FRISTAR

Version 2.01 EN

Manual version 3

Fresh water station

Operating manual

en

Table of contents

Safety instructions .................................................................................................................... 3

Mode of operation .................................................................................................................... 4

Hydraulic circuit diagram...................................................................................................... 4

Components ............................................................................................................................. 5

Installation ................................................................................................................................ 6

Preparation .......................................................................................................................... 6

Installation ............................................................................................................................ 7

Commissioning ........................................................................................................................ 7

Dimensions .............................................................................................................................. 8

Connection of a circulation line ................................................................................................ 9

Interchanging connections ..................................................................................................... 10

Cascade switching ................................................................................................................. 11

Hydraulic circuit diagram of a cascade with four FRISTAR fresh water stations ................ 11

Cascade switching control with UVR61-3R or UVR63 ....................................................... 12

Control of cascade switching with UVR1611 ..................................................................... 13

Cascade switching with circulation line .................................................................................. 13

Hydraulics schematic diagram ........................................................................................... 13

Circulation pump (optional) .................................................................................................... 14

Electrical circuit diagram ........................................................................................................ 14

Controller settings .................................................................................................................. 15

Technical data ........................................................................................................................ 16

Pressure loss characteristic curve plate heat exchanger: .................................................. 17

Pressure loss characteristic pump ..................................................................................... 17

Plate heat exchanger corrosion resistance ........................................................................ 18

3

Safety instructions

These instructions are intended exclusively for authorised professionals. To avoid accidents and damage due to incorrect operation,

carefully read through these operating instructions before you start

working with the freshwater station. If you carry out any alterations to

the construction of the freshwater station or the safety devices, you

may invalidate your right to make guarantee claims. Always observe

the local regulations.

Intended use

The freshwater station may only be installed in heating systems between the buffer tank and

the drinking water circuit. The technical limit values specified in this manual must be consid-

ered.

Incorrect use will result in the negation of any liability claims.

Electrical connection

Any electrical connections must be made by qualified electricians. Connection cables must

be routed in the recesses provided in the insulated base in such a way that direct contact

with the pump casing and the pipes is prevented.

Before switching on, check whether the supply voltage matches that stated on the power rat-

ing plates of the pump and the controller. All connections must correspond to the local regu-

lations.

Safety standards during installation, commissioning and maintenance

Installation, commissioning and maintenance may only be carried out by qualified persons

who are familiar with these operating instructions.

Before you start work on the system, ensure that the system is switched off and all compo-

nents are cooled down. When replacing the pump, turn the 4 ball valves into the closed posi-

tion.

In multi-occupancy dwellings, legionella protection must be observed in accordance with the

local regulations.

WARNING! Dependent on the pump and system operating conditions, the sur-

face temperatures can be very high. Direct contact with the pump or pipes can

result in burns!

Important note:

The secondary flow rate (cold / hot water)

must never be more than 40 l/min!

4

Mode of operation

Through use of the instantaneous heating concept, drinking water is heated both hygienically

and with low energy consumption in the FRISTAR freshwater station.

If water is drawn from the mains, the primary circuit pump transports tank water from a buffer

tank through the plate heat exchanger.

On the secondary side of the heat exchanger the drinking water flowing through is heated to

the temperature set in the controller. The cooled tank water is returned to bottom layer of the

buffer tank.

The speed control of the primary circuit pump takes place in the FRISTAR controller based

on the measurements of the volume flow sensor in the hot water pipe (temperature Tww and

volume flow Vww) and the temperature sensor in the primary flow TPri). The pump is con-

trolled using wave packet control. The optimum matching of the control behaviour to the

pump and the heat exchanger guarantees perfect constant maintenance of the outlet temperature.

