SERVICE & MAINTENANCE MANUAL

REV. 1.0

The information contained in this manual is intended for QUALIFIED TECHNICIANS who have

completed a specific TECHNOGYM training course and are authorized to perform machine start-

up and adjustment procedures as well as extraordinary maintenance or repairs which require a

thorough knowledge of the machine, its operation, its safety devices and working procedures.

CAREFULLY READ THE INFORMATION CONTAINED IN

THIS MANUAL BEFORE PERFORMING ANY MAINTENANCE

PROCEDURES ON THE MACHINE

DANGEROUS VOLTAGES

PRESENT

NOTE

The information contained in this document is subject to change without notice.

Technogym does not guarantee this documentation in any way. Technogym shall not be held

responsible for any errors contained in this manual and declines all liability for accidents or

damages resulting from the supply, characteristics or use of this manual.

This document contains proprietary information that is protected by copyright. All rights reserved.

No part of this document may be photocopied, reproduced or translated into another language

without the prior written consent of Technogym.

The Technogym™ trademark is property of Technogym S.p.A.

The Bike MED™ trademark is property of Technogym S.p.A.

BIKE MED: Service & Maintenance Manual - rev. 1.0

Contents

1. GENERAL NOTICES ........................................................................................................................................... 1.1

1.1. INTRODUCTION.................................................................................................................................................1.1

1.2. RECOMMENDATIONS........................................................................................................................................1.1

1.3. GENERAL RULES FOR REPAIR PROCEDURES ...................................................................................................... 1.2

2. TECHNICAL CHARACTERISTICS..................................................................................................................2.1

2.1. PRODUCT CODES...............................................................................................................................................2.1

2.2. MECHANICAL CHARACTERISTICS ..................................................................................................................... 2.2

2.3. FUNCTIONS AND CHARACTERISTICS TABLE ...................................................................................................... 2.3

2.4. AMBIENT SPECIFICATIONS................................................................................................................................2.3

2.5. CONFORMITY TO REGULATIONS........................................................................................................................2.4

2.6. WIRING DIAGRAM ............................................................................................................................................ 2.5

2.7. CABLES............................................................................................................................................................2.6

3. PRINCIPLES OF OPERATION..........................................................................................................................3.1

3.1. BLOCK DIAGRAM..............................................................................................................................................3.1

3.1.1. ARM display board ..............................................................................................................................3.1

3.1.2. CSafe Board .........................................................................................................................................3.2

3.1.3. TGS reader...........................................................................................................................................3.2

3.1.4. Hand sensor board...............................................................................................................................3.2

3.1.5. Cardio receiver .................................................................................................................................... 3.2

3.1.6. Brake board..........................................................................................................................................3.2

3.1.7. Brake 3.3

3.1.8. Speed sensor.........................................................................................................................................3.3

3.1.9. Power entry module ............................................................................................................................. 3.3

3.2. BRAKE CONTROL..............................................................................................................................................3.4

3.2.1. Mechanics ............................................................................................................................................ 3.4

3.2.2. Control 3.4

3.2.3. The signals involved.............................................................................................................................3.6

4. ACCESSORIES ..................................................................................................................................................... 4.1

4.1. CARDIO THEATER CONNECTION........................................................................................................................4.1

4.2. PC LINK FOR PROGRAMMING............................................................................................................................ 4.1

4.3. MONITOR PLUG FOR CSAFE PORT.....................................................................................................................4.2

5. INSTALLATION INSTRUCTIONS....................................................................................................................5.1

5.1. SPECIFICATIONS AND REQUIREMENTS .............................................................................................................. 5.1

5.2. INSTALLATION.................................................................................................................................................. 5.1

5.3. FIRST POWER-ON .............................................................................................................................................. 5.1

6. TROUBLESHOOTING ........................................................................................................................................ 6.1

6.1. SERVICE TROUBLESHOOTING MENU.................................................................................................................. 6.2

6.1.1. Automatic Test......................................................................................................................................6.2

6.1.1.1. I2C Devices Test.............................................................................................................................................................6.3

6.1.1.2. LED Test (not on 700iE models)....................................................................................................................................6.3

6.1.1.3. Serial Ports Test..............................................................................................................................................................6.3

6.1.2. Manual Test..........................................................................................................................................6.3

6.1.2.1. Man. Keyboard Test........................................................................................................................................................6.4

6.2. THE DISPLAY FAILS TO ILLUMINATE .................................................................................................................6.5

6.3. “THE EQUIPMENT IS BLOCKED” MESSAGE ON THE DISPLAY ................................................................... 6.7

6.4. ERROR DETECTED BY BRAKE BOARD ................................................................................................................ 6.8

6.4.1. Error 1 on brake board........................................................................................................................ 6.8

6.4.2. Error 2 on brake board........................................................................................................................ 6.8

Page i

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page ii

6.4.3. Error 4 on brake board........................................................................................................................ 6.8

6.4.4. Error 8 on the brake board ..................................................................................................................6.9

6.4.5. Error 16 or 32 on the brake board ....................................................................................................... 6.9

6.4.6. Error 128 on brake board.................................................................................................................... 6.9

6.5. THERE IS NO RESISTANCE ...............................................................................................................................6.10

6.6. THE RESISTANCE IS INCORRECT ......................................................................................................................6.11

6.7. THE SPEED SIGNAL IS INCORRECT ................................................................................................................... 6.13

6.8. THE MACHINE DOES NOT READ THE TGS .........................................................................................................6.15

6.9. THERE IS NO HEART RATE SIGNAL...................................................................................................................6.17

6.9.1. HFU telemetric receiver.....................................................................................................................6.17

6.9.2. Hand sensor ....................................................................................................................................... 6.18

6.10. THE TELEMETRIC HR SIGNAL IS INCORRECT....................................................................................................6.20

7. DISASSEMBLY OF COMPONENTS.................................................................................................................7.1

7.1. DISASSEMBLING THE DISPLAY..........................................................................................................................7.1

7.2. DISASSEMBLING THE CIRCUIT BOARDS ON THE DISPLAY................................................................................... 7.2

7.3. DISASSEMBLING THE KEYBOARD......................................................................................................................7.3

7.4. DISASSEMBLING THE CARDIO RECEIVER...........................................................................................................7.4

7.5. DISASSEMBLING THE HANDLEBAR....................................................................................................................7.6

7.6. DISASSEMBLING THE SENSORS .........................................................................................................................7.7

7.7. DISASSEMBLING THE GUARDS ..........................................................................................................................7.8

7.8. DISASSEMBLING THE SEAT GROUP....................................................................................................................7.9

7.9. DISASSEMBLING THE ADJUSTING KNOB .......................................................................................................... 7.11

7.10. DISASSEMBLING THE ELECTRONIC BOX ..........................................................................................................7.12

7.11. DISASSEMBLING THE BELT .............................................................................................................................7.13

7.12. DISASSEMBLING THE PEDALS AND THE PEDAL CRANKS .................................................................................. 7.14

7.13. DISASSEMBLING THE PULLEY ......................................................................................................................... 7.15

7.14. DISASSEMBLING THE BRAKE WINDING............................................................................................................7.16

7.15. DISASSEMBLING THE BRAKE GROUP ...............................................................................................................7.17

7.16. DISASSEMBLING THE SPEED SENSOR............................................................................................................... 7.19

