Technogym Run Excite 500, Run Excite 700, Run Excite 700E, Run Excite 900, Run Excite 900E Service Maintenance Manual

S

ERVICE

&

MAINTENANCE MANUAL

REV. 1.5

The information contained in this manual is intended for QUALIFIED TECHNICIANS who have

completed a specific TECHNOGYM training course and are authorized to perform machine start-

up and adjustment procedures as well as extraordinary maintenance or repairs which require a

thorough knowledge of the machine, its operation, its safety devices and working procedures.

CAREFULLY READ THE INFORMATION CONTAINED IN

THIS MANUAL BEFORE PERFORMING ANY MAINTENANCE

PROCEDURES ON THE MACHINE

DANGEROUS VOLTAGES

PRESENT

NOTE

The information contained in this document is subject to change without notice.

Technogym does not guarantee this documentation in any way. Technogym shall not be held

responsible for any errors contained in this manual and declines all liability for accidents or

damages resulting from the supply, characteristics or use of this manual.

This document contains proprietary information that is protected by copyright. All rights reserved.

No part of this document may be photocopied,

without the prior written consent of Technogym.

The Technogym™ trademark is property of Technogym S.p.A.

The Run Excite™ trademark is property of Technogym S.p.A.

reproduced or translated into another language

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

Contents

1. GENERAL NOTICES...........................................................................................................................................1.1

1.1. I

1.2. R

1.3. G

2. TECHNICAL CHARACTERISTICS..................................................................................................................2.1

2.1. A

2.2. M

2.3. E

2.4. C

2.5. A

2.6. P

2.7. W

2.8. W

NTRODUCTION

ECOMMENDATIONS

ENERAL RULES FOR REPAIR PROCEDURES

VAILABLE VERSIONS

ECHANICAL CHARACTERISTICS

LECTRICAL CHARACTERISTICS

ONFORMITY REGULATIONS

MBIENT SPECIFICATIONS

RODUCT CODES

IRING DIAGRAM

2.7.1. 900 model ....................................................................................................................................... 2.5

2.7.2. 700 model ....................................................................................................................................... 2.9

2.7.3. 500 model ..................................................................................................................................... 2.13

IRING

........................................................................................................................................................ 2.16

.............................................................................................................................................. 1.1

..................................................................................................................................... 1.1

.................................................................................................... 1.2

................................................................................................................................... 2.1

................................................................................................................... 2.1

..................................................................................................................... 2.2

.......................................................................................................................... 2.2

............................................................................................................................. 2.3

............................................................................................................................................ 2.3

.......................................................................................................................................... 2.5

2.7.1.1. EU 220 VAC lower assembly.....................................................................................................................................2.5

2.7.1.2. UL 220 VAC lower assembly.....................................................................................................................................2.6

2.7.1.3. UL 110 VAC lower assembly.....................................................................................................................................2.6

2.7.1.4. Upper assembly: LED version ....................................................................................................................................2.7

2.7.1.5. Upper assembly: Wellness TV version.......................................................................................................................2.8

2.7.2.1. EU 220 VAC lower assembly.....................................................................................................................................2.9

2.7.2.2. UL 220 VAC lower assembly...................................................................................................................................2.10

2.7.2.3. UL 110 VAC Lower assembly..................................................................................................................................2.10

2.7.2.4. Upper assembly, LED version ..................................................................................................................................2.11

2.7.2.5. Upper assembly: Wellness TV version.....................................................................................................................2.12

2.7.3.1. EU 220 VAC lower assembly...................................................................................................................................2.13

2.7.3.2. UL 220 VAC lower assembly...................................................................................................................................2.14

2.7.3.3. UL 110 VAC Lower assembly..................................................................................................................................2.14

2.7.3.4. Upper assembly, LED version ..................................................................................................................................2.15

3. PRINCIPLES OF OPERATION..........................................................................................................................3.1

3.1. B

3.2. T

LOCK DIAGRAM

3.1.1. Display boards................................................................................................................................3.1

3.1.1.1. 500 LED model ...........................................................................................................................................................3.1

3.1.1.2. 700 / 900 LED models ................................................................................................................................................3.2

3.1.1.3. 700E / 900E models (Wellness TV )...........................................................................................................................3.4

3.1.2. CSafe Board....................................................................................................................................3.6

3.1.3. TGS/Smart Card Board..................................................................................................................3.6

3.1.4. Hand sensor Board.........................................................................................................................3.6

3.1.5. Cardio receiver............................................................................................................................... 3.6

3.1.6. Joystick ........................................................................................................................................... 3.7

3.1.7. Emergency Switch...........................................................................................................................3.7

3.1.8. Relay............................................................................................................................................... 3.7

3.1.9. Inverter ........................................................................................................................................... 3.7

3.1.10. Belt motor.......................................................................................................................................3.8

3.1.11. Power supply Board ....................................................................................................................... 3.8

3.1.12. Download Board ............................................................................................................................3.8

3.1.13. Elevation + Cut-out Board.............................................................................................................3.9

3.1.14. Elevation motor ............................................................................................................................3.11

3.1.15. Autotransformer............................................................................................................................3.11

3.1.16. Limit switch...................................................................................................................................3.11

READ BELT MOTOR DRIVE

3.2.1. Mechanics.....................................................................................................................................3.12

3.2.2. Controls........................................................................................................................................3.12

........................................................................................................................................... 3.1

.......................................................................................................................... 3.12

Page i

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

3.2.3. The signals involved ..................................................................................................................... 3.13

3.3. E

3.4. E

LEVATION MOTOR DRIVE

3.3.1. Mechanics.....................................................................................................................................3.14

3.3.2. Control..........................................................................................................................................3.14

3.3.3. The reset procedure...................................................................................................................... 3.15

3.3.4. The signals involved ..................................................................................................................... 3.15

MERGENCY STOP MANAGEMENT

3.4.1. Control..........................................................................................................................................3.17

3.4.2. The signals involved ..................................................................................................................... 3.18

........................................................................................................................... 3.14

................................................................................................................ 3.17

4. ACCESSORIES ..................................................................................................................................................... 4.1

4.1. C

4.2. PC

4.3. P

4.4. C

4.5. M

4.6. W

5. INSTALLATION INSTRUCTIONS....................................................................................................................5.1

5.1. S

5.2. S

5.3. I

5.4. F

6. TROUBLESHOOTING ........................................................................................................................................ 6.1

6.1. T

6.2. T

6.3. T

6.4. T

6.5. T

6.6. N

6.7. NO TV

6.8. T

6.9. “EMERGENCY STOP”

6.10. “THE EQUIPMENT IS BLOCKED”

