Page 1

1

5

.

2

2015

VERSION

© TechnoKom

Page 2

AutoGRAPH-GSM • USER MANUAL

2

TechnoKom © 2015

Page 3

AutoGRAPH-GSM • USER MANUAL

3

TechnoKom © 2015

Table of contents

Software Copyright Notice ............................................................................................................................... 4

Introduction ............................................................................................................................................................5

Safe Operation Recommendations ............................................................................................................ 6

Product Overview ................................................................................................................................................ 7

Technical Specications ................................................................................................................................... 8

Scope of Supply ................................................................................................................................................ 10

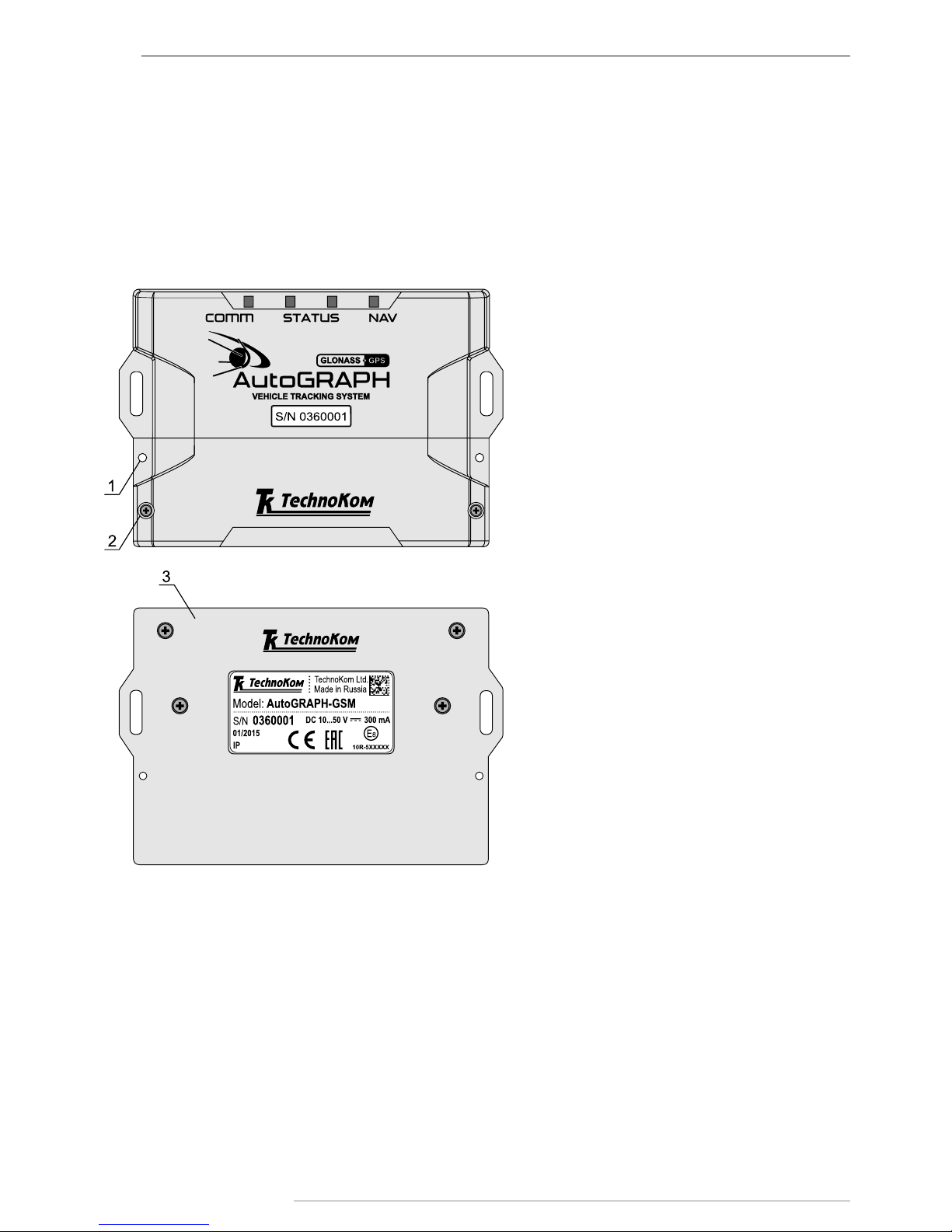

Components of AutoGRAPH-GSM Controller (standard case) .....................................................11

Components of AutoGRAPH-GSM Controller (protective case) .................................................. 12

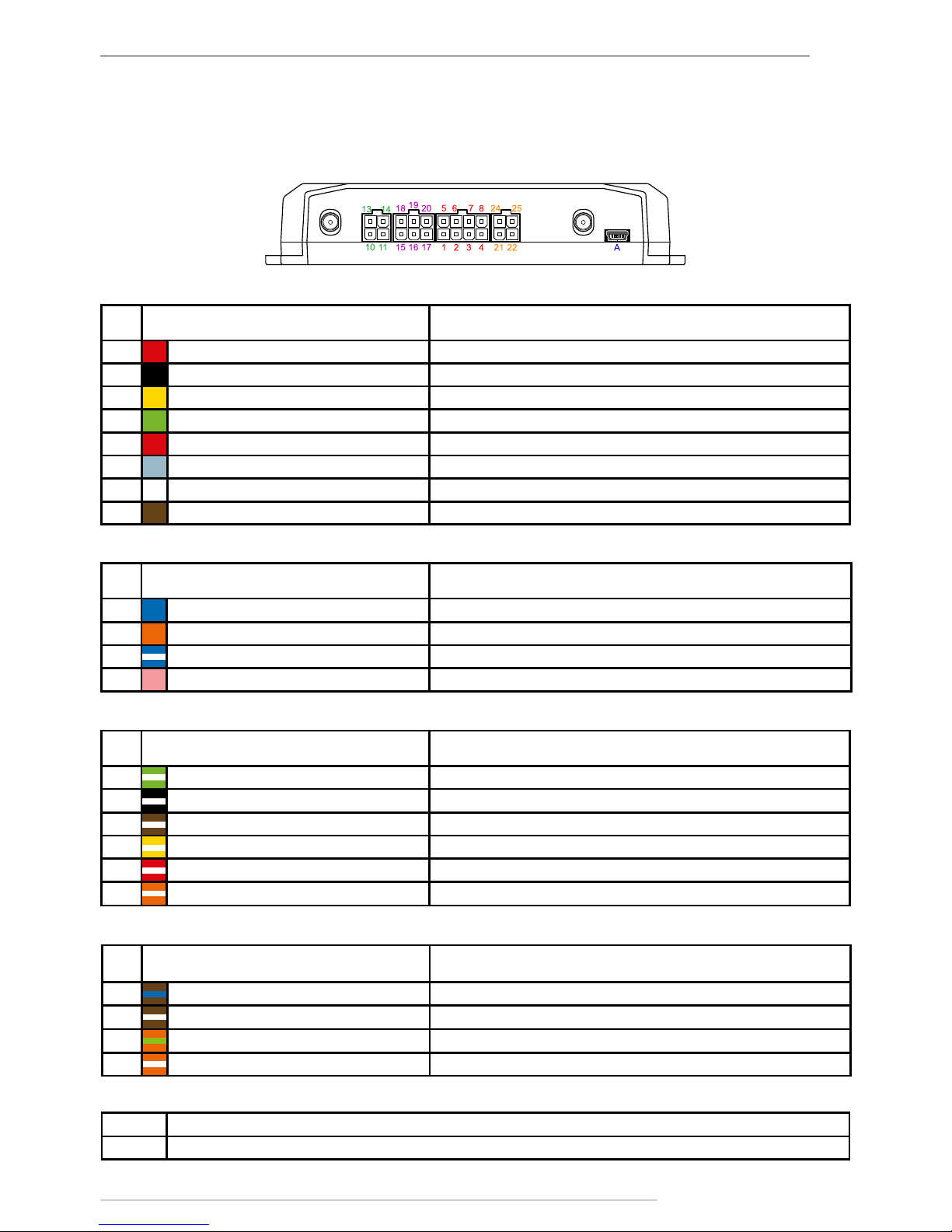

Interface Connectors ..................................................................................................................................... 13

Structure Diagram of AutoGRAPH-GSM (GPS/GLONASS) .......................................................... 16

Brief Description of Vehicle Tracking System Operation ................................................................ 22

Connection of AutoGRAPH-GSM controller .......................................................................................... 25

Installation of SIM Card ................................................................................................................................. 26

Installation of MicroSD Card ........................................................................................................................ 27

Connection of GPS/GLONASS Antenna ................................................................................................ 28

Connection of GSM Antenna ....................................................................................................................... 29

Power Supply Connection ............................................................................................................................ 30

Backup Power Supply Connection ............................................................................................................ 31

Connection of Digital Inputs 1...4 (active low) ...................................................................................... 32

Connection of Digital Inputs 7...8 (active high) .................................................................................... 35

Connection of Analogue Inputs................................................................................................................... 37

Connection of High-impedance Digital Input ........................................................................................ 39

Connection of Outputs.................................................................................................................................... 40

1-Wire .................................................................................................................................................................... 41

RS-232 (EIA / TIA-232-E) ............................................................................................................................. 42

RS-485 (TIA / EIA-485-A) ............................................................................................................................. 44

CAN Bus (SAE J1939 / FMS) ..................................................................................................................... 47

Connection of Backup Battery ................................................................................................................... 48

Audio Interface .................................................................................................................................................. 49

Indication of Operation .................................................................................................................................. 50

Drivers Installation ........................................................................................................................................... 53

Connection to PC ............................................................................................................................................. 55

Warranty Provisions (summary) ................................................................................................................. 56

Page 4

AutoGRAPH-GSM • USER MANUAL

4

TechnoKom © 2015

Some functions of AutoGRAPH-GSM Series controllers depend on capacities and conguration of

the existing mobile network operator (MNO). Furthermore, some functions may be disabled by

the operator, or their operating range may be limited due to the settings of the network. To check

availability of a certain function, contact your mobile network operator.

All information on functions, functional capabilities and other specications related to AutoGRAPHGSM Series on-board vehicle tracking controllers, as well as all information contained in this User

Manual is based on current data (at time of writing) and is deemed to be valid as of the date of

publication. Technokom reserves the right to modify the information or specications without prior

notice or commitment.

IMPORTANT

IMPORTANT

Products of TechnoKom referred to in this Manual may incorporate software stored in

semiconductor memory or other media, copyrights to which belong to TechnoKom or third

parties. Laws of the Russian Federation and other countries secure certain exclusive rights

of TechnoKom and third parties to the software, which is subjected to copyright, for example,

exclusive rights for distribution or reproduction.

Therefore, any alteration, reverse engineering, distribution or reproduction of any software

incorporated in TechnoKom products, is prohibited to the extent provided by law.

Furthermore, purchase of TechnoKom products does not imply direct, indirect or other

granting of any licenses related to copyrights, patents and patent applications of TechnoKom

or any third party, except for an ordinary, nonexclusive free license for use, which is granted

in virtue of law upon each sale of the product.

Communication protocol between AutoGRAPH-GSM Series on-board vehicle tracking

controllers and communication data server is considered to be condential information and

intellectual properly of TechnoKom.

The communication protocol between the AutoGRAPH-GSM Series on-board vehicle tracking

controllers and a communication data server shall be transferred by TechnoKom to integrators

and software manufacturers only upon signing the Condentiality Undertaking.

Unauthorized distribution of protocol being used for communication between AutoGRAPH-

GSM Series on-board vehicle tracking controllers and communication data server is strictly

prohibited.

Software Copyright Notice

Page 5

AutoGRAPH-GSM • USER MANUAL

5

TechnoKom © 2015

This User Manual applies to AutoGRAPH-

GSM Series on-board vehicle tracking

controller (hereafter - tracker) of hardware

revision 3.0 produced by TechnoKom Ltd1.