7.17. DISASSEMBLING THE PLATFORMS WITH CSAFE BOARD CONNECTORS AND POWER ENTRY MODULE ...............7.20

8. ADJUSTMENTS.................................................................................................................................................... 8.1

8.1. BELT TENSION .................................................................................................................................................. 8.1

8.2. PLAY OF SADDLE STEM.....................................................................................................................................8.2

8.3. SPEED SENSOR POSITION...................................................................................................................................8.3

8.4. BRAKE WINDING ASSEMBLY .............................................................................................................................8.4

9. MACHINE CONFIGURATION..........................................................................................................................9.1

9.1. USER MENU CONFIGURATION ...........................................................................................................................9.1

9.1.1. Language..............................................................................................................................................9.1

9.1.2. Distance................................................................................................................................................ 9.2

9.1.3. Priority setting...................................................................................................................................... 9.2

9.1.4. Maximum excercise time ......................................................................................................................9.2

9.1.5. Pause time ............................................................................................................................................ 9.3

9.1.6. Enable TGS ..........................................................................................................................................9.3

9.1.7. Enable keyboard................................................................................................................................... 9.3

9.1.8. Modifiable target heart rate.................................................................................................................9.3

9.1.9. Enable custom messages ...................................................................................................................... 9.4

9.1.10. Edit custom messages...........................................................................................................................9.4

9.1.11. Change messagges languages..............................................................................................................9.4

9.1.12. Enable multi-language mode............................................................................................................... 9.5

9.1.13. Resetting parameters to default values ................................................................................................ 9.5

9.1.14. SN 9.5

9.1.15. Communication protocols for external medical devices...................................................................... 9.5

9.2. SERVICE MENU CONFIGURATION ......................................................................................................................9.6

9.2.1. Low kit parameter ................................................................................................................................9.6

9.2.1.1. Read from low kit...........................................................................................................................................................9.7

9.2.1.2. Write to low kit...............................................................................................................................................................9.7

BIKE MED: Service & Maintenance Manual - rev. 1.0

9.2.1.3. Default Setting................................................................................................................................................................9.7

9.2.1.4. Configuration parameters table.......................................................................................................................................9.8

9.2.2. Operating data .....................................................................................................................................9.8

9.2.2.1. Read from low kit...........................................................................................................................................................9.9

9.2.2.2. Write to low kit...............................................................................................................................................................9.9

9.2.2.3. Machine usage data.........................................................................................................................................................9.9

9.2.3. Errors log............................................................................................................................................. 9.9

9.2.3.1. Read from low kit.........................................................................................................................................................9.10

9.2.3.2. Reset Errors...................................................................................................................................................................9.10

9.2.3.3. COM.Fault ....................................................................................................................................................................9.10

9.2.3.4. View Errors...................................................................................................................................................................9.11

9.2.4. Standard settings................................................................................................................................9.11

9.2.5. Low kit menu ......................................................................................................................................9.11

9.2.5.1. Low kit version.............................................................................................................................................................9.12

9.2.5.2. Low Kit fault code........................................................................................................................................................9.12

9.2.6. High kit version..................................................................................................................................9.12

9.2.7. BOOT version..................................................................................................................................... 9.12

10. SCHEDULED MAINTENANCE ....................................................................................................................... 10.1

10.1. DAILY MAINTENANCE OPERATIONS ................................................................................................................10.1

10.1.1. Setting up the operation.....................................................................................................................10.1

10.1.2. External cleaning operations ............................................................................................................. 10.1

10.2. MONTHLY MAINTENANCE OPERATIONS..........................................................................................................10.2

10.2.1. Play of the saddle stem.......................................................................................................................10.2

10.2.2. Check wear of foot straps...................................................................................................................10.2

10.2.3. Checking the operation of the cardiotester receiver..........................................................................10.2

10.2.4. Checking the operation of the hand sensor receiver.......................................................................... 10.2

10.3. TWICE-YEARLY MAINTENANCE OPERATIONS..................................................................................................10.3

10.3.1. Carrying out the monthly maintenance procedure.............................................................................10.3

10.3.2. Setting up the operation.....................................................................................................................10.3

10.3.3. Cleaning operations........................................................................................................................... 10.3

10.3.4. Checking the working conditions.......................................................................................................10.3

10.3.5. Checking the wear of rubber parts.....................................................................................................10.3

10.3.6. Checking the belt................................................................................................................................ 10.3

10.3.7. Checking the display..........................................................................................................................10.3

10.3.8. Checking the wiring and connections................................................................................................ 10.3

11. FUNCTIONAL TESTS .......................................................................................................................................11.1

11.1. ELECTRICAL SAFETY TEST..............................................................................................................................11.1

11.2. START-UP CHECK............................................................................................................................................11.2

11.3. CHECKING THE ASSEMBLY OF THE TRANSMISSION SYSTEM .....................................................11.3

11.4. CHECKING THE ASSEMBLY OF THE SEAT COMPONENTS..............................................................11.3

11.5. CHECKING THE ASSEMBLY OF THE GUARDS.......................................................................................11.3

12. APPENDIX...........................................................................................................................................................12.1

12.1. LIST OF CRITICAL SPARE PARTS ...................................................................................................................... 12.1

12.2. UPDATING THE SW ........................................................................................................................................ 12.1

12.3. REQUIRED TOOLS ...........................................................................................................................................12.2

Page iii

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page iv

Page intentionally left blank

BIKE MED: Service & Maintenance Manual - rev. 1.0

1. GENERAL NOTICES

1.1. INTRODUCTION

This document is reserved for Technogym Service technicians, and is intended to provide

authorized personnel with the necessary information to correctly carry out repairs and maintenance.

A thorough knowledge of the technical information contained in this manual is essential for

completing the professional training of the operator.

In order to facilitate consultation, the paragraphs are accompanied by schematic drawings which

illustrate the procedure being described.

This manual contains notices and symbols which have a specific meanings:

WARNING: non observance may result in accident or injury.

ATTENTION: non observance may cause damage to the machine.

Information about the operation in progress.

OBSERVE: observation about the operation in progress.

1.2. RECOMMENDATIONS

Technogym recommends the following steps for planning repair procedures:

• Carefully evaluate the customer’s description of the machine malfunction and ask all the

necessary questions to clarify the symptoms of the problem.

• Clearly diagnose the causes of the problem. This manual provides the fundamental theoretical

basis, which must then be integrated by personal experience and attendance at the training

courses periodically offered by Technogym.

• Rationally plan the repair procedure so as to minimize the downtime necessary for procuring

spare parts, preparing tools, etc.

• Access the component to be repaired, avoiding any unnecessary operations. In this regard it will

be useful to refer to the disassembly sequence described in this manual.

Page 1.1

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 1.2

1.3. GENERAL RULES FOR REPAIR PROCEDURES

1. Always mark any parts or positions which may be confused with each other at the time of

reassembly.

2. Use original Technogym spare parts and lubricants of the recommended brands.

3. Use special tools where specified.

4. Consult the Technical Newsletters, which may contain more up-to-date information on

adjustments and maintenance than those contained in this manual.

5. Before starting the repair procedure, make sure that the recommended tools are available and in

good condition.

6. For the procedures described in this manual, use only the specified tools.

OBSERVE: The tool sizes quoted in this manual are expressed in mm.

BIKE MED: Service & Maintenance Manual - rev. 1.0

2. TECHNICAL CHARACTERISTICS

2.1. PRODUCT CODES

The machine codes take into account all the possible variants and options available for the products.