6.11. T

6.12. I

ARDIO THEATER CONNECTION

LINK FOR PROGRAMMING

ROGRAMMING PLUG FOR CSAFE BOARD

ABLE FOR EXCHANGING

ONITOR PLUG FOR CSAFE PORT

ELLNESS

4.6.1. Installation procedure.................................................................................................................... 4.5

PECIFICATIONS AND REQUIREMENTS

PECIFICATIONS AND REQUIREMENTS TO INSTALL A WELLNESS

NSTALLATION

IRST POWER-ON

ROUBLESHOOTING SERVICE MENU FOR

6.1.1. Automatic Tests...............................................................................................................................6.3

6.1.2. Manual Test.................................................................................................................................... 6.5

ROUBLESHOOTING SERVICE MENU FOR

6.2.1. Automatic Tests...............................................................................................................................6.7

6.2.2. Manual Test.................................................................................................................................... 6.9

HE ENCODER DOES NOT WORK PROPERLY

HE DISPLAY FAILS TO ILLUMINATE

HE WELLNESS

O AUDIO SOUND

HE RADIO DOES NOT PLAY

HE INVERTER IS OFF

NVERTER ERROR

6.12.1. The inverter display shows OH.....................................................................................................6.36

6.12.2. The inverter display shows OC - OLi - OLm - Ot - OCH - MST.................................................. 6.37

TV

UPGRADE KIT

............................................................................................................................................... 5.2

........................................................................................................................................... 5.2

6.1.1.1. I2C Device Test...........................................................................................................................................................6.3

6.1.1.2. UpDown Test ..............................................................................................................................................................6.3

6.1.1.3. Inverter Test ................................................................................................................................................................6.4

6.1.1.4. LED Test (not on 700E and 900E models).................................................................................................................6.4

6.1.1.5. Serial Ports Test...........................................................................................................................................................6.4

6.1.1.6. Test Result...................................................................................................................................................................6.4

6.1.1.7. Reset Result.................................................................................................................................................................6.5

6.1.2.1. Man. Keyboard Test.................................................................................................................................................... 6.5

6.1.2.2. Man. Inverter Test.......................................................................................................................................................6.5

6.1.2.3. Man. UpDown Test .....................................................................................................................................................6.5

6.2.1.1. I2C Device Test...........................................................................................................................................................6.7

6.2.1.2. UpDown Test ..............................................................................................................................................................6.7

6.2.1.3. Inverter Test ................................................................................................................................................................6.7

6.2.1.4. LED Test .....................................................................................................................................................................6.8

6.2.1.5. Serial Ports Test...........................................................................................................................................................6.8

6.2.1.6. Test Result...................................................................................................................................................................6.8

6.2.1.7. Reset Result.................................................................................................................................................................6.9

6.2.2.1. Man. Keyboard Test.................................................................................................................................................... 6.9

TV

DISPLAY FAILS TO ILLUMINATE

........................................................................................................................................ 6.22

PICTURE

........................................................................................................................................... 6.23

................................................................................................................................... 6.31

......................................................................................................................................... 6.34

..................................................................................................................... 4.1

......................................................................................................................... 4.1

...................................................................................................... 4.2

TV

CHANNEL TUNING DATA BETWEEN TWO MACHINES

.................................................................................................................. 4.3

......................................................................................................................... 4.4

............................................................................................................ 5.1

TV

MACHINE

700

AND

900

MODELS

500

MODEL

..................................................................................... 6.6

.................................................................................................. 6.10

............................................................................................................. 6.11

.................................................................................... 6.16

......................................................................................................................... 6.25

MESSAGE ON THE DISPLAY

MESSAGE ON THE DISPLAY

................................................................................... 6.27

.................................................................... 6.2

.............................................................. 6.30

......................................... 4.2

.............................................. 5.1

Page ii

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

6.12.3. The inverter display shows UU.....................................................................................................6.39

6.12.4. The inverter display shows OU.....................................................................................................6.41

6.12.5. The inverter display shows EF .....................................................................................................6.42

6.12.6. The inverter display shows OLr....................................................................................................6.44

6.13. “SPEED ERROR”

6.14. T

6.15. “GRADIENT NOT WORKING”

6.16. T

6.17. T

6.18. T

6.19. T

READ BELT MOTOR IS JERKING

HE ELEVATION DOES NOT GO DOWN

HE MACHINE DOES NOT READ THE TGS/SMART CARD

HERE IS NO HEART RATE SIGNAL

6.18.1. Telemetric receiver HFU..............................................................................................................6.56

6.18.2. OwnZone telemetric receiver........................................................................................................ 6.57

6.18.3. Hand sensor.................................................................................................................................. 6.59

HE TELEMETRIC HR SIGNAL IS INCORRECT

MESSAGE ON THE DISPLAY

................................................................................................................... 6.47

MESSAGE ON THE DISPLAY

.......................................................................................................... 6.52

................................................................................................................ 6.56

................................................................................................. 6.60

............................................................................................ 6.45

..................................................................... 6.48

................................................................................ 6.54

7. DISASSEMBLY OF COMPONENTS.................................................................................................................7.1

7.1. D

7.2. D

7.3. D

7.4. D

7.5. D

7.6. D

7.7. D

7.8. D

7.9. D

7.10. D

7.11. D

7.12. D

7.13. D

7.14. D

7.15. D

7.16. D

7.17. D

7.18. D

7.19. D

ISASSEMBLING THE DISPLAY

ISASSEMBLING THE CIRCUIT BOARDS OF THE DISPLAY

7.2.1. 700 / 900 LED versions..................................................................................................................7.2

7.2.2. 700E / 900E Wellness TV versions................................................................................................. 7.4

7.2.3. 500 LED version.............................................................................................................................7.7

ISASSEMBLING THE HAND SENSOR BOARD AND THE CSAFE BOARD

ISASSEMBLING THE KEYBOARD

7.4.1. 700 / 900 LED versions................................................................................................................7.10

7.4.2. 700E / 900E Wellness TV versions............................................................................................... 7.11

7.4.3. 500 LED version...........................................................................................................................7.13

ISASSEMBLING THE DISPLAY FAN

ISASSEMBLING THE EMERGENCY BUTTON

ISASSEMBLING THE CARDIO RECEIVER

ISASSEMBLING THE SENSORS

ISASSEMBLING THE MOTOR GUARD

ISASSEMBLING THE MOTOR COMPARTMENT FAN AND THE LIMIT SWITCH

ISASSEMBLING THE ELECTRICAL BOX

ISASSEMBLING THE ELECTRONICS BOARDS

ISASSEMBLING THE INVERTER

ISASEMBLING THE TREAD BELT MOTOR ENCODER

7.14.1. HEDR encoder..............................................................................................................................7.25

7.14.2. ELTRA encoder.............................................................................................................................7.26

7.14.2.1. eassembling the same encoder................................................................................................................................7.27

