an aeromusical flight where you

need to change the flight style according to the music, but also in a

good freestyle, to differentiate the maneuvers and employ the own

imagination. In addition, a beginner can improve his skills gradually,

increasing step by step the movement of mobile surfaces.

The kit is composed by 3 mm and 2 mm depron, carbon rods (precutted!),

super lightweight carbon control horns and all the

necessary to complete the plane.

Before assembly, please spend some time to read our instructions.

Along the way you’ll learn how to properly assemble your new

airplane in the least amount of time possible. Below are some tips

that will help you in the assembly.

Before operating this unit, please read these instructions

completely.

MET I S I NSTRUCTION S

Page 2

2

1. You need to consider the reserved servo position when installing

the elevator and rudder. Also make sure that moving control

surfaces do not interfere with reinforcement parts such as

strings and linkage poles.

2. Before fixing carbon with C/A, paper the par t that is going to be

inser ted and fixed in the depron. In this way you can have a

stronger glueing.

3. Glue the carbon rods exactly as shown in the pictures. To obtain

a rigid and strong plane is very important that the ends of carbon

rods touch and are glued together.

4. Cor rect assembly can assure good flying, before using glue or

adhesive, please check the parts position and angle of alignment.

5. Remember to use less glue as possible and to use the lightest

electronic parts you find. Less weight means always better flying

characteristic!

6. If you want for your plane the best flying characteristic I suggest

you to use the high quality electronic parts that I tested and I use

on my planes.

Fil i p po Materazzi

Product S p e cification s

Fus e l a g e l e ngth: 95 cm (37.4 in. )

Wingspan: 90 c m ( 3 5.4 in.)

Flying we i ght without bat t er y: 120 - 130 g (4.2 3 – 4 . 58 Oz)

Flying we i ght with batte r y: 140 - 150 g (4.93 – 5.2 9 O z )

Mot o r : 15 – 22 g (0.52 – 0 . 7 7 Oz) (suggested: Hacker A10 - 9 L )

ESC : 7 - 1 0 A mp (suggested: Hacker Mast e r ECO 08)

Propell e r : about 8 x 4 (sugges t e d : Mejzlik 8x4)

Ser vo: 6g x 4pcs ( s u g g e sted: 4 x JR DS318 or 3 x JR DS 3 1 9 HV)

Rad i o : 5/more channel (su g g e s ted: 2 - 5 g receiver )

Batter y: 2S 250- 3 5 0 mAh LiPo (su g ge s t ed: 15 – 22 g batter y)

Page 3

3

Do not fly under the conditions below

Windy conditions

A street with many trees or street lamps

Close to high voltage electrical wires

High Population density areas

Cautions for flying

Metis is made for indoor flight. Of course it is able to fly outdoor in

not much windy condition. Make sure you have permission to fly and

follow safety guidelines set by local authorities.

