SERVICE & MAINTENANCE MANUAL

Rev. 1.2

The information contained in this manual is intended for QUALIFIED TECHNICIANS who have

completed a specific TECHNOGYM training course and are authorized to perform machine start-

up and adjustment procedures as well as extraordinary maintenance or repairs which require a

thorough knowledge of the machine, its operation, its safety devices and working procedures.

CAREFULLY READ THE INFORMATION CONTAINED IN

THIS MANUAL BEFORE PERFORMING ANY MAINTENANCE

PROCEDURES ON THE MACHINE

DANGEROUS VOLTAGES

PRESENT EVEN WHEN THE

MACHINE IS TURNED OFF

NOTE

The information contained in this document is subject to change without notice.

Technogym does not guarantee this documentation in any way. Technogym shall not be held

responsible for any errors contained in this manual and declines all liability for accidents or

damages resulting from the supply, characteristics or use of this manual.

This document contains proprietary information that is protected by copyright. All rights reserved.

No part of this document may be photocopied, reproduced or translated into another language

without the prior written consent of Technogym.

The Technogym® trademark is property of Technogym S.p.A.

The Element™ trademark is property of Technogym S.p.A.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page i

Contents

1. GENERAL NOTICES ............................................................................................................................................. 1.1

1.1. INTRODUCTION...................................................................................................................................................1.1

1.2. RECOMMENDATIONS..........................................................................................................................................1.1

1.3. GENERAL RULES FOR REPAIR PROCEDURES ........................................................................................................1.2

2. TECHNICAL CHARACTERISTICS....................................................................................................................2.1

2.1. COLOUR OPTIONS...............................................................................................................................................2.2

2.2. PRODUCT CODING...............................................................................................................................................2.3

2.2.1. Machines codes ...................................................................................................................................2.3

2.2.2. Benches codes......................................................................................................................................2.3

2.3. EQUIPMENTS: MECHANICAL CHARACTERISTICS..................................................................................................2.4

2.3.1. MA05 – Adductor ................................................................................................................................2.4

2.3.2. MA10 – Abductor ................................................................................................................................2.4

2.3.3. MA15 – Shoulder Press.......................................................................................................................2.5

2.3.4. MA20 – Chest Press ............................................................................................................................2.5

2.3.5. MA30 – Leg Extension ........................................................................................................................2.6

2.3.6. MA35 – Leg Curl.................................................................................................................................2.6

2.3.7. MA40 – Lat Machine...........................................................................................................................2.7

2.3.8. MA45 – Lower Back............................................................................................................................2.7

2.3.9. MA50 – Leg Press ...............................................................................................................................2.8

2.3.10. MA55 – Arm Curl................................................................................................................................2.8

2.3.11. MA60 – Arm Extension........................................................................................................................2.9

2.3.12. MA65 – Abdominal Crunch.................................................................................................................2.9

2.3.13. MA70 – Pectoral ...............................................................................................................................2.10

2.3.14. MA75 – Glute ....................................................................................................................................2.10

2.3.15. MA80 – Ercolina............................................................................................................................... 2.11

2.3.16. MA85 – Ercolina Crossover Cable ...................................................................................................2.11

2.3.17. MA90 – Ercolina Rehab....................................................................................................................2.12

2.3.18. MA95 – Low Row.............................................................................................................................. 2.12

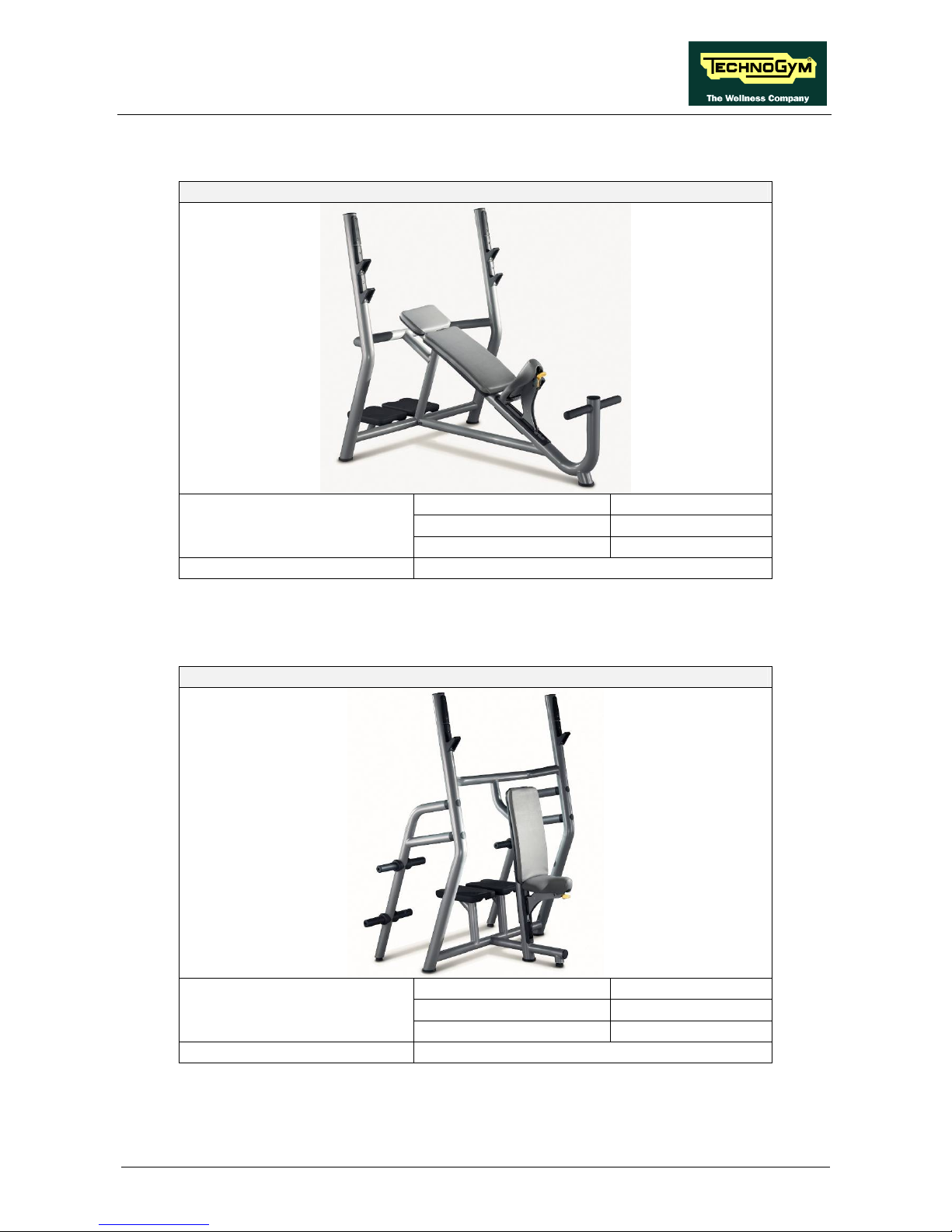

2.3.19. PA01 – Inclined bench ......................................................................................................................2.13

2.3.20. PA02 – Vertical bench.......................................................................................................................2.13

2.3.21. PA03 –Crunch bench.........................................................................................................................2.14

2.3.22. PA04 – Adjustable bench ..................................................................................................................2.14

2.3.23. PA05 –Lower Back bench .................................................................................................................2.15

2.3.24. PA06 –Scott bench.............................................................................................................................2.15

2.3.25. PA07 – Horizontal bench..................................................................................................................2.16

2.4. AMBIENT SPECIFICATIONS................................................................................................................................2.16

2.5. CONFORMITY TO REGULATIONS........................................................................................................................2.16

3. INSTALLING AND MOVING THE MACHINES.............................................................................................. 3.1

3.1. SPECIFICATIONS AND REQUIREMENTS ................................................................................................................3.1

3.2. INSTALLING AND MOVING THE MACHINES..........................................................................................................3.1

3.3. LIFTING AND MOVING.........................................................................................................................................3.2

3.4. INSTALLING THE MACHINE ALREADY ASSEMBLED..............................................................................................3.3

3.5. INSTALLING THE MACHINE TO BE ASSEMBLED.................................................................................................... 3.4

3.5.1. MA50 – Leg Press ...............................................................................................................................3.4

3.5.2. MA85 – Ercolina Crossover Cable .....................................................................................................3.5

3.5.3. PA02 – Vertical Bench ........................................................................................................................3.8

3.6. MACHINE SECURING.........................................................................................................................................3.10

3.6.1. Fixing a wall: Ercolina, Ercolina Rehab e Cross Cables................................................................. 3.10

3.6.2. Fixing the ceiling: Cavi Incrociati ....................................................................................................3.12

4. ACCESSORIES.......................................................................................................................................................4.1

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page ii

4.1. BARBELL HOLDER, PLATES HOLDER AND DUMBELL HOLDER..............................................................................4.1

4.1.1. A0000230: Barbell Rack.....................................................................................................................4.1

4.1.2. A0000231: Plate Rack........................................................................................................... .............. 4.2

4.1.3. A0000421: Urethane - Encased Dumbell Rack...................................................................................4.2

4.1.4. A0000364: Chrome Dumbbell Rack....................................................................................................4.3

4.2. WHAT TO ORDER TO AUGMENT THE WEIGHT STACK...........................................................................................4.4

5. HOW TO DISASSEMBLE THE ….......................................................................................................................5.1

5.1. WEIGHT STACK CASING...................................................................................................................................... 5.1

5.2. DISASSEMBLING THE WEIGHT STACK..................................................................................................................5.2

5.3. SEAT ON LOW MACHINES.................................................................................................................................... 5.3

5.4. SEAT ON TALL MACHINES...................................................................................................................................5.4

5.5. LEG PRESS SEAT.................................................................................................................................................5.6

5.6. RELEASE LEVER..................................................................................................................................................5.8