It contains installation and connection

procedures of this device, as well as its

function and control. This Manual constitutes

the Operating Rules to be observed to ensure

successful operation of the controller and its

compliance warranty provisions.

The Manual is intended for specialists who

are aware of maintenance and installation

principles typical for motor vehicles and are

procient in using the electronic and electrical

equipment of various vehicles.

To ensure the best performance of the

AutoGRAPH-GSM controller, they should

be installed and set up only by qualied

specialists.

For proper operation of the

AutoGRAPH-GSM controller, a user

should be aware of operating principles

of the vehicle tracking system as a whole,

as well as understand functions of its

individual components. Therefore, it is highly

recommended to study the fundamentals

of operation of GPS navigation, GSM

communication, peculiarities of short

message service (SMS), GPRS and the

Internet before starting.

Introduction

Version history

This table provides a summary of the document revision

Version Description Date

15.0 Initial release for AutoGRAPH-GSM 3.0. 12/2014

15.1 Added information on the AutoGRAPH-GSM+ modication 12/2014

15.2 Added correct structure diagram on p.16 02/2015

1

The AutoGRAPH-GSM on-board trackers of hardware revision 3.0 have been produced

from serial number 0360001.

Page 6

AutoGRAPH-GSM • USER MANUAL

6

TechnoKom © 2015

This section contains important information

for effective and safe operation. Please

read the information below before using

AutoGRAPH-GSM on-board vehicle tracking

controllers.

Performance Characteristics

AutoGRAPH-GSM on-board vehicle tracking

controllers operate using a GSM/GPRS

module and function as a low power receiver

and transmitter. When the device is ON,

it receives and transmits electromagnetic

energy in the radiofrequency range.

Operating band of the device ranges from

900 MHz to 1,990 MHz; the device uses

digital modulation techniques.

When the device is in operation, a call service

system controls the strength of sent-out RF

signal.

Exposure to Electromagnetic

Fields

The design of the AutoGRAPH-GSM onboard vehicle-tracking controller complies

with the following standards, which specify

the safe levels of exposure to radiofrequency

electromagnetic elds:

• EN 55022: 2010+AC:2011 / Class B

Information technology equipment. Radio

disturbance characteristics. Limits and

methods of measurement.

• EN 55024:2010 Information technology

equipment. Immunity characteristics. Limit

and methods of measurement.

• EN 61000-3-2:2006+A1:2009+A2:2009/

-3:2008 Electromagnetic compatibility

(EMC) Limits.

• EN 61000-6-3:2007+A1:2011

Electromagnetic compatibility (EMC)

Generic standards.

• EN 301 489-1 Electromagnetic

compatibility and radio spectrum Matters

(ERM); Electromagnetic Compatibility

(EMC) standards for radio equipments and

services.

Safe Operation Recommendations

Antennas

Use only original supplied antennas.

Antennas that have been modied may

damage the device or cause violations of

statutory rules and regulations.

DO NOT touch the GSM antenna of the

device while it is in operation. This can impair

communication quality and give rise to an

undesired increase in radiated power.

DO NOT touch the GPS antenna of the

device while it is in operation. This can

impair the quality of reception and result in

inaccurate positioning.

DO NOT use a device with a defective

antenna. If there are any defects in antenna

or antenna cable, replace the antenna or

consult your local dealer as soon as possible.

Electromagnetic Interference and

Compatibility

Almost any electronic device is subjected

to electromagnetic interference unless it is

adequately shielded, has proper construction

or is compatible with devices operating in

another frequency band.

Prohibition on Use of Mobile

Communication Devices

If you come across a signage or a notice, which

prohibits the use of mobile communication

devices, turn off your tracker. This is required

to avoid electromagnetic interference with

equipment sensitive to electromagnetic

elds often used in hospitals, health care

institutions or petrol stations.

Medical Devices

Cardiac Pacemakers

Medical Device Manufacturers Association

advises to use mobile communication devices

at distances greater than 15 cm from cardiac

pacemaker so as to prevent the failure of

the latter. These recommendations conform

to the studies carried out by independent

Page 7

AutoGRAPH-GSM • USER MANUAL

7

TechnoKom © 2015

medical laboratories and Research Centre

for Wireless Technologies.

Hearing Devices

Sometimes, use of mobile communication

devices may cause troubles for wearers of

certain hearing devices. In this case, consult

the manufacturer of your hearing device to

select another model.

Other Medical Devices

For other personal medical devices, contact

your physician or device manufacturer to

nd out whether your device is adequately

shielded from electromagnetic interference

generated by mobile communication devices.

General Information on Safe Use

Vehicle

Observe the rules on using hand-held

devices when driving.

• Use hands-free devices when driving.

• Stop to make or take a call.

Product Overview

The AutoGRAPH-GSM Series on-board vehicle tracking controller is an electronic recorder

which tracks all movements of a vehicle by recording the time and the route in the form

of geographic coordinates received from the satellites of global navigation system GPS

(NAVSTAR) or GLONASS.

In addition to coordinates, the device records a number of other parameters: speed, direction

of movement, event counters, etc., as well as the states of digital inputs of the controller,

external sensors and data buses.

Collected data is transferred by a GSM 900/1800 mobile network operator by means of

General Packet Radio Service (GPRS) to the dedicated server where they become available

via the Internet for further analysis and processing by dispatch software.

The device may be used for any type of vehicles.

Data transfer is possible only when GSM 900/1800 mobile network operator, which supports

General Packet Radio Service (GPRS), is available.

IMPORTANT

Explosion Hazard Zones

SWITCH OFF the device when entering the

explosion hazard zone. Explosion hazard

zones include: fuel stations, box girder decks

on sea vessels, facilities or plants for handling

and storage of fuels or chemicals, areas with

chemicals or solid particles such as grains,

dust or metal powder in atmosphere; and any

other locations where it is usually required to

shut off a vehicle’s engine. Explosion hazard

areas are often (yet not always) expressly

marked.

Blasting Areas

In order to avoid interference with blasting

operations, SWITCH OFF the device in

blasting areas or in any locations marked

with «Two-way radio-communication is

prohibited» signage. Observe the signage

instructions and rules.

Page 8

AutoGRAPH-GSM • USER MANUAL

8

TechnoKom © 2015

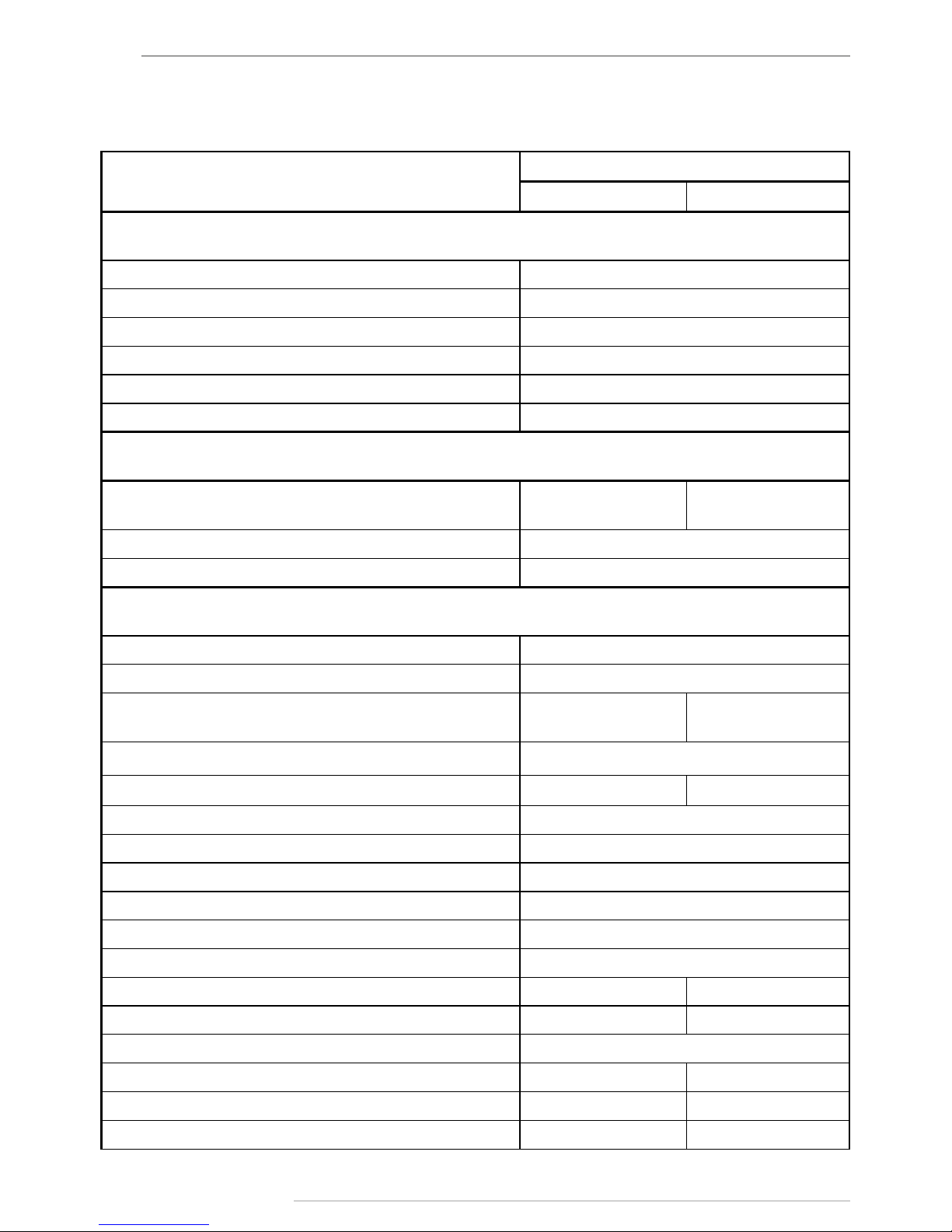

Technical Specifications

Description

Value for AutoGRAPH-

GSM GSM+

GNSS Receiver

Supported GNSS GLONASS + GPS / GALILEO / Beidou

GNSS receiver uBlox MAX-M8Q

Channels 72

A-GNSS service Yes

Differential GPS (D-GPS) Yes

Antenna (GPS/GLONASS) External (SMA)

GSM Module

Communication

GSM

(GPRS / SMS)

3G UMTS1 / GSM

(GPRS / SMS)

SIM card holders 2

Antenna (GSM) External (SMA)

General

Connection to PC USB 2.0

Internal FLASH memory, records > 270.000

Additional memory

External MicroSD

(up to 32GB)

Internal eMMC

(4GB)

Digital inputs, total number 6

High-impedance digital inputs, total number --- 1

Congurable inputs (analogue/digital), total number 2

Digital outputs, total number 2

Built-in accelerometer Yes

1-Wire 1

RS-232 1

RS-485 (TIA / EIA-485-A) 2

CAN (SAE J1939 / FMS) 1 2

Audio interface (GSM) / Loudspeaker amplier No Yes

Type of external backup battery (not supplied) Lead-acid

Rated backup battery voltage 12 / 24 12

Battery Charger No Ye s

Charging time, hours --- 30

Page 9

AutoGRAPH-GSM • USER MANUAL

9

TechnoKom © 2015

Operating voltage, V 10...50

Maximum supply voltage, V 60

Power consumption at 12 VDC:

- recording state, mА

- data transferring state, mА

70

300

80

320

Time to rst start2, sec 23

Protective case (IP54) Optional

Operating temperature, °С -40...+85

Dimensions, mm:

- standard case

- protective case

138 х 67 х 27

138 x 92 x 27

Weight, kg:

- standard case

- protective case

0,110

0,150

Average life time, years 10

1

Optional. Specied in «Hardware version» eld.

