HUSKY

2 Channel FM Radio Control System

USER'S GUIDE

FM

Proton Control Systems Inc.

Preparation

Husky

Adaptation for Left-hander

Antenna Installation

Loading the Batteries

Charging

Power switch

Direct Servo Control

USB Connection

Standing

Specification

Ken

Installation

Frequency Setting

Specification

Safety

Transmitter and receiver

Operating

Frequency

Battery

Maintenance

Data Setting

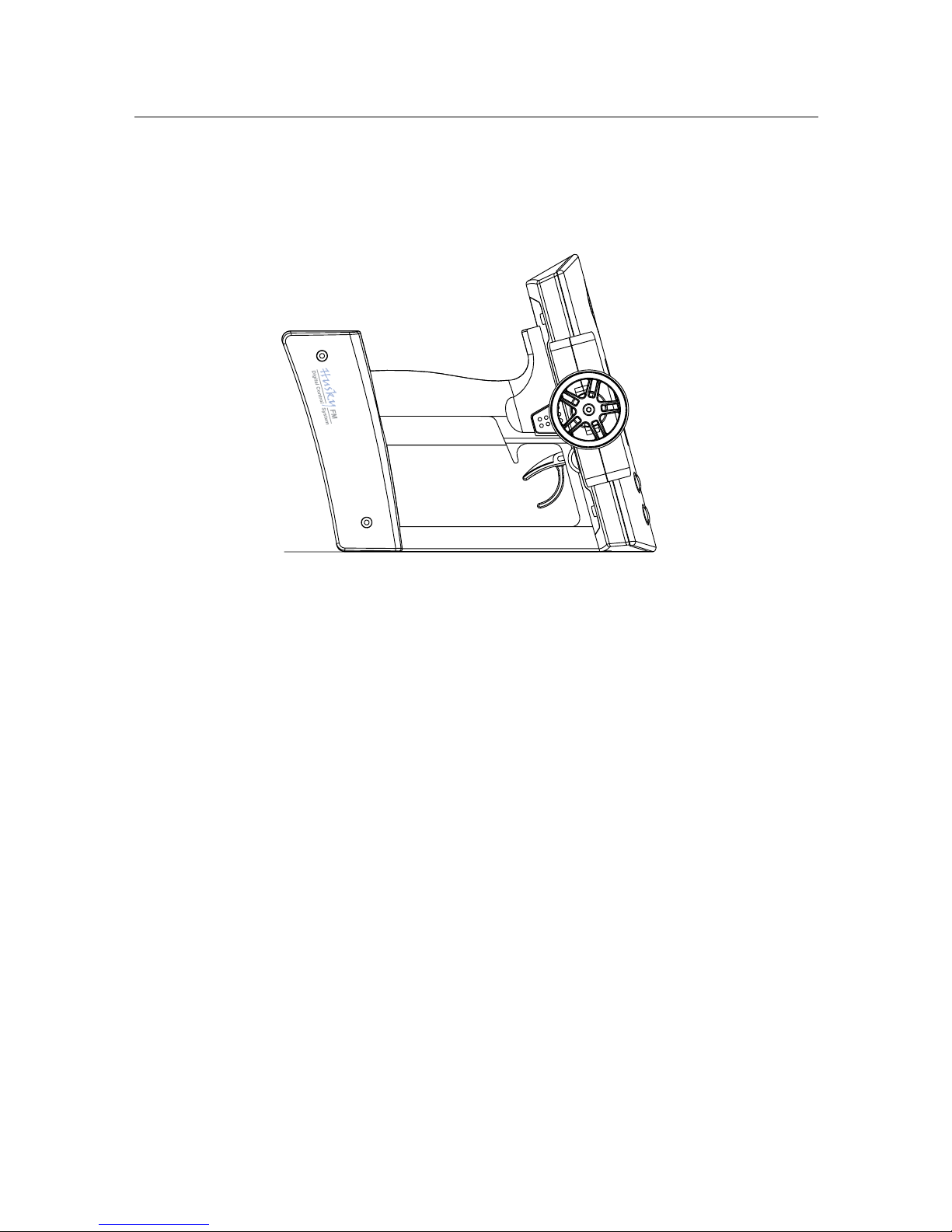

Control panel

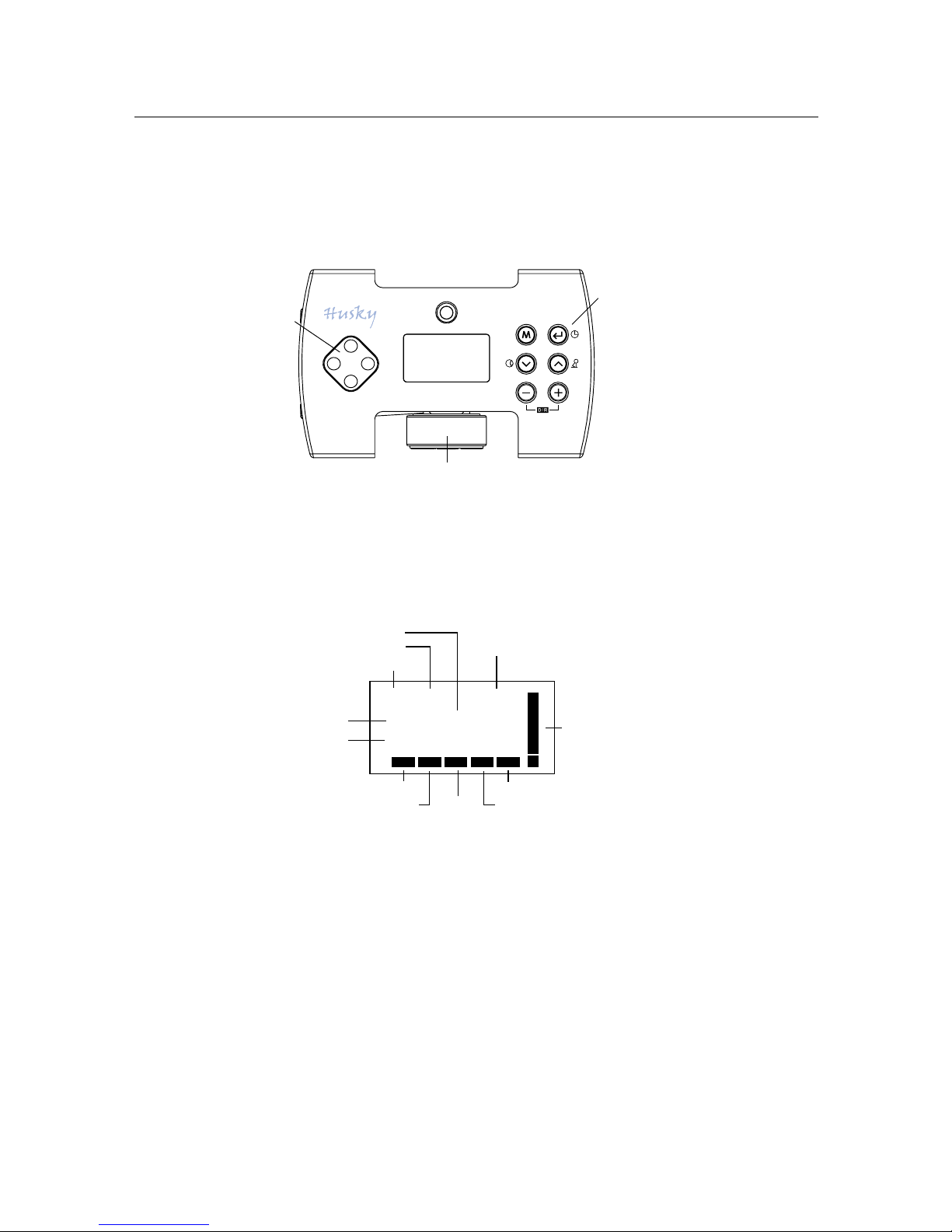

Normal display

Function map

Direct Access Functions

Digital Trim

Dual Rate

Stopwatch

System Mode Functions

Model Name

Trim Rate

LCD Contrast

Frequency

Data Copy

Pit Mode Functions

Model Select

Setting Level

Servo Reverse

Sub Trim

Data Reset

Circuit Mode Functions

End Point Adjustment

Response

Steering Speed

2-Step Steering Speed

Throttle Speed

2-Step Throttle Speed

Start

3-Step ABS

ABS

Auto Steering Control

Punch

Idle Up

Limited Warranty

Approvals

Frequency list

Table of Contents

Features

Thank you for purchasing a Proton Control Systems product. Before operating your Husky

transmitter and Ken receiver, please read this manual carefully. Then retain it for future

reference.

1. Features

No crystal needed to change frequencies

The frequencies of most transmitters and receivers are adjusted by changing the crystals.

Enthusiasts who want to change frequencies must purchase extra crystal sets to prevent

