CROSS

PERSONAL

REV. 1.1

The information contained in this manual is intended for QUALIFIED TECHNICIANS who have

completed a specific TECHNOGYM training course and are authorized to perform machine start-

up and adjustment procedures as well as extraordinary maintenance or repairs which require a

thorough knowledge of the machine, its operation, its safety devices and working procedures.

CAREFULLY READ THE INFORMATION CONTAINED IN

THIS MANUAL BEFORE PERFORMING ANY MAINTENANCE

PROCEDURES ON THE MACHINE

DANGEROUS VOLTAGES

PRESENT

NOTE:

The information contained in this document is subject to change without notice.

Technogym does not guarantee this documentation in any way. Technogym shall not be held

responsible for any errors contained in this manual and declines all liability for accidents or

damages resulting from the supply, characteristics or use of this manual.

This document contains proprietary information that is protected by copyright. All rights reserved.

No part of this document may be photocopied, reproduced or translated into another language

without the prior written consent of Technogym.

The Technogym™ trademark is property of Technogym S.p.A.

The Cross Personal™ trademark is property of Technogym S.p.A.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page i

Contents

1. GENERAL NOTICES ............................................................................................................................................. 1.1

1.1. INTRODUCTION ................................................................................................................................................... 1.1

1.2. RECOMMENDATIONS .......................................................................................................................................... 1.1

1.3. GENERAL RULES FOR REPAIR PROCEDURES ........................................................................................................ 1.2

2. TECHNICAL CHARACTERISTICS .................................................................................................................... 2.1

2.1. PRODUCT CODES ................................................................................................................................................. 2.1

2.2. SERIAL NUMBER STRUCTURE ............................................................................................................................. 2.2

2.3. TECHNICAL SPECIFICATION ................................................................................................................................ 2.3

2.4. MECHANICAL CHARACTERISTICS ....................................................................................................................... 2.3

2.5. DIMENSIONS .................................................................................................................................................. 2.4

2.6. PACKING DIMENSIONS EUROPE AND OVERSEAS ............................................................................................. 2.4

2.7. AMBIENT SPECIFICATIONS .................................................................................................................................. 2.5

2.8. CONFORMITY TO REGULATIONS .......................................................................................................................... 2.5

2.9. WIRING DIAGRAMS ............................................................................................................................................. 2.6

2.10. CABLES .............................................................................................................................................................. 2.7

2.10.1. CBQ Cables ............................................................................................................................................ 2.7

2.10.2. WB Cables .............................................................................................................................................. 2.7

2.10.3. CU Cables .............................................................................................................................................. 2.7

3. PRINCIPLES OF OPERATION ............................................................................................................................ 3.1

3.1. BLOCK DIAGRAM ................................................................................................................................................ 3.1

3.2. ELECTRONIC COMPONENTS................................................................................................................................. 3.2

3.2.1. CPU board ............................................................................................................................................. 3.2

3.2.1.1. BackUp battery ............................................................................................................................................................................ 3.2

3.2.2. LCD inverter .......................................................................................................................................... 3.3

3.2.3. Digital/Analog tuner board .................................................................................................................... 3.3

3.2.4. LAN network board (integrated) ............................................................................................................ 3.3

3.2.5. Wireless network board (without cables) ............................................................................................... 3.4

3.2.6. Audio/Video external device connector board ....................................................................................... 3.5

3.2.7. Jack cuffie ............................................................................................................................................... 3.5

3.2.8. Scheda C-Safe (integrata) ...................................................................................................................... 3.5

3.2.9. Porta USB di servizio (integrata) ........................................................................................................... 3.5

3.2.10. Capacitive Touch Screen control board ................................................................................................. 3.5

3.2.11. Power Supply board ............................................................................................................................... 3.5

3.2.12. Secondary ON/OFF switch .................................................................................................................... 3.6

3.2.13. Audio Amplifier board ............................................................................................................................ 3.6

3.2.14. Hand Sensor board ................................................................................................................................ 3.6

3.2.15. Cardio receiver HR ................................................................................................................................ 3.7

3.2.16. iPod docking station ............................................................................................................................... 3.7

3.2.17. Client USB port ...................................................................................................................................... 3.8

3.2.18. Dual TGS reader .................................................................................................................................... 3.8

3.2.19. Brake Board ........................................................................................................................................... 3.8

3.2.20. Electromagnetic brake ........................................................................................................................... 3.9

3.2.21. Speed sensor ........................................................................................................................................... 3.9

3.2.22. Power entry module ............................................................................................................................... 3.9

3.3. BRAKE CONTROL .............................................................................................................................................. 3.10

3.3.1. Mechanics ............................................................................................................................................ 3.10

3.3.2. Controls ................................................................................................................................................ 3.10

3.3.3. The signals involved ............................................................................................................................. 3.12

3.4. AUDIO SIGNAL AND AUDIO OUT CONTROL ........................................................................................................ 3.13

3.4.1. Control ................................................................................................................................................. 3.13

3.4.2. The signals involved ............................................................................................................................. 3.14

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page ii

4. ACCESSORIES ....................................................................................................................................................... 4.1

4.1. CARDIO THEATER CONNECTION .......................................................................................................................... 4.1

4.2. MONITOR PLUG FOR C-SAFE PORT ...................................................................................................................... 4.2

5. INSTALLATION INSTRUCTIONS ...................................................................................................................... 5.1

5.1. SPECIFICATIONS AND REQUIREMENTS ................................................................................................................ 5.1

5.2. MOVING THE EQUIPMENT ................................................................................................................................... 5.2

5.3. RECOMMENDED ANTENNA SIGNAL REQUIREMENTS ............................................................................................ 5.3

5.4. INSTALLATION .................................................................................................................................................... 5.3

5.5. FIRST POWER-ON ................................................................................................................................................ 5.3

6. TROUBLESHOOTING .......................................................................................................................................... 6.1

6.1. TROUBLESHOOTING MENU .................................................................................................................................. 6.2

6.2. THE DISPLAY STAYS OFF ..................................................................................................................................... 6.3

6.3. NO AUDIO SOUND ............................................................................................................................................... 6.8

6.4. NO TV PICTURE ................................................................................................................................................ 6.12

6.5. THE TOUCH SCREEN DOES NOT WORK / IT’S NOT CALIBRATED .......................................................................... 6.12

6.6. THE RADIO DOES NOT PLAY .............................................................................................................................. 6.12

6.7. THE IPOD DOES NOT WORK ............................................................................................................................... 6.13

6.8. “THE EQUIPMENT IS LOCKED (COM)” MESSAGE ON DISPLAY ................................................................. 6.15

6.9. THE BRAKE BOARD HAS DETECTED AN ERROR ................................................................................................. 6.16

6.10. THERE IS NO RESISTANCE ................................................................................................................................. 6.19

6.11. THE RESISTANCE IS NOT CORRECT .................................................................................................................... 6.22

6.12. THE SPEED SIGNAL IS NOT CORRECT ................................................................................................................. 6.24

6.13. THE MACHINE DOES NOT READ THE TGS KEY .................................................................................................. 6.26

6.14. THERE IS NO HEART RATE SIGNAL ..................................................................................................................... 6.28

6.14.1. Hand sensor ......................................................................................................................................... 6.28

6.14.2. Chest belt .............................................................................................................................................. 6.32

6.15. THE TELEMETRIC HEART RATE SIGNAL IS INCORRECT ....................................................................................... 6.35

6.15.1. Chest belt .............................................................................................................................................. 6.35

6.15.2. Hand Sensor ......................................................................................................................................... 6.39

7. PART DISASSEMBLY ........................................................................................................................................... 7.1

