Special Documentation

Proline Promass 300

EtherNet/IP

Web Server

SD02129O/06/EN/01.17

Valid as of version 01.00.zz (Device rmware)

71382455

MANUAL

Important

All information and technical specications in this documentation have been carefully checked and compiled by

the author. However, we cannot completely exclude the possibility of errors. TechnipFMC is always grateful to be

informed of any errors. Contact us on the website.

Smith Meter® is a registered trademark of TechnipFMC.

Technical Support

Contact Information:

Field Service Response Center

24/7 Technical Support/Schedule a Technician: 1-844-798-3819

System Installation Supervision, Start-Up, and Commissioning Services Available

Customer Support

Contact Information:

Customer Service

TechnipFMC

1602 Wagner Avenue

Erie, Pennsylvania 16510 USA

P: +1 814 898-5000

F: +1 814 899-8927

measurement.solutions@TechnipFMC.com

TechnipFMC.com

Literature Library:

http://fmctechnologies.com/en/MeasurementSolutions/OnlineServices.aspx

Proline Promass 300 EtherNet/IP Table of contents

Table of contents

1 About this document ................ 4

1.1 Document function ..................... 4

1.2 Target group .......................... 4

1.3 Using this document .................... 4

1.4 Symbols used .......................... 5

2 Basic safety instructions ............ 6

2.1 Requirements for personnel ............... 6

2.2 Designated use ........................ 6

2.3 Occupational safety ..................... 6

2.4 Operational safety ...................... 6

2.5 Product safety ......................... 6

2.6 IT security ............................ 7

2.7 Device-specific IT security ................. 7

3 Product features and availability ..... 8

3.1 Product features ....................... 8

3.2 Availability ........................... 8

3.3 Identification in the measuring device ....... 8

4 Commissioning ..................... 9

4.1 Prerequisites - computer ................. 9

4.2 Prerequisites - measuring device .......... 15

4.3 Connecting the computer to the measuring

device .............................. 16

4.4 Establishing a connection to the Web

server .............................. 19

4.5 Setting the IP address .................. 21

4.6 Overview of the Web server parameters ..... 21

5 Operation options ................. 24

5.1 Logging on .......................... 25

5.2 User interface ........................ 26

5.3 Logging out .......................... 27

5.4 Addressing Ethernet-based fieldbuses ...... 27

6 Diagnostics and troubleshooting ... 30

6.1 General Web server troubleshooting ........ 30

6.2 Diagnostic information in the Web browser .. 31

6.3 Diagnostic information in the measuring

device .............................. 33

6.4 Checking the network connection .......... 33

7 Technical data .................... 34

3

About this document Proline Promass 300 EtherNet/IP

1 About this document

1.1 Document function

This manual is a Special Documentation; it does not replace the Operating Instructions

pertaining to the device. It serves as a reference for using the Web server integrated in the

measuring device.

1.2 Target group

The document is aimed at specialists who work with the device over the entire life cycle

and perform specific configurations.

1.3 Using this document

1.3.1 Information on the document structure

This Special Documentation contains a range of information, including:

• Prerequisites for use on the computer and measuring device

• Connection of the computer via the service interface, WLAN interface or Ethernet-based

fieldbus

• Configuration of the communication interface

• Establishing a connection

• Diagnostics and troubleshooting

The information and safety instructions in the Operating Instructions pertaining to

the measuring device must always be observed → 4.

1.3.2 Device documentation

The Technical Documentation for the measuring device is available:

• On the CD-ROM supplied with the measuring device (depending on the device version,

the CD-ROM might not be part of the delivery!)

• Via the W@M Device Viewer: enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• Via the Endress+Hauser Operations App: enter the serial number from the nameplate or

scan the 2-D matrix code (QR code) on the nameplate.

Technical documentation can also be downloaded from the Download Area of the

Endress+Hauser web site: www.endress.com → Download. However this technical

documentation applies to a particular instrument family and is not assigned to a

specific measuring device.

4

Proline Promass 300 EtherNet/IP About this document

DANGER

WARNING

CAUTION

NOTICE

A

1.

1.

1.4 Symbols used

1.4.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.4.2 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are allowed.

Forbidden

Indicates procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Notice or individual step to be observed

, 2., 3.… Series of steps

Result of a step

1.4.3 Symbols in graphics

Symbol Meaning

1, 2, 3,... Item numbers

, 2., 3.… Series of steps

5

Basic safety instructions Proline Promass 300 EtherNet/IP

2 Basic safety instructions

2.1 Requirements for personnel

Personnel involved in installation, commissioning, diagnostics and maintenance must

meet the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the

application)

Follow instructions and comply with basic conditions

‣

Operating personnel must meet the following requirements:

Be instructed and authorized by the plant operator with regard to the requirements of

‣

the task

Follow the instructions in this manual

‣

2.2 Designated use

The designated use of the measuring device is described in the Operating Instructions

pertaining to the device → 4.

2.3 Occupational safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

If working on and with the device with wet hands:

It is recommended to wear gloves on account of the higher risk of electric shock.

‣

2.4 Operational safety

Risk of injury!

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Modifications to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

2.5 Product safety

This device is designed in accordance with good engineering practice to meet state-of-theart safety requirements, has been tested, and left the factory in a condition in which it is

safe to operate.

6

Proline Promass 300 EtherNet/IP Basic safety instructions

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

2.6 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

2.7 Device-specific IT security

The device offers a range of specific functions to support protective measures on the

operator's side. These functions can be configured by the user and guarantee greater inoperation safety if used correctly.

2.7.1 Access via CDI-RJ45 service interface

The device can be connected to a network via the CDI-RJ45 service interface. Devicespecific functions guarantee the secure operation of the device in a network.

