Page 1

SERVICE & MAINTENANCE MANUAL

REV. 3.0

Page 2

Page 3

The information contained in this manual is intended for QUALIFIED TECHNICIANS who have

completed a specific TECHNOGYM training course and are authorized to perform machine start-up

and adjustment procedures as well as extraordinary maintenance or repairs which require a thorough

knowledge of the machine, its operation, its safety devices and working procedures.

CAREFULLY READ THE INFORMATION CONTAINED IN

THIS MANUAL BEFORE PERFORMING ANY MAINTENANCE

PROCEDURES ON THE MACHINE

DANGEROUS VOLTAGES

PRESENT EVEN WHEN THE

NOTE

The information contained in this document is subject to change without notice.

Technogym does not guarantee this documentation in any way. Technogym shall not be held

responsible for any errors contained in this manual and declines all liability for accidents or

damages resulting from the supply, characteristics or use of this manual.

This document contains proprietary information that is protected by copyright. All rights reserved.

No part of this document may be photocopied, reproduced or translated into another language

without the prior written consent of Technogym.

The Technogym® trademark is property of Technogym S.r.l.

The Forma™ trademark is property of Technogym S.r.l.

MACHINE IS TURNED OFF

Page 4

Page 5

FORMA: Service & Maintenance manual - rev. 3.0

Contents

1. GENERAL NOTICES........................................................................................................................................... 1.1

NTRODUCTION

1.1. I

ECOMMENDATIONS

1.2. R

ENERAL RULES FOR REPAIR PROCEDURES

1.3. G

2. TECHNICAL CHARACTERISTICS .................................................................................................................. 2.1

2.1. M

2.2. E

2.3. A

2.4. C

2.5. W

3. PRINCIPLES OF OPERATION.......................................................................................................................... 3.1

3.1. B

3.2. T

3.3. UP-

3.4. F

ECHANICAL CHARACTERISTICS

LECTRICAL CHARACTERISTICS

MBIENT SPECIFICATIONS

ONFORMITY TO REGULATIONS

IRING DIAGRAM

2.5.1. Version currently in production........................................................................................................ 2.2

2.5.2. Connectors ........................................................................................................................................ 2.3

2.5.3. Wiring ............................................................................................................................................... 2.4

2.5.4. Previous model................................................................................................................................ 2.10

LOCK DIAGRAM

3.1.1. Cardio transmitter............................................................................................................................. 3.1

3.1.2. Cardio receiver ................................................................................................................................. 3.1

3.1.3. Display .............................................................................................................................................. 3.2

3.1.4. Driver board .....................................................................................................................................3.2

3.1.5. Inverter.............................................................................................................................................. 3.3

3.1.6. Belt motor.......................................................................................................................................... 3.3

3.1.7. Up-down motor ................................................................................................................................. 3.3

3.1.8. Power supply..................................................................................................................................... 3.3

3.1.9. Voltage selector switch .....................................................................................................................3.4

3.1.10. Transformer....................................................................................................................................... 3.4

3.1.11. Safety switch ...................................................................................................................................... 3.4

3.1.12. Fan .................................................................................................................................................... 3.4

3.1.13. Fan interface board........................................................................................................................... 3.4

READ-BELT MOTOR DRIVE

3.2.1. Mechanics ......................................................................................................................................... 3.5

3.2.2. Controls............................................................................................................................................. 3.5

3.2.3. The signals involved.......................................................................................................................... 3.6

DOWN MOTOR DRIVE

3.3.1. Mechanics ......................................................................................................................................... 3.8

3.3.2. Controls............................................................................................................................................. 3.8

3.3.3. The signals involved.......................................................................................................................... 3.9

AN DRIVE

3.4.1. Mechanics ....................................................................................................................................... 3.11

3.4.2. Controls........................................................................................................................................... 3.11

3.4.3. The signal involved ......................................................................................................................... 3.12

................................................................................................................................................. 1.1

........................................................................................................................................ 1.1

...................................................................................................... 1.2

...................................................................................................................... 2.1

........................................................................................................................ 2.1

................................................................................................................................2.1

........................................................................................................................ 2.1

............................................................................................................................................. 2.2

.............................................................................................................................................. 3.1

.............................................................................................................................. 3.5

................................................................................................................................... 3.8

...................................................................................................................................................... 3.11

4. ACCESSORIES...................................................................................................................................................... 4.1

ONNECTING TO THE TGS

4.1. C

5. INSTALLATION INSTRUCTIONS .................................................................................................................... 5.1

PECIFICATIONS AND REQUIREMENTS

5.1. S

NSTALLATION

5.2. I

IRST POWER-ON

5.3. F

6. TROUBLESHOOTING.........................................................................................................................................6.1

.................................................................................................................................................. 5.1

.............................................................................................................................................. 5.1

................................................................................................................................. 4.1

............................................................................................................... 5.1

Page i

Page 6

FORMA: Service & Maintenance manual - rev. 3.0

HE DISPLAY DOES NOT ILLUMINATE

6.1. T

HE DISPLAY SHOWS

6.2. T

HE DISPLAY SHOWS

6.3. T

6.3.1. The inverter display shows E01, E02, E03, E04 or E05................................................................... 6.9

6.3.2. The inverter display shows E06 or E07 ..........................................................................................6.11

6.3.3. The inverter display shows E08, E10, E11 or E22.......................................................................... 6.12

6.3.4. The inverter display shows E09 ...................................................................................................... 6.13

6.3.5. The inverter display shows E12 ...................................................................................................... 6.15

6.3.6. The inverter display shows E14 ...................................................................................................... 6.17

6.3.7. The inverter display shows E15 ...................................................................................................... 6.18

6.3.8. The inverter display shows E21 ...................................................................................................... 6.20

6.3.9. The inverter display does not show any error................................................................................. 6.21

HE BELT MOTOR IS JERKING

6.4. T

HE BELT MOTOR STARTS WITH DELAY

6.5. T

HE DISPLAYED SPEED IS INCORRECT

6.6. T

HE DISPLAY SHOWS

6.7. T

HE UP-DOWN MOVES IN ONLY ONE DIRECTION

6.8. T

HE DISPLAYED ELEVATION IS INCORRECT

6.9. T

HE FAN IS NOT WORKING

6.10. T

HERE IS NO HEART RATE SIGNAL

6.11. T

HE HEART RATE SIGNAL IS INCORRECT

6.12. T

“SAFETY SWITCH”..................................................................................................... 6.6

“E 3”............................................................................................................................... 6.7

.......................................................................................................................... 6.23

“E 5”............................................................................................................................. 6.28

.............................................................................................................................. 6.36

................................................................................................................ 6.2

.......................................................................................................... 6.24

............................................................................................................. 6.25

.............................................................................................. 6.32

..................................................................................................... 6.34

................................................................................................................... 6.39

......................................................................................................... 6.40

7. DISASSEMBLY OF COMPONENTS ................................................................................................................. 7.1

ISASSEMBLING THE DISPLAY

7.1. D

ISASSEMBLING THE

7.2. D

ISASSEMBLING THE DISPLAY BOARDS

7.3. D

ISASSEMBLING THE KEYBOARD

7.4. D

ISASSEMBLING THE CARDIO RECEIVER

7.5. D

ISASSEMBLING THE SAFETY SWITCH

7.6. D

ISASSEMBLING THE MOTOR GUARD

7.7. D

ISASSEMBLING THE REAR ROLLER

7.8. D

ISASSEMBLING THE MOTOR ROLLER AND DRIVE-BELT

7.9. D

ISASSEMBLING THE TREAD-BELT AND RUNNING TRACK

7.10. D

ISASSEMBLING THE SHOCK ABSORBERS

7.11. D

ISASSEMBLING THE FOOTREST GUIDE

7.12. D

ISASSEMBLING THE SIDE GUARDS

7.13. D

ISASSEMBLING THE MOTOR GUARD GRILLE

7.14. D

ISASSEMBLING THE TREAD-BELT MOTOR

7.15. D

ISASSEMBLING THE ELECTRONIC CIRCUIT BOARDS

7.16. D

MONTAGGIO SCHEDA INTERFACCIA VENTOLA

7.17. S

ISASSEMBLING THE INVER TER

7.18. D

ISASSEMBLING THE COLUMN AND RUBBER GUARD

7.19. D

ISASSEMBLING THE UP-DOWN MOTOR

7.20. D

ISASSEMBLING THE UP-DOWN FRAME

7.21. D

ISASSEMBLING THE HANDLEBARS

7.22. D

8. ADJUSTMENTS.................................................................................................................................................... 8.1