5.7. DISASSEMBLING UNLOCKING LEVER ON ABDUCTOR - ADDUCTOR...................................................................5.10

5.8. DISASSEMBLING SHOULDER REST LEVER ON ABDOMINAL CRUNCH.................................................................5.12

5.9. DISASSEMBLING ROLLERS ADJUSTING SYSTEM ON LAT MACHINE .................................................................... 5.13

5.10. DISASSEMBLING HANDLES ADJUSTING SYSTEM ON CHEST PRESS ..................................................................... 5.15

5.11. DISASSEMBLING EASY START SYSTEM ON PECTORAL.......................................................................................5.17

5.12. DISASSEMBLING THE ADDITIONAL WEIGHT ......................................................................................................5.18

6. WHAT IF ….............................................................................................................................................................6.1

6.1. THE WEIGHT STACK DOES NOT SLIDE SMOOTHLY ...............................................................................................6.1

6.2. THE WEIGHT STACK CABLE IS NOT TAUT.............................................................................................................6.2

6.3. THE MACHINE IS NOT FLAT.................................................................................................................................6.3

6.4. THE LEVERS OF DUAL-AXIS MACHINES ARE NOT ALIGNED..................................................................................6.4

7. SPECIAL OPERATIONS.......................................................................................................................................7.1

7.1. LOCKING DOWN THE CABLE FIXING DOWELS......................................................................................................7.1

7.2. LOCKING DOWN THE PULLEYS............................................................................................................................ 7.2

7.3. LOCKING DOWN THE DOWELS ON THE ARM EXTENSION LEVER..........................................................................7.3

8. WEIGHT STACK CABLE.....................................................................................................................................8.1

8.1. LENGTH OF THE WEIGHT STACK CABLES.............................................................................................................8.1

8.2. ROUTING OF THE WEIGHT STACK CABLE.............................................................................................................8.2

8.2.1. MA05 – Adductor ................................................................................................................................8.2

8.2.2. MA10 – Abductor ................................................................................................................................8.3

8.2.3. MA15 – Shoulder Press.......................................................................................................................8.3

8.2.4. MA20 – Chest Press ............................................................................................................................8.4

8.2.5. MA25 – Vertical Traction....................................................................................................................8.4

8.2.6. MA30 – Leg Extension ........................................................................................................................8.5

8.2.7. MA35 – Leg Curl.................................................................................................................................8.5

8.2.8. MA40 – Lat Machine...........................................................................................................................8.6

8.2.9. MA45 – Lower Back............................................................................................................................8.6

8.2.10. MA50 – Leg Press ...............................................................................................................................8.7

8.2.11. MA55 – Arm Curl................................................................................................................................8.7

8.2.12. MA60 – Arm Extension........................................................................................................................8.8

8.2.13. MA65 – Abdominal Crunch.................................................................................................................8.8

8.2.14. MA70 – Pectoral .................................................................................................................................8.9

8.2.15. MA75 – Glute ......................................................................................................................................8.9

8.2.16. MA80 – Ercolina............................................................................................................................... 8.10

8.2.17. MA85 – Ercolina Cross Over Cable .................................................................................................8.10

8.2.18. MA90 – Ercolina Rehab....................................................................................................................8.11

8.2.19. MA95 – Low Row.............................................................................................................................. 8.11

9. MAINTENANCE.....................................................................................................................................................9.1

9.1. DAILY MAINTENANCE OPERATIONS....................................................................................................................9.1

9.1.1. Cleaning upholstery ............................................................................................................................9.1

9.2. WEEKLY MAINTENANCE OPERATIONS ................................................................................................................ 9.2

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page iii

9.2.1. Cleaning the frame and painted parts.................................................................................................9.2

9.3. MONTHLY MAINTENANCE OPERATIONS.............................................................................................................. 9.3

9.3.1. Check the cross, bars and weight stack plates ....................................................................................9.3

9.3.2. Check the cables..................................................................................................................................9.3

9.3.3. Check the mechanisms.........................................................................................................................9.3

9.3.4. Check the gas springs.......................................................................................................................... 9.3

9.3.5. Check the weight stack stops...............................................................................................................9.4

9.3.6. Check the Leg Press seat mechanism..................................................................................................9.4

9.3.7. Checking the seat mechanism on low machines..................................................................................9.4

9.3.8. Checking the seat mechanism on tall machines ..................................................................................9.4

9.3.9. Checking the upholstery...................................................................................................................... 9.4

9.3.10. Checking various rubber parts............................................................................................................9.4

9.4. TWICE-YEARLY MAINTENANCE OPERATIONS......................................................................................................9.5

9.4.1. Check the pulleys.................................................................................................................................9.5

9.4.2. Check the cam group...........................................................................................................................9.5

9.4.3. Check the lever stops...........................................................................................................................9.5

9.4.4. Replacing the cables............................................................................................................................ 9.5

9.4.5. Lubricating the release systems...........................................................................................................9.5

9.4.6. Screw and bolt check...........................................................................................................................9.6

9.4.7. Checking for mechanism play .............................................................................................................9.6

9.4.8. Checking cross alignment....................................................................................................................9.6

10. APPENDIX.............................................................................................................................................................10.1

10.1. TOOLS TO USE ..................................................................................................................................................10.1

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page iv

Page intentionally left blank

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 1.1

1. GENERAL NOTICES

1.1. INTRODUCTION

This document is reserved for Technogym Service technicians, and is intended to provide

authorized personnel with the necessary information to correctly carry out repairs and maintenance.

A thorough knowledge of the technical information contained in this manual is essential for

completing the professional training of the operator.

In order to facilitate consultation, the paragraphs are accompanied by schematic drawings which

illustrate the procedure being described.

This manual contains notices and symbols which have a specific meaning:

WARNING: non observance may result in accident or injury.

CAUTION: non observance may cause damage to the machine.

Information about the operation in progress.

observation about the operation in progress.

1.2. RECOMMENDATIONS

Technogym recommends the following steps for planning repair procedures:

• Carefully evaluate the customer’s description of the machine malfunction and ask all the

necessary questions to clarify the symptoms of the problem.

• Clearly diagnose the causes of the problem. This manual provides the fundamental theoretical

basis, which must then be integrated by personal experience and attendance at the training

courses periodically offered by Technogym.

• Rationally plan the repair procedure so as to minimize the downtime necessary for procuring

spare parts, preparing tools, etc.

• Access the component to be repaired, avoiding any unnecessary operations. In this regard it will

be useful to refer to the disassembly sequence described in this manual.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 1.2

1.3. GENERAL RULES FOR REPAIR PROCEDURES

1. Always mark any parts or positions which may be confused with each other at the time of

reassembly.

2. Use original Technogym spare parts and lubricants of the recommended brands.

3. Use special tools where specified.

4. Consult the Technical Newsletters, which may contain more up-to-date information on

adjustments and maintenance than those contained in this manual.

5. Before starting the repair procedure, make sure that the recommended tools are available and in

good condition.

6. For the procedures described in this manual, use only the specified tools.

The tool sizes quoted in this manual are expressed in mm.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.1

2. TECHNICAL CHARACTERISTICS

The Element machine code is a sequence of 14 alphanumeric characters arranged as follows:

ELEMENT LINE

Characters description key to values

1,2 Element Line

MA = Element machine

PA = Element benches

3,4 Machine code See paragraph: 2.1. “Colour options”

5 Weight stack configuration

N = None

0 = Standard

2 = enhanced +20 Kg (

1

)

3 = enhanced +30 Kg (

2

)

5 = enhanced +50 Kg (

3

)

6 Additional weight

N = None

C = 2.5 Kg additional weight

7 Isocontrol

0 = None

1 = Isocontrol

-

8,9 Frame colour

AL = silver

10,11 Upholstery colour

AN = silver

V0 = black

K0 = aviation blue

M0 = Bordeaux (benches only)

12,13 Rubber colour

GG = grey RAL 7024

14 Casing colour

A = white

G = grey

J = I-Pac

15 Unit of measurement

K = Kg

L = pound

NOTES:

(

1

) Valid on Abdominal Crunch, Abductor, Adductor, Arm Curl, Arm Extension, Leg Extension,

Leg Curl, Lower Back, Shoulder Press and Vertical Traction.

(

2

) Valid on Chest Press, Lat Machine, Low Row and Pectoral.

(

3

) Valid on Ercolina, Ercolina Rehab and Cross Over Cables.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.2

For example, a possible product code would be:

MA150N0-ALANGGAK

which is interpreted as follows:

MA 15 0 N 0 - ALANGG A K

Unit of measurement, Kg

Casing colour, white

Rubber colour, grey RAL 7024

Upholstery colour, silver

Frame colour, aluminium

NO, Isocontrol

NO, additional weight

Weight stack configuration, standard

Shoulder Press

Element Line machine

2.1. COLOUR OPTIONS

The following table shows the possible combinations for ordering the Classic Selection line

machines:

CONFIGURATION -1- CONFIGURATION -2- CONFIGURAZIONE -3-

FRAME AL - SILVER AL - SILVER AL - SILVER

CASING A - WHITE G –GREY J – I PAC

UPHOLSTERY AN - SILVER V0 - BLACK K0 - BLUE

Table 2-1

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.3

2.2. PRODUCT CODING

2.2.1. MACHINES CODES

Code Machine

05 Adductor

10 Abductor

15 Shoulder Press

20 Chest Press

25 Vertical traction

30 Leg Extension

35 Leg Curl

40 Lat Machine

45 Lower Back

50 Leg Press

55 Arm Curl

60 Arm Extension

65 Abdominal Crunch

70 Pectoral Machine

75 Glute

80 Ercolina

83 Multipower

85 Crossover Cable

90 Ercolina Rehab

95 Low Row

2.2.2. BENCHES CODES

Code Machine

01 Inclined bench

02 Vertical bench

03 Crunch bench

04 Adjustable bench

05 Lower Back bench

06 Scott bench

07 Horizontal bench

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.4

2.3. EQUIPMENTS: MECHANICAL CHARACTERISTICS

2.3.1. MA05 – ADDUCTOR

MA05 - Adductor

stand by max during exercise

141 x 82 x 142 cm

Dimensions

55.5 x 32.3 x 55.9 in

Overall weight 140 Kg – 280 lbs

Standard weight stack 60 Kg – 120 lbs

Enhanced weight stack 80 Kg – 160 lbs

2.3.2. MA10 – ABDUCTOR

MA10 – Abductor

stand by max during exercise

141 x 82 x 142 cm

Dimensions

55.5 x 32.3 x 55.9 in

Overall weight 140 Kg – 280 lbs

Standard weight stack 60 Kg – 120 lbs

Enhanced weight stack 80 Kg – 160 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.5