interference between same frequencies. To complicate matters further there are so many

types of crystals based on modulation (FM/AM, PPM/PCM), conversion type (Single/Dual)

and Radio makers.

To solve this problem, Proton Control Systems adapted PLL (Phase Loop Lock) technology

to your Husky transmitter and Ken receiver. The preferred frequencies are selectable simply by pressing buttons.

Works with all popular FM transmitters & receivers

Your Husky transmitter and Ken receiver are each compatible with all popular FM transmitters and receivers. These include A class (FutabaTM, HitecTM) and B class (JRTM, SanwaTM,

KO

TM

). This flexibility allows you to use different brand transmitters and receivers.

USB port for PC game control

Your Husky is more than a transmitter for your R/C models. Use your Husky transmitter

to control your PC games too! Husky comes with a built-in USB port for connecting to your

personal computer. Now you can practice at home before the big race. Better still, your

race will never be rained out.

Easy to change grip direction for left or right-hander

Husky's symmetrical design allows you to quickly change format from right- to left-hand

grip. Just unscrew 4 screws and rotate the body 180

O

degrees. Who's better than Husky?

Programming features

The program settings on your Husky consist of 3 levels (Expert, Standard, Basic) and 3

modes (System, Pit, Circuit). The programs are simple to set, but offer many powerful functions.