The machine code, which does not include the Serial Number, consists of 16 alphanumeric

characters arranged as follows:

Characters description key to values

1,2,3 Machine type: Bike

D82

4 Product version

7 = Bike MED

5 Type of power supply

M = multi-voltage EU

U = multi-voltage UL

6 Type of display

L = LED display

7

Device for downloading data used by the Wellness

System

N = not available

T = TGS

8, 9 Color of the frame

AL = aluminum

10, 11 Color of paddings

AG = gray

M0 = bordeaux

12 Guard color

G = gray

13 Type of TV model

0 = none

14,15 Language

IT = Italian

DE = German

FR = French

US = American English

NL = Dutch

BR = Portuguese

JP = Japanese

UK = British English

ES = Spanish

16 Type of packaging

I = Italy

E = standard international

S = overseas international

0 = none

The above coding is used for the entire Excite line. For this reason, options not relevant

to the Bike MED machine have also been included.

Page 2.1

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 2.2

For example, a possible product code would be:

D827MLTALM0G0UKE

which is interpreted as follows:

D82 7 M L T AL M0 G 0 UK E

standard international packing

British English language

no TV model

gray guards

burgundy paddings

aluminum frame color

interfaced to TGS key reader

LED display

mains powered supply with multi-voltage inlet EU

MED model

Bike

2.2. MECHANICAL CHARACTERISTICS

BIKE MED

Width

52 cm - 20.5 in

Length

120 cm - 47.3 in

Height

150 cm - 59.1 in

Weight

67 kg - 147 lbs

BIKE MED: Service & Maintenance Manual - rev. 1.0

2.3. FUNCTIONS AND CHARACTERISTICS TABLE

BIKE MED

Power supply

Multitension 90-260 Vac

Frequency

50 - 60 Hz

Resistance

10-1000 Watt

Consumption

100 W

Hand sensor

YES

Touch sensor

YES

CSafe

YES

HR receiver

HFU

Difficulty level

1-30

Program training

Quick start

Goal

6 profiles

Training Zone

CPR

Weight Loss

Custom program

Constant Power

Constant Torque

Sub Maximal Test

Fitness

Single stage

Multistage

PWC test

PWC test modified

YMCA test

Maximal Test

Technogym maximal test

Custom maximal test

Astrand

McArdle

Anaerobic power test

CHARACTERISTICS

Military Test

Air Force PRT

2.4. AMBIENT SPECIFICATIONS

Operating from 5° to 35° C

Temperature

Storage from -10° to 70° C

Operating from 30% to 80% non-

condensing

Humidity

Storage from 5% to 85% non-

condensing

Page 2.3

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 2.4

2.5. CONFORMITY TO REGULATIONS

The machine conforms to the following standards:

Europe USA

Safety

EN 957-1

EN 957-5 classe SA

EN 60601-1

EN 60601-1-2

UL 60601-1

In addition:

• Electrical isolation class: Class I;

• Marks and Certificates: CE – GM (TUV) and UL;

• Protection rating: IP20.

BIKE MED: Service & Maintenance Manual - rev. 1.0

2.6. WIRING DIAGRAM

DISPLAY

HAND

SENSOR

BOARD

ARM DI SPLAY BOARD

KEYBOARD

CSAFE

BOARD

HFU

RECEIVE R

C

N

7

C

N

8

C

N

1

TGS

BOARD

C

N

1

C

N

9

C

N

1

C

N

3

C

N

2

BRAKE

POWER

ENTRY

MODU L E

BRAKE

BOARD

C

N

4

C

N

3

C

N

1

C

N

2

SPEED

SENSOR

CU122

Patch

Conn. 2

C

N

4

J

3

J

2

-

J

4

L UPPER

SENSOR

R LOWER

SENSOR

L LOWER

SENSOR

R U PPER

SENSOR

CBQ-30

RIGHT

TOUCH

SENSOR

C

N

6

LEFT

TOUCH

SENSOR

C

N

5

Patch

Conn. 1

CU106

CU108

VAC

CB-4 CB-3

CB-51

CB-26

CBQ-25-1

CBQ-32

CBQ-13

C

N

FE

FE

Page 2.5

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 2.6

2.7. CABLES

CB-3: Cable connecting upper and lower assemblies

Brake board – Display board

Brake board

CN1

Signal Color Display Board

CN1

2 Digital Gnd White 2

3 Power Gnd Orange 3

4 - sensing +5 Vdc digital Red 4

6 +12 Vdc Black 6

7 +5 Vdc Green 7

8 +sensing +5 Vdc digital Blue 8

CB-4: Serial communication cable between upper and lower assemblies

Brake board – Display board

Brake board

CN4

Signal Color Display Board

CN9

1 Digital Gnd Orange-White 1

2 Digital Gnd Orange 2

3 NC Green-White 3

4 Download Blue 4

5 Reset Blue-White 5

6 NC Green 6

7 485 Tx/Rx + Brown-White 7

8 485 Tx/Rx - Brown 8

CB-26: Touch sensor cable

Display board – Touch sensor

Display board

CN5 / CN6

Signal Color Touch sensor

1 + 5Vdc White 1

2 Lever button Brown 3

4 Reference Green 4

CB-51: Brake supply cable

Brake board – Brake – Speed sensor

Brake board

CN2

Signal Color Brake Speed sensor

1 Brake supply + Brown 10

2 Brake supply - Pink 5

3 RPM Orange Faston connected

to brown cable

4 RPM reference Blue eyelet

BIKE MED: Service & Maintenance Manual - rev. 1.0

CBQ-13: CSafe board cable

Display Board – CSafe Board

Display Board

CN8

Signal Color CSafe Board

CN1

1 Digital #1 Flat cable 1

… … … …

14 Digital #14 Flat cable 14

CBQ-25-1: Hand sensor board cable

Display Board – Hand Sensor Board

Display Board

CN4

Signal Color Hand sensor

board

J3

1 +5 Vdc power supply Red 2

5 Pulse out Blue 3

6 Reference Black 1

CBQ-30: Sensor cable

Hand Sensor Board - Sensors

Hand sensor

board

Sensors

J2 - J4

Signal Color

RH 1 RH 2 LH 1 LH 2

1 Right sensor signal Red up up - 2 Sensor signal reference White down down - 3 Gnd Shield - - - 4 Left sensor signal Black - - up up

5 Sensor signal reference Green - - down down

6 Gnd Yellow/green - - - -

CBQ-32: TGS cable

Display Board – TGS Board

Display Board

CN7

Signal Color TGS Board

CN1

1 +12 Vdc power supply Yellow 1

3 Rx White 8

5 Tx Green 7

9 Gnd Brown 3

Page 2.7

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 2.8

CU106: HFU receiver cable

HFU receiver – Patch conn. 1

HFU receiver Signal Color Patch conn.1

1 +5 Vdc power supply Blue 1

2 Pulse (beat to beat) Red 2

4 Gnd Black 4

CU108: HFU receiver cable

Patch conn. 1 –Display board

Patch conn.1 Signal Color Display board

CN3

1 +5 Vdc power supply Blue 8

2 Pulse (beat to beat) Red 1

4 Gnd Black 7

CU122: High voltage cable

Power entry module – Brake board

Power entry

module

Signal Color Brake board

CN3

F Line Blue 1

N Neutral Brown 3

T Earth Yellow/Green 5

BIKE MED: Service & Maintenance Manual - rev. 1.0

3. PRINCIPLES OF OPERATION

3.1. BLOCK DIAGRAM

The machine block diagram is illustrated in the figure below:

POWER

ENTRY

MODULE

DISPLAY

DISPLAY BOARDS

CSAFE

BOARD

RIGHT

SENSORS

LEFT

SENSORS

HAND

SENSOR

BOARD

TGS BO ARD

BRAKE

BOARD

CARDIO

RECEIVER

VAC

SPEED

SENSOR

BRAKE

KEYBOARD

TOUCH

SENSOR DX

TOUCH

SENSOR SX

3.1.1. ARM DISPLAY BOARD

This is the heart of the display: this is the circuit board which comprises the CPU, an ARM

microprocessor, its logic circuits and a FLASH EPROM containing the operating program for

the machine moreover, acts as the interconnection hub for all the components of the display

and serves as the point of connection with the electrical box. In fact it receives and process

signals from:

- Keyboard;

- Cardio receiver;

- TGS board;

- CSafe Board;

>

distributes the voltages received from the Brake board to the display;

Page 3.1

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 3.2

> exchanges, via the RS-485 serial link to the Brake board, the commands for controlling the

brake;

> controls the LEDs and the 7-segment displays which provide feedback about the exercise

session.

The board includes the following indicator LEDs:

LED name Color Description

LED1 yellow

if ON the +5 Vdc power supply from the

Brake board correctly reaches the board.

LED2 green

if ON the +12 Vdc power supply from the

Brake board correctly reaches the board.

3.1.2. CSAFE BOARD

This board makes available a communication port, on 1 externally accessible connector, which can

be used for interfacing compatible CSafe devices such as the CardioTheater readers. This connector

is situated on the back of the display. Another free connector is available on the board.

These connectors can also be interfaced, using a special cable, to an external PC for programming

the FLASH EEPROM.

3.1.3. TGS READER

This board enables the machine to read and write on the user's TGS key for performing workouts

programmed with the Wellness System.

3.1.4. HAND SENSOR BOARD

This is the board which manages the hand sensors, interfacing them to the display board. It

processes the analogue signal received from the sensors and outputs one pulse for each heart beat

that is detected. The signal level is normally 5 Vdc; it goes to 0 Vdc when the user’s hands are

placed on the contacts, and a 5 Vdc pulse (having a width of approximately 30 msec) is output at

each detected heart beat.

3.1.5. CARDIO RECEIVER

This board manages the signal received from the telemetric transmitter used by the person

exercising. It receives the power supply signal from the display board and outputs a negative logic

pulse for every heart beat that is detected: the signal level is normally 5 Vdc, with a pulse at 0 Vdc

(having a width of approximately 30 msec) at each heart beat.

The receiver reception area is approximately a circle with a 1 m radius. If there is electromagnetic

noise (produced by high voltage lines, radio transmitters, monitors, motors etc.) within this area, the

receiver becomes saturated and no longer receives any signal.

3.1.6. BRAKE BOARD

There are 2 versions of the brake board, one which is used on the mains powered version and the

other on the self-powered version. In either case, the brake board consists of:

BIKE MED: Service & Maintenance Manual - rev. 1.0

• Power supply section which generates the low voltages used by the machine: +5 Vdc and +12

Vdc. Depending on the machine version, these voltages will be generated either from the 110

VAC or 220 VAC mains supply, or from the alternator-battery.

• Section for RS-485 serial communications with the display board for:

- commands determining the resistance that is required of the brake;

- brake error messages;

- the commands for modifying the circuit board configuration parameters;

- the commands for viewing the errors logged by the circuit board.

• Section which generates the current for the brake winding: varying the current produces a

proportional variation in the resistance of the brake. The excitation current supplied to the brake

is a function of the effort level selected on the display and the RPM value measured by the

speed sensor (angular velocity of the brake disk and is determined by the values stored in the

braking table.

The board includes the following indicator LEDs:

LED name Color Description

LED1 green

if ON the board is supplying the brake winding.

if BLINKING the brake board is in an error condition.

LED2 yellow

if ON there is the +5 Vdc power supply from the

circuit board.

3.1.7. BRAKE

This is an eddy current brake, consisting of a flywheel mass and a flat copper disk that rotates in the

air gap of a winding. Variations in the winding current produce a change in the resulting field,

which consequently varies the eddy currents induced within the copper disk and hence its resistance

to movement.

The winding has a resistance of approximately 4.8 Ohm.

3.1.8. SPEED SENSOR

This consists of a magnetic induction sensor which detects the heads of the brake disk fixing

screws.

3.1.9. POWER ENTRY MODULE

This is a block consisting of:

• power inlet socket;

• power outlet socket;

• fuse-holder for protecting line voltage and neutral with two 3.15A fast-blow fuses.

Situated on the side of the rear platform, the power entry module has a maximum current rating of

10A.

Page 3.3

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 3.4

3.2. BRAKE CONTROL

3.2.1. MECHANICS

The movement of the pedals puts the brake into rotation by means of a belt. The speed sensor (only

on mains operated models) attached to the frame detects the heads of the screws which secure the

disk to the flywheel, and generates a signal proportional to the speed. On self powered machine, the

speed value is detected measuring a phase of the alternator.

3.2.2. CONTROL

The control block diagram is as follows:

CN9

RS-485

CN4

Brake board

1-2/CN2

Brake

Excitation Current

3-4/CN2

Pulses

Speed

sensor

Display Board

The resistance which the user perceives on the pedals is a combination of 2 factors:

• mechanical: mechanical efficiency of the linkages and more generally the mechanical friction

of the system as a whole. The mechanical friction has been measured in the laboratory and is

determined by a specific SW function of the upper kit.

• electrical: resistance produced by the brake;

To obtain a given exercise effort level, the display board sends the required value of “electrical”

resistance to the brake board via the RS-485 serial link. Based on the commands received and the

feedback signal from the speed sensor, the brake board will then apply the appropriate excitation

current to the brake winding and generate an electromagnetic field.

The value of the current applied is based on the value of the brake table memorized into

the brake board.

BIKE MED: Service & Maintenance Manual - rev. 1.0

When the brake interface board receives the signal to generate resistance, the green

LED illuminates.

The electromagnetic field produced by the winding and the rotation of the disk will induce eddy

currents in the disk itself, giving rise to a force which tends to brake its motion. This produces the

exercise resistance.

A higher brake excitation signal will produce a correspondingly higher exercise resistance. In

addition, for a given value of brake excitation, a higher speed of disk rotation will produce a

correspondingly higher exercise resistance.

Due to the eddy currents, energy is dissipated on the brake disk in the form of heat.

The brake board effects an open loop control of the brake, with no provision for

regulating the value of resistance produced. The precision of the braking system has a

tolerance of ±10%.

During the movement, the speed sensor detects the heads of the brake disk fixing screws, and

produces a speed feedback signal that is sent to the Brake board, on the mains operated machines.

On the self powered machines, the speed signal comes directly from the measure of an alternator

phase.

If the brake board does not receive a speed signal which indicates that an exercise

session is in progress, the machine will not produce any resistance.

During the movement, the brake board checks for possible malfunctions. The errors which can

occur are:

Error

Code

Description

1

OVERHEATING: this condition occurs when the temperature measured

by the sensor on the circuit board exceeds 90°C.

2

OVERCURRENT: this condition occurs when the current going to the

solenoid measured by the board exceed the max value.