2.3.3. MA15 – SHOULDER PRESS

M8A15 – Shoulder Press

stand by max during exercise

144 x 87 x 142 cm

Dimensions

56.7 x 34.3 x 55.9 in

Overall weight 170 Kg – 340 lbs

Standard weight stack 60 Kg – 120 lbs

Enhanced weight stack 80 Kg – 160 lbs

2.3.4. MA20 – CHEST PRESS

MA20 – Chest Press

stand by max during exercise

139 x 83 x 162 cm

Dimensions

54.7 x 32.7 x 63.8 in

Overall weight 190 Kg – 380 lbs

Standard weight stack 90 Kg – 180 lbs

Enhanced weight stack 120 Kg – 240 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.6

2.3.5. MA30 – LEG EXTENSION

MA30 – Leg Extension

stand by max during exercise

127 x 104 x 142 cm

Dimensions

50 x 41 x 56.9 in

Overall weight 200 Kg – 400 lbs

Standard weight stack 80 Kg – 160 lbs

Enhanced weight stack 100 Kg – 200 lbs

2.3.6. MA35 – LEG CURL

MA35 – Leg Curl

stand by max during exercise

127 x 104 x 142 cm

Dimensions

50 x 41 x 56.9 in

Overall weight 200 Kg – 400 lbs

Standard weight stack 80 Kg – 160 lbs

Enhanced weight stack 100 Kg – 200 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.7

2.3.7. MA40 – LAT MACHINE

MA40 – Lat Machine

stand by max during exercise

120 x 120 x 223 cm

Dimensions

47.8 x 47.8 x 88 in

Overall weight 270 Kg – 540 lbs

Standard weight stack 90 Kg – 180 lbs

Enhanced weight stack 120 Kg – 240 lbs

2.3.8. MA45 – LOWER BACK

MA45 – Lower Back

stand by max during exercise

120 x 95 x 142 cm

Dimensions

47.8 x 37.4 x 55.9 in

Overall weight 200 Kg – 400 lbs

Standard weight stack 70 Kg – 140 lbs

Enhanced weight stack 90 Kg – 180 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.8

2.3.9. MA50 – LEG PRESS

MA50 – Leg Press

stand by max during exercise

210 x 115 x 152 cm

Dimensions

82.7 x 45.3 x 59.9 in

Overall weight 570 Kg – 1140 lbs

Standard weight stack 200 Kg – 400 lbs

Enhanced weight stack -

2.3.10. MA55 – ARM CURL

MA55 – Arm Curl

stand by max during exercise

139 x 80 x 142 cm

Dimensions

54.7 x 31.5 x 55.9 in

Overall weight 155 Kg – 310 lbs

Standard weight stack 60 Kg – 120 lbs

Enhanced weight stack 80 Kg – 160 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.9

2.3.11. MA60 – ARM EXTENSION

MA60 – Arm Extension

stand by max during exercise

141 x 80 x 142 cm

Dimensions

55.5 x 31.5 x 55.9 in

Overall weight 170 Kg – 340 lbs

Standard weight stack 70 Kg – 140 lbs

Enhanced weight stack 90 Kg – 180 lbs

2.3.12. MA65 – ABDOMINAL CRUNCH

MA65 – Abdominal Crunch

stand by max during exercise

133 x 89 x 142 cm

Dimensions

52.4 x 35 x 55.9 in

Overall weight 180 Kg – 360 lbs

Standard weight stack 60 Kg – 120 lbs

Enhanced weight stack 80 Kg – 160 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.10

2.3.13. MA70 – PECTORAL

MA70 – Pectoral

stand by max during exercise

149 x 82 x 142 cm

Dimensions

59 x 32 x 56 in

Overall weight 190 Kg – 380 lbs

Standard weight stack 90 Kg – 180 lbs

Enhanced weight stack 120 Kg – 240 lbs

2.3.14. MA75 – GLUTE

MA75 – Glute

stand by max during exercise

114 x 132 x 142 cm

Dimensions

45 x 52 x 56 in

Overall weight 225 Kg – 450 lbs

Standard weight stack 60 Kg – 120 lbs

Enhanced weight stack –

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.11

2.3.15. MA80 – ERCOLINA

MA80– Ercolina

stand by max during exercise

66 x 69 x 242 cm

Dimensions

26 x 27.2 x 95.3 in

Overall weight 130 Kg – 260 lbs

Standard weight stack 27,5 Kg – 55 lbs

Enhanced weight stack 50 Kg – 100 lbs

2.3.16. MA85 – ERCOLINA CROSSOVER CABLE

MA85 – Ercolina Crossover Cable

stand by max during exercise

66 x 324 x 231 cm

Dimensions

26 x 127.6 x 91 in

Overall weight 280 Kg – 560 lbs

Standard weight stack 27,5x2 Kg – 55x2 lbs

Enhanced weight stack 50x2 Kg – 100x2 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.12

2.3.17. MA90 – ERCOLINA REHAB

MA90– Ercolina Rehab

stand by max during exercise

66 x 69 x 242 cm

Dimensions

26 x 27.2 x 95.3 in

Overall weight 130 Kg – 260 lbs

Standard weight stack 27,5 Kg – 55 lbs

Enhanced weight stack 50 Kg – 100 lbs

2.3.18. MA95 – LOW ROW

MA95 – Low Row

stand by max during exercise

124 x 82 x 142 cm

Dimensions

49 x 32 x 56 in

Overall weight 170 Kg – 340 lbs

Standard weight stack 90 Kg – 180 lbs

Enhanced weight stack 120 Kg – 240 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.13

2.3.19. PA01 – INCLINED BENCH

PA01– Inclined bench

stand by max during exercise

189.6 x 126.7 x 152.8 cm

Dimensions

75 x 50 x 60 in

Overall weight 71 Kg – 142 lbs

2.3.20. PA02 – VERTICAL BENCH

PA02 –Vertical bench

stand by max during exercise

119.7 x 160.6 x 177.6 cm

Dimensions

47 x 63 x 70 in

Overall weight 71 Kg – 142 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.14

2.3.21. PA03 –CRUNCH BENCH

PA03–Crunch bench

stand by max during exercise

143.6 x 69.7 x 110.8 cm

Dimensions

57 x 27 x 44 in

Overall weight 75 Kg – 150 lbs

2.3.22. PA04 – ADJUSTABLE BENCH

PA04 – Adjustable bench

stand by max during exercise

119.8 x 69.7 x 131.2 cm

Dimensions

47 x 27 x 52 in

Overall weight 59 Kg – 118 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.15

2.3.23. PA05 –LOWER BACK BENCH

PA05–Lower Back bench

stand by max during exercise

106.9 x 757 x 769 cm

Dimensions

42 x 30 x 30 in

Overall weight 36 Kg – 72 lbs

2.3.24. PA06 –SCOTT BENCH

PA06 –Scott bench

stand by max during exercise

101.1 x 780 x 998 cm

Dimensions

40 x 31 x 39 in

Overall weight 36 Kg – 72 lbs

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 2.16

2.3.25. PA07 – HORIZONTAL BENCH

PA07 – Horizontal bench

stand by max during exercise

172.5 x 160.6 x 130.2 cm

Dimensions

68 x 63 x 39 in

Overall weight 59 Kg – 118 lbs

Be aware:

• The weights in the above tables refer to machines with standard weight stack.

• The dimensions are “length x width x height” related to the user in exercise position.

• The stand by dimensions are the minimum machine dimensions without any

disassembling.

2.4. AMBIENT SPECIFICATIONS

Operating from 5° to 35° C

Temperature

Storage from -20 to 55° C

Operating from 30% to 80% non-condensing

Humidity

Storage from 5% to 85% non-condensing

2.5. CONFORMITY TO REGULATIONS

The machine conforms to the following directives:

Directive Europe USA

Machinery directive

98/37/CEE

Mechanical safety

EN 957-1

EN 957-2

EN 957-4

EN 957-1

EN 957-2

EN 957-4

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.1

3. INSTALLING AND MOVING THE

MACHINES

3.1. SPECIFICATIONS AND REQUIREMENTS

For proper installation of the equipment, make sure that:

1. The equipment is installed on a level, vibration-free surface with a sufficient capacity to support

its weight plus that of the user.

2. The area is not dusty or sandy.

3. You have observed the temperature and humidity operating requirements indicated in

paragraph 2.4. “Ambient specifications”.

3.2. INSTALLING AND MOVING THE MACHINES

The equipment is supplied on a pallet, to which it is secured by means of straps. To remove the

equipment from the packing:

1. Cut the carton along the bottom and pull it away from the top;

2. Remove the cellophane by pulling it away from the top;

3. Untie the straps securing the equipment to the pallet;

4. Lift the equipment from the weight stack side and place it on the ground;

5. Remove the spacer from between the two panels of the weight stack.

Do not throw the spacer (A) away as it must be used (putting it in the same position) in

case of any further moving of the machine.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.2

3.3. LIFTING AND MOVING

In case of raising or moving the machine, do not press against casings or other

breakable parts, but only against the frame.

To move the machine, preferably use a tipping trolley, lifting it from the weight stack end using the

wooden insert fitted on the machine for transport

Figure 3.3-1

• If you use different means of transportation as pallet changer or lift truck, adequately protect

the parts of the frame that will be in contact with it.

