SERVICE & MAINTENANCE MANUAL

REV. 1.1

The information contained in this manual is intended for QUALIFIED TECHNICIANS who have

completed a specific TECHNOGYM training course and are authorized to perform machine start-

up and adjustment procedures as well as extraordinary maintenance or repairs which require a

thorough knowledge of the machine, its operation, its safety devices and working procedures.

CAREFULLY READ THE INFORMATION CONTAINED IN

THIS MANUAL BEFORE PERFORMING ANY MAINTENANCE

PROCEDURES ON THE MACHINE

DANGEROUS VOLTAGES

PRESENT

NOTE

The information contained in this document is subject to change without notice.

Technogym does not guarantee this documentation in any way. Technogym shall not be held

responsible for any errors contained in this manual and declines all liability for accidents or

damages resulting from the supply, characteristics or use of this manual.

This document contains proprietary information that is protected by copyright. All rights reserved.

No part of this document may be photocopied, reproduced or translated into another language

without the prior written consent of Technogym.

The Technogym™ trademark is property of Technogym S.p.A.

The Jog Excite™ trademark is property of Technogym S.p.A.

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

Contents

1. GENERAL NOTICES............................................................................................................................................. 1.1

1.1. INTRODUCTION................................................................................................................................................1.1

1.2. RECOMMENDATIONS ....................................................................................................................................... 1.1

1.3. GENERAL RULES FOR REPAIR PROCEDURES......................................................................................................1.2

2. TECHNICAL CHARACTERISTICS.................................................................................................................... 2.1

2.1. PRODUCT CODES.............................................................................................................................................. 2.1

2.2. FEATURES AND FUNCTIONS. ............................................................................................................................2.2

2.3. MECHANICAL CHARACTERISTICS.....................................................................................................................2.3

2.4. CONFORMITY REGULATIONS............................................................................................................................ 2.3

2.5. AMBIENT SPECIFICATIONS ...............................................................................................................................2.3

2.6. WIRING DIAGRAM............................................................................................................................................2.4

2.6.1. Lower assembly................................................................................................................................2.4

2.6.2. Upper assembly: LED ARM version.................................................................................................2.5

2.7. WIRING............................................................................................................................................................2.6

3. PRINCIPLES OF OPERATION............................................................................................................................ 3.1

3.1. BLOCK DIAGRAM.............................................................................................................................................3.1

3.1.1. Display board................................................................................................................................... 3.2

3.1.2. TGS reader.......................................................................................................................................3.2

3.1.3. HS / cardio receiver board...............................................................................................................3.2

3.1.4. Emergency switch.............................................................................................................................3.3

3.1.5. Belt motor.........................................................................................................................................3.3

3.1.6. Elevation motor................................................................................................................................3.3

3.1.7. Limit switch.......................................................................................................................................3.3

3.1.8. AT driver...........................................................................................................................................3.3

3.1.9. Power supply box..............................................................................................................................3.5

3.2. TREAD BELT MOTOR DRIVE.............................................................................................................................. 3.6

3.2.1. Mechanics.........................................................................................................................................3.6

3.2.2. Controls............................................................................................................................................3.6

3.2.3. The signals involved.........................................................................................................................3.7

3.3. ELEVATION MOTOR DRIVE............................................................................................................................... 3.8

3.3.1. Mechanics.........................................................................................................................................3.8

3.3.2. Control..............................................................................................................................................3.8

3.3.3. The reset procedure..........................................................................................................................3.9

3.3.4. The signals involved.........................................................................................................................3.9

3.4. EMERGENCY STOP MANAGEMENT..................................................................................................................3.11

3.4.1. Control............................................................................................................................................3.11

3.4.2. The signals involved.......................................................................................................................3.12

3.1.8.1. AT driver board............................................................................................................................................................. 3.4

3.1.8.2. AT power supply board................................................................................................................................................. 3.5

3.1.8.3. Fans................................................................................................................................................................................ 3.5

3.1.8.4. Breaking resistor ...........................................................................................................................................................3.5

4. ACCESSORIES .......................................................................................................................................................4.1

4.1. CARDIO THEATER CONNECTION.......................................................................................................................4.1

4.2. PC LINK FOR PROGRAMMING ...........................................................................................................................4.1

4.3. MONITOR PLUG FOR CSAFE PORT ....................................................................................................................4.2

5. INSTALLATION INSTRUCTIONS...................................................................................................................... 5.1

5.1. SPECIFICATIONS AND REQUIREMENTS..............................................................................................................5.1

5.2. INSTALLATION.................................................................................................................................................5.2

5.3. FIRST POWER-ON .............................................................................................................................................5.2

Page i

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

6. TROUBLESHOOTING ..........................................................................................................................................6.1

6.1. TROUBLESHOOTING SERVICE MENU.................................................................................................................6.2

6.1.1. Automatic Tests.................................................................................................................................6.3

6.1.2. Manual Test......................................................................................................................................6.4

6.2. THE DISPLAY FAILS TO ILLUMINATE.................................................................................................................6.5

6.3. “PRESS A KEY” MESSAGE ON THE DISPLAY ..................................................................................................6.9

6.4. “THE EQUIPMENT IS BLOCKED” MESSAGE ON THE DISPLAY .................................................................6.10

6.5. AT DRIVER ERROR.........................................................................................................................................6.11

6.5.1. Error OH........................................................................................................................................6.13

6.5.2. Errors OC - OLi - OLm - Ot - OCH - MST - SHC.........................................................................6.14

6.5.3. Error UU........................................................................................................................................6.15

6.5.4. Error OU........................................................................................................................................6.16

6.5.5. Error OtM.......................................................................................................................................6.17

6.5.6. Error OLr.......................................................................................................................................6.18

6.5.7. Error PE.........................................................................................................................................6.19

6.5.8. Error EM........................................................................................................................................6.20

6.6. TREAD BELT MOTOR IS JERKING.....................................................................................................................6.21

6.7. “GRADIENT NOT WORKING” MESSAGE ON THE DISPLAY .......................................................................6.22

6.8. THE MACHINE DOES NOT READ THE TGS.........................................................................................................6.24

6.9. THERE IS NO HEART RATE SIGNAL.................................................................................................................. 6.26

6.9.1. Telemetric receiver HFU................................................................................................................6.26

6.9.2. Hand sensor....................................................................................................................................6.27

6.10. THE TELEMETRIC HR SIGNAL IS INCORRECT ...................................................................................................6.29

6.1.1.1. I2C Device Test............................................................................................................................................................. 6.3

6.1.1.2. UpDown Test ................................................................................................................................................................6.3

6.1.1.3. Inverter Test ..................................................................................................................................................................6.3

6.1.1.4. LED Test ....................................................................................................................................................................... 6.4

6.1.1.5. Serial Ports Test............................................................................................................................................................. 6.4

6.1.2.1. Man. Keyboard Test......................................................................................................................................................6.4

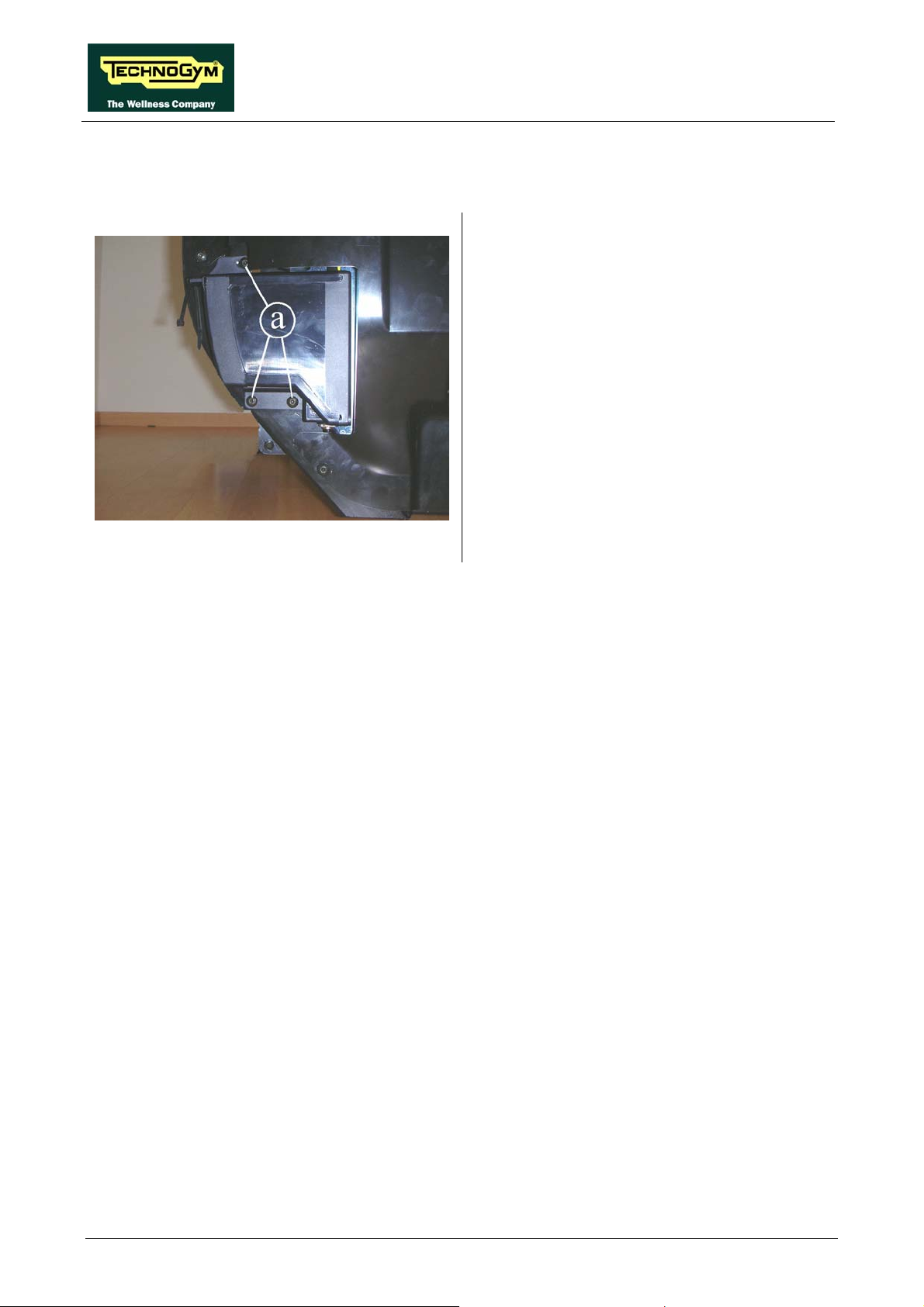

7. DISASSEMBLY OF COMPONENTS................................................................................................................... 7.1