Note for Storage

Please disconnect the lipo packs when finished flying

Do not press or crush the airplane when storing

CG Position: 23.5-24.5 cm from the nose

Page 4

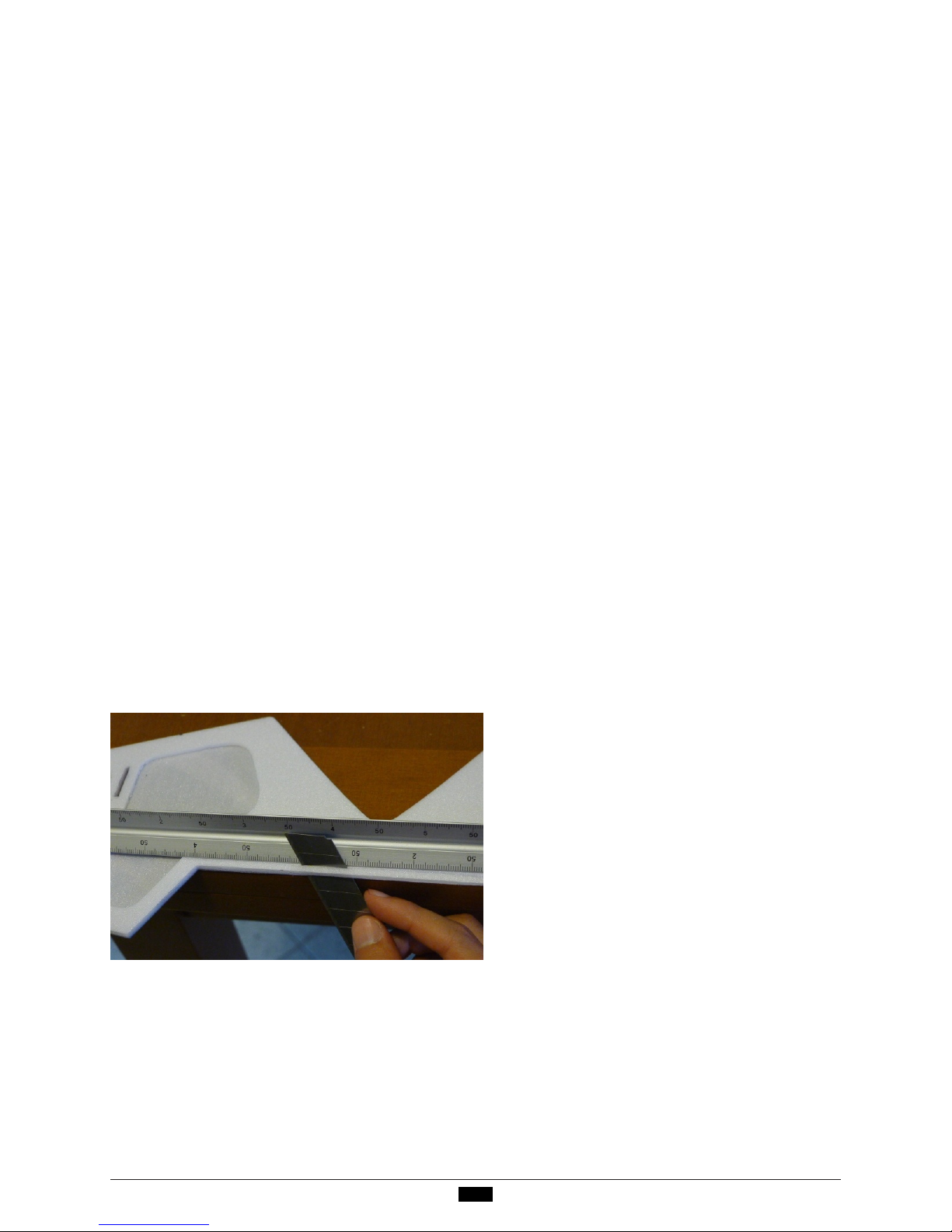

Use some C/A to glue the two carbon strip

(73 and 79.2 cm long) on both sides of the

wi n g as s how n i n th e pi c t ur e . NOTE:

pos i t ion the wing on a flat s urface.

Fix t he e l ev ator w ith 3 M ta p e.Do the

same with ailer ons.