EPROM.......................................................................................................................... 7.2

.......................................................................................................................... 7.1

............................................................................................................. 7.3

...................................................................................................................... 7.4

........................................................................................................... 7.5

............................................................................................................... 7.6

................................................................................................................ 7.7

.................................................................................................................. 7.8

.................................................................................. 7.10

................................................................................ 7.12

....................................................................................................... 7.14

........................................................................................................... 7.15

................................................................................................................. 7.16

.................................................................................................. 7.17

...................................................................................................... 7.18

....................................................................................... 7.19

............................................................................................... 7.21

...................................................................................................................... 7.22

....................................................................................... 7.23

.......................................................................................................... 7.24

........................................................................................................... 7.25

................................................................................................................ 7.26

ENSIONING A NEW TREAD-BELT

8.1. T

ENSIONING A USED TREAD-BELT

8.2. T

ENTERING THE TREAD-BELT

8.3. C

LIGNING THE TREAD-BELT MOTOR DRIVE-BELT

8.4. A

ENSIONING THE TREAD-BELT MOTOR DRIVE BELT

8.5. T

ALIBRATING THE TREAD-BELT SPEED

8.6. C

DJUSTING THE UP-DOWN MOTOR CURRENT LIMITER

8.7. A

9. MACHINE CONFIGURATION .......................................................................................................................... 9.1

LANGUAGE CONFIGURATION

9.1.

IEWING THE WORKING PARAMETERS

9.2. V

...................................................................................................................... 8.1

..................................................................................................................... 8.2

........................................................................................................................... 8.3

.............................................................................................. 8.4

........................................................................................... 8.5

............................................................................................................. 8.6

....................................................................................... 8.7

............................................................................................................................. 9.1

.............................................................................................................. 9.2

Page ii

Page 7

FORMA: Service & Maintenance manual - rev. 3.0

9.2.1. Hours of machine operation ............................................................................................................. 9.2

9.2.2. Hours of tread-belt motor operation................................................................................................. 9.2

9.2.3. Minutes of up-down motor operation................................................................................................ 9.2

9.2.4. Distance Covered.............................................................................................................................. 9.2

9.3. M

9.4.

9.5. P

ODIFYING THE WORKING PARAMETERS

9.3.1. Hours of machine operation ............................................................................................................. 9.3

9.3.2. Hours of tread-belt motor operation................................................................................................. 9.3

9.3.3. Minutes of up-down motor operation................................................................................................ 9.3

9.3.4. Distance covered............................................................................................................................... 9.3

UP-DOWN TEST

ROGRAMMING THE

9.5.1. Monitor function parameters ............................................................................................................ 9.6

9.5.2. Modified parameter settings ............................................................................................................. 9.6

................................................................................................................................................. 9.4

HITACHI SJ100

.......................................................................................................... 9.3

INVERTER

............................................................................................. 9.5

10. SCHEDULED MAINTENANCE ....................................................................................................................... 10.1

XTERNAL CLEANING OPERATIONS

10.1. E

10.1.1. Setting up the operation .................................................................................................................. 10.1

10.1.2. Cleaning operations ........................................................................................................................ 10.1

10.1.3. Operazione di lubrificazione del nastro e pianale di corsa per Forma 3 ....................................... 10.1

OUTINE MAINTENANCE OPERATIONS

10.2. R

10.2.1. Internal cleaning operations ........................................................................................................... 10.3

10.2.2. Checking the state of wear............................................................................................................... 10.3

10.2.3. Checking the tension and centering of the tread-belt...................................................................... 10.3

10.2.4. Checking the “Safety switch”.......................................................................................................... 10.3

PECIAL MAINTENANCE OPERATIONS

10.3. S

10.3.1. Carrying out the routine maintenance procedure ........................................................................... 10.4

10.3.2. Checking the working conditions ....................................................................................................10.4

10.3.3. Checking the wiring and connections.............................................................................................. 10.4

10.3.4. Checking the display........................................................................................................................ 10.4

10.3.5. Checking the wear and lubrication of the tread-belt and running track......................................... 10.4

10.3.6. Checking the wear of the motor roller............................................................................................. 10.5

10.3.7. Checking the wear of the rear roller ............................................................................................... 10.5

10.3.8. Checking the shock absorbers......................................................................................................... 10.5

10.3.9. Checking the wear of the rubber handlebar cover.......................................................................... 10.5

10.3.10. Checking the tread-belt motor drive-belt ........................................................................................10.5

10.3.11. Checking the speed calibration ....................................................................................................... 10.5

10.3.12. Checking the operation of the cardio receiver ................................................................................ 10.5

11. APPENDIX........................................................................................................................................................... 11.1

................................................................................................................. 10.1

............................................................................................................ 10.3

.............................................................................................................. 10.4

ECHNICAL NOTES ON CARDIO RECEIVERS

11.1. T

11.1.1. Type of ASIC.................................................................................................................................... 11.2

11.1.2. Presence of electromagnetic fields.................................................................................................. 11.2

11.1.3. Reducing receiver sensitivity ........................................................................................................... 11.3

11.1.4. Mechanical vibrations..................................................................................................................... 11.4

11.1.5. Position of the receiver.................................................................................................................... 11.4

11.1.6. Routing of cables ............................................................................................................................. 11.5

11.2. HITACHI SJ100

ROCEDURE FOR CLEARING THE ERROR MEMORY ON HITACHI

11.3. P

INVERTER ERROR CODES

..................................................................................................... 11.1

..................................................................................................... 11.6

INVERTER

SJ100

............................................ 11.8

Page iii

Page 8

FORMA: Service & Maintenance manual - rev. 3.0

Page intentionally left blank

Page iv

Page 9

FORMA: Service & Maintenance manual - rev. 3.0

1. GENERAL NOTICES

1.1. INTRODUCTION

This document is reserved for Technogym Service technicians, and is intended to provide

authorized personnel with the necessary information to correctly carry out repairs and maintenance.

A thorough knowledge of the technical information contained in this manual is essential for

completing the professional training of the operator.

In order to facilitate consultation, the paragraphs are accompanied by schematic drawings which

illustrate the procedure being described.

This manual contains notices and symbols which have a specific meanings:

WARNING: non observance may result in accident or injury.

ATTENTION: non observance may cause damage to the machine.

Information about the operation in progress.

OBSERVE: observation about the operation in progress.

1.2. RECOMMENDATIONS

Technogym recommends the following steps for planning repair procedures:

• Carefully evaluate the customer’s description of the machine malfunction and ask all the

necessary questions to clarify the symptoms of the problem.

• Clearly diagnose the causes of the problem. This manual provides the fundamental theoretical

basis, which must then be integrated by personal experience and attendance at the training

courses periodically offered by Technogym.

• Rationally plan the repair procedure so as to minimize the downtime necessary for procuring

spare parts, preparing tools, etc.

• Access the component to be repaired, avoiding any unnecessary operations. In this regard it will

be useful to refer to the disassembly sequence described in this manual.

Page 1.1

Page 10

FORMA: Service & Maintenance manual - rev. 3.0

1.3. GENERAL RULES FOR REPAIR PROCEDURES

1. Always mark any parts or positions which may be confused with each other at the time of

reassembly.