Features

Preparation

2. Preparation

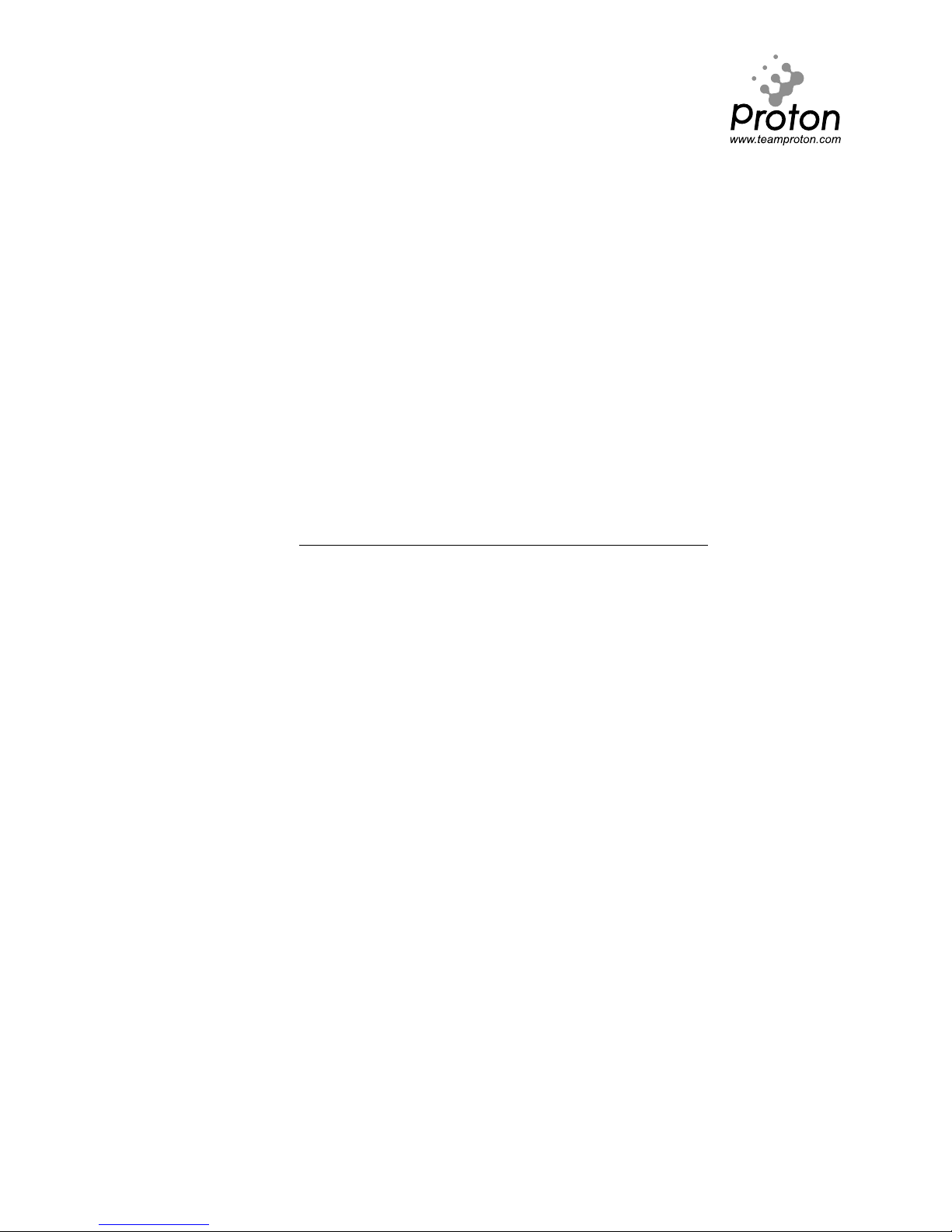

- Husky, 2 Channel FM transmitter

Adaptation for Left-hander

Huskies are produced for right-handers. However the grip direction can be changed

for left-handers.

1. Make sure that the Power switch in set to OFF.

2. Carefully remove the 4 screws from the bottom cover of the control panel.

3. Separate control panel and body

4. Rotate head 180

O

degrees and reinstall the 4 screws being careful not over tight-

en them.

Preparation

Antenna Installation

The antenna included with your Husky is safely stored in a slot under the control

panel. To remove the antenna, pull back the plastic retainer cap located at the

front of your Husky transmitter, then slide the antenna out. Insert the base of the

antenna into the antenna receptacle at the top of the control panel. Then screw the

antenna clockwise until it is firmly attached. Be careful not to over tighten the antenna.

NOTE The antenna should be fully extended while transmitting. Otherwise the operating

range of the system will be reduced and loss of control may occur.

Loading the batteries

Your Husky transmitter requires 8 AA batteries (not included). Alkaline batteries

will provide power for approximately 7 hours of use. The battery box is located at

the bottom of the transmitter body.

1. Make sure that the Power switch is set to the OFF position.

2. Release the hook and pop up automatically the battery cover.

3. Pull down the battery holder and disconnector from the battery case and install

the batteries into the holder.

4. Plug in the connector and replace battery holder into the battery case and push

down the battery cover until it locks in place.

Charging

The changing jack is located on the back side of control panel and marked "12V

". Before start charging, make sure the rechargeable NiCd batteries are installed and power switch is set to the OFF position. For charging the transmitter, the

charger must have below specification. Otherwise it may damage the transmitter or

not be charged.

Input voltage : 110V 60 Hz for USA, 230V 50 Hz for Europe

Output voltage : DC 10.8V 150 mAh

Charge jack polarity :

Typical slow charge rates are DC 10.8V, 150mA for 12 hours, while most Sanyo

brand AAs can be charged at up to 1 Amp.

NOTE Never charge a dry cell type (Non-NiCd) battery. Charging a non NiCd battery may

damage the transmitter, and could cause the battery electrolyte to leak and cause additional

damage.

Preparation

Power switch

The Power switch is a small toggle switch located back of the Control Panel near

the base of the antenna. It can be set to On, Off and Standby (S/B) modes. Power

On and Off is same as any other electronic device. Standby (S/B) allows you to program all functions without transmitting a signal. This is useful for making adjustments while not affecting others that may be on the same frequency. Standby (S/B)

mode also uses about 2/3 less power. If you plan to work in a programming mode

for any length of time or use your Husky as a PC game controller, using Standby

will extend your battery life. "STB" appears on the LCD display in Standby (S/B)

mode.

Battery voltage is displayed both numerically and graphically on the LCD display.

The graphical depiction is a vertical bar on the right side of the display. The length

of the power level bar is gradually reduced according to current consumption.

When voltage drops below 8.7 volts, the bar flashes and an alarm will sound.

NOTE At low voltage, immediately stop the model and change the batteries. Otherwise loss

of model control may result.

Direct Servo Control (using optional cable)

DSC allows you to operate the servos and speed controller in your system without

transmitting (RF) radio frequency. This is ideal for pit checking your radio setup

while others are operating on the same frequency.

To operate, plug the radio connector end of the DSC cable into the DSC jack located behind the control panel of your Husky. The other male end of the DSC cable is

inserted in the battery slot on your Ken receiver.

USB Connection (using optional cable)

Your Husky has a USB port located behind the control panel. It allows connecting

Husky to your computer to control PC games. To transfer control data from your

Husky transmitter, you need to connect the transmitter to your computer. With the

transmitter switch on standby position, plug the "B" type end of the USB cable into

the USB port located on the back of your Husky.

The "A" type end of the USB cable plugs in the USB slot on the backor front of your

computer.

NOTE USB cables are available in a variety of lengths at your local computer store.

