Page 1

V

V

e

e

c

c

t

t

o

o

r

r

L

L

E

E

D 11

D

6

6

0

0

S

S

p

p

o

o

t

t

Information specifically for:

DM-VectorLED160S

This manual contains important information.

Please read before operating fixture.

V1.0

Page 2

© 2010 Techni-Lux Inc.

2

Page 3

IMPORTANT INFORMATION

Save original packing and documentation for warranty, service and return issues.

Limited Warranty: This warranty covers defects or malfunctions in this equipment. This warranty lasts for

a period of one year from date of purchase. It is the owner’s responsibility to provide invoices for proof of

purchase, purchase date and dealer or distributor. If purchase date can not be provided, warranty period

will start at manufacture date. It is the sole discretion of Techni-Lux to repair or replace parts or

equipment. All shipping will be paid by purchaser. This warranty does not cover lamps, fuses, belts,

power semiconductors, relays, cleaning, standard maintenance adjustments or normal wear items or any

problem resulting from the following: improper wiring, incorrect voltage (including low or over voltage

conditions and lightning), abuse, misuse, improper maintenance or an act of God or damage resulting

from shipping. Warranty will be null and void if the product is altered, modified, misused, damaged, or

subjected to unauthorized repairs. Lamps are covered by relevant manufacturer warranty. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. Any

liability for consequential and incidental damages is expressly disclaimed. No other warranty, expressed

or implied is made. Techni-Lux liability in all events is limited to, and shall not exceed, the purchase

price paid.

Returning equipment and Repairs: All returns must be accompanied by a Return Merchandise

Authorization (RMA) number and sent pre-paid. Contact the dealer or Techni-Lux directly to obtain an

RMA. The RMA number must be clearly listed on the shipping label. Due care must be exercised in

packing all merchandise to be returned. All repairs must be accompanied by a written explanation of the

claimed problem or error encountered. Techni-Lux is solely responsible for determining a product’s

eligibility for coverage under warranty. If returning for consideration of credit, all accessories and

documentation, original protective material and cartons must be included and the equipment, packing

and carton must be in new resalable condition. Credit for returned merchandise will be issued at the

lowest current price and is subject to a restocking fee. No returns accepted on discontinued items.

Techni-Lux is not responsible for merchandise damaged in transit and reserves the right to refuse any

return that is damaged by the carrier, not accompanied by a Return Authorization Number (RMA#) or

sent by freight collect.

Claims: All claims must be made within seven (7) days of receipt of merchandise. Any physical damage

must be reported to carrier upon receipt of merchandise.

Please record the following information for future reference:

Model Number: DM-VectorLED160S

Serial Number: ________________________________________

Dealer: ______________________________________________

Date of Purchase: ______________________________________

www.Techni-Lux.com

10900 Palmbay Drive

Orlando, FL 32824

U.S.A.

3

Page 4

Table of Contents

Specifications .............................................................................................................................5

Fixture Overview.......................................................................................................................5

Physical.....................................................................................................................................5

Lamp Source.............................................................................................................................5

Environmental...........................................................................................................................6

Electrical ...................................................................................................................................6

Control ......................................................................................................................................6

Optics........................................................................................................................................6

Gobo Size.................................................................................................................................6

Rigging......................................................................................................................................6

Unit Parts.....................................................................................................................................7

Unpacking ...................................................................................................................................8

Power...........................................................................................................................................9

Voltage Selection........................................................................................................................9

LED Engine .................................................................................................................................9

Mounting ...................................................................................................................................10

Control Panel Menu..................................................................................................................11

DMX-512 Start Address............................................................................................................12

DMX-512 Channel Assignment................................................................................................12

CH 1 : Shutter / Strobe / Reset ............................................................................................... 13

CH 2 : Dimmer ........................................................................................................................13

CH 3 : Color Wheel.................................................................................................................13

CH 4 : Rotating Gobo Wheel................................................................................................... 14

CH 5 : Gobo Rotation and Index.............................................................................................14