2. Use original Technogym spare parts and lubricants of the recommended brands.

3. Use special tools where specified.

4. Consult the technical circulars, which may contain more up-to-date information on adjustments

and maintenance than those contained in this manual.

5. Before starting the repair procedure, make sure that the recommended tools are available and in

good condition.

6. For the procedures described in this manual, use only the specified tools.

OBSERVE: The tool sizes quoted in this manual are expressed in mm.

Page 1.2

Page 11

FORMA: Service & Maintenance manual - rev. 3.0

2. TECHNICAL CHARACTERISTICS

2.1. MECHANICAL CHARACTERISTICS

Width 73 cm

Length 180 cm

Height 132 cm

Weight 130 Kg

2.2. ELECTRICAL CHARACTERISTICS

Mains voltage 220 V

Frequency 50 Hz

Consumption 1500 VA

Fuses 5x20 2xT8AH

2.3. AMBIENT SPECIFICATIONS

Temperature

Humidity

Operating from 5° to 35° C

Storage from -20 to 55° C

Operating from 30% to 80% non-condensing

Storage from 5% to 85% non-condensing

2.4. CONFORMITY TO REGULATIONS

The machine conforms to the following directives:

EMI

Safety

Exercise equipment

Directive

Europe USA

EN 60601-1-2

EN 60601-1:90

+A1:93

+A12:93

+A2:95

+A13:96

EN 957-1

73/23/EEC

93/68/EEC

89/336/EEC

N.A.

Page 2.1

Page 12

FORMA: Service & Maintenance manual - rev. 3.0

2.5. WIRING DIAGRAM

2.5.1. VERSION CURRENTLY IN PRODUCTION

This machine version, subsequently identified with the name Forma 3, has been in production

starting from SN 01000881. It differs from the preceding version as follows:

• Fan for improved cooling of the motor group;

• Electronic circuit board for starting the fan when the motor is running;

• New motor group equipped with scaled-up flywheel;

• New driving roller with larger diameter pulley;

• Hole in the guard for lubrication of the table;

• New inverter configuration parameters;

• New operating SW.

The wiring diagram is given below:

Page 2.2

Page 13

FORMA: Service & Maintenance manual - rev. 3.0

2.5.2. C

• CPU board

name type of connector connection

K1 AMP MODU I 4x1 pin f. to driver board (low voltage input)

K2 AMP MODU I 2x1 pin f. to LED board (low voltage output)

K4 AMP MODU II 9x2 pin f. to driver board (actuator drives)

K6 AMP MODU II 4x1 pin f. to serial connector for TGS

K12 Flat 5x2 pin f. to LED board (LED driver output)

K14 AMP MODU II 4x1 pin f. to cardio receiver

EM AMP MODU II 2x1 pin f. to emergency button

• LED board

name type of connector connection

K2 AMP MODU I 2x1 pin f. to CPU board (low voltage input)

K12 Flat 5x2 pin f. to CPU board (LED driver input)

• Driver board

name type of connector connection

J1 AMP MATE-N-LOCK 3x2 pin f. to up-down motor

J2 2 pin terminal block to transformer (low voltage ac input)

J3 AMP MODU I 4x1 pin f. to power supply (low voltage input)

J4 AMP MODU I 4x1 pin f. to CPU (low voltage output)

J5 AMP MODU II 6x1 pin f. to inverter (inverter drive)

J6 AMP MODU II 9x2 pin f. to CPU board (actuator drive)

• Power supply

name type of connector connection

CN1 PANDUIT 6 pin m. to filter (mains voltage input)

CN2 PANDUIT 6 pin m. to driver board (low voltage output)

• Fan interface board

name type of connector connection

CN1 AMP MODU I 2x1 pin f. to inverter

CN2 4-pin terminal block IN: from power inlet block (mains voltage

ONNECTORS

input)

OUT: to fan (mains voltage output with

isolating relay on the circuit board)

Page 2.3

Page 14

FORMA: Service & Maintenance manual - rev. 3.0

• Portable connectors

name type of connector connection

CN28 MOLEX mini-fit 7x2 m. portable to CPU board (actuator drive)

CN29 MOLEX mini-fit 7x2 f. portable to driver board (actuator drive)

CN39 Terminal block to filter, power supply, inverter and selector

CN46 MOLEX mini-fit 3x2 f. portable to up-down motor

2.5.3. W

IRING

FR-1/A: Power supply cable

Power inlet socket – Filter - Fan interface board

Power inlet

socket

Fast on Live

Fast on Neutral

Fast on - -

-

This cable incorporates a 348 Ohm, 100 Mhz ferrite with coil on the live and neutral conductors.

Signal Color Filter Fan

Black Fast on - Black - Fast on -

Blue Fast on - Blue - Fast on -

Earth

Yellow-green

Yellow-green

Fast on -

PE

interface

board

Eyelet

FR-2: High voltage power supply cable

Filter – High voltage distribution terminal block

Filter Signal Color Terminal block

Fast on Live Black L

Fast on Neutral Blue N

Fast on Earth Yellow PE

CN39

FR-3/L: Power supply high voltage input cable

High voltage distribution terminal block – Power supply

Terminal block

CN39

N Neutral Blue 4

L Live Black 6

Signal Color Power supply

CN1

FR-4: Inverter high voltage input cable

High voltage distribution terminal block – Inverter

Terminal block

CN39

N Neutral Blue N

L Live Black L1

Signal Color Inverter

Page 2.4

Page 15

FORMA: Service & Maintenance manual - rev. 3.0

FR-5: Transformer high voltage input cable

High voltage distribution terminal block – Selector

Terminal block

CN39

N Neutral Blue 4

L Live Black 1

Signal Color Selector

FR-6: Low voltage power supply cable

Power supply – Driver board

Power supply

CN2

1 + 12 Vdc Red 1 3 + 5 Vdc Orange 4 4 ground Grey 3 -

5 ground

Signal Color Driver

FR-7: Inverter cable

Driver board – Inverter

Driver board

J5

- Thermal cutout Green 3 2

1 White -

- White P24

2 Start Grey 1 3 Alarm Red AL0 4 Alarm Gnd Purple AL1 5 Speed Brown O 6 Speed Gnd Black L -

Signal Color Inverter CN43

Thermal cutout Gnd

FR-8: Tread-belt motor cable

Inverter – Tread-belt motor

Inverter Signal Color Motor CN43

U Phase U Black 1 already connected V Phase V Black 2 already connected -

W Phase W Black 3 already connected -

- Thermal cutout Black 4 already connected 1

- Thermal cutout Gnd Black 5 already connected 2

PE Earth Black 6 already connected -

Terminal

board

J3

Black 2 -

Yellow-

green

Orange 11

- PE

block

CN39

1

Page 2.5

Page 16

FORMA: Service & Maintenance manual - rev. 3.0

FR-9: Up-down motor cable

Portable connector – Up-down motor cable

Portable

CN46

1 Motor + White already connected

2 Motor - Blue already connected

5 Up-down motor pulses Red already connected

6 Pulse Gnd Black already connected

Signal Color Up-down motor

FR-10: Braking resistor cable

Inverter – Braking resistor

Inverter Signal Color Resistor

1 Positive White already connected

RB Negative White already connected

FR-11: CPU cable – upper section

CPU board – Portable connector

CPU board

K1 K4

1 - +12 Vdc Red 6

2 - Gnd Black 7

3 - Gnd Grey 13

4 - +5 Vdc Orange 14

- 2 +5 Vdc Red 8

- 3 Up-down motor “down” Green 1

- 4 tread-belt motor speed PWM Grey 9

- 5 Up-down motor “up” Yellow 2

- 6 Start tread-belt motor Brown 10

- 7 Up-down motor alarm Blue 3

- 8 Tread-belt motor alarm Orange-

- 9 Up-down motor pulses Purple 4

- 11 Pulse Gnd Black-green 5

- 12 Gnd Black 12

This cable incorporates a 348 Ohm, 100 Mhz coil-less ferrite.

