Page 1

Navigator

Table Of Contents

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/navigator.html[30/09/2009 12:13:01]

Page 2

Table Of Contents

COVER

1 Safety Precaution

2 Before Repair and Adjustment

3 Handling Precautions For Traverse Deck

4 Precaution of Laser Diode

5 Protection Circuitry

6 Accessories

7 Front Panel Controls

7.1 Front Panel

8 Operation Checks and Main Component Replacement Procedures

8.1 Checking Procedure for each major P.C.B.

9 Self-Diagnostic Display Function

10 Type Illustrations of ICs, Transistors& Diodes

11 Terminal Functions of ICs

11.1 IC701 (AN8885SBE1) Servo Amplifier

11.2 IC702 (MN662790RSC) Servo processor/ Digital signal processor/ Digital filter/ D/A converter

11.3 IC703 (AN8739SBE2) Focus coil/ Tracking coil/ Traverse motor/ Spindle motor driver

11.4 IC401 (C2BBGD000075) Microprocessor

12 Block Diagram

13 Schematic Diagram

14 Printed Circuit Board

15 Troubleshooting Guide

16 Wiring Connection Diagram

17 Parts Location and Replacement Parts List

17.1 CD Loading Mechanism

17.1.1 CD Loading Mechanism Part Location

17.1.2 CD Loading Mechanism Part List

17.2 Cabinet

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/slpd7p.html[30/09/2009 12:13:32]

Page 3

17.2.1 Cabinet Parts Location

17.2.2 Cabinet Parts List

17.3 Electrical Parts List

17.4 Packing Materials& Accessories Parts List

17.5 Packaging

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/slpd7p.html[30/09/2009 12:13:32]

Page 4

Service Manual

TOP NEXT

Order No. MD0102030C1

A2

Compact Disc Changer

SL-PD7

Colour

(K) ... Black Type

P ... U.S.A.

PC ... Canada

TRAVERSE DECK

RAE0152Z-3 Mechanism Series

AUDIO

No. of channels 2 (left and right, stereo)

Frequency response 2-20000 Hz,±1 dB

Output voltage 2V (at 0 dB)

Dynamic range 92 dB

S/N 100 dB

Total harmonic distortion 0.007% (1kHz, 0 dB)

Wow and flutter Below measurable limit

DA converter MASH (1 bit)

Output impedance Approx. 1kO

Load impedance More than 10 kO

PICKUP

Wavelength 780 nm

GENERAL

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0000000000.html[30/09/2009 12:14:24]

Page 5

Power supply AC 120 V, 60 Hz

Power consumption 9 W

Dimensions (W x H x D) 430 x 125 x 374 mm

Mass 4.5 kg (9.9 lb.)

Power consumption in standby mode: 1 W

Notes:

1. Specifications are subject to change without notice./Mass and dimensions are approximate.

(16- 15/16” x 4- 29/32” x 14-23/32”)

© 2001 Matsushita Electronics (S) Pte. Ltd. All rights reserved. Unauthorized copying and distribution is a

violation of law.

TOP NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0000000000.html[30/09/2009 12:14:24]

Page 6

1 Safety Precaution

TOP PREVIOUS NEXT

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance

test to prevent the customer from being exposed to a shock hazard.

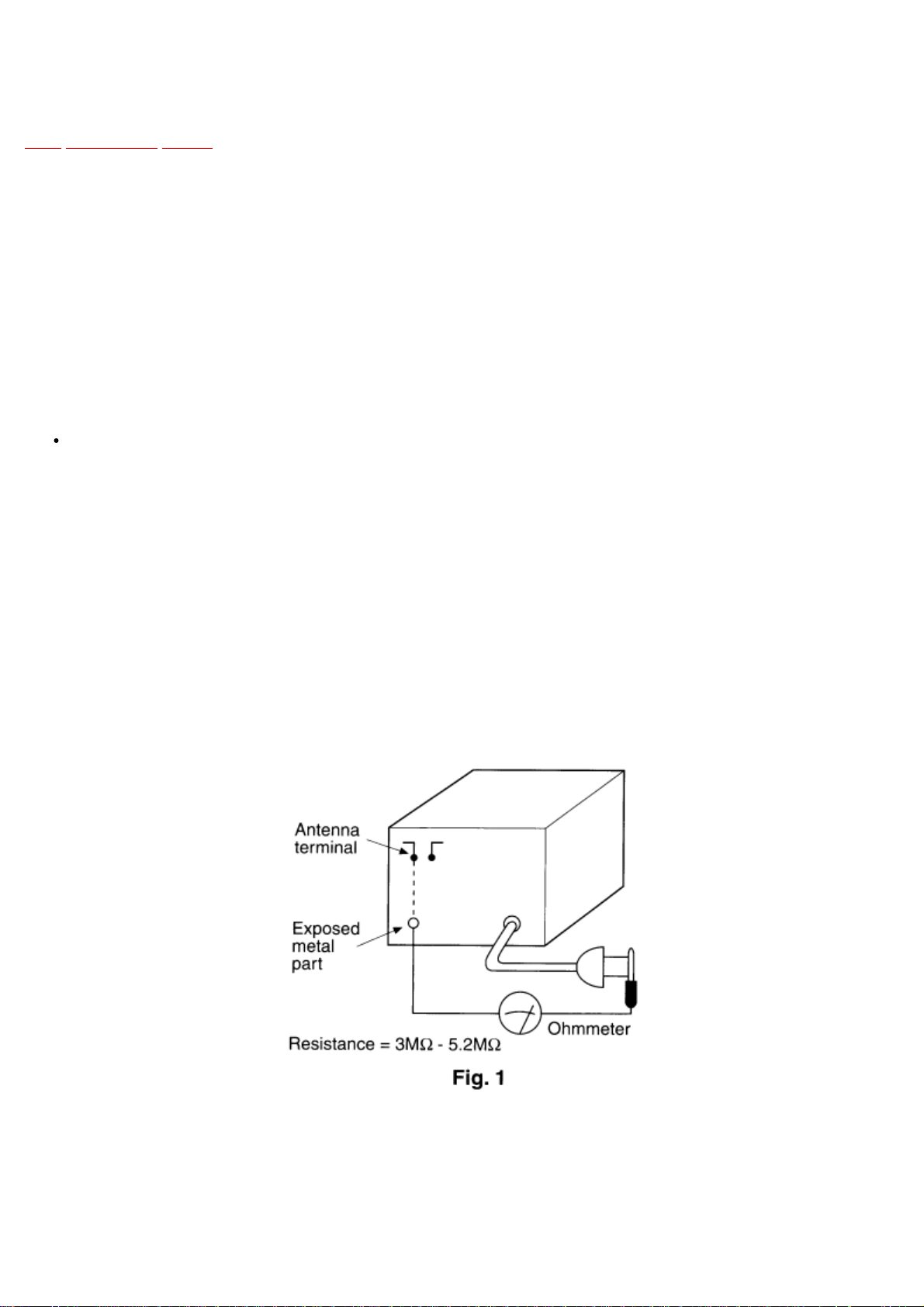

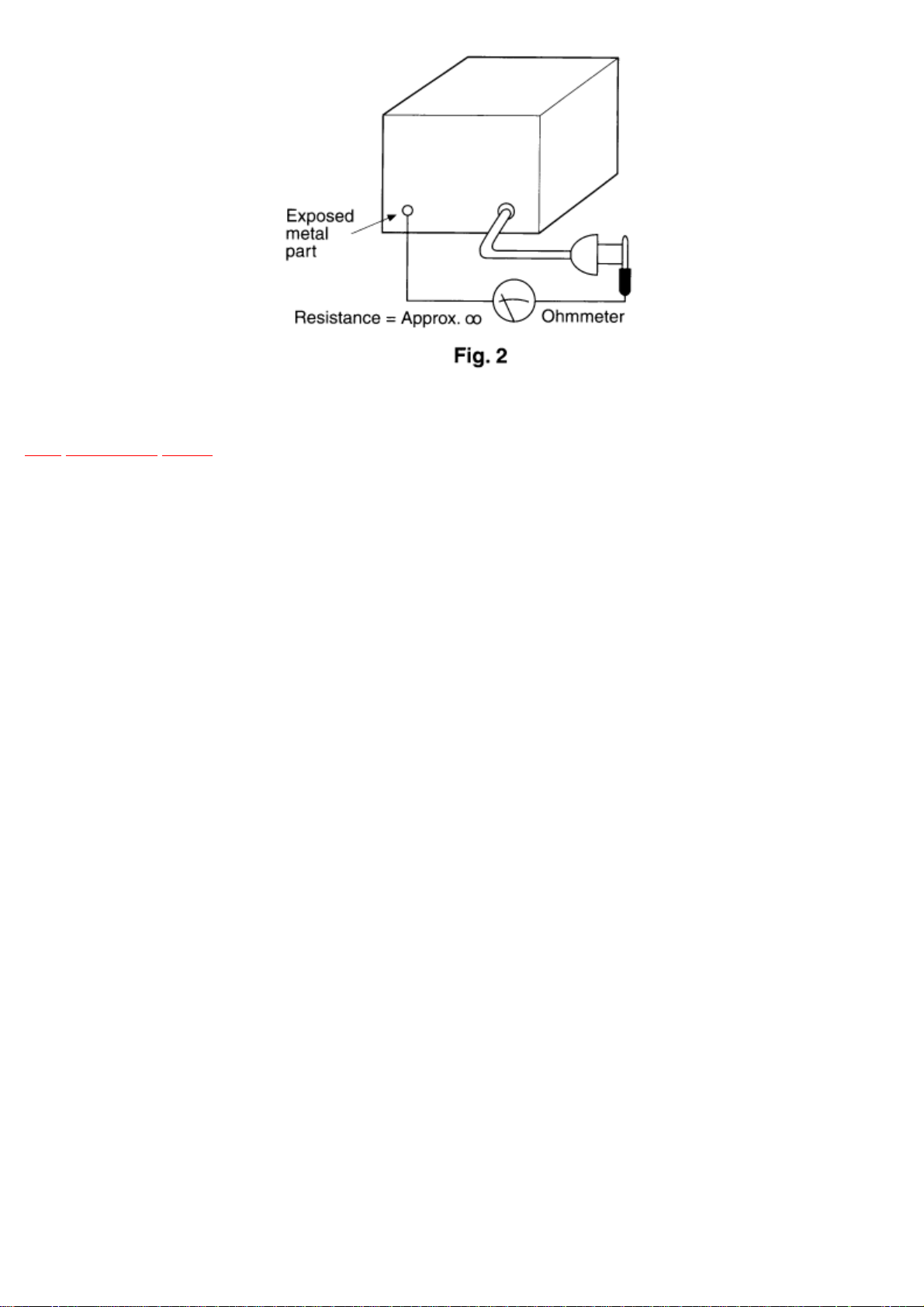

Insulation Resistance Test

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with ohmmeter between the jumper AC plug and each exposed metal cabinet

part, such as screw heads, antenna, control shafts, handle brackets, etc. Equipment with antenna terminals

should read between 3MO and 5.2MO toall exposed parts*. (Fig 1) Equipment without antenna terminals

should read approximately infinity to all exposed parts. (Fig 2)

*Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard. The equipment

should be repaired and rechecked before it is returned to the customer.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0100000000x.html[30/09/2009 12:14:25]

Page 7

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0100000000x.html[30/09/2009 12:14:25]

Page 8

2 Before Repair and Adjustment

TOP PREVIOUS NEXT

Disconnect AC power, discharge Power Supply Capacitors C12 through a 10 O, 5 W resistor to ground. DO NOT

SHORT-CIRCUIT DIRECTLY (with a screw driver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid over current.