R

7.14.2.2. Assembling a new encoder........................................................................................................................................7.27

ISASSEMBLING THE TREAD BELT MOTOR

ISASSEMBLING THE ELEVATION MOTOR

ISASSEMBLING THE TREAD BELT GROUP

ISASSEMBLING THE JOYSTICKS

ISASSEMBLING THE AUTOTRASFORMER

....................................................................................................................... 7.1

................................................................................ 7.2

............................................................. 7.8

................................................................................................................. 7.10

.............................................................................................................. 7.14

................................................................................................. 7.15

...................................................................................................... 7.16

..................................................................................................................... 7.18

........................................................................................................... 7.19

.................................................. 7.20

........................................................................................................ 7.21

............................................................................................... 7.22

................................................................................................................... 7.24

..................................................................................... 7.25

................................................................................................... 7.29

.................................................................................................... 7.30

.................................................................................................... 7.31

.................................................................................................................. 7.35

..................................................................................................... 7.37

8. ADJUSTMENTS.................................................................................................................................................... 8.1

8.1. T

8.2. T

8.3. C

8.4. H

8.5. A

8.6. P

9. MACHINE CONFIGURATION..........................................................................................................................9.1

9.1. U

ENSIONING A NEW TREAD BELT

ENSIONING A USED TREAD BELT

ENTERING THE TREAD BELT

EIGHT OF RUNNING DECK TABLE

LIGNING THE TREAD-BELT MOTOR DRIVE-BELT

OSITION OF THE LIMIT SWITCH

SER MENU CONFIGURATION FOR

9.1.1. Language........................................................................................................................................9.1

9.1.2. Change message language ............................................................................................................. 9.2

9.1.3. Distance..........................................................................................................................................9.2

................................................................................................................... 8.1

.................................................................................................................. 8.2

......................................................................................................................... 8.3

................................................................................................................. 8.5

........................................................................................... 8.6

..................................................................................................................... 8.7

700

AND

900

MODELS

.............................................................................. 9.1

Page iii

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

9.1.4. Priority setting................................................................................................................................9.2

9.1.5. Maximum exercise time .................................................................................................................. 9.3

9.1.6. Pause time ......................................................................................................................................9.3

9.1.7. Modifiable target heart rate...........................................................................................................9.3

9.1.8. Enable TGS..................................................................................................................................... 9.4

9.1.9. Enable keyboard............................................................................................................................. 9.4

9.1.10. Enable custom messages ................................................................................................................9.4

9.1.11. Edit messages .................................................................................................................................9.5

9.1.12. Enable up/down motor....................................................................................................................9.5

9.1.13. Enable multi-language mode.......................................................................................................... 9.5

9.1.14. Resetting parameters to default values........................................................................................... 9.5

9.1.15. Format P&P...................................................................................................................................9.6

9.2. U

9.3. S

SER MENU CONFIGURATION FOR

9.2.1. Language........................................................................................................................................9.7

9.2.2. Change message language ............................................................................................................. 9.8

9.2.3. Distance..........................................................................................................................................9.8

9.2.4. Maximum exercise time .................................................................................................................. 9.8

9.2.5. Pause time ......................................................................................................................................9.8

9.2.6. Default age ..................................................................................................................................... 9.9

9.2.7. Default weight.................................................................................................................................9.9

9.2.8. Default time .................................................................................................................................... 9.9

9.2.9. Default calories ............................................................................................................................9.10

9.2.10. Default distance............................................................................................................................ 9.10

9.2.11. Enable TGS................................................................................................................................... 9.10

9.2.12. Enable keyboard........................................................................................................................... 9.11

9.2.13. Modifiable target heart rate.........................................................................................................9.11

9.2.14. Enable custom messages ..............................................................................................................9.11

9.2.15. Enable up/down motor..................................................................................................................9.12

9.2.16. Resetting parameters to default values......................................................................................... 9.12

9.2.17. Format P&P.................................................................................................................................9.12

ERVICE MENU CONFIGURATION

9.3.1. Time and date...............................................................................................................................9.14

9.3.1.1. Hour........................................................................................................................................................................... 9.15

9.3.1.2. Minutes......................................................................................................................................................................9.15

9.3.1.3. Day ............................................................................................................................................................................9.15

9.3.1.4. Month ........................................................................................................................................................................9.15

9.3.1.5. Year ...........................................................................................................................................................................9.15

9.3.1.6. Set Clock ...................................................................................................................................................................9.15

9.3.2. Low kit parameter.........................................................................................................................9.15

9.3.2.1. Read from low kit......................................................................................................................................................9.16

9.3.2.2. Write to low kit..........................................................................................................................................................9.16

9.3.2.3. Default setting ...........................................................................................................................................................9.16

9.3.2.4. Table of configuration parameters............................................................................................................................9.17

9.3.3. UpDown settings...........................................................................................................................9.17

9.3.3.1. Read from low kit......................................................................................................................................................9.18

9.3.3.2. Write to low kit..........................................................................................................................................................9.18

9.3.3.3. Default setting ...........................................................................................................................................................9.18

9.3.4. Usage data.................................................................................................................................... 9.18

9.3.4.1. Read from low kit......................................................................................................................................................9.19

9.3.4.2. Write to low kit..........................................................................................................................................................9.19

9.3.4.3. Machine usage data ...................................................................................................................................................9.19

9.3.5. Errors log .....................................................................................................................................9.20

9.3.5.1. Read from low kit......................................................................................................................................................9.20

9.3.5.2. Reset errors................................................................................................................................................................ 9.21

9.3.5.3. View Errors ...............................................................................................................................................................9.21

9.3.6. Standard settings .......................................................................................................................... 9.22

9.3.7. Low kit menu.................................................................................................................................9.22

9.3.7.1. Low kit version Low kit version ...............................................................................................................................9.22

9.3.7.2. Config. registers ........................................................................................................................................................ 9.23

9.3.7.3. Config. coils ..............................................................................................................................................................9.23

9.3.8. High kit version ............................................................................................................................ 9.24

9.3.9. TV Standard.................................................................................................................................. 9.25

9.3.10. Mains voltage ...............................................................................................................................9.25

500

MODEL

............................................................................................... 9.7

.................................................................................................................. 9.13

Page iv

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

9.4. TV

9.5. R

9.6. T

9.7. P

9.8. I

MENU CONFIGURATION FOR

9.4.1. TV channel tuning.........................................................................................................................9.26

9.4.2. Wellness TV adjustments ..............................................................................................................9.28

ADIO MENU CONFIGURATION FOR

9.5.1. Radio channel tuning....................................................................................................................9.29

9.6.1. Using the TGS...............................................................................................................................9.32

9.6.2. Using the connecting cable...........................................................................................................9.32