2

With nominal navigation signals level -130dBm.

Page 10

AutoGRAPH-GSM • USER MANUAL

10

TechnoKom © 2015

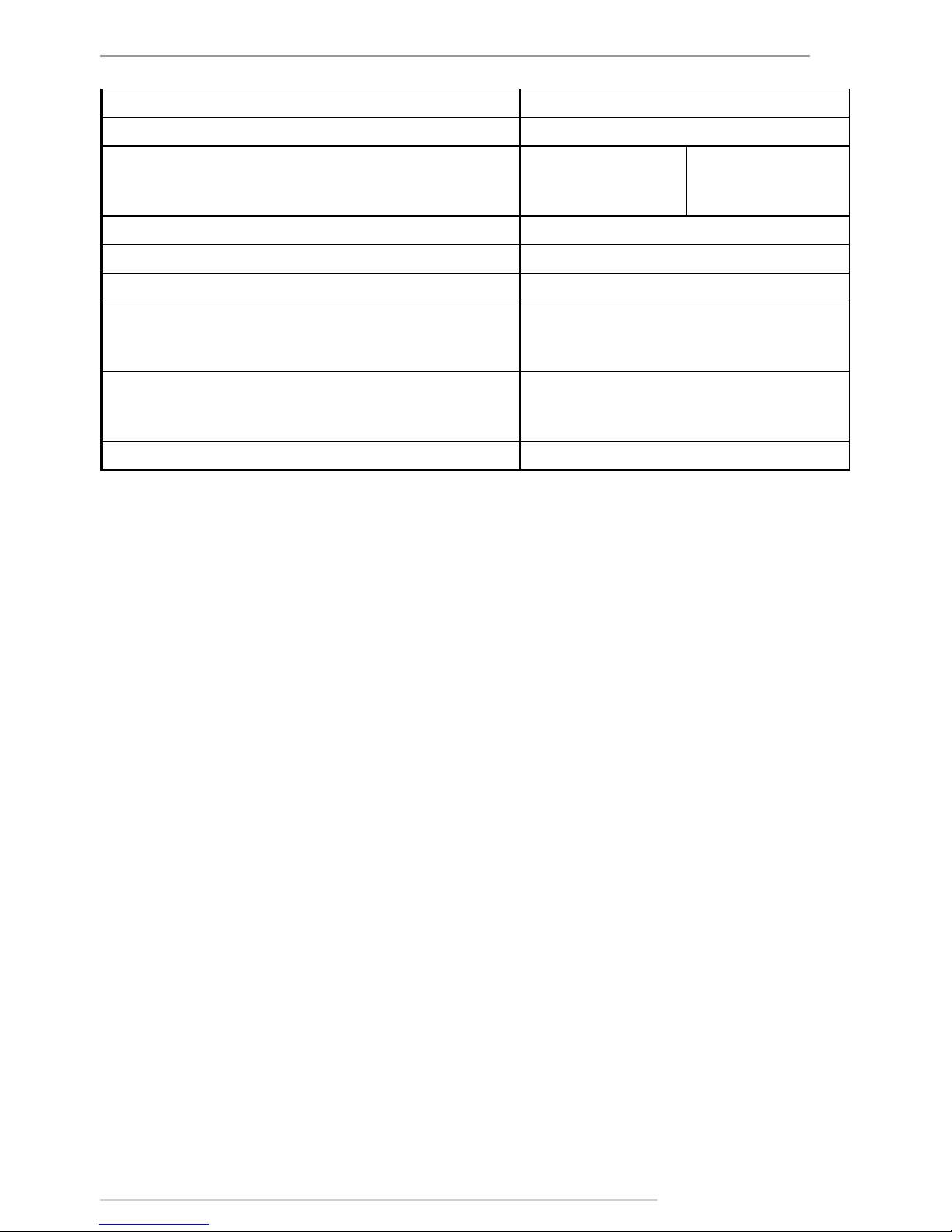

Scope of Supply

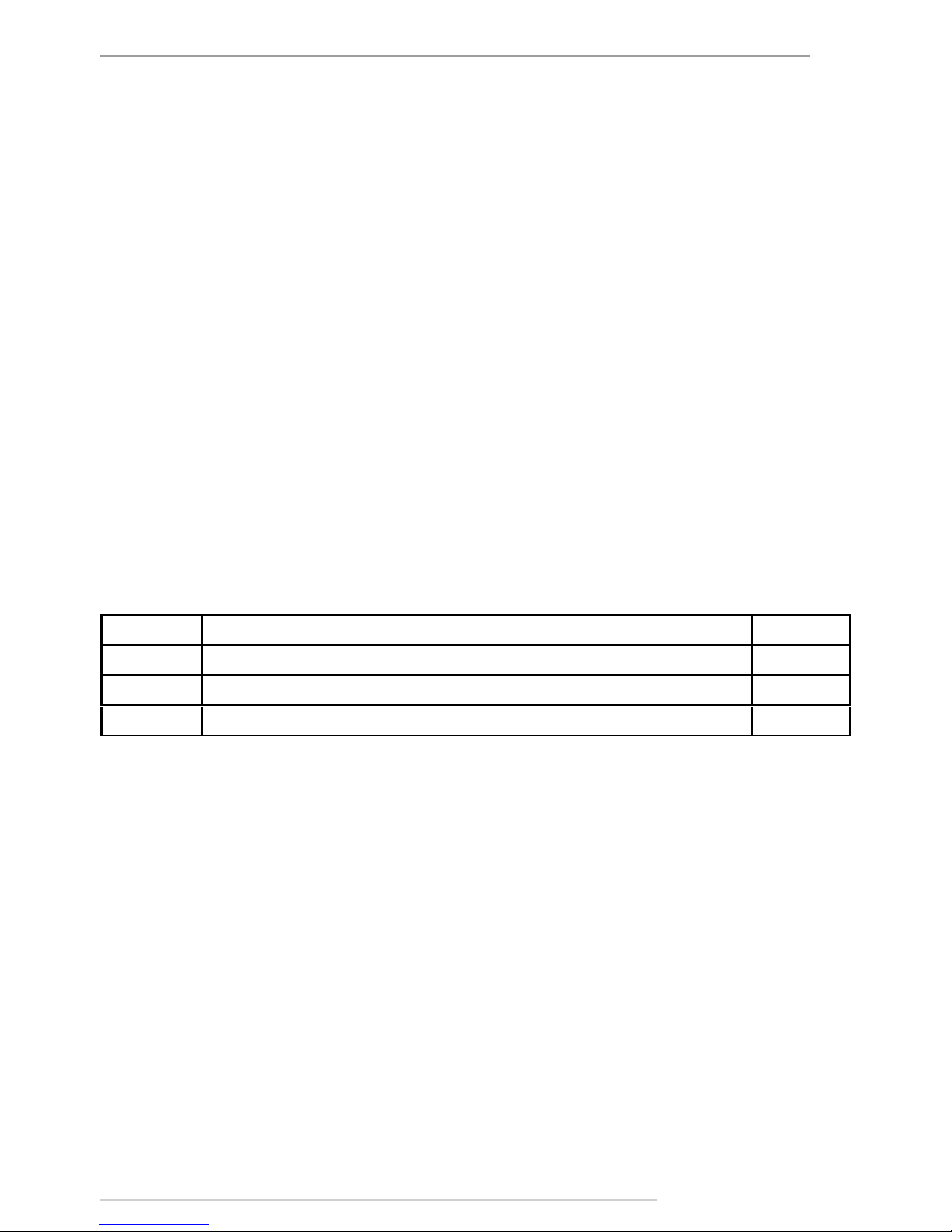

№ Description GSM

1 AutoGRAPH-GSM (GPS/GLONASS) on-board controller 1

2 Interface Cable (primary) 1

3 Additional 4/6-pin interface cable 1*

4 6-pin RS-485 / CAN interface cable 1*

5 4/6-pin RS-232 / RS-485-2 interface cable 1*

6 «AGNA-G2» GPS/GLONASS Antenna 1

7 «AGCA-4G» GSM Antenna 1

8 1A fuse with a holder 1

9 Warrantee certicate 1

*on request

Page 11

AutoGRAPH-GSM • USER MANUAL

11

TechnoKom © 2015

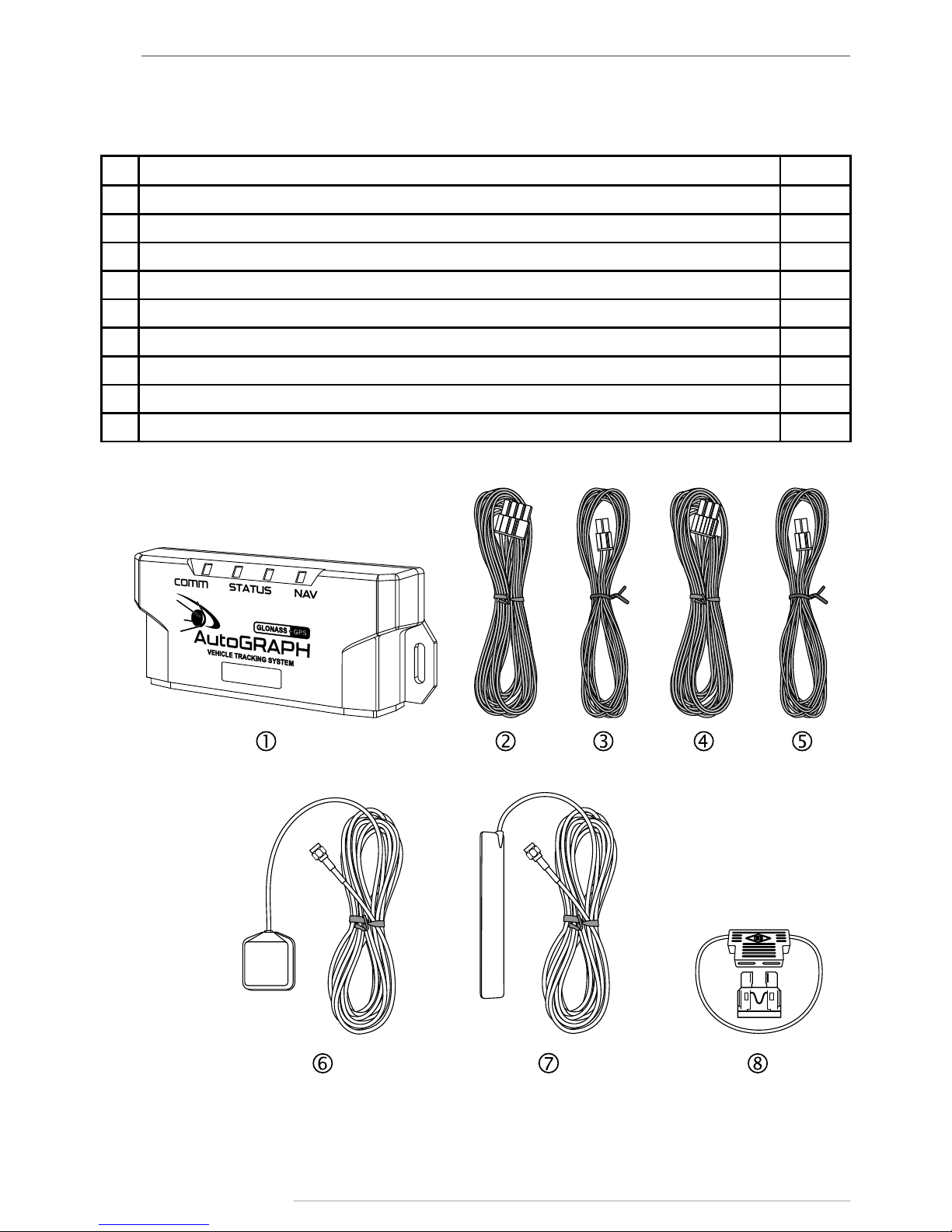

Components of AutoGRAPH-GSM

Controller (standard case)

1. COMM LED (bi-colour).

2. STATUS LEDs.

3. NAVIGATION LED (bi-colour).

4. Mounting bracket.

5. Label with serial number.

6. Fastening screw of a back cover (x4).

7. Manufacturer’s label.

8. GSM antenna

9. Interface connectors.*

10. GPS / GLONASS antenna.

11. Mini USB connector

* For more detailed information on assignment of inter face connectors see «Interface Connectors» section of this User Manual.