7.1. DISASSEMBLING THE DISPLAY .........................................................................................................................7.1

7.2. DISASSEMBLING THE CIRCUIT BOARDS OF THE DISPLAY ..................................................................................7.2

7.3. DISASSEMBLING THE KEYBOARD.....................................................................................................................7.3

7.4. DISASSEMBLING THE EMERGENCY BUTTON .....................................................................................................7.4

7.5. DISASSEMBLING THE CARDIO RECEIVER/HAND SENSOR BOARD .......................................................................7.5

7.6. DISASSEMBLING THE SENSORS.........................................................................................................................7.7

7.7. DISASSEMBLING THE READY TO RUN BOARD ..................................................................................................7.8

7.8. SMONTAGGIO MANIGLIONI ..............................................................................................................................7.9

7.9. DISASSEMBLING THE MOTOR GUARD............................................................................................................. 7.10

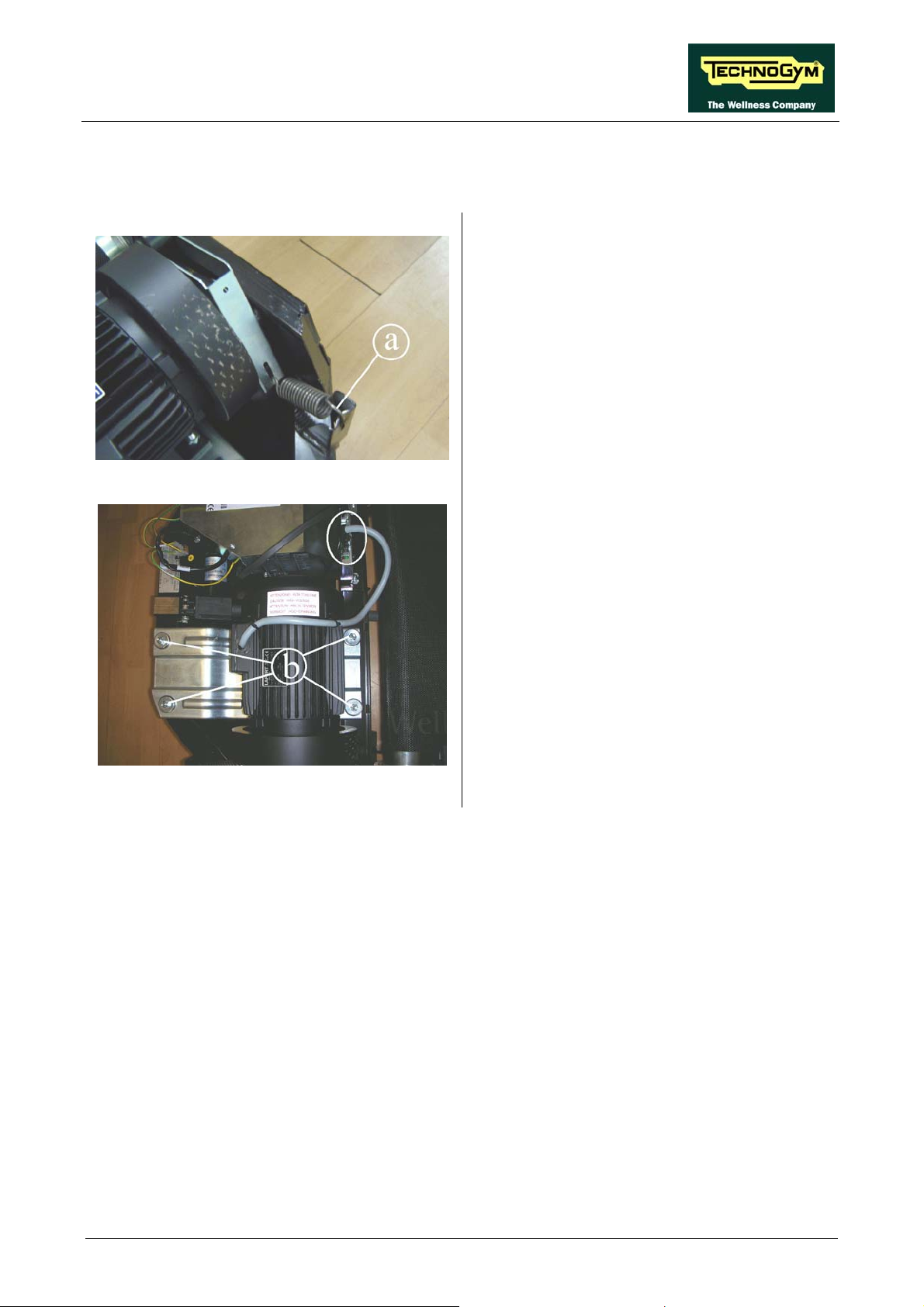

7.10. DISASSEMBLING THE MOTOR COMPARTMENT FAN.........................................................................................7.11

7.11. DISASSEMBLING THE LIMIT SWITCH...............................................................................................................7.12

7.12. DISASSEMBLING THE ELECTRICAL BOX.......................................................................................................... 7.13

7.13. DISASSEMBLING THE ELECTRONICS BOARDS ................................................................................................. 7.14

7.14. DISASSEMBLING THE POWER SUPPLY BOX ..................................................................................................... 7.16

7.15. DISASSEMBLING THE TREAD BELT MOTOR.....................................................................................................7.17

7.16. DISASSEMBLING THE ELEVATION MOTOR ...................................................................................................... 7.18

7.17. DISASSEMBLING THE TREAD BELT GROUP...................................................................................................... 7.19

8. ADJUSTMENTS...................................................................................................................................................... 8.1

8.1. TENSIONING A NEW TREAD BELT ..................................................................................................................... 8.1

8.2. TENSIONING A USED TREAD BELT ....................................................................................................................8.2

8.3. CENTERING THE TREAD BELT........................................................................................................................... 8.3

8.4. POSITION OF THE LIMIT SWITCH.......................................................................................................................8.4

9. MACHINE CONFIGURATION............................................................................................................................ 9.1

9.1. USER MENU CONFIGURATION...........................................................................................................................9.1

9.1.1. Language..........................................................................................................................................9.1

9.1.2. Distance............................................................................................................................................ 9.2

Page ii

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

9.1.3. Maximum exercise time....................................................................................................................9.2

9.1.4. Pause time ........................................................................................................................................9.2

9.1.5. Default age.......................................................................................................................................9.3

9.1.6. Default weight...................................................................................................................................9.3

9.1.7. Default time......................................................................................................................................9.3

9.1.8. Default calories................................................................................................................................9.4

9.1.9. Default distance................................................................................................................................9.4

9.1.10. Enable TGS.......................................................................................................................................9.4

9.1.11. Enable keyboard ...............................................................................................................................9.5

9.1.12. Modifiable target heart rate.............................................................................................................9.5

9.1.13. Enable custom messages ..................................................................................................................9.5

9.1.14. Enable up/down motor......................................................................................................................9.6

9.1.15. Resetting parameters to default values.............................................................................................9.6

9.1.16. Format P&P.....................................................................................................................................9.6

9.1.17. User Detect ....................................................................................................................................... 9.6

9.1.18. SN.....................................................................................................................................................9.7

9.1.19. Ready2Run........................................................................................................................................9.7

9.2. SERVICE MENU CONFIGURATION......................................................................................................................9.8

9.2.1. Low kit parameter.............................................................................................................................9.9

9.2.2. UpDown settings.............................................................................................................................9.10

9.2.3. Usage data......................................................................................................................................9.12

9.2.4. Errors log.......................................................................................................................................9.13

9.2.5. Standard settings............................................................................................................................9.15

9.2.6. Low kit menu...................................................................................................................................9.15

9.2.7. High kit version ..............................................................................................................................9.20

9.2.8. BOOT version ................................................................................................................... .............. 9.20

9.2.9. Key Reader Version........................................................................................................................9.20

9.3. DRIVER AUTOTUNING....................................................................................................................................9.21

9.4. RECALL PARAMETERS....................................................................................................................................9.21

9.5. DEFAULT PARAMETERS ................................................................................................................................. 9.22

9.2.1.1. Read from low kit.......................................................................................................................................................... 9.9

9.2.1.2. Write to low kit.............................................................................................................................................................. 9.9

9.2.1.3. Default setting ............................................................................................................................................................... 9.9

9.2.1.4. Table of configuration parameters..............................................................................................................................9.10

9.2.2.1. Read from low kit........................................................................................................................................................ 9.11

9.2.2.2. Write to low kit............................................................................................................................................................ 9.11

9.2.2.3. Default setting ............................................................................................................................................................. 9.11

9.2.3.1. Read from low kit........................................................................................................................................................ 9.12

9.2.3.2. Write to low kit............................................................................................................................................................ 9.12

9.2.3.3. Machine usage data..................................................................................................................................................... 9.13

9.2.4.1. Read from low kit........................................................................................................................................................ 9.13

9.2.4.2. Reset errors.................................................................................................................................................................. 9.14

9.2.4.3. COM.Fault................................................................................................................................................................... 9.14

9.2.4.4. View Errors ................................................................................................................................................................. 9.14

9.2.6.1. Low kit version............................................................................................................................................................ 9.16

9.2.6.2. Config. registers..........................................................................................................................................................9.16