Hydraulic circuit diagram

Temperature

Primary flow

Volume flow sensor

Hot water temperature Tww

Volume flow Vww

Pre-mixer

(recommended)

Safety valve max. 8 bar

Pump

5

Components

Flow

primary circuit

Return

primary circuit

Ball valve

Ball valve

with

gravity brake

Ball valve

Ball valve

Hot water

Secondary circuit

Cold water

Secondary circuit

Volume

flow sensor

Primary

sensor

Controller

Pump

Power cable

Plate heat

exchanger

Circulation

pipe connection

Ventilation

primary circuit

6

Installation

Preparation

A safety valve (max. 8 bar) must be installed in the cold water supply corresponding

to standards DIN 1988 und 4753, part 1 and TRD 721.

If the cold water pressure > 8 bar, fit a diaphragm pressure reducer max. 8 bar.

The installation of flushing equipment before and after the plate heat exchanger in

the primary and secondary circuits is recommended for descaling or cleaning as nec-

essary.

Special accessories: VMS pre-mixing set

If the tank is operated at a temperature higher than 70°C a pre-mixer that restricts the temperature to less than 70°C must be used in the primary circuit.

The VMS pre-mixing set is suitable for both Fristar models (left pump, right pump).

Figure: Connection for Fristar with right pump

Technical data

Setting range:

45°C – 65°C

Flow coefficient of mixing valve

4.5m³/h

Connections for Fristar

¾”

The thermal mixing valve is also available as an extra under the TMV designation.

Thread 3/4“

Thread 3/4“

Thread 3/4“

Thread 1“

7

Installation

Mounting position: Only vertical

Pull off the cowling in a forwards direction.

If necessary: Interchange the right/left connections (see chapter "Interchanging con-

nections").

Mark the fastening points, insert rawlplugs, fasten the station to the wall.

Fitting and connection of the pipe connections (3/4" outside thread connector). Plan for

as short as possible pipes in the primary circuit (tank -> freshwater station).

Electrical connection

The freshwater station is pre-wired ready for installation, connection to the electricity

mains takes place on site:

- using a plug in a wall socket or

- using a double pole isolator with a permanent connection.

Commissioning

Before filling the system, thoroughly flush both the primary and secondary side sys-

tems. To do this the locking bolt of the return valve with the gravity brake is placed in a

45° position so that it is non-operational.

Slowly fill the house system with drinking water via the secondary side ball valves.

Vent the house system at the draw-off valves.

Slowly fill the system with hot water via the ball valves in the primary flow.

Vent the primary circuit using the venting opening of the plate heat exchanger.

Set the pump to continuous operation and check pump running. Audible background

noise during operation of the circulating pump indicates air in the system. Warning!

Only start the pump when it is filled.

Check all connections, including in the freshwater station, for correct seating and leak-

tightness. If necessary, retighten to the necessary torque.

Activate the gravity brake at the primary system return valve (place locking bolt verti-

cally)

Place the cowling on the bottom part

Set the pump in automatic mode and select the setpoint temperature.

8

Dimensions

Housing dimensions:

W x H x D = 366 x 573 x 160 mm

38

38

160

228

¾“

¾“

¾“

¾“

9

Connection of a circulation line

The plate heat exchanger is provided with a connection for a circulation line. To lead the

circulation line through to the heat exchanger, the isolation cap must be cut out to suitable

dimensions.

Hydraulic circuit diagram with circulation line:

Connection

Circulation line

Heat

exchanger

Circulation

pump

Pump

10

Interchanging connections

For optimum matching of the pipelines to the freshwater station it is possible to interchange

the connections (right/left). Doing this does not change the circulation line heat exchanger

openings or the venting of the primary circuit.

Version Version

"Pump right" "Pump left"

Procedure:

1. Demounting of pipe elements 1 - 4 including pump from the heat exchanger

2. Removal of the pump and installation in the correct position.

3. Remount pump connection plug 5 on the other side.

4. Mounting of pipe elements 1 - 4 and the pump on the heat exchanger (see figures

above) on the other side, correct positional setup of the volume flow sensor

5. Commissioning according to the "Commissioning" chapter

Important: The primary and secondary connections must be exchanged together!