Page 12

AutoGRAPH-GSM • USER MANUAL

12

TechnoKom © 2015

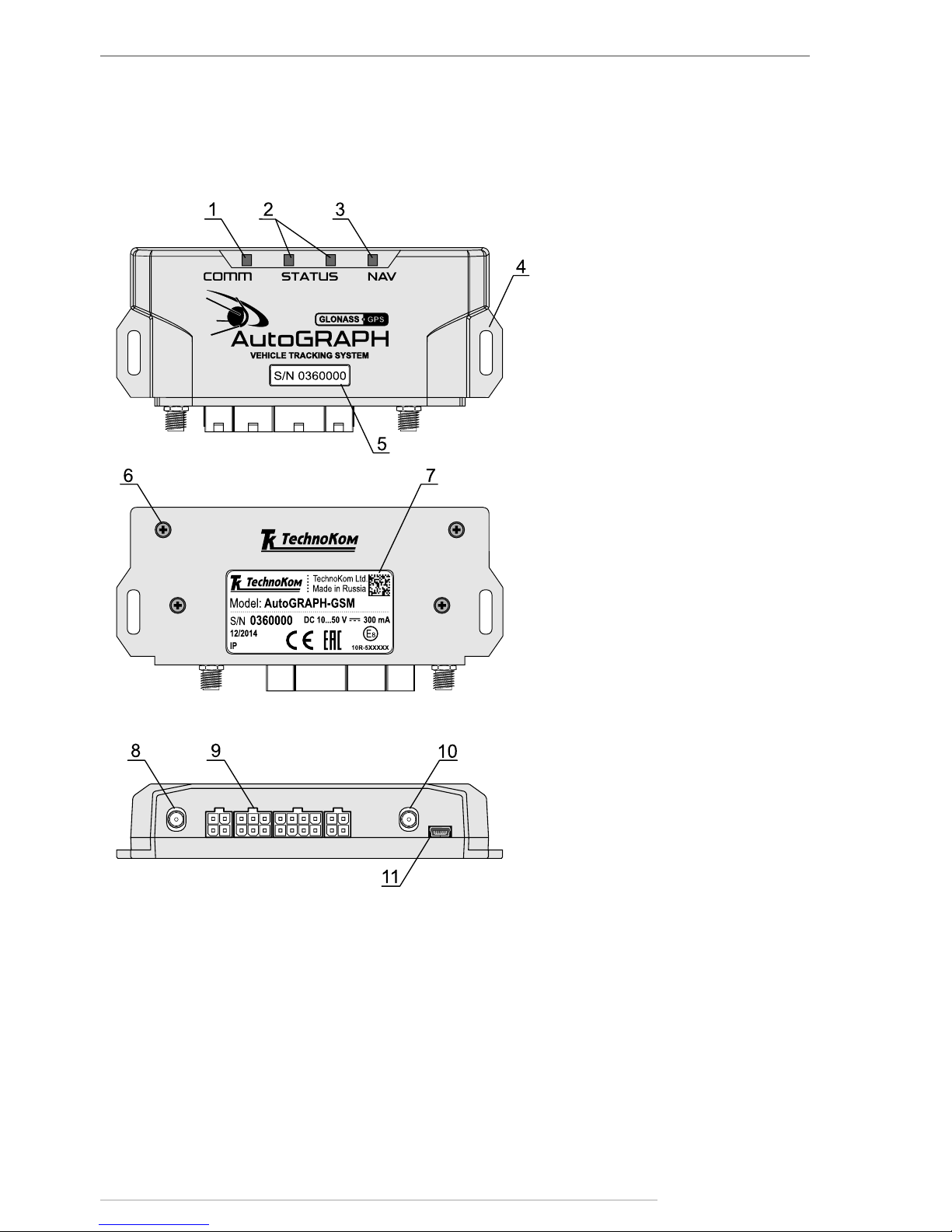

Components of AutoGRAPH-GSM

Controller (protective case)

1. Sealing hole (x2).

2. Fastening screw of a protective cover (x2)

3. Back protective cover.

Optionally, the AutoGRAPH-GSM may be supplied in a protective case providing high ingress

protection rate and sealing option. The protective case has built-in case tamper switch

intended to x any attempts of the case disclosing.

Page 13

AutoGRAPH-GSM • USER MANUAL

13

TechnoKom © 2015

Interface Connectors

AutoGRAPH-GSM (GPS/GLONASS)

Primary interface connector

4-pin interface connector

6-pin CAN / RS-485 interface connector

№ Colour of a wire in a cable Assignment

1 Red (long) + Vin

2 Black -Vin

3 Yellow Digital input 1 (active low)

4 Green Analogue input 1 (0…10 V) / Digital input 5 (active high)

5 Red (short) + Backup supply voltage

6 Gray Open collector output 1 (0.5 А)

7 White Digital input 2 (active low)

8 Brown Analogue input 2 (0…24 V) / Digital input 6 (active high)

№ Colour of a wire in a cable Assignment

10 Blue Digital input 3 (active low)

11 Orange Open collector output 2 (0.5 А)

13 Blue with a white stripe Digital input 4 (active low)

14 Pink 1-Wire

№ Colour of a wire in a cable Assignment

15 Green with a white stripe CAN (H)

16 Black with a white stripe Digital input 7 (active high)

17 Brown with a white stripe RS-485 (B)

18 Yellow with a white stripe CAN (L)

19 Red with a white stripe Digital input 8 (active high)

20 Orange with a white stripe RS-485 (A)

4-pin RS-232 / RS-485 interface connector

№ Colour of a wire in a cable Assignment

21 Brown with a blue stripe RS-232 TxD

22 Brown with a white stripe 2: RS-485 (B)

24 Orange with a green stripe RS-232 RxD

25 Orange with a white stripe 2: RS-485 (A)

Additional connectors

ID Assignment

A Mini USB connector (programming / data reading / GPS mouse)

Page 14

AutoGRAPH-GSM • USER MANUAL

14

TechnoKom © 2015

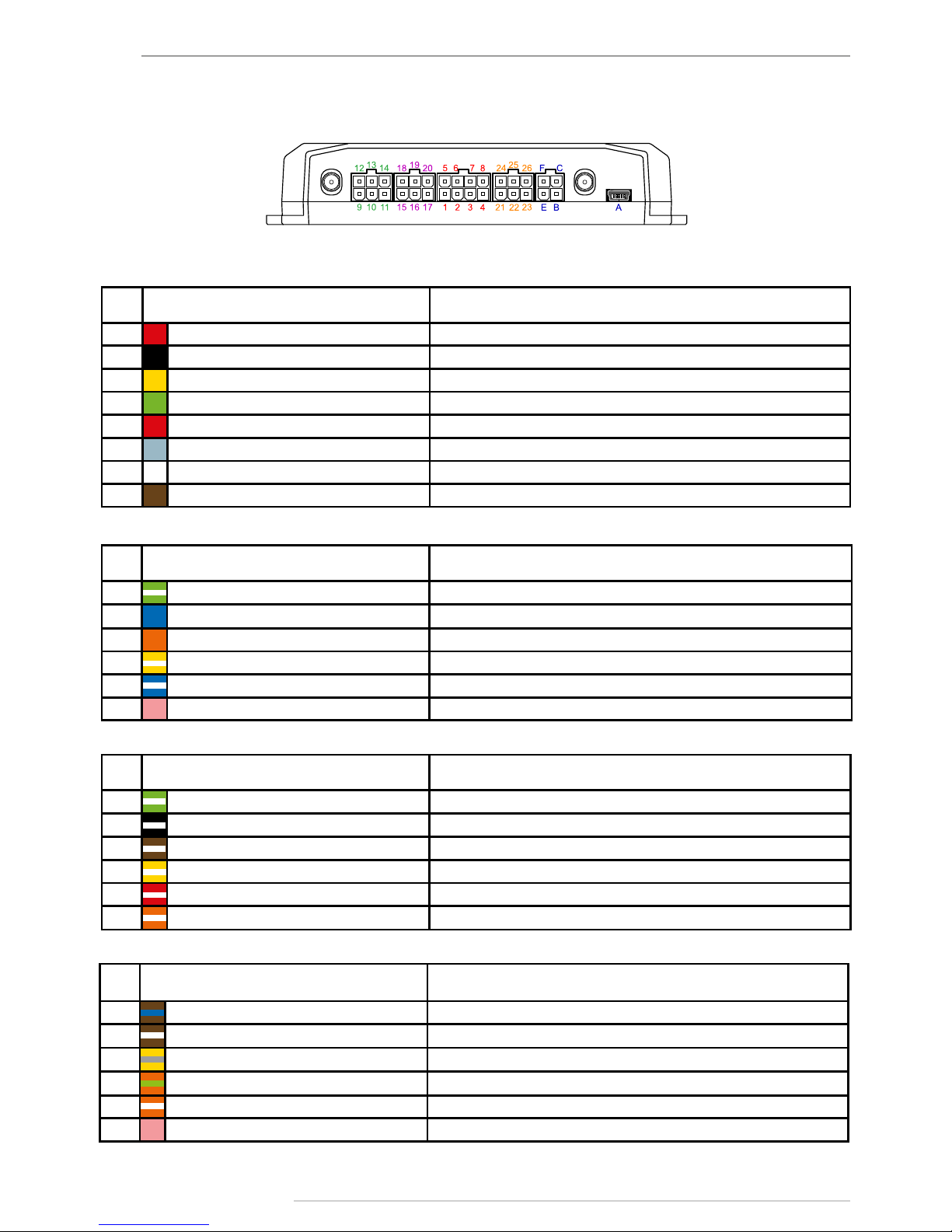

Primary interface connector

6-pin interface connector

6-pin CAN / RS-485 interface connector

№ Colour of a wire in a cable Assignment

1 Red (long) + Vin

2 Black -Vin

3 Yellow Digital input 1 (active low)

4 Green Analogue input 1 (0…10 V) / Digital input 5 (active high)

5 Red (short) + Backup rechargeable battery

6 Gray Open collector output 1 (0.5 А)

7 White Digital input 2 (active low)

8 Brown Analogue input 2 (0…24 V) / Digital input 6 (active high)

№ Colour of a wire in a cable Assignment

9 Green with a white stripe CAN2 (H)

10 Blue Digital input 3 (active low)

11 Orange Open collector output 2 (0.5 А)

12 Yellow with a white stripe CAN2 (L)

13 Blue with a white stripe Digital input 4 (active low)

14 Pink 1-Wire

№ Colour of a wire in a cable Assignment

15 Green with a white stripe CAN (H)

16 Black with a white stripe Digital input 7 (active high)

17 Brown with a white stripe RS-485 (B)

18 Yellow with a white stripe CAN (L)

19 Red with a white stripe Digital input 8 (active high)

20 Orange with a white stripe RS-485 (A)

6-pin RS-232 / RS-485 interface connector

№ Colour of a wire in a cable Assignment

21 Brown with a blue stripe RS-232 TxD

22 Brown with a white stripe 2: RS-485 (B)

23 Yellow with a grey stripe RPM input*

24 Orange with a green stripe RS-232 RxD

25 Orange with a white stripe 2: RS-485 (A)

26 Pink Digital input 9 (high-impedance)

AutoGRAPH-GSM+ (GPS/GLONASS)

* Unavailable in h/w 3.0

Page 15

AutoGRAPH-GSM • USER MANUAL

15

TechnoKom © 2015

Additional connectors

ID Assignment

A Mini USB connector (programming / data reading / GPS mouse)

B +Microphone signal input

C Loudspeaker signal output (2.65 W amplier)

E Ground

F Call / Answer button input

Page 16

AutoGRAPH-GSM • USER MANUAL

16

TechnoKom © 2015

Structure Diagram of

4

DIGITAL INPUTS

(active low)

DIGITAL INPUTS

(active low)

AUDIO INTERFACE

*

2xSIM

GLONASS• GPS

RECEIVER

CENTRAL PROCCESSING UNIT

FLASH MEMORY

SD-card / еMMC MEMORY

*

ACCELEROMETER

INPUTS / OUTPUTS

2

ANALOGUE /

DIGITAL

INPUTS

ANALOGUE /

DIGITAL

INPUTS

RPM INPUT

*

RS-232

RS-485 I

RS-485 II

USB

1-WIRE

CAN I

BACKUP BATTERY

CHARGER

*

POWER SUPPLY DRIVER

GSM MODEM / 3G GSM MODEM

*

2

2

DIGITAL

OUTPUTS

CAN II

*

1

DIGITAL HIGH

IMPEDANCE

INPUT*

DIGITAL HIGH

IMPEDANCE

INPUT*

DIGITAL INPUTS

(active high)

DIGITAL INPUTS

(active high)

AutoGRAPH-GSM (GPS/GLONASS)

*Module is built-in only in the AutoGRAPH-GSM+.