Current consumption at AC 120 V, 50 Hz and 60 Hz in NO SIGNAL mode should be 50~130 mA and 40~80 mA

respectively.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0200000000x.html[30/09/2009 12:14:25]

Page 9

3 Handling Precautions For Traverse Deck

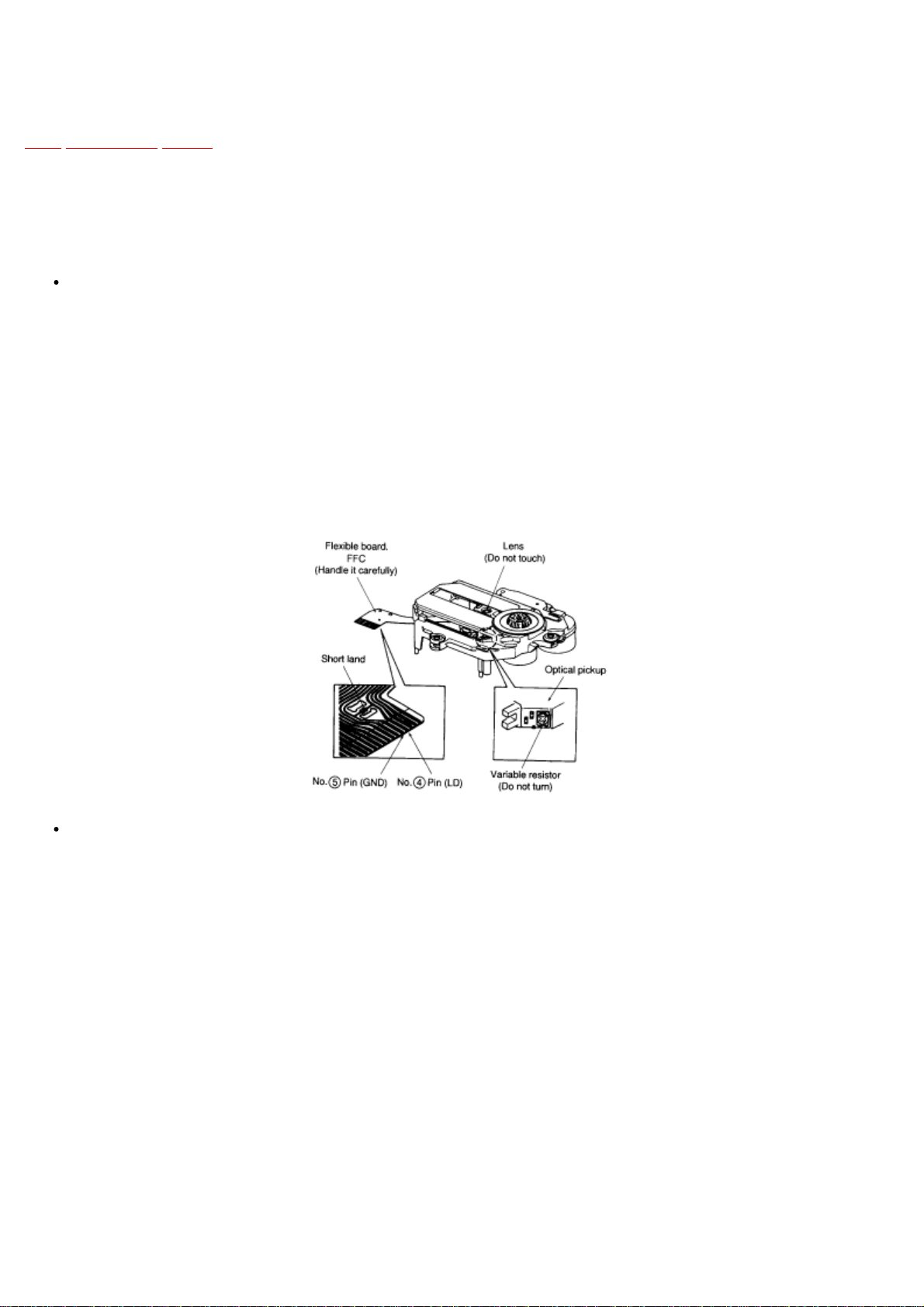

TOP PREVIOUS NEXT

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static

electricity of clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical

shock.

2. The short land between the No.4(LD) and No.5(GND) pins on the flexible board (FFC) is shorted with a

solder build-up to prevent damage to the laser diode.To connect to the PC board, be sure to open by

removing the solder build-up, and finishthe work quickly.

3. Take care not to apply excessive stress to the flexible board (FFC).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

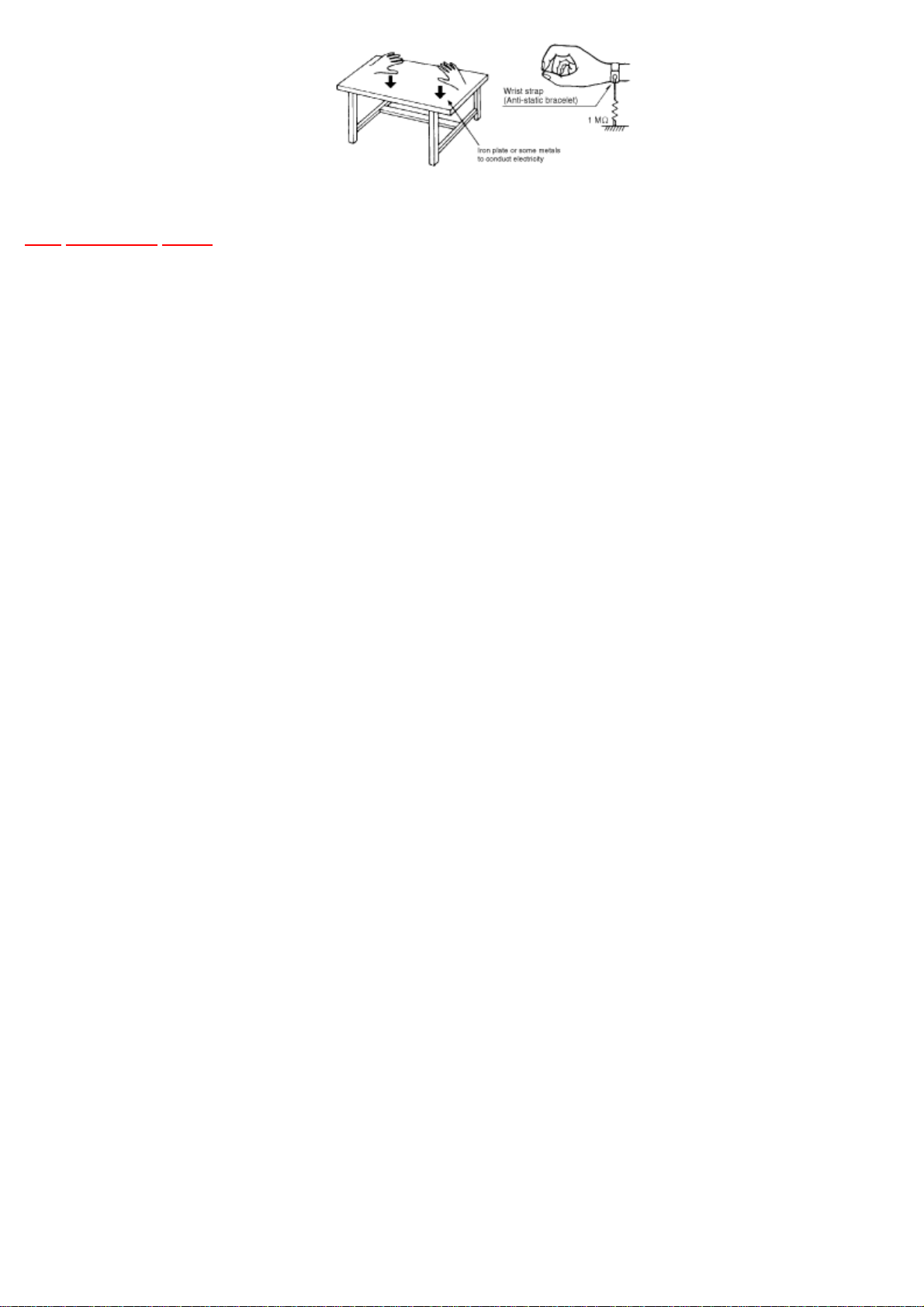

Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is

placed, and ground the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your

clothes touch the traverse deck (optical pickup).

Caution when Replacing the Traverse Deck:

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics

breakdown. Be sure to remove the solder from the short point before making connections.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0300000000x.html[30/09/2009 12:14:26]

Page 10

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0300000000x.html[30/09/2009 12:14:26]

Page 11

4 Precaution of Laser Diode

TOP PREVIOUS NEXT

Caution:

This unit utilizes a class 1 laser. Invisible laser radiation is emitted from the optical pickup lens. When the unit is

turned on:

1. Do not look directly into the pickup lens.

2. Do not use optical instruments to look at the pickup lens.

3. Do not adjust the preset variable resistor on the pickup lens.

4. Do not disassemble the optical pickup unit.

5. If the optical pickup is replaced, use the manufacturer’s specified replacement pickup only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0400000000x.html[30/09/2009 12:14:26]

Page 12

5 Protection Circuitry

TOP PREVIOUS NEXT

The protection circuitry may have operated if either of the following conditions are noticed:

No sound is heard when the power is turned on.

Stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker

connection wires are “shorted”, or if speaker systems with an impedance less than the indicated rated impedance

ofthe amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on

again.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0500000000x.html[30/09/2009 12:14:27]

Page 13

6 Accessories

TOP PREVIOUS NEXT

AC power supply cord... 1 pc.

Stereo connection cable... 1 pc.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0600000000x.html[30/09/2009 12:14:27]

Page 14

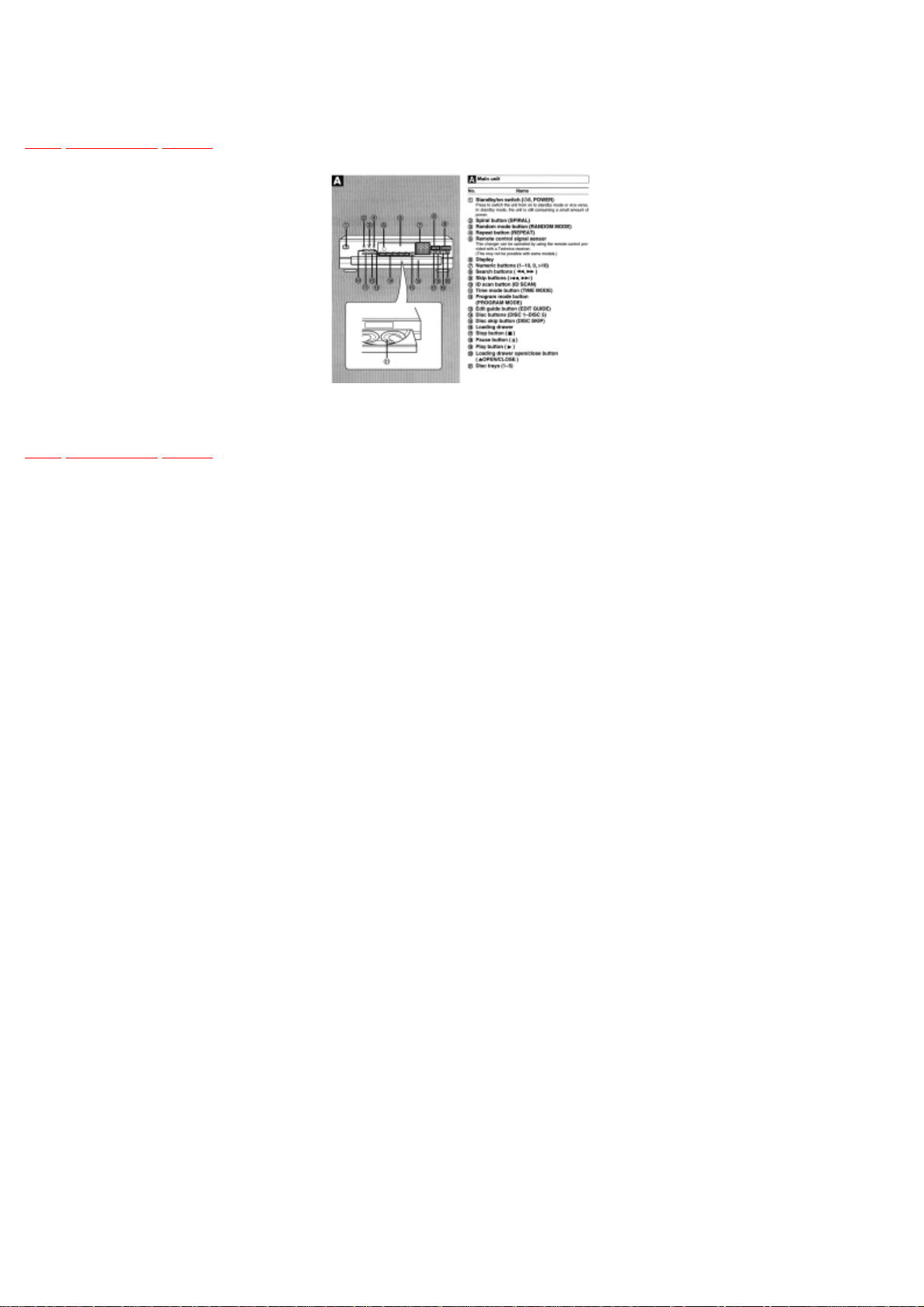

7 Front Panel Controls

TOP PREVIOUS NEXT

7.1 Front Panel

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0700000000x.html[30/09/2009 12:14:28]

Page 15

7.1 Front Panel

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0701000000.html[30/09/2009 12:14:28]

Page 16

8 Operation Checks and Main Component

Replacement Procedures

TOP PREVIOUS NEXT

“ATTENTION SERVICER”

Some chassis components maybe have sharp edges. Be careful when diassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing

the main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures./Special reassembly

procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Content

Checking Procedure for each major P.C.B.