It is advisable to take relevant security concepts into consideration, such as those issued by

the Federal Office for Information Security. This includes organizational security measures

such as the assignment of access authorization as well as technical measures such as

network segmentation.

The device can be integrated in a ring topology. The device is integrated via the

terminal connection for signal transmission (output 1) and the connection to the

service interface (CDI-RJ45) .

7

Product features and availability Proline Promass 300 EtherNet/IP

Service Int. (CDI)

IP 192.168.1.212

1

2

3 Product features and availability

3.1 Product features

Thanks to the integrated Web server, the device can be operated and configured via a Web

browser and via a service interface (CDI-RJ45) or via a WLAN interface. The structure of

the operating menu is the same as for the local display. In addition to the measured values,

status information on the device is also displayed and allows the user to monitor the status

of the device. Furthermore the device data can be managed and the network parameters

can be configured.

A device that has a WLAN interface (can be ordered as an option) is required for the

WLAN connection: order code for "Display; operation", option G "4-line, illuminated; touch

control + WLAN". The device acts as an Access Point and enables communication by

computer or a mobile handheld terminal.

3.2 Availability

The integrated Web server is a standard feature. It does not need to be ordered for the

device ex works as it is provided as standard when the device is delivered to the customer.

No particular measures are required to put the feature into operation.

3.3 Identification in the measuring device

An adhesive label on the inside of the electronics compartment cover or the connection

compartment describes all the available hardware components, and their functions, for the

measuring device. The service interface (CDI-RJ45) has the following identification:

A0030874

1 Example of the CDI-RJ45 service interface

1 Symbol for service interface

2 Information on the default setting for the WLAN IP address

8

Proline Promass 300 EtherNet/IP Commissioning

4 Commissioning

Establishing a connection to the integrated Web server

1. Configure the computer → 9.

2. Check the settings on the measuring device and change them if necessary → 15.

3. Connect the measuring device to the computer .

4. Establish a connection to the Web server → 19.

5. Start the Web browser and access the operating menu → 20.

The measuring device can be operated via the Web server.

4.1 Prerequisites - computer

4.1.1 Hardware

Hardware Interface

CDI-RJ45 WLAN

Interface The computer must have an RJ45

interface.

Connection Standard Ethernet cable with RJ45

connector.

Screen Recommended size: ≥12" (depends on the screen resolution)

The operating unit must have a

WLAN interface.

Connection via Wireless LAN.

4.1.2 Software

Software Interface

CDI-RJ45 WLAN

Recommended operating

systems

Web browsers supported • Microsoft Internet Explorer 8 or higher

• Microsoft Windows 7 or higher.

• Mobile operating systems:

– iOS

– Android

Microsoft Windows XP is supported.

• Microsoft Edge

• Mozilla Firefox

• Google Chrome

• Safari

4.1.3 Configuring the computer

User rights Appropriate user rights (e.g. administrator rights) for TCP/IP and proxy server

settings are necessary (for adjusting the IP address, subnet mask etc.).

Proxy server settings of the

Web browser

The Web browser setting Use a Proxy Server for Your LAN must be

deselected .

9

Commissioning Proline Promass 300 EtherNet/IP

JavaScript JavaScript must be enabled.

If JavaScript cannot be enabled:

enter http://192.168.1.212/basic.html in the address line of the Web

browser. A fully functional but simplified version of the operating menu

structure starts in the Web browser.

When installing a new firmware version: To enable correct data display,

clear the temporary memory (cache) of the Web browser under Internet

options.

Network connections Only the active network connections to the measuring device should be used.

Switch off all other network connections such as WLAN.

10

Proline Promass 300 EtherNet/IP Commissioning

adapter

Configuring IP settings for Windows

• To configure the IP settings, appropriate user rights (e.g. administrator rights) are

required for the computer.

• Before configuring the IP settings, close all the windows of the Web browser.

1. Click Start (Windows icon).

The Start menu appears.

2. In the Start menu, select Control Panel.

This opens a new window with the control panel elements.

3. Enter the term "adapter" in the search field.

The Network and Sharing Center is listed in the search results.

4. Select the Network Connections option under Network and Sharing Center.

This opens a new window with the network connections.

5. In this window, select the Local Area Connection (LAN).

A0024277

A0024293

11

Commissioning Proline Promass 300 EtherNet/IP

6. Right-click to open the picklist and select Properties.

The Local Area Connection Properties dialog box opens.