• Insert the means of transportation (pallet changer or lift truck from the weight stack side.

• Move the machine carefully, making sure it does not overbalance.

Once the machine is in the desired place of installation, level it by adjusting the height of

one or more of the machine feet as described in paragraph 6.3. “The machine is not

flat”.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.3

3.4. INSTALLING THE MACHINE ALREADY ASSEMBLED

Figure 3.4-1

1. The machine is supplied on a wooden pallet,

wrapped in nylon bag and packed in a carton.

2. To move the machine, it is necessary to use a

pallet truck or fork lift truck.

Figure 3.4-2

3. Remove the carton, the nylon bag and the

fixing straps which secure the machine on

the pallet.

4. Use a trolley to position the machine in the

place of installation, lifting it from the

weight stack end as shown by the arrows in

the figure, and leaving the wooden slat in

place.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.4

3.5. INSTALLING THE MACHINE TO BE ASSEMBLED

3.5.1. MA50 – LEG PRESS

Figure 3.5-1

1. The Leg Press is delivered on a wooden

pallet, wrapped in nylon bag and packed in a

carton.

2. To move the machine, it is necessary to use a

pallet truck or fork lift truck

Figure 3.5-2

3. Remove the carton and the nylon bag.

4. The machine is delivered with the rear guard

disassembled, and is fitted with the wooden

spacer (a) to protect it during handling with a

trolley as shown in the figure.

5. The support (b) at the base of the weight

stack prevents the base of the truck from

damaging the frame.

6. Remove the spacer (a) and mount the rear

casing on the machine.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.5

3.5.2. MA85 – ERCOLINA CROSSOVER CABLE

Figure 3.5-3

1. The Crossover Cable is delivered on a

wooden pallet, wrapped in nylon bag and

packed in a carton.

2. To move the machine, it is necessary to use a

pallet truck or fork lift truck

Figure 3.5-4

3. Remove the carton and the nylon bag and

arrange the various components needed to

assemble the machine on the floor:

• The two columns with the weight stack

(Ercolina) (a);

• The crossbar (b),

• The box which contains all the fixing

screws and some accessories.

Continued on the following page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.6

Figure 3.5-5

4. In particular, the carton box contains:

• The set of screws and hooks (1) to fix the

machine on the floor or on the wall;

• The set of screws (2) used to fix the

crossbar;

• The cable end pieces (3) and (4) with

some extra grub screws;

• Four cable ducts (5) for frame’s holes;

• Four snap links (6) to use with

accessories;

• A set of accessories (7) for the machine

usage.

Figure 3.5-6

5. Insert the crossbar on the post at the top of

the weight stack column, and fix it using the

screws (3) shown in Figure 3.5-5, locking

down 3 of them

in the position s shown in the

picture to side.

Carry out this operation on both the Ercolina

modules.

Figure 3.5-7

6. Insert two of the cable duct (5), of Figure

3.5-5, on the frame’s holes (d) shown in the

picture to side.

Carry out this operation on both the Ercolina

modules.

Continued on the following page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.7

Figure 3.5-8

7. Remove the cable from the hole on the

frame, pulling it out toward the inside, and

pass it through the pulley as indicated in the

figure to side.

8. After passing the cable on the pulley, insert a

rubber protection (5) on it.

9. Assemble one of the end piece (4) on the

cable as shown in the figure and lock down

the grub screws (e) using a 4-mm Allen

wrench.

10. Hide the end piece (4) with the rubber

protection.

Carry out this operation on both the Ercolina

modules.

WARNING: is necessary, at the end of the installation, set the machine on the wall or

ceiling.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.8

3.5.3. PA02 – VERTICAL BENCH

Figure 3.5-9

1. The Vertical Bench is delivered on a wooden

pallet, wrapped in nylon bag and packed in a

carton.

2. To move the machine, it is necessary to use a

pallet truck or fork lift truck

Figure 3.5-10

3. Remove the carton and the nylon bag and

arrange the various components on the floor:

• the bench;

• a cartoon box.

Continued on the following page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.9

Figure 3.5-11

4. In particular, the carton box contains:

• the four plates holders (a);

• the four covering pieces (b);

• the four stud bolt pin (c).

Figure 3.5-12

5. Screw the stud bolt pin c in the plates holder

(a).

Figure 3.5-13

6. Insert one of the covering piece (b) on the

post in the external side of the frame.

Figure 3.5-14

7. Screw the plates holder on the frame.

Carry out the previous operations for all the four

plates holders supplied with the machine.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.10

3.6. MACHINE SECURING

WARNING: it is necessary that some machines detailed below, are fixed to the wall or

ceiling, for their particular shape and / or how to use.

3.6.1. FIXING A WALL: ERCOLINA, ERCOLINA REHAB E CROSS CABLES

1. Insert the screws (a) in frame holes (b) as indicated in the figure,

2. insert brackets (c) and washers (d) in the protruding screw section,

The brackets may be rotated around the fastening axis to facilitate sub sequent wall-

fastening and then repositioned correctly.

3. tighten the brackets slightly using selflocking nuts (e) to hold them in position,

Figure 3.6-1

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.11

4. mark the position of two Ø 14 holes on the wall,

5. fully tighten brackets (c) to the frame,

6. drill the wall and insert rawl plugs (f) in the wall holes,

7. bring the equipment up to the wall and ensure the holes in the wall are aligned with the holes on

the bracket,

8. screw in screws (g) and tighten to the wall.

Figure 3.6-2

WARNING: is obligatory to secure the equipment to the wall using the appropriate

screw and brackets.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.12

3.6.2. FIXING THE CEILING: CAVI INCROCIATI

Use cables, ropes or chains that strictly meet the following minimum requirement: minimum

guaranteed workload of 90 Kg.

Figure 3.6-3

1. Tighten the eyebolts (a) into the threaded holes(b),

Figure 3.6-4

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.13

2. drill two holes in the ceiling or wall for the hooks (c) and insert the real plugs (d) into the holes,

3. screw in the hooks (c) into the rawl plugs(d) and tighten,

4. connect the hooks (c) to the eyebolts(a) using cables, ropes or chain (e).

The cables, ropes and chain are not supplied with the equipment.

The cables, ropes and chain must be under slight tension.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 3.14

Page intentionally left blank

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 4.1

4. ACCESSORIES

4.1. BARBELL HOLDER, PLATES HOLDER AND DUMBELL

HOLDER

The Element + line barbell support and weight storage plate posts are available as accessories. The

order codes for these accessories are:

4.1.1. A0000230: BARBELL RACK

The code above should be complemented with colour variation:

CODE

-ALGG

-ANGG

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 4.2

4.1.2. A0000231: PLATE RACK

The code above should be complemented with colour variation:

CODE

-ALGG

-ANGG

4.1.3. A0000421: URETHANE - ENCASED DUMBELL RACK

The code above should be complemented with colour variation:

CODE

-ALGG

-ANGG

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 4.3

4.1.4. A0000364: CHROME DUMBBELL RACK

The code above should be complemented with colour variation:

CODE

-ALGG

-ANGG

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 4.4

4.2. WHAT TO ORDER TO AUGMENT THE WEIGHT STACK

Weight stack

Cod. Machine

Standard Powere

d

Parts to power the

weight stack

Assembly

code

MA65 – Abdominal

Crunch

MA10 – Abductor

MA05 – Adductor

MA55 – Arm Curl

MA15 – Shoulder Press

60 kg

120 lbs

80 kg

160 lbs

0F137AA-GG x 4 (weight)

0B178AA

(2)

x 8 (bushing)

0E000018-(KG/LB) x 1 (sticker)

0P000653AA X 1 (selector rod)

R0003980AA-KG

R0003980AA-LB

MA60 – Arm Extension

MA45 – Lower Back

70 kg

140 lbs

90 kg

180 lbs

0F137AA-GG x 4 (weight)

0B178AA

(2)

x 8 (bushing)

0E000018-(KG/LB) x 1 (sticker)

0P000697AA x 1 (selector rod)

R0003981AA-KG

R0003981AA-LB

MA35 – Leg Curl

MA30 – Leg Extension

80 kg

160 lbs

100 kg

200 lbs

0F137AA-GG x 4 (weight)

0B178AA

(2)

x 8 (bushing)

0E000018-(KG/LB) x 1 (sticker)

0P000697AA x 1 (selector rod)

R0003981AA-KG

R0003981AA-LB

MA20 – Chest Press

MA40 – Lat Machine

MA95 – Low Row

MA70 – Pectoral Machines

90 kg

180 lbs

120 kg

240 lbs

0F137AA-GG x 6 (weight)

0B178AA

(2)

x 12 (bushing)

0E000018-(KG/LB) x 1 (sticker)

0P000732AA x 1 (selector rod)

R0003982AA-KG

R0003982AA-LB

MA85 – Crossover cable

(1)

MA80 – Ercolina

MA90 – Ercolina Rehab

25 kg

50 lbs

50 kg

100 lbs

0F137AA-GG x 10 (weight)

0B178AA

(2)

x 20 (bushing)

0E000145-(KG/LB) x 1 (sticker)

0P000745AA x 1 (selector rod)

R0003983AA-KG

R0003983AA-LB

MA25 – Vertical Traction

90 kg

18 lbs

110 kg

220 lbs

0F137AA-GG x 4 (weight)

0B178AA

(2)

x 8 (bushing)

0E000018-(KG/LB) x 1 (sticker)

0P000732AA x 1 (selector rod)

R0003984AA-KG

R0003984AA-LB

CAUTION:

(1)

For the Cable Cross, the elements specified in the upgrade table must be included for each of

the two Ercolina modules which make up the machine.

(2)

Bushings of different thickness are available for more precise adjustment of the weight stack

plates, so that they can all be easily selected using the pin.