Preparation

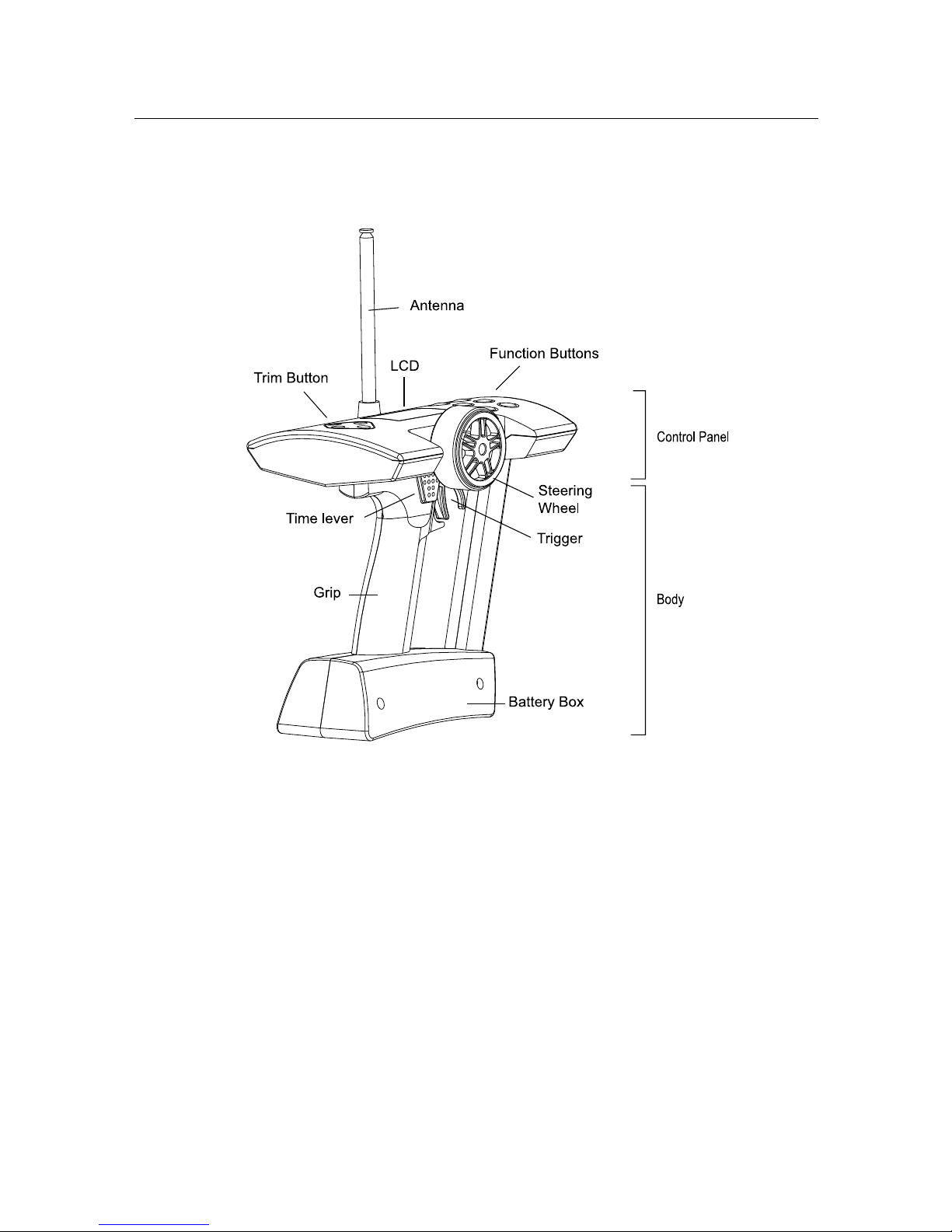

Standing

The large control panel at the top of your Husky makes the unit somewhat topheavy. We recommend your Husky stands as illustrated right. This allows better

stability, grip direction and easy of pick-up.

Specifications

Number of Channels : 2

Modulation : FM, PPM

Size : 190 X 185 X 118 mm (7.48" X 7.28" X 4.65")

Weight : 500 g (17.64 oz) w/o batteries

Output power : less than 0.75 W

Current drain : Approx. 250 mA

Power requirements : DC 12V (1.5V X 8, "AA" Size Alkaline batteries)

DC 9.6V (1.2V X 8, "AA" Size NiCd batteries)

Operating temperature : 0

o

C ~ 40o C

LED

1st digit button

2nd digit button

Servo & power slot

Preparation

- Ken, 2 Channel FM Receiver

Installation

For best performance, your Ken receiver should be firmly affixed and connected on

the model according to the procedure below.

1. Clean surface where your Ken is to be mounted.

2. Mount Ken with double-side adhesive tape (included) as close to the antenna

mast as possible.

3. Run the antenna wire up through the plastic antenna tube.

4. Put servo plugs into slots 1 & 2; power plug into slot B.

(Your Ken receiver accepts standard Futaba, JR, Hitec, new Ko and Sanwa Z

connectors).

NOTE Do not cut or bundle the receiver antenna. Cutting, bundling or routing the receiver

antenna near any device that produces noise (RF) will reduce the operating range of the

system and result in loss of control.

Some drivers remove the case to reduce weight, but this can cause serious damage to the

circuitry from dirt or water. Removing the case will void Proton Control System's product

warranty.

Frequency setting

The Ken is a crystal-free receiver. It does not need crystals for changing frequencies. Each available frequency has been assigned a two-digit channel number,

which you can locate at the back of this manual. There is a two-digit LED display

on your Ken receiver with corresponding adjustment buttons. Select the correct

channel number from the back of this manual and then enter that number into

your Ken receiver using the adjustment buttons. When power is first applied to

the receiver, the LED will light for 3 seconds and then turn off. Pressing either adjustment button will light the display again.

NOTE The receiver frequency should be changed on same frequency transmitting. Otherwise it casue servo damage and unexpected accident.

Specification

Number of Channel : 2

Modulation : FM, PPM

Voltage range : 3.5 ~ 10.0 V

Size : 38.1 X 30.5 X 16.5 mm (1.5" X 1.2" X .65")

Weight : 18.70 g (0.66 oz)

Antenna length : 450 mm (17.75")

Safety

2. Safety

Transmitter and receiver

- Do not operate two or more models on the same frequency at the same time. This

will cause interference and loss of control of both models. AM, FM(PPM) and PCM

are different methods of modulation. Nonetheless the same frequency cannot be

used at the same point in time, regardless of the signal format.

- Extend the transmitter antenna to its full length. If the transmitter antenna is not

fully extended the operating range of the radio will be reduced.

- Always perform an operating range check prior to use. Problems with the radio

control system as well as improper installation in a model could cause loss of

control.

- Check the transmitter antenna to be sure it is not loose. If the transmitter anten-

na works itself loose, or is disconnected while the model is running, signal transmission will be lost. This will cause you to lose control of your model.

- Be sure to turn on power switches in the proper sequence. At startup, turn on

transmitter first, then the receiver. At shutdown, turn off the receiver first, then

the transmitter.

NOTE Before powering on, always check the throttle trigger on the transmitter to be sure it

is at the neutral position. When turn off the system power switches always be sure the engine is not running. If the power switches are turned off in reverse order, your model may

unexpectedly and dangerously run out of control.

The signal is transmitting after 5 seconds from turning on the power switch. The 5 seconds

are needed for synthesizing the frequency. So receiver power is turned on at least after 5

seconds from the transmitter power on.

Operating

- Use this product in surface models only. (Car, Boat etc.)

- Do not operate outdoors on rainy days, run through puddles of water or when

visibility is limited. Should any type of moisture (water or snow) enter any component of the system, erratic operation and loss of control may occur.

- Do not operate your R/C system when you are tired, not feeling well or under the

influence of alcohol or drugs. Your judgment is impaired and could result in serious injury to yourself as well as others.

