Page 1

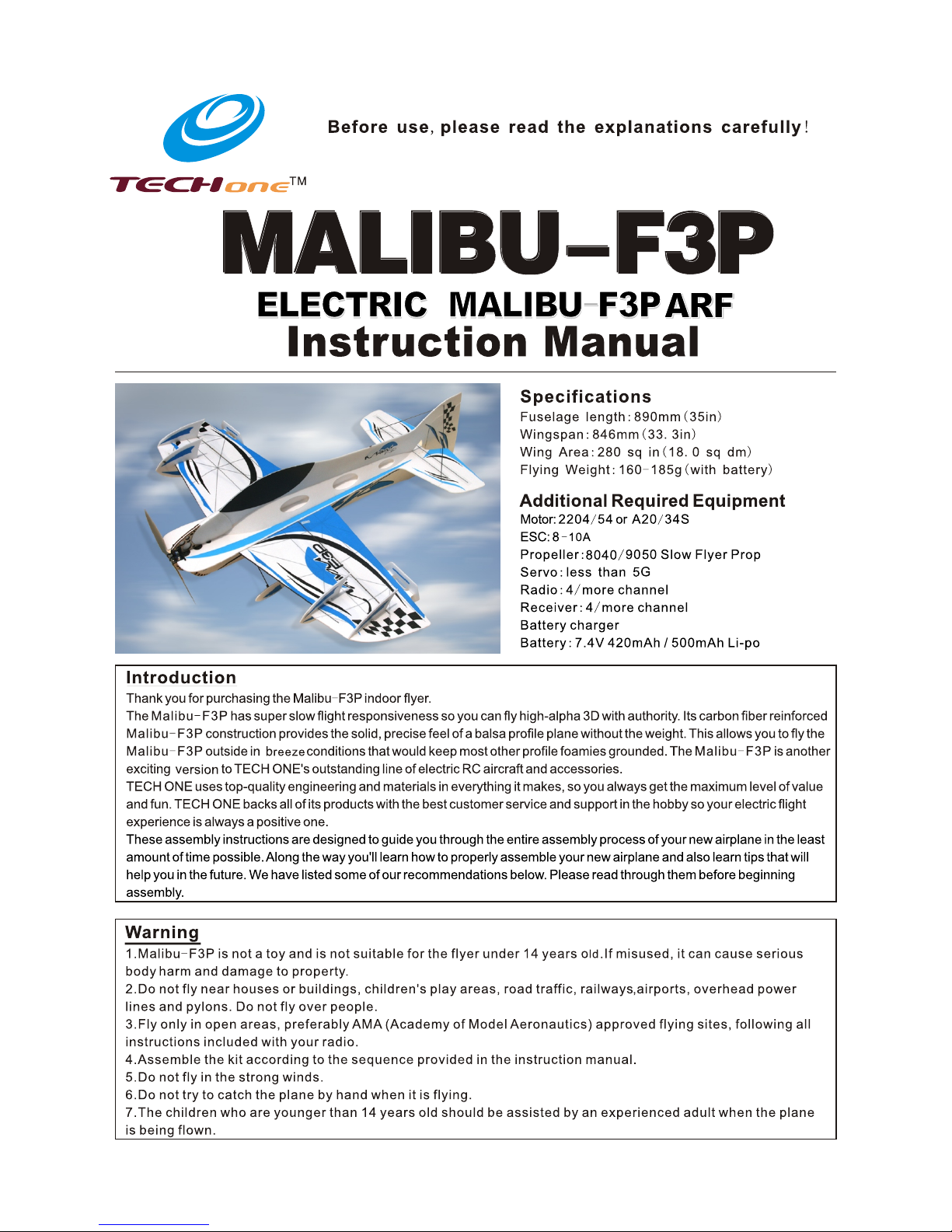

Page 2

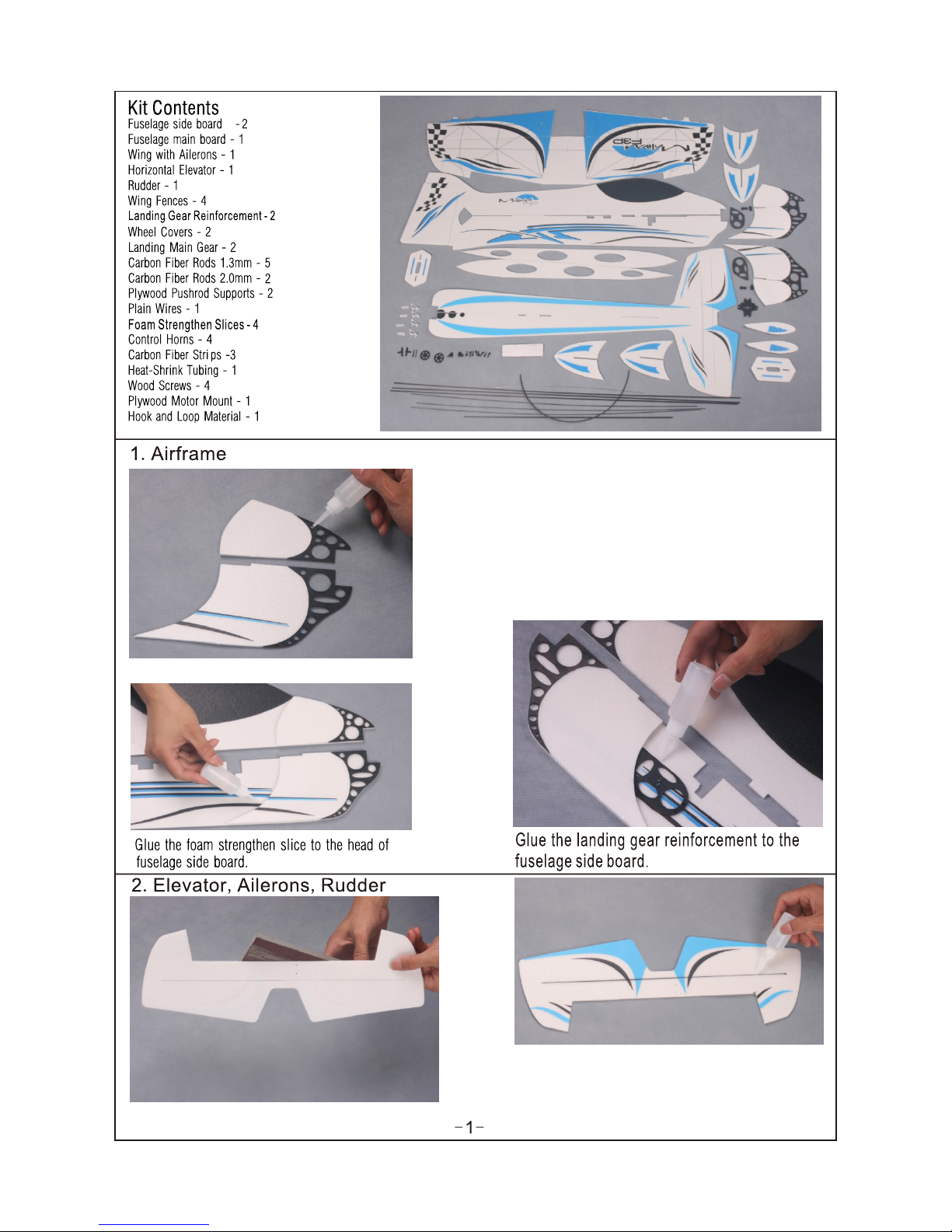

Sand a 45º bevel into the bottom leading edge of the

elevator.

Cut a piece of carbon fiber strip to a length of 14-2/3"

(376mm), then glue it to the below of the elevator, using some

foam-friendly C/A. Make sure the elevator is flat and the

leadingedge is straight while the glue cures.