CODE THICKNESS (mm)

0B178AA 2.5

0B000563AA 2

0B000562AA 1.5

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.1

5. HOW TO DISASSEMBLE THE …

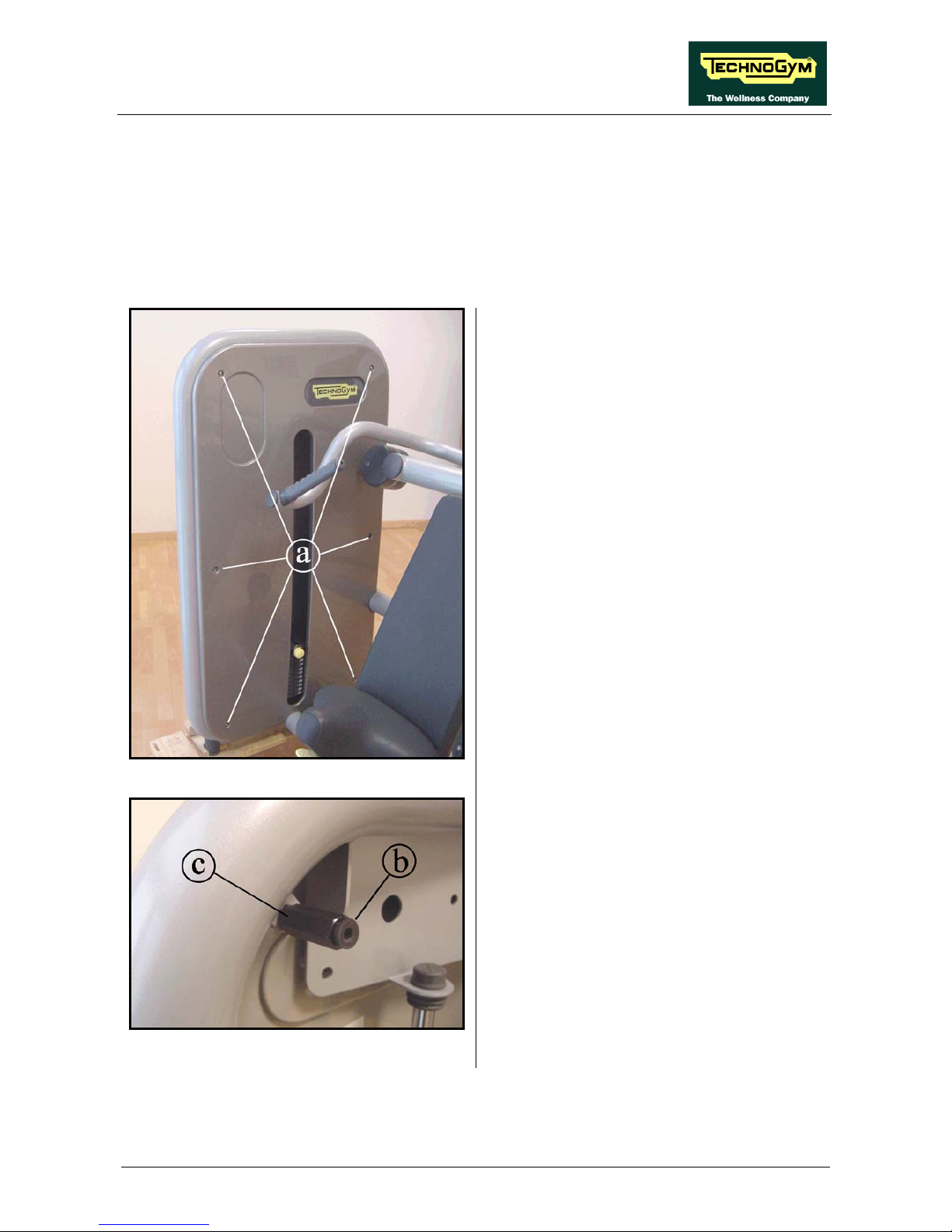

5.1. WEIGHT STACK CASING

Figure 5.1-1

1. Back off the screws (a), using a 4-mm hex

wrench.

2. Remove the front weight stack casing.

Figure 5.1-2

3. Before reassembling the casing, check all the

plastic bushing (b), with threaded piece, are

correctly inserted inside the support (c).

To disassemble the rear casing, carrying out the

procedure here above, on the rear side of the

machine.

To reassemble the weight stack casing, carry out

the above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.2

5.2. DISASSEMBLING THE WEIGHT STACK

Figure 5.2-1

Carry out the procedure described in paragraph

5.1. “Weight stack casing”.

1. Back off the screws (a), using a 5-mm hex

wrench.

2. Remove the weight stack casing support.

Figure 5.2-2

3. For both the weight stack rods, back off the

grub screws which secure the rods, reaching

them by the two holes (c) in the shock

absorbers. Use a 4-mm hex wrench.

The rod will move down by a few

centimetres.

Figure 5.2-3

4. Use a 4-mm hex wrench to back off the grub

screws (d) and remove the stop from both the

rods.

Figure 5.2-4

5. Back off the counter nut (e) and then the

threaded pin (f), using a 22-mm wrench.

6. Push the rods toward the back in order to

remove, from the top, all the plate of the

weight stack, additional weight assembly if

present.

To reassemble the weight stack, carry out the

above steps in reverse order.

After complete this procedure, adjust

the cable tension as detailed in

paragraph 6.2. “The weight stack cable

is not taut”.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.3

5.3. SEAT ON LOW MACHINES

This operation applies to Leg Curl and Leg Extension.

Figure 5.3-1

1. Back off the grub screws (a) which are fixing

the position of the seat position system lever,

using a 3-mm hex wrench. Carry out the

operation on both side of the seat.

Figure 5.3-2

2. Release the spring (b) of the seat position

system.

3. Slide the two plastic bushings (c) toward the

external side of the seat.

4. Remove the lever, sliding it out from the

lower side of the seat frame.

Figure 5.3-3

5. Move the seat into position 1 (all the way

forward) so that the gas spring is as fully

extended as possible.

6. Back off the screw (d) using a 5-mm hex

wrench.

7. Back off the screw (e) using a 6-mm hex

wrench and remove the plastic stop. Carry

out the operation on both side of the

machine.

8. Remove the seat, sliding it out from behind.

During the reassembling procedure

remember to place the spacer in the

inner side of the stop, as shown in the

picture.

To reassemble the weight stack, carry out the

above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.4

5.4. SEAT ON TALL MACHINES

This operation applies to Arm Curl, Arm Extension, Chest Press, Low Row, Pectoral,

Shoulder Press and Vertical Traction.

Figure 5.4-1

1. Remove the two rivets (a) and rotate the

plastic casing with the seat position numbers,

of 90° on the seat support.

Figure 5.4-2

2. Back off the screw (b) using a 5-gauge

hexagonal T-wrench.

3. Remove both the screw and the spacer which

are fixing the gas spring.

4. Remove the plastic cap (c).

Figure 5.4-3

5. Use an object such as a hammer handle to

compress the gas piston, then hold the piston

rod in place by inserting a screwdriver into

the hole underneath cap (c) and then into

hole underneath the spring as shown in the

figure.

6. Remove now the seat assembly from the

guides, pushing it toward the lower side.

Continued on next page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.5

Figure 5.4-4

To reassemble the seat assembly, carry out the

above steps in reverse order, compressing the

gas spring inside the tube as shown in the

picture to side.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.6

5.5. LEG PRESS SEAT

Figure 5.5-1

1. Remove the platform (a) using a 6-mm hex

wrench to back off the screws (b) (2 on each

side) indicated by the arrows in the figure,

which are accessed from the bottom.

Before continuing, use a strap to secure

the seat in the all-back position on the

guide bars, to prevent the cam (c) from

covering the screws (b).

Figure 5.5-2

2. Back off the screws (e) using a 3-mm hex

wrench.

3. Move the seat to the all-back position on the

guide bars.

4. Remove the cover plate (d) by pulling it

toward the front.

During reassembly, fit the spacers (f) on

the screws securing the cover plate.

Figure 5.5-3

5. Loosen the 4 dowels (g), using a 4-gauge

hexagonal T-wrench.

6. Remove the cable.

Continued on next page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.7

Figure 5.5-4

On both side of the machine:

1. Remove the cap (h).

2. Back off the screw (i) using a 3-mm hex

wrench.

3. Remove the plastic guard (l).

Figure 5.5-5

7. Back off the screw (m) using a 6-mm hex

wrench.

8. Remove the eccentric pin (n) by pulling it on

the side.

During reassembly, adjust the position

of the cam so that the wheel is in contact

with the bar, and clamp it by locking

down screw (m).

Figure 5.5-6

9. Remove the wheel (o) from the pin (p).

10. Back off the pin (p) using a 12-mm hex

wrench.

11. Remove the seat assembly by pulling it

upward.