IMPORTANT

Page 17

AutoGRAPH-GSM • USER MANUAL

17

TechnoKom © 2015

The GSM modem is intended to provide a

connection between the controller and the

GSM mobile network. The GSM signal is

received and transmitted via an external

GSM antenna. The controller is equipped

with a SIM card to be identied by the GSM

network and to be able to access the services

provided by the mobile network operator. The

GSM modem performs several functions:

• Enables the device to access the GSM

network and to be identied by the network

using the SIM card.

• Enables data exchange (including transfer

of track points) between the AutoGRAPHGSM controller and the server via TCP/IP

through the Internet by means of General

Packet Radio Service (GPRS).

• Enables exchange of information and

control SMS messages and USSD requests

(for example, for subscriber’s personal

account monitoring).

GSM-modem

GPS / GLONASS module

CPU

The GNSS module is designed using a highly

sensitive receiver based on high performance

u-blox M8 engine. It receives coded

signals by means of external active GPS/

GLONASS antenna from the satellites of the

Global Positioning System (NAVSTAR) and

GLONASS, and uses its internal computer

to determine the geographical coordinates

of the receiver position, the exact time,

speed and direction of movement. Received

data is transferred via NMEA protocol from

the GNSS module output to the central

processing unit for further processing.

The u-blox MAX-M8 supports concurrent

reception of two GNSS systems and, as

a result, the information being received is

highly accurate and available even in the

case of very poor visibility of satellites.

The central processing unit is the core of the

AutoGRAPH-GSM controller, which unites

all of the system components together and

ensures their interaction in accordance

with the program stored in the device. The

processing unit is a high-speed single-chip

microcomputer able to perform computations

of at a speed and accuracy level that is

sufcient to meet various navigation and

service challenges. The custom rmware,

developed by TechnoKom specialists,

enables the CPU to receive data from the

different modules of the system, to perform

logical and mathematical processing of

the data and to control the modules as

appropriate. It should be noted that the

functional capability of the controller rmware

is being constantly enhanced and extended

so as to provide users with new and improved

features and options.

Power Supply Driver

The power supply driver with protection

circuits generates all of the necessary

supply voltages for controller components.

The primary power supply input ensures

operation at vehicle system voltage of 1050 V, which makes it possible to use the

controller on the majority of vehicles without

employing any additional voltage regulation.

Furthermore, the power supply driver

protects the controller against polarity

reversal, voltage overload, interference, etc.

A resettable fuse is installed in the supply

circuit of the printed circuit board in order to

provide extra protection.

Page 18

AutoGRAPH-GSM • USER MANUAL

18

TechnoKom © 2015

The Non-Volatile FLASH memory module serves as a black box storage device to store the

collected data. The FLASH memory module is designed to store up to 270,000 records for

up to 10 years – even when the device is powered off. The FLASH memory module in the

AutoGRAPH-GSM is designed to use the ring buffer principle, which means that new records

will be written over the oldest records rst, ensuring that the most recent data is always

available.

The AutoGRAPH-GSM controller is equipped with additional memory to store log-les and

photos from cameras connected to the controller. The AutoGRAPH-GSM controller uses an

external micro SD card to store additional data.

Non-Volatile FLASH Memory Module / Additional Memory

Inputs / Outputs

The I/O block is designed for monitor and measure parameters of external equipment and

devices, as well as for control various actuators and warning devices.

The I/O block is divided into three sections:

Digital inputs.

These inputs have two states: «1» and «0» , and are able to show a change of input state,

count pulses and measure frequency.

The controller has the four active low inputs and 2 active high inputs.

In addition, analogue inputs of the controller can operate as digital inputs with the congurable

switching threshold.

Logic of the discrete inputs operation is shown in the table below:

Physical state of the input

Logic state of

active low input active high input

High (connected to supply voltage) 1 1

Open-Circuit 1 0

Low (connected to ground) 0 0

IMPORTANT

Note that logic states of the two inputs dier in open-circuit state (see the table above).

This must be taken into account when making connections.

Operation modes of the discrete inputs are fully programmable for each input and include:

• Normal input. In this mode, the digital inputs are monitored. When the input state

changes, the time and location data is stored into the device memory. Normal mode is useful

for recording the time of different sensors’ activation and for monitoring the performance of

Long-term exposure of the controller to the maximum values of the supply circuit may cause

irreparable damage to the protection circuits due to overheating or disruption. This may lead to

failure of the device. DO NOT exceed the maximum values stated. Operating voltage range and

maximum supply voltage values are specied in Technical Specications section.

IMPORTANT

Page 19

AutoGRAPH-GSM • USER MANUAL

19

TechnoKom © 2015

equipment and mechanisms, such as an alarm button, oil pressure sensor, ignition system,

passenger presence sensor, security alarm triggering, opening of doors, limit switches of

various special-purpose and construction machinery mechanisms, etc. This mode also

enables the device to perform unscheduled transmission of data to the server via GPRS

upon input state changes, as well as to send an SMS message to the specied phone

number.

• Storage counter. This mode is intended to track the input switching states and to count

various events. This may include counting of pulses from fuel-ow pulse output sensor (of

DRT-5 or VZO type), passenger count, speed sensor, tipper body lift sensor, etc. In storage

counter mode, the number of pulses from each sensor is stored in memory. The location

data is not stored.

• Periodic counter. This mode is intended for counting of pulses within one minute. Periodic

counter mode is used for taking the readings of sensors, which transmit measured values in

pulse bursts in amounts proportional to the measured value. This mode is used, for example,

for fuel level, temperature and engine speed sensors with pulse outputs. This mode does

not involve recording of a track point into the storage memory when the input state changes.

• Frequency. This mode is intended for sensors with frequency outputs. The device is

capable of measuring frequencies of 0 – 2,500 Hz. Frequency measurement mode is used,

for example, for fuel level sensors with frequency outputs, engine and shaft speed sensors,

proximity sensors etc.

High-impedance inputs

Furthermore, the AutoGRAPH-GSM+ controller is equipped with one digital high-impedance

active high input with logic levels independent of the supply voltage of the device connected

to this input.

Analogue inputs

Analogue inputs are designed to measure the signal level generated by analogue sensors

and can be used to measure fuel level in a tank, temperature, pressure and other properties.

The AutoGRAPH-GSM controller is equipped with two 10-bit analogue inputs, which are fully

congurable. Each analogue input of the controller can be set up to record data when the

level of the analogue signal changes by a specied value.

The measuring range of the rst analogue input is 0 to 10 V or 0 to 1023 ADC stages.

The measuring range of the second analogue input is 0 to 24 V (but not more than supply

voltage level of the controller) or 0 to 1024 ADC stages.

Furthermore, the analogue inputs of the controller can be set up to operate as active high

digital inputs with a congurable switching threshold. When an analogue input operates as

a digital one, the controller simultaneously records both analogue data and corresponding

logical state. This allows analogue inputs to be used to measure an analogue value and

detect a threshold crossing (for example, critical pressure level, temperature or fuel level etc.).

Digital outputs

Digital outputs are intended to control any external actuators and turn on warning devices.

The controller has two programmable, open collector, discrete outputs. The outputs are

controlled by an SMS command and can be set up to send a pulse of a specied length or

to switch to specied state. Advanced users can send control commands via the data server.

In simple case, the discrete output can be used to warn about speeding, an entrance or exit

of the geofenced area, etc.

Page 20

AutoGRAPH-GSM • USER MANUAL

20

TechnoKom © 2015

USB Port

The USB port embedded into controller is intended to:

• congure and check the performance of the controller by means of the conguration

program – GSMConf;

• read data from the device so as to deliver them to the AutoGRAPH Dispatch Software;

• update processor microcode (rmware) of the device;

• use the controller in the «GPS mouse» mode.

When using the device as a GPS mouse, the tracker, which is connected to the USB port of

a PC, laptop or PDA with a data cable via virtual serial port (СОМ port), transmits the location

data in RMC format through the NMEA protocol once per second. This enables the users to

locate the object equipped with the AutoGRAPH-GSM using software such as OziExplorer,

Google Earth Plus/Pro, 2GIS for PC 3.0, Garmin, Navitel and many others. For details please

refer to «Using the GPS mouse» document.

CAN Bus (SAE J1939/FMS)

The CAN bus is an industrial network standard primarily designed for interconnection of

various actuators and sensors in a single network. It is used in the automotive industry as a

management and control line. The CAN interface of the controller may be connected to the

CAN bus of a vehicle and is intended for use with SAE J1939 / FMS standard protocol. This

standard is widely used in vehicles of well-known truck manufacturers, such as SCANIA,

MAN, VOLVO, DAF, IVEKO, RENAULT, MERCEDES (DaimlerChrysler), KAMAZ and MAZ

trucks of latest models etc. Advanced users can set up the tracker to receive data in any CAN

protocol using the GSMConf program.

Use of the two-wire CAN bus enables quick connection and allows access to a great number

of parameters directly from the sensors of vehicles.

Using the CAN bus, the following information would become available: vehicle speed, cruise

control status, accelerator pedal position, brakes and clutch switch statuses, fuel consumption,

fuel level in tanks (up to 6 sensors), engine speed, service distance, engine hours, engine

coolant temperature, oil and fuel temperatures, total vehicle distance and vehicle distance

per day and axle weight. Furthermore, it enables monitoring of some custom parameters not

covered by SAE J1939 / FMS standard.

RS-485 (TIA / EIA-485-A)

RS-485 (TIA / EIA-485-A) is a data transfer standard for data transmission via a two-wire

serial channel. This bus serves to simultaneously connect up to 32 different devices and

sensors compatible with the controller’s rmware by two wires.

The controller is equipped with two RS-485 buses. Additional RS-485-2 Bus is designed for

connecting a photo camera to the tracker.

The bus enables users to connect up to 8 fuel level LLS sensors, as well as Escort-TD,

Strela-D485, DUT-E-485, DT7.3-06, UZI-1.х and other sensors, and some extra expansion

modules to extend the controller’s functions, e.g. display for indication and messaging with a

vehicle driver, passenger trafc metering unit, expansion modules for discrete and analogue

inputs, barometrical altimeter, RS-232/RS-485 converters, etc.