10. SCHEDULED MAINTENANCE .........................................................................................................................10.1

10.1. DAILY MAINTENANCE OPERATIONS ...............................................................................................................10.1

10.1.1. Setting up the operation..................................................................................................................10.1

10.1.2. External cleaning operations..........................................................................................................10.1

10.2. WEEKLY MAINTENANCE OPERATIONS............................................................................................................10.2

10.2.1. Checking the “Emergency stop”.................................................................................................... 10.2

10.2.2. Complete operation........................................................................................................................10.2

10.3. MONTHLY MAINTENANCE OPERATIONS .........................................................................................................10.3

10.3.1. Internal cleaning operations ..........................................................................................................10.3

10.3.2. Checking the state of wear..............................................................................................................10.3

10.3.3. Checking the operation of the cardiotester receiver.......................................................................10.3

10.3.4. Checking the operation of the hand sensor receiver......................................................................10.3

10.4. TWICE-YEARLY MAINTENANCE OPERATIONS................................................................................................. 10.4

10.4.1. carrying out the monthly maintenance procedure..........................................................................10.4

10.4.2. Checking the working conditions....................................................................................................10.4

Page iii

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

10.4.3. Checking the wiring and connections.............................................................................................10.4

10.4.4. Checking the wear and lubrication of the tread belt and running deck.........................................10.5

10.4.5. Checking the wear of the driving roller..........................................................................................10.5

10.4.6. Checking the wear of the rear roller..............................................................................................10.5

10.4.7. Checking the shock absorbers........................................................................................................ 10.5

10.4.8. Checking the tread belt motor drive-belt........................................................................................10.5

10.4.9. Checking and centering the tread belt............................................................................................10.5

10.4.10. Checking the display.......................................................................................................................10.6

11. APPENDIX............................................................................................................................................................. 11.1

11.1. UPDATING THE SW.........................................................................................................................................11.1

11.2. TOOLS TO USE................................................................................................................................................11.2

Page iv

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

1. GENERAL NOTICES

1.1. INTRODUCTION

This document is reserved for Technogym Service technicians, and is intended to provide

authorized personnel with the necessary information to correctly carry out repairs and maintenance.

A thorough knowledge of the technical information contained in this manual is essential for

completing the professional training of the operator.

In order to facilitate consultation, the paragraphs are accompanied by schematic drawings which

illustrate the procedure being described.

This manual contains notices and symbols which have a specific meanings:

WARNING: non observance may result in accident or injury.

ATTENTION: non observance may cause damage to the machine.

Information about the operation in progress.

OBSERVE: observation about the operation in progress.

1.2. RECOMMENDATIONS

Technogym recommends the following steps for planning repair procedures:

• Carefully evaluate the customer’s description of the machine malfunction and ask all the

necessary questions to clarify the symptoms of the problem.

• Clearly diagnose the causes of the problem. This manual provides the fundamental theoretical

basis, which must then be integrated by personal experience and attendance at the training

courses periodically offered by Technogym.

• Rationally plan the repair procedure so as to minimize the downtime necessary for procuring

spare parts, preparing tools, etc.

• Access the component to be repaired, avoiding any unnecessary operations. In this regard it will

be useful to refer to the disassembly sequence described in this manual.

Page 1.1

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

1.3. GENERAL RULES FOR REPAIR PROCEDURES

1. Always mark any parts or positions which may be confused with each other at the time of

reassembly.

2. Use original Technogym spare parts and lubricants of the recommended brands.

3. Use special tools where specified.

4. Consult the Technical Newsletters, which may contain more up-to-date information on

adjustments and maintenance than those contained in this manual.

5. Before starting the repair procedure, make sure that the recommended tools are available and in

good condition.

6. For the procedures described in this manual, use only the specified tools.

OBSERVE: The tool sizes quoted in this manual are expressed in mm.

Page 1.2

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

2. TECHNICAL CHARACTERISTICS

2.1. PRODUCT CODES

The machine codes take into account all the possible variants and options available for the products.

The machine code, which does not include the Serial Number, consists of 16 alphanumeric

characters arranged as follows:

Characters description key to values

1,2 Machine type: Excite

3,4 Product version

5 Type of power supply

6 Type of display

7

8, 9 Color of the frame

10, 11 Color of the paddings

12 Color of the guards

13 Type of TV model

14,15 Language

16 Type of packaging

The above coding is used for the entire Excite line. For this reason, options not relevant

to the Jog machine have also been included.

For example, a possible product code would be:

which is interpreted as follows:

Device for downloading data used by the

Wellness System

D443ELNAL0000UKE

D4

43 = Jog Excite 700

E = European driver

L = LED display

N = not available

T = TGS

AL = aluminium

00 = none

0 = none

0 = none

BR = portoguese

CN = chinese

DE = german

ES = spanish

FR = franch

IT = italian

JP = japanese

NL = dutch

RU = russian

UK = british english

US = american english

I = Italy

E = international (standard)

S = international (overseas)

0 = none

Page 2.1

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

D4 43 E L N AL 00 0 0 UK E

British English language

no TV model

guard color

no paddings

aluminum frame color

Not interfaced to TGS key reader

LED display

European driver

Jog 700 model

Excite

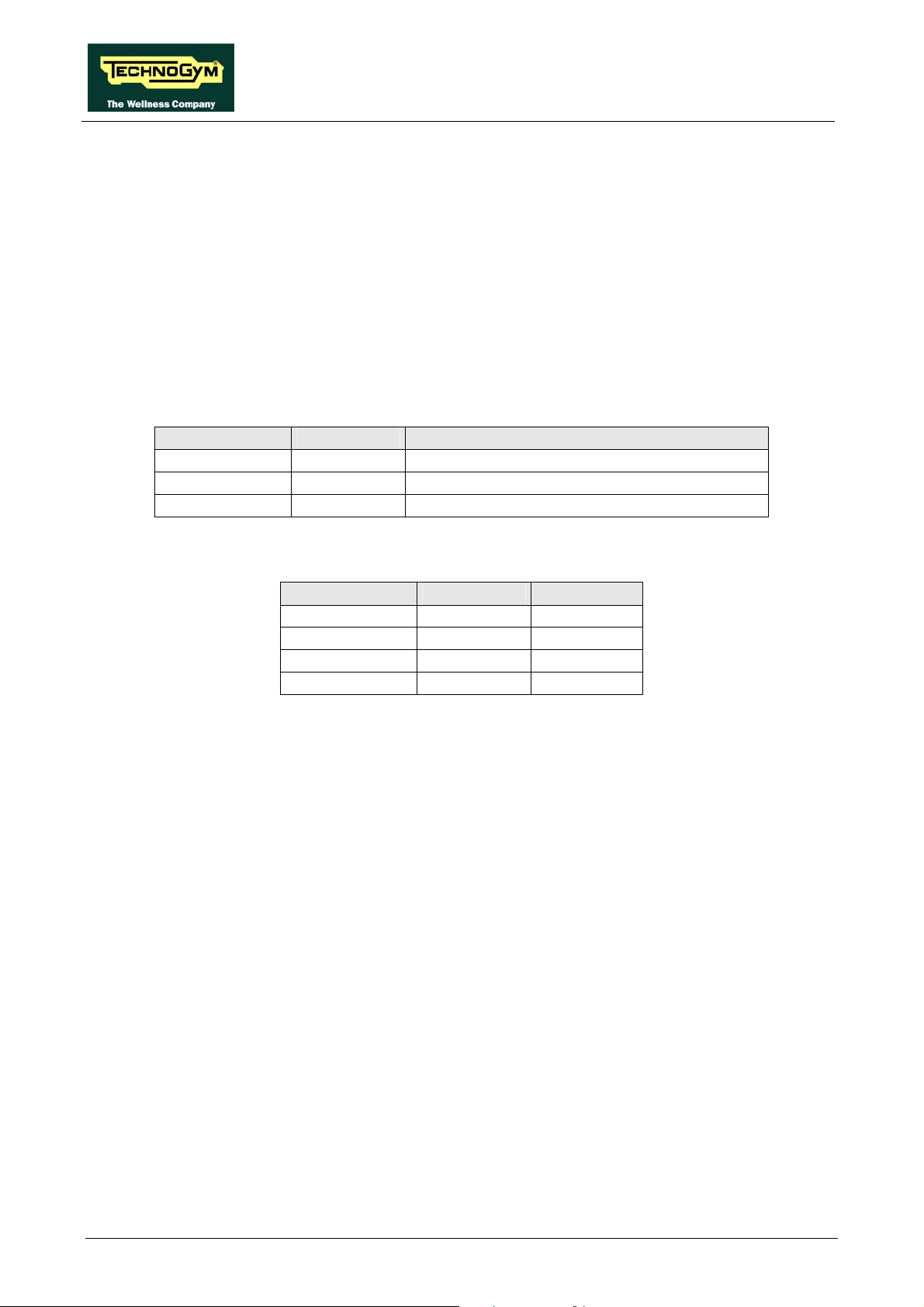

2.2. FEATURES AND FUNCTIONS.

Mains voltage

Frequency

Consumption

Speed

Incline

Fast track control

Hand sensor

Cardio receiver

Ready to Run

Calorie coach

Runner Detection

CHARACTERISTIC

Training

programs

Test functions

Goal (Time, Distance, Calorie)

standard international packing

VERSION

700

180-260 Vac

50-60 Hz

2200 W

0.8-18 Km/h

0.5-12 mph

0-15 %

NO

YES

HFU

YES

YES

YES

Quick Start

6 profiles

CPR

Test

Fitness test

Page 2.2

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

2.3. MECHANICAL CHARACTERISTICS

Width

Length

Height

Running deck height from the floor

Weight

2.4. CONFORMITY REGULATIONS

The machine conforms to the following standards:

Standards

Directives

In addition:

• Electrical isolation class under EN60335-1: Classe I;

• Protection rating: IP20.