CH 6 : Focus...........................................................................................................................15

CH 7 : Prism / Prism Rotation .................................................................................................15

CH 8-11 : Pan / Tilt Position....................................................................................................15

CH 12 : Pan / Tilt Speed, Auto, Sound....................................................................................15

DMX-512 Background...............................................................................................................16

Data Link DMX-512.................................................................................................................17

Adapter 5-to-3 pin ...................................................................................................................17

Data Terminator......................................................................................................................17

Maintenance..............................................................................................................................18

Troubleshooting .......................................................................................................................19

Accessory Items.......................................................................................................................20

4

Page 5

Specifications

Fixture Overview

• Long Life 60W LED Engine

• Pan range of movement: 540°

• Tilt range of movement: 270°

• High resolution 16 Bit Pan/Tilt movement for accurate positioning

• Pan/Tilt motor speed

• Consistent & auto correcting Pan/Tilt positioning

• Color wheel with 6+open dichroic colors

• Bi-directional Color wheel continuous rotation for rainbow effect

• Gobo wheel with 7+open rotating

• Continuous Gobo wheel rotation

• 3-facet rotating prism, variable speed in both directions

• Beam angle 11°

• Motorized focus

• Digital shutter for 0 – 20 FPS strobing effects and quick blackouts

• Digital dimming 0-100% for smooth fades and even fields

• DMX512 Control thru 12 Channels and 3 pin In/Out XLRs

• Remote reset

• Digital display for DMX addressing and fixture settings

• Forced Air Ventilation

• Precision Anti-Reflective Coated Optics

• Luminous output: 720 lumen

• Light weight 18.7 pounds

Physical

Color Black

Width 12.8 in (32.5cm)

Depth 9.8 in (25.0 cm)

Height 15.8 in (40.1 cm)

Weight 18.7 lbs (8.5 kg)

Gross Weight 24 lbs (10.9 kg)

Lamp Source

Lamp Type Long Life 60W LED Engine

Lamp Specs 720 lumens

5

Page 6

Environmental

Environmental Protection Rating IP20

Maximum ambient temperature 105°F (40°C)

Maximum exterior surface temperature 176°F (80°C)

Minimum distance to flammable surface 3.3ft (1m)

Minimum distance to illuminated surface 3.3ft (1m)

Electrical

Selectable Voltages Auto Switching 90-240v @ 50 or 60Hz

Connection IEC (C13) Power Inlet with Fuse

Rated Power 170W, 1.5A @ 115v

Fuses 5A Fast Blow Size: 5x20mm

Control

Protocol USITT DMX512 (1990)

Channels 12

Pan/Tilt Resolution 16 bit

Data I/O 3 Pin XLR (Cannon)

Modes Master / Slave / DMX

Optics

Lenses Precision Anti-Reflective Coated Optics

Beam Angle 11°

Gobo Size

Gobo Rotating Outside Diameter 0.984” (25mm)

Image Diameter 0.787” (20mm)