- Do not operate your R/C model in the following places: sites where you may in-

terfere with other radio control activity, where the general public can be found, on

public roads and near high-tension power lines or communication broadcasting

antennas.

- Do not leave your R/C system or model within the reach of small children. A

small child may accidentally operate the system and injuries may result.

Battery

- Ni-Cd batteries can be very dangerous when mishandled and cause chemical

damage.

- In the unlikely event that battery fluid leaks onto your skin, immediately wash

the contaminated skin with soap and plenty of water. Contact your local health

care provider.

- In the unlikely event that battery fluid leaks inside the transmitter. Contact the

PCS service center.

- When the model is not being used, always remove or disconnect the Ni-Cd Bat-

tery. Should the battery be left connected this could created a dangerous situation if someone accidentally turns on the receiver power switch. Loss of control

would occur.

- Always follow your battery manufacturer's directions fully. Do not attempt to dis-

assemble, short circuit, or subject the battery to high temperature or fire.

- Your transmitter has been designed to operate correctly using a variety of AA-size

batteries currently available. These include 1.5 volt alkaline and rechargeable 1.2

volt Nickel Cadmium (Ni-Cd) batteries.

- Replace all batteries of a set at the same time. New batteries should not be mixed

with used ones. Do not mix rechargeable and non-rechargeable batteries. Do not

mix alkaline or Ni-Cd types of batteries. Do not mix different grades or brands of

batteries. Failure to observe this precaution may result in some batteries in a set

being driven beyond their normal exhaust point and increase their possibility of

leakage.

- Always check to be sure your batteries have been charged prior to operating the

model. Should the battery go dead while the model is operating loss of control will

occur and create a very dangerous situation.

- When disposing of batteries, follow the manufacturer's instructions and all feder-

al, state, and local regulations. PCS suggests customers take advantage of any

community battery-recycling programs that may exist in your area. Contact your

local waste remover or recycler for details.

Maintenance

- To keep from damaging your transmitter, avoid exposing it to moisture, extreme

temperatures, direct sunlight, vibration and dust.

- Clean the outside of the transmitter by wiping with a clean, dry cloth. Never use

harsh or abrasive cleaners or organic solvents on the transmitter.

- Do not expose plastic parts to fuel, motor spray, waste oil or exhaust. These will

penetrate and damage the plastic.

- Never disassemble or touch the inside of the transmitter. This could result in

electrical shock.

- If you notice smoke or a burning smell coming from the transmitter, immediately

turn off the transmitter, wait a few minutes until the transmitter cools, and then

remove the batteries.

Safety

Trim

Button

LCD

Function

Buttons

Steering Wheel

1 : RC10B

12.0 VEx

A40.665 MHz50

D/R STA IDL ABS

ASC

STB

Model #

Model name

Setting level

Voltage

Channel # &

Frequency

Dual rate

Start

Idle up

Anti-lock bracking system

Auto steering control

Power level

bar

Standby

Data Setting

3. Data Setting

There are 3 setting modes (System Mode, Pit Mode and Circuit Mode) in your Husky

setting program.

Control Panel

Normal Display

When the power switch is set to ON or STANDBY the normal display appears as

shown below.

Function

Mode

Circuit Basic

EPA

Response

Dual rate

Standard

EPA

Response

Steering speed

Throttle speed

Start

3-Step ABS

Dual rate

Punch

Idle up

Expert

EPA

Response

2- Step steering speed

2- Step throttle speed

Start

ABS

Auto steering control

Punch

Idle up

Pit

Model select

Setting level

Servo reverse

Sub trim

Data reset

System

Model name

Trim rate

LCD contrast

Frequency

Data copy

Function Map

Data Setting

150%

Dual rate

off

100%

RL

0

Direct Access Functions

Direct set programming lets you program quickly using easily accessible buttons on

the control panel. Make instant fine adjustments without moving through the main

menu.

Digital Trim

The digital trim button is located on the left side of the control panel. Steering and

Throttle trim adjustments can be made by pressing the trim button in one of the 4

available directions. Up and down are for Throttle trim and right and left are for

Steering trim.

You will hear a beep with each increment of trim adjustment. Digital trim position

is displayed both numerically and graphically on the LCD.

NOTE Throttle trim changes only the center (neutral) point and not the end points. This is

done to maintain your maximum speed and braking points.

Dual Rate

Dual rate affects the total steering servo throw (both sides, right and left) simultaneously, so reducing the dual rate value makes the steering less sensitive and also reduces the maximum amount of steering available.

Dual rate values are adjusted and displayed on the LCD by pressing the or

buttons on the control panel.

Pressing dual rate buttons on the control panel, "D/R" will appear on the lower side

of the Normal LCD display.

Stopwatch

Pressing the start button " " on the control panel can activate the stopwatch and display

timer on the LCD. The timer can be started when the throttle is triggered and the stop is available by pressing the start lever behind the steering wheel. Pressing the start button again resets

the stopwatch.

St :

Th:

Trim

R10

F12

Digital Trim / Dual Rate / Stopwatch

00 : 00 : 00

Stopwatch

System Mode Functions

This mode contains programming features, model name, trim rate, LCD contrast,

frequency, data copy and data reset. These basic settings manage the transmitter

system regardless of the pit and circuit mode setting. The System Mode menu is accessible as below.

1. Press button at normal display.

2. Press button 2 times until the cursor is at System Mode.

3. Press button for displaying System Mode menu.

(Display automatically reverts back to Normal mode if there is no activity in System Mode for a period of 5 seconds).

Model Name

For ease of identification, the model name function allows you to assign names up

to 8 characters in length for each of your models

In System Mode, press button to display Model Name screen.

1. Press or button until desired letter appears.

2. Press button and press / button to select next letter.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

3. After model name is completed, press the button to return to the System

menu.

Trim Rate

The trim rate function allows the trim authority (the amount of trim available) to be adjusted. It

allows trim control with fine or rough adjustment.

1. Press button until the cursor is at Trim Rate.

2. Press button to display Trim Rate screen.

3. Press or button to adjust steering trim rate.

4. Press button to select throttle trim rate.

5. Press or button to adjust throttle trim rate.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

6. After setting is completed, press button to return to the System menu.

1 : RC10B2

Model name

Model name

Trim rate

LCD contrast

System Mode

Model Name / Trim Rate

Model name

Trim rate

LCD contrast

System Mode

Steering : 10

Throttle : 10

Trim rate

LCD Contrast

This function allows an eight-step contrast adjustment of the LCD screen.

