Page 1

Specifications

Fusel age len gth: 850mm (33. 5i n)

Wings pan: 800mm (31. 5i n)

Flyin g Weigh t: 150- 180g( with b atter y)

Instruction Manual

AEOLUS F3PAEOLUS F3P

Before use,please read the explanations carefully!

lLaser-cut 3mm genuine EPS parts for optimum stre ngth an d

Minim um weig ht .

lLightweight carbon fiber truss system virtually eliminates flex .

lIdeal for indoor flight and capable of outdoor flight in low winds.

lMinimal assembly required flight ready in as little as 3 hours .

lVibrant screen printed trim scheme.

Warning

An R/C aircraft is not a toy! If misused, it can cause seriousbodily harm and

damage to property. Fly only in open areas,preferably AMA (Academy of

Model Aeronautics) approved flying sites, following all instructions included

with your radio.Always assume the electric motor can come on at any time

souse extreme caution.Before beginning assembly of your ,

we strongly uggest that you read through this instruction manual so you

canbecome familiar with the parts and the assembly sequence.Assemble the

kit according to the sequence provided in the instruction manual. Do not

attempt to modify or change the kit design as doing so could adversely

change the models flying characteristics.

AEOLU S-F3P

s

Additional Required Equipment

Motor: 2404 KV:1600

ESC: 10 A

GWS 8040

Radio 4 m ore cha nnel

Recei ver 4 mor e chann el

Batte ry char ger

7.4V mAh

Prope ller: -905 0 Slow Fl yer Pro p

Servo :5G* 3

: /

: /

Batte ry: 350- 500

Introduction

Thank you for purchasing the AEOLUS-F3P.

The AEO LUS-F 3P ARF has super slow flight responsiveness so you can fly

high-alpha 3D with authority. Its carbon fiber reinforced AEOL US-F3 P

construction provides the solid, precise feel of a balsa profile plane without the

weight. This allows you to fly the AEOLUS -F3P ARF outside in windier

conditions that would keep most other profile foamies grounded. The AE OLUSF3P ARF is another exciting addition to TECH ONE's outstanding line of electric

RC aircraft and accessories.

TECH ONE uses top-quality engineering and materials in everything it makes, so

you always get the maximum level of value and fun. TECH ONE backs all of its

products with the best customer service and support in the hobby so your electric

flight experience is always a positive one.

These assembly instructions are designed to guide you through the entire

assembly process of your new airplane in the least amount of time possible. Along

the way you'll learn how to properly assemble your new airplane and also learn

tips that will help you in the future. We have listed some of our recommendations

below. Please read through them before beginning assembly.

Required Tools and Adhesives (not included in the kit)