.................................................................................................................. P.g. 7~9

8.1 Checking Procedure for each major P.C.B.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0800000000x.html[30/09/2009 12:14:29]

Page 17

8.1 Checking Procedure for each major P.C.B.

TOP PREVIOUS NEXT

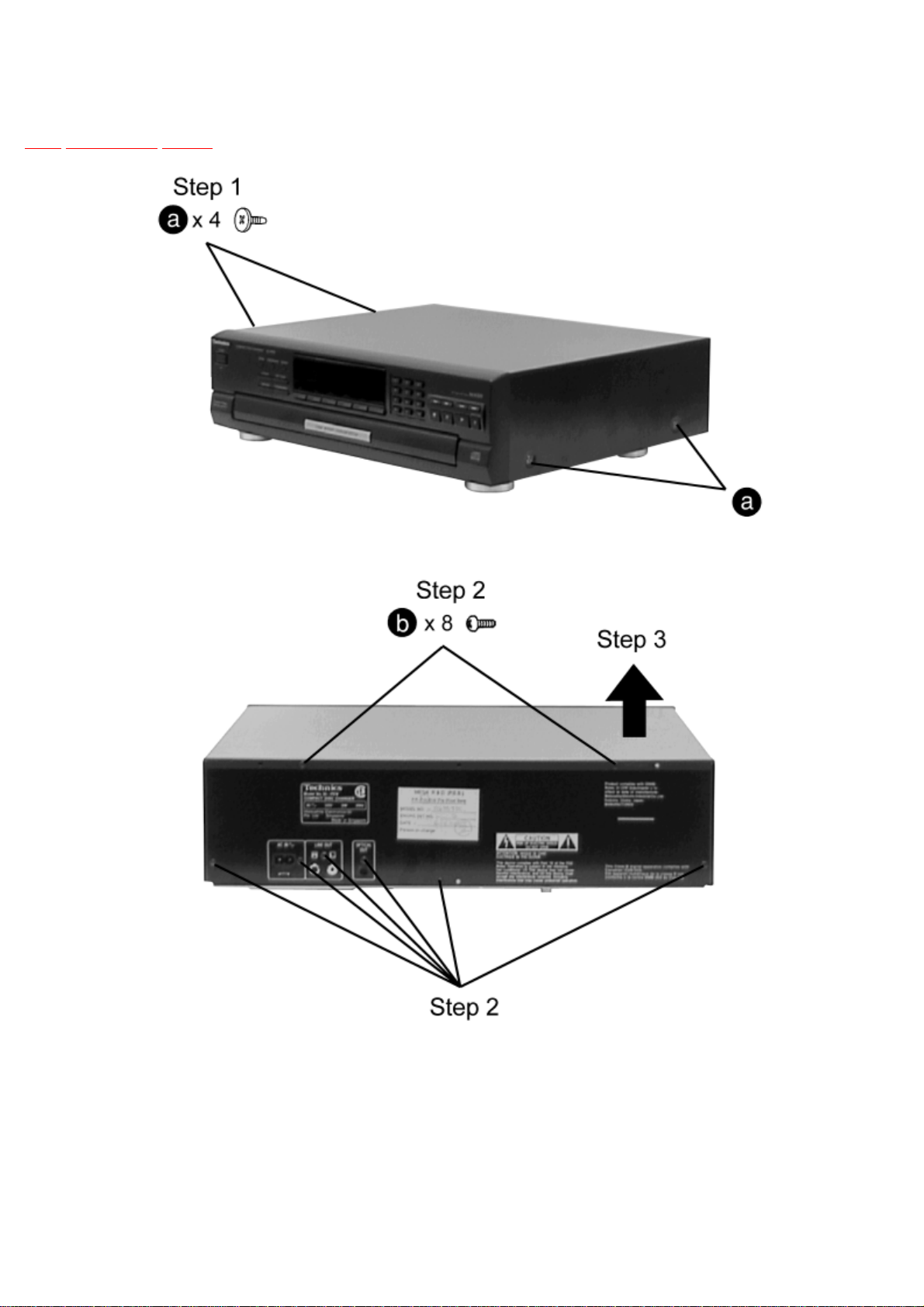

Step 1 Remove all the screws.

Step 3 Remove all the screws and remove top cabinet as shown.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0801000000.html[30/09/2009 12:14:30]

Page 18

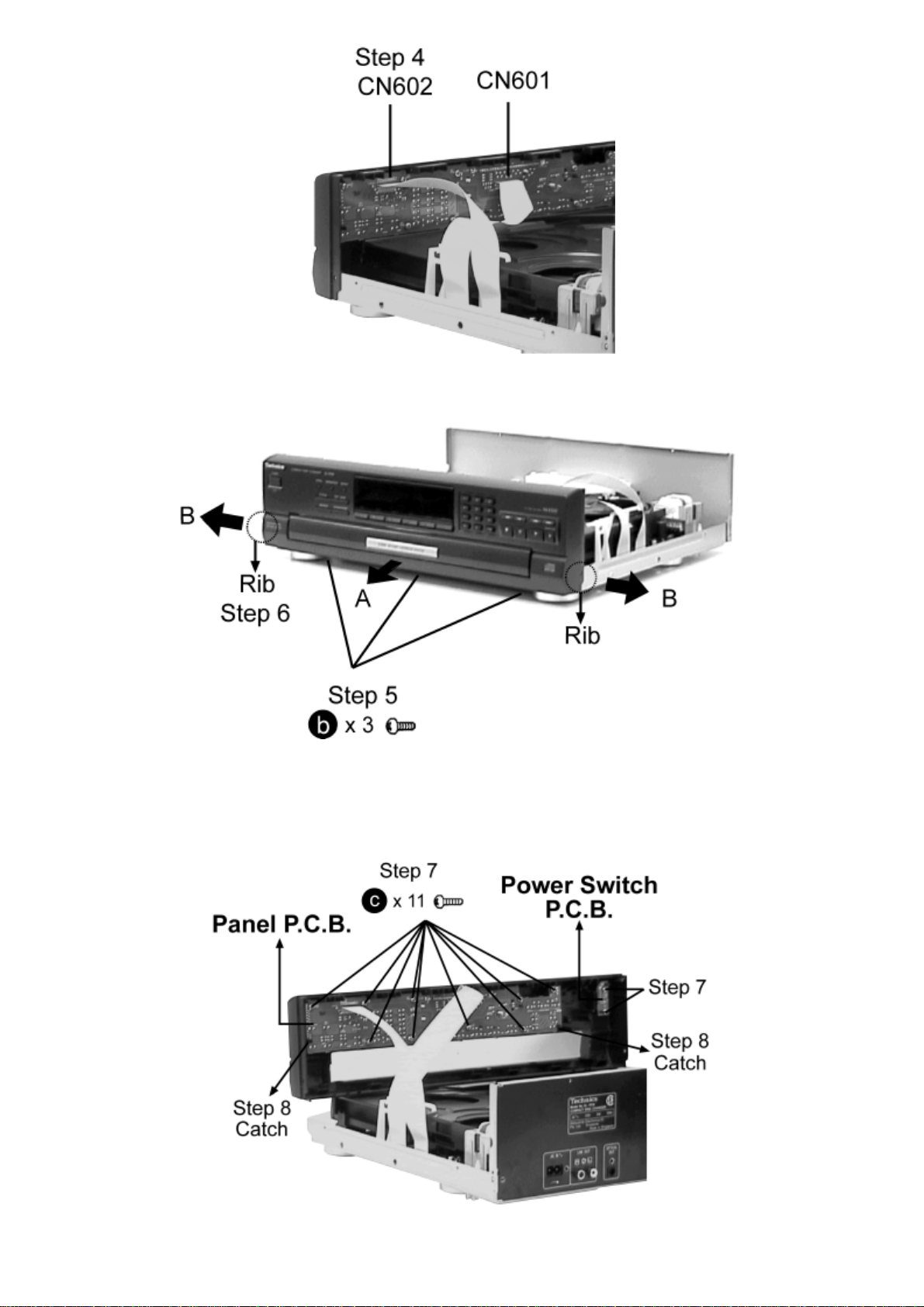

Step 4 Release the connectors CN601 and CN602.

Step 5 Remove all the screws.

Step 6 Pull the front panel in both direction of arrow B to unlock the rib and then remove the front in the direction

of arrow A.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0801000000.html[30/09/2009 12:14:30]

Page 19

Step 7 Remove all the screws.

Step 8 To check Panel P.C.B. component side release both catches.

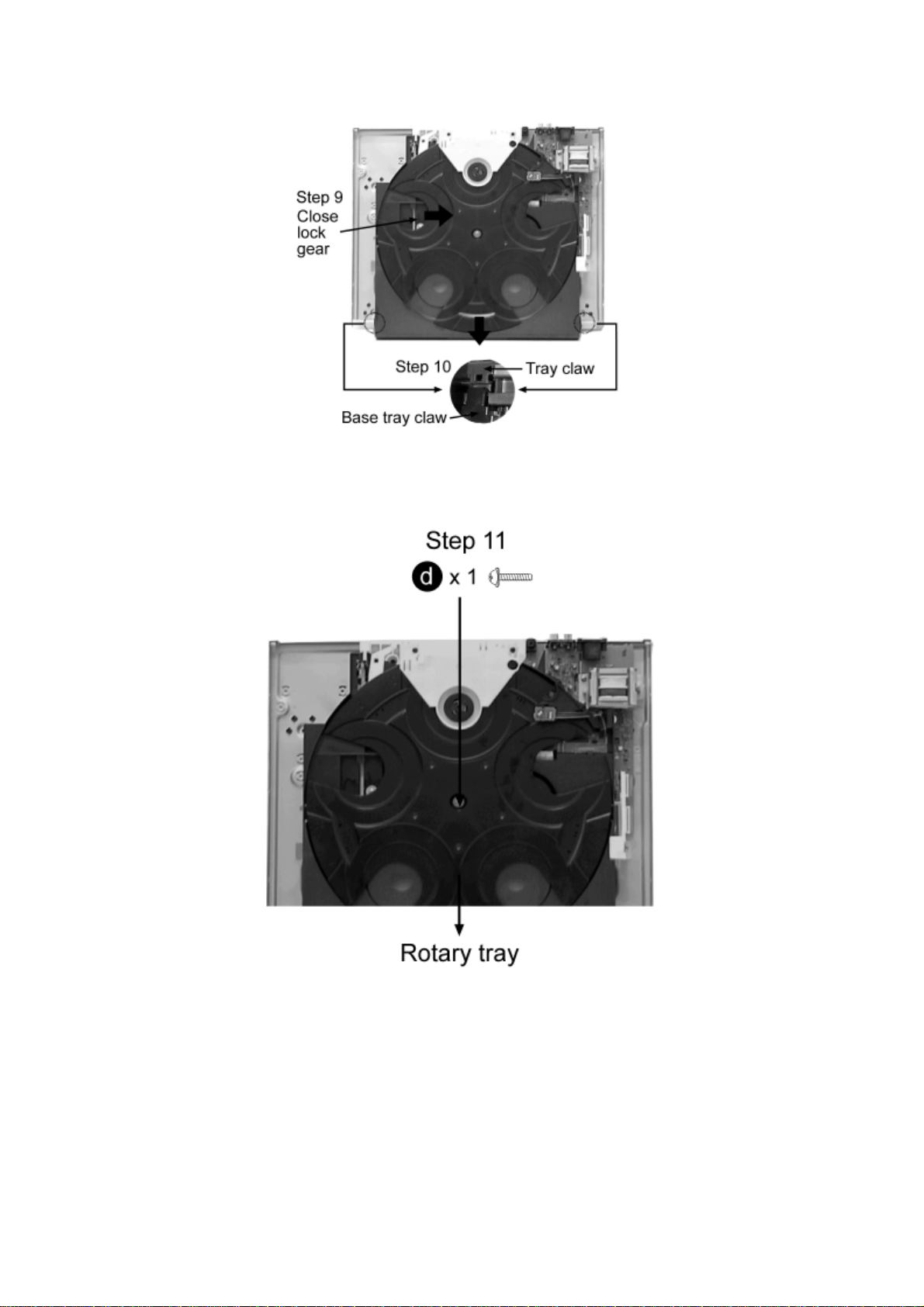

Step 9 Keep the close lock gear pressed in the direction shown, and move the tray in the direction shown.

Step 10 Fit the claw of the tray and the claw of the Base tray guide (left & right side).