4

UNDERVOLTAGE: this condition occurs when the +12 Vdc voltage

drops below 9.7 Vdc.

8

OVERVOLTAGE: this condition occurs when the +12 Vdc voltage goes

above 13.7 Vdc.

16

WATCHDOG: this condition occurs when the brake board SW crashes.

32

EPROM: SW error on the brake board.

128

MACHINE NOT CALIBRATED: this error condition occurs when the

calibration parameter stored in the brake board is incorrect.

In the case of error 128, the machine will continue to function completely, but the braking

resistance produced will not correspond to the value entered on the display. In all other cases, the

Page 3.5

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 3.6

brake board interrupts the supply of current to the brake and sends an error message to the display

board which displays the “THE EQUIPMENT IS BLOCKED” message.

3.2.3. THE SIGNALS INVOLVED

The machine uses the following control signals:

• RS-485 Signal

This is a digital signal exchanged between the brake board and the display board. There is no

provision for monitoring its state.

• Excitation current

This is the current generated by the brake board (pins 1-2 of connector CN2) which supplies the

brake winding. The current supplied is a function of the selected effort level and the speed of

the exercise.

• Pulses

This is the signal produced by the speed sensor, and has the waveform shown below:

Figure 3.2-1

The signal enters the brake board (pins 3-4 on connector CN2), where it is used to determine the

speed value that is sent to the display board via the RS-485 serial link.

This signal can also be measured qualitatively using a multimeter. With the machine

stopped the voltage measured across the sensor terminals should be 0 Vdc, and while

pedaling it should go to a few hundred mV: the higher the speed, the higher the

measured value.

BIKE MED: Service & Maintenance Manual - rev. 1.0

4. ACCESSORIES

4.1. CARDIO THEATER CONNECTION

The machine can be connected to the CardioTheater by means of the RJ45 connector on the CSafe

board. The CardioTheater unit must be provided with a power cable having the following pin-out:

RJ45 Connector Signal

5 +5 Vdc

7 Ground

ATTENTION: for the numbering of the pins, on RJ45 connector, please refer to the

diagram below:

4.2. PC LINK FOR PROGRAMMING

The machine can be connected to a PC for programming by means of the RJ45 connector on the

CSafe board.

The cable to use (code 0WC00434AB) must be wired as follows:

ATTENTION: for the numbering of the pins, on RJ45 connector, please refer to the

diagram below:

Page 4.1

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 4.2

When programming the machine sometimes it is necessary to fit plug into the free RJ-45

port on the back of the display, to avoid any type of interference during the operation.

The wiring diagram of the RJ-45 plug is as follows:

Programming cable and plug can be ordered using the code H0002534AA.

4.3. MONITOR PLUG FOR CSAFE PORT

When the plug code 0WC00639AA is fitted into any one of the CSafe ports on the machine, the

corresponding LED should illuminate to indicate the presence of the 5 Vdc supply on the port.

During the CSafe port test function, the plug connects the transmit channel directly to the receive

channel, thereby producing a positive test outcome if the port is functioning correctly.

BIKE MED: Service & Maintenance Manual - rev. 1.0

5. INSTALLATION INSTRUCTIONS

5.1. SPECIFICATIONS AND REQUIREMENTS

For correct machine installation, make sure that:

1. The machine is installed on a level surface that is free of vibrations and has sufficient carrying

capacity for the combined weight of the machine and user.

2. The place of installation is free of dust and sand.

3. The place of installation meets the operating temperature and humidity conditions specified in

paragraph 2.4. “Ambient specifications”.

4. The machine is not positioned close to sources of heat, sources of electromagnetic noise

(television sets, electrical motors, antennas, high voltage lines, household appliances, etc...) or

medical equipment.

5. To eliminate any interference with the cardio receiver, no transmitters should be placed less

than 1 meter from the display.

6. The mains voltage must match the value specified on the machine rating plate.

7. The electrical system must be correctly earthed.

8. The wall outlet used should be reserved for the machine and have a rating of at least 50 VA.

9. Position the mains lead of the machine where it will not be underfoot.

5.2. INSTALLATION

To correctly install the machine, proceed as follows:

1. Ensure that the specifications and requirements for installation have been met (see paragraph

5.1. “Specifications and requirements”).

2. Position the machine as specified above, on a level surface that is free of vibrations and has

sufficient carrying capacity for the combined weight of the machine and user.

3. The machine is shipped fully assembled and packed in a carton fixed to a wooden pallet.

4. Connect the mains lead to the power inlet socket on the machine.

5. Place the on/off switch in the “0” position.

6. Plug the mains lead into the wall outlet.

5.3. FIRST POWER-ON

After completing the installation procedure, the machine is ready for use.

Simply turn the on/off switch from position 0 to position 1, to get on the machine.

On power-up the machine performs a self test of the upper and lower assemblies. At the end of this

the machine goes into standby, awaiting a keyboard command.

To check the correct operation of the machine:

Page 5.1

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 5.2

• get on the machine;

• begin exercising;

• check that the displayed speed varies accordingly;

• check that the exercise resistance varies when the “+” and “-” keys and the touch sensor are

pressed and the effort level change from 1 to 30;

• put on the heart rate meter and check that the machine correctly reads the heart rate value;

• grasp the sensors and check that the machine correctly reads the heart rate value;