9.7.1. Parameter editing procedure........................................................................................................9.33

9.7.2. Parameter settings........................................................................................................................9.34

NVERTER AUTOTUNING

9.5.1.1. Procedure for manually entering radio channel frequencies ....................................................................................9.30

9.5.1.2. Automatic radio channel tuning procedure...............................................................................................................9.31

RANSFERRING THE TUNING DATA

ROGRAMMING THE QUIXDRIVE

9.7.2.1. Menu D......................................................................................................................................................................9.34

9.7.2.2. Menu F ......................................................................................................................................................................9.35

9.7.2.3. Menu P ......................................................................................................................................................................9.35

9.7.2.4. Menu B ......................................................................................................................................................................9.37

9.7.2.5. Menu C ......................................................................................................................................................................9.38

............................................................................................................................... 9.39

700

AND

900 W

700E

AND

.............................................................................................................. 9.32

_V

INVERTER

............................................................................................. 9.33

ELLNESS

900E W

TV

MODELS

ELLNESS

....................................................... 9.26

TV

MODELS

............................................. 9.29

10. SCHEDULED MAINTENANCE.......................................................................................................................10.1

10.1. D

10.2. W

10.3. M

10.4. T

11. APPENDIX...........................................................................................................................................................11.1

AILY MAINTENANCE OPERATIONS

10.1.1. Setting up the operation................................................................................................................10.1

10.1.2. External cleaning operations........................................................................................................10.1

EEKLY MAINTENANCE OPERATIONS

10.2.1. Checking the “Emergency stop”..................................................................................................10.2

10.2.2. Complete operation ......................................................................................................................10.2

ONTHLY MAINTENANCE OPERATIONS

10.3.1. Internal cleaning operations ........................................................................................................ 10.3

10.3.2. Checking the state of wear............................................................................................................10.3

10.3.3. Checking and centering the tread belt.......................................................................................... 10.3

10.3.4. Checking the display..................................................................................................................... 10.3

WICE-YEARLY MAINTENANCE OPERATIONS

10.4.1. carrying out the monthly maintenance procedure........................................................................ 10.4

10.4.2. Checking the working conditions..................................................................................................10.4

10.4.3. Checking the wiring and connections........................................................................................... 10.4

10.4.4. Checking the wear and lubrication of the tread belt and running deck ....................................... 10.4

10.4.5. Checking the wear of the driving roller........................................................................................ 10.5

10.4.6. Checking the wear of the rear roller ............................................................................................ 10.5

10.4.7. Checking the shock absorbers......................................................................................................10.5

10.4.8. Checking the tread belt motor drive-belt......................................................................................10.5

10.4.9. Checking the operation of the cardiotester receiver.....................................................................10.5

10.4.10. Checking the operation of the hand sensor receiver .................................................................... 10.5

............................................................................................................. 10.1

.......................................................................................................... 10.2

....................................................................................................... 10.3

............................................................................................... 10.4

11.1. U

11.2. C

11.3. T

PDATING THE SW

OMPATIBILITY BETWEEN

11.2.1. CPU board HW version for Wellness TV.....................................................................................11.1

OOLS TO USE

....................................................................................................................................... 11.1

HW

AND

SW ..................................................................................................... 11.1

.............................................................................................................................................. 11.2

Page v

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

Page intentionally left blank

Page vi

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

1. GENERAL NOTICES

1.1. INTRODUCTION

This document is reserved for Technogym Service technicians, and is intended to provide

authorized personnel with the necessary information to correctly carry out repairs and maintenance.

A thorough knowledge of the technical information contained in this manual is essential for

completing the professional training of the operator.

In order to facilitate consultation, the paragraphs are accompanied by schematic drawings which

illustrate the procedure being described.

This manual contains notices and symbols which have a specific meanings:

WARNING: non observance may result in accident or injury.

ATTENTION: non observance may cause damage to the machine.

Information about the operation in progress.

OBSERVE: observation about the operation in progress.

1.2. RECOMMENDATIONS

Technogym recommends the following steps for planning repair procedures:

• Carefully evaluate the customer’s description of the machine malfunction and ask all the

necessary questions to clarify the symptoms of the problem.

• Clearly diagnose the causes of the problem. This manual provides the fundamental theoretical

basis, which must then be integrated by personal experience and attendance at the training

courses periodically offered by Technogym.

• Rationally plan the repair procedure so as to minimize the downtime necessary for procuring

spare parts, preparing tools, etc.

Access the component to be repaired, avoiding any unnecessary operations. In this regard it will

•

be useful to refer to the disassembly sequence described in this manual.

Page 1.1

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

1.3. GENERAL RULES FOR REPAIR PROCEDURES

1. Always mark any parts or positions which may be confused with each other at the time of

reassembly.

2. Use original Technogym spare parts and lubricants of the recommended brands.

3. Use special tools where specified.

4. Consult the Technical Newsletters, which may contain more up-to-date information on

adjustments and maintenance than those contained in this manual.

5. Before starting the repair procedure, make sure that the recommended tools are available and in

good condition.

6. For the procedures described in this manual, use only the specified tools.

OBSERVE: The tool sizes quoted in this manual are expressed in mm.

Page 1.2

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2. TECHNICAL CHARACTERISTICS

2.1. AVAILABLE VERSIONS

There machine is available in 5 versions:

• Run 500: machine with LED display

• Run 700: machine with LED display

• Run 700E: machine with Wellness TV display

• Run 900: machine with LED display

• Run 900E: machine with Wellness TV display

all of which have the same structure but are differentiated by certain features and functions.