7.1. DISASSEMBLY OF THE REAR DISPLAY COVER ...................................................................................................... 7.1

7.2. DISMANTLING THE WHOLE DISPLAY ................................................................................................................... 7.2

7.3. DISMANTLING THE TOUCH SCREEN .................................................................................................................... 7.3

7.4. DISMANTLING THE DISPLAY BOARDS ................................................................................................................. 7.4

7.5. DISMANTLING THE SECONDARY ON SWITCH CARD ............................................................................................ 7.5

7.6. DISMANTLING THE FRONT GUARDS .................................................................................................................... 7.6

7.7. DISMANTLING THE AMPLIFIER/SPEAKERS .......................................................................................................... 7.7

7.8. DISMANTLING THE TOTAL LEVERS ..................................................................................................................... 7.8

7.9. DISMANTLING THE TWEETER FROM THE TOTAL LEVER ...................................................................................... 7.9

7.10. DISMANTLING THE PLATFORM LEVER .............................................................................................................. 7.10

7.11. DISMANTLING THE MECHANICS/CRANK ASSEMBLY ......................................................................................... 7.11

7.12. DISMANTLING THE CRANK ASSEMBLY BELT ..................................................................................................... 7.12

7.13. DISASSEMBLY OF THE REAR GUARDS ................................................................................................................ 7.13

7.14. DISMANTLING THE BRAKE BELT ...................................................................................................................... 7.14

7.15. DISMANTLING THE BRAKE BELT PULLEY ......................................................................................................... 7.15

7.16. DISMANTLING THE LOW KIT, POWER CARD, BRAKE AND FLYWHEEL .............................................................. 7.16

8. ADJUSTMENTS ...................................................................................................................................................... 8.1

8.1. MECHANICS/CRANK ASSEMBLY SHAPING .......................................................................................................... 8.1

8.2. BRAKE BELT TENSION ......................................................................................................................................... 8.4

8.3. LEVELLING ......................................................................................................................................................... 8.5

9. EQUIPMENT CONFIGURATION ....................................................................................................................... 9.1

9.1. CONFIG.: VISIO - VISIOWEB USER MENÙ .................................................................................................... 9.1

9.2. SERVICE MENU CONFIG.: VISIO - VISIOWEB .......................................................................................... 9.3

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page iii

9.2.1.1. Table of configuration parameters .............................................................................................................................................. 9.4

10. UPDATING THE SW ............................................................................................................................................ 10.1

11. SCHEDULED MAINTENANCE ......................................................................................................................... 11.1

12. APPENDIX ............................................................................................................................................................. 12.1

12.1. MENU PASSWORD TABLE .................................................................................................................................. 12.1

12.2. REQUIRED TOOLS ............................................................................................................................................. 12.2

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page iv

Page intentionally left blank.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 1.1

1. GENERAL NOTICES

1.1. INTRODUCTION

This document is reserved for Technogym Service technicians, and is intended to provide

authorized personnel with the necessary information to correctly carry out r epairs and maintenance.

A thorough knowledge of the technical information contained in this manual is essential for

completing the professional training of the operator.

In order to facilitate consultation, the paragraphs are accompanied by schematic drawings which

illustrate the procedure being described.

This manual contains notices and symbols which have a specific meanings:

WARNING: non observance may result in accident or injury.

ATTENTION: non observance may cause damage to the machine.

Information about the operation in progress.

Observation about the operation in progress.

1.2. RECOMMENDATIONS

Technogym recommends the following steps for planning repair procedures:

• Carefully evaluate the customer’s description of the machine malfunction and ask all the

necessary questions to clarify the symptoms of the problem.

• Clearly diagnose the causes of the problem. This manual provides the fundamental theoretical

basis, which must then be integrated by personal experience and attendance at the training

courses periodically offered by Technogym.

• Rationally plan the repair procedure so as to minimize the downtime necessary for procuring

spare parts, preparing tools, etc.

• Access the component to be repaire d, avoiding any unneces sary operat ions. In this regard it will

be useful to refer to the disassembling sequence described in this manual.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 1.2

1.3. GENERAL RULES FOR REPAIR PROCEDURES

1. Always mark any parts or positions which may be confused with each other at the time of

reassembly.

2. Use original Technogym spare parts and lubricants of the recommended brands.

3. Use special tools where specified.

4. Consult the Technical Newsletters, which may contain more up-to-date information on adjusts

and maintenance than those contained in this manual.

5. Before starting the repair procedure, make sure that the recommended tools are available and in

good condition.

6. For the procedures described in this manual, use only the specified tools.

The tool sizes quoted in this manual are expressed in mm.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.1

2. TECHNICAL CHARACTERISTICS

2.1. PRODUCT CODES

The machine codes take into account all the possible variants and options available for the products.

The machine code, which does not include the Serial Number, consists of 16 alphanumeric characters

arranged as follows:

Characters

Description

key to values

1, 2, 3,

Machine type

D94 = Run Personal

4,

Model

7 = 700

5,

Power supply type

3 = Powered

6,

Display type

Y = VISIOWEB

7,

Accessories

F = Full

8, 9,

Colour of the frame

00 = None

10, 11,

Colour of the upholstery

00 = None

12,

Colour of the guards

R = Renault Grey

13,

TV standard receiver

C = DVB-T

A = ATSC

I = ISDB-T

14, 15,

Language

00 = Multilanguage

16.

Type of packaging.

A, B, C, D, E, F, G, H, I, J, K, S, U

See the following table.

For example, a possible product code would be:

D9573YF0000RD00E

all of the machines will be shipped with the specific power cable for the destination

country. In particular this means a cable with the standard plug used in the

installation country.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.2

This implementation also means a change in the product code. Specifically the last character of the

product code will be characterised based on the options shown in the table below:

16th Character

Product code

Main country

of use

Plug standard

Type of

packaging

A

Australia

A S/NZS 3112

Overseas

B

Brazil

NBR 14136

Overseas

C

China

CPC S-CCC

Overseas

D

South Africa

SANS 164-2

Overseas

E

Europe (EC)

EEC 7/16

European

F

USA (UL 250 V)

NEMA 5-15/

NEMA 5-20

Overseas

G

Great Britain

BS1363

European

H

Argentina

IRAM 2073

Overseas

I

Italy

EEC 7/16

Italy

J

Japan

JIS 8303

Overseas

K

Great Britain

BS1363

Overseas

S

Europe (EC)

EEC 7/16

Overseas

U

USA (UL 110 V)

NEMA 6-15/ NEMA 6-20

Overseas

As shown in the table above, the 16th characte r also identifies the type of packaging depending on

the destination country, i.e. D9573YF0000RD00E.

2.2. SERIAL NUMBER STRUCTURE

The Serial Number, consists of 14 alphanumeric characters arranged as follows:

Characters

Description

key to values

1,2,3,4,5,6,

Product type,

D957 = Cross Personal

3 =Powered

Y = VISIO WEB

7,8,

Year of production,

13 = 2013

9,10,11,12,13,14.

Progressive.