Europe USA

EN60335-1

EN55014-1

EN55014-2

EN61000-3-2

EN61000-3-3

EN957-1

EN957-6 class SA

73/23/CEE

89/336/CEE

98/37/CEE

85.9 cm - 34 in

210 cm - 83 in

141.5 cm - 56 in

21.5 cm – 8.5 in

164 Kg - 361 lbs

UL 60601-1

2.5. AMBIENT SPECIFICATIONS

Temperature

Humidity

Operating from 10° to 25° C

Storage from -10 to 70° C

Operating from 20% to 90% non-condensing

Storage from 20% to 90% non-condensing

Page 2.3

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

2.6. WIRING DIAGRAM

The machine consists of 2 assemblies which are connected together as illustrated below:

UPPER

ASSEMBLY

CU133

LOWER

ASSEMBLY

Depending on the model, these 2 assemblies can have the different configurations illustrated below.

2.6.1. LOWER ASSEMBLY

CU133

MOTOR

ELEVATION

MOTOR

Fan

24VDC

J

J

3

J

2

C

B

C

I

R

C

U

I

T

B

R

I

R

E

R

E

A

C

A

K

U

K

E

I

E

R

T

R

CU145

J

1

4

X

U

1

J

5

MAI N BOARD

X

U

2

J

7

X

P

W

R

EAM2069 EAM2068

LIMIT

SWITCH

N

C

TRM-54

8

J

X

X

J

F

C

O

M

R

1

R

2

RESISTANCE

VAC

CU143

L

4

ON/OFF

SWITCH

L

3

CU143

L

POWER

SUPPLY

SOCKET

N

1

N

2

CU177

N

POWER

SUPPLY BOX

CU143

I

N

2

FILTER

BOARD

FE

X

U

X

U

1

2

X

P

W

R

Fan

24VDC

I

N

1

O

U

T

1

O

U

T

2

POWER S UPP L Y BO ARD

AT DRIVER BOX

X

V

1

Fan

24VDC

CU144 CU156

Page 2.4

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

2.6.2. UPPER ASSEMBLY: LED ARM VERSION

KEYBOARD

C

N

CN6

RJ45

DISPLAY BOARD

C

N

4

C

N

C

N

7

9

5

C

N

1

C

N

8

CU137

READYtoRUN

BOARD

CBQ-32

C

N

1

TGS

BOARD

CU133

CU135

H

D

4

HS / RECEIV ER

BOARD

H

H

D

1

D

3

N

C

MICRO

CU138

&

2

C

C

N

MICRO

C

EMERGENCY

BUTTON

DISPLAY

L UPPER

SENSOR

CU136

L LOWER

SENSOR

R UPPER

SENSOR

R LOWER

SENSOR

Page 2.5

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

2.7. WIRING

TRM-32: TGS Cable

Display Board – TGS reader

Display Board

CN3

1 +12 Vdc power supply Yellow 1

3 Rx White 8

5 Tx Green 7

9 Gnd Brown 3

CU133: Cable connecting upper and lower assemblies

Display Board

CN7

1 Gnd +12 Vdc Black J3 – pin 2

2 Not connected - 3 485 Tx/Rx + White/brown J4 – pin 7

4 485 Tx/Rx - Brown J4 – pin 8

5 +12 Vdc Red J3 – pin 6

6 Digital Gnd Light orange J4 – pin 6

7 Emergency Orange J3 – pin 9

8 Reset Purple J3 – pin 10

ATTENTION: The pins 1-2-3-4-5 on the J4 connector are engaged by cables not connected

Display Board

CN9

1 +5 Vdc power supply Brown 2

4 Pulse out White 3

5 Reference Green 1

Signal Color TGS reader

CN1

Display board – AT driver board

Signal Color AT driver board

J3 or J4

anywhere.

The pins 3-4, 3-12, 6-11 and 7-8 are short-circuited each other.

CU135: HS / cardio receiver board cable

Display board - HS / cardio receiver board

Signal Color HS / receiver

board

HD4

Page 2.6

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

CU136: Sensor Cable

Hand Sensor Board - Sensors

HS/receiver

board

HD3&2

1 Right sensor signal Yellow up 2 Sensor signal reference White down 4 Left sensor signal Brown - up

5 Sensor signal reference Green - down

Signal Color

CU137: Ready to Run board cable

Display board – Ready to Run board.

Display board

CN1

1 +5 Vdc power supply Brown 1

4 Reference White 2

Signal Color Ready to Run

CU138: Emergency button cable

Display board – Microswitch

Display board

CN8

1 Emergency Brown C 2 Reference White - C

- Bridge Black NC NC

Signal Color Micro Micro

CU143: High voltage cable

Power supply box – AT driver box

Filter

board

OUT1 Neutral Brown 1

OUT2 Line Blue 2

Signal Color AT driver

TRM-05: Motor compartment fan cable

AT driver board - Fan

ATmain board

J2

1 24 Vdc power supply Red

2 Gnd Black

Signal Color Fan

Sensors

RH LH

board

board

internally

connected cable

Page 2.7

AT driver board

AT driver board

AT driver board

AT Power supply

board

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

TRM-06: Belt motor cable

AT driver board - Motor

Signal Color Motor

J5

1 U Black 1

2 V Black 2

3 W Black 3

4 thermal cutout + Black 4

5 thermal cutout - Black 5

6 GND Black 6

internally

connected cable

TRM-08: Elevation motor cable

AT driver board – Elevation motor

Signal Color Elevation motor

J7

1 Motor - Black

2 Motor + Black

4 Gnd Black

5 +5 Vdc power supply for encoder Red

6 Pulses White

internally

connected cable

TRM-54: Limit switch cable

AT driver board – Limit switch

Signal Color Limit switch

J8

3 Contact White COM

8 Reference Brown NC

EAM2068: AT Driver board connecting cable

AT Power supply board – AT driver board

Signal Color AT driver board

XU2

XU2

1 +12 Vdc power supply Blue 1

2 Gnd +12 Vdc Blue 2

3 + Sensing +5 Vdc Blue 3

4 - Sensing +5 Vdc Blue 4

5 +5 Vdc power supply Blue 5

6 Gnd +5 Vdc Blue 6

Page 2.8

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

EAM2069: AT Driver board connecting cable

AT Power supply board – AT driver board

AT Power supply

board

XU1

1 +24 Vdc power supply Blue 1

2 Gnd +24 Vdc Blue 2

3 +5 Vdc power supply Blue 3

4 Gnd +5 Vdc Blue 4

Signal Color AT driver board

XU1

Page 2.9

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

Page intentionally left blank

Page 2.10

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3. PRINCIPLES OF OPERATION

3.1. BLOCK DIAGRAM

The machine block diagram is illustrated in the figure below:

DISPLAY

KEYBOARD

TGS

READER

DISPLAY BOARD

HS / CARDI O REC.

BOARD

RIGHT

SENSOR

VAC

C

B

I

R

R

E

C

A

U

K

I

E

T

R

POWER

ENTRY

SOCKET

Fan

24VDC

C

B

I

R

R

E

C

A

U

K

I

E

T

R

AT POWER

SUPPLY BO X

FILTER

BOARD

MOTOR

AT POWER S UPPLY BOARD

AT DRIVER BOX

ELEVATION

AT DRI VER BOARD

MOTOR

LEFT

SENSOR

EMERGENCY

BUTTON

LIMIT

SWITCH

RESISTANCE

Fan

24VDC

Fan

24VDC

Page 3.1

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3.1.1. DISPLAY BOARD

This is the heart of the display: this is the circuit board which comprises the CPU, an ARM

microprocessor, its logic circuits and a FLASH EPROM containing the operating program for the

machine moreover, acts as the interconnection hub for all the components of the display and serves

as the point of connection with the electrical box. In fact it receives and process signals from:

- Keyboard;

- HS / Cardio receiver board;

- TGS reader;

>

receives from the AT driver the +12 Vdc power supply, which is used to produce the +5 Vdc

and then distributes the correct voltagesto the various devices;

> Exchanges, over the RS-485 serial link to the AT driver box, commands for controlling the belt

and elevation motors;

> Makes available a communication port, on 1 externally accessible connector, which can be used

for connecting compatible CSafe devices such as the CardioTheater readers. This connector is

situated on the back of the display.

These connector can also be interfaced, using a special cable, to an external PC for

programming the FLASH EEPROM.

> controls the LEDs and the 7-segment displays which provide feedback about the exercise

session.

The board includes the following indicator LEDs:

LED name Color Description

LED1 green

if ON the +12 Vdc power supply from the

AT Driver correctly reaches the board.

3.1.2. TGS READER

This board enables the machine to read the TGS key inserted by the user for performing workouts

programmed with the Wellness System.

3.1.3. HS / CARDIO RECEIVER BOARD

This is the board which:

> manages the hand sensors, interfacing them with the display board. It processes the analogue

signal received from the sensors and outputs one positive logic pulse for each heart beat that is

detected. The signal level is normally 5 Vdc; it goes to 0 Vdc when the user’s hands are placed

on the contacts, and a 5 Vdc pulse (having a width of approximately 30 msec) is output at each

detected heart beat.

> manages the signal received from the telemetric transmitter used by the person exercising. It

receives the power supply signal from the display board and outputs a negative logic pulse for

every heart beat that is detected: the signal level is normally 5 Vdc, with a pulse at 0 Vdc

(having a width of approximately 30 msec) at each heart beat.

The receiver reception area is approximately a circle with a 1 m radius. If there is

electromagnetic noise (produced by high voltage lines, radio transmitters, monitors, motors etc.)

within this area, the receiver becomes saturated and no longer receives any signal.

Page 3.2

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3.1.4. EMERGENCY SWITCH

This is the user safety device. It consists of 2 microswitches connected in series, which can be

tripped either by pressing the emergency button or by pulling a cord clipped to the garment of the

person exercising.

The emergency switch, which provides a NC contact, acts on both the display board and the AT

driver. When the emergency is tripped the AT driver disables the operation of the tread belt and

elevation motors. The display board also detects tripping of the emergency switch, upon which it

interrupts the exercise and shows the “PRESS ANY KEY…” message on the display.