To reassemble the seat assembly, carry out the

above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.8

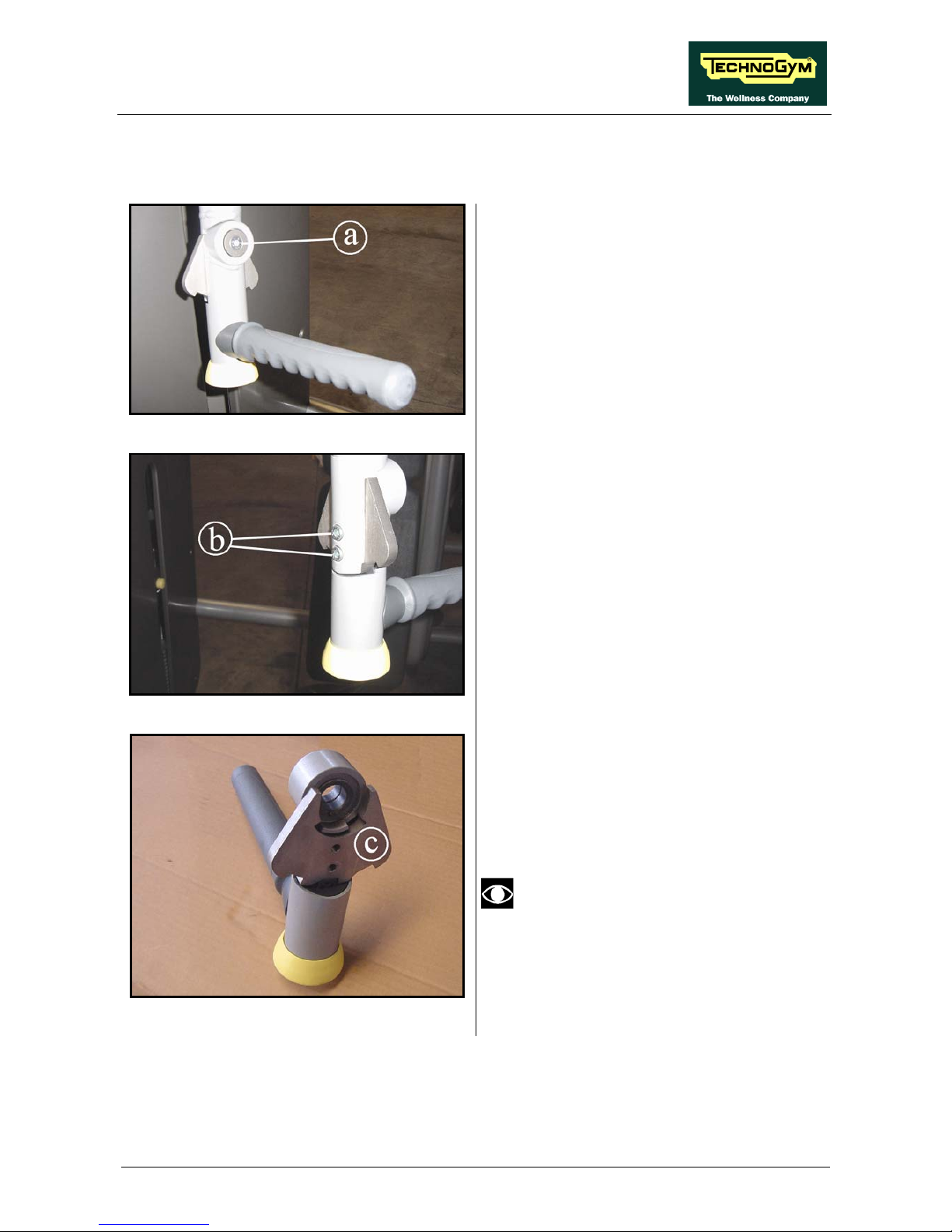

5.6. RELEASE LEVER

This operation applies to Leg Curl, Leg Extension Lower Back, and Glute.

Figure 5.6-1

1. Remove the plastic cap (a) using a flat

screwdriver.

Figure 5.6-2

2. Use a 10-mm wrench to back off the 3

screws (b).

3. Remove the plastic cover (c).

Figure 5.6-3

4. Back off the screw (d) using a 13-mm

wrench.

5. Remove the plate (e).

6. Back off the 4 screws (f) using a 4-mm hex

wrench.

7. Remove the tube (g) sliding it upward.

8. Slide the lever (h) a couple of cm toward the

external side, following the direction of the

arrow.

Continued on next page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.9

Figure 5.6-4

9. Remove the complete release button i and the

spring (l), sliding them upward.

Figure 5.6-5

10. Remove the spiral pin (m) and separate the

metal part of the release button from the

plastic one (n).

To reassemble the release button, carry out the

above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.10

5.7. DISASSEMBLING UNLOCKING LEVER ON ABDUCTOR -

ADDUCTOR

Figure 5.7-1

1. Remove the plastic cap (a).

2. Back off the screw (b) using an 8-mm hex

wrench, locking down the nut on the other

side with a 17-mm wrench.

Figure 5.7-2

3. Remove the two seeger (c) using the proper

pliers.

4. Remove the unlocking lever (d).

Figure 5.7-3

To disassemble the selector pin:

1. Back off the screws (e) using an 8-mm

wrench, locking down the pin with a pliers.

When reassemble the group, be careful

to insert all the bushings and the

washers in the same order, as shown in

the picture to side.

Continued on next page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.11

Figure 5.7-4

2. Back off the screw (f), using a 8-mm hex

wrench.

3. Remove the plastic stop (g).

Figure 5.7-5

4. Release the tension on the weight stack cable

by clamping the first plate as shown in the

figure.

Figure 5.7-6

5. Lift the selector pin using a pair of pliers and

turn the cam toward the back of the machine,

disengaging the cable from it.

6. Remove the pin (h) and its spring, pulling it

out from the bottom of the machine.

To reassemble the unlocking lever, carry out the

above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.12

5.8. DISASSEMBLING SHOULDER REST LEVER ON

ABDOMINAL CRUNCH

Figure 5.8-1

1. Back off the 4 screws (a) using a medium

Phillips screwdriver and remove the upper

plastic housing.

2. Back off the 2 screws (b) using a 5-mm hex

wrench and remove the lower plastic

housing.

Figure 5.8-2

3. Back off the 4 screws (c) using a 5-mm hex

wrench, remove the shoulder rest upholstery

d and its fixing plate.

4. Remove the cap (e) using a small flat

screwdriver.

Figure 5.8-3

5. Back off the plastic cap (g) using a 17-mm

hex wrench.

6. Pull out the roller upholstery (h) from the

lever tube.

7. Carry out the steps from 1 to 4, on the right

shoulder rest too.

To reassemble the shoulder rest lever, carry out

the above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.13

5.9. DISASSEMBLING ROLLERS ADJUSTING SYSTEM ON

LAT MACHINE

Figure 5.9-1

On both the rollers:

1. Remove the plastic cap (a).

2. Back off the screw (b) using a 5-mm hex

wrench and pull the roller out from the side.

Figure 5.9-2

3. Back off the screws using a 4-mm hex

wrench on both side and remove the plastic

guard.

Figure 5.9-3

4. Back off the screw (d) using a 5-mm hex

wrench, locking down the pin on the

opposite side using a 6-mm hex wrench.

5. Remove the pin e and the rollers support

frame (f).

Take care during reassembly procedure

to replace the spacer (g) as shown in the

figure to side.

Continued on next page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.14

Figure 5.9-4

6. Back off the pin (h), using a 30-mm wrench.

7. Remove the pin i from the lower side.

Figure 5.9-5

8. Remove the cylindrical pin (l) to disassemble

the plastic part from the metal one and to

remove the spring.

To reassemble the adjusting system, carry out

the above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.15

5.10. DISASSEMBLING HANDLES ADJUSTING SYSTEM ON

CHEST PRESS

Figure 5.10-1

1. Back off the screw (a) using a 6-mm hex

wrench.

Figure 5.10-2

2. Back off the screws (b) using a 6-mm hex

wrench.

3. Remove the handle assembly from the

machine lever.

Figure 5.10-3

4. Remove the selector plate (c).

Take care during reassembly procedure

to replace the plate “c” in the right way

as shown in the figure to side.

Continued on next page

→

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.16

Figure 5.10-4

9. Back off the 2 screws (d) using a medium

Phillips screwdriver.

10. Remove the yellow knob from the lower side

and the spring (e) from the handle frame.

To reassemble the handle adjusting system,

carry out the above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.17

5.11. DISASSEMBLING EASY START SYSTEM ON PECTORAL

Figure 5.11-1

1. Remove the cap (a).

2. Back off the screw under the cap, using a 6-

mm hex wrench locking down the nut on the

opposite side with a 17-mm wrench.

3. Remove the lever (b).

Figure 5.11-2

4. Back off the screw (c) using a 8-mm hex

wrench.

5. Back off the rubber stop (d).

6. Remove the selecting plate (e).

7. Back off the screw (f) using a 3-mm hex

wrench.

8. Remove the piece (g).

Figure 5.11-3

9. Remove the selector plate (c).

During reassembly, take care to insert

the pin (h) so that the flattened part is

toward the grub screw (i).

To reassemble the easy start system, carry out

the above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 5.18

5.12. DISASSEMBLING THE ADDITIONAL WEIGHT

Figure 5.12-1

1. Carry out the procedure at paragraph 5.2.

“Disassembling the weight stack” as far as

step 5, disassembling only the front casing.

2. Push the rods toward the front side in order

to remove, from the top, the additional

weight assembly (a).

Figure 5.12-2

3. To remove the additional weight support

plate (b) back off the two screws (c) using a

6-mm wrench locking down the nuts on the

other side using a 17-mm wrench.

To reassemble the additional weight, carry out

the above steps in reverse order.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 6.1

6. WHAT IF …

6.1. THE WEIGHT STACK DOES NOT SLIDE SMOOTHLY

This problem is due to insufficient lubrication of the bars or grime build-up from a mixture of dust

and oil. Clean and lubricate as illustrated below:

ATTENTION: When the bars and bushings are particularly dirty, if the only cross or at

most the first plate is selected, it is possible that these can not lay down on the weight

stack. In this case you must clean and lubricate the bars and the internal side of the

bushes.

Figure 6.1-1

1. Use a paper towel slightly dampened with

ethyl alcohol to clean the weight stack bars

of the machine, removing dust and grime.

2. Reassemble the cross and add a few drops of

the oil found in the service box to the cross

bushings as shown in the photo below.

3. Move the cross up and down, making sure to

distribute the oil evenly along the full length

of the bars.

4. Dry excess oil from the bushings with a dry

cloth.

ATTENTION: Do not use too much oil,

and dry all excess thoroughly since too

much oil could cause more dust to build

up.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 6.2

6.2. THE WEIGHT STACK CABLE IS NOT TAUT

This problem is due to lengthening of the weight stack cable. Therefore, to solve the problem you

must use the cable tension adjustment system.

If the cable is new, before adjusting its tension, it is necessary to do a few reps at

maximum load to “stretch” the cable itself.