000001

For example, a possible product code would be:

D9573Y13000001

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.3

2.3. TECHNICAL SPECIFICATION

SPECIFICATIONS & PERFORMANCE

Power Supply

100-240 VAC – 50-60 Hz

Energy Consumption

160VA

Stand-By Consumption

47,9 Watt (97 VA)

Resistance

56-436 Watt ±10% (at 70 RPM)

Difficulty Level

1-25

Max user weight

160 Kg – 353 Lbs

Fast Track Control

SI

HR monitoring:

Hand sensor, Telemetria

Goal oriented display

YES

Wellness System:

YES

Total Number of

Programs

23

Quick-Start, Goal (Time, Distance, Calories), CPR, Profiles (6

predefined + 12 customizable), Custom, Training Zone, Weight Loss)

Sub-maximal Test:

Fitness test

Available Language

13

Italian, UK English, USA English, German, Spanish, French, Dutch,

Portuguese, Japanese, Chinese, Russian, Turkish, Danish

2.4. MECHANICAL CHARACTERISTICS

MECHANICAL CHARACTERISTICS

Length (mm – in)

1938 mm – 76”

Width (mm – in)

685 mm – 28”

Height (mm – in)

1756 mm – 69”

Weight (Kg – lbs)

145 Kg – 320 lbs

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.4

2.5. DIMENSIONS

2.6. PACKING DIMENSIONS EUROPE AND OVERSEAS

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.5

2.7. AMBIENT SPECIFICATIONS

Temperature

Operating

from 10° to 25° C

Storage

from -10 to 70° C

Humidity

Operating

from 20% to 90% non-condensing

Storage

from 20% to 90% non-condensing

2.8. CONFORMITY TO REGULATIONS

EUROPE

USA

EMI regulations

EN61000-6-1 (2007)

EN61000-6-3 (2007)

EN61000-3-2 (2007)

EN61000-3-3 (2009)

-

Electrical safety

regulations

EN 60335-1 (2008)

UL 1647

FCC 15

Mechanical safety

regulations

EN957-1 (2006)

EN957-6 (2003)

-

Directives

2006/42/CE

2004/108/CE

2006/95/CE

-

Moreover:

Electrical isolation class: Class I;

Protection rating: IP20.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.6

2.9. WIRING DIAGRAMS

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.7

2.10. CABLES

The colour of the cables can be changed, refer in particular to the Pin Out.

2.10.1. CBQ CABLES

CBQ32: TGS cable

(Patch conn.– CPU Board)

CPU Board

CN19

Signal Colour Patch conn.

1

+12 Vdc power supply

Red 8 3

Rx

Brown 1 5

Tx

Blue 2 9

Gnd

Black

6

2.10.2. WB CABLES

WB657: Flat Tuner Board cable

(CPU Board –TUNER Board)

CPU Board

J9

Signal

TUNER Board

J13

1

Capacitive Signal

flat

…50

Capacitive Signal

flat

2.10.3. CU CABLES

CU132: TGS signal cable

(Patch conn. –TGS Dual reader)

Patch conn. Signal Colour

TGS Dual reader

CN1

8

+12Vdc power supply

Black

2

1

RX

Green 1 2

TX

Black 4 6

GND

Black

5

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.8

CU331: iPod signal cable

(CPU Board– Docking Station)

Scheda CPU

CN26

Signal Colore Docking Station

1

+V bus USB

Black

14

2

GND bus USB

Black

13

3

TX - RX

Black

11

4

RX – TX

Black

12

5

CTS

Black

10

6

+5Vdc

Black 9 7

GND

Black 8 8

GND

Black 7 9

Video Gnd

Black 6 10

Video signal

Black 5 11

Audio L Gnd

Black 4 12

Audio L signal

Black 3 13

Audio R signal

Black 2 14

Audio R Gnd

Black

1

CU308: User USB port cable

(CPU Board –USB Port)

CPU Board

CN14

Signal Colour USB Port

1

+5 Vdc

Red 1 2

USB-

White 2 3

USB+

Black 3 4

GND

Green 4 5

Shield

Blue

5

CU611: HS board cable

(CPU Board –HS board)

CPU Board

CN24

Signal Colour

HS board:

HD4

1

+5 Vdc power supply

White 2 5

HS cardio signal

Brown 3 6

Gnd

Green

1

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.9

CU613: IN/OUT Audio signal

(Amplifier - CPU Board – Headphone Jack)

Amplifier

J3

Signal Colour

Headphone

Jack

(Display)

Headphone

Jack

(Frame)

CPU

J5

1

Audio IN R

Yellow 2 2

Audio IN L/Power OFF

White 5 3

Gnd

Grey 1 4

Audio OUT L

Brown 4 5

Audio OUT R

Green 3 6

Power OFF

Brown 4 7

Audio OUT R

White 1 8

Audio OUT L/Power OFF

Brown 4 9

Gnd

Green 3 10

Audio IN L/Power OFF

White 5 11

Audio IN R

Green 2 12

Gnd

Yellow 1

CU614: AUX Audio/Video & Antenna signal cable

(CPU Board –AUX connector /Tuner Board – Antenna connector)

CPU Board

CN27

Signal Colour

AUX connector

board

1

n.c.

- 1 2

Audio IN LEFT

Black 2 3

Gnd IN LEFT

Black 3 4

Audio IN RIGHT

Black 4 5

Gnd IN RIGHT

Black 5 6

IN Video

Black 6 7

Gnd IN Video

Black 7 8

n.c.

-

8

Tuner

Segnale

Colore

Conn. Antenna

J12

Antenna

White

-

CU615: Amplifier power supply cable

(CPU board – Amplifier)

CPU board

CN15

Signal Colour

Amplifier:

J5

3

Gnd

White

2

6

+12 Vdc Power supply

Brown

1

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.10

CU616: Audio/HS signal Upper levers cable

(CPU board– Amplifier – frame speakers – Patch Conn.)

CPU

HS

Receiver

Frame

speakers

Ampl.

Signal Colour

Patch.

Conn.2

Patch.

Conn.3

CN31

CN29

CN1

DX

SX

J2

1 +5 Vdc Fast Track +

White 7 2

Fast Track + Signal

Green 3 4

Gnd Fast Track +

Brown 6 1

+5 Vdc Fast Track -

White 7 2

Fast Track - Signal

Green

3 4 Gnd Fast Track -

Brown

6 1

Left UP HS

White 1 2

Left DOWN HS

Brown

5 3

Left HS shield

- - 4

Right UP HS

White 1 5

Right DOWN HS

Brown 5 6

Right HS shield

- - 1 3

Gnd Right

Black 4 2 4

OUT R amplified

Red 8 1 2

Gnd Left

Black

4

2 1

OUT L amplified

Red 8

CU617: Total Lever cable

(Patch connector 2/3– HS board, Fast Track and Lever Tweeter)

Patch Connector

(2) and (3)

Signal Colour

RIGHT LEVER

LEFT LEVER

HS

Fast

Track

Tweeter

1

High HS signal

White

Fast-on

2

Shield

Shield - 3

Fast Track signal

Green 2

4

Gnd. Audio

Black

1

5

Low HS signal

Brown

Fast-on

6

Gnd. Fast Track

Brown 4

7

+ 5Vdc Fast Track

White 1

8

Audio signal

Red

2

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.11

CU618: Display Power supply & signals cable

(Patch conn. – CPU board – ON/OFF button)

Patch Conn.

CN1

Signal Colour

CPU

CN17

CPU

JP10

ON/OFF

button

1 485 –signal

Green

Twisted cable

6

2 485 + signal

Yellow

Twisted cable

12

3

Gnd

Black

1

4

+12Vdc power supply

Red

7

5

+12Vdc (ON/OFF)

White

1

6

Relay control(ON/OFF)

Brown

2

7

Remote OFF (ON/OFF)

Green

3

8

Gnd (ON/OFF)

Yellow

4

-

Gnd.

Yellow/green

5

Faston

CU619: Display Power supply & signals cable

(Patch conn. – Brake board – Power Supply board)

Patch Conn.