4

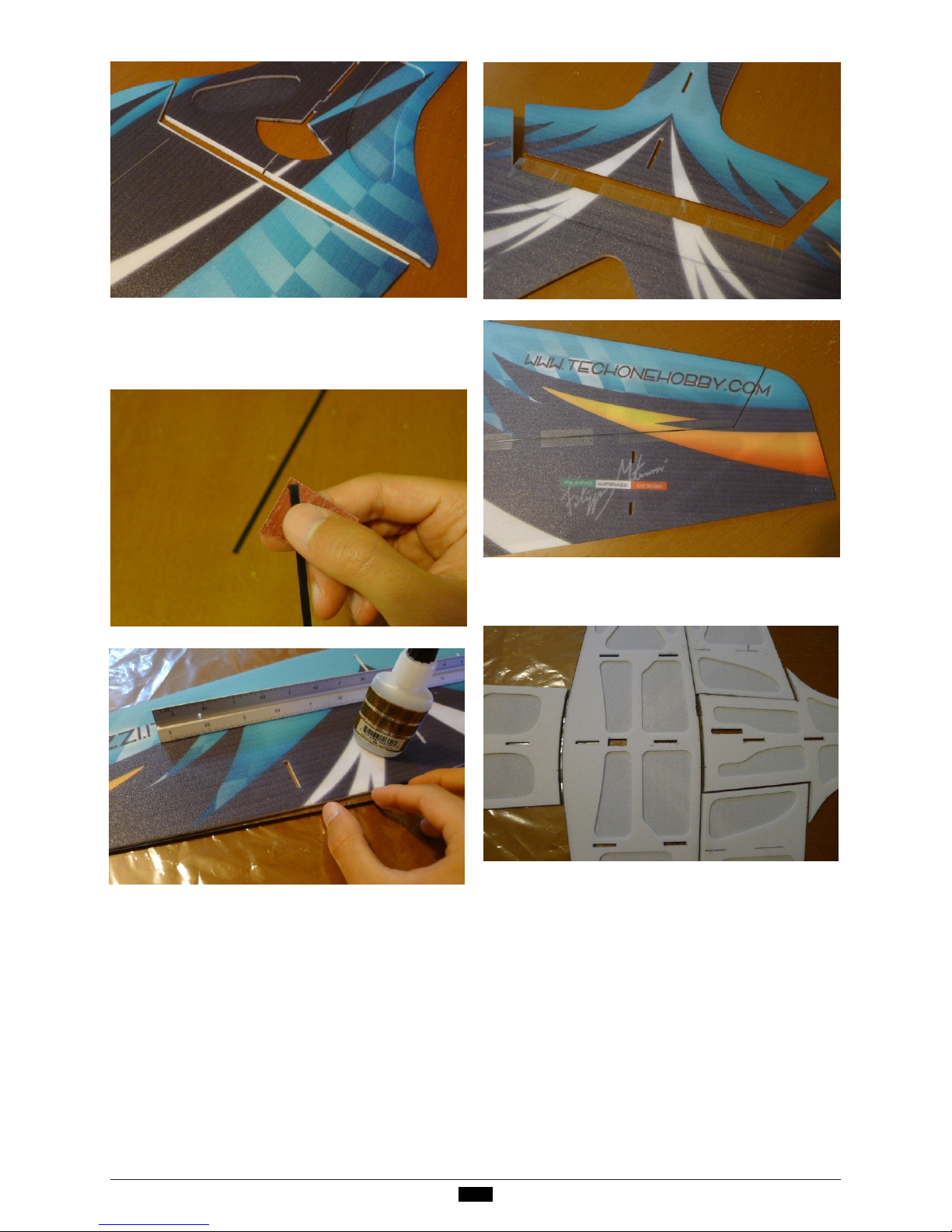

Cut a 55º bevel on ailerons. On elevator

and r udder cut a 40° b eve l on m obil e

and f i xed surface .

Fix the horizontal fuselages to the wing

with C/A.

Page 5

Ins e r t the dow n s ide vertical wingl e ts

int o t h e pr e -r e s er ved sl o ts o n the dow n s i d e o f t h e w i n g a n d a p p l y s ome

C/A t o f i x.

Inse r t the p ar ts t o r e infor c e c o n tro l

surfa c e s i n t o t h e pr e-r e s er ved s l ots

on ai l e r o n s and a ppl y some C/A to fix.

Fix w i t h C/A the two 2 mm de p r on r ei-

nforcement parts on both sides of lower

vertical fuselage. A micro hole indicates

the position. In a consecutive step you

will have to inser t in it the four 1.5 mm

car b o n r o d s to r e i nforce the wings.

Fix w i t h C/A the two 2 mm de p r on r einforcement parts on both sides of lower

vertical fuselage where there is the hole

for the landing gear le gs.

5

Use s o m e C/A to fix the lower ver tical

fus e l a g e o n th e ho r iz o n t al f u s e la g e .

Be ver tical a n d no distor tio n !

Page 6

Ins t a ll all the carbon rods as shown in

the pict u res . Fir st o f all fix w it h C/ A

the f o ur 1 . 5 mm ( 29 .3 c m l on g) w i ng

car b o n r o d s . T hen t h e o ther s 1 m m carb o n r o d s .