Step 11 Remove the screw and the Rotary tray.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0801000000.html[30/09/2009 12:14:30]

Page 20

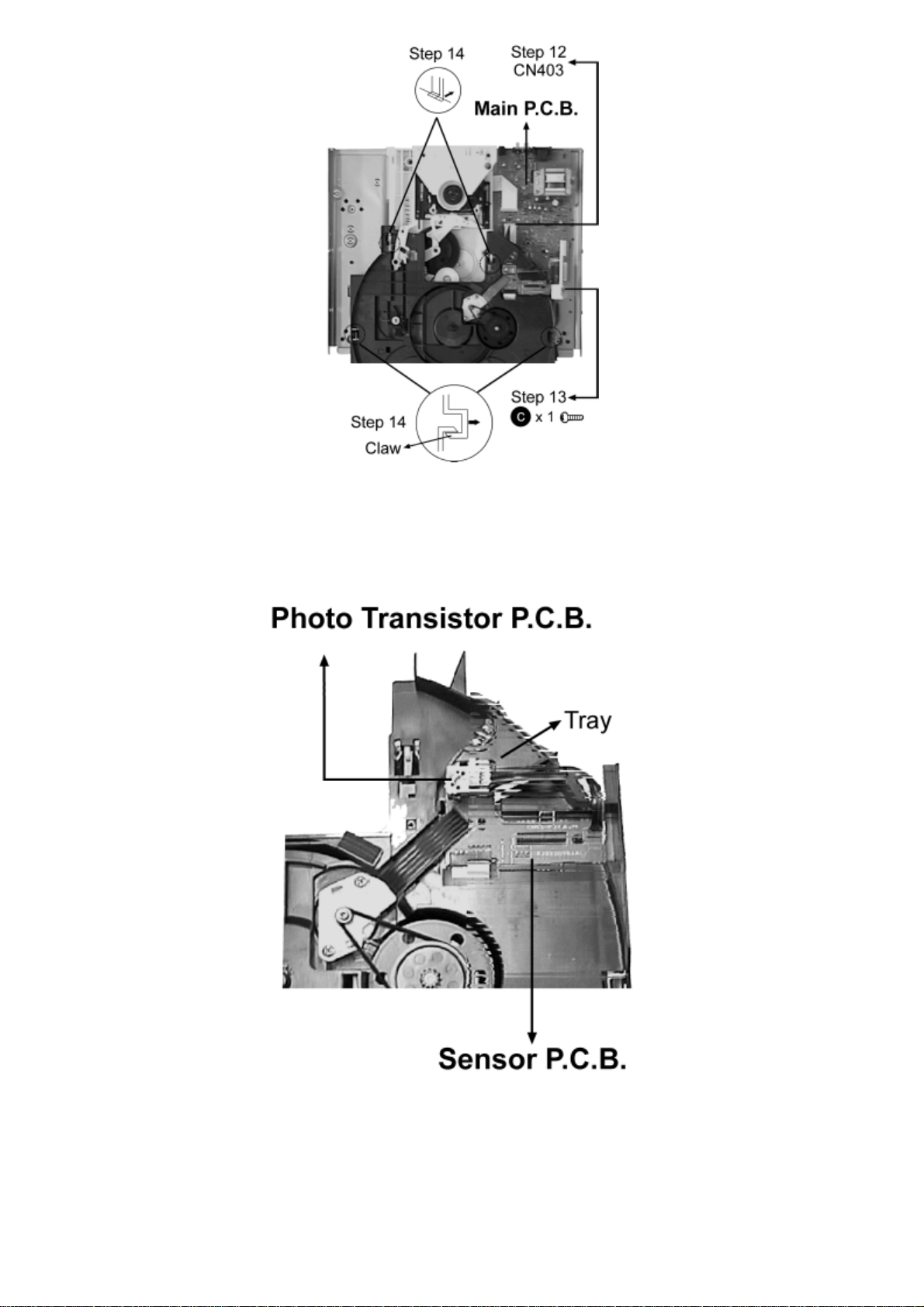

Step 12 Remove the connector CN403.

Step 13 Remove the screw.

Step 14 Pull the claw in the direction shown and remove the tray.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0801000000.html[30/09/2009 12:14:30]

Page 21

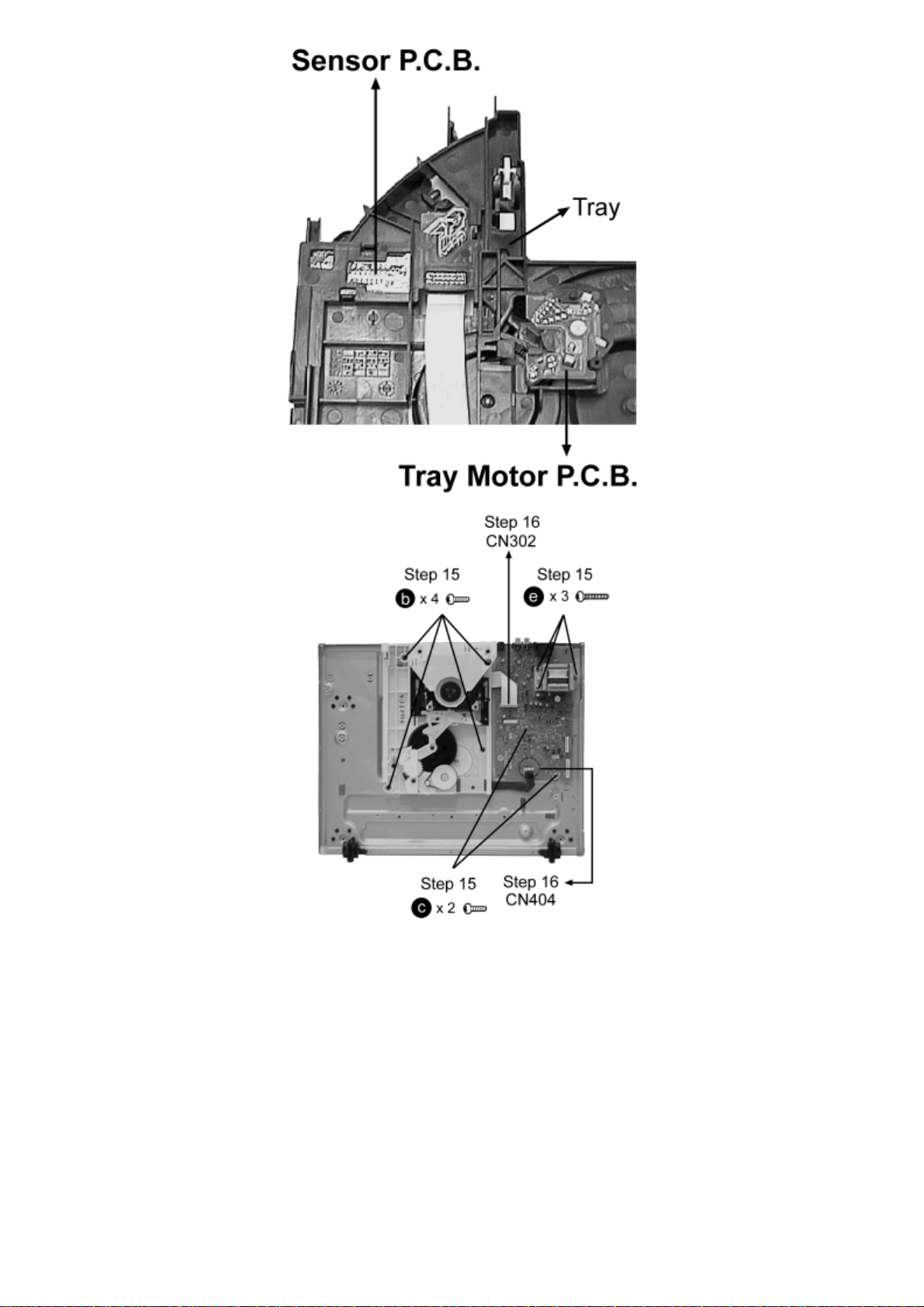

Step 15 Remove all the screws.

Step 16 Release the connectors CN302 and CN404.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0801000000.html[30/09/2009 12:14:30]

Page 22

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0801000000.html[30/09/2009 12:14:30]

Page 23

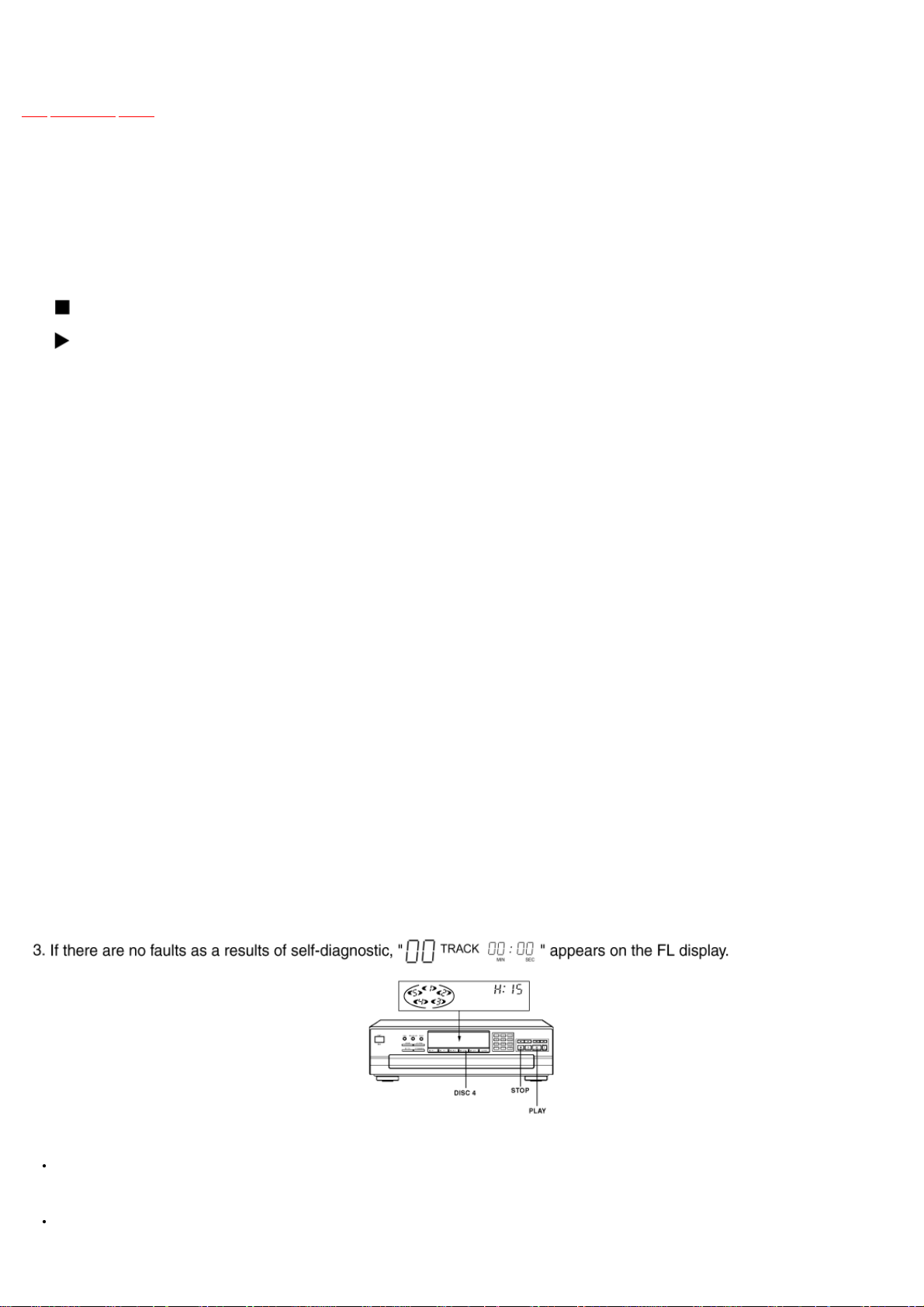

9 Self-Diagnostic Display Function

TOP PREVIOUS NEXT

Self-diagnostic display

This unit is equipped with a self-diagnostic display function which, if a problem occurs, will display an error code correcsponding to the problem.

Use this function when performing maintenance on the unit.

Entering the Self-Diagnostic Mode

1. With no CD loaded in the tray, turn on the unit.

2. Unplug the power cord of the unit, and then plug it back in while pressing the STOP (

), PLAY (

) and DISC 4 buttons together.This will bring up the FL display.

3. Release the above three buttons.

To Display Self-Diagnostics Results

1. When the FL display lights up, the unit automatically repeats an approximately 50-second cycle of the following operations.

START

A. Tray opens. -------- (A)

B. Tray closes. -------- (B)

C. Traverse deck lifts.

D. Tray opens.

E. Tray closes. -------- (B)

F. Traverse deck lower down.

G. Rotary tray turns counter-clockwise two disc slots. -------- (C)

H. Traverse deck lifts once, and then lowers

I. Rotary tray turns clockwise one disc slot. -------- (C)

J. Traverse deck lifts once, and then lowers

K. Rotary tray turns clockwise three disc slots. -------- (C)

L. Traverse deck lifts once, and then lowers

M. Rotary tray turns counter-clockwise one disc slot. -------- (C)

N. Traverse deck lifts once, and then lowers

O. Rotary tray turns counter-clockwise two disc slots./(Repeats from a - o).

2. Self-diagnostic fault results appear on the FL display for approximatelly one second as “H15” at location (A), “H16” at (B) and “H18” at (C), during the

above cycle.

To Return to Normal Display

Press the power button to off the unit, and then turn it on again.

To Display Self-Diagnostics Results Again

Follow steps 1 through 3 of “Entering Self-Diagnostic Mode” above.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0900000000x.html[30/09/2009 12:14:32]

Page 24

To Clear the Display of Self-Diagnostics Results

Turn off the unit to clear the contents of the stored faults results.

Interpretation of error codes

Error

code

H15 CD tray does not open or close when CD tray open/close(

H16

) button is pressed./When the CD open/close (

) button is pressed, the CD tray closes momentarily but then opens again, or opens momentarily and then

closes again.

F18 Faulty rotary turret rotation detection. Example : The turret continues to turn at the inintial position without

stopping.

Problem condition Correction procedure

TOP PREVIOUS NEXT

Faulty loading motor and motor drive IC (IC501), or faulty contact or short-circuit on open/close detect switch, S551. (Check

and replace)

Check the optical sensor (D501) and replace if necessary.