To resume normal machine operation, it is necessary to press any key on the display.

3.1.5. BELT MOTOR

An asynchronous three-phase motor which, by means of a pulley and poly-v belt, turns the driving

roller of the tread belt. Each motor phase is equipped with a normally-closed thermal cutout which

opens when the temperature exceeds a preset threshold, in order to safeguard the integrity of the

motor. The 3 thermal cutouts are connected in series and reach the AT driver as a NC external input

signal. When this contact opens, the AT driver generates an alarm.

It is equipped with a high inertia flywheel, to permit more gradual deceleration of the tread belt in

the event of a power outage or emergency stop.

ATTENTION: dangerous voltages are present at the motor, the flywheel and the metal

plate on which the motor is fixed.

3.1.6. ELEVATION MOTOR

This is a linear actuator equipped with 24 Vdc motor, integral reduction gear and a rod that is

pushed backward and forward by the motor. This rod acts upon a frame connected to the front

wheels of the machine: when the rod moves so does the frame, thereby lowering raising the

machine.

The actuator has a built-in Hall effect sensor which acts as an encoder, generating pulses when the

motor moves. This furnishes a feedback signal on the motor movements, which is used for tracking

the position of the rod and hence the elevation of the machine.

3.1.7. LIMIT SWITCH

This is a NC microswitch which defines the zero-reference position for the elevation mechanism:

the switch is positioned so that it is pressed by the machine during the reset procedure, thereby

defining the reference position.

3.1.8. AT DRIVER

This is the electronic device that acts as an interconnection hub for the main components of the

lower assembly, and serves as the point of connection with the display. In fact:

• Controls the motors:

>

it exchanges, over the RS-485 serial link to the display board, the commands for controlling

the tread belt and elevation motors;

Page 3.3

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

> it supplies the tread belt motor with a variable-frequency sinusoidal voltage: varying the

frequency varies the speed of rotation of the motor, and consequently the speed of the tread

belt;

> it exchanges, over the RS-485 serial link to the display board, the error signals pertaining to

the tread belt and elevation motors;

> it exchanges, over the RS-485 serial link to the display board, the commands for viewing

and configuring the inverter parameters;

> it exchanges, over the RS-485 serial link to the display board, the commands for viewing

the errors logged by the inverter.

• Receives the mains voltage at its inputs and outputs the DC supply voltages for the machine

circuit boards listed below:

Supply voltage Connector Description

+24 Vdc XU1 Power supply for the fans of the electrical box

+5 Vdc XU1 Power supply for elevation motor encoder

+12 Vdc XU2 Power supply for display

The board includes the following indicator LEDs:

LED name Color Description

H2 green +5 Vdc

H3 green +12 Vdc

H4 green +24 Vdc

H5 red 400 Vdc

It contains:

• The AT driver board

• The AT power supply board

• 2 fans

• A breaking resistor

3.1.8.1. AT driver board

It is the upper board of the assembly and it is the heart of the driver: it does everything was

described above for the AT driver except the function of the AT power supply board described

below. In details:

• It receives the line voltage and, through a PFC module, it rectifies the voltage to the 400 Vdc

used to generate the 3 phase voltage for the belt motor and to power up the AT power supply

board.

• Internally it houses an inverter to control the belt motor;

• Internally it houses a DC driver to control the elevation motor.

Page 3.4

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

The board includes the following indicator LEDs visible when the AT driver cover is removed:

LED name Colour Description

If ON indicates that the AT driver has detected

ALARM red

an error (EdC) when it was moving the elevation

motor. This LED stay ON for about 1 second and

then goes OFF.

if ON indicates that the motor has received the

EN_UP green

supply voltage for movement in the upward

direction

if ON indicates that the motor has received the

EN_DOWN red

supply voltage for movement in the downward

direction

green functioning of elevation motor encoder: if

TACHO

blinking, indicates that the board is receiving the

pulses from the encoder

DWN_SW

green status of Limit switch contact: if ON indicates

that the microswitch is pressed

3.1.8.2. AT power supply board

It is the lower board of the assembly and it receives the 400 Vdc from the AT driver board and

outputs to the AT driver board the low voltages used by the machine.

3.1.8.3. Fans

There are 2 fans powered with 24 Vdc used to cool down the AT driver.

3.1.8.4. Breaking resistor

It is a 150 Ohm used by the AT driver board to dissipate the energy produced by the motor when it

is working as a generator.

3.1.9. POWER SUPPLY BOX

It is a box that contains:

• Power entry socket;

• ON-OFF switch;

• 2 circuit breakers that check the overload on line and neutral;

• A filter board.

Page 3.5

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3.2. TREAD BELT MOTOR DRIVE

3.2.1. MECHANICS

The tread belt is actuated by the motor through a linkage consisting of the motor pulley, the driving

roller and the belt which connects them. In this way, a given belt motor speed corresponds to a

predetermined linear tread belt speed.

3.2.2. CONTROLS

The control block diagram is as follows:

Display Board

To actuate the motor, the display board communicates with the AT driver via the RS-485 serial

link. Based on the commands received, the AT driver drives the motor by applying a variable

frequency sinusoidal voltage: the frequency determines the speed of rotation of the motor and hence

the linear tread belt speed. The control may happen in “Open loop”, where the AT driver provides

to the motor a sinusoidal voltage at a frequency that theoretically set the motor running at the

selected speed.

During its movement, the AT driver continually checks the motor by monitoring its current draw. If

any problems are detected (low voltage, overcurrent, SW or HW problems with the AT driver itself,

etc....) it halts the motor and sends an alarm signal to the display board, which displays a “THE

EQUIPMENT IS BLOCKED” error message which can be associated with different inverter error

codes.

In addition, to protect the motor from overheating, each motor phase has a thermal cut-out

connected in series. If the temperature exceeds the threshold value, the thermal cut-outs open and

interrupt the circuit. The AT driver detects this condition as the opening of a NC external contact.

CN2

RS-485

J4

AT driver

1-2-3/J5

with variable frequency

M

4-5/J5

VAC

Cut-out

Page 3.6

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

In such a case the AT driver halts the motor and outputs an alarm signal to the display board which

displays the “THE EQUIPMENT IS BLOCKED” message.

3.2.3. THE SIGNALS INVOLVED

The machine uses the following control signals:

• RS-485 Signal

This is a digital signal exchanged between the AT driver and the display board.

• Variable frequency VAC signal

This is the variable alternating-voltage signal output by the AT driver (pins 1-2-3 connector J5)

to supply the motor. Increasing the frequency of this signal increases the motor speed.

• Thermal cut-out signal

Each motor phase is equipped with a normally-closed thermal cutout which opens when the

temperature exceeds a preset threshold. The 3 thermal cutouts are connected in series and exit

the motor via a 2-wire cable connected to the AT driver (pins 4-5 of connector J5).

When this input signal is an open contact, the AT driver detects the alarm, halts the motor and

sends an alarm signal over the RS-485 line to the display board.

Page 3.7

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3.3. ELEVATION MOTOR DRIVE

3.3.1. MECHANICS

The machine incline is varied by moving a frame connected to the front wheels by means of the

elevation motor rod. The motor movement is detected by a hall sensor which provides the motor

motion control signal: each motor revolution generates a predetermined number of pulses and

produces a known displacement of the rod and hence of the machine incline. The direction of

rotation of the motor determines whether the machine moves up or down.

3.3.2. CONTROL

The control block diagram is as follows:

Display Board

3-8/J8

Limit

switch

To actuate the motor, the display board communicates over the RS-485 serial link with the AT

driver. Based on the commands received, the AT driver, by means of a relay on the board that

switches, applies a +24 or -24 Vdc voltage to the motor. When the motor is powered, it starts

turning.

To control the incline position, the machine reads the signals outputted by:

• a limit switch which defines a zero-reference position, acquired by the machine during its

power-on reset procedure. In normal condition, the limit switch outputs a NC contact that goes

open when it is pressed.

WARNING: when the limit switch outputs an open contact (limit switch pressed,

broken or cable disconnected), the SW gives the pulses to move upward the machine

CN2

RS-485

J4

AT driver

2-1/J7

Vdc

M

Hall sensor

6-4/J7

Pulses

Page 3.8

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

until the contact is closed again. If after some pulse the contact doesn’t change its

status, the elevation movement is disabled.

• an encoder consisting of a Hall effect sensor integrated into the elevation motor: when the

motor is running it outputs train of pulses which represent the motor movement. The AT driver

counts the pulses received and is thus able to determine the exact position of the incline. When

the target position is reached, it disables the elevation motor movement.

If, during the elevation motor operation, the AT drives detects problems on these signals and in

particular:

• if no pulses arrive to the AT driver for a time period of approximately 1.5 sec;

• if the limit switch outputs an open contact and it doesn’t change if the elevation is moved

upward more than 2%.

Then:

• the AT driver locks out with error code “EdC”;

• the machine displays the error message “GRADIENT NOT WORKING” and halts all

movements of both the elevation and tread belt motors;

• The parameter Par 07 is set to 1 to disable the usage of the elevation motor.

If an exercise is started, the machine will resume operation with only the tread belt motor enabled.

Only if the machine is turned off and on again, it will reset the Par 07 to 0 and will restart using the

elevation motor too.

3.3.3. THE RESET PROCEDURE

On power-up, the machine performs a reset procedure in order to determine the zero-reference

position for the incline. The procedure consists of the downward movement of the machine until the

limit switch is tripped then it moves upward until the contact on the limit switch is closed again.

This defines the reference “zero position” for the incline: all movements for reaching different

elevations will be variations relative to this reference.

3.3.4. THE SIGNALS INVOLVED

The machine uses the following control signals:

• RS-485 Signal

This is a digital signal exchanged between the AT board and the display board.

• Motor voltage signal (Vdc)

This is the DC voltage generated by the AT driver (pins 2-1 of connector J7) for supplying the

elevation motor. Its absolute value is 24 Vdc and, depending on its polarity, it causes the motor

to rotate in either a clockwise or anticlockwise direction. The incline of the machine will

increase or decrease accordingly.