BIKE MED: Service & Maintenance Manual - rev. 1.0

6. TROUBLESHOOTING

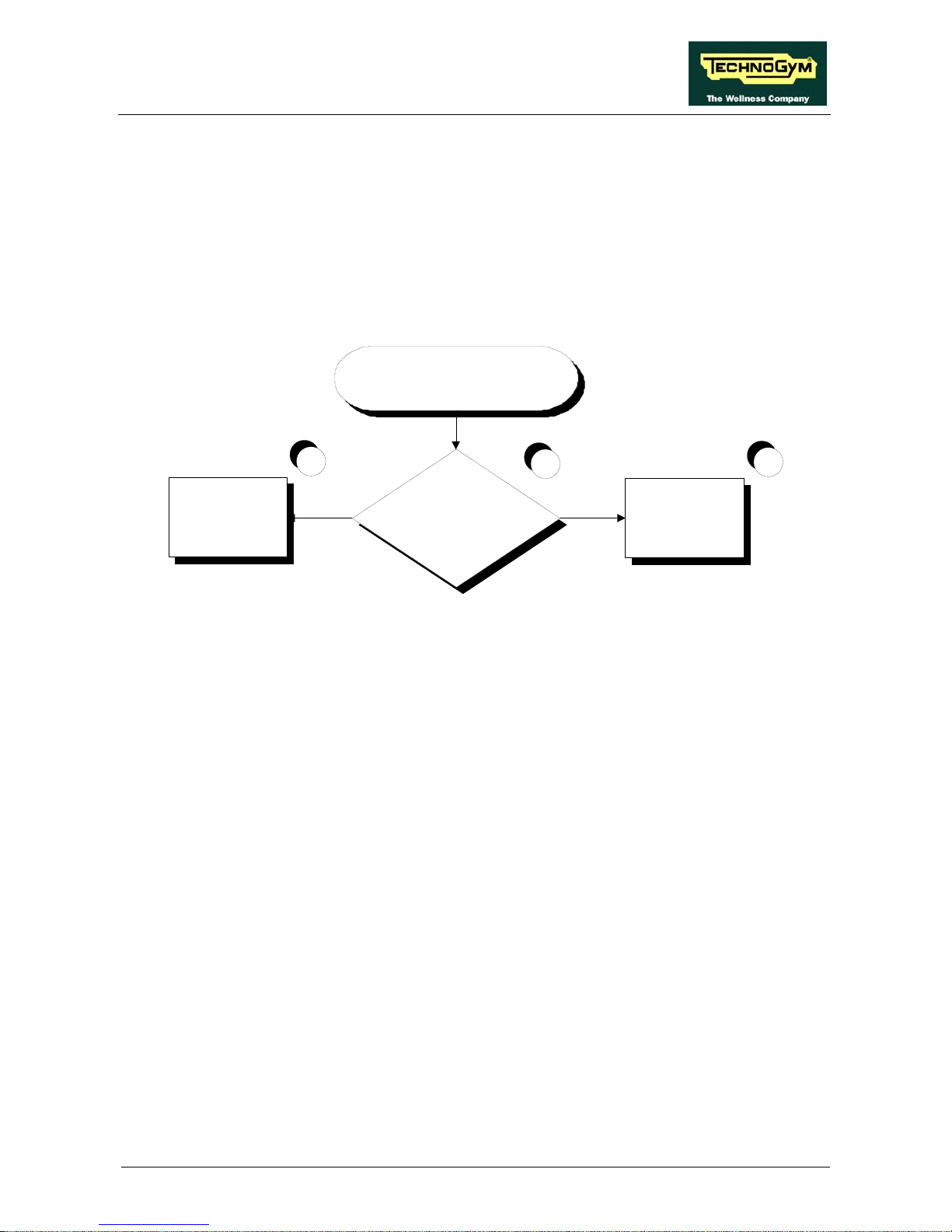

The troubleshooting procedures are shown in the form of flow charts. In order to facilitate

consultation, the following standard box shapes are used.

This type of box is the START point of the troubleshooting procedure. It

typically contains a description of the problem or malfunction.

This type of box represents a decision point in the troubleshooting procedure.

It typically contains a description of the CHECK to be made, with an outcome

that can be either a positive (YES) or negative (NO) response.

This type of box is a step in the troubleshooting procedure where an ACTION

must be carried out. It typically contains a description of the ACTION

necessary to resolve the problem. Therefore, after executing the specified

ACTION:

1. Check whether the problem has been resolved;

2. If the problem persists, it is recommended to resume the troubleshooting

procedure from the point before the action was carried out.

A circled number (such as that shown on the left) next to a box of the

troubleshooting procedure indicates that detailed instructions for performing

that particular check or action are provided below the flowchart.

A circled letter (such as that shown on the left) is used to highlight a point in

the procedure. Typically, this indicator is used in page changes.

Page 6.1

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.2

6.1. SERVICE TROUBLESHOOTING MENU

Simultaneously press the keys 369. The following prompt appears on the display:

ENTER PASSWORD:

To access the procedure, type in the password 2501 which protects against unauthorized access and

press the “Enter” key to confirm. At this point there are two options available:

1 = Tech Config

2 = Troubleshooting

Press numeric key 1 to access the menu for configuring technical parameters; the machine display

will begin showing the current configuration, structured as in the diagram below:

MAN.KEYBOARD

TEST

TROUBLESHOOTING

I2C Devices Test

AUTOMATIC TEST MANUAL TEST

LED Test

SERI AL PORT S

TEST

CSafe COM Test

TGS COM Test

Low Kit COM Test

To scroll through the list of available functions, press the + or – effort level keys to display the next

or the preceding item; confirm the choice by pressing ENTER. To cancel the operation, press the

CLEAR key for a few seconds.

The tests are divided into two groups: Automatic and Manual, and the prompt for a choice appears

immediately on accessing the troubleshooting menu.

6.1.1. AUTOMATIC TEST

The tests grouped under this section conduct checks on the machine’s operation in a fully automatic

manner. After selecting the desired test using the + and – effort level keys, press ENTER to initiate

the test and then await the result. Press ENTER again to continue, and use the CLEAR key to

BIKE MED: Service & Maintenance Manual - rev. 1.0

return to the higher menu level, holding it down for a few seconds. The various tests are described

below.

6.1.1.1. I2C Devices Test

The I2C Devices test checks the communication following the 32K and 256K. The test can have

outcomes:

• “Test Successful, press Enter to continue”: Signifies that the transmission and reception of

data packets between the I2C devices and the display board was completed successfully.

• “EEPROM Error, press Enter to continue”: Signifies that the display board is having

problems communicating with its memories.

6.1.1.2. LED Test (not on 700iE models)

The LED test checks the functioning of the display by lighting all the LEDs in the matrix. It also

tests the buzzer by changing the frequency to produce a variation in the tone of the sound.

There is no message displayed concerning the outcome of this test, which must therefore be

checked visually.

6.1.1.3. Serial Ports Test

The serial ports test checks the communications on the following interface ports:

• CSafe COM test;

• Low Kit COM test;

• TGS COM test.

Using the + and – effort level keys, select the desired test item and confirm by pressing ENTER.

The test can have two outcomes:

• “Test Successful, press Enter to continue”: This means that the test was completed

successfully, i.e. that the communications on the selected serial port are functioning correctly.

• “COMx error, press Enter to continue”: This means that the outcome of the test was

negative: the message will specify COM1 in the case of the CSafe COM test, COM2 in the case

of communications with the low kit, or COM3 in the case of the TGS COM test.

The “TGS COM test” done on machine not provided with the key reader gives a fail

outcome. The same if the “CSafe COM test” is done on a machine which CSafe port is

not plugged with the monitor plug described at paragraph 4.3. “Monitor plug for CSafe

port”.

6.1.2. MANUAL TEST

The tests grouped under this section conduct checks on the machine’s operation in a fully automatic

manner. After selecting the desired test using the + and – effort level keys, press ENTER to initiate

the test and then await the result. To exit test mode, press and hold down the CLEAR key for a few

seconds.

Page 6.3

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.4

6.1.2.1. Man. Keyboard Test

The manual keyboard test checks the functioning of all the keys on the keyboard. After accessing

the test by pressing ENTER, the message “Press all buttons (beep=OK)” appears on the display.

Pressing each key will produce an audible signal; if a key does not produce the beep it means it is

not working properly.

On Wellness TV machines, pressing the keys does not produce an audible signal, but if the key is

working correctly it lights up green.

BIKE MED: Service & Maintenance Manual - rev. 1.0

6.2. THE DISPLAY FAILS TO ILLUMINATE

This error occurs when the power supply voltage does not reach the upper assembly.

Does t he wall outlet s upply t he

correct voltag e?

Is t he m ains lead OK?

Is t h e v olt age at the

output of the machine's

power entry modul e

correct?

Plug the mac hi ne int o a

working elec trical out l et

Replac e the mains lead

Replac e the power

entry m odul e on the

machine

THE DISPLAY

DOES NO T

ILLUMINATE

NO

YES

NO

YES

NO

YES

A

1

Replace the f us es

YES

NO

Are the f uses OK?

Page 6.5

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.6

A

Are the DC v oltages at the

output of the brake board

correct?

3

YES

NO

Replac e the brake

board

Are the D C v oltages at t he

input t o t he dis play board

correct?

Replac e the display

board and/ or 3 86 board

Replace cable CB-3

NO

YES

4

Does t he m ai ns v oltage

reach t he input to the

brake boar d?