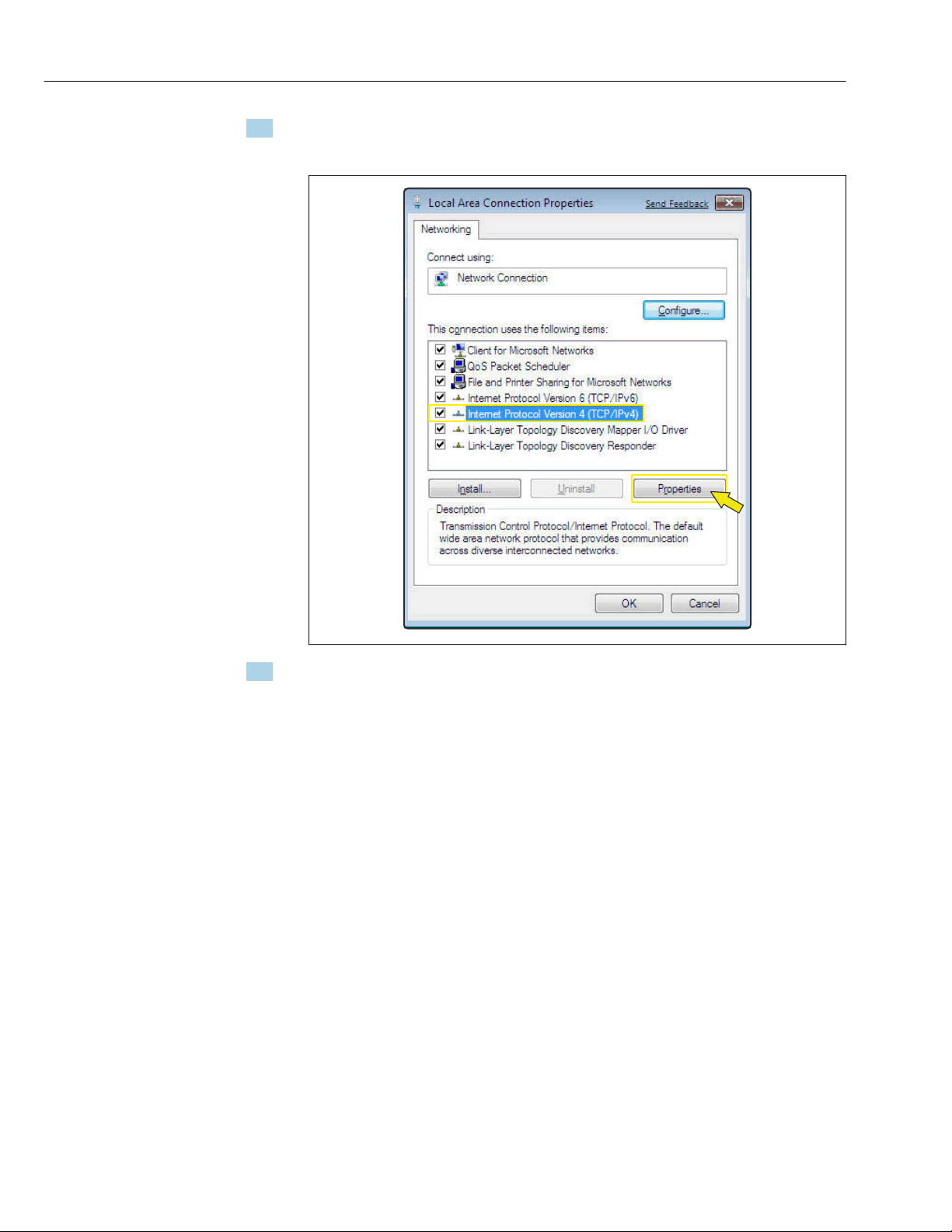

7. Select the Internet Protocol Version 4 (TCP/IPv4) item.

A0024300

12

Proline Promass 300 EtherNet/IP Commissioning

8. Click the Properties button.

The Internet Protocol Version 4 (TCP/IPv4) Properties window opens.

A0024309

9. In the General tab, select the Use the Following IP Address option.

10. Enter the IP address, subnet mask and default gateway as indicated in the following

table and then click Ok to confirm.

Standard settings for IP address, subnet mask and default gateway

IP address 192.168.1.XXX

For XXX all numerical sequences except: 0, 212 and 255 → e.g.

192.168.1.213

Subnet mask 255.255.255.0

Default gateway 192.168.1.212 or leave cells empty

The standard settings correspond to those for private networks. In the case of

Ethernet-based networks, the settings can deviate from these standard settings and

must be changed if necessary.

13

Commissioning Proline Promass 300 EtherNet/IP

Changing the proxy server settings

To establish communication, the proxy server setting Use a Proxy Server for Your LAN must

be deselected for the Web browser.

To change the proxy server setting, appropriate user rights (e.g. administrator rights)

are required for the computer.