• Pulse signal

Page 3.9

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

This is a square wave signal with frequency 50 Hz (T=20 msec) and 50% duty cycle generated

by the Hall sensor when the elevation motor moves. This signal enters the AT driver (pins 6-4

of connector J7) and provides the feedback of the motor movement.

This signal alternates between a low value of 0 Vdc and a high value of 5 Vdc. When measured

with a multimeter, this signal is at either 0 or 5 Vdc when the motor is stopped, while during

motor movements it is approximately 2.5 Vdc.

In order to function correctly, the Hall sensor requires a +5 Vdc supply voltage which it

receives from the elevation board (pins 5-4 of connector J7).

• Limit switch signal

The limit switch is a NC contact entering the AT driver (pins 3-8 of connector J8), which opens

when the machine pressed it during the power-on reset procedure.

Page 3.10

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3.4. EMERGENCY STOP MANAGEMENT

3.4.1. CONTROL

The control block diagram is as follows:

Keyboard

Key

Display Board

8-1/CN7

Reset

When the user presses the emergency button, the display board stops the exercise, displays the

message “PRESS ANY KEY …” and sends to the AT driver the Emergency signal and the

commands for halting the motors over the 485 serial link. When the AT driver receives these

signals, it stops driving both the tread belt and elevation motors.

ATTENTION: the “PRESS ANY KEY…” message is displayed even in case the serial

communication between the upper assembly and the lower assembly is lost.

If the AT driver receives the emergency only via the serial link and not via the Emergency signal,

locks out with error code “EM” and the machine displays the error message “HW EMERGENCY

ERROR”.

Once the AT driver has received an alarm signal, even if the emergency reverts to the non-tripped

state, the alarm condition will persist until the display board sends the reset signal resulting from

any key being pressed. This forces the AT driver to reinstate the serial communication to the

display board and after that to redo the reset procedure.

If the serial communication fails, the machine will try several time to reinstate it. Each attempt is

recorded increasing the value of the COM.FAUL counter that can be checked as indicated at

paragraph 9.2.4.3 “COM.Fault”. After about 30 seconds it will interrupt and will display the error

message “THE EQUIPMENT IS BLOCKED”.

Emergency

Contact

1-2/CN8

7-1/CN7

9-2/J3 10-2/J3

RS-485

Emergency

AT driver

Page 3.11

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

3.4.2. THE SIGNALS INVOLVED

The machine uses the following control signals:

• Emergency contact

This is the contact provided by the 2 emergency stop microswitches. They provide a NC contact

which opens when the emergency is pressed. This signal enters the display board (pins 1-2 of

connector CN8).

• RS-485 Signal

This is a digital signal exchanged between the inverter and the display board.

• Emergency signal

This is the signal generated by the display board (pins 7-1 of connector CN7), sent to the AT

driver (pins 9-2 of connector J3). This signal is 0 Vdc under normal conditions, and goes to 11.9

Vdc in the emergency condition.

• Reset signal

This is the signal generated by the display board (pins 8-1 of connector CN7), sent to the AT

driver (pins 10-2 of connector J3) to signal to the lower assembly the resumption of normal

operation following an emergency condition. This signal is 0 Vdc under normal conditions and

goes to approximately 8 Vdc for few seconds when the user presses a key.

When this happens, the display board resets the Emergency signal to 0 Vdc, thereby enabling

the AT driver to operate.

Page 3.12

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

4. ACCESSORIES

4.1. CARDIO THEATER CONNECTION

The machine can be connected to the CardioTheater by means of the RJ45 connector on the CSafe

board. The CardioTheater unit must be provided with a power cable having the following pin-out:

RJ45 Connector Signal

5 +5 Vdc

7 Ground

ATTENTION: for the numbering of the pins, on RJ45 connector, please refer to the

diagram below:

4.2. PC LINK FOR PROGRAMMING

The machine can be connected to a PC for programming by means of the RJ45 connector on the

CSafe board.

The cable to use must be wired as follows:

ATTENTION: for the numbering of the pins, on RJ45 connector, please refer to the

diagram below:

Page 4.1

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

When programming the machine sometimes it is necessary to fit plug into the free RJ-45

port on the back of the display, to avoid any type of interference during the operation.

The wiring diagram of the RJ-45 plug is as follows:

Programming cable and plug can be ordered using the code H0002534AA.

4.3. MONITOR PLUG FOR CSAFE PORT

When the plug code 0WC00639AA is fitted into any one of the CSafe ports on the machine, the

corresponding LED should illuminate to indicate the presence of the 5 Vdc supply on the port.

During the CSafe port test function, the plug connects the transmit channel directly to the receive

channel, thereby producing a positive test outcome if the port is functioning correctly.

Page 4.2

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

5. INSTALLATION INSTRUCTIONS

5.1. SPECIFICATIONS AND REQUIREMENTS

For correct machine installation, make sure that:

1. The machine is installed on a level surface that is free of vibrations and has sufficient carrying

capacity for the combined weight of the machine and user.

2. The place of installation is free of dust and sand.

3. The place of installation meets the operating temperature and humidity conditions specified in

paragraph 2.5. “Ambient specifications”.

4. The m

(television sets, electrical motors, antennas, high voltage lines, household appliances, etc...) or

medical equipment.

5. Each machine must have a dedicated supply line.

6. The socket outlet and other devices on the dedicated line should be appropriately sized for the

required load of 16A.

7. The socket outlets must be earthed.

8. No multiple connections are permitted on the earth and/or the neutral cables.

9. The ratio between the length and cross section ratio of the cables must be sufficient to assure a

maximum voltage drop of 4% of nominal value at full load (see table below) at the socket

outlet.

10. Position the mains lead of the machine where it will not be underfoot.

11. There is plenty of free space around each item of equipment and a free space of 2x1 min front of

the machine as shown in the picture:

achine is not positioned close to sources of heat, sources of electromagnetic noise

12. To eliminate any interference with the cardio receiver, no transmitters should be placed less

than 1 meter from the display.

Page 5.1

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

5.2. INSTALLATION

To correctly install the machine, proceed as follows:

1. Ensure that the specifications and requirements for installation have been met (see paragraph

5.1. “Specifications and requirements”).

2. Position the machine as specified above, on a level surface that is free of vibrations and has

sufficient carrying capacity for the combined weight of the machine and user.

3. The machine is shipped partially assembled and packed in a carton fixed to a wooden pallet.

Follow the assembly procedure described in the “Operating and Service Instructions” supplied

with each machine.

Follow the assembly operations described in the instruction sheets supplied with the machines.

4. Connect the mains lead to the power inlet socket on the machine.

5. Place the on/off switch in the “0” position.

6. Plug the mains lead into the wall outlet.

5.3. FIRST POWER-ON

After completing the installation procedure, the machine is ready to be powered up. To turn on the

machine, simply toggle the on/off switch from the “0” position to the “1” position.

During power-up the machine resets the incline. After completing the power-on reset, the machine

goes into standby, awaiting a keyboard command.

To check the correct operation of the machine:

• get on the machine;

• press the “Quick Start” key to begin exercising and check that the tread belt motor starts;

• press the “+” and “-” keys on the keyboard and check that the tread belt speed varies

accordingly;

• press the “↑” and “↓” keys and check that the incline varies accordingly;

• press the emergency button and check that the tread belt stops;

• put on the heart rate meter and check that the machine correctly reads the heart rate value;

• grasp the sensors and check that the machine correctly reads the heart rate value.

Page 5.2

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

6. TROUBLESHOOTING

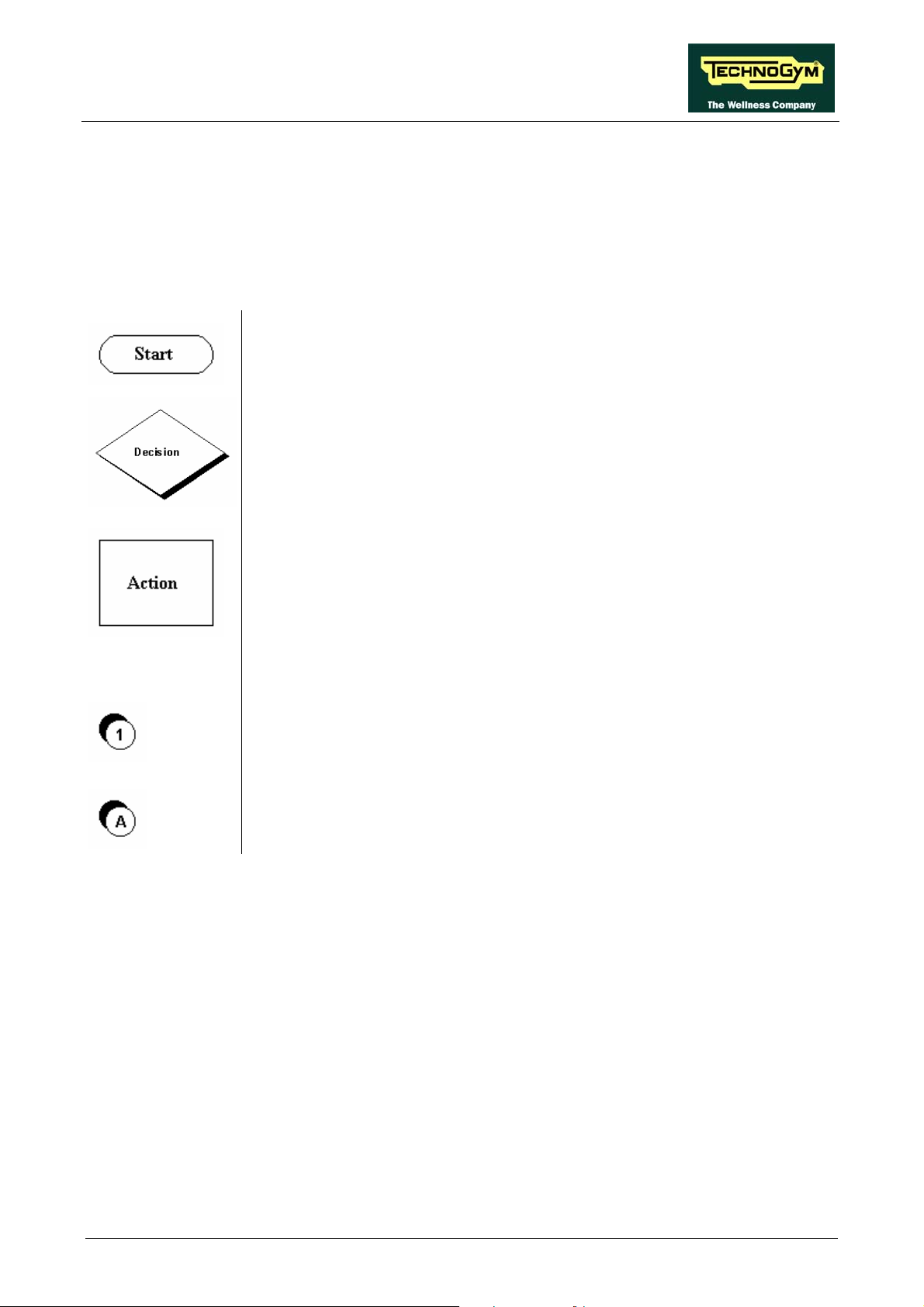

The troubleshooting procedures are shown in the form of flow charts. In order to facilitate

consultation, the following standard box shapes are used.