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s0900000000x.html[30/09/2009 12:14:32]

Page 25

10 Type Illustrations of ICs, Transistors& Diodes

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1000000000x.html[30/09/2009 12:14:33]

Page 26

AN8885SBE1 (28p)

3

2

1

1

UPD78044F186 (80p)

MN662790RSC (80p)

1

BA4558FDXE2

8

1

4

BA6247N

5

1

10

BA033T

AN8739SBE2

2SD2037ETA

B

C

E

2SD1862QTV2

B

RSQGP1S53V

Ca

C

E

SG-206S

E

A

Ca

A

2SA1037AKSTX

C

B

E

KRC101MTA MTZJ3R6BTA

E

C

B

2SB1238QRTV2

2SD1859QRTV2

B

C

E

GL380

PT381

Anode

Cathode

A

Ca

2SD2144STA

B

C

E

RVD1SS133TA

A

Anode

Ca

Cathode

B

A

Anode

2SC2785FETA

KRA103MTA

KRC107MTA

C

E

Ca

Cathode

KRC111MTA

MTZJ30BTA

MTZJ5R1BTA

MTZJ5R6BTA

MTZJ6R2CTA

MTJZ6R8CTA

MTJZ9R1BTA

MTZJ9R1CTA

RL1N4003S-P

Ca

Cathode

C

C

E

A

Anode

Page 27

11 Terminal Functions of ICs

TOP PREVIOUS NEXT

11.1 IC701 (AN8885SBE1) Servo Amplifier

11.2 IC702 (MN662790RSC) Servo processor/ Digital signal processor/ Digital filter/ D/A converter

11.3 IC703 (AN8739SBE2) Focus coil/ Tracking coil/ Traverse motor/ Spindle motor driver

11.4 IC401 (C2BBGD000075) Microprocessor

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1100000000x.html[30/09/2009 12:14:33]

Page 28

11.1 IC701 (AN8885SBE1) Servo Amplifier

TOP PREVIOUS NEXT

Pin No. Mark I/O Function

1 PDE I Tracking signal input 1

2 PDF I Tracking signal input 2

3 VCC I Power supply

4 PDA I Focus signal input terminal 1

5 PDB I Focus signal input terminal 2

6 LPD I APC amp input

7 LD O APC amp output

8 RF O RFsumming output

9 RFIN I Detector’s input

10 CSBRT I Capacitor for OFTR connection

11 CEA I Capacitor for HPF amp connection

12 BDO O BDO output (“H” : drop out)

13 LDON I APC control

14 GND - Ground

15 /RFDET O NRFDET output (“L” : detection)

16 PDOWN O Power- down input

17 OFTR O OFTR output

18 NC O N.C.

19 ENV O 3T - ENV output

20 NC I N.C.

21 NC I N.C.

22 TEN I TE amp input

23 TEOUT O TE amp output

24 FEOUT O FE amp output

25 FEN I FE amp input

26 VREF O Reference voltage output

27 TBAL I Tracking balance control

28 FBAL I Focus balance control

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1101000000.html[30/09/2009 12:14:34]

Page 29

11.2 IC702 (MN662790RSC) Servo processor/ Digital

signal processor/ Digital filter/ D/A converter

TOP PREVIOUS NEXT

Pin

Mark I/O Function

No.

1 BCLK O N.C.

2 LRCK O N.C.

3 SRDATA O N.C.

4 DVDD1 I Power supply input (for digital circuit)

5 DVSS1 I GND (for digital circuit)

6 TX O Digital audio interface signal output (Latches data at first transition)

7 MCLK I Microprocessor command clock signal input

8 MDATA I Microprocessor command data signal input

9 MLD I Microprocessor command load signal input

10 SENSE O Sense signal output (OFT, FESL,MAGEND,NAJEND, POSAD,SFG) (Not used, open)

11 /FLOCK O Focus servo feeding signal output (“L” : Feed)

12 /TLOCK O Tracking servo feeding signal output (“L” : Feed)

13 BLKCK O Sub-code block clock signal output (BLKCKf = 75Hz during normal playback)

14 SQCK I External clock signal input for sub- code Q resistor

15 SUBQ O Sub- code Q code output

16 DMUTE I Muting input (“H” : mute)

17 STAT O Status signal output(CRC,CUE,CLVS,TTSTVP,/FCLV,SQCK)

18 /RST I Reset signal input

19 SMCK O 1/2- diveded clock signal of crystal osscillating at MSEL = “H” (fSMCK = 8.4672 MHz) 1/4 - divided clock signal of crystal oscillating at MSEL = “L”

20 CSEL I Frequency Selection Terminal H = 33.8688 MHz ; L = 16.9344 MHz

21 TRV O N.C

22 TVD O Traverse drive output

23 PC O Spindle motor ON output ("L" : ON)

24 ECM O Spindle motor drive signal output(forced mode output)

25 ECS O Spindle motor drive signal output(servo error signal output)

26 KICK O N.C.

27 TRD O Tracking drive output

28 FOD O Focus drive output

29 VREF I D/A (drive) output (TVD, ECS, TRD, FOD, FBAL, TBAL) Reference voltage input

30 FBAL O Focus balance adjustment output

31 TBAL O Tracking balance adjustment output

32 FE I Focus error signal input (analog input)

33 TE I Tracking error signal input (analog input)

34 RFENV I RF envelope signal input

35 VDET I Vibration detection signal input ("H" :detection)

36 OFT I Off- track signal input ("H" : off track)

37 TRCRS I Track cross signal input

38 /RFDET I RF detection signal input ("L" : detection)

39 BDO I Dropout signal input ("H" : Dropout)

40 LDON O Laser on signal output ("H" : ON)

41 PLLF2 I/O N.C.

42 DSLF2 O Tracking Offset alignment output/DSL Balance Output (DA Output)

43 WVEL O N.C.

44 ARF I RF signal input

(fSMCK = 4.2336MHz)

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1102000000.html[30/09/2009 12:14:35]

Page 30

45 IREF I Reference current input

46 DRF I DSL bias terminal (Not used, open)

47 DSLF I/O DSL loop filter terminal

48 PLLF I/O PLL loop filter terminal

49 VCOF I/O VCO loop filter terminal

50 AVDD2 I Power supply input (for analog circuit)

51 AVSS2 I GND (for analog circuit)

52 EFM - EFM signal output

53 PCK - PLL extraction clock output (fPCK = 4.321 MHz during normal playback)

54 VCOF2 I/O VCO Loop filter for 33.8688 MHz conversation terminal for 16.9344 MHz crystal mode, must use other circuit

55 SUBC O Sub-code serial data output

56 SBCK I Clock input for sub- code serial data

57 VSS I GND

58 X1 IN I Crystal oscillating circuit input (f = 16.9344MHz)

59 X2 OUT O Crystal oscillating circuit input (f = 16.9344 MHz)

60 VDD I Power supply input (for oscillating circuit)

61 BYTCK - Byte clock output

62 /CLDCK - Sub - code frame clock signal output (fCLDCK = 7.35 kHz during normal playback)

63 FCLK - Crystal frame clock signal output (fCLK = 7.35 kHz, double = 14.7 kHz)

64 IPFLAG - Interpolation flag output (“H” : Interpolation)

65 FLAG - Flag output

66 CLVS - Spindle servo phase synchronizing signal output ("H" : CLV, "L" : rough servo)

67 CRC - Sub - code CRC checked output (“H’ :OK, “L” :NG)

68 DEMPH - De- emphassis ON signal output (“H” :ON)

69 RESY - Frame re - synchronizing signal output

70 IOSEL I Mode Switching Terminal

71 /TEST I Test input

72 AVDD1 I Power supply input (for analog circuit)

73 OUTL O Left channel audio signal output

74 AVSS1 I GND

75 OUTR O Right channel audio signal output

76 RSEL I RF signal polarity assignment input (at "H" level, RSEL="H", at "L" level, RESL="L")

77 IOVOD I 5V supply input

78 PSEL I Test terminal (connected to Gnd)

79 MSEL I SMCK oscillating frequency designation input (“L”:4.2336 MHz, “H”:8.4672 MHz)

80 SSEL I SUBQ output mode select (“H”:Q - code buffer mode)

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1102000000.html[30/09/2009 12:14:35]

Page 31

11.3 IC703 (AN8739SBE2) Focus coil/ Tracking coil/

Traverse motor/ Spindle motor driver

TOP PREVIOUS NEXT

Pin No. Mark I/O Function

1 /RST - RESET output terminal

2 NC - N.C.

3 IN2 I Motor Drive (2) input

4 PC2 I Turntable motor drive signal (“L :ON)

5 NC - N.C.

6 IN1 I Motor driver (1) input

7 NC I N.C.

8 PVCC1 I Power supply (1) for driver

9 PGND1 - Ground connection (1) for driver

10 NC - N.C.

11 D1- O Motor driver (1) reverse- action output

12 D1+ O Motor driver (1) forward-action output

13 D2- O Motor driver (2) reverse- action output

14 D2+ O Motor driver (2) forward-action output

15 D3- O Motor driver (3) reverse- action output

16 D3+ O Motor driver (3) forward-action output

17 D4- O Motor driver (4) reverse- action output

18 D4+ O Motor driver (4) forward-action output

19 NC - N.C.

20 PGND2 - Ground connection (2) for driver

21 PVCC2 I Power supply (2) for driver

22 NC - N.C.

23 VCC I Power supply terminal

24 VREF I Reference voltage input

25 IN4 I Motor driver (4) input

26 IN3 I Motor driver (3) input

27 RSTIN I Reset terminal

28 NC - N.C.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1103000000.html[30/09/2009 12:14:37]

Page 32

11.4 IC401 (C2BBGD000075) Microprocessor

54 SYNCHRO - Not used, open

TOP PREVIOUS NEXT

Pin No. Mark I/O Function

1~7 G7~G1 O Grid signal of FL display

8 VDD - Power supply terminal

9 MCLK O Command clock signal

10 MDATA O Command data signal

11 MLD O Command load signal (“L” LOAD.)

12 SENSE I Sense signal

13 DMUTE O Muting control signal

14 SQCK O Sub-code Q register clock

15 NC - Not connected

16 SUBQ I Sub- code Q data

17 /RESET I Reset signal input

18 ZSENSE - Not used, connected to GND

19 REC.EN I Synchro. rec. control terminal

20 AVSS - GND terminal

21 /RSTSV O Reset signal output

22 OPEN I Open detect terminal

23 DIR O Motor control signal

24 TURN O Motor control signal

25 LOAD O Motor control signal

26 AD3 I Key input 3

27 AD2 I Key input 2

28 AD1 I Key input 1

29 AVDD I Power supply terminal

30 AVREF - Power supply terminal

31 NC - Not used, connected to GND

32 XT2 - Not used, open

33 VSS - GND Terminal

34 X1 I Crystal Osc. Input terminal (4.2336MHz)

35 X2 O Crystal Osc. Output terminal (4.2336MHz)

36 RESETSW O Rest position detect

37 UP/DOWN I Traverse deck up/down fetection input

38 Unused I Not used, connected to GND

39 Unused I Not used, connected to GND

40 Unused I Not used, connected to GND

41 Unused I Not used, connected to GND

42 Unused I Not used, connected to GND

43 PWM O Mechanism control signal (PWM output)

44 POFF I Power OFF detection input

45 POSITION I Rotary tray position detecting sensor input

46 SPEED I Loading motor speed sensor input

47 REMOCON I Remote control sensor input

48 IC - Not used, connected to GND

49 /TLOCK I Optical servo condition (tracking) input

50 /FLOCK I Optical servo condition (focus) input

51 STAT I Status signal (CRC,CUE,CLVS,TTSTOP, FCLV,SQCK)

52 VDD - Power supply terminal (+5V)

53 POWER O Power ON/OFF output terminal

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1104000000.html[30/09/2009 12:14:38]

Page 33

55 DISC1 O DISC 1 LED control output

56 DISC2 O DISC 2 LED control output

57 DISC3 O DISC 3 LED control output

58 DISC4 O DISC 4 LED control output

59 DISC5 O DISC 5 LED control output

60 NC I Not used, connected to GND

61 S16 O Segment signal of FL display

62 S15 O Segment signal of FL display

63 S14 O Segment signal of FL display

64 S13 O Segment signal of FL display

65 S12 O Segment signal of FL display

66 S11 O Segment signal of FL display

67 S10 O Segment signal of FL display

68 S9 O Segment signal of FL display

69 S8 O Segment signal of FL display

70 S7 O Segment signal of FL display

71 VPP I Power supply terminal

72 S6 O Segment signal of FL display

73 S5 O Segment signal of FL display

74 S4 O Segment signal of FL display

75 S3 O Segment signal of FL display

76 S2 O Segment signal of FL display

77 S1 O Segment signal of FL display

78 NC I Not used, connected to GND

79 NC I Not used, connected to GND

80 G8 O Grid signal of FL display

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1104000000.html[30/09/2009 12:14:38]

Page 34

12 Block Diagram

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1200000000x.html[30/09/2009 12:14:40]

Page 35

RF

TRAVERSE

MOTOR

SPINDLE

MOT

OPTICAL PICKUP

SEMICONDUCTOR

+B

PHOTO DETECTOR

EDE

DAC

F F

TRACKING

COIL

T+ T-

M

_

M

_

OR

LASER

POWER DRIVE

C

B

FOCUS

COIL

F-F+

IC703

AN8739SBE2

FOCUS COIL/

TRACKING COIL/

VERSE MOTOR/

TRA

SPINDLE MOTOR DRIVER

D4+

18

D4-

17

D3+

16

TRACKING

D3-

15

D1+

12

TRAVERSE

D1-

11

D2+

14

D2-

13

IC701

AN8885SBE1

SERVO AMP

6

LPD

Q701

LASER

+B

IC702

MN662790RSC

SERVO PROCESSOR/

DIGIT

PROCESSOR/

DIGITAL FILTER/

D/A CONVERTER

RESET

SIGNAL

GEN.