Speed

Incline

Fast track control

Hand sensor

Motor encoder

Display fan

CSafe

Cardio receiver

HARACTERISTIC

C

Training

programs

Test functions

220 Vac

110 Vac

500 700 – 700E 900 – 900E

0.8-18 km/h

0.5-11.2 mph

0-15 % 0-15 % 0-18 %

NO NO YES

NO YES YES

NO YES YES

NO YES YES

YES YES YES

HFU (standard) Ownzone Ownzone

Quick Start

Goal

CPR

Fitness test Fitness test

V

ERSION

0.8-22 km/h

0.5-13.7 mph

0.8-16 km/h

0.5-10 mph

Quick Start

Manual

Goal

6 profiles

CPR

Weight Loss

Ownzone

0.8-25 km/h

0.5-15.5 mph

Quick Start

Manual

Goal

6 profiles

CPR

Weight Loss

Ownzone

Custom program

Fitness test

Maximal test

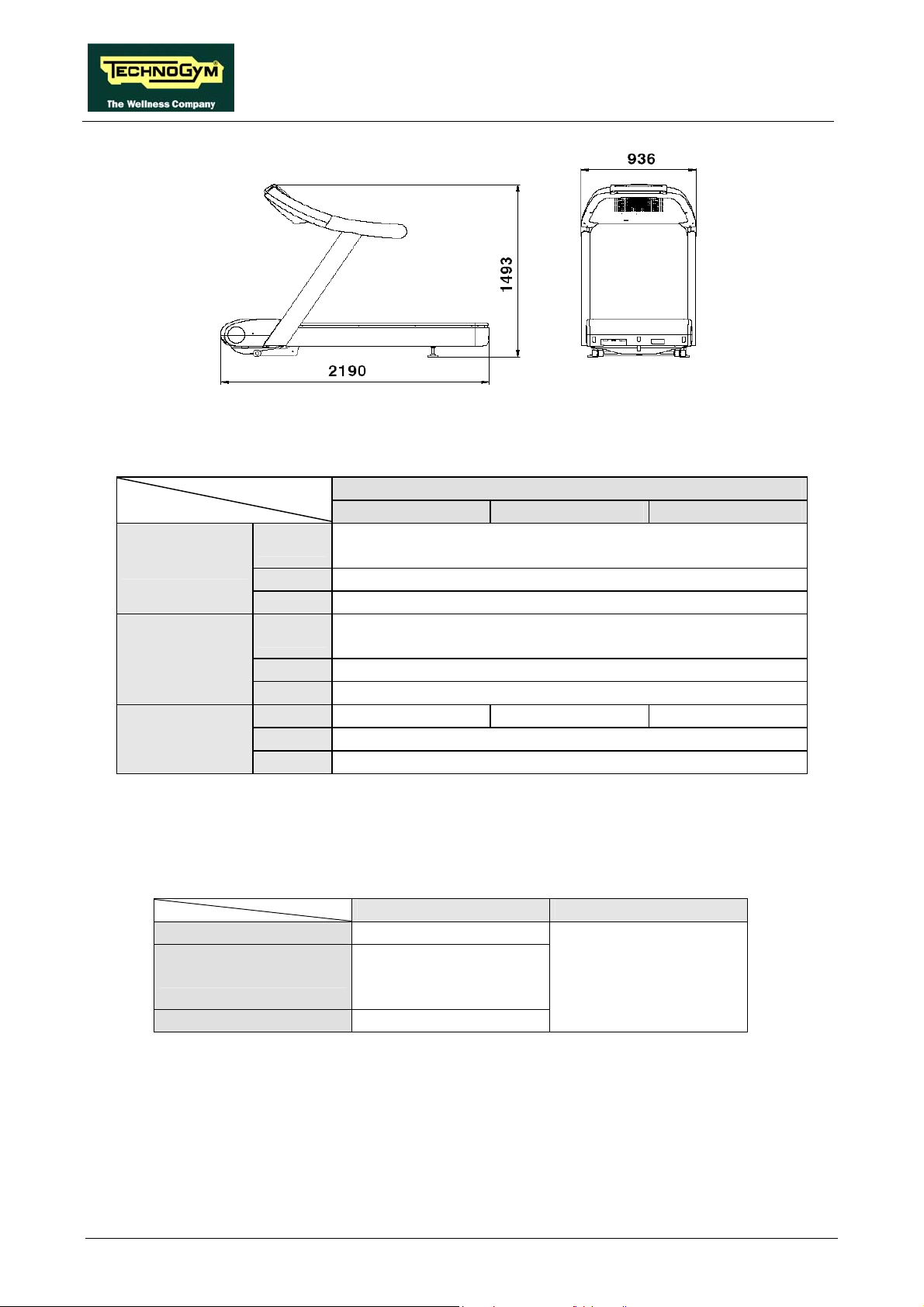

2.2. MECHANICAL CHARACTERISTICS

Width

Length

Height

Weight

93.6 cm - 36.8 in

219 cm - 86.2 in

149.3 cm - 58.8 in

194 kg - 428 lbs

Page 2.1

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.3 RI HARACTERISTIC. ELECT CAL C S

500 700 900

180-265 VAC European version

180-242 VAC US version

108-132 VAC USA - Canada version

95-105 VAC Japan version

50 - 60 Hz European version

60 Hz USA version

Mains voltage

Frequency

220 Vac

120 Vac

100 Vac

220 Vac

120 Vac

100 Vac

2300 V 3300 VA – 15 A A 2600 VA – 12 A – 10.5 A

Consumption

220 Vac

120 Vac

100 Vac

2.4. CONFORMITY REGULATIONS

: The machine conforms to the following standards

EMI

Safety

Directives

In a

ddition:

•

Risk category under 93/42/EEC : Class IIA;

• Electrical isolation class under EN60601-1: Class I;

• Applied parts: Type B (not for 500 model);

• Protection rating: IP20.

Europe USA

EN 60601-1-2

EN 60601-1

EN 957-1

SB EN 957-6 class

93/42/CEE

V

ERSION

60 Hz

50 - 60 Hz

1920VA – 16 A

2000VA – 20 A

UL 2601-1

Page 2.2

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.5. AMBIENT SPECIFICATIONS

Temperature

Humidity

Operating from 5° to 35° C

Storage from -10 to 70° C

Operating from 30% to 80% non-condensing

Storage from 5% to 85% non-condensing

2.6. PRODUCT CODES

The machine codes take into account all the possible variants and options available for the products.

The machine code, which does not include the Serial Number, consists of 16 alphanumeric

cha ters arrang

rac ed as follows:

Characters description key to values

1,2,3 Machine type: Run Excite

4 Product

5 Type of power supply

6 Type of display

7

8, 9 Color of the frame

10, 11 Color of the paddings

12 Color of the guards

13 Type of TV model

Device for downloading data used by the

Wellness System

version

D44

5 = Run 50

7 = Run 700

9 = Run 900

1 = 110 VAC

T = Wellness TV

N = not availab

= TGS

T

S = smart

L = aluminum A

00 = none

0 = none

0 = none

E = 1, 2, 5, 6,

U = 3, 4, 7, B

Where:

1 = Pal B/G

2 = Pal I

3 = Pal N

4 = NTSC M

5 = Secam E/L

6 = Secam D/K

7 = NTSC M44

8 = Pal D/K

9 = Secam B/G

A = Secam K1

B = Pal M

0

AC 2 = 220 V

display L = LED

le

card

8, 9, A

Page 2.3

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

Characters description key to values

IT = Itali

an

DE = German

FR = French

US = American English

14,15 Language

NL = Dutch

BR = Portuguese

JP = Japanese

UK = British English

ES = Spanish

I = Italy

16 Type of packaging

E = international (standard)

S = international (overseas)

0 = none

The above coding is used for the entire Excite line. For this reason, options not relevant

to the Run machine have also been included.