Rigging

Position Floor or Truss mount

Orientation Any

Mounting Omega clamp adapter with 0.5” hole

6

Page 7

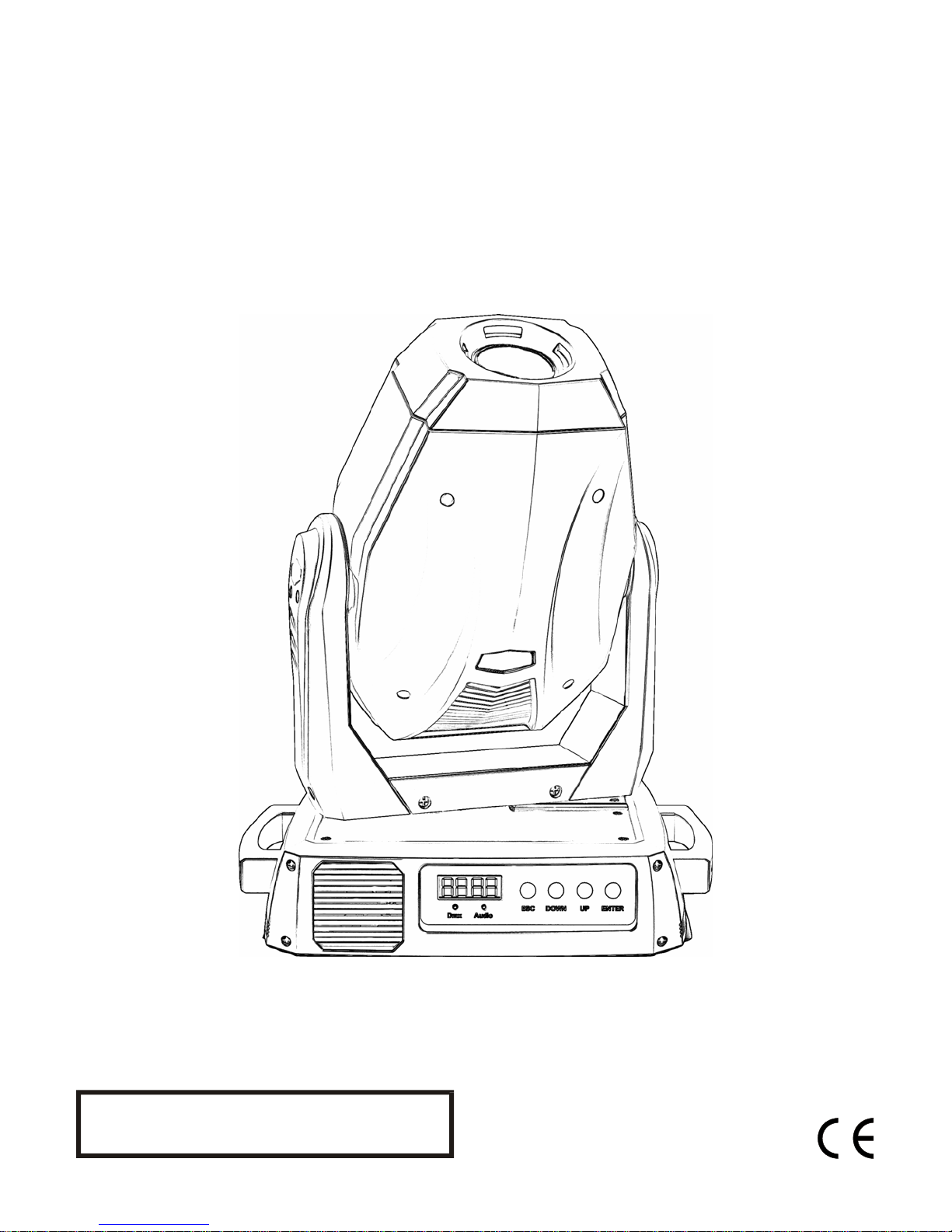

Unit Parts

1 Head

2 Yoke

3 Base

4 Control Panel

5 Base Bottom

6 Omega Clamp Adapter

7

Page 8

Unpacking

Immediately upon receipt, carefully unpack and inspect the fixture to verify that all parts are

present and have been received in good condition. If any parts appear damaged from shipping

or the shipping carton shows signs of mishandling, retain all packing material for inspection and

notify the shipper immediately. Save original carton and packing. In the event that the

merchandise is to be returned, the original carton and packing must be used. The customer will

be billed for a new carton and packing if merchandise is received without the original carton and

packing. The plastic bag shipped with the fixture can be used to keep the fixture clean if stored

or installed in a temporarily dusty environment. Do not operate fixture with plastic bag in place.

Save Shipping Materials

The packing and carton are designed to provide the fixture with protection during

shipping. Save original packing and documentation for warranty, service and return

issues. Additional charges will be applied to return items not received in original or

incomplete packing.