NO

2

Replace cable CB-0

YES

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

To speed up the troubleshooting procedure, check the state of the power indicator LEDs

on the various circuit boards.

(1) Slightly lift up the Faston connectors on the machine power inlet socket. Place the tester

probes across the live and neutral pins on the same connector. The measured value should be

approximately 220 VAC or 110 VAC depending on the mains voltage.

(2) As for step (1) but across pins 3 and 1 of connector CN3 on the brake board.

(3) Using a tester, check that all the output voltages on connector CN1 of the brake board are

correct, referring to paragraph 2.7. “Cables”.

(4) As for step (3) but on connector CN1 of the display board.

BIKE MED: Service & Maintenance Manual - rev. 1.0

6.3. “THE EQUIPMENT IS BLOCKED” MESSAGE ON THE

DISPLAY

This error message can be caused by:

• loss of communication between the lower and upper assemblies;

• the brake board has detected an error condition, causing it to generate an alarm and store the

error code in memory.

Is the serial

comm unic at ion bet ween

display and lower

elect ronic correct?

Reins tate t he

communication link

between the upper and

lower ass emblies

NO

"THE EQUIPMENT IS BLOCKED"

MESS A G E ON TH E DISPLAY

1

Carry out the "Error

detected by brak e

board" tr oubl es hooting

procedure

YES

2

3

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Use the serial communications test described in paragraph 6.1.1.3 “Serial Ports Test”.

(2) To reinstate communications between the lower and upper assemblies:

• check that cable CB-4 is correct using the Test Box Excite;

• try replacing the brake board and the display board in turn, and check whether the

communication works.

(3) Check whether the brake interface board is in an error condition, by accessing the “Low kit

fault code” function in the “Low kit menu” described in paragraph 9.2.5.2 “Low Kit fault

code”.

If the displayed parameter value is “0”, there is no error condition.

Page 6.7

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.8

6.4. ERROR DETECTED BY BRAKE BOARD

When the brake board detects an error, it stops and interrupts the power supply to the brake

winding, and an error code identifying the fault condition is saved in the error history log. When

this error is received by the display board, it halts the exercise and shows the “THE EQUIPMENT

IS BLOCKED” message on the display.

The errors logged by the brake board can also be viewed from the machine keyboard as described

in paragraph 9.2.3. “Errors log” or in paragraph 9.2.5.2 “Low Kit fault code”.

ERROR DETECTED BY

BRAKE BOARD

Check the error code

st or ed in m em or y

Error 1

Error 4

Error 8

Error 16 - 32

Error 2

Error 128

The following paragraphs describe the troubleshooting procedures for these cases.

6.4.1. ERROR 1 ON BRAKE BOARD

This code indicates an overheating error: this condition occurs when the temperature detected by

the sensor on the circuit board exceeds 90°C.

Try switching the machine off for 1 hour. If it resumes working correctly, the machine probably

overheated as a result of intensive use. If, on the other hand, the error persists, it is necessary to

replace the brake board.

6.4.2. ERROR 2 ON BRAKE BOARD

This code indicates an overcurrent error: this condition occurs when the current going to the

solenoid measured by the board exceed the max value.

This error is caused by an HW problem on the brake board or a short circuit on the solenoid. To

solve the problem, it is necessary to replace the brake board or the solenoid.

6.4.3. ERROR 4 ON BRAKE BOARD

This code indicates a low voltage error: this condition occurs when the +12 Vdc voltage drops

below 9.7 Vdc.

BIKE MED: Service & Maintenance Manual - rev. 1.0

This error is caused by drops in the voltage output by the power supply section of the brake board,

as a result of defective components. If the error persists or recurs frequently, replace the brake

board.

6.4.4. ERROR 8 ON THE BRAKE BOARD

This code indicates an overvoltage error: this condition occurs when the +12 Vdc voltage exceeds

13.7 Vdc.

This error is caused by surges in the voltage output by the power supply section of the brake board,

as a result of defective components. If the error persists or recurs frequently, replace the brake

board.

6.4.5. ERROR 16 OR 32 ON THE BRAKE BOARD

This code indicates an error in the EPROM of the brake board or a watch dog error: this condition

occurs when the board is unable to read the memory.

If the error persists or recurs frequently, replace the brake board.

6.4.6. ERROR 128 ON BRAKE BOARD

This code indicates an error in the calibration of the brake board: this condition occurs when the

value of the calibration parameter read by the board is incorrect. In these conditions, the board

continues to function but will not necessarily produce the correct value of exercise resistance.

When this error occurs, replace the brake board.

Page 6.9

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.10

6.5. THERE IS NO RESISTANCE

The machine will not produce resistance if:

• the display board does not receive a speed signal;

• the brake board does not generate current;

• the brake is defective.

Does the brake board supply

current to t he brake winding?

TH ER E IS N O

RESISTANCE

Are the Watt and RPM v al ues

shown on t he di s pl ay dif f erent

from zero?

NO

YES

1

Carry out the "RPM v alue

is incorrect "

troubles hoot ing proc edure

Replace the brake board

YES

Does t he br ak e winding receive

current f rom the brake board?

NO

Replace the brake winding

YES

Replac e cable CB-51

NO

2

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Disconnect the brake winding and measure the current output by the brake board with a load

of at least 5 Ohm and 80 Watts. The value should be different from 0 A.

(2) As for step (1) but with everything reconnected, and across the brake winding.

BIKE MED: Service & Maintenance Manual - rev. 1.0

6.6. THE RESISTANCE IS INCORRECT

The machine will produce an incorrect resistance if:

• the mechanics are not in perfect condition;

• the speed measurement is incorrect;

• the brake board is defective;

• the brake is defective.

Are the m echanics of t he

machine in good condition?

Has the brake board generated

error 128?

Does t he br ak e boar d out put

the correct current to the brake

winding?

3

Replace the brake board

NO

Replace the brake winding

YES

THE

RESIST ANCE IS

INCORRECT

1

Repair t he f ault y

mechanic al part s

NO

Carry out the "Speed is

Inc orrec t " t roubles hoot ing

procedure

2

Replace the brake board

YES

YES

NO

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

Page 6.11

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.12

(1) Check that the mechanical system, consisting of the pedals, belt and brake, moves smoothly

and without unusually high friction or resistance.

(2) Refer to paragraph 9.2.3. “Errors log”.

(3) Measure the voltage supplied by the brake board to the winding. In constant power mode

(custom – time), pedaling at 80 RPM and with a user weighing 75 kg, the values, according to

the firmware version of the brake board, should be approximately those in the tables below:

Low kit version 9.161.104

Power (Watt) Voltage (Vdc)

50 1.48

80 2.0

150 3.02

200 3.55

BIKE MED: Service & Maintenance Manual - rev. 1.0

6.7. THE SPEED SIGNAL IS INCORRECT

The speed signal is incorrect if:

• The brake disk is incorrectly fixed to the flywheel;

• The speed sensor is defective;

• The brake board is defective.

Does t he speed sens or s end

the c orr ec t signal to t h e brak e

board?

2

Replace the speed sensor

NO

SW not c orr ec t l y loaded

YES

Is t he brak e di s k correctly f ixed

to t he f l y wheel?

TH E SPEED IS

INCORRECT

1

Fix it correctly

NO

YES

Check if t he parameters

conf iguration is r ight. I s the

speed signal correct?

3

Configuration param et er

not c orrec t

YES

YES

Upload t he brak e board SW. Is

the s peed signal corre c t ?