1. Press button until the cursor is at LCD contrast.

2. Press button to display LCD contrast screen.

3. Press or button until the desired contrast is achieved.

(To return to the default setting, press , buttons simultaneously for 3

seconds)

4. Press button return to the System menu.

Frequency

The frequency feature allows selecting not only frequencies but also classes. There

are 2 classes-A class for Futaba

TM

, KOTM, HitecTM type receivers and B class is for JRTM,

Sanwa

TM

(AirtronicsTM) receivers. BY selecting frequencies and classes, Husky can

control all FM receivers of other manufacturers.

Note Band change is not possible (for example: 27MHz to 75Mhz or 75MHz to 27MHz). To

control a 27MHz FM receiver, you must purchase a 27MHz transmitter. Frequencies can be

changed, but only within a specific band.

1. Press button until the cursor is at Frequency.

2. Press button to display Frequency screen.

3. Press / and button to select the class A or B.

4. Press or button until the cursor is on the desired frequency.

5. Pressing button return to the System menu.

Data Copy

This function copies the entire contents of the currently stored model memory to

another model memory.

1. Press button until the cursor is at Data Copy.

2. Press button to display Data Copy screen.

3. Press / until the desired target model number appears.

4. Press button to copy.

"Complete" is displayed, and then the Data copy menu screen reappears.

Frequency

LCD contrast

Data copy

System Mode

IIIIIIIIIllllllllIIIIIIIIIIII

LCD Contrast

LCD Contrast / Frequency / Data Copy

Frequency

LCD contrast

Data copy

System Mode

Frequency

LCD contrast

Data copy

System Mode

1 : RC10B3

to

2 : Pure 10

Data copy

50 : 40.665 MHz

51 : 40.675 MHz

52 : 40.685 MHz

Frequency A class

Model select

Setting level

Servo direction

Pit Mode

1 : RC10B3

2 : Kyosho

3 : Pure 10

Model select

1

Pit Mode Functions

This mode contains programming for setup during model building, electronics

installation and maintenance. Pit Mode programming features include model select,

setting level, servo direction and sub trim. The Pit Mode menu is accessible as

follows.

1. Press button at normal display.

2. Press button until the cursor is at Pit Mode.

3. Press button to display Pit Mode menu.

(Display automatically reverts back to Normal Mode if there is no activity in Pit

Mode for a period of 5 seconds).

Model Select

The Husky can keep and handle the data for 10 individual models. All programmed

parameters including Digital trim positions are automatically stored in each

memory and up load anytime.

This function is not only useful for someone who has many cars, but great for quick

setting changes based on circuit condition and race type.

1. Press button until the cursor is at Model Select.

2. Press button to display Model Select screen.

3. Press or button until the desired model # appears.

4. Press button return to the Pit menu.

Setting Level

The Husky allows 3 setting levels. The Basic setting allows for easy programming. It

works well for beginners who quickly set-up to go the race circuit. The Standard

and Expert levels offer more advanced programming features.

1. Press button until the cursor is at the Setting Level.

2. Press button to display Setting Level screen.

3. Press or button until the cursor is at desired level.

4. Press button to return to the Pit menu.

Model Select / Setting Level

Model select

Setting level

Servo direction

Pit Mode

Basic

Standard

Expert

Setting level B

Servo Reverse

This function allows you to change the direction a servo rotates, clockwise or counter clockwise.

NOTE When the trim position deviates from the center, the deviation will be on the opposite

side when the servo is reversed.

1. Press button until the cursor is at Servo Reverse.

2. Press button to display Servo Reverse screen.

3. Press / button to change steering servo rotation direction.

4. Press and / button to change throttle servo rotation direction.

(To return to the default setting, press , buttons simultaneously for 3 sec-

onds)

5. Press button to return to the Pit menu.

Sub Trim

Use this function to adjust the neutral position of the steering and throttle.

NOTE Sub trim changes both the center and the end point servo positions. You may want to

recheck your end point positions if you adjust the Sub trim.

Do not use excessive Sub trim, as it's possible to over-run the servo's travel. Instead reposition the servo horn or servo saver on the servo and inspect your linkage installation.

1. Press button until the cursor is at the Sub Trim.

2. Press button to display the Sub Trim screen.

3. Press / button to change the sub trim steering value.

4. Press and / button to change sub trim value of throttle.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

5. Press button return to the Pit menu.

Data Reset

The data reset function resets all the memory (in the current model only) back to

the factory default setting except data in System mode.

1. Press button until the cursor is at Data Reset.

2. Press button to display the Data Reset screen.

3. Press button to move cursor from EXIT to RESET.

4. Press button to reset all data to default values.

"Complete" is then displayed.

NOTE To keep the present data instead of re-setting, press button with the cursor at

Steering Throttle

Servo reverse

Normal

Normal

Model select

Setting level

Servo reverse

Pit Mode

Servo Reverse / Sub Trim / Data Reset

St :

Th:

R4

F2

Sub trim

Sub trim

Servo direction

Pit Mode

Data reset

Sub trim

Servo direction

Pit Mode

Data reset

reset

Data reset

exit

Circuit Mode Functions

Circuit Mode contains the most commonly used programming features that you'll

likely be changing on the circuit. Circuit Mode programming is laid out in 3 levels

that are accessed in user's capability and the kind of race.

The Circuit Mode menu is accessible as shown below.

1. Press button at normal display

2. Press button for displaying Circuit Mode menu.

(Display automatically reverts back to Normal Mode if there is no activity in Circuit Mode for a period of 5 seconds).

End Point Adjustment (EPA)

End Point Adjustment, also referred to as travel adjust or travel volume, allows the

precise maximum servo throw in either direction to be independently adjusted. The

travel adjust range is from 0 - 150% (0 to 60

o

servo travel). This is used to set the

maximum right/left steering and forward/brake position independently. Remember, dual rate and brake trimmers work in unison with travel adjusts.

Note: Be sure that steering and throttle operation does not apply unreasonable

force to the servo horn. Unreasonable force applied to the servo horn may result in

damage to the servo and loss of control.