Page 3

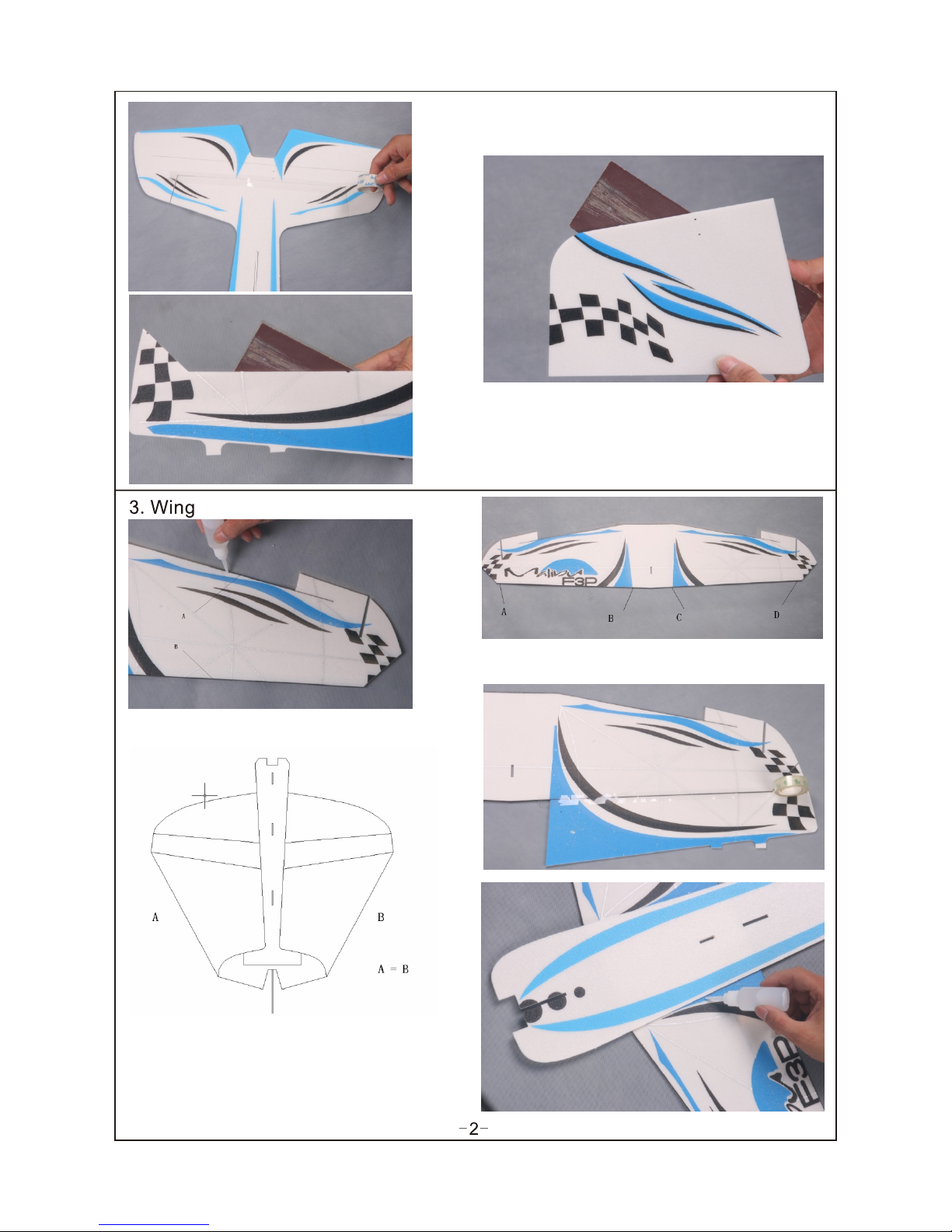

While holding the elevator tight against the stabilizer, apply a strip of

clear plastic tape (not included) to the top of the hinge line on both

sides of the elevator.

Sand a 45º bevel into the left side of the leading edge of the

rudder.

Sand a 45º bevel into the bottom of the leading edge of

the two ailerons.

Use foam-friendly C/A to glue the carbon strips to A and

B to strengthen the wings.

Use some tape to warp the carbon strips on A,B,C and D showed in

the picture to avoid the carbon falling off.

Glue the wings with aileron to fuselage.

Notice:Measure from the tips of the wing to the rear of

the fuselage. The measurements must match from right

to left. If not, adjust the position of the wing until both

measurements are equal.

Page 4

Glue the side board and main board of fuselage.

Make sure the side board is vertical to the main board.

Hinge the rudder to the back of the fuselage, using the same

techniques that you used to hinge the elevator to the

stabilizer.

Locate the two carbon rods. Pass the rods through the fin and

stabilizer. Put the rods together in the fin and use foam-friendly

C/A to glue the rods to the fin ONLY at this time.

Use a square to align the stabilizer with the fin.Once the fin is

perpendicular to the stabilizer, use foam-friendly C/A to glue the

carbon rod to the stabilizer. Square each side before gluing the rod

on that particular side.

Installing the wing bracing is similar to installing

the fuselage bracing, as you want the rods to be

glued to the carbon bracing that has been preinstalled

on the wing and fuselage. The rods are staggered and

fit into notches in the fuselage. Make sure the rods

are straight and are not flexing the wing. Use foam-friendly C/A

to glue the rods in position. The wing

should be flat and parallel to the horizontal stabilizer,

while also being perpendicular to the horizontal stabilizer

While also bei ng perpendicul ar t o the vertic al

fuselage.

Page 5

Install the prope lle r adapter onto yo ur motor, using

the screws p rovided with you r mot or. In sta ll th e motor

mount ont o your motor, using the sc rews provided

with your motor.

Glue the firewal l to th e hea d of th e plane.

Install the moto r ass emb ly on to the firewall, using t he

four wood screws p rov ide d.