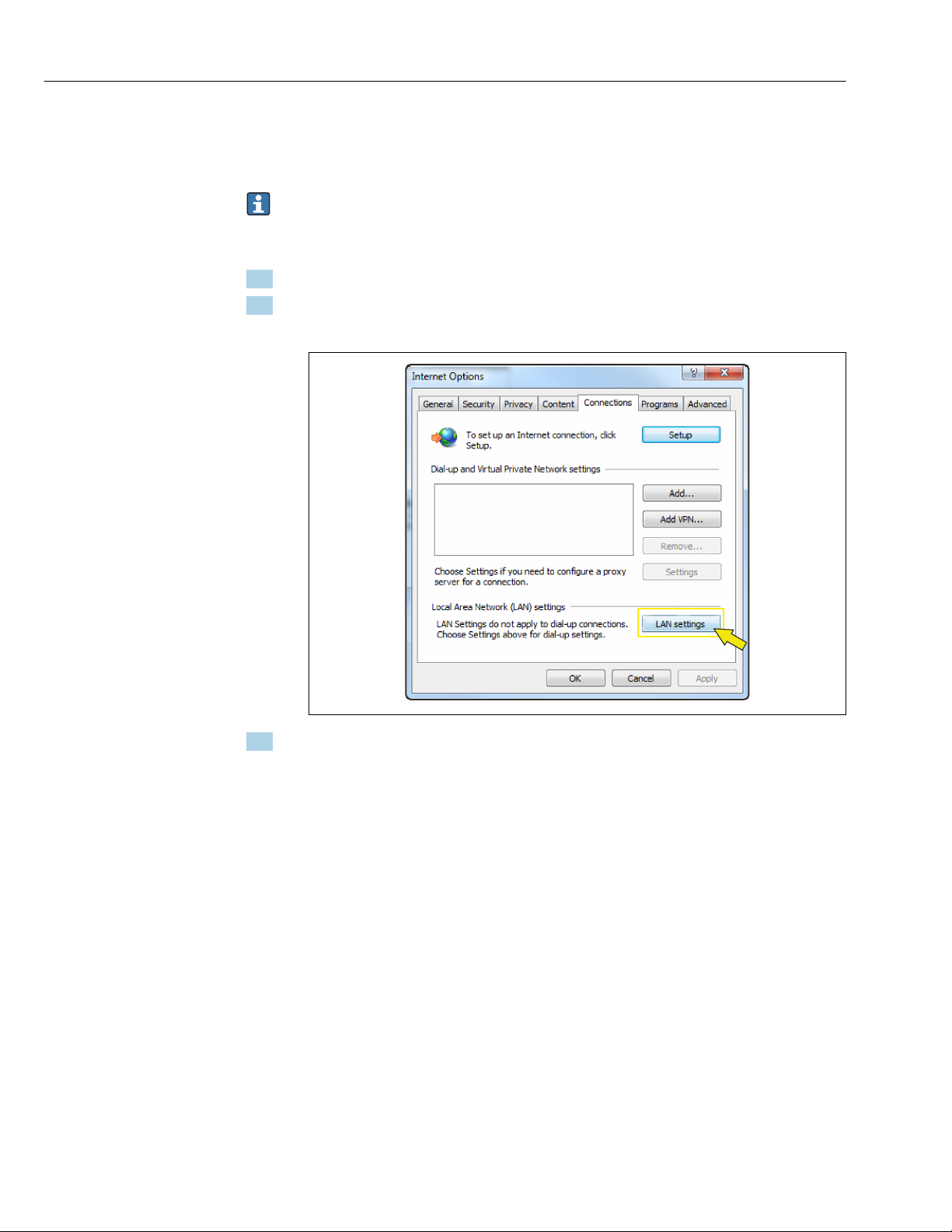

Changing the proxy server settings taking Internet Explorer as the sample browser

1. Open the Web browser.

2. In the Options menu, select the Internet Options item.

This opens a new window with the Internet options.

3. Select the Connections tab.

A0024310

14

Proline Promass 300 EtherNet/IP Commissioning

4. Under Local Area Network Settings click the LAN Settings button.

This opens a new window with the Local Area Network Settings.

A0024311

5. Deselect the Use a Proxy Server for Your LAN checkbox and then click Ok to confirm.

4.2 Prerequisites - measuring device

4.2.1 Enabling the Web server

The Web server must be enabled in the measuring device (factory setting).

If the Web server is disabled it be enabled again via the Web server functionality

parameter (→ 23). To do so, users can choose from the following operation options:

• Local display

• Operating tool e.g. FieldCare, DeviceCare, AMS Device Manager , SIMATIC PDM

4.2.2 Determining the IP address of the measuring device

The IP address of the measuring device is required to establish communication between

the measuring device (Web server) and a computer (client). The IP address used depends

on the setting of the DIP switches or on the system settings.

The IP address can be assigned to the measuring device in a variety of ways:

• Dynamic Host Configuration Protocol (DHCP), factory setting:

The IP address is automatically assigned to the measuring device by the automation

system (DHCP server).

• Hardware addressing:

The IP address is set via DIP switches

• Software addressing:

The IP address is entered via the IP address parameter (→ 23)

• DIP switch for "Default Ethernet Network Settings":

For establishing the network connection via the service interface (CDI-RJ45). The fixed

IP address 192.168.1.212 is used .

15

Commissioning Proline Promass 300 EtherNet/IP

IP address

assigned or

specified via:

Dynamic Host

Configuration Protocol

(DHCP), factory setting

Hardware addressing of

the IP address via DIP

switches

Software addressing of

the IP address via the IP

address parameter

DIP switch for "Default

Ethernet Network

Settings", use the fixed IP

address: 192.168.1.212

Determine IP address settings via parameters or DIP switches

Local display

(if available)

Operating tool e.g.

FieldCare, DeviceCare,

AMS Device Manager,

SIMATIC PDM

DIP switches in

electronics compartment

Position of the DIP switches → 8

Using the local display or an operating tool

The IP address parameter can be used to determine the IP address via the local display or

via an operating tool e.g. FieldCare, DeviceCare, AMS Device Manager, SIMATIC PDM.

4.3 Connecting the computer to the measuring device

The measuring device can be connected to the computer via:

• Service interface (CDI-RJ45)

• WLAN interface

• Ethernet-based fieldbuses

4.3.1 Via service interface (CDI-RJ45)

Preparing the measuring device

1. Depending on the housing version:

Release the securing clamp or securing screw of the housing cover.

2. Depending on the housing version:

Unscrew or open the housing cover.

3. The location of the connection socket depends on the measuring device and the

communication protocol:

Connect the computer to the RJ45 connector via the standard Ethernet connecting

cable → 8.

16

Proline Promass 300 EtherNet/IP Commissioning

Configuring the Internet protocol of the computer

NOTICE

Risk of electric shock! Components carry dangerous voltages!

Never open the measuring device while it is connected to the supply voltage.

‣

The information and safety instructions in the Operating Instructions pertaining to the

‣

measuring device must always be observed → 4.

The IP address can be assigned to the measuring device in a variety of ways:

• Dynamic Host Configuration Protocol (DHCP), factory setting:

The IP address is automatically assigned to the measuring device by the automation

system (DHCP server).

• Hardware addressing:

The IP address is set via DIP switches .

• Software addressing:

The IP address is entered via the IP address parameter (→ 23) .

• DIP switch for "Default IP address":

To establish the network connection via the service interface (CDI-RJ45): the fixed IP

address 192.168.1.212 is used .