Signal Color Portable

CN28

11

yellow

Page 2.6

Page 17

FORMA: Service & Maintenance manual - rev. 3.0

FR-12: CPU cable – lower section

Portable connector – Driver board

Signal

CN29

1 Up-down motor “down” Green - 3

2 Up-down motor “up” Yellow - 5

3 Up-down motor alarm Blue - 7

4 Up-down motor pulses Purple - 9

5 Pulse Gnd Black-green - 11

6 +12 Vdc Red 1 7 Gnd Black 2 8 +5 Vdc Red - 2

9 Tread-belt motor speed PWM Grey - 4

10 Start tread-belt motor Brown - 6

11 Tread-belt motor alarm Orange-

12 Gnd Black - 12

13 Gnd Grey 3 14 +5 Vdc Orange 4 -

FR-13: LED board supply cable

CPU board – LED board

CPU board

K2

1 +5 Vdc Red 1

2 Gnd Black 2

Signal Color LED board

FR-14: LED board signal cable

CPU board – LED board

CPU board

K12

1 - 1

2 STROLED 2

3 MUX2 3

4 MUX1 4

5 MUX0 5

6 OELED 6

7 SCK 7

8 MOSI 8

9 DOE 9

10 - 10

This cable incorporates a 65 Ohm, 100 MHz coil-less ferrite.

Signal Color LED board

Color Driver board Portable

J4 J6

- 8

yellow

K2

K12

Page 2.7

Page 18

FORMA: Service & Maintenance manual - rev. 3.0

FR-15: Up-down motor cable extension

Portable connector – Driver board

Portable

CN46

1 Motor + White 1

2 Motor - Blue 2

5 Up-down motor pulses Red 5

6 Pulse Gnd Black 6

Signal Color Driver board

J1

FR-16: Fan power supply cable

Fan interface board – Fan

Fan interface

board

OUT Live Black Fast on

OUT Neutral Blue Fast on

Signal Color Fan

FR-17: Fan driving cable

Fan interface board – Inverter

Fan interface

board

1 Fan enable Black L

2 Gnd Red CM2

Signal Color Inverter

RL-14: Heart rate meter cable

CPU board – Heart rate receiver

CPU board

K14

1 +5 Vdc Red 1

2 Pulse per beat Blue 2

3 Gnd Black 3

Signal Color Receiver

RL-17: Emergency cable

CPU board – Emergency button

CPU board

EM

1 Gnd White Already connected

2 Signal Black Already connected

Signal Color Emergency

button

Page 2.8

Page 19

FORMA: Service & Maintenance manual - rev. 3.0

RL-20: TGS cable

CPU board – Serial connector

CPU board

K6

1 +12 Vdc Yellow 1

2 Gnd Green 5

3 Tx White 3

4 Rx Brown 2

Note that this is a simplified description of the cables, which does not include the ground node

connections of the electronics box, the rear roller and the front roller.

Signal Color Serial connector

Page 2.9

Page 20

FORMA: Service & Maintenance manual - rev. 3.0

2.5.4. P

This machine version, subsequently identified with the name Forma 2:

REVIOUS MODEL

For the cables, refer to the description in the preceding paragraph with the exception of cables FR1/A and FR-7 which are described below:

FR-1/A: Filter cable

Power inlet

Page 2.10

Power inlet socket – Filter

Signal Color Filter PE

socket

Fast on Live Black Fast on Fast on Neutral Blue Fast on Fast on Yellow-green -

-

Earth

Yellow-green Fast on

Eyelet

Page 21

FORMA: Service & Maintenance manual - rev. 3.0

FR-7: Inverter cable

Driver board – Inverter

Driver board

J5

- Thermal cutout Green 3 2

1 White -

2 Start Grey 1 3 Alarm Red AL0 4 Alarm Gnd Purple AL1 5 Speed Brown O 6 Speed Gnd Black L -

Signal Color Inverter CN43

Thermal cutout Gnd

White P24

1

Page 2.11

Page 22

FORMA: Service & Maintenance manual - rev. 3.0

Page intentionally left blank

Page 2.12

Page 23

FORMA: Service & Maintenance manual - rev. 3.0

3. PRINCIPLES OF OPERATION

3.1. BLOCK DIAGRAM

The block diagram of the machine is shown in the figure below:

3.1.1. C

It is worn by the person using the machine, and transmits to the cardio receiver one pulse for every

heart beat that is detected.

Only the traditional version of the component (non coded) is used.

ARDIO TRANSMITTER

3.1.2. CARDIO RECEIVER

It is connected to the machine’s CPU board and receives the pulses sent by the transmitter. Its

reception area is approximately a circle of 1 meter of radius. If there is electromagnetic noise

(produced by high voltage lines, radio transmitters, monitors, motors, etc.) within its reception area,

Page 3.1

Page 24

FORMA: Service & Maintenance manual - rev. 3.0

the receiver becomes saturated and stops receiving any signal. If there are 2 transmitters within its

area of reception, it will receive signals from both, and may produce an error or irregular reading.

Only the traditional version of the component (non coded) is used.

3.1.3. D

This is the heart of the machine, which controls all the machine functions by executing the program

stored in EPROM. It receives information from the user (age, weight, etc.) during set-up of the

training session, from the cardio receiver (user’s heart rate), and from the driver board. It controls

the speed selected with the “+” “−” keys and the elevation selected with the “↑” “↓” keys or

according to the chosen training program. It receives the error signals for the tread-belt motor and

the up-down motor from the driver board, as well as the up-down motor pulses.

It consists of 2 circuit boards:

CPU board: contains the microprocessor and all the control logic of the machine. This circuit board

incorporates a set of 4 dip-switches which is not currently used.

LED board: contains the circuits for the LED indicators and the 7 segment display.

ATTENTION: The EPROM SW versions used on Forma 2 and Forma 3 are different,

due to differences in certain mechanical characteristics between the two machines. In

consequence:

• Forma 2: SW usable up to version 2.1.10;

• Forma 3: SW usable as of version 3.1.02.

ISPLAY

3.1.4. D

Consists of 3 distinct sections integrated into a single circuit board:

• Driver: receives from the display a digital inverter-enable signal and a PWM signal proportional

to the programmed speed, which it converts into a dc voltage for driving the inverter. In the

event of an anomaly, receives the error signal from the inverter and transmits it to the CPU

board.

The circuit board includes a trimmer, component R36, labeled “Reg. velocità” on the printed

circuit board, which regulates the conversion of the PWM into an analog signal in order to

adjust the motor speed.

• Up-down motor control: receives the incline “up” or “down” signals from the display, and

converts them into a voltage for driving the up-down motor. Generates its own supply voltage

and the dc supply voltage for the motor by means of the transformer and rectifier bridge.

Receives the pulses output by the sensor incorporated into the motor, filters them and sends

them to the CPU board. In the event of a motor overcurrent condition, shuts down the motor

drive and sends an alarm signal to the display.

The circuit board includes a trimmer, component R68, labeled “Reg. I Max” on the printed

circuit board, which adjusts the motor current limit.

RIVER BOARD

Page 3.2

Page 25

FORMA: Service & Maintenance manual - rev. 3.0

• DC voltages by-pass: receives the low voltages generated by the power supply and sends them

to the CPU board.

3.1.5. I

This is the device which supplies the three-phase belt motor. It receives a DC reference voltage

from the driver board. Variations in this voltage cause corresponding variations in the operating

frequency of the sinusoidal wave provided by the inverter to the motor phases, and hence change the

speed of the tread-belt. It handles motor drive errors and, in the event of an error, shuts down the

power supply to the motor and sends an alarm signal through the driver board to the display. The

event which caused the error is memorized as an error code.