CN1

Signal Colour

Brake Board

CN3

Power supply

board

P3

1 485 –signal

Green

Twisted cable

5

2 485 + signal

Yellow

Twisted cable

1

3

Gnd

Black 2

4

+12Vdc power supply

Red 6

5

+12Vdc (ON/OFF)

White

1 6

Relay control(ON/OFF)

Brown

2 7

Remote OFF (ON/OFF)

Green

3 8

Gnd (ON/OFF)

Yellow

4

CU620: High Voltage cable

(Power entry module – Patch connector)

Power entry

module

Signal Colour Patch conn.

Faston (F)

Line

Brown

Commercial

connector

Faston (N)

Neutral

Blue

Faston (T)

Earth

Yellow/green

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 2.12

CU621: High Voltage cable

(Patch connector – Power Supply board)

Patch conn. Signal Colour

Power supply

Board

K1

Commercial

connector

Line

Brown

1

Neutral

Blue

3

Earth

Yellow/green

5

CU622: High Voltage cable

(Patch connector – Power Supply board)

Power supply

board

P2

Signal Colour

Brake board

CN4

1

Line

Brown 3 5

Neutral

Blue 1 3

Earth

Yellow/green

5

CU623: Cavo Freno

(Scheda Freno – Freno – Sensore velocità)

Scheda Freno

CN2

Signal Colour Brake

Speed

sensor

1

Power Supply Brake +

Brown

Faston

2

Power Supply Brake -

Blue

Faston

3

RPM signal

Yellow

Faston

4

Gnd. RPM

Black

eyelet

CU471: HR Cardio Receiver cable

(CPU Board – HR Cardio Receiver)

CPU Board:

CN23

Signal Colour

HR Cardio

Receiver: CN1

1

+5 Vdc power supply

White

2

7

Pulse (beat to beat)

Black

4

8

Gnd

Green

1

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.1

3. PRINCIPLES OF OPERATION

3.1. BLOCK DIAGRAM

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.2

3.2. ELECTRONIC COMPONENTS

3.2.1. CPU BOARD

The Circuit Board includes: a microprocessor, its control logic, a first FLASH EPROM (containing

the Operating System), a second FLASH EPROM, partitioned in two sections (HD1 and HD2) the

first used for the training program of the machine, for storing video and other information/support

material, the second partition for saving messages coming from the COMMUNICATOR and a third

FLASH EPROM (HD3) used for a back-up process.

It is the Circuit Board that connects all components of the display and acts as point of connection to

the Brake board.

The main functions of the board are:

Manages and process signals from and to:

Secondary ON/OFF switch;

LCD;

LCD Inverter;

Touch screen control board;

Capacitive Touch Screen;

TUNER board;

C-Safe and USB connector board;

Dual TGS reader;

User USB port;

iPod docking station.

Wireless network Board ;

LAN network Board (integrated);

HR receiver;

HS board

Touch Sensors;

Audio/Video external device Connectors Board,

Amplifier board;

Headphone Jack.

Distributes the voltages received from the Brake board;

Exchanges, via the RS-485 serial link to the Brake board, the operating controls.

Manage the display of images on the LCD.

The board includes the following indicator LED:

LED mane

Colour

Description

LED 1

GREEN

if ON, the +12 Vdc power supply from the Brake board

correctly reaches the board.

3.2.1.1. BackUp battery

The CPU board has a battery that act to maintain powered the internal clock when the machine is

not connected to a power source.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.3

3.2.2. LCD INVERTER

This device powers the LCD Display lamps. It receives DC power supplies (12 Vdc supply and

3.3Vdc enable signal) from the CPU Board, and generates the AC voltage (380 Vac) needed to

power the LCD.

3.2.3. DIGITAL/ANALOG TUNER BOARD

This is the board for receiving and managing the Audio/Video signal incoming from the antenna; it

receives both digital and analog signals.

It is directly connected to the antenna cable, whose signal is then amplified, split between a video

and audio channel, encoded by the decoder and processed by a tuner that permits searching and

tuning of both TV and radio channels.

The data is then sent to the CPU Board where it is processed and managed in order to correctly

display it on the LCD Display.

LED name

Colour

Description

D4 RED

ON if the power supply reaches the board.

OFF if the power supply does not reach the board.

FLASHING:

if loading/starting the SW in the first seconds after it switch on;

During the firmware upload;

In case of HW/SW malfunctioning (and it continue to blink).

3.2.4. LAN NETWORK BOARD (INTEGRATED)

The CPU board integrate a LAN network (Local Area Network) which can be used to connect the

VISIO device in a local network. The connection should be realised through a UTP cable, with

RJ45 connectors cat.5e/6.

VISIO device is compatible with LAN networks, which have a max. transmission speed between 10

and 100 Mbps.

The integrated network is obligatory in case of use for receiving IPTV stream

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.4

3.2.5. WIRELESS NETWORK BOARD (WITHOUT CABLES)

This is a board connected directly to the CPU, which enables the VISIO device to connect to a

WLAN (wireless local area network) as an alternative to a wired network.

The VISIO device has been constructed to be compatible with Wi-Fi technology (and in particular

with the IEEE 802.11b/g standard), which offers a theoretical bandwidth capacity of up to 54Mbps

over distances dependent on the characteristics of the setting where it is installed.

The typical indoor range is 30 m (open space):

• Standard: IEEE 802. 11b/g

• Frequency band: 2.4GHz

• Security protocol: WPA/WPA2 or also less recent ones (e.g. WEP).

The WLAN connection may not guarantee the same performance as a wired network.

The advantage of Wi-Fi is the absence of cables, but this is also a limitation in terms of

protection against interference/disturbance, performance (the stability of service and

bandwidth may be intermittent) and security (vulnerability to attacks by hackers). Where

possible, it is in any case preferable to use the wired network. The possibility of using

Wi Fi also depends greatly on the type of service/application that is to be used in

VISIO.

In particular:

• Technogym Communicator: usable with suitable Wi-Fi network

• IPTV: NOT usable with Wi-Fi network; for this application, use of a wired network is

essential.