This type of box is the START point of the troubleshooting procedure. It

typically contains a description of the problem or malfunction.

This type of box represents a decision point in the troubleshooting procedure.

It typically contains a description of the CHECK to be made, with an outcome

that can be either a positive (YES) or negative (NO) response.

This type of box is a step in the troubleshooting procedure where an ACTION

must be carried out. It typically contains a description of the ACTION

necessary to resolve the problem. Therefore, after executing the specified

ACTION:

1. Check whether the problem has been resolved;

2. If the problem persists, it is recommended to resume the troubleshooting

procedure from the point before the action was carried out.

A circled number (such as that shown on the left) next to a box of the

troubleshooting procedure indicates that detailed instructions for performing

that particular check or action are provided below the flowchart.

A circled letter (such as that shown on the left) is used to highlight a point in

the procedure. Typically, this indicator is used in page changes.

Page 6.1

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

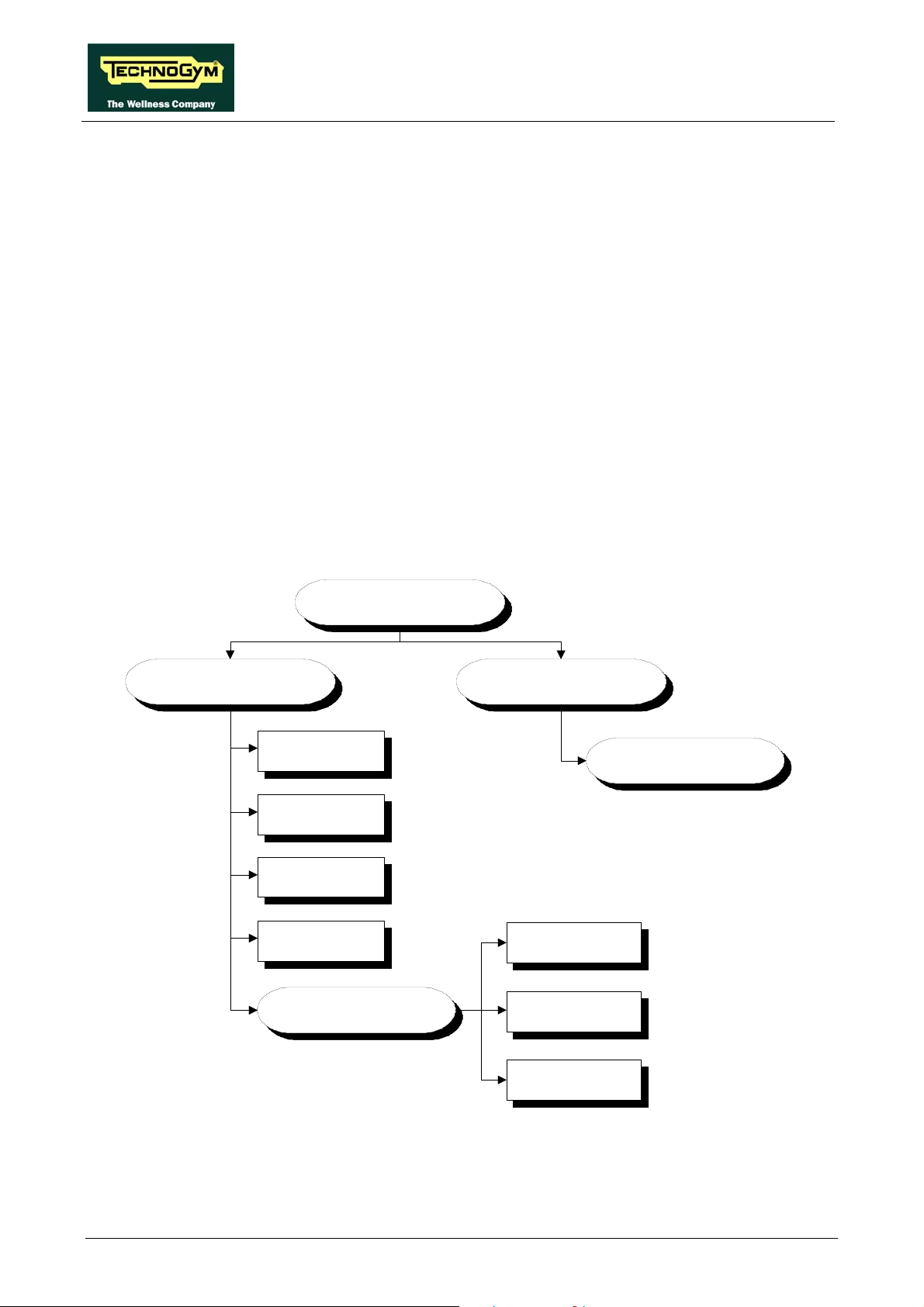

6.1. TROUBLESHOOTING SERVICE MENU

This section can be used to test the operation of certain machine components (AC/DC Motors, LED

display, keyboard, serial ports, inverter). It is invoked, when the machine is in standby mode, by

simultaneously pressing the keys ENTER, ↑, CLEAR. The following prompt appears on the LED

display:

ENTER PASSWORD:

To access the procedure, insert the password 2501 which protects against unauthorized access and

press ENTER to confirm. To enter the password without the numeric keypad, enter one digit at a

time using the ↑ and ↓ keys to change the value and the +/- GOAL keys to scroll to the next

character. At this point there are two options available:

↑ = Tech Config

↓ = Troubleshooting

Press the number key 2 to access the troubleshooting menu, which is structured as shown in the

figure below.

TROUBLESHOOTING

AUTOMATIC TEST MANUAL TEST

I2C Devices Test

UpDown Tes t

Inverte r Test

LED Test

SERIAL PORT S

TEST

TGS COM Test

Low Kit COM Test

MAN.KEYBOARD

TEST

CSafe COM Test

To scroll through the list of available functions, press the + or – speed keys to display the next or

previous item. Confirm the choice by pressing ENTER. To cancel the operation, press the CLEAR

key for a few seconds.

Page 6.2

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

The tests are divided into two groups: Automatic and Manual. The machine prompts for a choice

immediately upon accessing the troubleshooting menu.

6.1.1. AUTOMATIC TESTS

The tests grouped under this section conduct checks on the machine’s operation in a fully automatic

manner. After selecting the desired test using the + and – speed keys, press ENTER to initiate the

test and then await the result. Press ENTER again to continue, or press the CLEAR key for a few

seconds to return to the higher menu level. The various tests are described below.

6.1.1.1. I2C Device Test

The I2C Device test checks the communication following the 32K and 256K memories. The test

can have two outcomes:

• “Test Successful, press Enter to continue”: Signifies that data packets were successfully

transmitted and received toward the display board.

• “EEPROM Error, press Enter to continue”: Signifies that the display board has

communication problems with the memories.

6.1.1.2. UpDown Test

The UpDown test checks whether the number of pulses output by the encoder corresponds to the

values of the UpDown table stored in the low kit. During the test, the machine incline is moved

from 0 to 15% and then back to 0. Each incline position is converted into a number of pulses and

compared with the value in the UpDown table.

Two messages appear during the test:

- “Incline =15%”: This message appears during the upward movement, when the machine incline

reaches 15%.

- “Incline =3%”: This message appears during the downward movement, when the machine

incline reaches 3%.

The test can have two outcomes:

• “DC Error (Up/Down), press Enter to continue”: The message indicates that the values do

not correspond. The specific message (Up or Down) indicates whether the error occurred during

the upward (Up) or downward (Down) movement of the test.

• “Test Successful, press Enter to continue”: This message indicates that the test was

completed without errors.

6.1.1.3. Inverter Test

The inverter test checks the condition of the AT driver. The test can have two outcomes:

• “Test Successful, press Enter to continue”: This means that the test was completed

successfully and the inverter is not in an error condition.

• “Inverter Error, press Enter to continue”: This means that the test was not completed

successfully, i.e. that the serial link is inactive and/or the inverter is in an error condition.

Page 6.3

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

6.1.1.4. LED Test

The LED test checks the functioning of the display by lighting all the LEDs in the matrix. It also

tests the buzzer, varying the frequency to produce different tones of sound.

The test does not produce a result message, so the user must visually check the outcome.

6.1.1.5. Serial Ports Test

The serial ports test checks the following communication ports:

• CSafe COM test;

• Low Kit COM test;

• TGS COM test.

Using the + and – speed keys, select the desired test item and confirm by pressing ENTER. The test

can have two outcomes:

• “Test Successful, press Enter to continue”: This means that the test was completed

successfully, i.e. that serial communications on the selected port are correct.