1. Press button until the cursor is at EPA.

2. Press button to display EPA screen.

3. Press / button until desired EPA value appears on steering left.

4. Press and / button until desired EPA value appears on steering right.

5. Press and / button until desired EPA value appears on throttle forward.

6. Press and / button until desired EPA value appears on throttle back.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

7. Press button to return to the Circuit menu.

EPA

Response

Steering speed

Circuit Mode

Steering

right 100

Throttle

left 100

forw 100

back 100

EPA

EPA

EPA

Response

Steering speed

Circuit Mode

Steering Throttle

10 % forw 10 %

back 10 %

Response

Max

Servo

Angle

Neutral Max

Steering / Throttle Angle

+100%

0%

-100%)

0

Response

This function is used to change the sensitivity of the steering and throttle servos

around the neutral position. It has no effect on the maximum servo travel.

For the throttle servo, the function changes the sensitivity of the throttle servo in

the throttle trigger forward side and brake side directions independently.

1. Press button until the cursor is at Response.

2. Press button to display the Response screen.

3. Press / button until the desired response value appears on steering.

4. Press and / button until desired response value appears on throttle for-

ward.

5. Press and / button until desired response value appears on throttle back.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

6. Press button return to the Circuit menu.

Steering Speed

Steering speed allows you to adjust the steering servo's speed away from center

(turning), and back to center (return) independently.

1. Press button until the cursor is at Steering Speed.

2. Press button to display the Steering Speed screen.

3. Press / button until desired value appears on turning.

4. Press and / button until desired value appears on

returning.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

5. Press button return to the Circuit menu.

Response

EPA

Response

Steering speed

Circuit Mode

turn : 80 retn : 70

Steering speed

Neutral

0

100%

80%

70%

Right / Left

return speed

turn speed

EPA

Response

2-Step St speed

Circuit Mode

turn1 : 80 retn1 : 60

retn2 : 45turn2 : 75

c.p 45 c.p 50

2-Step steering speed

100%

Neutral

Right / Left

turn speed

return speed

80%

75%

0

60%

45%

45 50

change point

2-Step Steering Speed

This function is similar to Steering Speed, but it has speed change points. You adjust the steering servo's speed independently away from center (turning), and back

to center (return), as above. You can also select points in both turn and return,

and the speed between each point can be independently selected.

1. Press button until the cursor is at 2-Step Steering Speed.

2. Press button to display the 2-Step Steering Speed screen.

3. Press / button until the desired value appears on turning 1.

4. Press and / button until the desired value appears on turning change

point.

5. Press and / button until the desired value appears on turning 2.

6. Press and / button until the desired value appears on returning 1.

7. Press and / button until the desired value appears on returning change

point.

8. Press and / button until the desired value appears on returning 2.

(To return to default setting, press , buttons simultaneously for 3 seconds)

9. Press button to return to the Circuit menu.

Throttle Speed

This function allows you to adjust the throttle servo's speed independently away

from neutral (at acceleration), and back to neutral (at deceleration).

1. Press button until the cursor is at Throttle Speed.

2. Press button to display the Throttle Speed screen.

3. Press / button until desired value appears on throttle speed forward.

4. Press and / button until desired value appears on throttle speed back.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

5. Press the button to the return to the Circuit menu.

2-Step Steering Speed / Throttle Speed

change point

acceleration speed

decelelration speed

Trigger

Speed

Max

100%

Neutral

90%

75%

0

50

accel : 90 decel : 75

Throttle speed

Response

Steering speed

Throttle speed

Circuit Mode

acceleration speed

decelelration speed

Trigger

Speed

Max

change point

100%

Neutral

80%

75%

0

50

Response

Steering speed

2-Step St speed

Circuit Mode

turn1 : 80 retn1 : 60

retn2 : 45turn2 : 75

c.p 45 c.p 50

2-Step steering speed

60%

45%

45

2-Step Throttle Speed

This function is similar with Throttle speed but it has speed change points. You adjust the throttle servo's speed independently away from neutral (at acceleration),

and back to neutral (at deceleration), as above. You can also select points in both

acceleration and deceleration, and the speed between each point can be independently selected.

1. Press button until the cursor is at 2-Step Throttle Speed.

2. Press button to display 2-Step the Throttle Speed screen.

3. Press / button until the desired value appears on acceleration low.

4. Press and / button until the desired value appears on acceleration

change point.

5. Press and / button until the desired value appears on acceleration high.

6. Press and / button until the desired value appears on deceleration low.

7. Press and / button until the desired value appears on deceleration

change point.

8. Press and / button until desired value appears on deceleration high.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

9. Press button return to the Circuit menu.

Start

This feature allows for smooth and even acceleration under adverse conditions,

such as a wet circuit. When the start function is activated, merely operating the

throttle trigger slowly causes the throttle servo to automatically switch from the set

trigger position to a preset point so that the tires do no loose their grip and the car

accelerates smoothly. By pressing the start button " " on control panel, "STA" will

appear on the lower side of the Normal LCD display. The Start function is only

available at the first triggering. For activating again, press the start button on the

control panel.

1. Press button until the cursor is at Start.

2. Press button to display the Start screen.

3. Press / button until desired value appears on throttle position.

4. Press and / button until desired value appears on trigger position.

(To return to the default setting, press , buttons simultaneously for 3 sec-

onds)

5. Press button return to the Circuit menu.

2-Step Throttle Speed / Start

Throttle speed

Start

A.B.S

Circuit Mode

throttle : 0

trigger : 5

Start off

Positon

3-Step A.B.S / A.B.S

3-Step A.B.S

This function allows you to select 1 of 3 A.B.S settings based on circuit and race

conditions.

1. Press button until the cursor is at 3-Step ABS.

2. Press button to display the 3-Step ABS screen.

3. Press / button until the cursor is at the desired level.

(To return to the default setting, press , buttons simultaneously for 3

seconds)

4. Press button return to the Circuit menu.

Anti-lock Breaking System (A.B.S)

Your Husky features an advanced anti-lock breaking system! A.B.S works as a

pulse brake, allowing greater stability and control during hard braking. The pulse

width ("on" time versus "off" time) is called duty, the pulse height (how hard the

brakes pulse) is called width, and the braking point where ABS actually begins is

called position. A delay can be programmed so that regular braking occurs first,

then at a pre-set delay ABS braking begins.