The model used is Hitachi SJ100 version SJ100-011NFE with a power rating of 1.1 KW (1.5 Hp).

WARNING: The inverter is isolated from earth. It is fixed using plastic screws and

3.1.6. B

An asynchronous three-phase motor which, by means of a pulley and a poly-v belt, turns the driving

roller of the tread-belt. Each motor phase is equipped with a normally-closed bimetallic safety

which opens when the temperature exceeds a preset threshold, in order to safeguard the integrity of

the motor. The 3 bimetallic safeties are connected in series and reach the inverter as a NC external

input signal. When this contact opens, the inverter generates an alarm.

The tread-belt motor has a power of 1.1 KW (1.5 Hp).

NVERTER

washers to ensure its isolation from the machine frame.

ELT MOTOR

The motor used on Forma 3 is different from the one used on Forma 2.

WARNING: The tread-belt motor is isolated from earth. It is fixed using plastic

bushings and dowels to ensure its isolation from the machine frame.

3.1.7. UP-

This is a linear actuator equipped with a 24 V DC motor, incorporating a reduction unit and a rod

that is moved backward and forward by the motor. The rod actuates a frame connected to the front

wheels of the machine: when the rod moves it causes the frame to move, thereby raising or lowering

the machine.

The actuator has a built-in reed sensor which functions as an encoder, outputting pulses as the motor

turns. This provides the necessary feedback signal for determining the position of the rod and hence

the machine incline.

DOWN MOTOR

3.1.8. POWER SUPPLY

Receives the mains voltage at its input and outputs the DC voltages (+5 V and +12 V) which supply

the display and the inverter interface board. This power supply is equipped with mains voltage

autosensing.

Page 3.3

Page 26

FORMA: Service & Maintenance manual - rev. 3.0

3.1.9. V

This is a selector which, when used together with a transformer having 2 primary 110 VAC circuits,

ensures the correct power supply to the transformer when powered at either 110 VAC or 230 VAC.

Switching positions changes the connection of the 2 primary circuits on the standard transformer

from serial (for 230 VAC power supply) to parallel (for 110 VAC power supply). It is located on the

low kit electrical box to prevent accidental selections by clients that could interfere with machine

operation.

OLTAGE SELECTOR SWITCH

3.1.10. T

Is equipped with two 110 VAC primaries and one 18VAC/5A secondary. This transformer powers

the driver boards for the up-down section.

3.1.11. S

This is the user safety device. It is implemented by a reed relay which is NC when the “Safety

switch”, a plastic button containing a magnet, is correctly positioned on the display panel. Its signal

is input to the CPU board. If the user is in difficulty and detaches the “Safety switch” from the

display by pulling the attached cord, the contact opens and the CPU board detects the transition,

braking the motor to prevent the user from falling.

RANSFORMER

AFETY SWITCH

3.1.12. FAN

It is a supplementary fan which provides improved cooling of the motor, especially during low

speed operation. The fan receives a supply voltage from the fan interface board when the motor is

running.

3.1.13. F

The circuit board takes care of enabling the fan when the motor is running. In fact, it receives a

signal from the inverter which closes a relay contact on the circuit board, causing the supply voltage

to be sent to the fan input.

AN INTERFACE BOARD

Page 3.4

Page 27

FORMA: Service & Maintenance manual - rev. 3.0

3.2. TREAD-BELT MOTOR DRIVE

3.2.1. MECHANICS

The tread-belt is actuated by the motor through a linkage consisting of the motor pulley, the driving

roller and the belt which connects them. In this way, a given belt motor speed corresponds to a

predetermined linear tread-belt speed. The belt motor is controlled by the inverter which generates a

variable-frequency sine wave signal: variations in frequency cause the motor speed and hence the

tread-belt speed to vary.

3.2.2. C

To start the motor, the CPU board sends a Start signal to the inverter through the driver board,

enabling the inverter to drive the motor. After outputting this enable signal, the CPU board sets the

motor speed by sending a PWM signal to the driver board, which the driver board converts into an

analog input voltage to the inverter. The relationship between the analog input voltage and the

inverter output frequency is determined by the values of the configuration parameters in the inverter

program.

During its movement, the inverter checks the motor and, if any problems are detected (overvoltage,

overcurrent, SW and HW problems to the inverter, etc.) it halts the motor and sends an alarm signal

to the CPU board, which displays the error message “E3”.

To protect the motor from overheating, each motor phase has a thermal cutout connected in series. If

the temperature exceeds the threshold value, the thermal cutout opens and interrupts the circuit. The

inverter detects this condition as the opening of a NC external contact. In such a case the inverter

halts the motor and outputs an alarm signal to the CPU board, which displays the error message

cited above.

ONTROLS

Page 3.5

Page 28

FORMA: Service & Maintenance manual - rev. 3.0

3.2.3. T

HE SIGNALS INVOLVED

The machine controls the speed of the belt motor by means of the CPU board and the inverter

interface board, as shown in the following figure:

CPU board

4-12 6-12 8-12 K4

Start PWM

9-12 10-12 11-12 CN28

Start PWM

4-12 6-12 8-12 J6

Driver board

Alarm

Alarm

5-6 2-1 3-4 J5

Start Vref

Alarm

O-L 1-P24 AL1-AL0

Inverter

3-P24

with variable frequency

VAC

U-V-W

Thermal

protection

M

The speed control utilizes the following signals:

• Start signal

This is the signal generated by the CPU board to enable starting of the motor (pin 6-12 on

connector K4). When the tread-belt is stopped this signal is at logic level low (0.2 Vdc), whereas

immediately after the “Start” key on the display is pressed it goes high (4.8 Vdc).

This signal enters the driver board (pin 6-12 on connector J6), is processed and sent out (pin 2-1

on connector J5 of the driver board) to the inverter (pin 1-P24). In the belt-stopped conditions it

is -23.8 Vdc, while immediately after pressing the “Start” key on the display it is 0 Vdc.

Page 3.6

Page 29

FORMA: Service & Maintenance manual - rev. 3.0

• Speed reference signal

This is the signal generated by the CPU board (pin 4-12 on connector K4) to control the motor

speed. It is a PWM signal, i.e. a fixed-frequency square wave signal with variable duty cycle.

The logic of this control has the duty cycle decreasing with increasing speed, from a maximum

of approximately 5 Vdc down to a few hundred mVdc.

The signal enters the driver board (pin 4-12 on connector J5), is converted into a variable analog

signal between 0 and 10 Vdc, and sent out (pin 5-6 on connector J5 of the driver board) to the

inverter (pin O-L). The signal input to the inverter increases with increasing speed.

The relationship between the speed reference voltage and the inverter output frequency is

determined by the values of the configuration parameters in the inverter program.

• Variable frequency VAC signal

This is the variable frequency alternating voltage generated by the inverter (pin U-V-W) for

supplying the motor. The motor speed increases with increasing frequency.

• Thermal cutout signal

Each motor phase is equipped with a normally-closed thermal cutout which opens when the

temperature exceeds a preset threshold. The 3 thermal cutouts are connected in series and exit

the motor via a 2-wire cable connected to the inverter (3-P24). The inverter is programmed to

expect a NC signal on these pins. When at least one thermal cutout is tripped, the contact opens

and the inverter, detecting the open-circuit condition, generates an alarm signal.

• Alarm signal

This is the signal generated by the inverter (AL1-AL0) if a problem is detected in the motor

drive, or if the motor thermal cutouts open. It enters the driver board (pin 3-4 on connector J5)

and its value is 0 Vdc under normal conditions, 5 Vdc under alarm conditions.

The signal is then sent from the driver board (pin 8-12 on connector J6) to the CPU board (pin

8-12 on connector K4); its value is 0.2 Vdc under normal conditions, 5 Vdc under alarm

conditions. When this alarm signal switches to 0 Vdc, the CPU disables the Start signal, resets

the PWM signal and shows error message “E3” on the display.