1

1

2

2

3

3

4

4

Pump

connection-plug

5

11

Cascade switching

At most, a maximum of 4 FRISTAR fresh water stations may be used in parallel in cascade

switching.

The first module is fed directly, all others stations are added with stop valves, if necessary.

These valves must open or close in at least 30 seconds.

Valves are added via overriding controller with a volume flow sensor that measures the total

volume flow. Sensor FTS5-85DL is sufficient for up to three modules, sensor FTS9-150DL

must be used with 4 modules.

Because the sensors in the FRISTAR stations must never be loaded with more than 40 litres

per minute, the overriding controller must increase the number of stations in steps of approx.

8-10 l/min. This ensures that the sensors in the FRISTAR stations are not strained excessively. In the following “step-by-step“ instructions, the first stage with 9l/min was selected because sensor FTS9-150DL is activated properly starting at 9 l/min only.

A three circuit controller UVR61-3R (or UVR63) can switch the modules. Of course, the cascade switching can also be integrated in the program of a UVR1611.

Hydraulic circuit diagram of a cascade with four FRISTAR fresh

water stations

Figure with fresh water stations version, version “Pump on the right“

The initial designations for stop valves A1 – A3 refer to controllers UVR61-3R or UVR63.

12

Cascade switching control with UVR61-3R or UVR63

Controllers UVR61-3R and UVR63 have exactly the same settings.

Step-by-step instructions for UVR61-3R:

Menu

ENTER

Access to menu Men with Code 64, to menu Par with

Code 32.

1

Men

EXT DL

Adoption of the volume flow on sensor FTS9-150DL as

external sensor E1.

With use of FTS5-85DL, “E1 17“ is entered.

2

Men

SENSOR

Adoption of external sensor value E1on sensor S1

3

Men

SENSOR

Fixed temperature value 0°C on sensor S2

4

Men

SENSOR

Adoption of external sensor value E1 on sensor S3

5

Men

SENSOR

Adoption of external sensor value E1 on sensor S4

6

Par

Selection of program 496

7

Par

The LO OFF setting remains set to factory setting

8

Par

All three max input and output thresholds are left with

factory settings 75/70°C because they do not influence

control.

9

Par

Because the flow values of the sensors are displayed as

temperatures, the switch-on value means “54°C“ 540 l/h

(= 9l/min) for threshold min1. The switch-off value of

49°C is entered for min1. Output A1 is switched via these

thresholds.

10

Par

Switch-on value “96°C“ (= 960l/h = 16 l/min) for value

min2. The switch-off value of 91°C is entered for min2.

Output A2 is switched via these thresholds.

11

Par

Switch-on value “144°C“ (=1440ll/h = 24 l/min) for value

min3. The switch-off value of 139°C is entered for min3.

Output A3 is switched via these thresholds.

12

Par

All three diff input and output thresholds are left at factory

settings 8.0/4.0K because they do not influence control.

All other settings in the Par menu are likewise left at factory settings.

13

The three outputs A1, A2 and A3 for the stop valves are switched on if the associated flow

thresholds min1 (540 l/h), min2 (960 l/h) and min3 (1440 l/h) are exceeded.

The low switch-on thresholds makes it probable that the last workstation is rinsed at least

several times a day and that no standing water collects.

Control of cascade switching with UVR1611

The outputs for stop valves A1 – A3 are switched on via comparison functions. The associated switch-on and switch-off thresholds are identical to those of the UVR61-3.

Cascade switching with circulation line

Hydraulics schematic diagram

Figure with fresh water stations version, version “Pump on the right“

The circulation pump is connected only to the always ready FRISTAR 1 and must not generate a flow larger than 18 l/min.

If the system is to be switched via UVR61-3R or UVR63, three FRISTAR modules at most

are possible. Program 480 for switching modules 2 and 3 via outputs A1 and A2 must then

be used. The circulation pump is switched via the distance S5 – S4 on output A3.

If UVR1611 is used, the circulation pump can be controlled with the “circulation” function.