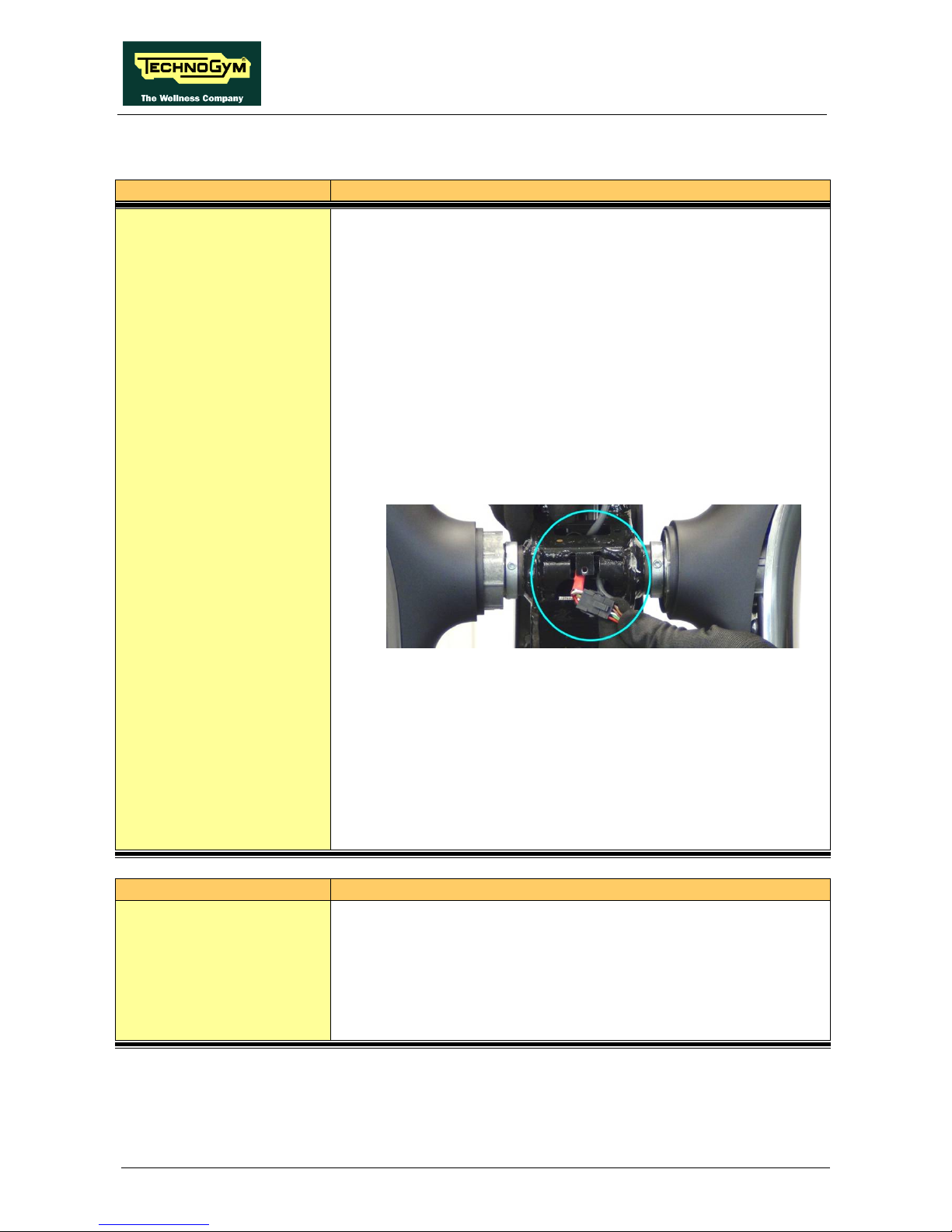

There are 2 different models of Wi-Fi network board used by Technogym, one produced by VIA

and the other by Billionton. The 2 boards, are physically different as shown below:

VIA model

Billionton model

Whenever you replace the board with anot her that is not the same model, you always

have to carry out the “System recovery” procedure using the Recovery USB stick.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.5

3.2.6. AUDIO/VIDEO EXT E RNAL DEVICE CONNECTOR BOARD

The board is positioned at the bottom of the lower guard of the equipment and makes available

some connectors for connecting Audio / Video source and the external display on the base-band of

LCD.

3.2.7. JACK CUFFIE

The machine display has one jack for connecting headphones. The jack is connected on a stereo

output of the CPU Board.

3.2.8. SCHEDA C-SAFE (INTEGRATA)

It 'a function that allows the connection using a appropriate cable for connecting other devices, such

as: external PC suitably, programmed to control the machine (speed, level of difficulty, etc ...)

3.2.9. PORTA USB DI SERVIZIO (INTEGRATA)

It is used to connect USB keys for updates: High Kit, Low Kit, Digital TV Board, Dual TGS reader

and the transfer of Radio and TV channels, from one VISIO device to another.

3.2.10. CAPACITIVE TOUCH SCREEN CONTROL BOARD

It’s the board that manages the Touch Screen through 2 flat cables and connect it to the CPU board.

The board includes the following 2 LEDs indicator:

LED name

Colour

Description

LED 1

GREEN

It light up when switch ON the machine then immediately

turn off; it light up again every time you press on the Touch

Screen.

LED 2

RED

If ON the power supply reaches the board.

If OFF the power supply does not reach the board.

ATTENTION: If the Green LED blinks continuously without anyone touching the

Touch Screen, this might be because the capacitive Touch Screen control board is

affected by interference from either the network supplying the machine, or from other

outside sources such as: amplifiers, PCs, USB accessories, etc…

3.2.11. POWER SUPPLY BOARD

The Power Supply board isolates the high voltage between the input Module and the Brake Board

and is controlled via the infra-red Start switch on the column, which changes the status of the relay

switch. It consists of two zones: one dedicated to the switching power supply; the second consists

of relay switch dedicated to supplying power to the Brake Board and which consequently powers

the equipment.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.6

3.2.12. SECONDARY ON/OFF SWITCH

The Secondary Switch Board contains an (SW) logic which governs the switching ON/OFF of the

equipment via a relay switch on the Secondary Switch Power Board (acts as controller). The Board

has, in particular, an infra-red transmitter and receiver. The transmitter is always on. When you

brush the start switch with your finger, this acts as a mirror for the signal, which is detected by the

receiver and switch ON the equipment. To turn OFF the equipment, touch the switch for 3 seconds.

3.2.13. AUDIO AMPLIFIER BOARD

This Board allows the audio signal from the Display to be amplified so that it is played through the

loud-speakers on the machine.

3.2.14. HAND SENSOR BOARD

This is the Board that manages the signal sent by the Hand Sensors, used by the user during training

sessions. The Receiver Board receives a power supply of +5Vdc from the Display Board.

The Receiver Board communicates with the Display Board using positive logic procedures. When it

is in stand-by, the signal has a +5Vdc value and as soon as it receives a signal indicating the

presence of a heart beat, it passes to 0Vdc and then with every heart beat it picks up, it generates an

impulse and returns to +5Vdc.

The Display Board receives a signal generated by the Hand Sensors (signal through contact) with

an amplitude of 100msec.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.7

3.2.15. CARDIO RECEIVER HR

This is the Board that manages the signal sent by the Telemetric Transmitter (Heart Rate Band),

used by the user during training sessions. The Receiver Board receives a power supply of +5Vdc

from the Display Board.

The Receiver Board communicates with the Display Board using negative logic procedures. When

it is in stand-by, the signal has a +5Vdc value and with every heart beat it picks up, it generates an

impulse of +0Vdc with an amplitude of 30msec.

3.2.16. IPOD DOCKING STATION

The Board allows you to connect iPod devices and to control them directly from the VISIO

interface.

Connecting with VISIOWEB allows you to: power, recharge and fully control iPod devices.

In the table below, you can see all the compatible iPod (APPLE) models:

Recharging battery

All iPod & iPhone models

(exception: iPod shuffle and first generations*)

Play & Control Audio

All iPod & iPhone models

(exception: iPod shuffle and first generations*)

Play & Control Video

All iPods starting from iPod 5th generation, all iPod Nano starting from

Nano 3G & 4G, all iPod Touch from iPod Touch 1G & 2G, all iPhone

from iPhone & iPhone 3G

Nike+Gym

All iPod Nano from iPod Nano 3G, all iPod from Touch 2G all iPhone

from iPhone 3GS

(for more information: http://www.apple.com/ipod/nike/workout.html)

* The equipment is compatible with all devices which have the standard iPod connector. That

means ALL iPod devices EXCEPT the iPod shuffle and EXCEPT the iPod release before July

2004 (1st, 2nd and 3rd generation).

NOTE: In order to have video in iPhone and iPod Touch it i s necessary to update the device

with the latest firmware via iTunes.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.8

3.2.17. CLIENT USB PORT

This is an additional port which can be insta lled on the VISIO Display, and makes available a USB

port for connecting to external devices. The user can conne ct USB devices for playing a vast range

of multimedia files, including: mp3, wma, wav, wmv, MPEG2, MPEG4, DivX, XVID jpg.

3.2.18. DUAL TGS READER

It’s the device which allows the machine to interact with the Wellness System.

This board enables the machine to read the user's TGS key for performing workouts programmed

with the proper SW of the Wellness System.

With Dual TGS reader it is possible to use both the Botom and the Mifare TGS keys.