The measuring device works with the Dynamic Host Configuration Protocol (DHCP), on

leaving the factory, i.e. the IP address of the measuring device is automatically assigned by

the automation system (DHCP server).

To establish a network connection via the service interface (CDI-RJ45): the "Default IP

address" DIP switch must be set to ON. The measuring device then has the fixed IP address:

192.168.1.212. This address can now be used to establish the network connection.

If the IP address of the measuring device is assigned via hardware or software

addressing and the IP address is known, the network connection can also be

established directly via the Ethernet network → 16.

1. Via DIP switch 2, activate the default IP address 192.168.1.212: .

2. Switch on the measuring device.

3. Connect to the computer using a cable → 8.

4. If a 2nd network card is not used, close all the applications on the notebook.

Applications requiring Internet or a network, such as e-mail, SAP applications,

Internet or Windows Explorer.

5. Close any open Internet browsers.

6. Configure the properties of the Internet protocol (TCP/IP) as defined in the table:

IP address 192.168.1.XXX; for XXX all numerical sequences except: 0, 212 and 255 → e.g.

192.168.1.213

Subnet mask 255.255.255.0

Default gateway 192.168.1.212 or leave cells empty

4.3.2 Via WLAN interface

Configuring the Internet protocol of the mobile terminal

NOTICE

If the WLAN connection is lost during the configuration, settings made may be lost.

Make sure that the WLAN connection is not disconnected while configuring the device.

‣

17

Commissioning Proline Promass 300 EtherNet/IP

NOTICE

In principle, avoid simultaneous access to the measuring device via the service

interface (CDI-RJ45) and the WLAN interface from the same mobile terminal. This

could cause a network conflict.

Only activate one service interface (CDI-RJ45 service interface or WLAN interface).

‣

If simultaneous communication is necessary: configure different IP address ranges, e.g.

‣

192.168.0.1 (WLAN interface) and 192.168.1.212 (CDI-RJ45 service interface).

Preparing the mobile terminal

Enable WLAN reception on the mobile terminal.

‣

Establishing a connection from the mobile terminal to the measuring device

1. In the WLAN settings of the mobile terminal:

Select the measuring device using the SSID (e.g. EH_Promass_300_A802000).

2. If necessary, select the WPA2 encryption method.

3. Enter the password: serial number of the measuring device ex-works (e.g.

L100A802000).

LED on display module flashes: it is now possible to operate the measuring device

with the Web browser.

The serial number can be found on the nameplate.

To ensure the safe and swift assignment of the WLAN network to the measuring

point, it is advisable to change the SSID name. It should be possible to clearly assign

the new SSID name to the measuring point (e.g. tag name) because it is displayed as

the WLAN network.

Disconnecting

After configuring the device:

‣

Terminate the WLAN connection between the operating unit and measuring device.

18

Proline Promass 300 EtherNet/IP Commissioning

4

21 3

5 5 5

4.3.3 Via Ethernet-based fieldbus

If the IP address of the measuring device is assigned via hardware or software addressing,

the network connection can be established directly via the Ethernet network.

The device is configured at the factory to work with the Dynamic Host Configuration

Protocol (DHCP), i.e. the IP address of the measuring device is automatically assigned

by the automation system (DHCP server). To establish a network connection via the

service interface (CDI-RJ45): the "Default Ethernet network settings" DIP switch must

be set to ON. The measuring device then has the fixed IP address: 192.168.1.212.

This address can now be used to establish the network connection → 16.

2 Ethernet network

1 Automation system, e.g. "RSLogix" (Rockwell Automation)

2 Workstation for measuring device operation: with Add-on Profile Level 3 for "RSLogix 5000" (Rockwell

Automation) or with Electronic Data Sheet (EDS)

3 Computer with Web browser (e.g. Internet Explorer) for accessing the integrated device Web server or with

operating tool (e.g. FieldCare, DeviceCare) with COM DTM "CDI Communication TCP/IP"

4 Ethernet switch

4.4 Establishing a connection to the Web server

4.4.1 Prerequisites

The IP settings in the measuring device and computer must match before a connection can

be established successfully. In particular this concerns the IP addressing and Web browser

settings.

The following conditions must be met to connect:

• The Web server of the measuring device is enabled → 15.

• The IP address of the measuring device is known → 15.

• The computer used meets the requirements for hardware and software → 9.

• The measuring device and computer are connected to one another → 16

• The measuring device is switched on.

A0016961

19

Commissioning Proline Promass 300 EtherNet/IP

4.4.2 Starting the Web browser

If JavaScript cannot be enabled:

enter http://192.168.1.212/basic.html in the address line of the Web browser. A

fully functional but simplified version of the operating menu structure starts in the

Web browser.

When installing a new firmware version: To enable correct data display, clear the

temporary memory (cache) of the Web browser under Internet options.

Prerequisite: The IP address of the measuring device is known.

1. Start the Web browser on the computer.

2. Enter the defined device address in the address line of the Web browser.

The login page appears.

Prerequisite: The IP address of the measuring device is not known.

1. Start the Web browser on the computer.

2. Read out the IP address via local operation (Diagnostics → Device information → IP

address).

3. Or set the upper DIP switch No. 2 to ON.

4. Restart the device.

5. Enter the default IP address 192.168.1.212 .

The login page appears.

If a login page does not appear, or if the page is incomplete → 30

20

Proline Promass 300 EtherNet/IP Commissioning

4.5 Setting the IP address

The IP address of the measuring device is required to establish communication between

the measuring device (Web server) and a computer (client). There are various options to

assign or specify the IP address depending on the hardware and software settings.