FOCUS

COIL

DRIVE

COIL

DRIVE

MOT

OR

DRIVE

SPINDLE

MOT

DRIVE

LDON

RF

AL SIGNAL

/RST

OR

7

LD

13

LDON

PDA

4

PDB

5

1

PDE

2

PDF

BDO

/RFDET

RFENV

FE

TE

OFT

VREF

TBAL

FBAL

LDON

1

26

IN3

IN4

25

IN1

6

IN2

3

PC2

4

+

-

+B

+B

ARF

44

39

BDO

/RF DET

38

RF ENV

34

FE

32

TE

33

OFT

36

TRCRS

37

VDET

35

VREF

29

TBAL

31

FBAL

30

PLLF2

41

WVEL

43

DSLF2

42

LDON

40

+B

+B

+

F

+

47 48

SYNCHRONIZING

PROTECTION

+B

+B

DSLF

DSL

SERVO

INPUT

POR

CONVER

TRD

28

+B

8

RF

RFIN

-

VCBA

+B

Ech

VCBA

Fch

TBAL

27

TBAL

ARATOR

RAM

ADDRESS

TOR

CLV

SER

VO

SERVO OUTPUT

POR

ECM

TRV23PC

24

Ach

Bch

PLLF

COMP

VCO

DEMODULA

TION

T

SENSE

10 11

+

FBAL

28

FBAL

FREQUENCY

ARATOR

EFM DATA

TOR

16K

SRAM

DETECT

AUTO CUE

SUB-CODE

DEMODULA

CHECK

CHECK

FLOCK

/RST

TLOCK

/RST

Subtracter

PEAK

CRCC

CRCC

OR/

TOR

Subtracter

+B

+B

TEIN

PDOWN

22 23

16

+B

SYNDROME

CALCULA

CIRC

DECODER

INTERPOLATION/

SOFT MUTING/

DIGITAL

ATTENUATION

BLKCK

SQCK

SUBQ

1418 1312 15

SQCK

SUBQ

+B

-

A

+

B

+

+B

+B

PHASE

COMP

SYNCHRONING

INTERPOLA

PROTECTION

T

A/D

GENERA

CONVERTER

SERVO

CPU

D/A

TER

TVD27FOD

KICK

ECS

22

25

2126

RF

.

DET

+

+

-

+B

TEOUT

TE

TION

109

CSBRT

OFTR

DET

BDO

.

DET

+B

21

CONVER

DIGITAL DE-EMPHASIS

DIGITAL FILTER

MASH LOGIC

.

+B

N.C.

S/P

TER

PWM

LOGIC

PWM

LOGIC

MICROMPUTER

INTERF

MDATA

STAT

8 7 9

17

MDATA

STAT

11

TENV

+

DIGITAL AUDIO

INTERF

ACE

MCLK

MCLK

+B

CEA

3

+

+

+

ACE

TIMING

GENERA

PITCH

CONTROL

MLD

MLD

TOR/

ENV

19

OFTR

17

BDO

12

/RFDET

15

FEN

25

FEOUT

24

VCC

3

26

VREF

GND

14

N.C.

18

TX

6

DMUTE

16

X2

59

X1

58

SMCK

19

RSEL

76

29

VREF

OUTL

+

-

73

OUTR

75

+

-

SUBC

55

SBCK

56

5

DVSS1

20

CSEL

78

PSEL

79

NSEL

/CLDCK

62

ENV

OFTR

BDO

/RFDET

FE

+B

+B

JK321

-B

X701

+B

+B

CD SIGNAL

RCH

Page 36

IC11

BA033T

REGULATOR

SIGNAL LINES

CD SIGNAL LINE

JK801

LCH OUT

STAT

Q801(Q802)

Q851,Q852

+B

S701(RESET)

Q475

SWITCH

MUTING

MUTING

IC801

BA4558FDXE2

L.P.F.

FILTER AMP

D801,D802

Q853

+B

MUTING

CD SIGNAL

+B

+B

Q18,Q19

POWER

SUPPL

CONTROL

D16

D42,D43

Y

REGULATOR

CURRENT

CONTROL

Q11,Q12

SWITCH

Q15

Q42

+B

TO FL DISPLAY

8

+B

6

4

5

D11~D14

D51,D52

-B

REGULATOR

IC501

BA6247N

MOTOR DRIVE

& AMP

CONTROL CIRCUIT

PT11

Q31

D21

MOTOR

DRIVE

MOTOR

DRIVE

MOTOR

DRIVE

D31,D32

Q32,Q33

FL DRIVE

M501

(LOADING MOTOR)

10

3

2

+

M

-

-

M

+

POWER TRANSFORMER

M551

(TRAY MOTOR)

JK11

AC INLET

SUBQ

SQCK

/RST

MCLK

MDATA

MLD

Q474

SWITCH

14

21

9

10

11

SQCK

/RST

MCLK

MDATA

MLD

16 51

SQCK

Q501

STAT

45

36

RESTSW

POSITION

D502,D551

UP/DOWN

SPEED

D501

13

+B

DMUTE

53

23

DIR

POWER

UPD78044F186

OPEN

2237,46

S551

Q462

MOTOR

CONTROL

25

24 43

LOAD

TURN

IC401

MICRO-PROCESSOR

G8

G1

S1

1~7,80

(OPEN/CLOSE DET.)

FL601

FL DISPLAY

61~70,72~77

D462

S16

Q461

MOTOR

CONTROL

PWM

KEYOUT1

26~28

KEY MATRIX

KEYOUT6

X401

3534

X1

X2

RESET

17

Q401

RESET

Page 37

13 Schematic Diagram

TOP PREVIOUS NEXT

(All schematic diagrams may be modified at any time with the development of new technology.)

Notes:

The voltage value and waveforms are the reference voltage of this unit measured by DC electronic voltmeter

(high impedance) and oscilloscope on the basis of chassis. Accordingly, there may arise some error in

voltage values and waveformsdepending upon the internal impedance of the tester or the measuring unit.

< > ...FM

( ) ...AM

Importance safety notice:

Components identifed by mark have special characteristics important for safety. Furthermore, special parts

which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors), etc.

are used. Whenreplacing any of components, be sure to use only manufacturer’s specified parts shown in the

parts list.

Caution!

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

Cover the parts boxes made of plastics with aluminium foil.

Put a conductive mat on the work table.

Ground the soldering iron.

Do not touch the pins of IC, LSI or VLSI with fingers directly.

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1300000000x.html[30/09/2009 12:14:40]

Page 38

SCHEMATIC DIAGRAM -1

: +B SIGNAL LINE

CD SERVO CIRCUIT

: CD SIGNAL LINE

OPTICAL PICKUP CIRCUIT

LASER DIODE

6

8

11

C

12

10

5

4

9

2

3

C

C

NBOUT

1

8

GND

GND

2

VCC

NAOUT

3

BIN

VREF

4

AIN

C

7

6

5

C

R701

4.7

3.2V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VCC

PDF

PDE

LD

LD GND

GND

NB

GND

NA

VREF

LPD

GND

TT+

FF+

Q701

R750

4.7

0.9V

((2V))

C713

C750

0.1

C751

0.1

0.1

CN701

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

C701

6.3V33

2.7V

((2.3V))

Q701

2SA1037AKSTX

LASER POWER DRIVE

C714

6.3V100

IC701

AN8885SBE1

SER

VO AMP

C712

C711

29

30

C703

6.3V100

C704

0.1

0.1

2700P

C707

C702

0.027

C706

1.6V

1.6V

1.6V

0V((0.2V))

3.2V

2.7V((2.3V))

1

1.6V

3

2

4

876

5

LD

LPD

PDB

PDF

PDA

VCC

PDE

IC701

TEN

TEOUT

FEOUT

TBAL

FEN

VREF

FBAL

24

23 2228

25

26

27

1.6V

1.6V

C747

180P

R744

120K

0.1

C749

2200P

0.1

R708

R707

22K

39K

21

1.6V

1.6V

1.6V

1.6V

1.6V

C710

120P

R702

R705

10K

150K

C742

0.027

R704

R706

1K

0.9V((1.4V))

9

RF

RFIN

NC

NC

20

1K

0V

0.7V

0V((3.1V))

1.6V

1.9V

14

1312

10

11

CEA

BDO

GND

LDON

CSBRT

NC

ENV

OFTR

PDOWN

/RFDET

17

15

19

16

18

0V

1.6V

0V((3.2V))

33

C735

0.1

C734

10V220

14 13 12 11 10

36

SP MOTOR

38

3.3V((3V))

3.3V((3V))

3.3V((3.5V))

D3-

D4-

D3+

D2+

D2-

D1+

3.3V

3.3V((3.5V))

3.7V((3.5V))

C737

0.1

M

M702

C736

0.1

M

M701

TRV MOTOR

3.3V

1915 16 17 18

D4+

NC

NC

D1-

3.7V((4.1V))

IC703

AN8739SBE2

FOCUS COIL/

TRACKING COIL/

VERSE MOTOR/

TRA

SPINDLE MOTOR DRIVE

7.3V

7.3V

29

2120

22 282726

23

GND

NC

GND

NC

7 6 5 4 3 2 1

30

VCC

IN1

PGND2

PGND1

9 8

PVCC2

IC703

PVCC1

35

1.6V

R735

100

1.6V

7.3V

1.6V

1.6V

25

24

VREF

NC

1.6V

IN4

PC2NCIN2

3.2V((0V))

NC

IN3

RSTIN

1.6V

R724

18K

1.6V

R725

390

R715

/RST

C715

2700P

1K

R727

3.9K

R736

100

C752

1000P

R749

4.7K

C738

0.01

R729

3.9K

C739

1500P

R728

3.9K

37

R723

6.8K

R731

6.8K

Page 39

X701

RSXB16M9J02T

C722

10P

R711

82K

C716

820P

SCHEMATIC DIAGRAM - 2

C754

470P

C723

C717

0.1

R714

120

C744

5600P

R709

47K

C721

10P

C718

0.22

10V220

C724

0.1

R712

220

R741

47K

R742

220K

626364 65

61

FCLK

60

VDD

BYTCK

3.2V

/CLDCK

59

X2

OUT

1.5V

58

IN

X1

1.5V

57

VSS

56

SBCK

55

SUBC

54

VCOF2

53

PCK

52

EFM

51

AVSS2

50

AVDD2

3.2V

49

VCOF

48

PLLF

0.5V

DSLF

47

1.6V

46

DRF

1.6V

45

IREF

1V

44

ARF

1.6V

43

WVEL

DSLF2

42

1.5V

PLLF2

41

/RFDET

BDO

LDON

40

39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21

0V

0V((3.2V))

0V((3.2V))

6667686970

CRC

CLVS

FLAG

IPFLAG

IC702

MN662790RSC

SERVO PROCESSOR

DIGIT

DIGITAL FILTER/

D/A CONVERTER

TRCRS

RFENV

VDET

OFT

0V

: +B SIGNAL LINE

R721

100

C731

6.3V220

C730

0.1

3.2V

2.9V

3.2V

73

71

72

RESY

/TEST

IOSEL

AVDD1

DEMPH

AL SIGNAL PROCESSOR/

VREF

FBAL

TBAL

TE

FE

1.6V

1.6V

1.6V

1.6V

1.6V

1.6V

OUTL

FOD

: CD SIGNAL LINE

20

18

13

23

R717

1K

R718

1K

C733

C732

0.1

6.3V220

3.2V

2.9V

1.5V

1.5V

74

76

75

RSEL

OUTR

AVSS1

TRD

KICK

1.6V

1.6V

3.2V

80

77

78

79

SSEL

PSEL

MSEL

1.6V

PC

3.2V((0V))

SRDATA

DVDD1

DVSS1

MDATA

SENSE

/FLOCK

/TLOCK

BLKCK

SQCK

SUBQ

DMUTE

SMCK

TVD

1.6V

BCLK

LRCK

MCLK

STAT

/RST

CSEL

1

2

3

4

3.2V

5

TX

6

1.6V

7

3.2V

8

0.5V

MLD

9

3.2V

10

11

12

13

0V

14

0V((0.2V))

15

3.2V((3.1V))

16

17

0V((3.1V))

18

3.1V

19

20

TRV

IOVDD

ECM

ECS

1.6V

C725

1000P

C726

1000P

C745

1000P

C727

50V1

C728

50V1

22

21

CN702

Lch OUT

19

A.GND

18

Rch OUT

17

11

10

9

C753

470P

C743

0.1

8

6

7

4

R753

10

3

+3.3V

D.GND

LD SW

+7.5V

P.GND

MCLK

MDATA

MLD

SPEED

BLKCK

SQCK

SUBQ

STAT

/RST

REST SW

17

16

15

14

TX

13

TO

12

MAIN

11

CIRCUIT

10

(CN302) ON

9

SCHEMA

8

7

6

5

4

3

2

1

TIC

DIAGRAM-3

2

TJ

TJ701

S701

REST SW

16

1

15

Page 40

SCHEMATIC DIAGRAM-3

TO

LOADING

OR

MOT

CIRCUIT

(CN551) ON

SCHEMATIC

DIAGRAM-6

TO

SENSOR

CIRCUIT

(CN501) ON

TIC

SCHEMA

DIAGRAM-6

TO

VO

CD SER

CIRCUIT

(CN702) ON

SCHEMATIC

DIAGRAM-2

CN404

CN403

CN302

MAIN CIRCUIT

LH+

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LH-

LED

UP/DOWN

DGND

OPEN

P.GND

LH+

LHLOAD

TURN

DIREC

+8.5V

VREF

P.GND

+8.5V

LED

SPEED

POSITION

D.GND

OUTL

AGND

OUTR

3.3V

DGND

LD SW

TX

PVCC (8.0v)