5 Minute Epoxy

Glue

Aerosol Zip-Kicker

# 0 and #1 Phillips Head Screwdrivers

1.5mm Hex Wrench

Adjustable Wrench

Wire Cutters

Z-Bend Pliers

Needle Nose Pliers

Modeling Knife

Scissors

Electric or Hand Drill

Assorted Drill Bits

Straight Edge Ruler

Pencil

T-Pins

Builder's Triangle

220 Grit Sandpaper with Sanding Block

Masking Tape

Paper Towels

Rubbing Alcohol

Epoxy Mixing Sticks

Epoxy Mixing Cups

Soldering Iron

Page 2

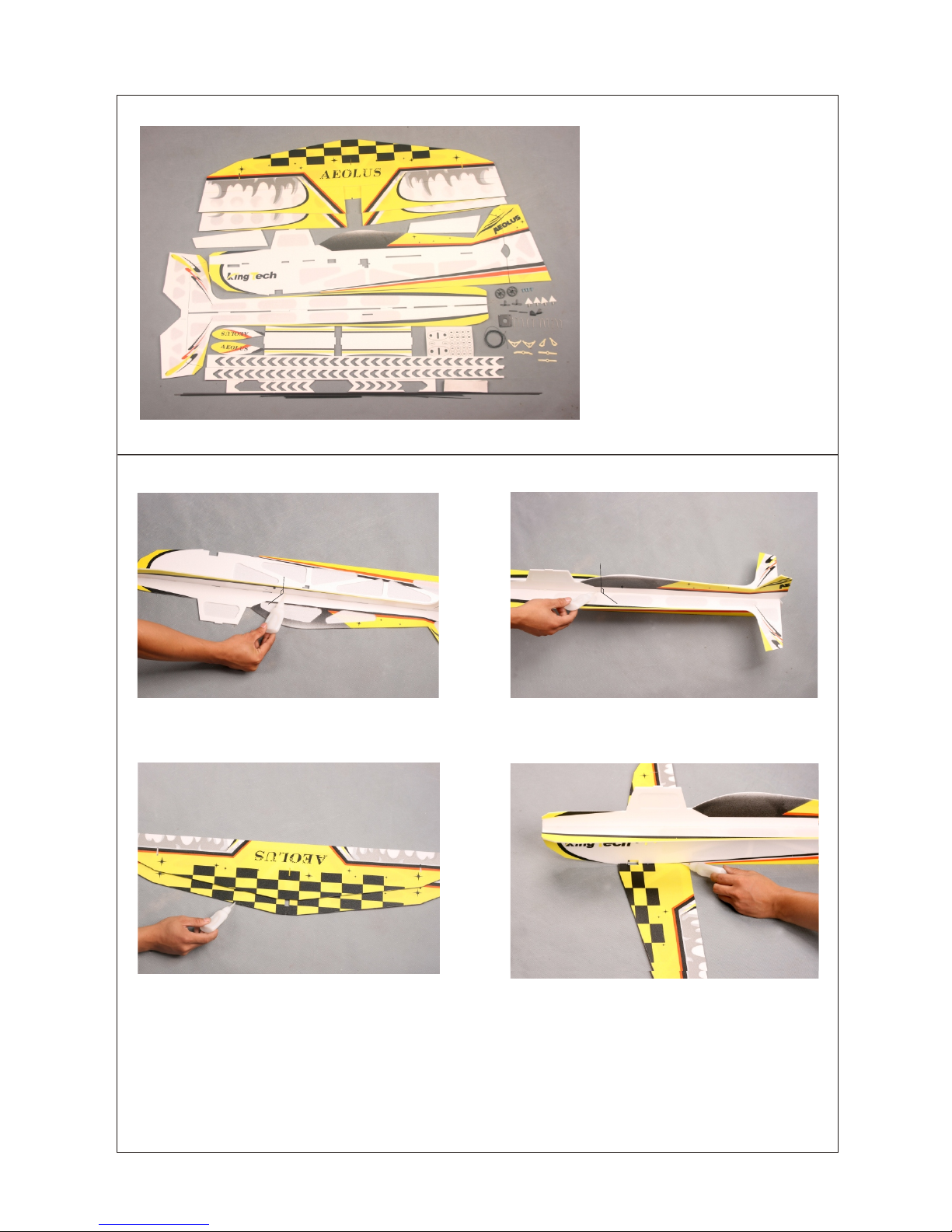

Kit Contents

Fuselage and Wing Assembly

-1-

1.

Glue 2p cs carb on stri ps on the f ront of t he wing s with

some fo am-fr iendl y C/A.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

90

Glue th e fusel age sid e board t o main bo ard wit h foam-friendl y C/A.

Note: N o disto rtion o f the fus elage

Use foa m-fri endly C /A to glue t he lowe r wing to t he

fusel age. No te: The l ower wi ng shou ld be

beper pendi cular t o the fus elage .