The RS-485 port of AutoGRAPH-GSM controllers support MODBUS protocol that enables the

users to connect the controller to the thermal sensors, which transmit data via this protocol.

Page 21

AutoGRAPH-GSM • USER MANUAL

21

TechnoKom © 2015

RS-232 (EIA/TIA-232-E)

RS-232 is a communication standard for serial communication between two devices: the

AutoGRAPH-GSM controller and any external device compatible with the controller’s

rmware.

The AutoGRAPH-GSM controller supports interaction with the external GPS/GLONASS

receiver via NMEA 0183 standard, the CAN-LOG module and the AutoGRAPH-NAVIGATOR

Display via RS-232.

The AutoGRAPH-GSM is equipped with 3-axis digital accelerometer with wide range of

full scales from ±2g to ±16g intended to detect motion, determine the tracker’s orientation,

measure vibration level, etc. The tracker can be set up to send a notication to a preset

telephone number or data to a preset server, when detecting the acceleration exceeding a

preset threshold.

Accelerometer

1-Wire

1-Wire, designed by Dallas Semiconductor Corporation, is a simple and convenient bus

typically used to communicate with small devices and sensors such as digital thermometers,

iButton keys, card readers, and other devices equipped with 1-Wire bus and compatible with

the controller’s rmware.

The AutoGRAPH-GSM+ has a built-in charger to charge an external backup battery. When

the controller is powered by the vehicle power system, the power supply driver turns on the

charger. The controller sends a notication to a preset telephone number when the backup

battery voltage falls below the threshold.

RS-232 (EIA/TIA-232-E)*

Battery Charger*

Audio Interface (with loudspeaker amplier)*

The audio interface provides voice communication between vehicle driver and a dispatcher

via GSM.

The AutoGRAPH-GSM+ is equipped with a loudspeaker, a microphone and an Answer/Call

button to make a two-way voice communication.

A built-in amplier increases the signal amplitude 2.65 times and transfers it into the speaker.

The speaker output, microphone input and pins for connecting an external Answer/Call button

are arranged on the singular 4-pin Mini-Fit connector.

Answering and making a call are performed by means of the button on the loudspeaker.

Furthermore, the controller automatically answers calls coming from numbers those have

masks specied in the controller. For example, if the number «543» is specied, the tracker

will automatically answer a call from all numbers that contain «543».

Page 22

AutoGRAPH-GSM • USER MANUAL

22

TechnoKom © 2015

Brief Description of Vehicle

Tracking System Operation

CSV

DBF

OLE

TXT

RTF

PPT

XML

XLS

ODP

ODS

ODT

TIFF

PNG

JPG

SVG

HTML

Dropbox

FTP

GoogleDrive

SkyDrive

Internet & local area network

Mobile Internet

3G/GPRS (GSM)

WI-FI

DATA SERVER

DATA BASE

DESKTOP SOFTWAREMOBILE APP. WEB-SERVICE

VOICE CALL & SMS

DATA EXPORT & REPORTS

VEHICLES equipped with AutoGRAPH-GSM

GLONASS+GPS

Page 23

AutoGRAPH-GSM • USER MANUAL

23

TechnoKom © 2015

AutoGRAPH-GSM controllers, installed on

vehicle, constantly receive coded signals

from Global Positioning System (NAVSTAR)

and GLONASS satellites. These signals are

used to determine exact coordinates of the

vehicle location.

The coordinates are written to the non-volatile

memory of the AutoGRAPH-GSM controller,

either on a regular basis or adaptively.

Furthermore, the storage memory records

and stores the statuses of various sensors

connected to the tracker or data buses, and

other parameters required by the software.

Either on a regular basis or upon occurrence

of a preset event, the collected data is

transferred to the dedicated AutoGRAPH

server over the Internet using General Packet

Radio Service (GPRS) supported by a GSM

mobile network operator.

The server is a computer running Microsoft

Windows Server with an Internet connection,

permanent IP-address and reliable data

storage device. The server is responsible

for receiving data from AutoGRAPH-GSM

controllers, storing the data and transmission

upon request to the dispatcher stations. Key

les are used to provide data access security

on the server.

Dispatcher workstations are personal

computers or laptops with the AutoGRAPH

dispatch software installed (and with the

key les required for particular vehicles)

that has either Internet access or server

connection via LAN. An Internet connection

and computer with the Dispatch Software

will enable users to obtain data from

anywhere in the world. Easy deployment of

the Dispatch Software without the need to

install third-party database support enables

users to immediately create new dispatcher

workstations with any PC running MS

Windows 2000/XP/Vista/7/8. The number of

workstations is unlimited. Dispatch Software

is completely free of charge and the latest

version may be downloaded from the ofcial

website of TechnoKom: http://www.tk-chel.ru.

Mobile users can easily track vehicle

movement in real-time using WEB based

AutoGRAPH.WEB dispatch software run on

any mobile device connected to the Internet.

Upon the user’s request or on a regular basis

the dispatcher workstation connects with

the server to update data on. Depending on

version of the AutoGRAPH Server Software,

access to the data is provided according

the controller key or the personal login and

password. The received data is stored in a

local folder on the dispatcher workstation

that enables processing of the data without

being connected to the server. Furthermore,

to reduce the web trafc, the dispatching

network may be organized in such a way as

to send any missing data through the Internet

to only one workstation, while all other users

may use these downloaded data via LAN

by retrieving them from the local data folder

of the workstation. The users may use this

data to track the vehicles on a map, browse

through various parameters, events and

readings of various sensors. In addition, it is

possible to generate various types of reports

and charts both for each particular vehicle

and in groups.

To interact with various external applications

and handlers (including 1С), AutoGRAPH

Software incorporates OLE server application

(COM server) which enables data exchange

between AutoGRAPH Software and the

programs written in the majority of existing

programming languages which support OLEenabled data exchange, as well as programs

and systems based on their own embedded

programming language (1С Enterprise, MS

Ofce, various databases, etc.).

Furthermore, there is an option to upload all

tracking data and reports in the form of MS

Excel, DBF and CSV les, as well as to use

an external customizable reporting module

which allows users not only to generate a

large number of reports with fully customized

layout, data and charts to be presented, but

also to save them in many different formats

to enable further processing, sending or

presentation: PDF, Open Ofce ODS, Open

Page 24

AutoGRAPH-GSM • USER MANUAL

24

TechnoKom © 2015

Ofce ODT, MS Excel (OLE), MS Excel

(XML), XML, RTF, HTML, TEXT, CSV, BMP,

JPEG, TIFF, GIF.

Control SMS commands and preset

events enables sending of vehicle location

coordinates and various notication

messages to an ordinary cell phone of GSM

standard by means of SMS messages.

Furthermore, SMS commands can be used

to congure AutoGRAPH-GSM+ tracker

directly from a cell phone or a PDA.

i

NOTE

It should be noted that this brief description covers just one of the simple operation schemes of the

vehicle tracking system based on AutoGRAPH-GSM hardware and software. The device has a range

of customizations available to tailor the product to the users’ needs.

i

NOTE

There are various third-party software solutions that can be interfaced with the AutoGRAPH-GSM,

which may support some specic functionality.

i

NOTE

To obtain detailed information on the implementation of particular features for customization

of the monitoring system in accordance with your needs, please contact your regional authorized

representative of TechnoKom and the manufacturer’s technical support service.

Page 25

AutoGRAPH-GSM • USER MANUAL

25

TechnoKom © 2015

Connection of AutoGRAPH-GSM

controller

This section covers connection procedures of AutoGRAPH-GSM/GSM+ controllers:

• Installation of a SIM card

• Installation of an microSD card

• Connection of a GPS/GLONASS antenna

• Connection of a GSM antenna

• Power supply connection

• Digital inputs connection

• Analogue inputs connection

• Outputs connection

• 1-Wire connection

• RS-485 bus (TIA / EIA-485-A) connection

• RS-232 bus connection

• CAN bus (SAE J1939 / FMS) connection

To make the device ready for the simplest operation scheme it would be sufcient just to

install a SIM card, GPS/GLONASS and GSM antennas, and to connect a device to a power

supply source.

However, the hardware and software of AutoGRAPH-GSM controllers includes an extensive

range of features and capabilities, which allow for easy conguration, customization and

adaptation of the system to the needs of the user.

Application of digital and analogue inputs, outputs and data buses enables permanent

monitoring of various parameters (for example, fuel consumption and fuel level), as well as

to monitor operating conditions and performance of external equipment and devices and to

promptly respond to various events (for example, to the pushing of an alarm button). The

output of the controller enables the device to control various actuators and warning devices.

An external backup battery enables the controller to operate even when the main power fails.

All of these features allow the creation of diverse variants of the system able to perform

monitoring of a great number of parameters and to respond to various events.

The following sections focus on basic connection diagrams of various interfaces, inputs and

outputs of the AutoGRAPH-GSM controller.

Page 26

AutoGRAPH-GSM • USER MANUAL

26

TechnoKom © 2015

Installation of SIM Card

The AutoGRAPH-GSM controller is equipped with a dual SIM holder.

To insert SIM cards:

• Unscrew the four fastening screws and remove the back cover of the tracker.

• Insert a SIM card in the lower retaining slot of the SIM card holder with the card’s contacts

facing the PCB (see g.1). Be sure that the card’s keying matches the key on the PCB (see

g.2).

• If necessary, insert a second SIM card in the upper retaining slot of the SIM card holder

with the card’s contacts facing the PCB (see g.3). Be sure that the SIM card is inserted into

the retaining slot with its cut angle facing the edge of the printed circuit board (see g.4).

• When the SIM cards are connected place the back cover back and tighten the four

fastening screws.

The SIM card installed in the lower retaining slot of the SIM card holder is the main card.

When switched on, the AutoGRAPH-GSM controller will operate with this SIM card. The SIM

card installed in the upper retaining slot of the SIM card holder is the backup card. The tracker

will switch to the backup SIM card when the main card is unavailable (disabled, damaged or

not inserted).

For proper operation it is quite sufcient to insert the main SIM card into the tracker. But the

backup card provides the appropriate operation of the controller even if the main SIM card is

damaged. Due to this the controller will stay connected and be able to transfer data full time.

Do a test of a new SIM card in a cell phone before you install it into the controller. This ensures that

GPRS / SMS / USSD services are enabled and operate properly, the PIN code matches the code preset in

the controller (in order to prevent locking), and a personal account associated with the SIM card has

the sucient balance for successful operation of the services.

IMPORTANT

Page 27

AutoGRAPH-GSM • USER MANUAL

27

TechnoKom © 2015

Installation of MicroSD Card

The AutoGRAPH-GSM controller is equipped with a microSD card slot located on the upper

side of the PCB. The microSD card is used to store photos from cameras connected to the

tracker. The tracker supports operation with microSD cards with maximum capacity of 32GB.

To insert microSD card:

• Unscrew the four fastening screws and remove the back cover of the tracker.

• Insert a microSD card in the slot with the card’s contacts facing the PCB (see g.1).

• When the microSD card is inserted, place the back cover back and tighten the four

fastening screws.

To remove the microSD card, gently push the card’s external edge and release it. Then

remove the card.

Page 28

AutoGRAPH-GSM • USER MANUAL

28

TechnoKom © 2015

Connection of GPS/GLONASS

Antenna

The controller is supplied with magnetic mounted waterproof, active GPS/GLONASS antenna.

The GPS/GLONASS antenna is connected to the connector in the lower-right part of the

AutoGRAPH-GSM controller.

The position of the GPS/GLONASS antenna is critical to goof performance of the GPS

receiver, therefore it is highly recommended to plan the antenna’s position on a vehicle before

installation.

The antenna should be located in an open area, which shall ensure free GPS signal

transmission; its active surface should face the sky and be parallel to the celestial sphere.