3.2.19. BRAKE BOARD

At the moment there are 2 models of Brake board which have to be used on version: powered and

self-powered (500SP/700SP), due to the fact they need different characteristics.

Each brake board consists of:

1. Power supply sect ion which generates the low voltages used by the machine: +5Vdc (only for

700 and 700SP version) and +12Vdc (all version). Depending on the machine version, these

voltages will be generated either from the 110VAC or 220VAC mains supply, or from the

alternator-battery.

2. Section for RS-485 serial communications with the Display Board for:

commands determining the resistance that is required of the Electromagnetic Brake;

Electromagnetic Brake error messages;

commands for modifying the circuit board configuration parameters;

commands for viewing the errors logged by the circuit board;

Commands of equipment usage (RPM, WATT, distance, etc…).

3. Section which generates the current for the brake winding: varying the current produces a

proportional variation in the resistance of the brake. The exci tation cur rent suppli ed to the bra ke

is a function of the effort level selected on the display and the RPM value measured by the

speed sensor (angular velocity of the brake disk) and is determined by the values stored in the

braking table.

The board includes the following indicator 2 LEDs:

LED name

Colour

Description

LED1 GREEN

if ON the board is supplying the brake winding.

if BLINKING the Brake Board is in an error condition.

LED2

YELLOW

ON if the Brake Board is powered

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.9

3.2.20. ELECTROMAGNETIC BRAKE

This is an eddy current brake, consisting of a flywheel weight and a flat copper disk that rotates in

the air gap of a winding. Variations in the winding current produce changes in the magnetic field,

which in turn varies the eddy currents induc ed within the copper disk and hence its resistance to

"vertical" movement of the machine.

Two solenoids (cylindrical-shaped coil composed of a series of very closely wound circular turns of

a single strand of conducting material) connected in series are supplied by an adjustable direct

current generat or to obtain a magnetic field of varying intensity. The inertia disk (flywheel) rotates

between the coils.

As a result of its movement, each sector of the disk is crossed by a magnetic field flux that varies

continuously, giving rise to electromotive forces within it that cause induced currents to circulate.

These currents flow in a direction which opposes the cause that induced them, i.e. the movement of

the disk inside the magnetic field. Consequently, they have a braking effect that slows down the

movement of the disk. The braking effect is intensified as the magnetic field strength of the coils

increases, and therefore with increasing speed of the disk. This operating principle also means that

when the disk is stationary the braking action will be zero.

Unlike the majority of mechanical brakes, which operate by taking advantage of attrition forces,

there electromagnetic brake has no parts subject to wear.

The winding resistance is approximately 5Ω Ohm, consequently the brake absorbs a maximum

current of 2.2 A.

3.2.21. SPEED SENSOR

This consists of a magnetic induction sensor which detects the heads of the Electromagnetic brake

disk fixing screws.

3.2.22. POWER ENTRY MODULE

This is a module consisting of:

• power inlet socket;

• power outlet socket;

• fuse-holder for protecting line voltage and neutral with two 3.15A fast-blow fuses.

It is situated on the side of the rear footboard.

WARNING: The maximum current extractable from the output of power entry

module is 7A. This places an upper limit on the number of machines that can be

connected together: do not connect more than N°8 equipments with a 220Vac mains

supply and N°5 equipments with a 110Vac mains supply. If other types of machines are

connected together, the maximum number is determined by their current draw.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.10

3.3. BRAKE CONTROL

3.3.1. MECHANICS

The motion of the pedals imparts a rotation to the primary shaft via the belts connected to the 2

pedals. The primary shaft is connected to the secondary shaft and so to the brake, by means of a

belt. The speed sensor attached to the frame detects the heads of the screws which secure the disk to

the flywheel, and generates a signal proportional to the speed.

3.3.2. CONTROLS

The control block diagram is as follows:

CPU

BOARD

BRAKE

BOARD

BRAKE

Excitation current

RS-485

CN18/CN9

CN2

CN4

Speed

Sensor

CN2

Gr een LED

Pulses

To obtain a given exercise effort level, the display board sends the required value of exercise speed

in rpm per minut e to the Brake board via the RS-485 serial link. Based on the commands received

the brake board will then apply the appropriate excitation current to the brake winding, which

generates an electromagnetic field.

When the brake interface board receives the signal to generate resistance, the green

LED illuminates.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.11

The electromagnetic field produced by the winding and the rotation of the disk will induce eddy

currents in the disk itself, giving rise to a force that tends to brake its motion. This generates the

exercise resistance.

The higher is the value of current generated from the Brake Board on the winding, the greater is the

resistance produced. Furthermore, with the same excitement of the brake, the higher is the

rotational speed of the disc, the greater is the resistance produced.

Due to the eddy currents, energy is dissipated on the brake disk in the form of heat.

The control on the CURRENT is of type CLOSED LOOP. The Brake Board calculates

the current value to send on the winding of the brake, it controls the supply with a

special driver circuit, and finally checks the actual presence on the brake circuit

through reading and A/D conversion of current signal read.

Control over the Resistance actually present on the pedals (effective user torque) is

Open Loop. The system (Brake Board) + (brake) provides no adjustment to calibrate

the resistance value produced, but only using the braking table stored in the Brake

Board. The accuracy of the braking system has a tolerance of ± 10%.

During the movement, the speed sensor detects the heads of the brake disk fixing screws, and

produces a speed feedback signal that is sent to the Brake board. The brake board will adjust s the

excitation current of the brake winding so that the speed detected by the speed sensor is equal to the

set value.

If the brake board does not receive a speed signal, which indicates that an exercise

session is in progress, the machine will not produce any resistance.

During the movement, the brake board monitors for possible malfunctions. The errors which can

occur are detailed at paragraph: 6.9. “The Brake Board has detected an error”.

In all that cases, the Brake Board interrupts the supply of current to the brake, the green LED

changes from being steadily on to blinking and sends an error message to the Display Board which

displays the “THE EQUIPMENT IS BLOCKED CONTACT TECHNOGYM TECHNICAL

SUPPORT (X)” where “X” represents the Error Code detected.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.12

3.3.3. THE SIGNALS INVOLVED

The machine uses the following control signals:

• RS-485 Signal

This is a digital signal exchanged between the Brake Board and the Display Board. There is no

provision for monitoring its state.

• Excitation current

This is the current generated by the Brake Board (pins 1-2 of connector CN2) which supplies

the brake winding. The current supplied is a function of the adjustment algorithm.

• Pulses

This is the signal produced by the speed sensor, and has the waveform shown in the figure

below:

Figure 3.3-1

The signal enters the Brake Board (pins 3-4 on connec tor CN2), where it is used to determine

the speed value (RPM)that is sent to the Display Board via the RS-485 serial link.

This signal can also be measured qualitatively using a multimeter. The voltage

measured across the sensor terminals should be 0Vdc when the machine is stopped,

and should increase to a few hundred mV during pedal movement: the higher the

speed, the higher the measured voltage.

Since on the SP models the spee d is cal culat ed on the VAC generated by the alternator,

it’s not possible to measure or monitoring this signal using a multi meter.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.13

3.4. AUDIO SIGNAL AND AUDIO OUT CONTROL

The equipment provides the following outputs for listening to and playing audio devices:

- Two speakers positioned on the central upright of the frame.

- Two tweeters, on the upper part of the Total levers, one on the right and one on the left.

- One non-amplified audio output jack socket, in the uppe r/central part of the frame in the area

where the Total levers are connected, normally used for connecting headphones.

- One non-amplified audio output jack socket, at the base of the equipment in the power input

area, normally used for connection to an external audio system.