S

A Upper an d Lower W ings wi th Ailer on

B Fusel age Mai n Board

C Fusel age Sid e Board

D Wing Fe nces

E Wheel C overs

F Fusel age Str inger s

G Carbo n Fiber R ods

H Velcro

I Threa ds

J Landi ng Gear S tiffe ners an d Round

Doubl ers

K Eleva tor and R udder C ontro l Horns

L Aile ron Con trol Ho rns

M Servo Ar ms

N Z Bend

O Motor M ount

P Landi ng Gear s

Q Ailero n Contr ol Horn s

R Motor S crews

S Wing St rengt henin g Foam St rip

90

Page 3

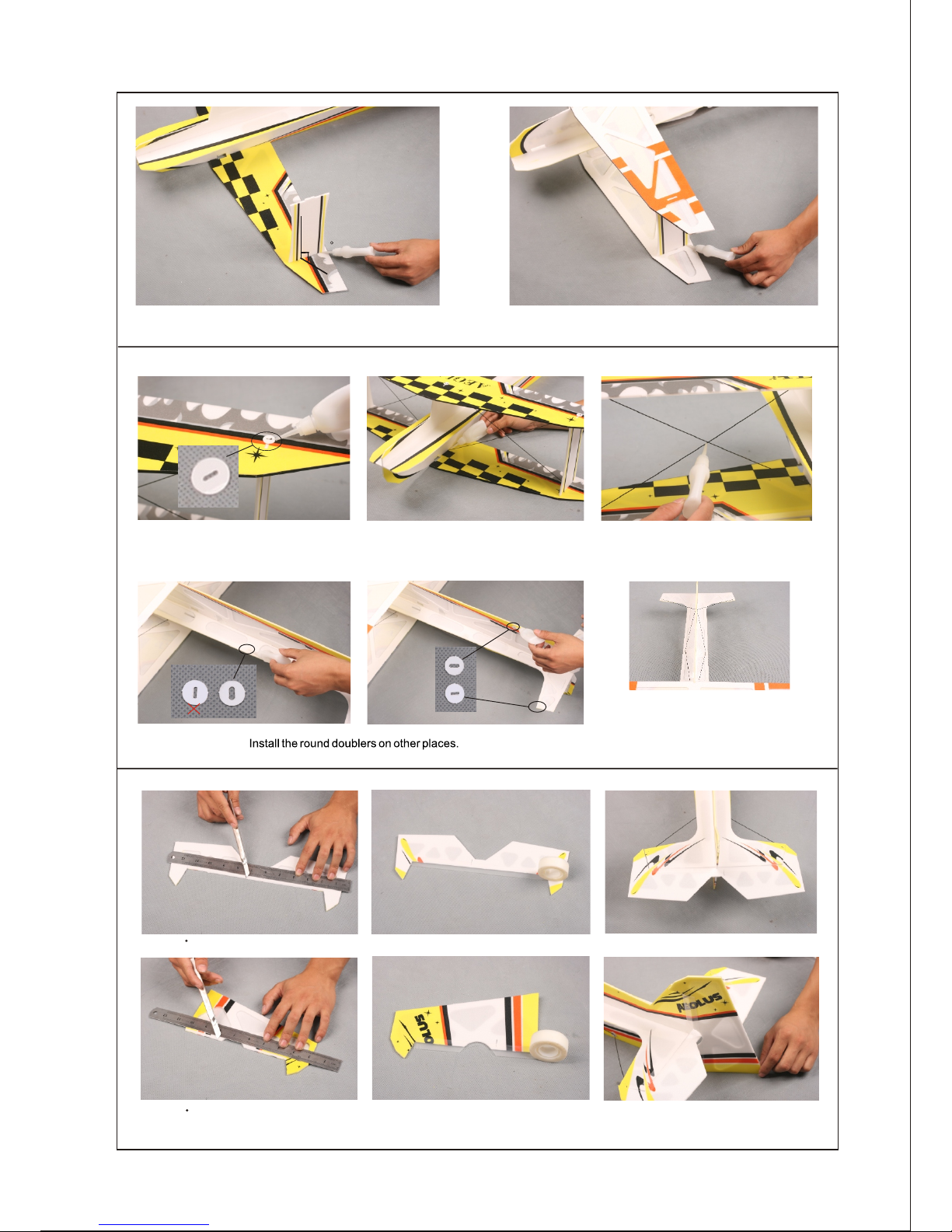

-2-

90

Bracing

Cut proper length of carbon fiber rods,

then install them into corresponding

round doublers. Note: The fuselage side

board should be perpendicular to the

fuselage main board.

2.

3. Others Assembly

Fix the w ing fen ces on th e lower w ing wit h some

foam- frien dly C/A .

Fix the u pper wi ng and th e wing fe nces to gethe r with

foam- frien dly C/A .

Insta ll the ro und dou blers o nto the

pre-r eserv ed hole s on uppe r and low er

wings t o stren gthen t he join t of carb on

fiber r ods and f oam.

Insta ll the ca rber fi ber rod s as show n

to stre ngthe n the fus elage a nd wing s.

Apply s ome foa m-fri endly C /A on the

inter secti on of the t wo carb er fibe r

rods an d fix.

Cut a 45 be vel on th e eleva tor as sh own.

Cut a 45 be vel on th e eleva tor as sh own.

Fix the e levat or and ho rizon tal sta biliz er with 3 M magic tape.

Fix the r udder a nd fuse lage wi th 3M mag ic tape .

1

4

5

mm

1

4 m

m5

20

0

m

m

Page 4

-3-

Cut 45 be vel on th e four ai leron s.

Use 3M ma gic tap e to spli ce the fo ur aile rons an d the upp er and

lower w ings.

Glue th e ailer on horn s onto th e upper a nd lower

ailer ons wit h some fo am-fr iendl y C/A.

Attac h the inc luded z -bend s to the su itabl e lengt h of carbon

fiber p ushro d using h eat shr ink tub e. Use a so ldering iron

or heat g un to shr ink the p ushro d to the z- bend.

Insta ll the mo tor mou nt.

Cut a 45 be vel as sh own.

Cut a 45 be vel as sh own.

Glue th e fusel age str inger s onto th e sides o f the fus elage .

Cut the b oth end s of the fo am stri ps as 45 be vel.

Glue su itabl e lengt h of carb on fibe r strip t o the

front o f the foa m strip a s show, th en atta ch the

foam st rips to t he uppe r wing an d fusel age and

fix the m with fo am-fr iendl y C/A.