PGND

MCLK

MDATA

MLD

SPEED

BLKCK

SQCK

SUBQ

STAT

/RST

REST_SW

G8

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

C462

0.01

R462

C301

((0.6V))

R431

((0.7V))

R435

10K

G1

2

1

3

R463

120

R461

220

0.01

10K

Q475

4.7K

R406

4

5

((2.5V))

6

120

((0V))

Q474

Q474, 475

KRC101MTA

SWITCHING

((0V))

R432

4.7K

R433

4.7K

R434

4.7k

((0V))

((-25.06V))

80

((0V))

79

((0V))

78

((-20.44V))

77

((-9.50V))

76

((-9.50V))

75

((-24.13V))

74

((-27.86V))

73

((-24.42V))

72

((-28.02V))

71

((-24.08V))

70

((-13.08V))

69

((-24.08V))

68

((-13.08V))

67

((-16.74V))

66

((-24.09V))

65

4.7K

R407

R447

4.7K

R442 4.7K

4.7K

R443

R444

R445

S3

S4

S1

S2

G8G7G6G5G4G3G2

897

TO

PANEL CIRCUIT

(CN601) ON

SCHEMATIC DIAGRAM-5

D461

((3.64V))

R436

1K

G7

G8

NC

NC

S1

S2

S3

S4

S5

S6

VPP

S7

S8

S9

S10

S11

S12

S13

4.7K

4.7K

S5

64

1413121110

D462

C314

0.01

R429

REST_SW

((-27.43V))

((-27.60V))

2

1

63

((-24.09V))

((-24.30V))

S6

S7S8S9

15

Q461, 462

KRC111MTA

MOTOR CONTROL

((6.83V))

((0V))

Q462

10K

((0V))

((0V))

R427

10K

10K

R430

4.7K

7

13

15

STAT

14

((-24.98V))

((-24.96V))

((-24.96V))

((-24.97V))

((-25.03V))

3

54

G1

G4

G3

G2

G5

G6

S14

S16

S15

DISC5

NC

DISC4

61

62

((0V))

((0V))

((-24V))

((4.99V))

((-23.50V))

4.7K

R440

S11

S12

S10

1918

1716

: +B Signal Line

C461

Q461

10K

((5.03V))

VDD

((0V))

R425

10K

R428

4.7K

((3.94V))

((3.56V))

9876

10

MCLK

((4.89V))

11

MDATA

MLD

R423

((0V))

10K

SENSE

((0V))

10V 47

10

((4.97V))

141312

SQCK

DMUTE

IC401

IC401

UPD78044F186

MICRO-P

STAT

SYNCHRO

VDD

DISC1

DISC2

POWER

DISC3

54

53

52

555657585960

51

((0V))

((0V))

((0V))

((0V))

S13

2120

C406

50V 1

CN401

((5.05V))

((4.98V))

0.01

C405

((2.60V))

STAT

R437

R438 10K

R439 10K

R420

10K

R424

R426

4.7K

((2.50V))

((5.03V))

((0.10V))

((0V))

((5V))

17

1615

NC

SUBQ

/RESET

REC.EN

ZSENSE

PWM

/FLOCKICSPEED

/TLOCK

REMOCON

50

((5V))

((0V))

((0V))

((0V))

((0.13V))

10K

CN402

: -B Signal Line

R422

MCLK

4.7K

4.7K

((0V))

((5V))

201918

AVSS

*

POSITION

((2.80V))

((0.80V))

C421

11

MDATA

MLD

SQCK

SUBQ

((0V))

((5V))

((0V))

2221

24

23

TURN

((0V))

DIR

25

LOAD

OPEN

((5.02V))

26

AD3

/RSTSV

((5.02V))

AD2

27

((5.02V))

AD1

28

((5.02V))

AVDD

29

((5.02V))

30

AVREF

((0V))

NC

31

((5.02V))

XT2

32

((0V))

33

VSS

((2.20V))

34

X1

((2.30V))

35

X2

((5.03V))

REST_SW

36

((5.03V))

37

UP/DOWN

((0V))

38

EE_CS

((0V))

39

EE_CLK

((0V))

EE_DATA

40

NC

NC

POFF

41

4243444546474849

((0V))

((0V))

((0V))

C423

10K

1000P

R421

1000P

+5V

S14

S16

AD3

AD2

GND

AD1

S15

8

4

7 5

9

6

10

TO

PANEL CIRCUIT

(CN602) ON

SCHEMATIC DIAGRAM-5

3

C424

1000P

: CD Signal line

R412 22K

R411 4.7K

10K

1.8K

R410

R409

Q401

2SC2785FETA

RESET

REST_

SW

470

Q401

0.01

R418

C402

100K

((0V))

6.3V 470

C408

C409

R414

C404

R415

100P

0.01

25V 4.7

56K

R416

22K

R417

47K

22K

R419

10k

R413

((5.05V))

C403

50V 1

((0V))

C401

J133

out

GND

in

X401

4.23MHz

4.7K

R402

4.7K

R401

R446

4.7K

C422

1000P

E400

SNE1004-2

C410

C407

0.1

0.1

FL1

FL2

2

1

Page 41

SCHEMATIC DIAGRAM-4

3

D23, 24

MTZJ9R1BTA

Z301

2

((8.62V))

D17

C17

6.3V 100

MTZJ3R6BTA

8

D54

RVD1SS133TA

4

D23

D24

5

9

((-18.85V))

Q32, 33

2SD2144STA

FL DRIVE

RL1N4003S-P

BA033T

REGULATOR

R21

560

RVD1SS133TA

Q32

Q33

3

IC11

D16

IC11

2

((0.02V))

D53

MTZJ5R1BTA

D46

R22

560

6

: +B Signal Line

C801

10V 47

C802

10V 47

1

4.7

R13

1

((3.26V))

D43

RL1N4003S-P

D42

RL1N4003S-P

C42

6.3V 100u

D44

((15.16V))

RVD1SS133TA

((15.24V))

Q12

2SB1238QRTV2

SWITCHING

D47

RVD1SS133TA

R32

((-18.17V))

10K

((-18.84V))

R33

((-18.16V))

10K

C803

16V 10

C804

16V 10

Q15

2SD2037ETA

REGULATOR

Q15

((9.63V))

((8.61V))

((9.27V))

C16

10V 470

D15

MTZJ9R1CTA

Q42

2SD1862QTV2

CURRENT CONTROL

Q42

R42

1

((8.61V))

((6.32V))

D41

MTZJ6R2CTA

Q11

KRC107MTA

SWITCHING

R43

22K

R44

10K

((14.52V))

Q12

((0V))

1000P

((-36.7V))

Q31

((-28.08V))

Q31

2SB1238QRTV2

D34

REGULATOR

MTZJ9R1CTA

R803

R804

C15

((9.67V))

((0V))

10K

47K

C33

((-28.66V))

220K

220K

1000P

R11

180

C43

Q11

1000P

((5V))

R805

8.2k

R806

8.2K

R12

180

((0V))

R41

470

: -B Signal Line

R807

12k

C815

82P

C816

82P

R808

12K

22K

22K

Q853

D21

RL1N4003S-P

C21

35V 100

C22

D22

25V 100

D31

C32

D32

50V 47P

RL1N4003S-P

12K

R31

R34

100

C807

560P

C808

560P

((5V))

C12

C31

C805

((5V))

390P

C806

390P

R852

1K

16V 3300

50V 47

: CD Signal line

JK321

DGND

1 2

1000P

1000P

0.01

1

+5.0V

2

TX

3

JK801

Lch

Rch

0.01

C30

JK11

AC IN

120V

2

60HZ

C322

R819

R820

PT11

C321

0.01

10

47K

C811

R817

47k

R818

C812

10

C11

CN14

5

4

CN11

1

1

6.3V 100

Q801, 802

2SD2144STA

IC801

((8.93V))

((0.01V))

5

8

((0.03V))

7

((0.01V))

6

R811

68K

R809

R810

((5V))

33K

33K

((0.01V))

((0.01V))

IC801

Q852

22K

R812

22K

((0V))

68K

2

1

((0.03V))

4

3

((-8.83V))

((0V))

22K

22k

Q851

D18

RL1N4003S-P

((0V))

11

12

BA4558FDXE2

5.6K

R851

((0V))

((0V))

C20

((0V))

Q18

((5V))

D33

MTZJ30BTA

Q19

R19

220

MUTING

R813

C809

1k

6.3V 47

D801

R815

((0V))

4.7K

D802

((0V))

R816

4.7K

((0V))

C810

R814

1K

6.3V 47

IC801

L.P. FILTER AMP

Q851, 852, 853

KRA103MTA

MUTING

D12

D14

D51, 52

RL1N4003S-P

R51

5.6K

R52

5.6K

CN21

1

1

CN20

1

CN19

1

CN18

1

CN17

50V 0.01u

CN16

1

Q18

2SD1859QRTV2

POWER SUPPLY CONTROL

((0.73V))

Q19

KRC107MTA

POWER SUPPLY CONTROL

((0.86V))

((0V))

Q801

((0V))

Q802

D11, 12, 13, 14

RL1N4003S-P

D11

D13

D51

D52

RTP1K4C030-X

2

11

2

10

9

2

8

2

7

6

2

2

Page 42

SCHEMATIC DIAGRAM-5

PANEL CIRCUIT

5

21

6

:+B Signal Line

FL601

RSL0274-F

1312

1514

11

9

10

87

181716

22

21

20

19

2625

2423

30292827

31

35

34

CN601

S13

1

S12

2

S11

3

S10

4

S9

5

S8

6

S7

7

S6

8

S5

9

TO

S4

10

12

13

14

15

16

17

18

19

20

11

21

S3

S2

S1

G8

G7

G6

G5

G4

G3

G2

G1

MAIN CIRCUIT

(CN401) ON

SCHEMATIC

DIAGRAM-3

R660

68K

S612

STOP

R671

68K

S624

REV SRCH

R680

10K

S634

EDIT GUIDE

R659

22K

0

S611

R670

22K

S623

FWD SRCH

R679

6.8K

S633

ID SCAN

R658

10K

10

S610

R669

10K

S622

REV SKIP

R678

4.7K

S632

TIME MODE

R657

6.8K

9

S609

R668

6.8K

S621

FWD SKIP

R677

2.7K

S631

PROGRAM

R656

4.7K

8

S608

R667

4.7K

S620

OPEN/CLOSE

R676

2.2K

S630

DISC1

R655

2.7K

S607

R666

2.7K

S619

R675

1.8K

S629

7

PLAY

DISC2

R654

2.2K

S606

R665

2.2K

S618

R674

S628

6

PAUSE

1.2K

DISC3

R652

R653

1.8K

1.2K

5

S604

S605

R663

R664

1.2K

1.8K

>10

S616

S617

R6731KR672

S626

S627

DISC4

4

REPEAT

1K

DISC5

R6511KR650

3

S603

R662

1K

S615

RANDOM

S625

DISC SKIP

1K

S602

R661

1K

S614

2

SPIRAL

S601

CN602

FL2

1

FL1

2

STBY

3

+5V

4

TO

GND

5

MAIN CIRCUIT

AD3

(CN402) ON

6

AD2

SCHEMA

DIAGRAM-3

TIC

7

AD1

8

S14

9

S15

10

S16

11

1

POWER

SWITCH

FC601

1

2

NC

3

CIRCUIT

S613

POWER

AD2

POWER

NC

AD3

1

2

3

FC601

Page 43

SCHEMATIC DIAGRAM-6

: +B Signal line

TRAYMOTOR

CIRCUIT

M

M501

D502

RSQGP1S53V

Q501

PT381

PHOTO

TRANSIST

CIRCUIT

SENSOR CIRCUIT

IC501

BA6247N

MOTOR DRIVE

Direction Select Amp Drive

6

9

8

10

0.5V

6

5

4

3

2

1

FC502

NC

3

2

1

FC503

6

5

4

3

2

1

FC502

3

2

1

FC503

8.6V

6.8V

7

5

0V0V0V

D501 GL380

IC501

1

2

3

4

0.5V

0.5V

P.GND

14

LH+

13

LH-

12

LOAD

11

TURN

10

DIREC

9

8

7

NC

6

+8.5V

5

4

3

2

1

CN501

+8.5V

VREF

P.GND

LED

SPEED

POSITION

D.GND

TO

MAIN CIRCUIT

(CN403) on

SCHEMATIC

DIAGRAM-3

OR

LOADING MOTOR

CIRCUIT

M551

M

D551

SG-206S

S551

SWITCH

6

5

4

3

2

1

CN551

LH+

LHLED

UP/DOWN

DGND

OPEN

TO

MAIN CIRCUIT

(CN404) on

SCHEMATIC

DIAGRAM-3

Page 44

14 Printed Circuit Board

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1400000000x.html[30/09/2009 12:14:41]

Page 45

ABCDEFG

1

CD SERVO P.C.B (REPX0192E)

(RF)