For example, a possible product code would be

:

D4492LTAL0000UKE

which is interpreted as follows:

D44 9 2 L 0 0 UK E

900 model

Run Excite

T AL 00

guard color

no paddings

aluminum frame color

interfaced to TGS key reader

LED display

220 VAC power supply

no TV model

standard international packing

British English language

Page 2.4

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.7. WIRING DIAGRAM

The machine consists of 2 assemblies which are connected together as illustrated below:

Patch

Conn. D

UPPER

ASSEMBLY

TRM-19TRM-20

Patch

Conn. F

Depending on the model, these 2 assemblies can have the different configurations illustrated below.

2.7.1. 900 MODEL

2.7.1.1. EU 220 VAC lower assembly

LOWER

ASSEMBLY

220

VAC

LEDs

CIRCUIT

BRAKER

TRM -02

POWER

ENTRY

SOCKET

TRM -01

Fan

24VDC

Fan

24VDC

TRM -4 4

TRM -0 3

FILTER

TRM -04

RELAY

X

A

X

1

TRM -0 5

8

-

4

6

-

2

Patch

conn. P

0

1

-

TRM -35

X

U

POWER SUPPLY

BOARD

X

V

Patch

conn. L

FE1

X

2

ELEVATION

MOTOR

TRM -08

Patch

conn. G

TRM -AZI O N

X

2

ELEVATION & CUT-OUT

R+,R-

TRM -14

TRM -1 8

V

5

TRM -42

TRM -3 8

BOARD

LIMIT

SWITCH

TRM -10

Patch

conn. M

TRM -3 6

X3

X1

X4

X

6

TRM -AZI O N

X5

X

X

A

E

L

DOWNLOAD

BOARD

X

1

BELT

MOTOR

TRM -0 6

Patch

conn. I

TRM -3 6

3

X

L

2

X

TRM -AZION

U

V

-

W

-

INVERTER

3

-

1

2

7

2

-

1

L

2

L

TRM -AZION

N

K

X

P

R

G

2

Q

A

Encoder

TRM -0 7

Patch

conn. H

A

M

2

-

P

8

LOWER

ASSEMBLY

Patch

conn. R

TRM -4 6

R

R

,

+

H

E

N

O

L

Antenna

inlet

WELLNESS TV

VERSION

TRM -1 9

Page 2.5

2.7.1.2. UL 220 VAC lower assembly

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

220

VAC

LEDs

CIRCUIT

BRAKER

TRM-02A

POWER

ENTRY

SOCKET

TRM-01

Fan

24VDC

Fan

24VDC

TRM-4 4

TRM-03A

FILTER

TRM-04

4

-

8

RELAY

2

-

6

X

A

POWER SUPPLY

X

1

Patch

conn. P

TRM-05

0

-

1

BOARD

FE1

X

E

TRM-35

X

U

X

V

Patch

conn. L

X

2

ELEVATION

MOTOR

TRM-0 8

Patch

conn. G

TRM-AZION

X

2

ELEVATI O N & CUT -O UT

R+,R-

TRM-14

TRM-18

V

5

TRM-42

TRM-38

BOARD

LIMIT

SWITCH

TRM-1 0

Patch

conn. M

TRM-36B

X3

X1

TRM-36A

X9

X

X5

X4

6

TRM-AZION

A

X

DOWNLOAD

L

E

BOARD

X

1

BELT

MOTOR

TRM-06

Patch

conn. I

TRM-36A

X

2

X

U-V

-

W

3

1

3

-

2

L

1

-

L

2

TRM-AZION

L

K

N

X

P

2

R

G

X

A

Q

Encoder

TRM-0 7

Patch

conn. H

TRM-AZION

INVERTER

M

A

2

7

-

2

8

LOWER

ASSEMBLY

Patch

conn. R

TRM-46

R

+

,

R

P

E

H

NOL

Antenna

inlet

WELLNESS TV

VERSION

2.7.1.3. UL 110 VAC lower assembly

AUTOTRANSFORMER

ELEVATION

Patch

conn Q

TRM-50

4

-

8

0

-

1

-

2

6

E

X

POWER SUPPLY

BOARD

Patch

conn. P

TRM-35

U

X

V

X

Patch

conn. L

2

TRM-AZION

X

5

V

110

VAC

LEDs

TRM-03A

CIRCUIT

BRAKER

TRM-02A

POWER

ENTRY

SOCKET

TRM-01

Fan

24VDC

TRM-44

Patch

conn R

FILTER

TRM-04

RELAY

A

X

X

1

MOTOR

TRM-08

Patch

conn. G

2

X

ELEVATI O N & CUT - O UT

R+,R-

BOARD

TRM-14

TRM-18

TRM-42

TRM-38

LIMIT

SWITCH

TRM-10

Patch

conn. M

TRM-36B

X3

X1

TRM-36A

X9

X

X5

X4

6

TRM-AZION

A

L

X

DOWNLOAD

TRM-1 9

E

BOARD

X

1

BELT

MOTOR

TRM-06

Patch

conn. I

TRM-36A

X

2

X

U

-

-

V

W

3

-

1

2

3

1

L

2

-

L

TRM-A ZION

L

N

K

R

P

X

G

2

X

Q

A

Encoder

TRM-07

Patch

conn. H

TRM-AZION

INVERTER

A

M

-

7

2

2

8

LOWER

ASSEMBLY

Patch

conn. R

TRM-46

R

+

,

R

H

P

N

O

E

L

Antenna

inlet

WELLNESS TV

VERSION

Page 2.6

Fan

24VDC

TRM-05

FE1

TRM-19

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.7.1.4. Upper assembly: LED version