4

Replace the brake board

NO

YES

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

Page 6.13

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.14

(1) Check that the 6 screws fixing the disk brake to the flywheel are all locked down.

The speed sensor detects the heads of these screws.

(2) Place the tester probes across the terminals of the speed sensor. The measured signal should

be that indicated in Figure 3.2-1. In addition, when pedaling at 80 RPM the frequency of the

signal should be 107 Hz.

The speed signal can also be observed qualitatively, using a multimeter. The value

should be 0 Vdc when the machine is stopped, and gradually increase as the speed

increases.

(3) Launch the default setting for the low kit parameters.

(4) Update the low kit SW uploading both firmware and brake table. At the end launch the

default setting for the low kit parameters.

BIKE MED: Service & Maintenance Manual - rev. 1.0

6.8. THE MACHINE DOES NOT READ THE TGS

The machine displays this error if the TGS reader is not working properly, or if it is not supplied by

the display board.

TH E MACHINE DO ES

NOT READ THE TGS

Does t he s upply voltage

correc t ly reach t he input t o t he

TGS reader?

Is t he s upply v olt age correct at

the output to the display board

correct?

Replac e cable CBQ-32

1

2

YES

NO

YES

Replace the display board

NO

A

Is t he serial comm unic at ion l ink

between the display board and

the TGS reader OK?

Replac e the TGS reader. Is the

comm unic at ion li nk bet ween the

displ ay board and t he TGS

reader OK?

TGS reader defect iv e

3

3

YES

NO

YES

Replace the display board

NO

A

Replace the TGS reader

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

Page 6.15

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.16

(1) Place the tester probes across pins 1 and 3 of connector CN1 of the TGS reader. The

measured value should be +12 Vdc.

(2) As for step (1) but across pins 1 and 9 of connector CN7 on the display board.

(3) Use the serial communications test described in paragraph 6.1.1.3 “Serial Ports Test”.

BIKE MED: Service & Maintenance Manual - rev. 1.0

6.9. THERE IS NO HEART RATE SIGNAL

6.9.1. HFU TELEMETRIC RECEIVER

The machine displays this error if:

1. electromagnetic noise saturate the HR receiver which does not display any value due to a

specific SW filter which cut every signal, greater than 220 bpm;

2. the receiver is not working properly;

3. the receiver is not supplied by the display board.

TH ER E IS N O HR

SIGNAL

Is t he supply v olt age c orrec t at

the input to t he rec e iv er?

Is t he supply v olt age c orrec t at

the output of t he di s pl ay board?

Replace the receiver

Replac e C BQ- 28 c abl e

2

3

YES

NO

YES

Replace display board

NO

Carry out the

troubl es hooting procedur e

"THE TELEMETRIC

SIGN AL I S INCOR R EC T"

1

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Carry out the troubleshooting procedure 6.10. “The telemetric hr signal is incorrect”.

(2) Place the tester probes across pins 1 and 3 of connector CN1 of the receiver. The measured

value should be +5 Vdc.

(3) As for step (1) but across pins 1 and 8 of connector CN3 on the display board.

Page 6.17

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.18

6.9.2. HAND SENSOR

The machine displays this error if the HS interface board is not working, or if it is not supplied by

the display board.

For an easier and quicker diagnosis of the problem, we recommend to use the

functions of Test Box Excite.

TH ER E IS N O HR

SIGNAL

Are the s ens ors c orrectly

connected to the HS interface

board?

Is t he supply v olt age c orrec t at

the output of t he di s pl ay board?

Reins tate t he c onnection

Replac e cable CBQ-25-1

Replace the display board

2

4

YES

NO

YES

NO

Is t he supply v olt age c orrec t at

the input to the HS interf ace

board?

Replace the HS interf ace

board

3

YES

NO

Check the earth c onnec t i on

of the mac hine

1

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Check the earthing of the machine using a tester to measure the resistance between the ground

pin on the power supply cable and the ground node to which the hand sensor are connected

inside the display. The value must be less than 1 Ohm.

BIKE MED: Service & Maintenance Manual - rev. 1.0

(2) Check the connections, referring to paragraph 2.6. “Wiring diagram”.

(3) Place the tester probes across pins 2 and 1 of connector J3 on the HS interface board. The

measured value should be +5 Vdc.

(4) As for step (2) but across pins 1 and 6 of connector CN4 on the display board.

Page 6.19

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.20

6.10. THE TELEMETRIC HR SIGNAL IS INCORRECT

The machine displays this error if the receiver is disturbed by sources of electromagnetic noise.

THE TELEMETRIC

HR SIGNAL IS

INCORRECT

Are the m achines c orrectly

spac ed by t he r equire d m inim u m

distance?

Is the receiver correctly

positioned and are the

connec ting cables properly

routed?

Are there s ourc es of

electromagnet ic noi s e near t he

receiv er?

Reposition the machines

so t hey are adequately

spaced

Correc t the pos ition of the

receiv er and the rout ing of

the c abl es

Move the machine away

from t he noi s e s ource or

att enuat e the power of the

noise

NO

YES

NO

YES

NO

YES

4

A

Check the earth c onnec t ion

of the mac hine

1

3

2

Continued on the following page.

BIKE MED: Service & Maintenance Manual - rev. 1.0

Is the transmitter always within

the 80 cm range f rom t he rec eiv er

NO

Reposition the transmitter

within range

YES

Replac e the receiv er

A

Is t h e t ransmitter in good

working order?

Us e a c orr ec t l y

funct ioni ng t r ans m itter

YES

NO

5

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) Check the earthing of the machine using a tester to measure the resistance between the ground

pin on the power supply cable and the ground node to which the receiver is connected inside

the display. The value must be less than 1 Ohm.

(2) In the table below , the minimum distances at which machines should be installed to avoid

crosstalk problems.

B

I

K

E

B

I

K

E

2

BIKE

2

2

BIKE

2

DISTANCE CASING-CASING

machine 2 machine 2 machine 2 machine 2

Bike Recline Run Bike Recline Run Bike Recline Run Bike Recline Run

20 30 10 50 40 50 0 0 10 30 60 10

DISTANCE RECEIVER-RECEIVER

machine 2 machine 2 machine 2 machine 2

Bike Recline Run Bike Recline Run Bike Recline Run Bike Recline Run

130 140 195 100 90 115 80 50 130 170 230 225

Page 6.21

BIKE MED: Service & Maintenance Manual - rev. 1.0

Page 6.22

For machine positioning layouts different from those indicated above, use the following

diagram as a reference.

where:

1. The distances are in centimeters.

2. The smaller number indicates the maximum locking distance for signal reception at the

start of the exercise.

3. The higher number indicates the maximum reception distance during the exercise.

(3) Check that the cardio receiver has been assembled properly as described in the procedure 7.4.

“Disassembling the cardio receiver”.

(4) To check for electromagnetic noise near the machine, use Test Box Excite as detailed here

below. You can use one of the following cables ELT-16 (0WC00518AB), CBQ-28

(0WC00390AC) or TRM-28 (0WC00336AC) as connection cable.

The circuit lights the LED for each heart beat and/or disturbance received: in this way it is

possible to determine whether there is any interference, and identify its sources.

(5) Check the battery power level, using a tester if possible. Otherwise use a receiver or another

“reference” machine to check the operation up to a distance of about 80 cm from the receiver.

115

86

102

70

99

77

99

78

89

60

Receiver