Assign or specify the IP

address via:

DHCP (Dynamic Host

Configuration

Protocol)

Hardware addressing • The measuring device uses the IP address configured via the "IP address setting"

Software addressing The measuring device uses the IP address configured in the IP address parameter

Use of the DIP switch:

Default Ethernet

Network Settings

1) Factory setting

2) For a temporary connection when servicing, for example, or if the IP address is not known. The measuring

1)

2)

device is disconnected from the network/automation system.

Description

• The measuring device is automatically assigned the IP address by the

automation system.

• DHCP client (→ 23)

DIP switches.

• "IP address setting" DIP switch = ON/OFF, depending on the address

(→ 23)

• The measuring device uses the fixed IP address: 192.168.1.212

• DIP switch: default Ethernet network settings = ON

• The device is connected via the CDI-RJ45 service interface.

• Following a restart, the measuring device can be connected via the CDI-RJ45

service interface or via the Ethernet network.

• To avoid conflict between IP addresses, the DIP switch should never be used

simultaneously on two measuring devices in the same Ethernet network.

4.6 Overview of the Web server parameters

4.6.1 Language

Navigation

"Operation" menu → Web server language

21

Commissioning Proline Promass 300 EtherNet/IP

Parameter overview with brief description

Parameter Description Selection Factory setting

Web server language Set web server language. • English

• Deutsch

• Français

• Español

• Italiano

• Nederlands

• Portuguesa

• Polski

• русский язык (Russian)

• Svenska

• Türkçe

• 中文 (Chinese)

• 日本語 (Japanese)

• 한국어 (Korean)

• Bahasa Indonesia

• tiếng Việt (Vietnamese)

• čeština (Czech)

* Visibility depends on order options or device settings

*

*

*

*

*

*

*

*

*

*

*

*

*

*

English

*

*

4.6.2 "Configuration" submenu

Navigation

"Expert" menu → Communication → Configuration

Configuration

‣

Configurable input assembly

‣

Web server language (7221)

MAC address (7214)

Default network settings (7401)

DHCP client (7212)

IP address (7209)

Subnet mask (7211)

→ 23

→ 23

→ 23

→ 23

→ 23

→ 23

22

Default gateway (7210)

Web server functionality (7222)

Login page (7273)

→ 23

→ 23

Proline Promass 300 EtherNet/IP Commissioning

Capability flags (7439)

User description (7432)

Parameter overview with brief description

Parameter Description Selection / User interface /

User entry

Web server language Set web server language. • English

• Deutsch

• Français

• Español

• Italiano

• Nederlands

• Portuguesa

• Polski

• русский язык (Russian)

• Svenska

• Türkçe

• 中文 (Chinese)

• 日本語 (Japanese)

• 한국어 (Korean)

• Bahasa Indonesia

• tiếng Việt (Vietnamese)

• čeština (Czech)

MAC address Displays the MAC address of the measuring

device.

MAC = Media Access Control

Unique 12-digit character

string comprising letters and

numbers, e.g.:

00:07:05:10:01:5F

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Default network settings Select whether to restore network settings. • Off

• On

DHCP client Select to activate/deactivate DHCP client

functionality.

• Off

• On

Result

If the DHCP client functionality of the Web

server is activated, the IP address, Subnet

mask and Default gateway are set

automatically.

Identification is via the MAC address

of the measuring device.

IP address Displays the IP address of the Web server of

the measuring device.

4 octet: 0 to 255 (in the

particular octet)

Subnet mask Displays the subnet mask. 4 octet: 0 to 255 (in the

particular octet)

Default gateway Displays the default gateway. 4 octet: 0 to 255 (in the

particular octet)

Web server functionality Switch the Web server on and off. • Off

• HTML Off

• On

Factory setting

English

*

*

Each measuring device is given

an individual address.

Off

Off

192.168.1.212

255.255.255.0

0.0.0.0

On

* Visibility depends on order options or device settings

23

Operation options Proline Promass 300 EtherNet/IP

1

2 3

5 Operation options

A0031139

3 Example of a Proline flowmeter with an integrated Web server

1 Mobile end device with Web browser (e.g. Internet Explorer) and WLAN interface

2 Computer with Web browser (e.g. Internet Explorer), connection via cable or WLAN interface

3 Control station via network

24

Proline Promass 300 EtherNet/IP Operation options

6

7

8

9

10

1 52 3 4

5.1 Logging on

A0029417

1 Picture of device

2 Device name

3 Device tag

4 Status signal

5 Current measured values

6 Web server language

7 User role

8 Access code

9 Login

10 Reset access code

1. Select the required operating language for the Web browser (6).

2. Enter the user-specific access code (8).

3. Confirm entry with Login(9).

Access code 0000 (factory setting); can be changed by customer

If no action is performed for 10 minutes, the Web browser automatically returns to

the login page.

25

Operation options Proline Promass 300 EtherNet/IP

2

1

3

5.2 User interface

A0029418

1 Function row

2 Local display language

3 Navigation area

5.2.1 Header

The following information appears in the header:

• Device name

• Device tag

• Device status with status signal → 32

• Current measured values

26

5.2.2 Function row

Functions Meaning

Measured values Displays the measured values of the measuring device

• Access to the operating menu from the measuring device

Menu

Device status Displays the diagnostic messages currently pending, listed in order of priority

Data

management

Network

configuration

Logout End the operation and call up the login page

• The structure of the operating menu is the same as for the local display

For detailed information on the structure of the operating menu, see the Operating

Instructions for the measuring device

Data exchange between PC and measuring device:

• Device configuration:

– Load settings from the device

(XML format, save configuration)

– Save settings to the device

(XML format, restore configuration)

• Logbook - Export Event logbook (.csv file)

• Documents - Export documents:

– Export backup data record

(.csv file, create documentation of the measuring point configuration)

– Verification report

(PDF file, only available with the "Heartbeat Verification" application package)

• File for system integration - If using fieldbuses, upload device drivers for system

integration from the measuring device:

EtherNet/IP: EDS file

• Firmware update - Flashing a firmware version

Configuration and checking of all the parameters required for establishing the connection to

the measuring device:

• Network settings (e.g. IP address, MAC address)

• Device information (e.g. serial number, firmware version)

Proline Promass 300 EtherNet/IP Operation options

5.2.3 Navigation area

If a function is selected in the function bar, the submenus of the function open in the

navigation area. The user can now navigate through the menu structure.