3.4.1. CONTROL

The control diagram is as follows:

The audio signal in this equipment is controlled and sent towards the output channels (sockets and

speakers) by an amplifier, which, in the case of the sockets, simply channels to signal towards them,

or, in the case of the speakers, amplifies the signal before sending it.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 3.14

The CPU card sends a 12 Vdc signal to the amplifier to power it as well as the audio signal.

To avoid creating disturbances for the end user, by reproducing the audio signal from more than

one channel, the system permits the signal to be listened to from only one of the 3 channels, with

the following order of priority: Headphone jack socket, audio output jack socket, speakers.

In particular, when headphones are connected to the jack socket on the frame immediately under the

display, the signal to the output jack socket at the base of the frame is “mechanically” cut off and a

signal is sent to switch off the amplifier so that no sound is put out by the speakers (POWER OFF

signal interrupted).

In the same way, if an external system is connected to the jack socket at the base of the frame, a

signal is sent to switch off the amplifier so that no sound is put out by the speakers (POWER OFF

signal interrupted).

If no device is connected to the 2 jack sockets, the audio will be played through the equipments

speakers, and the signal will be further amplified than the one sent out by the CPU.

3.4.2. THE SIGNALS INVOLVED

The following signals are involved in the control:

• Power signal

This is a 12Vdc signal that the CPU card sends to the amplifier to power it.

• Audio signal

This is the signal that includes the two R-L audio channels, sent by the CPU to the amplifier and

then to the audio output jack socket or to the speakers.

• Amplifier Power OFF signal

This is the signal sent by the two jack sockets to the amplifier, to switch it off, thus avoiding

audio reproduction by the equipment's speakers.

It is not an actual separate signal, but uses one of the audio channels output by the j ack socket

which, when cut off due to connection of a jack into the jack socket, is interpreted by the

amplifier as a switch-off signal.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 4.1

4. ACCESSORIES

4.1. CARDIO THEATER CONNECTION

The machine can be connected to the Cardio Theater by means of the RJ45 connector on the C-Safe

board. The Cardio Theater unit must be provided with a power cable having the following pin-out:

RJ45 Connector

Signal

5

+5Vdc

7

Ground

ATTENTION: for the numbering of the pins, on RJ45 connector, please refer to the

diagram below:

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 4.2

4.2. MONITOR PLUG FOR C-SAFE PORT

When the plug code 0WC00639AA is fitted into any one of the C-Safe ports on the machine, the

corresponding LED should illuminate to indicate the presence of the 5 Vdc supply on the port.

During the C-Safe por t test function, the plug connects the transmit channel directly to the receive

channel, thereby producing a positive test outcome if the port is functioning correctly.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 5.1

5. INSTALLATION INSTRUCTIONS

5.1. SPECIFICATIONS AND REQUIREMENTS

For correct machine installation, make sure that:

1. The machine is installed on a level surface that is free of vibrations and has sufficient carrying

capacity for the combined weight of the machine and user.

2. The place of installation is free of dust and sand.

3. The place of installati on meets the operating temperature and humidity conditions specified in

paragraph: 2.7. “Ambient specifications”.

4. The machine is not positioned close to sources of heat, sources of electromagnetic noise

(television sets, electrical motors, antennas, high vol tage lines, household appliances, etc...) or

medical equipment.

5. To eliminate any interference with the cardio receiver, no transmitters should be placed less

than 90cm from the display.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 5.2

5.2. MOVING THE EQUIPMENT

The equipment has two fixed front wheels. To move the equipment, lift it up slightly, as shown in

the illustration, and push it forwards and backwards.

Given the weight of the equipment, we recommend 2 person be involved in lifting it.

AVVERTENZA: Lift the equipment by holding onto the frame and not the levers or

the control panel. Take great car e when moving the equipment and positioning it on

the ground, as it may overbalance.

If wheels cannot be used on the floor, move the equipment using standard lifting and transport

devices.

Figure 5.2-1

After every moving, check if the equipment is flat, adjusting the left foot, as indicated

at the paragraph: Errore. L'origine riferimento non è stata trovata.“Errore. L'origine

riferimento non è stata trovata.”.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 5.3

5.3. RECOMMENDED ANTENNA SIGNAL REQUIREMENTS

All the information about the minimum requirements concerning the antenna signal

are detailed in the proper manual “Electrical and antenna requirements” you can find

and download into the Technogym Direct.

5.4. INSTALLATION

To correctly install the machine, proceed as follows:

1. Ensure that the specifications and requirements for installation have been met (see paragraph:

5.1. “Specifications and requirements”).

2. Position the machine as specified above, on a level surface that is free of vibrations and has

sufficient carrying capacity for the combined weight of the machine and user.

3. Depending on the destination country, the machine may be shipped partially disassembled,

packed inside a special carton and fixed to a pallet, or fully assembled, wrapped in clear plastic

and fixed to a wooden pallet.

Follow the assembly operations described in the instruction sheets supplied with the machines.

4. Connect the mains lead to the power inlet socket on the machine.

5. Place the on/off switch in the 0 position.

6. Plug the mains lead into the wall outlet.

7. Connect the antenna cable t o the wall outlet and make sure all the technical requirements are

respected according to the specific paragraph of this manual.

5.5. FIRST POWER-ON

After completing the installation procedure, the machine is ready for use.

On power-up the machine performs a Check-Up of the High Kit and Low Kit assemblies. After

completing the Check-Up, the machine enters the Stand-By state, awaiting a command from the

keyboard.

To check the correct operation of the machine:

• Get on the machine;

• Check that exercise resistance varies when the “+” and “-“ effort level keys are pressed, or

the touch sensors, and the effort level change from 1 to 25;

• Put on the heart rate meter and check that the machine correctly reads the heart rate value;

• Grasp the sensors and check that the machine correctly reads the heart rate value;

• Carry out the “Touch Screen calibration” procedure described in the relevant paragraph of

the User menu.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 5.4

Page intentionally left blank.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.1

6. TROUBLESHOOTING

The troubleshooting procedures are illustrated by means of flow diagrams. To facilitate

interpretation of these diagrams, the following standard box shapes are used:

START

This type of box is the START point of the troubleshooting

procedure. It typically contains a description of the problem or

malfunction.

Decision

This type of box represents a decision point in the troubleshooting

procedure. It typically contains a description of the CHECK to be

made, with an outcome that is either a positive (YES) or negative

(NO) response.

Action

This type of box is a step in the troubleshooting procedure where an

ACTION must be carried out. It typically contains a description of

the ACTION necessary to resolve the problem Therefore, after

executing the specified ACTION:

1. Check whether the problem has been resolved;

2. If the problem persists, it is recommended to resume the

troubleshooting procedure from the point before the action was

carried out.

Note

Clarification of the operation in progress or that will be below

1

A circled number (such as that shown on the left) next to a box of

the troubleshooting procedure indicates that more detailed

instructions for performing that particular check or action are

provided below the flowchart.

A

A circled letter (such as that shown on the left) is used to mark a

point in the procedure. Typically, this indicator is used in page

changes.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.2

6.1. TROUBLESHOOTING MENU

The procedure is activated by pressing the top right-hand corner, the bottom left-hand corner and the bottom righthand corner of the screen in that sequence when the equipment is in Stand-By, as shown in the figure below.

A new display will appear from which you can gain access to the various configuration menus, by

entering the password on the number keyboard:

Enter the password 2501 and press the ENTER key to confirm or EXIT to quit.

By selecting the key which is highlighted in red, you will gain access to the TROUBLESHOOTING

menu:

For the following menu, please refer to the relevant chapter in the VISIO manual.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.3

6.2. THE DISPLAY STAYS OFF

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.4

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.5

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.6

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Check that LED 1 (green) is lit on the Display Board.