TP20

C726

R718

80

TP11

TP7

TP6

TP3

J731

R717

1

C733

TP17

TP9

C728

TP25

TP26

C727

TP27

R753

J734

TP24

C745

TP1

C753

CN702

19

17

15

13

11

9

7

5

3

1

TP23

TP22

18

16

14

12

10

8

6

4

2

TP21

C725

C730

C754

C743

TP5

TP4

TP2

C731

R721

J716

C732

J715

TP10

TP8

TP12

2

TP19

TP18

3

4

5

X701

R714

C721

C744

C722

C724

60

61

IC702

20

21

J732

TP36

M702

SPL MOTOR

C717

C723

R731

R723

J721

S701

REST.SW

C738

M

R711

R741

41

40

R735

C703

R709

R712

R742

C718

TP42

C742

TP33

R724

R725

J724

R715

C715

C752

C704

C716

J701

28

C707

R705

R704

R749

R727

C706

14

15

C749

R728

R729

TJ701

TP29

C702

IC701

R702

C710

C747

R744

R706

R707

J728

C739

R736

28

R708

14

C714

1

C711

12

1516

J709

C712

C713

R750

11

13

15

J722

J710

J750

4

56

78

910

R701

J727

J702

J712

12

3

Q701

C750

C701

CN701

C

B

C751

E

(VREF)

6

TP37

M

M701

TRV MOTOR

C736

J704

TP16

TP15

TP38

C737

J707

J708

TP35

IC703

1

14

C735

C734

7

8

9

Page 46

D

R

J

9

J122

1

P

ABCDEFG

1

2

3

4

5

6

MAIN P.C.B. (REPX0249D)

TP11

C321

1

2

3

JK321

D801

R815

2

3

1

C811

JK801

JK11

J121

J120

J118

J114

R817

R818

Q802

B

C

R820

E

R819

Q801

B

C

E

C812

AC IN

120V 60HZ

OUT

OPTICAL

LINE

OUT

TP12

TP2

R816

C322

C809

R813

R814

J211

C810

D802

J301

J321

R811

X

C815

C807

R809

C801

R810

C808

C816

IC801

C806

C805

R807

58

R805

R803

4

1

R804

R812

R808

X

R806

PT11 (POWER TRANSFORMER)

PRIMARY

CN11

CN14

TP4

C803

C804

J220

J145

J601

J143

X

J312

C802

J131

SECONDARY

CN17

CN19

CN18

CN20

C30

CN16

J700

Q15

J503

D15

CN21

TP1

J504

J406

J405

J403

C15

C20

C11

B

X

J113

J505

R11

D17

C17

J308

Z301

C

C16

X

J407

D13

E

J119

TP3

X

X

IC11

C314

J136

D14

Q475

J134

J210

D16

3

2

1

C12

J169

C301

B

C

E

D11

J147

R851

TP5

J408

R13

D12

R435

C21

C22

C32

J112

J106

R41

D52

D51

CN302

18

16

14

12

10

8

6

4

2

R427

B

C

Q851

E

J310

J302

J102

J101

19

17

15

13

11

9

7

5

3

1

Q852

C31

Q18

D41

B

C

E

B

C

E

R852

D21

D22

J205

J149

R431

D31

C43

R42

R52

R51

R434

B

C

E

D32

Q42

J154

B

C

Q474

E

R429

J602

J204

D18

B

C

E

R463

C461

R461

D461

C

EB

J144

R428

J142

J218

J216

R432

Q853

J124

D23

D46

R12

D44

J116

R19

C33

J202

D53

D54

R433

J132

E

R43

D42

D43

R21

C

R44

Q11

B

C

E

C42

Q33

R420

R423

R425

14

13

12

11

10

9

8

Q461

7

6

5

4

3

2

1

CN403

J212

J223

X

B

Q12

D47

C

EB

Q1

C

EB

D33

R34

R31

Q31

J105

J600

B

C

R32

E

TP

J31

J137

R33

J400

T

7

CAUTION

RISK OF ELECTRIC SHOCK

AC VOLTAGE LINE. PLEASE DO NOT

TOUCH THIS P.C.B

8

9

Page 47

HG

5

B

IJKLM

J214

J309

J203

B

C

E

J221

J314

J215

R462

J107

J222

J315

J108

Q32

X

J316

J139

C404

R409

R410

J123

J401

J109

TP7

R415

R414

J156

J300

X

C423

J200

R430

D462

R413

C422

J305

R422

R424

R426

J306

D34

CN402

Q401

X

X

X

C

EB

C403

J129

J208

R419

R416

R402

R401

C408

C409

R417

J307

C421

J111

R437

J201

1

5

2346

TP10

J154

C461

J149

D461

B

C

Q474

E

R431

R429

R434

2

B

C

Q853

E

R852

D21

J124

D22

D31

D32

J602

R12

J205

J116

J204

D18

8

J202

B

C

C43

E

Q42

R42

D53

R52

R51

R463

R461

C

EB

J144

R428

J142

J218

J216

R433

R432

J132

R21

D23

D46

E

R43

D44

R19

C33

D42

D54

D43

R420

R423

R425

Q461

J212

X

C

B

R44

EB

EB

Q11

B

C

E

C42

B

C

E

Q33

13

11

9

7

5

3

1

CN403

J223

D47

C

C

D33

R34

R31

Q31

J600

14

12

10

8

6

4

2

Q12

Q19

R32

J311

J105

J137

D24

R22

R33

J209

J122

J400

J501

R418

7

R421

R446

X

8

J141

R436

9

10

J135

J125

J304

J104

111213

J126

Q462

J206

J115

R443

15

14 16

TP14TP15TP13

R412

B

C

E

C401

C405

J506

C402

R447

17

J313

X401

R444

J133

40

41

R442

R445

J127

321

J217

J800

C406

J100

C410

R438

R439

25

J140

J138

C424

IC401

64

J500

J110

R440

J404

J402

J502

J213

CN404

1

C407

2

3

C462

J303

4

5

6

J207

1

80

R407

65

15

R406

E400

CN401

9111213

5

1

7

6

14161718

234

10

8

24

1921

20

TP8

TP9

TP6

Page 48

ABCDEFG

C

R

2

1

1

2

3

PANEL P.C.B. (REPX0248D)

CN602

15

9111213

1

5

10

J616

3467

8

S624

REV SEARCH

R665

S612

STOPPAUSE

2

S621

FWD SKIP

S620

REV SKIP

R669

R668

PLAYOP/CLOSE

S622

S619

R667

17

1416

J615

J614

S623

FWD SEARCH

R671R670

R666

S618

J620

J621

S606

S609

S617

FL601

5

1

R652

S605

R660

S602

2

5

0

S611

R651

R654R655

S608

R657

S601

1

R650

S604

4

R653

S607

8

10

R659

7

R656R658

S610

S603

3

6

9

>10

J612

J613

J601

S625

DISC

SKIP

R672

S626

DISC 5

J622

J623

J624

10

2

4

POWER SWITCH P.C.B. (REPX0248D)

5

FC601

3

2

1

S613

POWER

6

PHOTO TRANSISTOR

P.C.B. (REPX0096A-N)

1

2

3

Q501

FC503

7

D501

5

4

3

2

CN501

1

2

1

FC502

3

11

13

5

79

101214

4

668

8

SENSOR P.C.B.

(REPX0096A-N)

FC503

321

IC501

110 2

3

456789

J501

9

Page 49

GHI J KL M

J601

FL601

1

S625

R672 R673

DISC

SKIP

5

S626

DISC 5

J622

J623

J624

CN601

1921

20

15

15

14161718

DISC 4

S627

20

789111213

6

10

10

25 30

1

5

3

2

4

S628

R674

DISC 3 DISC 2

R675

J610

35

J611

S629

TRAY MOTOR P.C.B. (REPX0096A-N)

6

5

4

3

2

1

FC502

M501

R676

S630

DISC 1

S634

R664

R663

S615

ID SCAN

R662

S632

TIME MD

R679R680

S633

S614

R661

S616

REPEAT RANDOM MODE SPIRAL

EDIT

GUIDE

S631

R677

PROGRAM

3

2

1

FC601

R678

D502

LOADING MOTOR P.C.B. (REPX0095A-N)

6

5

4

3

2

1

CN551

D551

S551

M551

Page 50

15 Troubleshooting Guide

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1500000000x.html[30/09/2009 12:14:42]

Page 51

16 Wiring Connection Diagram

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1600000000x.html[30/09/2009 12:14:42]

Page 52

17 Parts Location and Replacement Parts List

TOP PREVIOUS NEXT

Notes:

Important safety notice:

Components identified by mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors),

low-noise (resistors), etc. are used.

When replacing any of these components, be sure to use only manufacturers’s specified parts shown in the

parts list.

The parenthesized indications in the Remarks column specify the areas or color. (Refer to the cover page for

area or color.)

Parts without these indications can be used for all areas.

Capacitor values are in microfarad (µF) unless specified otherwise, P=Pico-farads(pF); Farads.

Resistance values are in ohms, unless specified otherwise, 1K=1,000(ohms).

The marking (RTL) indicates that the Retention Time is limited for this item. After the discontinuation of this

assembly in production, the item will continue to be available for a specific period of time. The retention

period of availabilityis dependant on the type of assembly, and in accordance with the laws govening part

and product retention. After the end of this period, the assembly will no longer be available.

[M] indicates in the Remarks columns indicates parts that are supplied by MESA .

The “(SF)” mark denotes the standard part.

Reference for O/I book languages are as follows :

Ar : Arabic Cf : Canadian French Cz : Czech Da : Danish

Du : Dutch En : English Fr : French Ge : German

It : Italian Ko : Korean Po : Polish Ru : Russian

Sp : Spanish Sw : Swedish Co : Traditional Chinese Cn : Simplified Chinese

17.1 CD Loading Mechanism

17.1.1 CD Loading Mechanism Part Location

17.1.2 CD Loading Mechanism Part List

17.2 Cabinet

17.2.1 Cabinet Parts Location

17.2.2 Cabinet Parts List

17.3 Electrical Parts List

17.4 Packing Materials& Accessories Parts List

17.5 Packaging

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1700000000x.html[30/09/2009 12:14:43]

Page 53

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1700000000x.html[30/09/2009 12:14:43]

Page 54

17.1 CD Loading Mechanism

TOP PREVIOUS NEXT

17.1.1 CD Loading Mechanism Part Location

17.1.2 CD Loading Mechanism Part List

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1701000000.html[30/09/2009 12:14:44]

Page 55

17.1.1 CD Loading Mechanism Part Location

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1701010000.html[30/09/2009 12:14:44]

Page 56

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/loading.jpg[30/09/2009 12:56:30]

Page 57

17.1.2 CD Loading Mechanism Part List

TOP PREVIOUS NEXT

Ref. No. Part No. Part Name & Description Remarks

TRAVERSE DECK

301 RDG0270 SPEED REDUCTION GEAR [M]

302 RDG0271 DRIVE GEAR A [M]

303 RDG0272 DRIVE GEAR B [M]

304 RDK0025 DRIVE CAM [M]

305 RDP0050 PULLEY GEAR [M]

306 RFKPLPD667PB LOADING MOTOR ASS’Y [M]

307 RHD26019 SCREW [M]

308 RMG0268-K BELT [M]

309 RML0334 CHANGE LEVER [M]

310 RMM0117 SLIDE PLATE 1 [M]

311 RMM0118-1 SLIDE PLATE 2 [M]

312 RMR0746-W STRENGTHENING PLATE [M]

313 RFKNDCV51CAK MECHA BASE ASS’Y [M]

314 RMX0094 TRAY GUIDE [M]

315 RXQ0346-1 SLIDER ASS’Y [M]

316 XTB3+10JFZ SCREW [M]

358 RAE0152Z-3 TRAVERSE [M]

358-1 SHGD113-1 FLOATING CUSHION [M]

358-10 XQS17+A35FZ TRAVERSE MOTOR SCREW [M]

358-2 SNSD38 TRAVERSE MOTOR ASS’Y [M]

358-3 RAF0150A-4S 50A OPU [M]

358-4 RDG0247 DRIVE GEAR [M]

358-5 RDG0248 RELAY GEAR [M]

358-6 RXQ0339 TRAVERSE MOTOR ASS’Y [M]

358-7 RXQ0304-1 NUT PLATE ASS’Y [M]

358-8 XQN17+CG5 NUT PLATE ASSY SCREW [M]

358-9 XQS2+A3FZ SPINDLE MOTOR SCREW [M]

359 RME0142 FLOATING SPRING A [M]

360 RME0109 FLOATING SPRING B [M]

361 RMR0698-K1 TRAVERSE CHASSIS [M]

362 RMS0123-1 FIXED PIN B [M]

363 XTN2+6G SCREW [M]

364 RMS0350 FIXED PIN A [M]

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1701020000.html[30/09/2009 12:14:45]

Page 58

17.2 Cabinet

TOP PREVIOUS NEXT

17.2.1 Cabinet Parts Location

17.2.2 Cabinet Parts List

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1702000000.html[30/09/2009 12:14:46]

Page 59

17.2.1 Cabinet Parts Location

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

file:///E|/_MANUALS/TECHNICS/technics_sl-pd7nasvc_[ET]/NA/SL-PD7/SVC/s1702010000.html[30/09/2009 12:47:57]

Page 60