Page 3.7

Page 30

FORMA: Service & Maintenance manual - rev. 3.0

3.3. UP-DOWN MOTOR DRIVE

3.3.1. MECHANICS

The machine incline is varied by the up-down motor rod, which moves a frame connected to the

front wheels. The motor movement is detected by a hall sensor which provides the motor motion

control signal: each motor revolution corresponds to a predetermined number of pulses and to a

predetermined displacement of the rod, and hence of the machine incline. The direction of rotation

of the motor determines whether the machine moves up or down.

3.3.2. CONTROLS

To vary the incline, the CPU board sends the driver board an Up signal (move the motor in the up

direction to increase the elevation) or a Down signal (move the motor down to decrease the

elevation). The driver board accordingly actuates the motor in the appropriate direction, by

supplying it with a positive or negative voltage. When the motor moves, the sensor generates the

pulses which are received by the driver board. The driver board filters the pulses and sends them to

the CPU board which counts the pulses received, and on reaching the number corresponding to the

desired incline, resets the Up or Down signal which produced the movement.

If, after having asserted the Up or Down signal, the driver board detects a motor overcurrent, it shuts

down the supply to the motor and sends an alarm signal to the CPU board. On receiving the alarm

signal, the CPU board resets the Up or Down signal which generated the problem, and displays error

message “E5”.

On power-up, the machine performs a reset procedure in order to determine the reference incline.

The procedure consists of the following steps:

• Small upward movement of the machine;

• Downward movement of the machine until the motor rod is fully inserted and blocked. This

causes the motor to be supplied with the rotor blocked. In these conditions, the motor draws

such a high current that the driver board shuts down its supply and sends an alarm signal to the

CPU. The receipt of this alarm signal defines the reference “zero position” for the incline: all the

movements for reaching different elevations will be variations referred to this reference.

• Upward movement of the machine until the CPU board receives a predetermined number of

pulses, corresponding to the movement of the rod to the established 0.0% incline position.

Page 3.8

Page 31

FORMA: Service & Maintenance manual - rev. 3.0

3.3.3. T

HE SIGNALS INVOLVED

The machine controls the incline through the CPU board and the driver board, as illustrated in the

figure below:

-

-

CPU board

9-11

K4

7-12

Alarm Pulses Down Up

2-12 1-12 4-5 CN28 3-12

Pulses Down Up

Alarm

-

-

J6

9-11

Driver

board

-

-

-

4-5/CN25

Vdc

M

3-12/CN25

Pulses

Reed sensor

The control logic involves the following signals:

• Up Signal

This is the signal generated by the CPU board (pin 5-12 on connector K4) to enable movement

of the up-down motor in the “up” direction. In normal conditions the signal is at logic level low

(0 Vdc), and it goes high (4.65 Vdc) to actuate the motor. The signal remains high for the entire

duration of the movement.

The signal enters the driver board (pin 5-12 of connector J6) and enables the movement of the

motor in the desired direction.

• Down signal

This is the signal generated by the CPU board (pin 3-12 on connector K4) to enable movement

of the up-down motor in the “down” direction. In normal conditions the signal is at logic level

low (0 Vdc), and it goes high (4.65 Vdc) to actuate the motor. This signal remains high for the

entire duration of the movement.

The signal enters the driver board (pin 3-12 on connector J6) and enables movement of the

motor in the desired direction.

Page 3.9

Page 32

FORMA: Service & Maintenance manual - rev. 3.0

• Motor voltage signal (Vdc)

This is the DC voltage generated by the driver board (pin 1-2 of connector J1) to supply the updown motor. Its absolute value is 24 Vdc, and the motor will rotate either clockwise or

anticlockwise depending on its polarity, causing the rod to become longer or shorter, thereby

increasing or decreasing the machine incline.

• Pulse signal

This is a square wave signal alternating between logic level low (8.8 Vdc) and logic level high

(11.4 Vdc), generated by the hall sensor incorporated into the motor. This signal reaches the

driver board (pin 5-6 on connector J1).

The signal is level-converted, filtered, squared and output (pin 9-11 on connector J6) to the CPU

board (pin 9-11 on connector K4) for controlling the movement. The output signal is still a

square wave signal, but alternating between 0 and 5 Vdc.

• Alarm signal

This is the signal generated by the driver board (pin 7-12 on connector J6) when it detects a

motor overcurrent condition. This signal is sent to the CPU board (pin 7-12 on connector K4).

As soon as the CPU board receives this signal, it resets the up or down command which caused

the alarm condition, to protect the motor from damage due to overcurrent.

The control logic enables the weight stack motor interface board to freely drive the motor when

the alarm signal is at logic level high (5 Vdc). As soon as this signal goes low ( 0 Vdc) the CPU

board resets the previously asserted up or down motor signal, causing the weight stack motor

interface board to reset the alarm signal, which thus returns high. All this takes place within a

few msec.

Page 3.10

Page 33

FORMA: Service & Maintenance manual - rev. 3.0

3.4. FAN DRIVE

3.4.1. MECHANICS

The fan is independent of the treadmill motor and assembled on its axis, on the other side of the

flywheel. It is a larger sized fan than the one used on Forma 2, which resolves the overheating

problems of the preceding version, especially during operation at low speeds.

3.4.2. C

The fan is directly controlled by the fan interface board. However, the enable signal for starting the

fan comes from the inverter: when the motor starts, the fan must also start.

To start the motor, the CPU board sends a Start signal to the inverter via the driver board, in order to

enable the inverter for driving the motor. On receiving this enable signal the inverter generates a

signal which enables the fan interface board to start the fan.

The fan interface board receives this input enable signal which, via a relay, supplies an input voltage

to fan, causing it to start moving.

ONTROLS

Page 3.11

Page 34

FORMA: Service & Maintenance manual - rev. 3.0

3.4.3. T

HE SIGNAL INVOLVED

The machine controls the operation of the fan as illustrated in the diagram below:

CPU board

6-12

K4

Start

10-12

Start

CN28

6-12

Driver board

J6

2-1 J5

Start

1-P24

Inverter

CM2-L

Enable

Fan interface board

IN

2-1

OUT

Fan

• Start Signal

This is the signal generated by the CPU board to enable starting of the motor (pins 6-12 of

connector K4). When the treadmill is halted it is at logic level low (0.2 Vdc), and immediately

switches to logic level high (4.8 Vdc) when the "Start" button on the control panel is pressed.

This signal enters the driver board (pins 6-12 of connector J6), where it is processed and sent

(pins 2-1 of connector J5 on the driver board) to the inverter (pin 1-P24). When the treadmill is

halted it is at logic level low (-23.8 Vdc), and immediately switches to 0 Vdc when the "Start"

button on the control panel is pressed.

Page 3.12

Page 35

FORMA: Service & Maintenance manual - rev. 3.0

• Enable signal

This is the signal generated by the inverter (pin CM2-L) for enabling the fan. When the treadmill

is halted it is at logic level low (0 Vdc), and immediately switches to logic level high (24.55

Vdc) when the "Start" button on the control panel is pressed.

This signal enters the fan interface board (pin 1-2 of connector CN1) and drives the relay on the

circuit board.

• VAC power supply

This is the mains power supply that enters the fan interface board (IN pin of connector CN2): it

must always be 220 VAC.

Depending on the state of the relay, this voltage is supplied to the fan (OUT pin of connector

CN2): it must be 0 when the motor is stopped, and 220 VAC when the motor is running.

Page 3.13

Page 36

FORMA: Service & Maintenance manual - rev. 3.0

Page intentionally left blank

Page 3.14

Page 37

FORMA: Service & Maintenance manual - rev. 3.0

4. ACCESSORIES

4.1. CONNECTING TO THE TGS

The machine can be connected to the Technogym System by installing a special upgrade kit. The

CPU board is connected to the serial connector via the cable described below, which is supplied

together with the upgrade kit.