1. Press button until the cursor is at ABS.

2. Press button to display the ABS screen.

3. Press / button until desired value appears on width.

4. Press and / button until desired value appears on position.

5. Press and / button until desired value appears on cycle.

6. Press and / button until desired value appears on delay.

7. Press and / button until desired value appears on duty.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

8. Press button return to the Circuit menu.

Throttle speed

Start

A.B.S

Circuit Mode

Fast

Off

Slow

Medium

A.B.S off

Throttle speed

Start

A.B.S

Circuit Mode

width : 0

position : B5

cycle : 1

A.B.S off

width

A

B

Position

cycle

A : B = Duty

Start Max

Auto St control

Punch

Idle

Circuit Mode

Low High

Steering

Speed

change point

100%

80%

70%

0

50

speed L : 80

speed H : 70

Th c.p 50

Auto steering control

Auto Steering Control

This function allows two steering servo speeds, automatically adjusted at high- and

low-speed range of throttle. When it is activated, "ASC" appears on the lower side of

the Normal LCD display.

If you want sensitive steering at corners and less sensitive steering on the straightaway, reduce the auto steering speed value at high-speed range and increase the

value at low-speed range. The reverse is also available.

NOTE 2-Step steering speed is deactivated on Auto steering control.

1. Press button until the cursor is at Auto Steering Control.

2. Press button to display the Auto Steering Control screen.

3. Press / button until the desired value appears on speed low.

4. Press and / button until the desired value appears on change point.

5. Press and / button until the desired value appears on speed high.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

6. Press button to return to the Circuit menu.

Auto Steering Control

Auto St speed

Punch

Idle

Circuit Mode

Steering

Throttle

20%

30%

40%

forw

back

Punch

Punch

The Punch throttle feature is used to reduce or eliminate the dead throttle area

that exists from neutral to the starting point of throttle and from neutral to the

starting point of braking.

This area is sometimes known as dead band. As more throttle trim (also known as

static brake) is applied, more of the dead trigger area right off neutral exists. Adjust

a forward value such that your vehicle's wheels just start to turn when the trigger

is slightly squeezed. This gives the most accurate feel and eliminates this dead

area.

This feature is also available for steering. Steering Punch can eliminate dead band

around neutral.

1. Press button until the cursor is at Punch.

2. Press button to display the Punch screen.

3. Press / button until the desired value appears on steering position.

4. Press and / button until the desired value appears on throttle forward

position.

5. Press and / button until the desired value appears on throttle back position.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

6. Press button return to the Circuit menu.

Idle Up

The Idle up function is normally used to advance the throttle position slightly,

making it easier to start gas cars. Pressing the Idle up button " " on the control

panel can activate this function, the throttle servo will offset to the pre-programmed position, and "IDL" will appear on the lower side of the Normal LCD display.

NOTE Idle up is available only at first triggering. For activating, press Idle up button on the

control panel again.

1. Press button until the cursor is at Idle Up.

2. Press button to display the Idle Up screen.

3. Press / button until the desired value appears on throttle position.

(To return to the default setting, press , buttons simultaneously for 3 seconds)

4. Press button return to the Circuit menu.

Max

Servo

Angle

Neutral Max

Steering/Throttle Angle

100%

0

Punch

Auto St speed

Punch

Idle

Circuit Mode

Throttle

Idel up

off

position : 0

4. Limited Warranty

Proton Control Systems, Inc. guarantees your Husky and Ken to be free from defects in materials and workmanship for a period of 120 days from original date of

purchase (verified by dated, itemized sales receipt). Warranty does not cover incorrect installation, components worn by use or excessive force, altering the antenna,

exceeding the recommended input voltage, using the Ken without its case, tampering with the electronics, allowing water, moisture, or any foreign material to enter

your Husky and Ken or come in contact with the PC board, incorrect installation,

or any damage caused by vibration, shock, or a crash. In no case shall our liability

exceed product's original cost. We reserve the right to modify warranty provisions

without notice. Because Proton Control Systems, Inc. has no control over connection and use of receiver, no liability may be assumed nor will be accepted for damage resulting from the use of this product. Every Husky and Ken are thoroughly

tested and tuned before leaving our facility, and is therefore considered operational.

By the act of connecting/operating Husky and Ken, the user accepts all resulting

liability.

5. Approval

CE

The R&TTE (Radio Equipment & Telecommunications Terminal Equipment) directive is the new European directive relating to radio equipment and telecommunications transmission equipment. It also covers the collective recognition of the conformity of such equipment. One part of the R&TTE directive regulates the

introduction and operation of radio systems in the European Community.

An important change is the abolition of approval. The manufacturer or importer

must subject radio equipment to a conformity appraisal process before that equipment is introduced.

The CE symbol is attached to the device to indicate that it conforms with the valid

European norms.

An exclamation mark is also to be attached to radio transmitting equipment, to indicate that the permissible frequencies are not yet uniform throughout Europe.

This requirement applies to all the countries included in the list attached.

It is essential to note that these radio control systems may only be operated on the

approved frequencies, as listed in the table.

Please note that the user bears the responsibility for compliance with this requirement, and for ensureing that the radio system complies with the directives.

In Germany the requirement to purchase a licence for the operation of 35 MHz systems remains in effect; please refer to the operating instructions, or the separate

sheet included with them.

Limited Warranty / Approval

Proton Control Systems Inc.

182-4 Dodang-dong Wonmi-ku Bucheon-city

6. Frequency List

- 40MHz, Europe

50 40.665

51 40.675

52 40.685

53 40.695

54 40.715

55 40.725

56 40.735

57 40.765

58 40.775

59 40.785

81 40.815

82 40.825

83 40.835

84 40.865

85 40.875

86 40.885

87 40.915

88 40.925

89 40.935

90 40.965

91 40.975

92 40.985

D 50 ~ 92 40.665 ~ 40.985

B 50 ~ 53 40.665 ~ 40.695

DK 50 ~ 53 40.665 ~ 40.695

GB 50 ~ 92 40.665 ~ 40.985

SF 50 ~ 57, 59 40.665 ~ 40.765, 40.785

GR 50 ~ 92 40.665 ~ 40.985

IRL 51 ~ 91 40.665 ~ 40.975

IS 50 ~ 91 40.665 ~ 40.975

I 50 ~ 84 40.665 ~ 40.865

L 50 ~ 54 40.665 ~ 40.695

NL 50 ~ 53 40.665 ~ 40.715

N 50 ~ 59 40.665 ~ 40.785

A 50 ~ 53 40.665 ~ 40.695

P 50 ~ 54 40.665 ~ 40.695

S 50 ~ 56 40.665 ~ 40.735

E 50 ~ 53 40.665 ~ 40.695

CH 50 ~ 92 40.665 ~ 40.985

Frequency List

Proton Control Systems Inc.

182-4 Dodang-dong Wonmi-ku Bucheon-city

Loading...

Loading...