170mm

Page 5

-4-

4. Landing Gear

Glue together the contron horns

and their backplates.

Aileron carbon fiber push rods wit h

Z bend.

Assem ble the l andin g gears a nd fix th em with s ome

foam- frien dly C/A .

Insta ll the la nding g ear sti ffene rs.

Insta ll the la nding g ear sti ffene rs.

Insta ll the la nding g ears wi th some

foam- frien dly C/A .

Fix the w heel co vers wi th some

foam- frien dly C/A .

5. C ontrol Horns and Servos

Glue th e anti- diffe renti al arm to t he serv o if you wa nt to ext end the

lengt h of the se rvo arm .

Fix the a ilero n contr ol horn s with

some C/ A.

Cut a 40mm long carbon fiber strip and a 20mm slot on the bottom vertical fuselage as shown.

Insert the strip into the slot, then apply some C/A to fix it. The strip is used as a tail skid.

Page 6

-5-

Insta l the pus h rods to c onnec t the ail eron se rvos an d

contr ol horn s.

Fix the e levat or cont rol hor ns with s ome C/A .

Fix the r udder c ontro l horns w ith som e C/A.

Page 7

-6-

6. Control System

Link th e servo s and con trol ho rns wit h threa ds, mak e sure th e threads a re taut a nd

the two e nds of th e servo a rms are t ied wit h threa ds.

Mount y our ESC t o the fus elage , using o ne piec e of velc ro.

Insta ll the mo tor

Insta ll the ba ttery i nto the

pre-r eserv ed plac e on the he ad of

plane a s shown .

Use one p iece of v elcro t o fix you r

recei ver on th e fusel age.

PRO TIP: After flying the airplane, you may want

to add right and/or down thrust to the motor. You

can do this by adding thin washers between the

motor mount and the firewall.

Page 8

Seek Assistance

If you are new to R/C we suggest you find an experienced pilot to check out your aircraft and help you with

the first few flights.This will help prevent damage to your model and will speed up the learning process

and making your R/C experience all the more enjoyable. You can contact local R/C clubs or your dealer

to obtain the names of experienced R/C pilots who would be willingto help you with your first few flights.

Although this is an ARF (Almost-Ready-to-Fly) kit, it does have some construction features that can be

challenging to the less experienced modeler. If you encounter difficulty in any construction sequence,

please feel free to contact one of our technicians, we stand ready to provide any assistance we can.

Contact us at:

E-Mail: techonehobby@gmail.com

Copyright 2009 Techonehobby

Http://www.techonehobby.com

TM

C

Balance Point

The Center of Gravity (C/G or Balance Point) is 2.3 6" (60mm)

from the leading edge of the wing, measured at the center of

the wing.

WARNING For test flying and general sport flying, we suggest

you balance the airplane at the C/G recommended above. For

3D flying, you may want to experiment moving the C/G back in

small increments until you're satisfied with the result.

Control thr ow s

Sport Flyin g

Ailerons: 2 8m m( 1.10" ) Up and Down

Elevator: 2 2m m( 0.87" ) Up and Down

Rudder: 36m m( 1.4 2" ) Ri ght and Left

3D Flying

Ailerons: 7 7m m( 3.03" ) Up and Down

Elevator: 6 6m m( 2.60" ) Up and Down

Rudder: 108 mm (4. 25")R ight and Left

The control t hr ows are measu red from the wide st

point of the co nt rol surface s

Exponenti al

Sport Flyin g

Ailerons: 2 0%

Elevator: 2 0%

Rudder: 20%

3D Flying

Ailerons: 4 5% - 5 5%

Elevator: 4 5% - 6 0%

Rudder: 45% - 6 0%

Exponenti al s oftens the re sponse of the c on trol

surfaces ar ou nd neutral st ick. This m akes the airpla ne

easier to con tr ol while usin g such large cont rol throws.

The Exponen ti al values sho wn are given as a per cent.

Please note t ha t diffe re nt brands of ra dio control

systems may c al l for + or - Expo. Pl ease check yo ur

transmitt er 's owners man ual for more in fo .

-7-

Motor Thrust

To ensure great flight performance and to be able

to trim your airplane properly, it is critical that you

adjust the motor thrust as described. We suggest

that you add 2 degrees of down-thrust and 1

degrees of right-thrust. This can be achieved by

adding a washer or two behind the top and right

side of the motor (between the motor and the

firewall). When set properly, the trim for the

elevator and the rudder should be neutral. Finetune the down-thrust and right-thrust until this trim

is achieved.

Made in China

Loading...

Loading...