Circulation pump

14

Circulation pump (optional)

If an external circulation pump is connected then it will work in pulse mode. If water is drawn,

the circulation pump runs with the run time (20 or 40 seconds) set with the selector switch.

After the end of the run time, pump start-up is permitted only after a 10 minutes break.

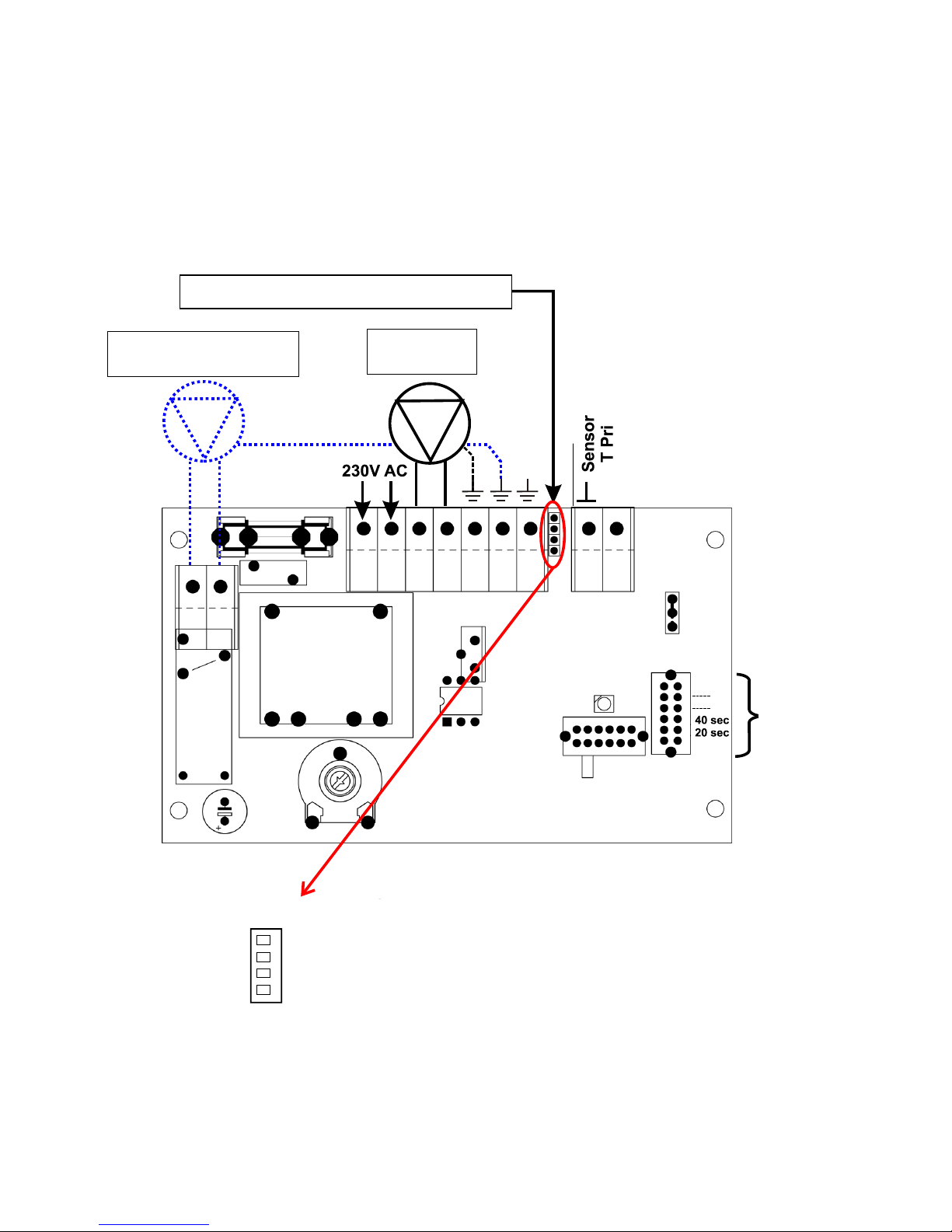

Electrical circuit diagram

Plug for volume flow sensor VFS

Fuse 3.15A

quick-acting

Note the plug layout:

brown

green

white

yellow

Optional:

Circulation pump

Primary

pump

Selection switch

Runtime

circulation pump

15

Controller settings

Operation of the controller has been kept as simple as possible, so that it can also be operated by inexperienced users.