Claims

Physical damage must be reported to the Freight Carrier or Shipping Company upon

receipt of merchandise. Damage incurred in shipping is the responsibility of the Freight

Carrier or Shipping Company. It is the customer's obligation in the event that

merchandise is received damaged caused by shipping to notify the Freight Carrier or

Shipping Company immediately. All other claims not related to damage incurred during

shipping must be made to the Dealer or Distributor within 7 (seven) days of receiving

merchandise.

Returns

Returned merchandise must be sent prepaid, in the original packing with a Return

Merchandise Authorization number (RMA) clearly listed on the shipping label. Items

sent by Freight Collect or without a RMA number will be refused. Call your sales person

and request a RMA prior to shipping. Be prepared to provide the model number, serial

number and a brief description of the nature of the return. Shipping damage resulting

from inadequate packaging is the customer’s responsibility. Customer will be charged

additional shipping charges to return products received in non original packing and or

cartons.

8

Page 9

Power

Power is connected to the fixture with an IEC power inlet and cord.

Before applying power to fixture, set the power switch to “OFF” and

verify input voltage matches the power source voltage. Check all power

cords to verify they are of proper type and sufficient rating for the

equipment attached. For protection against electric shock, fixture must be

connected to suitable earth ground. The listed current rating is its average draw

under normal conditions. All fixtures must be powered directly from a switched

circuit. This fixture cannot be run on rheostat or dimmer circuits - even if used

solely for a 0% to 100% switching. Consult a qualified electrician if there are any

concerns about proper connection to power.

Voltage Selection

This Fixture is equipped with an Auto Switching Power Supply. It will automatically adjust to any

line voltage within the specified range.

LED Engine

This unit is equipped with a Long Life LED Engine that is aligned at the factory. There is no

need for the user to change lamps or perform any alignment.

Do not stare directly into the light source.

9

Page 10

Mounting

Always consult a qualified professional when rigging. This fixture may be placed on any flat

surface or truss that is capable of safely supporting the weight. When selecting a mounting

position, take into consideration access for routine maintenance. This fixture may be mounted in

any position provided there is adequate room for movement and ventilation. Mount the fixture

securely using an appropriate clamp and a safety cable. Safety cables must always be attached

to the fixture. Do not use handles as secondary mounting points. Do not mount in a place

where the fixture will be exposed to rain, high humidity, extreme temperature changes or

restricted ventilation. Do not obstruct the vents or fans. Keep fixture a minimum of 3.3ft (1m)

from flammable materials.

10

Page 11

Control Panel Menu

Use the fixture’s Control Panel to access the Control Menu.

The MODE Key moves between options, UP/DOWN selects

the Action of the option and ENTER confirms the selection.

Settings are stored and recalled on subsequent power

cycles. ESC moves back in the menu.

Menu Function / Option Description

Addr 001 - 512

Pset 16bt

suAP

On

OFF

PAtI

P.Inu

On

OFF

T.InU

ON

OFF

NorM

Ptsp

FAST

Slow

ON

dISP

TURN

1OS

Pers

DRES

ON

OFF

ScUT

ON

OFF

DFSE FACT LOAD

THRS

TOTL

RSET

INFO

TLHR

TLST

TOTL

RESET

TOTL

RSET

UER.

MAN

x.xx Firmware Version

RST

CH.NO

TSEQ RUN

DMX Start Address

16 Bit

Swap Pan/Tilt Assignment

Normal Pan/Tilt Assignment

Inverted Pan (100% to 0%)

Normal Pan (0% to 100%)

Inverted Tilt (100% to 0%)

Normal Tilt (0% to 100%)