Possible variants are illustrated in the picture below:

1. The recommended position for

GPS/GLONASS antenna location

2. A possible position for GPS/

GLONASS antenna location

3. Un-recommended position for

GPS/ GLONASS antenna location

When locating the antenna make allowance for the length of its cable. When laying the cable, avoid

sharp edges. Cable bend radius should be at least 10 cable diameters (about 3…5 cm).

Do not x antenna before you make settings and congure your system, it is highly recommended

to determine its nal position and install only when you are absolutely sure that the system is

congured and operates properly.

Do not splice or cut the antenna cable.

i

NOTE

IMPORTANT

Page 29

AutoGRAPH-GSM • USER MANUAL

29

TechnoKom © 2015

Connection of GSM Antenna

The AutoGRAPH-GSM controllers are supplied with a at GSM antenna. The antenna has an

adhesive coating for it to be stuck to the window.

The GSM antenna is connected to the connector in the lower-left part of the controller.

The position of the GSM antenna is critical to good performance of the GSM and GPRS

communication; therefore it is highly recommended to plan the antenna’s position on a vehicle

before installation.

The antenna should be located in an open area, which shall ensure free GSM signal

transmission.

Wipe the window surface with the cloth supplied with the antenna before you attach the

GSM antenna. If antenna is supplied without a cloth, clean the window surface with any cloth

damped with alcohol-based liquid before sticking the antenna.

When locating the antenna make allowance for the length of its cable. When laying the cable, avoid

sharp edges. Cable bend radius should be at least 10 cable diameters (about 3-5 cm).

Do not x antenna before you make settings and congure your system, it is highly recommended

to determine its nal position and install only when you are absolutely sure that the system is

congured and operates properly.

i

NOTE

Do not splice or cut the antenna cable.

In order to avoid cross-talk eects place the GSM and GPS/GLONASS antennas at least 50 cm away from

each other.

IMPORTANT

IMPORTANT

Page 30

AutoGRAPH-GSM • USER MANUAL

30

TechnoKom © 2015

Power Supply

Connection

The AutoGRAPH-GSM controller is

connected to the power supply source

through the interface cable supplied with the

device. The device is supplied with a fuse

intended to provide a short circuit protection

of power supply. The fuse holder is installed

on a wire ring, which should be cut before

operation.

When making connections, pay special

attention to the safety rules stipulated by

the regulations for motor vehicle repair

procedures. All connections should be

properly isolated and securely connected. If

the wire is too short, it can be spliced with

a wire of at least 0.5 mm2 cross section (20

AWG or thicker).

The power supply input of the controller

is rated for the vehicle system operating

voltage of 10-50 V DC.

Power can be fed to the controller either

before or after the vehicle’s battery

disconnect switch:

DISCONNECTING

SWITCH

BLACK (2)

RED (1)

DISCONNECTING

SWITCH

RED (1) BLACK (2)

Power connection before the vehicle battery

disconnect switch

Power connection after the vehicle batter y

disconnect switch

The fuse should be placed as close as possible to the point where the AutoGRAPH-GSM is

connected to the vehicle power system.

ВНИМАНИЕ

If power is connected before the vehicle battery disconnect switch, the controller shall always

be ON, therefore, it is highly recommended to use adaptive position recording for this case so

as to minimize an amount of data to be transferred, as well as to reduce GPRS and web trac.

IMPORTANT

Page 31

AutoGRAPH-GSM • USER MANUAL

31

TechnoKom © 2015

Backup Power

Supply Connection

To avoid the tracker turning off, if the main power supply shuts down, the power supply driver

supports connection of a backup power supply.

Switching between the main power supply and the backup power supply is performed

automatically. If the main power supply turns off, the tracker switches to the backup power

supply. As soon as the main power supply is restored, the controller will switch back to the

main power supply.

The tracker can be setup to send a low voltage notication via SMS to a preset telephone

number, if the backup supply voltage falls below 11 V.

It should be note, that the AutoGRAPH-GSM is not equipped with the battery charger.

Backup Power Connection Diagram:

Page 32

AutoGRAPH-GSM • USER MANUAL

32

TechnoKom © 2015

Connection of Digital Inputs 1...4

(active low)

The AutoGRAPH-GSM controller has four active low digital inputs: two inputs - on primary

interface connector (pin 3, pin 7), two inputs – on additional 4-pin interface connector (pin 9,

pin 11).

Active low digital input has two states:

logical «1» , when the input is connected to the supply voltage or open-circuit.

logical «0» , when the input connected to the ground. This state is considered to be active.

The input is able to show change of the input state, count pulses and measure frequency

and is intended for connection to various dry contact sensors. Ensure that the sensors are

in good order and able to maintain reliable operation. The manufacturer shall not bear any

responsibility for correct state recording of these sensors (chatter, loss of contact and etc.).

It should be noted that all voltage levels of active low digital inputs under 5 V shall be considered to

be logical ‘0’, while all voltage levels above 6 V shall be considered to be logical «1» . If the input is

disconnected it shall denote logical «1» .

It is convenient to connect the active low digital input to an emergency oil pressure relief sensor to

control the engine performance. In this case, the AutoGRAPH dispatch software shall enable metering

of engine hours and application of various lters related to the engine’s operating time. For example,

«Skip the coordinates» lter when the engine is shut down reduces trac and lters coordinate drift

at stops when the engine is not running.

i

NOTE

i

NOTE

Internal Connection Diagram of Active Low Digital Input

Internal connection diagram of the active low digital input is shown in the picture below:

External Connection Diagram of Active Low Digital Input

The external connection diagram for the active low digital input can vary depending on the

position of the vehicle battery disconnect switch in the circuit (see Power Supply Connection

diagrams).

AutoGRAPH-GSM

DIGITAL INPUT

(active low)

LIMIT SWITCH

or SENSOR

Page 33

AutoGRAPH-GSM • USER MANUAL

33

TechnoKom © 2015

RED (1) BLACK (2)

INPUT 1 - YELLOW (3)

INPUT 2 - WHITE (7)

INPUT 4 - BLUE with WHITE STRIPE (13)

INPUT 3 - BLUE (10)

LIMIT SWITCH

or SENSOR

INPUT 1 - YELLOW (3)

INPUT 2 - WHITE (7)

RED (1)

BLACK (2)

LIMIT SWITCH

or SENSOR

INPUT 4 - BLUE with WHITE STRIPE (13)

INPUT 3 - BLUE (10)

DISCONNECTING

SWITCH

DISCONNECTING

SWITCH

Connection Diagram for Active Low Digital Input

«Before Disconnect Switch» Option:

Connection Diagram for Active Low Digital Input «After

Disconnect Switch» Option:

This is due to the fact that when the sensors are connected to the vehicle body (after vehicle

battery disconnect switch option), and the disconnect switch opens; the tracker will not be

able to record sensor states on the digital input 1 correctly.

Page 34

AutoGRAPH-GSM • USER MANUAL

34

TechnoKom © 2015

RELAY or OTHER

INDUCTIVE LOAD

RELAY or OTHER

INDUCTIVE LOAD

INPUT 2 - WHITE (7)

LIMIT SWITCH,

SENSOR or BUTTON

LIMIT SWITCH,

SENSOR or BUTTON

SAFETY RELAY

PROTECTIVE DIODE

+V +V

Connection Diagram for Active Low Digital Input

Inductive Load Circuit:

Sometimes, it is necessary to integrate the controller’s digital input into a circuit with an

inductive load, such as a relay winding, solenoid valve or any other device that has an

inductance coil.

When an inductive load is being disconnected, stored current must be dissipated, this causes

a self-induced electromotive force of inversed polarity (back EMF) that may damage the

controller.

To prevent this, use one of the following protection options if an inductive load is being applied

to the controller:

1. Protective diode (g. 1) – to be installed in parallel to the inductive load. In this case,

forward current of the protective diode (Ifw) should be at least 1.5 • I

holding, coil

. If the coil

holding current is unknown or uncertain, use the option with safety relay protection.

2. Safety relay (g. 2) – to be installed in parallel to the inductive load. In this case, the

safety relay contacts are used for closing the controller’s input on ground.

Fig. 1.

Fig .2.

You may use following protective diodes: KD212, KD116-1 or similar.

Use may use safety relays designed for switching of direct current circuits with voltage

rating compatible with the vehicle system voltage. For example, relays of 901.3747 type

manufactured by AVAR, AO, (www.ellink.ru/co/avar) for a vehicle system voltage of 24 V.

i

NOTE

i

NOTE

Page 35

AutoGRAPH-GSM • USER MANUAL

35

TechnoKom © 2015

Connection of Digital Inputs 7...8

(active high)

AutoGRAPH-GSM controllers have two active high digital inputs, arranged on additional

6-pin CAN/ RS-485 interface connector (pin 14, pin 17).

Active high digital input has two states:

logical «1» , when the input is powered by supply voltage. This state is considered to be

active.

logical «0» , when the input is connected to the ground or open-circuit.

The input is able to show change of the input state, count pulses and measure frequency

and is intended for connection to various dry contact sensors. Ensure that the sensors are

in good order and able to maintain reliable operation. The manufacturer shall not bear any

responsibility for correct state recording of these sensors (chatter, loss of contact and etc.).

Internal Connection Diagram of Active High Digital Input

External Connection Diagram of Active High Input

It should be noted that all voltage levels of digital inputs on «+» under 5 V will be considered to

be logical zero (‘ground’), while all voltage levels above 6 V shall be considered to be logical «1»

(‘+’). If the input is open-circuit it shall denote logical «0» .

i

NOTE

AutoGRAPH-GSM

DIGITAL INPUT

(active high)

LIMIT SWITCH

or SENSOR

+V

LIMIT SWITCH

or SENSOR

+V

+V

INPUT 8 - RED with WHITE STRIPE (19)

INPUT 7 - BLACK with WHITE STRIPE (16)

Page 36

AutoGRAPH-GSM • USER MANUAL

36

TechnoKom © 2015

Connection Diagram for Active High Digital Input Inductive Load

Circuit:

Sometimes, it is necessary to integrate the controller’s digital input into a circuit with

an inductive load such as a relay winding, solenoid valve or any other device, which has

inductance coil.

When an inductive load is being disconnected, stored current must be dissipated, this causes

a self-induced electromotive force of inversed polarity (back EMF) that may damage the

controller.

To prevent such breakdown, use one of the following protection options, if an inductive load

is being applied to the tracker:

1. Protective diode (g. 1) – to be installed in parallel to the inductive load. In this case,

forward current of the protective diode (Ifw) should be at least 1.5 • I

holding, coil

. If the coil

holding current is unknown or uncertain, use the option with safety relay protection.

2. Safety relay (g. 2) – to be installed in parallel to inductive load. In this case, the

safety relay contacts are used for closing the controller’s input on supply voltage.

SAFETY RELAY

PROTECTIVE DIODE

RELAY or OTHER

INDUCTIVE LOAD

+V +V

RELAY or OTHER

INDUCTIVE LOAD

LIMIT SWITCH,

SENSOR or BUTTON

LIMIT SWITCH,

SENSOR or BUTTON

INPUT 8 - RED

with WHITE STRIPE (19)

INPUT 8 - RED with WHITE STRIPE (19)

Fig 1.

Fig 2.

You may use following protective diodes: KD212, KD116-1 or similar.

Use may use safety relays designed for switching of direct current circuits with voltage rating

compatible with the vehicle system voltage. For example, relays of 901.3747 type manufactured by

AVAR, AO, (www.ellink.ru/co/avar) for a vehicle system voltage of 24 V.

i

NOTE

i

NOTE

Page 37

AutoGRAPH-GSM • USER MANUAL

37

TechnoKom © 2015

Connection of Analogue Inputs

The AutoGRAPH-GSM controller has two 10-bit analogue inputs: pin 4 and pin 8 on the

primary interface connector. The analogue inputs allow measurement of voltage levels from

devices with an analogue voltage level output, i.e. signals from an analogue fuel level sensor.