Manual-automatic changeover switch

Switch position

OFF (AUS)

The pump is permanently switched off.

AUTO

The pump runs according to the controller settings.

ON (EIN)

The pump is switched on continuously at full speed, independent of

the control temperature.

Selection switch runtime circulation pump

The selection occurs by means of a slide switch on the right border of the board. There is no

access possible to the slide switch from outside.

Switch position

Runtime

PWM.I

Without function

PWM.N

Without function

PuT.2

40 seconds

PuT.1

20 seconds

LED display

Pump start-up

Manual-automatic

Changeover switch

Temperature selection

16

Technical data

Rated power

70 kW

Min. flow

2 l /min

Max. flow for 65°C tank and 45°C outlet temperature

30 l/min

Max. permissible flow

40 l/min

Max. operating pressure primary side (tank water)

4 bar

Max. operating pressure secondary side (cold water)

8 bar

Max. permissible water hammer pressure

15 bar

Rated temperatures primary flow / return

65 / 20 °C

Rated temperatures secondary flow / return

45 / 10 °C

Max. operating temperature primary/secondary

90 °C

Pressure loss secondary side (Kv value)

2.60 m³/h

Connection thread primary and secondary

G ¾” external thread

Materials (corresponding to DVGW/W270):

Fittings

Brass CW617N

Heat exchanger

Stainless steel 1.4401, copper

soldered

Pipes

Copper 99.96%

Seal material

PTFE, EPDM, Klingersil C-4324

Pump primary circuit

WILO ST20/7-3C

Volume flow sensor

Grundfos VFS 2-40

Primary sensor

PT1000

Controller

FWR21-FRISTAR

Indication referring to COMMISSION REGULATION (EU) No 622/2012:

The benchmark for the most efficient circulators is EEI ≤ 0.20.

Transmission power with different flow and outlet temperatures:

Pump mode

Buffer

flow [°C]

Return

[°C]

Cold water

supply [°C]

Hot water

outlet [°C]

Power

[kW]

Flow [l/h]

100%

59.3

25.0

10.3

45.0

68.7

1700

100%

55.4

27.0

10.3

45.0

56.5

1400

100%

50.3

33.2

10.3

45.4

34.7

850

100%

50.2

25.2

10.3

40.3

50.6

1450

17

Pressure loss characteristic curve plate heat exchanger:

Pressure loss characteristic pump

(1 m WC = 98 mbar)

Flow [l/min]

Pressure [mbar]

Durchfluss [m³/h]

Pressure [m WC]

Flow [m³/h]

0

100

200

300

400

500

600

0 5 10 15 20 25 30 35 40 45 50

18

Plate heat exchanger corrosion resistance

The corrosion behaviour of stainless steel and copper solder must be considered.

Water containing

material

Chloride

See diagram

Iron

< 0.2 mg/l

Manganese

< 0.1 mg/l

Ammonia

< 2 mg/l

pH value

7 - 9

Electrical conductivity

10 – 500 µS/cm

Free carbonic acid

< 20 mg/l

Nitrate

< 100 mg/l

Sulphate

< 100 mg/l

Saturation index SI

-0.2 < 0 < +0.2

Total hardness

6 – 15 °dH

Filterable substances

< 30 mg/l

Free chlorine

< 0.5 mg/l

Hydrogen sulphide

< 0.05 mg/l

Hydrogen carbonate

< 300 mg/l

Hydrogen car-

bonate/sulphate

> 1 mg/l

Sulphide

< 1mg/l

Nitrite

< 0.1 mg/l

We reserve the right to make technical changes. © 2014

Temperature [°C]

EC- DECLARATION OF CONFORMITY

Document- Nr. / Date:

TA12025 / 19.11.2012

Company / Manufacturer:

Technische Alternative elektronische SteuerungsgerätegesmbH.