5.2.4 Working area

Depending on the selected function and the related submenus, various actions can be

performed in this area:

• Configuring parameters

• Reading measured values

• Calling up help text

• Starting an upload/download

5.3 Logging out

Before logging out, perform a data backup via the Data management function

(upload configuration from device) if necessary.

1. Select the Logout entry in the function row.

The home page with the Login box appears.

2. Close the Web browser.

3. If no longer needed:

Reset modified properties of the Internet protocol (TCP/IP) → 17.

If communication with the Web server was established via the default IP address

192.168.1.212, DIP switch No. 10 must be reset (from ON → OFF). Afterwards, the IP

address of the device is active again for network communication.

5.4 Addressing Ethernet-based fieldbuses

5.4.1 Setting the device address

The IP address of the measuring device can be configured for the network via DIP switches.

Addressing data

IP address and configuration options

1st octet 2nd octet 3rd octet 4th octet

192. 168. 1. XXX

↓ ↓

Can only be configured via software addressing Can be configured via software addressing

and hardware addressing

IP address range 1 to 254 (4th octet)

IP address broadcast 255

27

Operation options Proline Promass 300 EtherNet/IP

1

2

3

4

5

6

7

8

128

64

32

16

8

4

2

1

IP Address setting

(last octet)

Addressing mode ex

works

IP address ex works DHCP server active

Software addressing; all DIP switches for hardware addressing are set to OFF.

Software addressing: The IP address is entered via the IP address parameter

(→ 23).

Setting the IP address

Risk of electric shock when opening the transmitter housing.

Before opening the transmitter housing:

‣

Disconnect the device from the power supply.

‣

The default IP address may not be activated .

A0029635

1. Depending on the housing version, loosen the securing clamp or fixing screw of the

housing cover.

2. Depending on the housing version, unscrew or open the housing cover and

disconnect the local display from the main electronics module where necessary.

3. Set the desired IP address using the corresponding DIP switches on the I/O

electronics module.

4. Reverse the removal procedure to reassemble the transmitter.

5. Reconnect the device to the power supply.

The configured device address is used once the device is restarted.

5.4.2 Activating the default IP address

The DHCP function is enabled in the device at the factory, i.e. the device expects an IP

address to be assigned by the network. This function can be disabled and the device can be

set to the default IP address 192.168.1.212 by DIP switch.

Activating the default IP address via the DIP switch

Risk of electric shock when opening the transmitter housing.

Before opening the transmitter housing:

‣

Disconnect the device from the power supply.

‣

28

Proline Promass 300 EtherNet/IP Operation options

On

Off

4

3

1

2

A0034499

1. Depending on the housing version, loosen the securing clamp or fixing screw of the

housing cover.

2. Depending on the housing version, unscrew or open the housing cover and

disconnect the local display from the main electronics module where necessary .

3. Set DIP switch No. 2 on the I/O electronics module from OFF → ON.

4. Reverse the removal procedure to reassemble the transmitter.

5. Reconnect the device to the power supply.

The default IP address is used once the device is restarted.

29

Diagnostics and troubleshooting Proline Promass 300 EtherNet/IP

6 Diagnostics and troubleshooting

For details on the diagnostic information, see the Operating Instructions for the

device → 4.

6.1 General Web server troubleshooting

For access

Error Possible causes Solution

Not connecting to Web server Web server disabled Using the "FieldCare" or "DeviceCare"

operating tool, check whether the

Web server of the measuring device

is enabled, and enable it if

necessary.

Incorrect setting for the Ethernet

interface of the computer

Not connecting to Web server • Incorrect IP address

• IP address is not known

Web browser setting "Use a Proxy

Server for Your LAN" is enabled

Apart from the active network

connection to the measuring device,

other network connections are also

being used.

Not connecting to Web server Incorrect WLAN access data • Check WLAN network status.

1. Check the properties of the

Internet protocol (TCP/IP) → 17.

2. Check the network settings with

the IT manager.

1. If addressing via hardware: open

the transmitter and check the IP

address configured (last octet).

2. Check the IP address of the

measuring device with the network

manager.

3. If the IP address is not known,

set DIP switch no. 10 to ON, restart

the device and enter the factory IP

address 192.168.1.212.

EtherNet/IP communication

is interrupted by enabling the

DIP switch.

Disable the use of the proxy server

in the Web browser settings of the

computer.

Using the example of MS Internet

Explorer:

1. Under Control Panel open

Internet options.

2. Select the Connections tab and

then double-click LAN settings.

3. In the LAN settings disable the

use of the proxy server and select

OK to confirm.

• Make sure that no other network

connections are established by

the computer (also no WLAN)

and close other programs with

network access to the computer.

• If using a docking station for

notebooks, make sure that a

network connection to another

network is not active.

• Log on to the device again using

WLAN access data.

• Verify that WLAN is enabled on

the measuring device and

operating device .