Default Pan/Tilt Speed

Maximum Pan/Tilt Speed

Slow Pan/Tilt Speed

Display Remains On

Display Inverted

Display Turns Off

Enable Reset by DMX

Disable Reset by DMX

Effect Takes Shortest Path

Effect Does Not Pass Thru Open

Load Factory Default Settings

Fixture Hour Counter

Reset Fixture Hours

LED Engine Hour Counter

Reset LED Engine Hours

LED Engine Strike Counter

Reset LED Engine Strikes

Reset

Channel Adjust 0-255

Run Test Sequence

11

Page 12

DMX-512 Start Address

The Start Address of a fixture is set using the “Addr” mode in the Control Panel Menu. Consult

the manual of the system’s DMX512 controller to select a desirable addressing scheme before

addressing fixtures. Each fixture connected to the DMX-512 data link requires a Start Address

to indicate the first DMX channel containing data designated for that fixture, see DMX-512

Background. Valid Start Addresses range from 1 to 512. Fixtures requiring more than one

channel for control will read subsequent channels up to the total number of channels required.

A fixture requiring five (5) channels of DMX, set to a Start Address of eleven (11), would read

data from channels: 11 and 12, 13, 14, 15. The next logical Start Address would be channel

16. Because all fixtures see the same data, fixtures may be set to any address without concern

to order in the DMX-512 chain or physical location. Choose a Start Address so the channels

used do not overlap with other fixtures. In some cases, it may be desirable to set two or more

same type fixtures to the same Start Address. In this case, the fixtures will be slaved together

and respond to the same data.

Example

Since these are the first fixtures added to the system, the first unit will be set to Start

Address=1. This fixture occupies DMX channels 1 thru 12. The next DMX channel

available for a Start Address is found by adding the previous fixture’s Start Address to its

channel requirement: 1+12=13. DMX channel 13 is the next available Start Address. In

this example, to maximize channel usage no empty channels are left between fixtures so

the second Start Address is set to DMX channel 13. The second fixture occupies DMX

channels 13 thru 24. Repeat the process for the remaining two fixtures: 13+12=25 and

25+12=37. Therefore, the four 12 channel fixtures have Start Addresses of 1, 13, 25 and

37. Repeat the technique once more for the next free channel in the system, 37+12=49.

Channels 49 thru 512 are available for expansion of the system.

Select Start Addresses for 4 fixtures each requiring 12 channels of DMX.

DMX-512 Channel Assignment

The Vector LED Spot requires 12 channels of DMX.

Channel Function

1 Shutter /Strobe / Reset

2 Dimmer

3 Color Wheel

4 Rotating Gobo Wheel

5 Gobo Rotation

6 Focus

7 Prism / Prism Rotation

8 Pan Coarse Position

9 Pan Fine Position

10 Tilt Coarse Position

11 Tilt Fine Position

12 Pan / Tilt Speed, Auto, Sound

12

Page 13

CH 1 : Shutter / Strobe / Reset

The Shutter channel works directly on the LED Light Engine. It is an electronic shutter

that enables instantaneous shutter Open and Closed “movements.” Because no

mechanical elements are involved it is completely silent with no wipe effect allowing for

incredibly fast strobing effects. In addition to the Shutter and Strobe control this channel

also controls the Reset Function when the value is held between 246-250 for 8sec.

CH 1 – Shutter / Strobe / Reset

DMX Value Function

0-10 Closed (Black Out)

11-39 Open

40-240 Strobe Effect – Long to Short Interval

241-245 Open

246-250 Reset (Hold for 8 Seconds)

251-255 Open

CH 2 : Dimmer

The Dimmer channel is used to vary the intensity of the beam from full open to dark. This

channel also works directly on the LED Light Engine. Electronic control makes for smooth

dimming while maintaining an absolutely flat field. Even at very low levels, there is no

distortion of the beam.

CH 2 – Dimmer

DMX Value Function

0-255 Intensity - Dark to Full Open

CH 3 : Color Wheel

The Color Wheel holds 6 colors plus open. These color filters can be used in conjunction

with the dichroic color Rotating Gobos to create exciting color combinations. A Rainbow

Color Scroll effect can also be created.