PRO TIP After flyin g the a irp lan e, you may want to add

right and/or dow n thr ust t o the m otor. You can do this

by adding thin was her s bet wee n the motor mount and

the firewall.

Cut two pieces of carbon fiber rod , then cut two

pieces of heat-shrink tubing to a length of 1-1/2" (38mm).

Cut two pieces of plain wire to a length of 1-1/2" (38mm), then

make a L-Bend in one end of each piece of wire and a 4mm

long 90º bend in the other end of each piece of wire.

Secure one piece o f wir e to on e end o f the carbon fiber

rod, using one pie ce of h eat -sh rink material. Th e pie ce

of wire should ove rla p the c arb on fiber rod at least 1"

(25mm). Heat the h eat -sh rin k material with a heat gun

to shrink it into pl ace .PR O TIP F or extra security, a pply

a few drops of foam- fri end ly th in C/A to the end of the

pushrod and allow it to " wic k" in to the joint.

Page 6

Slide one plywood pus hro d sup ports over the end of

the carbon fiber r od an d tem por arily push the

plywood pushro d sup por ts in to the one precut slots

in the fuselage.

Center the e lev ator and rudd er servo s, then glue the

servo arms on .

Install the horn of aileron same as the horn of stabilizer.

Install wheel covers on the chock beside the wheel.

Screw one more chock outside of the cover, glue it.

Make s ure that both landing

gear strut are even w ith eac h

other(the same distance from

the botto m o f the w ing )or else

the airplan e won 't sit l eve l on

the ground.

Install the two wheel s and w hee l cho cks .keep

1mm d ist an ce bet we en whe el and i ts

chock.Apply some foam-fr ien dly thic k C/A to

glue the chocks.

Install the elevator aileron an d rudder servos into

the se rvo mo unt ing ho le in the ri ght si de of the

fuselage.Use a dab of foam-f rie ndl y th ick C/ A t o

secure them into pla ce. Bec aus e the size of servos

are differe nt, you m ay ne ed to c ut th e ser vo mo unt ing

hole larger to fit y our p art icu lar servos.

Page 7

Glue four wing fen ces t o the w ing , make sure that

the trailing edg e of ea ch wi ng fe nce is even with

the aileron hinge lin e. Us e a bui lder's triangle to

make sure that the w ing f enc es ar e perpendicular

to the wing.

Mount your ESC to th e fus ela ge si de, using a piece

of double-side f oam t ape ( not i ncluded).

Plug the servo and E SC le ad in to th eir proper slots in

your receiver,t hen m oun t you r receiver to the side of

the fuselage, op pos ite t he ES C, using

a piece of double- sid ed fo am ta pe (not

included).Dr aw th e ant enn a out the bottom of the

fuselage and sec ure i t alo ng it s length, using pieces

of clear tape (not i ncl ude d). D o not cut the antenna

shorter. Allow the e xce ss to h ang b eyond the back of

the fuselage.

Insta ll yo ur battery into t he battery compart ment,

using a p iece of hook and loop ma terial.

Installing the p rop ell er an d decals.

Balance your pro pel ler, t hen i nstall it onto your

motor.Using a cle an cl oth w ipe t he airframe down

completely to re mov e any d ust , debris and oil.

Page 8

BALANCE POINT

The Center of Gravity (C/G or Balance Point) is 3" (77mm) back

from the leading edge of the TOP wing, measured at the center of

the wing.

WARNING For test flying and general sport flying, we suggest

you balance the airplane at the C/G recommended above. For 3D

flying, you may want to experiment moving the C/G back in small

increments until you're satisfied with the result.

Control throws

Sport Flying

Ailerons: (26 .4mm) 1. 04" U p and Down

Elevator: (24 .8mm) 0. 98" U p and Down

Rudder: (3 7. 2mm)1.46 " Rig ht and Left

3D Flying

Ailerons: (72 .6mm) 2. 86" U p and Down

Elevator: (74 .4mm) 2. 93" U p and Down

Rudder: (111.6m m) 4.40" Right a nd Le ft

The control thro ws ar e mea sur ed from the widest point

of the control sur fac es

Exponential

Sport Flying

Ailerons: 20%

Elevator: 20%

Rudder: 20%

3D Flying

Ailerons: 45% - 55%

Elevator: 45% - 60%

Rudder: 45% - 60%

Exponential softens the response of the control surfaces around

neutral stick. This makes the airplane easier to control while using

such large control throws. The Exponential values shown are

given as a percent. Please note that different brands of radio

control systems may call for + or - Expo. Please check your

transmitter's owners manual for more info.

Loading...

Loading...