OWNZONE

RECEIVER

C

1

N

TRM -32

C

N

1

TGS/

SMART

CARD

BOARD

LED BO ARD

C

N

2

FE2

C

N

5

C

N

1

0

CSAFE

BOARD

C

N

1

C

N

6

C

N

1

C

N

1

5

386 BOARD

DIGITAL PLAN BOARD

C

C

N

1

N

7

4

TRM -20

FAN

12 Vdc

TRM-28/B

TRM-2 1TRM -23 TRM-2 4 TRM-3 1

Patch

Conn. O

C

N

8

C

1

N

1

C

N

C

N

C

N

C

N

C

N

9

1

TRM -28

1

6

7

1

3

1

TRM-2 5

Patch

Conn. N

ELEVATION

JOYSTICK

TRM -29

TRM-2 9

SPEED

JOYSTICK

RIGHT

SENSOR

KEYBOARD

HAND

3

Patch

Conn. B

TRM -15

J

SENSOR

BOARD

-

2

J

4

J

TRM-2 6

LEFT

SENSOR

DISPLAY

Patch

Conn. D

TRM-19

FE1

EMERGENCY

BUT TON

Patch

Conn. F

Page 2.7

2.7.1.5. Upper assembly: Wellness TV version

CN11

C

N

1

J1

12 Vdc

TRM-21

0

Patch

Conn Q

HEADPHONE

JACK

DISPLAY

C

N

C

N

C

N

INVERTER

C

N

C

N

4

5

1

3

2

J8

CV-281

TRM-49

AUX INPUT

CN3

LCD

C

BOARD

TGS/

SMART

CARD

BOARD

C

N

1

TRM-32

C

N

8

SPLITTER

AMPLIFIER

N

5

CN15

TRM-48

4

J

1

J

LVDS

BOARD

C

N

1

C

N

BOARD

2

C

N

1

TRM-31

C

N

3

TUNER

CPU

BOARD

C

N

6

J1

CONNECTORS BOARD

C

N

5

1

C

N

1

C

N

1

8

C

N

6

1

TRM-20

CN5CN4

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

OWNZONE

RECEIVER

C

N

1

FAN

Patch

Conn O

TRM-25

TRM-28/B

TRM-28

3

J

SENSOR

BOARD

Patch

Conn N

HAND

ELEVATION

TRM-29

TRM-29

JOYSTICK

SPEED

JOYSTICK

SENSOR

-

J

2

J

4

TRM-26

SENSOR

FE3

KEYBOARDCSAFE

C

N

6

C

N

5

C

N

3

C

9

N

1

C

N

1

1

C

N

4

C

N

3

1

3

J

Patch

Conn B

RIGHT

LEF T

Patch

Conn D

FE1

TRM-19

Patch

Conn F

TRM-47

Patch

Conn R

TRM-46

TRM-15

EMERGENCY

BUTTON

Page 2.8

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.7.2. 700 MODEL

2.7.2.1. EU 220 VAC lower assembly

220

VAC

LEDs

CIRCUIT

BRAKER

TRM -02

POWER

ENTRY

SOCKET

TRM -01

Fan

24VDC

Fan

24VDC

TRM -4 4

TRM -0 3

FILTER

TRM -04

RELAY

X

A

X

1

TRM -0 5

8

-

4

6

-

2

Patch

conn. P

0

1

-

TRM -35

X

U

POWER SUPPLY

BOARD

X

V

Patch

conn. L

FE1

X

2

ELEVATION

MOTOR

TRM -08

Patch

conn. G

TRM -AZI O N

X

2

ELEVATION & CUT-OUT

R+,R-

TRM -14

TRM -1 8

V

5

TRM -42

TRM -3 8

BOARD

LIMIT

SWITCH

TRM -10

Patch

conn. M

TRM -3 6

X3

X1

X4

X

6

TRM -AZI O N

X5

X

X

A

E

L

DOWNLOAD

BOARD

X

1

BELT

MOTOR

TRM -0 6

Patch

conn. I

TRM -3 6

3

X

L

2

X

TRM -AZION

U

V

-

W

-

INVERTER

3

-

1

2

7

2

-

1

L

2

L

TRM -AZION

N

K

X

P

R

G

2

Q

A

Encoder

TRM -0 7

Patch

conn. H

A

M

2

-

8

LOWER

ASSEMBLY

Patch

conn. R

TRM -4 6

R

R

,

+

P

H

E

N

O

L

Antenna

inlet

WELLNESS TV

VERSION

TRM -1 9

Page 2.9

2.7.2.2. UL 220 VAC lower assembly

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

220

VAC

LEDs

CIRCUIT

BRAKER

TRM-02A

POWER

ENTRY

SOCKET

TRM-01

Fan

24VDC

Fan

24VDC

TRM-4 4

TRM-03A

FILTER

TRM-04

4

-

8

RELAY

2

-

6

X

A

POWER SUPPLY

X

1

Patch

conn. P

TRM-05

0

-

1

BOARD

FE1

X

E

Patch

conn. L

TRM-35

X

U

X

V

2

ELEVATION

MOTOR

TRM-0 8

Patch

conn. G

TRM-AZION

X

2

ELEVATI O N & CUT -O UT

R+,R-

TRM-14

X

V

5

TRM-42

TRM-38

BOARD

TRM-18

LIMIT

SWITCH

TRM-1 0

Patch

conn. M

TRM-36B

X3

X1

TRM-36A

X9

X

X5

X4

6

TRM-AZION

A

X

DOWNLOAD

L

E

BOARD

X

1

BELT

MOTOR

TRM-06

Patch

conn. I

TRM-36A

X

2

X

U-V

-

W

3

1

3

-

2

L

1

-

L

2

TRM-AZION

L

K

N

X

P

2

R

G

X

A

Q

Encoder

TRM-0 7

Patch

conn. H

TRM-AZION

INVERTER

M

A

2

7

-

2

8

LOWER

ASSEMBLY

Patch

conn. R

TRM-46

R

+

,

R

P

E

H

NOL

Antenna

inlet

WELLNESS TV

VERSION

2.7.2.3. UL 110 VAC Lower assembly

AUTOTRANSFORMER

ELEVATION

Patch

conn Q

TRM-50

4

-

8

0

-

1

-

2

6

X

E

POWER SUPPLY

BOARD

Patch

conn. P

TRM-35

X

U

X

V

Patch

conn. L

2

TRM-AZION

X

V

5

R+,R-

TRM-38

110

VAC

LEDs

TRM-03A

CIRCUIT

BRAKER

TRM-02A

POWER

ENTRY

SOCKET

TRM-01

Fan

24VDC

TRM-44

Patch

conn R

FILTER

TRM-04

RELAY

X

A

X

1

LIMIT

MOTOR

TRM-08

Patch

conn. G

SWITCH

TRM-10

Patch

conn. M

TRM-36B

X

2

ELEVATI O N & CUT - O UT

BOARD

X1

TRM-14

TRM-18

TRM-42

TRM-36A

X3

X9

X4

X

6

TRM-AZION

X5

X

TRM-1 9

X

A

L

E

DOWNLOAD

BOARD

X

1

BELT

MOTOR

TRM-06

Patch

conn. I

TRM-36A

U

3

-32

1

L

X

L

N

2

X

X

Q

TRM-07

TRM-AZION

-

V

-

W

INVERTER

-

7

2

2

1

-

L

2

TRM-A ZION

K

P

R

G

2

A

Encoder

Patch

conn. H

+

A

M

P

H

E

N

8

LOWER

ASSEMBLY

Patch

conn. R

TRM-46

R

,

R

O

L

Antenna

inlet

WELLNESS TV

VERSION

24VDC

Page 2.10

Fan

TRM-05

FE1

TRM-19

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.7.2.4. Upper assembly, LED version