CH 3 – Color Wheel

DMX Value Function

0 Color 0 (Open/White)

1-153 Continuous Indexed Positions

154-163 Color 6

164-169 Color 5

170-175 Color 4

176-181 Color 3

182-187 Color 2

188-193 Color 1

194-199 Color 0 (Open/White)

198-227 Rainbow Color Scroll – Fast to Slow - CCW

228-255 Rainbow Color Scroll – Slow to Fast - CW

13

Page 14

CH 4 : Rotating Gobo Wheel

The Rotating Gobo Wheel contains 7 gobos, 2 are dichroic glass. Adding colors and

varying the Focus can create many interesting effects.

CH 4 – Rotating Gobo Wheel

DMX Value Function

0-15 Open

16-31 Rotating Gobo 1 (Glass)

32-47 Rotating Gobo 2 (Metal)

48-63 Rotating Gobo 3 (Metal)

64-79 Rotating Gobo 4 (Metal)

80-95 Rotating Gobo 5 (Metal)

96-111 Rotating Gobo 6 (Glass)

112-127 Rotating Gobo 7 (Metal)

128-191 Rotating Gobo Scroll – Fast to Slow - CCW

192-255 Rotating Gobo Scroll – Slow to Fast - CW

CH 5 : Gobo Rotation and Index

Rotating gobos can be rotated in either direction or set to fixed positions. The fixed

position is not absolute and will change during use.

CH 5 – Gobo Rotation and Index

DMX Value Function

0-127 Fixed Positions – 0 to 450° – Non-absolute

128-191 Rotation – Fast to Slow CCW

192-255 Rotation – Slow to Fast CW

14

Page 15

CH 6 : Focus

The Focus is used to vary the focal point of the projection.

CH 6 – Focus

DMX Value Function

0-255 Focus – Far to Near

CH 7 : Prism / Prism Rotation

The Prism effect uses a 3 facet prism to split the beam. The effect can be rotated in

either direction at variable speeds or set to fixed positions. The fixed position is not

absolute and will change during use.

CH 7 – Prism / Prism Rotation

DMX Value Function

0-4 Open

5-139 Fixed Positions – 0 to 450° – Non-absolute

140-197 Rotation – Fast to Slow – CCW

198-255 Rotation – Slow to Fast – CW

CH 8-11 : Pan / Tilt Position

Pan range is 540°. Tilt range is 270°. A position feedback system is used to enable

auto correction of Pan and Tilt. Speed and Movement options are controlled by the

Pan/Tilt Speed, Auto, Sound Channel 12.

CH 8 – Pan Coarse Position (540°)

CH 9 – Pan Fine Position (3.6°)

CH 10 – Tilt Coarse Position (270°)

CH 11 – Tilt Fine Position (3.6°)

DMX Value Function

0 – 255 Position - Minimum to Maximum

CH 12 : Pan / Tilt Speed, Auto, Sound

When set to zero (0), movement speed is determined by the controller. Other values

under Tracking Speed allow user selectable movement speeds. Theatrical Mode

engages the shutter during movement or effect change. The internal programs can be

remotely activated. They can be run in Auto Trigger mode or in Sound Trigger mode

using the internal microphone.

CH 12 – Pan / Tilt Speed, Auto, Sound

DMX Value Function

0-120 Tracking Speed Fast to Slow

121-140 Theatrical Mode (shutter on change)

141-240 Internal Programs – Auto Trigger

241-255 Internal Programs – Sound Trigger

15

Page 16

DMX-512 Background

DMX-512 is a digital data transmission standard developed by the United States Institute for

Theater Technology (USITT). It is designed to enable control of lighting equipment, originally

dimmers. DMX deals solely with the formatting of data for transmission and does not dictate

how the data is created or used.

Under DMX, signals are transmitted in much the same way a computer modem transmits data.

The Data, divided in to channels, is "Framed" using a start bit, high (1), eight data bits and

finally, two stop bits, both high (1). DMX uses no parity to check the integrity of the signal.