• “COMx Error, press Enter to continue”: This means that the outcome of the test was

negative: the message will specify COM1 in the case of the CSafe COM test, COM2 in the case

of communications with the low kit, or COM3 in the case of the TGS COM test.

NOTE: The communication with the CSafe port and the TGS is not working if any device is not

connected to the port.

6.1.2. MANUAL TEST

This section groups together tests for manually checking the operation of certain peripheral devices.

After selecting the desired test item using the + and – speed keys, press ENTER to access the tests.

To exit test mode, hold down the CLEAR key for a few seconds.

The various manual tests are described below.

6.1.2.1. Man. Keyboard Test

The m

the test by pressing ENTER, the message “Press all buttons (beep=OK)” appears on the display.

Pressing each key will produce an audible signal, if a key does not produce the “beep” it means it is

not working properly.

anual keyboard test checks the functioning of all the keys on the keyboard. After accessing

Page 6.4

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

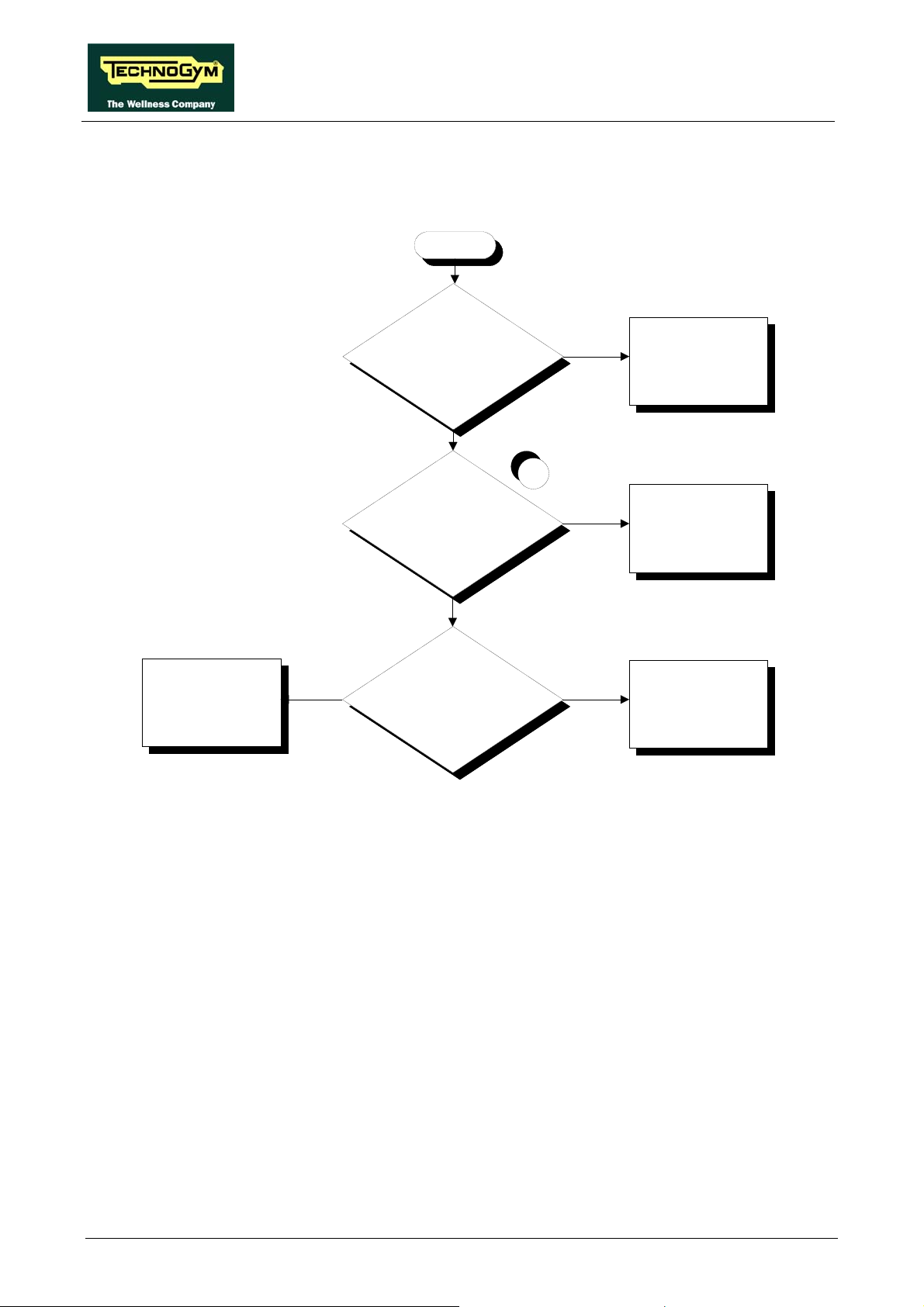

6.2. THE DISPLAY FAILS TO ILLUMINATE

This error occurs when the power supply voltage does not reach the upper assembly.

THE DISP LAY

FAILS TO

ILLUMINATE

NO

Does t h e wall out let s upply the

correct v oltage?

Plug th e m ac hine i nt o a

working elec tric al out l et

YES

Is t he m ains lead OK?

YES

Is the v oltage at t he

output of the mac hi ne's

power inlet block c orrec t?

YES

Is the voltage at t he input

to t he c i rc uit breakers

correct?

NO

Replace the mains l ead

1

NO

Replace t he power

inlet block on t he

machine

2

NO

Replace cable CU 143

Continued on the following page.

YES

A

Page 6.5

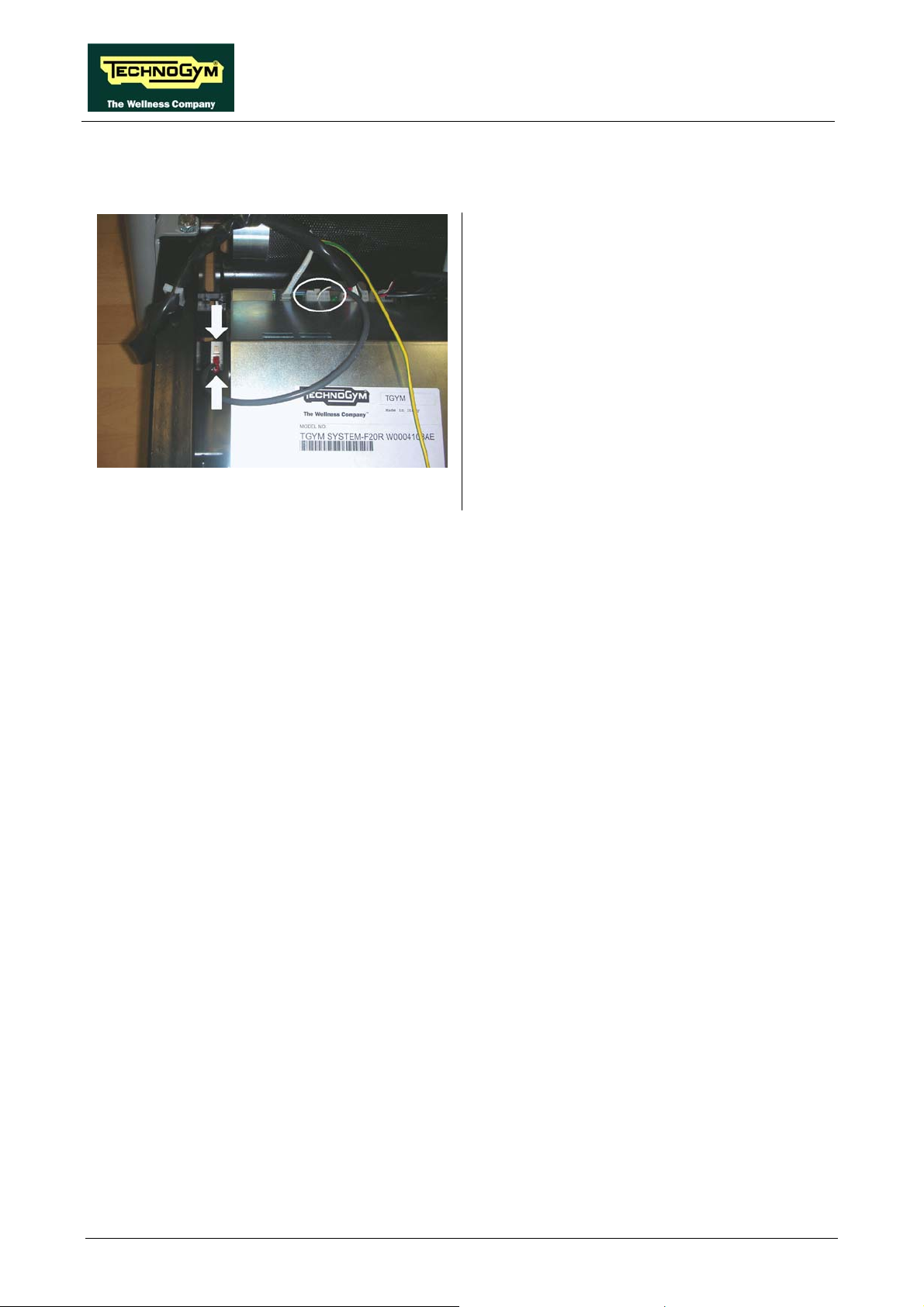

JOG EXCITE: Service & Maintenance Manual - rev. 1.1

A

3

Is the voltage at t he

output of the circ uit

breakers c orr ec t , when

they are pres s ed?

YES

Is the v oltage at t he inpu t

to t h e AT driver box ?

YES

Is the 400VdC v oltage

correct ly suppl ied by the

AT driver board?

NO

Replace t he c i rc ui t

breakers

4

NO

Replace f ilt er board

5

NO

Replace t he AT driv er

board

Is the EAM2068 cable

correc t ( c hec k pin to pin)?

Is the voltage at t he input

to t h e AT drive r board

Continued on the following page.

correct?

B

YES