Figure 6.2-1

1. Set the minimum weight: the only selected

weight will be the cross.

2. Loosen the counter-nut (a) using a 22-gauge

wrench.

3. Tighten the screw (b) at the end of the cable

so that the cable is taut and the cross raised.

4. Slowly loosen the screw (b) until the cable is

still taut, but the cross is resting on the

weight stack.

5. Tighten the counter-nut (a) using a 22-gauge

wrench.

Check the right tension of the cable,

making sure all the weight stack plates

are selecting by the weight stack pin.

Check the tension of the cable by carrying out a couple of repetitions with the minimum

weight, and then slowly resting the cross on the weight stack. The cross must rest firmly

on the weight stack, and the cable must be slightly taut.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 6.3

6.3. THE MACHINE IS NOT FLAT

To level the machine, you may adjust the height of the levelling foot as illustrated below:

Figure 6.3-1

1. Lift the machine on one side until you can

access the underside of the foot.

2. Loosen the foot cover piece (B).

3. Tighten or loosen the foot (A) until the

equipment is stable on the floor.

We recommend that 2 people carry out this operation.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 6.4

6.4. THE LEVERS OF DUAL-AXIS MACHINES ARE NOT

ALIGNED

This operation applies to Abductor, Adductor, Arm Curl, Arm Extension, Chest Press,

Low Row, Pectoral, Shoulder Press and Vertical Traction.

To align the levers of dual-axis machines, you may adjust the position of the stop buffers against

which the machine levers rest, as illustrated below:

Figure 6.4-1

1. Loosen the counter-nut (a) on both sides,

using a 17-gauge wrench.

2. Adjust the position of the 2 stop buffers (b),

tightening or loosening them until the levers

are aligned.

Use a lever for a more precise check.

3. When the adjustment is complete, tighten the

counter-nuts (a) once again.

This procedure may also be carried out

to adjust the starting position of the

levers on the other machines.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 7.1

7. SPECIAL OPERATIONS

The term special operations refers to those procedures whose correct execution is fundamental for

the safe and reliable operation of the machine.

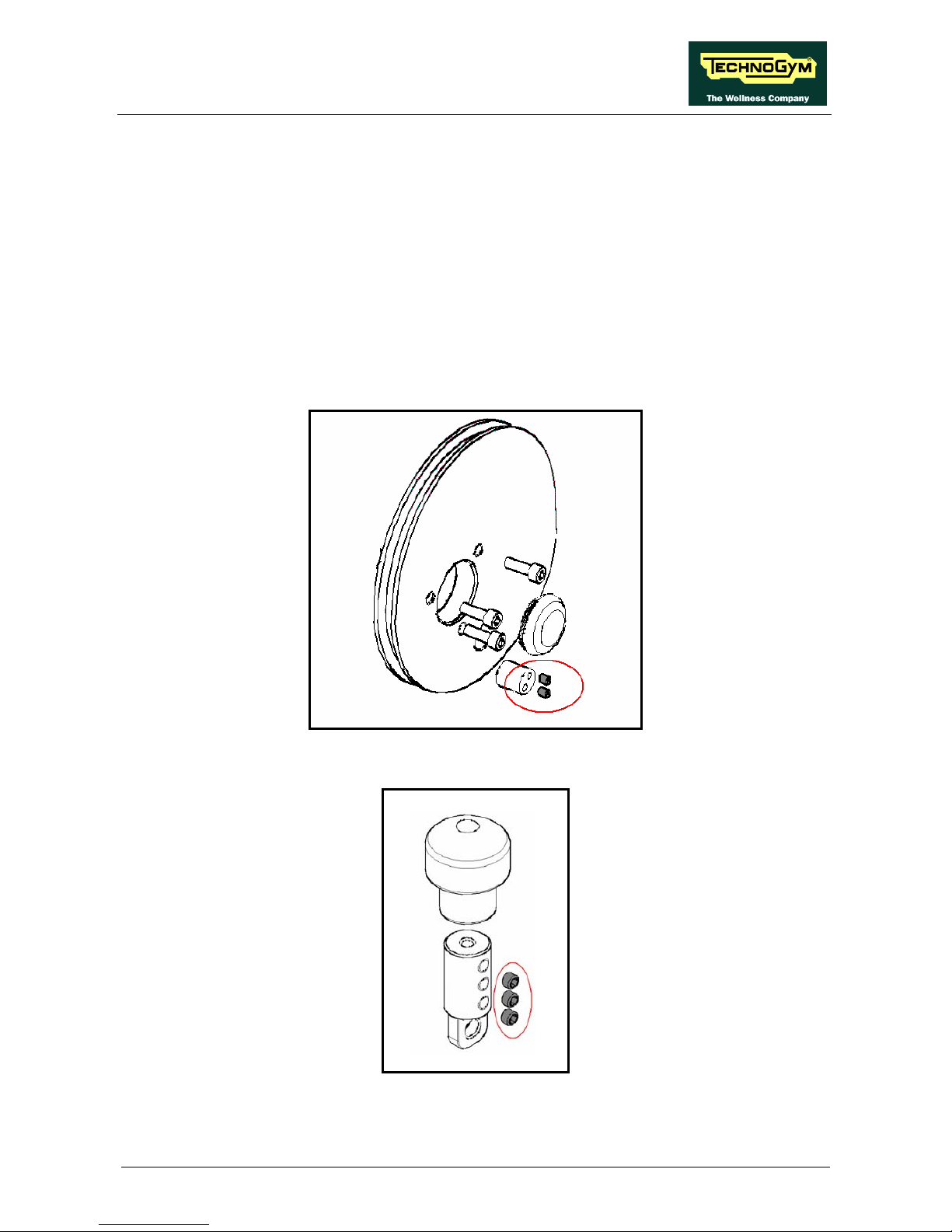

7.1. LOCKING DOWN THE CABLE FIXING DOWELS

At least one end of the weight stack cable is fixed to the wheel or to a stop by means of the dowel

screws highlighted in grey and circled in the figures below. The fixing dowels must be carefully

locked down to prevent them from working loose and allowing the cable to come out, causing

problems to the user.

Figure 7.1-1

Figure 7.1-2

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 7.2

Figure 7.1-3

Use a torque wrench to ensure that the dowels are locked down with the prescribed torque of 16.5

Nm / 12.2 ft.lbs.

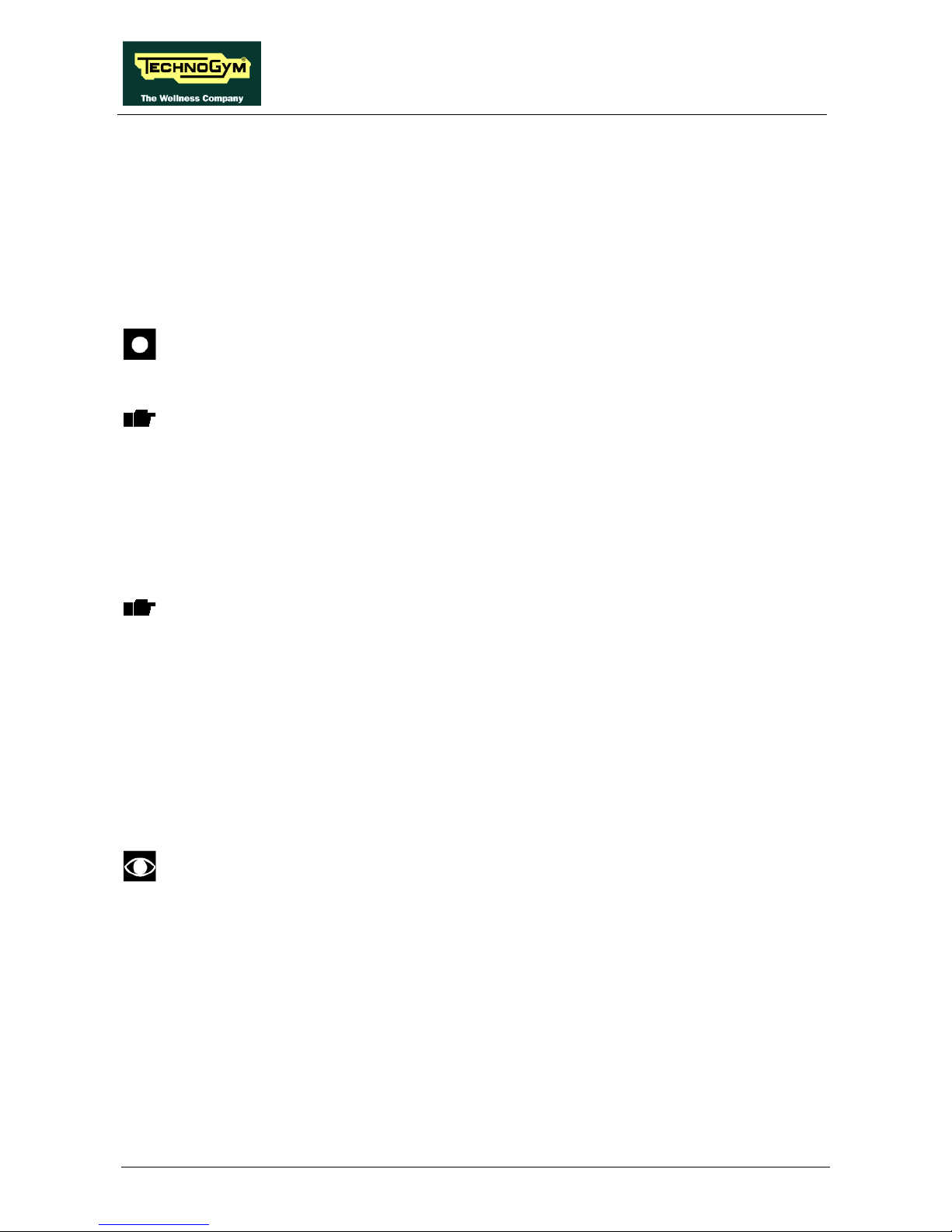

7.2. LOCKING DOWN THE PULLEYS

The screws of the pulleys, highlighted in grey and circled in the figure below, must be carefully

locked down to prevent them from working loose and causing problems to the user.