Address:

A- 3872 Amaliendorf, Langestraße 124

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Product name:

FRISTAR

Product brand:

Technische Alternative GmbH.

Product description:

Fresh water station

The object of the declaration described above is in conformity with Directives:

2006/95/EG

Low voltage standard

2004/108/EG

Electromagnetic compatibility

2011/65/EU

RoHS Restriction of the use of certain hazardous substances

2006/42/EG

Machinery Directive (WILO pump)

Employed standards:

EN 60730-1: 2011

Automatic electrical controls for household and similar use –

Part 1: General requirements

EN 61000-6-3: 2007

+A1: 2011

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission standard for residential, commercial and light-industrial environments

EN 61000-6-2: 2005

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments

For WILO pump: EN 809, EN ISO 12100-1, EN ISO 12100-2, EN ISO 14121-1, EN 60335-1, EN

60335-2-51, EN 61800-3, EN 61800-5-1

Position of CE - label: On packaging, manual and type label

Issuer:

Technische Alternative elektronische SteuerungsgerätegesmbH.

A- 3872 Amaliendorf, Langestraße 124

This declaration is submitted by

Kurt Fichtenbauer, General manager,

19.11.2012

This declaration certifies the agreement with the named standards, contains however no warranty of

characteristics.

The security advices of included product documents are to be considered.

Guarantee conditions

Note: The following guarantee conditions do not in any way limit the legal right to a guarantee, rather

expand your rights as a consumer.

1. The company Technische Alternative elektronische Steuerungsgerätegesellschaft m. b. H.

provides a two-year guarantee from the date of purchase by the end consumer for all the devices and parts which it sells. Defects must be reported immediately upon detection and within

the guarantee period. Technical support knows the correct solution for nearly all problems. In

this respect, contacting us immediately will help to avoid unnecessary expense or effort in

troubleshooting.

2. The guarantee includes the free of charge repair (but not the cost of on-site fault-finding, removal, refitting and shipping) of operational and material defects which impair operation. In the

event that a repair is not economically worthwhile according to the assessment of Technische

Alternative, the goods will be replaced.

3. Not included is damage resulting from the effects of overvoltages or abnormal ambient conditions. Likewise, no guarantee liability can be accepted if the device defect is due to: transport

damage for which we are not responsible, incorrect installation and assembly, incorrect use,

non-observance of operating and installation instructions or incorrect maintenance.

4. The guarantee claim will expire if repairs or actions are carried out by persons who are not authorised to do so or have not been so authorised by us or if our devices are operated with

spare, supplementary or accessory parts which are not considered to be original parts.

5. The defective parts must be sent to our factory with an enclosed copy of the proof of purchase

and a precise description of the defect. Processing is accelerated if an RMA number is applied

for via our home page www.ta.co.at. A prior clarification of the defect with our technical support is necessary.

6. Services provided under guarantee result neither in an extension of the guarantee period nor

in a resetting of the guarantee period. The guarantee period for fitted parts ends with the

guarantee period of the whole device.

7. Extended or other claims, especially those for compensation for damage other than to the device itself are, insofar as a liability is not legally required, excluded.

Legal notice

These assembly and operating instructions are protected by copyright.

Use outside the copyright requires the consent of the company Technische Alternative elektronische

Steuerungsgerätegesellschaft m. b. H.. This applies in particular to reproductions, translations and

electronic media.

elektronische Steuerungsgerätegesellschaft m. b. H.

A-3872 Amaliendorf Langestraße 124

Tel +43 (0)2862 53635 Fax +43 (0)2862 53635 7

E-Mail: mail@ta.co.at --- www.ta.co.at --- © 2014

Loading...

Loading...