OWNZONE

RECEIVER

C

N

1

C

FE2

TRM -3 2

C

N

1

TGS/

SMART

CARD

BOARD

LED BOARD

N

2

C

N

5

C

N

1

0

CSAFE

BOARD

C

N

1

C

N

6

C

N

1

C

N

5

1

386 BOARD

DIG ITAL PLAN BOARD

C

N

1

C

N

7

4

TRM-2 0

C

N

9

TRM -2 1TRM-2 3 TRM-24 TRM -3 1

C

N

8

KEYBOARD

Patch

Conn. B

C

N

C

C

1

TRM -1 5

FAN

12 Vdc

TRM -2 8/ B

Patch

Conn. O

N

1

1

TRM-2 8

N

1

3

Patch

Conn. N

TRM -2 5

RIGHT

SENSOR

HAND

3

J

SENSOR

J

J

-

2

4

TRM -2 6

BOARD

LEFT

SENSOR

DISPLAY

Patch

Conn. D

TRM-1 9

FE1

EMERGENCY

BUTTO N

Patch

Conn. F

Page 2.11

2.7.2.5. Upper assembly: Wellness TV version

DISPLAY

C

C

C

INVERTER

C

C

N

4

5

N

N

1

3

N

2

N

CV-281

J8

TRM-32

LCD

C

5

N

TRM-49

1

J

AUX INPUT

BOARD

CN3

TGS/

SMART

CARD

BOARD

C

N

1

C

N

8

SPLITTER

AMPLIFIER

CN15

TRM-48

J

4

CN5CN4

LVDS

BOARD

C

N

1

3

N

C

BOARD

TUNER

CPU

C

N

2

TRM-20

BOARD

C

1

N

TRM-31

6

N

C

J1

CONNECTORS BOARD

C

N

5

1

C

1

N

C

1

N

8

J1

N

C

6

1

CN11

N

C

0

1

HEADPHONE

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

OWNZONE

RECEIVER

C

N

1

FAN

12 Vdc

TRM-21

C

5

N

3

J

FE3

Patch

Conn Q

JACK

KEYBOARDCSAFE

C

6

N

C

3

N

N

C

4

N

C

3

1

Patch

Conn B

Patch

Conn O

TRM-25

TRM-28/B

TRM-28

HAND

3

J

SENSOR

BOARD

Patch

Conn N

RIGHT

SENSOR

2

J

4

-

J

TRM-26

LEFT

SENSOR

Patch

Conn D

FE1

TRM-19

Patch

Conn F

TRM-47

Patch

Conn R

TRM-46

TRM-15

EMERGENCY

BUTTON

Page 2.12

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

2.7.3. 500 MODEL

2.7.3.1. EU 220 VAC lower assembly

220

VAC

LEDs

CIRCUIT

BRAKER

TRM -02

POWER

ENTRY

SOCKE T

TRM -01

Fan

24VDC

TRM-4 4

TRM -03

FILTER

TRM -04

4

8

-

RELAY

0

6

-

2

A

X

POWER SUPPLY

X

1

Patch

conn. P

1

-

BOARD

TRM -35

X

X

V

Patch

conn. L

U

X

2

ELEVATION

MOTOR

TRM -08

Patch

conn . G

TRM -AZION

2

X

ELEV A TI ON & C UT-OUT

R+,R-

TRM-1 4

TRM -18

5

V

TRM-4 2

TRM -38

BOARD

LIMIT

SWITCH

TRM -10

Patch

conn. M

TRM -36

X3

X1

X4

X

6

TRM -AZION

X5

X

A

X

E

L

DOWNLOAD

BOARD

1

X

BELT

MOTOR

TRM -06

Patch

conn. I

TRM -36

3

1

L

X

2

X

TRM -AZION

V

-

U

W

-

INVERTER

3

-

2

7

2

L

1

-

2

L

TRM -AZION

K

N

P

X

2

G

R

Q

A

Patch

conn.. H

M

A

P

8

2

-

LOWER

ASSEMBLY

R

,

+

R

H

N

E

L

O

Fan

24VDC

TRM -05

FE1

TRM -19

Page 2.13

2.7.3.2. UL 220 VAC lower assembly

RUN EXCITE: Service & Maintenance Manual - rev. 1.5

220

VAC

LEDs

CIRCUIT

BRAKER

TRM-02A

POWER

ENTRY

SOCKET

TRM-01

Fan

24VDC

Fan

24VDC

TRM-44

TRM-03A

FILTER

TRM-04

RELAY

X

A

1

X

TRM-05

8

-

4

-

2

Patch

conn. P

1

-

0

6

X

E

X

POWER SUPPLY

BOARD

X

Patch

conn. L

FE1

TRM-35

U

X

V

2

V

ELEVATION

MOTOR

TRM-08

Patch

conn. G

TRM-AZION

2

X

ELEVATION & C U T-OU T

R+,R-

TRM-14

TRM-18

5

TRM-42

TRM-38

BOARD

LIMIT

SWITCH

TRM-10

Patch

conn. M

TRM-36B

X3

X1

TRM-36A

X9

X

X5

X4

6

TRM-AZION

L

A

X

DOWNLOAD

E

BOARD

1

X

BELT

MOTOR

TRM-06

Patch

conn. I

TRM-36A

1

3

L

X

2

X

X

TRM-AZION

-

U

W

-

V

2

3

2

L

L

-

1

2

TRM-AZION

K

N

R

P

X

2

G

A

Q

Patch

conn.. H

INVERTER

A

P

M

-

7

8

2

LOWER

ASSEMBLY

R

R

,

+

N

E

H

L

O

2.7.3.3. UL 110 VAC Lower assembly

AUTOTRANSFORMER

Patch

conn Q

TRM-50

4

-

8

0

-

1

2

-

6

X

POWER SUPPLY

BOARD

Patch

conn. P

110

VAC

LEDs

TRM-03A

CIRCUIT

BRAKER

TRM-02A

POWER

ENTRY

SOCKET

TRM-01

Fan

24VDC

TRM-44

Patch

conn R

FILTER

TRM-04

RELAY

X

A

X

1

E

TRM-35

X

U

X

V

2

Patch

conn. L

ELEVATION

MOTOR

TRM-08

Patch

conn. G

TRM-AZION

X

2

ELEVATI O N & CUT-O UT

R+,R-

TRM-14

X

V

5

TRM-42

TRM-38

BOARD

TRM-18

LIMIT

SWITCH

TRM-1 0

Patch

conn. M

TRM-36B

X3

X1

TRM-36A

X9

X

X5

X4

6

TRM-AZION

X

A

DOWNLOAD

TRM-19

L

E

BOARD

X

1

BELT

MOTOR

TRM-06

Patch

conn. I

TRM-36A

3

X

L

X

2

X

TRM-AZION

U

-

V

-

W

1

-

3