30

Proline Promass 300 EtherNet/IP Diagnostics and troubleshooting

Error Possible causes Solution

WLAN communication disabled –

Not connecting to Web server,

FieldCare or DeviceCare

Network connection not present or

unstable

Web browser frozen and operation

no longer possible

Content of Web browser

incomplete or difficult to read

No or incomplete display of

contents in the Web browser

No WLAN network available • Check if WLAN reception is

present: LED on display module

is lit blue

• Check if WLAN connection is

enabled: LED on display module

flashes blue

• Switch on instrument function.

WLAN network is weak. • Operating device is outside of

reception range: Check network

status on operating device.

• To improve network

performance, use an external

WLAN antenna.

Parallel WLAN and Ethernet

communication

Data transfer active Wait until data transfer or current

Connection lost 1. Check cable connection and

Not using optimum version of Web

server.

Unsuitable view settings. Change the font size/display ratio

• JavaScript not enabled

• JavaScript cannot be enabled

• Check network settings.

• Temporarily enable only the

WLAN as an interface.

action is finished.

power supply.

2. Refresh the Web browser and

restart if necessary.

1. Use the correct Web browser

version .

2. Clear the Web browser cache and

restart the Web browser.

of the Web browser.

1. Enable JavaScript.

2. Enter http://XXX.XXX.X.XXX/

basic.html as the IP address.

6.2 Diagnostic information in the Web browser

6.2.1 Diagnostic options

Any faults detected by the measuring device are displayed in the Web browser on the

home page once the user has logged on.

31

Diagnostics and troubleshooting Proline Promass 300 EtherNet/IP

2 3

1

A0031056

1 Status area with status signal

2 Diagnostic information

3 Remedy information with Service ID

In addition, diagnostic events which have occurred can be shown in the Diagnostics

menu:

• Via parameter

• Via submenu

Status signals

The status signals provide information on the state and reliability of the device by

categorizing the cause of the diagnostic information (diagnostic event).

Symbol Meaning

Failure

A device error has occurred. The measured value is no longer valid.

Function check

The device is in service mode (e.g. during a simulation).

Out of specification

The device is operated:

Outside its technical specification limits (e.g. outside the process temperature range)

Maintenance required

Maintenance is required. The measured value is still valid.

The status signals are categorized in accordance with VDI/VDE 2650 and NAMUR

Recommendation NE 107.

32

6.2.2 Calling up remedy information

Remedy information is provided for every diagnostic event to ensure that problems can be

rectified quickly. These measures are displayed in red along with the diagnostic event and

the related diagnostic information.

Proline Promass 300 EtherNet/IP Diagnostics and troubleshooting

6.3 Diagnostic information in the measuring device

6.3.1 Overview of Web server information events

Unlike a diagnostic event, an information event is displayed in the event logbook only and

not in the diagnostic list.

Information event Event text

I1000 --------(device OK)

I1110 Write protection switch changed

I1361 Web server login failed

I1627 Web server login successful

I1631 Web server access changed

6.4 Checking the network connection

The network connection between the computer and measuring device can be checked

using the "ping" utility of the Internet Control Message Protocol (ICMP).

The "ping" utility sends ICMP(v6) "echo request" packets (ping, ICMP packet type 8

(0x08)) to the target address of the measuring device. According to the protocol

specification, the measuring device must send back a response: ICMP "echo reply"

(pong, ICMP packet type 0 (0x00)).

1. Click Start (Windows icon).

The Start screen opens along with the search field.

2. In the search field, enter "cmd" (command).

A link to "cmd.exe" is displayed in the results field.

3. Select the "cmd.exe" link.

A new command window opens.

4. Enter ping and the IP address, e.g.: ping 192.168.1.212

The network connection status is displayed.

Depending on the operating system used, or the version of the operating system,

other tools can also be used, such as Powershell.exe, prompt etc.

If the measuring device cannot be reached the router responsible delivers the following

response:

• "Network unreachable"

or

• "Host unreachable"

1. Check the IP address settings → 15.

2. Check whether the Web server is enabled → 15.

33

Technical data Proline Promass 300 EtherNet/IP

7 Technical data

Web server Stack: standard TCP stack with IPv4 functionality

Connection and session management • Open ports:

– 80 (HTTP for Web server)

– 8000 (for Endress+Hauser Service communication)

• Only one connection possible at any one time via Hypertext Transfer Protocol (HTTP)

• Time out after 10 minutes

Supported functions • Java Script

• Communication protocol: Dynamic Host Configuration Protocol (DHCP)

• Hypertext Markup Language (HTML)

• Cascading Style Sheets (CSS)

Functions not supported • Domain Name System (DNS)

• Hyper Text Transfer Protocol Secure (HTTPS)

34

The specications contained herein are subject to change without notice and any user of said specications should verify from the manufacturer that the specications are currently in effect. Otherwise, the manufacturer assumes no responsibility for the use of specications which may have been changed and are no longer in effect.

Contact information is subject to change. For the most current contact information, visit our website at TechnipFMC.com and click on the “Contact Us” link.

USA Operation

1602 Wagner Avenue

Erie, Pennsylvania 16510 USA

P:+1 814.898.5000

Germany Operation

Smith Meter GmbH

Regentstrasse 1

25474 Ellerbek, Germany

P:+49 4101 304.0

TechnipFMC.com

© TechnipFMC 2017 All rights reserved. SD02129O/06/EN/01.17

TechnipFMC

Measurement Solutions, Inc.

500 North Sam Houston Parkway West,

Suite 100

Houston, Texas 77067 USA

P:+1 281.260.2190

Loading...

Loading...