Instead, DMX relies on the ultra low probability of an error occurring in the same place when the

data is resent. The rate at which data is sent is fixed at 250k bps, almost four and a half times

faster that a 56k modem. This speed allows all data on a DMX chain to be updated more than

44 times every second.

The transmitted data follows a specific format. DMX allows for 512 channels each with eight

data bits, giving each channel the possibility of 256 values. When a data "Packet" is sent, all

channels are transmitted one after another. Even if the data on a specific channel has not been

changed, it must be sent. In a packet, a "start code" of all zeros is sent before the data to

identify the signal as a Standard DMX transmission. This start code is transparent to the user

and is handled by the controller.

The physical signals are transmitted using a twisted pair of wires and a common shield, a

configuration called Balanced. The controller and all receiving equipment are connected using a

“Daisy Chain" connection. The signal is jumped from the controller to a piece of DMX

equipment. From there, the signal is jumped to the next piece of equipment and so on until the

last piece of equipment is connected. No branches are allowed and the signal does not come

back to the controller. The final piece of equipment will have only one cable connection. As a

result, all equipment connected to the chain will see exactly the same signal whether it is first or

last. When connecting equipment, no particular attention needs to be paid to the order in which

the equipment is connected. Depending on the conditions and equipment, a line terminator may

be required. If there is any question, in most circumstances the addition of a terminator will not

degrade the signal. To make a terminator, add a 120-ohm resistor between the Signal Data

Negative and Signal Data Positive pins of a connector in the last piece of equipment in the

chain.

The DMX Standard calls for connections between DMX compatible equipment to be made using

5 pin XLR connectors. However, it is common to see fixtures with 3 pin XLR connectors as

these types of balanced or “Lo-Z” cables are common in the audio industry. In either case, pin

numbers are the same and carry the same signals.

Pin 1 - Signal Common (Shield)

Pin 2 - Signal Data Negative

Pin 3 - Signal Data Positive

Pin 4 - (not used)

Pin 5 - (not used)

16

Page 17

Data Link DMX-512

Ω

:

X

For data, this fixture uses XLR (Cannon) type connectors and shielded twisted pair cable

approved for EIA-422/EIA485 use. Fixtures are connected in Daisy Chain topography

with only one data source and no branching. Systems using 3 or 5 pin DMX interfaces

can be accommodated by purchasing 3-to-5 pin adapters or building adapter cables.

DMX512

120

DMX-OUT

XLR Connector - Socket

1

- Ground

2

- Signal (-)

3

- Signal (+)

DMX-IN

LR Connector - Plug:

1

- Ground

2

- Signal (-)

3

- Signal (+)

Adapter 5-to-3 pin

Numbers designating each pin can be found on connectors. Converting between the two

XLR types is done in a pin-to-pin fashion. Connect the shields to pin 1, then connect pin

2 to pin 2 and pin 3 to pin 3. This is true for converting either 5 to 3 pin or 3 to 5 pin

regardless of either connector’s gender. Pins 4 and 5 are not used on the 5 pin XLR

connectors.

5 Pin XLR (Socket)

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin 4: N/C

Pin 5: N/C

3 XLR (S )

Pin ocket

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

3 XLR (Plug)

Pin

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

5 Pin XLR (Plug)

Pin 1: GND(Sheild)

Pin 2: Signal(-)

Pin 3: Signal(+)

Pin 4: N/C

Pin 5: N/C

Data Terminator

A Data Terminator can be connected to the DATA OUT connection

of the last fixture to reduce the effects of noise in the signal; it is not

required for all installations. To make a Data Terminator, connect a

120-ohm ¼ watt resistor across pin 2, Data Negative (S-) and pin 3,

Data positive (S+). A qualified technician can determine if a Data

Terminator is needed.

17

Page 18

Maintenance

Make sure fixture is cool and disconnected from power mains before any service.

Weekly operating hours and environmental conditions will establish how often the fixtures need

cleaning. Fixtures should be cleaned and inspected at least once a month to maintain optimum

performance. Accumulation of dust and fog residue increases heat build up, can lead to

malfunctions, overheating and reduction in maximum light output. This condition may cause

undue stress on electronics, mechanical elements, reduce LED Engine life, fixture life and over

all performance. Before conducting any maintenance, disconnect fixture from power mains.