The measuring range of the rst analogue input (pin 4) is 0 to 10 V which is converted to a

gure between 0-1023.

The measuring range of the second analogue input (pin 8) is 0 to 24 V (but not more than

supply voltage) which is converted to a gure between 0-1023.

The input resistance of the analogue inputs is 1 mega-ohm (1MΩ).

The analogue readings are smoothed using the moving average method with a congurable

averaging window.

The cut-off frequency of the input low-pass lter is 1600 Hz.

The analogue inputs of the controller can be used as active high digital inputs with a

congurable switching threshold: analogue input 1 can be set up as digital input 5; analogue

input 2 can be set up as digital input 6. The operational properties of the analogue inputs can

be specied using the GSMConf conguration program or remotely, using the control SMS

commands.

When the analogue input is used as a digital input, it is considered to be open-circuit in the

case of a logical «0» and a voltage below 6 V. In digital mode, the input operates both as

digital input and as analogue input. Along with the current logical state, voltage level on the

input is measured and recorded into the FLASH memory at the specied intervals.

The maximum frequency of the impulse signal on an analogue input in Pulse Counter mode

is 500 Hz.

Connection Diagrams of analogue inputs in digital mode is given in «Connection of Digital

Inputs 7..8 (active high)» section.

Internal Functional Diagram of Analogue Inputs:

10-BIT

ADC

AutoGRAPH-GSM

ANALOGUE INPUT

It is highly recommended to connect analogue inputs to –Vin line, if the inputs are not used.

IMPORTANT

Page 38

AutoGRAPH-GSM • USER MANUAL

38

TechnoKom © 2015

External Connection Diagram of Analogue Inputs:

ANALOGUE INPUT 2 (0..24V) - BROWN (8)

ANALOGUE INPUT 1 (0..10V) - GREEN (4)

BLACK (2)

ANALOGUE

SENSORS

+V +V

ANALOGUE INPUT 2 (0..24V) - BROWN (8)

ANALOGUE INPUT 1 (0..10V) - GREEN (4)

BLACK (2)

ANALOGUE

SENSORS

RELAY

+V+V

VEHICLE SYSTEM VOLTAGE (+)

IMPORTANT

Most analogue sensors are connected to the –Vin line of the vehicle power system. So, if the –Vin

line is disconnected (e.g., by a disconnecting switch), the state of the analogue input will be

undened and analogue readings will not be considered to be valid. Therefore, if the tracker is

connected to the vehicle power system via a disconnecting switch, it is highly recommended to

connect the analogue sensors via a relay.

It is recommended to use a relay intended to switch dc circuits and with operating voltage

equal to voltage of vehicle power system. For example, 901.3747 relay, designed by AVAR Corp.

(www.ellink.ru/co/avar) for 24 V vehicle network.

i

NOTE

Page 39

AutoGRAPH-GSM • USER MANUAL

39

TechnoKom © 2015

Connection of High-impedance Digital

Input

The AutoGRAPH-GSM+ controller has one high-impedance input (pin 26 on the 6-pin

RS-232 / RS-485 interface connector).

It is a high-impedance active high digital input intended to connect a device with a voltage

output to the tracker.

The high-impedance input has two states:

logical “1” – when input voltage is greater than 7 V;

logical “0” – when input voltage is lower than 3 V.

If the high-impedance input is open-circuit it shall denote logical “0”.

Internal Diagram of High-impedance Input:

AutoGRAPH-GSM+ controller

The input resistance of the high-impedance input is 1 mega-ohm (1MΩ).

The cut-off frequency of the input low-pass lter is 5,000 Hz.

Internal Diagram of High-impedance Input:

HIGH-IMPEDANCE INPUT - PINK (26)

Digital voltage

output sensor

+ U sensor

power supply

Page 40

AutoGRAPH-GSM • USER MANUAL

40

TechnoKom © 2015

Connection of Outputs

Internal Diagram of Outputs

External Connection Diagram of Digital Outputs:

The AutoGRAPH-GSM has two open collector digital outputs: the rst output is arranged

on the primary interface connector (pin 6), the second is arranged on the additional 4-pin

interface connector (pin 10).

The outputs are intended to control various external actuators, as well as to activate warning

devices

Minimum recommended load current is 10 mA.

Maximum load current should not exceed 500 mA.

AutoGRAPH-GSM

DIGITAL OUTPUT

The following is an example of a LED and relay connected to the controller output. To

avoid damage of the controller output due to back EMF, induced from disconnecting an

inductive load, connect a protective diode in parallel to the relay. To select a correct diode

make sure that direct current of this protective diode is at least 1.5 times greater than the

relay holding current.

OUTPUT 2 - ORANGE (11)

RELAY

VEHICLE SYSTEM VOLTAGE (+)

OUTPUT 1 - GRAY (6)

TO ACTUATOR

RED (1)

LED

PROTECTIVE DIODE

R

1кОhm*

* Use R = 1 … 2 kОhm, if supply voltage is 24 V.

Use R = 500 Ом … 1 kOhm, if supply voltage is 12 V.

Page 41

AutoGRAPH-GSM • USER MANUAL

41

TechnoKom © 2015

1-Wire

The AutoGRAPH-GSM controller are equipped with a 1-Wire bus intended to connect a touch

memory iButton reader and up to 8 temperature sensors, designed by TechnoKom Ltd. or

DS18B20 thermometers. Furthermore, proximity card readers compatible with the iButton

protocol can be connected to the controller via the 1-Wire bus. This provides supervising

drivers and identication of other staff using individual cards and keys.

Connection Diagram of Touch Memory iButton readers:

Connection of Temperature Sensors Designed by TechnoKom Ltd.:

DATA

GROUND

BLACK (2)

1-WIRE - PINK (14)

BLACK (2)

1-WIRE - PINK (14)

1-Wire data

+V sensor+V sensor

1-Wire data1-Wire data

SENS 1

SENS 2

SENS 8

For detailed information on operation and conguration of the controller for interaction

with the touch memory iButton reader and the temperature sensors via 1-Wire bus see

«1-Wire temperature sensors» document.

i

NOTE

Page 42

AutoGRAPH-GSM • USER MANUAL

42

TechnoKom © 2015

The AutoGRAPH-GSM controller is equipped with an RS-232 (EIA/TIA-232-E) bus.

RS-232 is bi-directional serial data transmission interface between a transceiver and

peripheral devices. The main advantages of the RS-232 interface are reliability, and exibility

of implementation.

RS-232 Serial Connector Pin

Assignment (DE-9):

RS-232 (EIA/TIA-232-E)

Connection Diagram:

1 DCD Not used

2 RxD Receive Data

3 TxD Transmit Data

4 DTR Not used

5 GND System Ground

6 DSR Not used

7 RTS Not used

8 CTS Not used

9 RI Not used

RS-232 «RxD» (24)

ORANGE with GREEN STRIPE

RS-232 «TxD» (21)

BROWN with BLUE STRIPE

The AutoGRAPH-GSM controller supports

interaction with following devices via RS-232

Bus:

1. AutoGRAPH-NAVIGATOR – is a

software-based vehicle tracking system

running on a laptop and designed by

TechnoKom Ltd. When connected to the

controller, the AutoGRAPH-NAVIGATOR

is capable of displaying current position

of the vehicle on a map, monitor of

movement parameters and routing.

Using the AutoGRAPH-Navigator, a

dispatcher can send a list of tasks to a

driver and monitor progress of the tasks.

In addition, the device is capable of

message handling between the driver

and the dispatcher. The AutoGRAPHNAVIGATOR is supplied with a special

connector for connecting to the controller.

2. CAN-LOG 2 (CAN-LOG) – is a device

intended for connecting to the vehicle

CAN Bus, scanning data and transferring

it to another device connected to the

CAN-LOG via RS-232. The CAN-LOG

2 supports many CAN protocols. When

connected to the controller, the CAN-LOG

is capable of reading data from the CAN

bus and transferring it to the controller,

even if the CAN protocol is not known in

advance. The data from the CAN-LOG 2

is transferred in text format.

3. External GPS / GLONASS receiver

with NMEA 0183 standard - is a high-

precision receiver, which allows to acquire

asset position with high accuracy.

RS-232 (EIA / TIA-232-E)

Page 43

AutoGRAPH-GSM • USER MANUAL

43

TechnoKom © 2015

Before connecting any device to the tracker, the RS-232 interface mode must be specied in

the controller. The customer can set this using the GSMConf conguration program or control

commands via SMS or the server.

Connection of CAN-LOG 2 to the controller

Designed by TechnoKom Ltd.:

The following is an example of connection the CAN-LOG 2 module to the tracker. This device

is powered by P145_20 controllers, designed by Farvater Ltd. .

RS-232 «RxD» (24)

ORANGE with GREEN STRIPE

VEHICLE SYSTEM VOLTAGE (+)

CAN-LOG 2

VEHICLE SYSTEM VOLTAGE (+)

RED (1)

BLACK (2)

RS-232 «TxD» (21)

BROWN with BLUE STRIPE

Page 44

AutoGRAPH-GSM • USER MANUAL

44

TechnoKom © 2015

RS-485 (TIA / EIA-485-A)

General Block Diagram of Connection of External Devices

to RS-485 Bus:

The AutoGRAPH-GSM controller is equipped with two RS-485 (TIA/EIA-485-A) interfaces.

RS-485 is one of the most commonly used industrial standards of communication. A network

based on an RS-485 interface consists of transceivers connected with twisted pair wires. All

devices are connected to one twisted pair in the same manner: non-inverting outputs (A) to

one wire and inverting outputs (B) to another wire.

The controller allows up to 16 devices to be connected simultaneously to one RS-485

bus. There are many sensors, interfaces and expansion modules that are compatible with

the tracker’s rmware. Amongst such devices are: fuel level sensors (up to 8 sensors

simultaneously), passenger trafc metering system, input expander, display for messaging

with a vehicle driver, AutoGRAPH-CR device, temperature sensors which support MODBUS

protocol, etc.

The additional RS-485-2 bus is intended for connecting photo cameras to the controller.

Interaction with photo cameras is supported by controllers equipped with additional memory.

The AutoGRAPH-GSM stores photos in an external microSD card.

RS-485-1 «A» (20)

ORANGE with WHITE STRIPE

RS-485-1 «B» (17)

BROWN with WHITE STRIPE

DEVICE (N) DEVICE (2) DEVICE (1)

RS-485-2 «A» (25)

ORANGE with WHITE STRIPE

RS-485-2 «B» (22)

BROWN with WHITE STRIPE

CAMERA (N)CAMERA (2)CAMERA (1)

RS-485-1

RS-485-2

Page 45

AutoGRAPH-GSM • USER MANUAL

45

TechnoKom © 2015

Before making any connections study the manuals for fuel level sensors supplied by the sensor

manufacturers. Pay attention to the supply voltage range of the sensors and peculiarities of

their conguration. Some sensors require external supply voltage stabilization. If you have

any doubts on making connections or conguration, consult the representative of the sensor

manufacturer or your regional TechnoKom dealer.

IMPORTANT

Connection of Fuel Level Sensors to RS-485 Bus

+V sensor +V sensor +V sensor

RS-485-1 «B» (17)

BROWN with WHITE STRIPE

RS-485-1 «A» (20)

ORANGE with WHITE STRIPE

Currently, the AutoGRAPH-GSM controller supports interaction with any fuel level sensors

with an RS-485 interface which use LLS protocol. The following is an example of connection

the TKLS fuel level sensors, designed by TechnoKom Ltd, to the tracker.

RS-485 Bus of the controller has to be customized to interact with fuel level sensors. It can be