To connect a TGS-ready machine, use the RS 232 serial port on the CPU board, made available

through a 9-pin D-connector situated at the rear of the control panel.

The TGS reader is of type 232.

For further details, including troubleshooting information, refer to the manual: “Technogym

System: Installation guide”.

Page 4.1

Page 38

FORMA: Service & Maintenance manual - rev. 3.0

Page intentionally left blank

Page 4.2

Page 39

FORMA: Service & Maintenance manual - rev. 3.0

5. INSTALLATION INSTRUCTIONS

5.1. SPECIFICATIONS AND REQUIREMENTS

For correct machine installation, make sure that:

1. The machine is installed on a level surface that is free of vibrations and has sufficient carrying

capacity for the combined weight of the machine and user.

2. The environment is dust or sand free.

3. The environment meets the operating temperature and humidity conditions specified in

paragraph 2.3. .

4. The machine is not positioned close to sources of heat, sources of electromagnetic noise

(television sets, electric motors, antennas, high voltage lines, appliances etc…) or medical

equipment.

5. To eliminate any interference with the cardio receiver, there should not be any transmitters at a

distance of 100 cm from the display.

6. The mains voltage must match the value specified on the machine rating plate.

7. The electrical system must be provided with an efficient ground connection.

8. The wall outlet used should be reserved for the machine and have a rating of at least 2000 Watt.

9. Do not connect other machines or users to the same wall outlet.

10. Position the mains lead of the machine where is will not be underfoot. For this purpose, it is

recommended to use the special trackways supplied with the machine.

5.2. INSTALLATION

To correctly install the machine, proceed as follows:

1. Ensure that the specifications and requirements for installation have been met (see paragraph

5.1. ).

2. Position the machine as specified above, on a level surface that is free of vibrations and has

sufficient carrying capacity for the combined weight of the machine and the user.

3. The machine is shipped disassembled, and packed in a carton fixed to a wooden pallet. For

assembling follow the procedure described in the “User and maintenance manual” supplied with

each machine.

4. Connect the mains lead to the inlet socket on the machine.

5. Place the on/off switch in the “0” position.

6. Plug the mains lead into the electrical outlet.

5.3. FIRST POWER-ON

After completing the installation procedure, the machine is ready to be powered up. To turn on the

machine, simply toggle the on/off switch from the 0 position to the 1 position.

Page 5.1

Page 40

FORMA: Service & Maintenance manual - rev. 3.0

When the machine is turned on it will perform a power-on test which:

• sounds the buzzer;

• lights all the LEDs;

• resets the elevation.

After completing this power-on test the machine enters standby mode, awaiting a keyboard

command.

To check the correct operation of the machine:

• get on the machine;

• press the “Start” key on the keyboard to begin exercising;

• check that the belt motor starts;

• press the “+” and “−” keys on the keyboard and check that the tread-belt speed changes

accordingly;

• press the “↑” and “↓” keys on the keyboard and check that the machine elevation changes

accordingly;

• operate the “Safety switch” and check that the tread-belt stops;

• put on the heart rate transmitter and check that the machine correctly measures the heart rate

value.

Page 5.2

Page 41

FORMA: Service & Maintenance manual - rev. 3.0

6. TROUBLESHOOTING

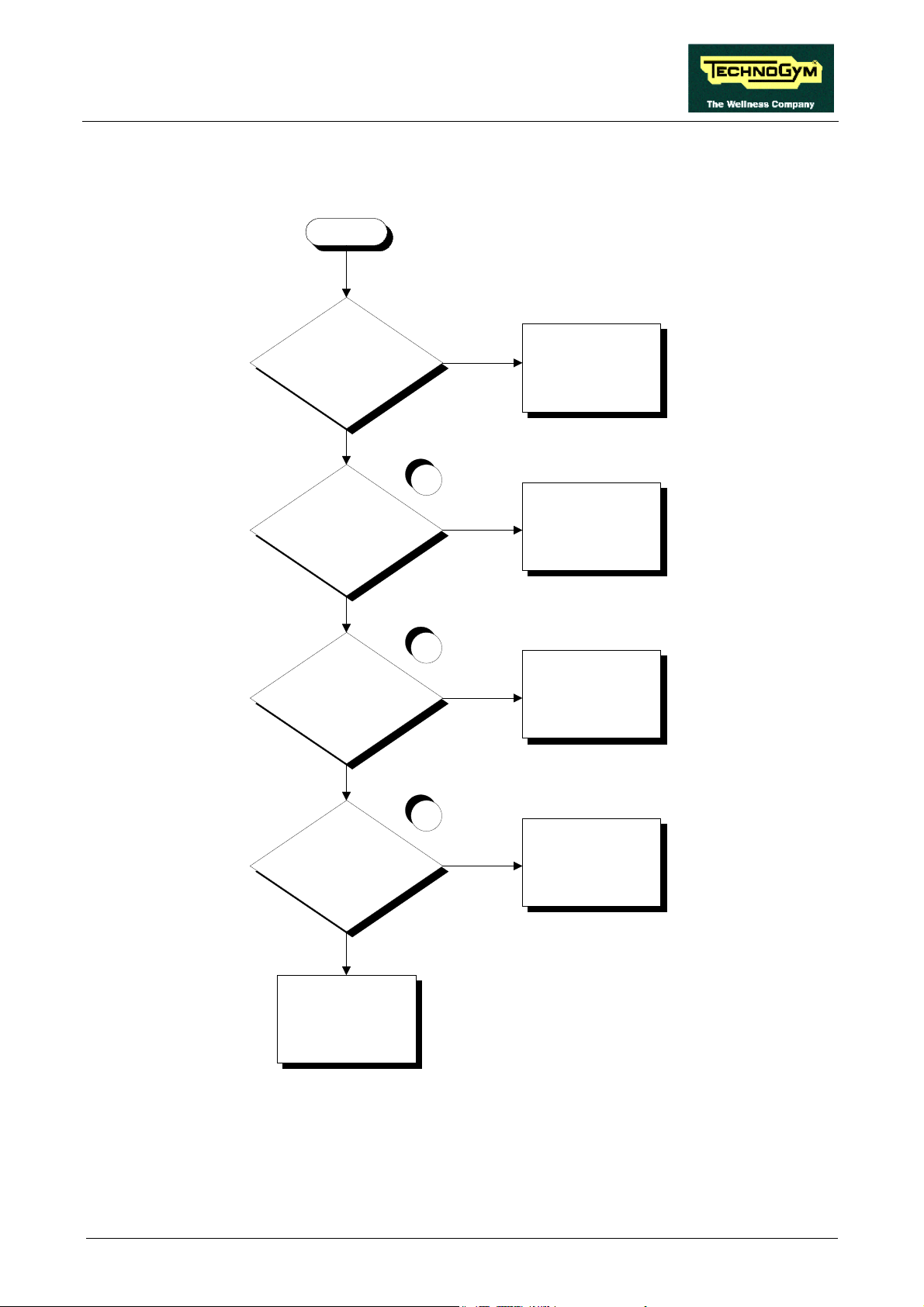

The troubleshooting procedures are shown in the form of flow charts. In order to facilitate

consultation, the following standard box shapes are used.

This type of box is the START point of the troubleshooting procedure. It

typically contains a description of the problem or malfunction.

This type of box represents a decision point in the troubleshooting procedure.

It typically contains a description of the DECISION to be made, with an

outcome that can be either a positive (YES) or negative (NO) response.

This type of box corresponds to a step in the troubleshooting procedure where

an ACTION must be carried out. It typically contains a description of the

ACTION necessary to resolve the problem. Therefore, after executing the

specified ACTION:

1. Check whether the problem has been resolved;

2. If the problem persists, it is recommended to resume the troubleshooting

procedure from the point before the action was carried out.