Figure 7.2-1

Use a torque wrench to ensure that the screws are locked down with the prescribed torque of 50 Nm

/ 36.9 ft.lbs.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 7.3

7.3. LOCKING DOWN THE DOWELS ON THE ARM

EXTENSION LEVER

Each lever of the Arm Extension machine has a joint consisting of 2 threaded ends and one with an

intermediate steel cable. This must be fixed without excessive force, to avoid over-tightening and

damaging the steel cable. Therefore, lock down until the end of the thread, and then use the 3 dowel

screws circled in the figure below to secure the components in place.

Figure 7.3-1

Use a torque wrench to check that they are locked down with the prescribed torque of 13 Nm / 9.6

ft.lbs.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 7.4

Page intentionally left blank

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.1

8. WEIGHT STACK CABLE

8.1. LENGTH OF THE WEIGHT STACK CABLES

Standard weight stack

Code Machine

code Length (mm)

MA05

Adductor 0R000131AA 4800

MA10

Abductor 0R000115AA 4400

0R000111AA

(1)

1090

MA15

Shoulder Press

0R000112AA 3360

0R000111AA

(1)

3050

MA20

Chest Press

0R000112AA 3360

0R000111AA

(1)

3050

MA25

Vertical Traction

0R000118AA 3000

MA30

Leg Extension 0R000119AA 3500

MA35

Leg Curl 0R000118AA 3000

MA40

Lat Machine 0R000130AA 2400

MA45

Lower Back 0R000119AA 3500

0R000128AC crimpato

MA50

Leg Press

0R000008

(1)

1500

0R000111AA

(1)

4100

MA55

Arm Curl

0R000112AA 3360

0R000111AA

(1)

4030

MA60

Arm Extension

0R000112AA 3360

MA65

Abdominal Crunch 0R000119AA 3500

0R000112AA 3360

MA70

Pectoral

0R000126AB 775

MA75

Glute 0R000124AA 2100

MA80

Ercolina

0R000111AA

(1)

6300

MA85

Ercolina Crossover Cable

0R000111AA

(1)

1140

MA90

Ercolina Rehab

0R000111AA

(1)

8300

MA95

Low Row 0R000131AA 4800

(1) You must indicate the length when ordering this cable.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.2

8.2. ROUTING OF THE WEIGHT STACK CABLE

The following pages illustrate the routing of the weight stack cables through the pulleys for each

machine, for use as reference when replacing the machine cables.

8.2.1. MA05 – ADDUCTOR

MA05 – ADDUCTOR

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.3

8.2.2. MA10 – ABDUCTOR

MA10 – ABDUCTOR

8.2.3. MA15 – SHOULDER PRESS

MA15 – SHOULDER PRESS

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.4

8.2.4. MA20 – CHEST PRESS

MA20 – CHEST PRESS

8.2.5. MA25 – VERTICAL TRACTION

MA25 – VERTICAL TRACTION

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.5

8.2.6. MA30 – LEG EXTENSION

MA30 – LEG EXTENSION

8.2.7. MA35 – LEG CURL

MA35 – LEG CURL

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.6

8.2.8. MA40 – LAT MACHINE

MA40 – LAT MACHINE

8.2.9. MA45 – LOWER BACK

MA45 – LOWER BACK

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.7

8.2.10. MA50 – LEG PRESS

MA50 – LEG PRESS

8.2.11. MA55 – ARM CURL

MA55 – ARM CURL

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.8

8.2.12. MA60 – ARM EXTENSION

MA60 – ARM EXTENSION

8.2.13. MA65 – ABDOMINAL CRUNCH

MA65 – ABDOMINAL CRUNCH

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.9

8.2.14. MA70 – PECTORAL

MA70 – PECTORAL

8.2.15. MA75 – GLUTE

MA75 – GLUTE

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.10

8.2.16. MA80 – ERCOLINA

MA80 – ERCOLINA

8.2.17. MA85 – ERCOLINA CROSS OVER CABLE

MA85 – ERCOLINA CROSS OVER CABLE

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.11

8.2.18. MA90 – ERCOLINA REHAB

MA90 – ERCOLINA REHAB

8.2.19. MA95 – LOW ROW

MA95 – LOW ROW

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 8.12

Page intentionally left blank

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 9.1

9. MAINTENANCE

To keep the machine in perfect working order and forestall possible problems it is necessary to

carry out the scheduled maintenance operations described below. The maintenance operations can

essentially be classified according to the frequency with which they need to be performed:

• Daily maintenance operations;

• Weekly maintenance operations;

• Monthly maintenance operations;

• Twice yearly maintenance operations.

The operations require different levels of operator qualification. The following paragraphs describe

the recommended procedures.

9.1. DAILY MAINTENANCE OPERATIONS

These operations can be carried out by the machine owner and do not require any

special skills.

The daily machine maintenance consists of simple external cleaning, for the purposes of general

hygiene.

For the daily maintenance of the machine, proceed as follows:

9.1.1. CLEANING UPHOLSTERY

1. We recommend that you perform this operation daily.

2. Clean the upholstery of the machine using a cloth moistened with Clean Well.

CAUTION: do not use alcohol, benzene, or chemical products in general.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 9.2

9.2. WEEKLY MAINTENANCE OPERATIONS

These operations can be carried out by the machine owner and do not require any

special skills.

The weekly machine maintenance operations consists of simple cleaning, lubrication and checking

the emergency stop to ensure the correct and safe functioning of the machine.

For the weekly maintenance operations, proceed as follows:

9.2.1. CLEANING THE FRAME AND PAINTED PARTS

1. Clean the frame and painted parts of the machine using a cloth moistened with Clean Well.

CAUTION: do not use alcohol, benzene, or chemical products in general.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 9.3

9.3. MONTHLY MAINTENANCE OPERATIONS

These operations can be carried out by the machine owner and do not require any

special skills.

The monthly machine maintenance operations consists of simple cleaning, lubrication and

checking the state of wear to ensure the correct and safe functioning of the machine.

For the monthly maintenance of the machine, proceed as follows:

9.3.1. CHECK THE CROSS, BARS AND WEIGHT STACK PLATES

1. Check the wear status of the cross bushings and weight stack plates. Repair and/or replace any

worn parts.

2. Check the wear status of the chrome plating of the weight stack bars. Repair and/or replace any

worn parts.

3. Check the wear status of the weight stack bars and weight stack support stops. Repair and/or

replace any worn parts.

4. Make sure the weight stack bars are firmly fastened. Repair and/or replace any worn parts.

5. Use a paper towel slightly dampened with ethyl alcohol to clean the weight stack bars of the

machine, removing dust and grime.

CAUTION: remove any surface rust spots with a metal scrubber.

6. Lubricate the bars and bushings of the plates and cross using the oil found in the service box.

7. Check the adhesive label indicating the load corresponding to the weight stack plates. Replace

any worn parts.

9.3.2. CHECK THE CABLES

1. Check the wear status of the machine cables, paying special attention to any hardened spots or

cracks in the protective plastic of the cable. Replace any worn parts.

2. Check the passage of the machine cables through cams, pulleys and/or the terminals connected

to ball joints.

3. Check the tension of the machine cables.

9.3.3. CHECK THE MECHANISMS

1. Check the wear status of the machine mechanisms: lever arms, shafts, lever systems. Repair

and/or replace any worn parts.

2. Lubricate the mechanisms using MOLYKOTE LONGTERM W 2.

9.3.4. CHECK THE GAS SPRINGS

1. Check the efficiency of the gas spring, making sure it sufficiently cushions the stem return to its

outward position.

2. Clean the stem using a dry cloth.

CAUTION: do NOT lubricate the gas spring stem for any reason.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 9.4

9.3.5. CHECK THE WEIGHT STACK STOPS

1. Check the wear status of the stops. Repair and/or replace any worn parts.

2. Check the position of the stops and make sure they are firmly fastened in place.

9.3.6. CHECK THE LEG PRESS SEAT MECHANISM

1. Check the wear status of the support bars and seat pulleys. Repair and/or replace any worn

parts.

2. Clean the seat support bars using alcohol.

CAUTION: lubricate the support bars with silicon oil.

9.3.7. CHECKING THE SEAT MECHANISM ON LOW MACHINES

Perform this check on the Leg Extension, Leg Curl.

1. Check the wear status of the pulleys, support bars and seat guide. Repair and/or replace any

worn parts.

2. Clean the seat support guide bars using alcohol.

3. Lubricate the seat support guide bars using the oil found in the box service.

9.3.8. CHECKING THE SEAT MECHANISM ON TALL MACHINES

Perform this check on the Arm Curl, Arm Extension, Chest Press, Low Row, Pectoral,

Shoulder Press, Vertical Traction, Scott Bench, Inclined Bench Press and Vertical

Bench.

1. Check the wear status of the seat guide pulleys. Repair and/or replace any worn parts.

2. Clean the seat guide pulleys using alcohol.

3. Lubricate the seat support guide bars using the oil found in the box service.

9.3.9. CHECKING THE UPHOLSTERY

1. Check the wear status of the upholstery. Replace any worn parts.

9.3.10. CHECKING VARIOUS RUBBER PARTS

These operations apply to handles, knobs, mats, frame guards, bell covers, feet …

1. Check the wear status of the rubber parts used on the machine. Repair and/or replace any worn

parts.

ELEMENT LINE: Service & Maintenance Manual - rev. 1.2

Page 9.5

9.4. TWICE-YEARLY MAINTENANCE OPERATIONS

These operations can only be carried out by a qualified technician specifically trained by

Technogym and authorized to carry out machine installation and adjustments, as well as

special maintenance operations or repairs which require special knowledge of the