Fix w i t h C/A the four 2 mm d e p r o n r einfor cement par ts on the bottom of wing

at the end of each 1 .5 mm wing carbon

rod.

6

Fix w i t h C/A the four 2 mm depron r einfor cement half-moons on the bott o m

of horizontal fuselage as shown in the

pic t u r e . T he micr o hole s indicate the

pos i t ion. T h e y ar e n ecessar y to reinfor c e t he points where the 1 mm carbon r ods wi l l b e fixed.

Page 7

Install the landing gear. Please inser t

through the pre-reserved holes on the

fus e l a g e a n d wing the two 2 mm x 24

cm ca r b on r o ds, then use C/A to fix.

Fix with C/A the three 1 mm carbon rods

as shown in the pictures.

Fix with C/A the 0. 8 mm carbon rods to

reinforce the a i l e r ons.

7

Fix with C/A the two 3 mm round depron

reinfor c e ments on the bottom of horizontal fuselage as shown in the picture.

The micro holes in d i c ate the position.

Th e y a r e n e c essa r y to r ein f o rce the

joi n t o f the landing gea r l e gs.

Page 8

Us e s om e C/A to fix the rudder ser vo in

the pre-reserved slot on the upper vertical fuselage as shown in the picture.

Use some C/A to fix the two aileron servos in the pre-reserved slots on the downside vertical winglets as shown in the

pic t u r e .

Use some C/A to fix the elevator ser vo

in the pr e-reser ve d s l o t on t h e lo w er

vertical fuselage as shown in the picture.

8

Send the lower par t of control hor ns.

Fix with C/A the two ailerons control horns.

Inst a l l th e 1 m m x 16 c m c a rb on r o d

payi n g attent i on to t he el evat o r deflect i o n. AT T ENTIO N : elevato r, wh e n

move s down, m u st no t touch t h is ca rbon r od!

Page 9

Insert the 0.5 mm x 32.5 cm carbon strip

in the elevator contr ol hor n. Then glue

them together in the pre-reser ved slot.

ATTENTION: elevator and rudder control

horns are asymmetric. The shorter part

goes on the side of mobile surface where

the r e is th e b eve l for movement.

9

Fix with C/A the 1 mm x 14 cm carbon rod.

Then fix the rudder control horn.

Ins t a ll the rudder to the fuselage with

som e 3 M t a p e.

Use C / A t o fix the upper vertical fuselage into t h e horizontal fuse l a ge. Be

ver tical, n o d i stor tion.

Ins e r t the four 2 mm winglets int o the

pre-reserved slots on the elevator and

apply some C/ A t o f ix.

Page 10

Connect the elevator and rudder servos

and c o n tr ol h or n s w i th thr ead. Make

su r e t h e th re ad i s t au t an d have t he

control surfaces in a horizontal position.

10

10

Install the motor with 3M tape and C/A.

Fix the small depron piece to the wheel

pa n ts t o re in f or ce th e m. P i er ce t h e

wheel pan t s a nd fi x the m wit h C/A in

the landing gear as shown in the picture.

Fix w i t h C/A a small piece of velcro on

each w h eel pant.

Use r ecei ver to trim the ser vo ar ms in

neutral, then fix the servo arms. Install

ail e r on s l i nka g es using the fo u r clips

and t h e t wo 1.3 mm x 5 cm carbon rods

included in the kit .

Page 11

2

11

Us e s ma ll p i ec es o f velcr o t o fix the

ESC , receiver and batter y. NOT E : you

can a d j ust the place of batter y according to the C G p o sition.

A per fect Metis is done a f t er your carefu l a s sembly. While assembly, th e f l yin g weight is really critical to t h e f light p e r for man c e a nd will be affected

by adding weight, so you should reduce

any unnecessary weight while assembly.

Then yo u ’ ll g e t t he best flying perfo r man c e .

Do th e s a me on “tail landing g e a r” as

shown in the picture.

Page 12

12

For technical informations about planes,

pls co n tac t with:

fili p p o.materazzi@gmail.com

www.fmdplanes.com

www.filippo-materazzi .it

www.techonehobby.com

Email:techonesales4@ gmail.com

Loading...

Loading...