A circled number (such as that shown on the left) next to a box of the

troubleshooting procedure indicates that detailed instructions for performing

that particular check or action are provided below the flowchart.

A circled letter (such as that shown on the left) is used to highlight a point in

the procedure. Typically, this indicator is used in page changes.

Page 6.1

Page 42

FORMA: Service & Maintenance manual - rev. 3.0

6.1. THE DISPLAY DOES NOT ILLUMINATE

This problem occurs when the supply voltage fails to reach the display.

THE DISPLAY

DOES NOT

ILLUMINATE

Are the fuses OK?

YES

Is mains lead OK?

YES

Does the wall outlet supply the

correct voltage?

NO

NO

NO

Replace the blown

fuses

Replace the mains lead

Connect machine to a

suitable

electrical outlet

Is the mains voltage present at

the power supply input?

Continued on the following page.

Page 6.2

YES

1

NO

B

YES

A

Page 43

FORMA: Service & Maintenance manual - rev. 3.0

A

2

Are DC voltages output by the

power supply correct?

YES

Do all DC voltages reach the

display?

NO

Do all DC voltages reach the

driver board?

NO

Replace the power

supply

3

YES

Replace the display

CPU board

4

NO

Replace cable FR-6

YES

Replace cable FR-11

Continued on the following page.

YES

Are all DC voltages present at the

output of the driver board?

YES

Are all DC voltages present at the

free connector CN28?

5

NO

Replace the driver

board

6

NO

Replace cable FR-12

Page 6.3

Page 44

FORMA: Service & Maintenance manual - rev. 3.0

B

7

Is the mains voltage present at

the output of the mains plug?

YES

Is the mains voltage present at

the input to the filter?

YES

Is the mains voltage present at

the output of the filter?

NO

Replace the mains plug

of the machine

8

NO

Replace the cable

FR-1/A

9

NO

Replace the filter

YES

10

Replace the cable

FR-3/L

YES

Is the mains voltage present at

the connector CN39?

NO

Replace the cable FR-2

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

WARNING: Carry out these checks with the machine powered up.

(1) Lift connector CN1 slightly from the power supply. Place the tester probes between pins 4 and

6 on the same connector. The measured voltage should be 220 VAC.

(2) Lift connector CN2 slightly from the power supply, in order to reach the pins with the tester

probes. Check that all the output voltages of the power supply are correct, referring to

paragraph 2.5. .

Page 6.4

Page 45

FORMA: Service & Maintenance manual - rev. 3.0

(3) As for step (2), but on connector K1 on the CPU board of the display.

(4) As for step (2), but on connector J3 of the driver board.

(5) As for step (2), but on connector J4 of the driver board.

(6) As for step (2), but on portable connector CN28.

(7) Slightly lift up the fast ons on the machine power inlet socket. Place the tester probes between

the live and neutral pins on the same connector. The measured voltage should be 220 VAC.

(8) As for step (7), but on the filter input.

(9) As for step (7), but on the filter output.

(10) As for step (7), but on connector CN39.

Page 6.5

Page 46

FORMA: Service & Maintenance manual - rev. 3.0

6.2. THE DISPLAY SHOWS “SAFETY SWITCH”

The machine displays this message if:

• The “Safety switch” is tripped during a training session.

• The emergency system is damaged.

THE DISPLAY SHOWS

“SAFETY TRIPPED”

YES

Correct operation

1

NO

Replace the reed relay

Replace the CPU board

YES

Did the user disconnect the safety

switch during the training session or at

the start?

NO

Does the reed contact switch from

open to close and vice versa when the

“safety switch” is connected and

disconnected?

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Place the tester probes between pins 1 and 2 of connector EM on the CPU board. The contact

should be closed when the Safety switch is correctly positioned on the display, and open when

the Safety switch is detached from the display.

Page 6.6

Page 47

FORMA: Service & Maintenance manual - rev. 3.0

6.3. THE DISPLAY SHOWS “E 3”

The machine displays this message if:

• it has detected a failure to actuate movement of the belt motor at the start of the training session;

• the movement of the belt motor is interrupted during the training session.

The most common causes are principally:

• One of the motor thermal cutouts has been tripped;

• The inverter has shut down for protection from a mains voltage fluctuation (spike or glitch).

In both cases it is recommended to turn off the machine — for at least one hour in the first case, and

for a few minutes in the second case — before resuming normal operation.

If the machine still does not operate correctly, follow the procedures (which differ depending on the

inverter model used) set out in the following paragraphs.

Page 6.7

Page 48

FORMA: Service & Maintenance manual - rev. 3.0

THE DISPLAY

SHOWS "E 3"

Check the error message

displayed and/or

memorized by the inverter

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

E11

E12

E14

E15

E21

None

The following paragraphs describe the troubleshooting procedures associated with the individual

errors.

Page 6.8

Page 49

FORMA: Service & Maintenance manual - rev. 3.0

6.3.1. T

HE INVERTER DISPLAY SHOWS

E01, E02, E03, E04

These inverter error messages are related to output short-circuit problems.

E02 E03 E04 E05E01

1

OR

E05

Is the inverter output

short-circuited?

NO

Is there a short-circuit on the

motor cable terminals?

NO

Does the machine resume

correct operation after being

turned off for 1 minute?

YES

2 3

YES

YES

Replace the inverter

Is the belt motor

short-circuited?

Probable interference. The

machine is OK

YES

Replace the belt motor

Replace the belt motor

cable

NO

NO

Replace the inverter

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Disconnect the motor cable from the inverter and place the tester probes between its U-V, U-

W and V-W terminals. The measured resistance should be very high, in the order of MOhm. It

is difficult to make a stable measurement of resistance, however a phase can be considered

short circuited or defective when the measured resistance is in the order of a few tens of

Ohms.

Page 6.9

Page 50

FORMA: Service & Maintenance manual - rev. 3.0

(2) Place the tester probes between the blue – black, blue – brown and black – brown conductors

of the motor cable. The measured resistance should be 4.4 Ohm.

(3) Disconnect the motor cable from the motor and place a tester between its terminals U-V, U-W

and V-W. The measured resistance should be approximately 4.4 Ohm.

Page 6.10

Page 51

FORMA: Service & Maintenance manual - rev. 3.0

6.3.2. T

HE INVERTER DISPLAY SHOWS

E06

OR

E07

These inverter error messages are related to problems with the inverter braking group or the braking

resistor.

E07E06

NO

Reinstate the connection

NO

Replace the braking

resistor

YES

Probable interference. The

machine is OK

Replace the inverter

NO

Is the braking resistor

correctly connected to the

inverter?

YES

1

Is the value of the braking

resistance correct?

YES

Does the machine resume

correct operation after being

turned off for 1 minute?

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) With the machine switched off, disconnect a resistor terminal from the inverter terminal block

and place the tester probes across it. The measured resistance should be 150 Ohm.

To reduce the occurrences of error E06, adjust inverter parameter b90, increasing its

setting from the default value to 20. This adjustment allows the inverter to increase its

use of the braking resistor.

Page 6.11

Page 52

FORMA: Service & Maintenance manual - rev. 3.0

6.3.3. T

HE INVERTER DISPLAY SHOWS

E08, E10, E11

OR

E22

These inverter error messages are related to HW and SW problems with the inverter.

E10E8 E11

1

E22

Does the error occur

frequently?

NO

Does the machine resume

correct operation after being

turned off for 1 minute?

NO

Re-program the inverter

YES

YES

Replace the inverter

Probable interference. The

machine is OK

YES

Programming correct. The

machine is OK

Replace the inverter

NO

Does the machine resume

correct operation after being

turned off for 10 minutes?

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Check the frequency of the errors by counting the occurrences in the inverter error memory,