(2) Check the vol tages between t he pins on the CN1 connector and a gr ound node on the Dis play. I t

should measure:

• +12Vdc on pin 7

• 0Vdc on pin 6;

• +4.3Vdc on pin 5;

• 0Vdc on pin 4;

• +12Vdc between pins 3;

• 0Vdc on pin 2.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.7

(3) Check the 220 Vac voltage on the K1 connector, between PINS 1 and 3.

(4) Check the 220 Vac voltage on the P2 connector, between PINS 1 and 5.

(5) Check the 220 Vac or 110 Vac voltage on the CN4 connector of the Brake Board, between

PINS 3 and 1.

(6) Check the +12 Vdc voltage on the CN3 connector of the Brake Board, between PINS 2 and 6.

(7) Check the +12 Vdc voltage on the CN17 connector of the Brake Board, on PINS 1 and 7.

(8) Check the +12 Vdc voltage on the P3 connector of the Power Board, on PINS 1 and 4.

(9) Check the voltage on the P3 connector of the Power Board, on PINS 2 and 4.

If you replace Display Board and/or Driver, check that its SW version is updated,

otherwise install the last version.

TV and RADIO channels, are only stored in a f ile in the f ixed memory of the board. So

the channels will be re-store in case of replacing of the Display Board.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.8

6.3. NO AUDIO SOUND

This error is due to the incorrect configuration of the equipment or problems with the audio circuit.

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.9

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.10

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.11

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Perform the test by substituting the Jack with a functioning one or disconnect it and short the

PINS 4-5 and 3-2 of the Jack connector (carriage side).

(2) Take the measurement on the J5 Audio OUT connector and check the resistance between the

earth node (on the Display) and the 4 PINS on the connector by disconnecting it.

DANGER: Take this measurement with the equipment switched off.

• PIN 1 – earth node = 1 K-Ohm;

• PIN 2 – earth node = 1 Ohm;

• PIN 3 – earth node = 1 Ohm;

• PIN 4 – earth node = 1 K-Ohm;

(3) Take the following measurements with ALTERNATING current, taking care not to short

circuit the PINS during the measurement.

• PIN 1 – earth node = 400 mVac;

• PIN 2 – earth node = 0 mVac;

• PIN 3 – earth node = 0 mVac;

• PIN 4 – earth node = 400 mVac;

WARNING: Turn the volume up to maximum.

(4) Perform the check on PINS 1 and 2 on the J5 connector and check that there is 12Vdc.

(5) Check that there is 12 Vdc on PINS 2 and 6 on the CN15 connector of the CU613 cable.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.12

6.4. NO TV PICTURE

For the following menu, please refer to the relevant chapter in the VISIO manual.

6.5. THE TOUCH SCREEN DOES NOT WORK / IT’S NOT

CALIBRATED

For the following menu, please refer to the relevant chapter in the VISIO manual.

6.6. THE RADIO DOES NOT PLAY

For the following menu, please refer to the relevant chapter in the VISIO manual.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.13

6.7. THE IPOD DOES NOT WORK

Continued on following page...

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.14

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Switch on the machine, connect the iPod on the docking station and check that the device is

correctly detected by the machine.

(2) Check that the audio/video files uploaded in the iPod are visible and selectable through the

VISIO interface.

(3) Carry out the troubleshooting procedure: Errore. L'origine riferimento non è stata

trovata.“Errore. L'origine riferimento non è stata trovata.”.

(4) To update the iPod SW you just need to connect to iTunes and it automatically upgrades to the

last version.

(5) Enable the iPod control as detailed at the relevant paragraph of the User menu.

(6) The CU167 cable has identical connectors on eit her end then it can sometimes be connected

the wrong way round.

(7) Place the tester probes across pins 8 and 9 of the connector on the docking station board

where the CU167 cable is connected. The measured value should be 5Vdc.

(8) As for step (7) but across pins 6 and 7 of the connector on the Display Board where CU167 is

connected.

If you replace Display Board, check that its SW version is updated, otherwise install

the last version.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.15

6.8. “THE EQUIPMENT IS LOCKED (COM)” MESSAGE ON

DISPLAY

The (COM) error indicates that there is no communication between the High Kit and

the Low Kit. This may occur essentially in the following cases:

• Interruption in communication on the serial line between the Display Board (High Kit)

and the Brake Board (Low Kit): communication cabling is defective. Replace cabling;

• The SW of the Brake Board Firmware (FW) and/or the Brake Table is incorrect/corrupt:

example where the operator manually loads the FW and chooses the wrong one. The

solution is to re-load the Firmware (FW) (an action which is always possible for any

brake board);

• The SW of the Display Board is incorrect/corrupt: the High Kit SW has not been

upgraded - proceed with upgrading.

The error is displayed with a message on the display and recorded in the “Errors Log” section.

In order to re-instate communication between the High Kit and the Brake Board, proceed as

follows:

1. Check that the cables (CU618-CU619) which bring the Serial Communication signals are

intact, by using the Test Box Excite and if necessary, replace it.

2. Upgrade the SW on the Brake Board by loading: the Firmware (FW) and the Brake Table and

run the Standard Setting.

3. Upgrade the SW on the Display Board.

4. Try and replace the Brake Board and the Display Board one at a time and check whether the

serial communication is re-enabled (you can use a standard network cable for the test).

If the Display Board is replaced, check that the upgraded SW version is installed or

proceed with the upgrade.

If the Brake Board is replaced, check that the correct SW version is installed or

proceed with the upgrading of the Firmware (FW), the Brake Table and the Standard

Settings.

CROSS PERSONAL: Service & maintenance manual - rev. 1.1

Page 6.16

6.9. THE BRAKE BOARD HAS DETECTED AN ERROR

When the Brake Board detects an error, it blocks by interr upting the power supply and memorizes

a numeric code in its memory which identifies the detected error. In addition it sends a signal

regarding the status of the error to the DISPLAY Board, via the serial line. When the DISPLAY

Board receives this signal, it interrupts the exercise and displays the following message on the

screen “THE EQUIPMENT IS BLOCKED”.

The errors memorized on the Brake Board can be displayed as illustrated in paragraph: Errore.

L'origine riferimento non è stata trovata."Errore. L'origine riferimento non è stata trovata.”.

The following table provides information regarding error codes, meanings and possible solutions:

Error

Code

Description Meaning Solution

0

Not used.

-

Upgrade the Firmware

(FW) on the Brake

Board. If the same

errors occur after

upgrading has been

successfully

completed, the

problem is NOT the

Brake Board.

1

Electrical

Overtemperature.

Overtemperature error - internal NTC. This

error occurs when the temperature measured by

the internal NTC probe exceeds 90°C (OLD

EFI board), 110°C (NEW EFI board) or 105°C

(Las

er board). In this case the board passes into

fault status and the error is recorded in the

error log.

Switch off the

equipment and switch

it back on again. If the

error persists, replace

the Brake Board.

2

Trip overcurrent

brake kit.

Trip overcurrent error. Equipment that only

provides for constant RPM training sessions

(e.g. STEP/WAVE) does not perform this

control. With equipment that provides various

kinds of training, the control for this error is not

performed if the selected training is of the

constant speed type.

The error occurs when the current on the brake

suddenly rises. The trip overcurrent

condition

happens if the level of braking current

corresponds to 150% of the maximum value

taken from the braking table, for 5 consecutive

iterations of the

brake control algorithm. In this

case the error must be recorded in EEPROM

and the equipment must be placed in fault.

Switch off the

equipment and switch

it back on again. If the

error persists, replace

the Brake Board.

Continues on the next page...