1) Disconnect fixture from power mains.

2) Use a vacuum with a soft brush to remove dust collected on external vents and internal

components. If using an air compressor, use low pressures and extreme care to prevent

damaging any internal parts or effects.

3) Vacuum dust buildup from fan intakes and check that all fans function correctly.

4) Clean all optical elements when the fixture is cold. Use a soft lint free cotton cloth or tissue

and either Isopropyl or Denatured Alcohol. Any cleaner approved for coated eyeglass lenses

will also work.

5) Inspect clamps and safety cables to ensure fixture is secure and safe.

18

Page 19

Troubleshooting

Symptom Possible Cause / Solution

No Power

No response to DMX

Incorrectly responds to DMX

(Diagnostic technique for DMX issues: Set

suspect fixture’s Start Address the same as a

correctly functioning fixture. If both units then

function correctly, issue is programming)

No Light Output / Low Output

Erratic operation

Check power switch

Check for power on mains

Check main fuse and fuse holder

Check data cables

Check Start Address

Check that fixture isn’t in the Demo mode

Check Start Address

Check for overlapping addresses

Check fixture set up (Pan/Tilt Invert…)

Check Data cables (faults and proper wiring)

Check that both Shutter and Dimmer values

are set properly

Inspect fixture light path and verify no effects

are blocking beam

Remove from DMX, Control Panel to test in

demo/manual mode

Over temperature – Turn fixture off and allow

to cool then attempt again. If condition

improves, check all fans.

Check Pan/Tilt are not blocked or coming in

contact with anything during movement

See “Incorrectly responds to DMX”

An effect wheel doesn’t go to correct position

Check for properly wired DMX cables

Check for broken wires inside unit

Check for damaged Data transceiver IC

Mains Voltage too low or noisy

Check sensor and magnet

Check belts (if applicable)

Check motor with no power, should be able

to move easily.

19

Page 20

Accessory Items

Order Code Description

CLAMP-MEGA/B Clamp-Mega Black - Heavy Duty

CLAMP-CBHALF Coupler Half Cheeseborough

SAFETYCABLE30S Safety Cable Silver 30”

SAFETYCABLE30B Safety Cable Black 30”

SAFETYCABLE18B Safety Cable Black 18”

SAFETYCABLE18S Safety Cable Silver 18”

CA-XLR3/1 Pre-made 1’ 3-pin XLR Cable

CA-XLR3/5 Pre-made 5’ 3-pin XLR Cable

CA-XLR3/10 Pre-made 10’ 3-pin XLR Cable

CA-XLR3/25 Pre-made 25’ 3-pin XLR Cable

CA-XLR3/50 Pre-made 50’ 3-pin XLR Cable

CA-XLR3/100 Pre-made 100’ 3-pin XLR Cable

CA-XLR5/1 Pre-made 1’ 5-pin XLR Cable

CA-XLR5/5 Pre-made 5’ 5-pin XLR Cable

CA-XLR5/10 Pre-made 10’ 5-pin XLR Cable

CA-XLR5/25 Pre-made 25’ 5-pin XLR Cable

CA-XLR5/50 Pre-made 50’ 5-pin XLR Cable

CA-XLR5/100 Pre-made 100’ 5-pin XLR Cable

CO-XLR3M XLR Connector 3-pin Male

CO-XLR3F XLR Connector 3-pin Female

CO-XLR5M XLR Connector 5-pin Male

CO-XLR5F XLR Connector 5-pin Female

CO-XLRTERM3 XLR 3 Pin Data Terminator

CO-XLR3MTO5F XLR 3 Pin Male to 5 Pin Female Adapter

CO-XLR5MTO3F XLR 5 Pin Male to 3 Pin Female Adapter

20

Loading...

Loading...