Page 1

AD0303010C8

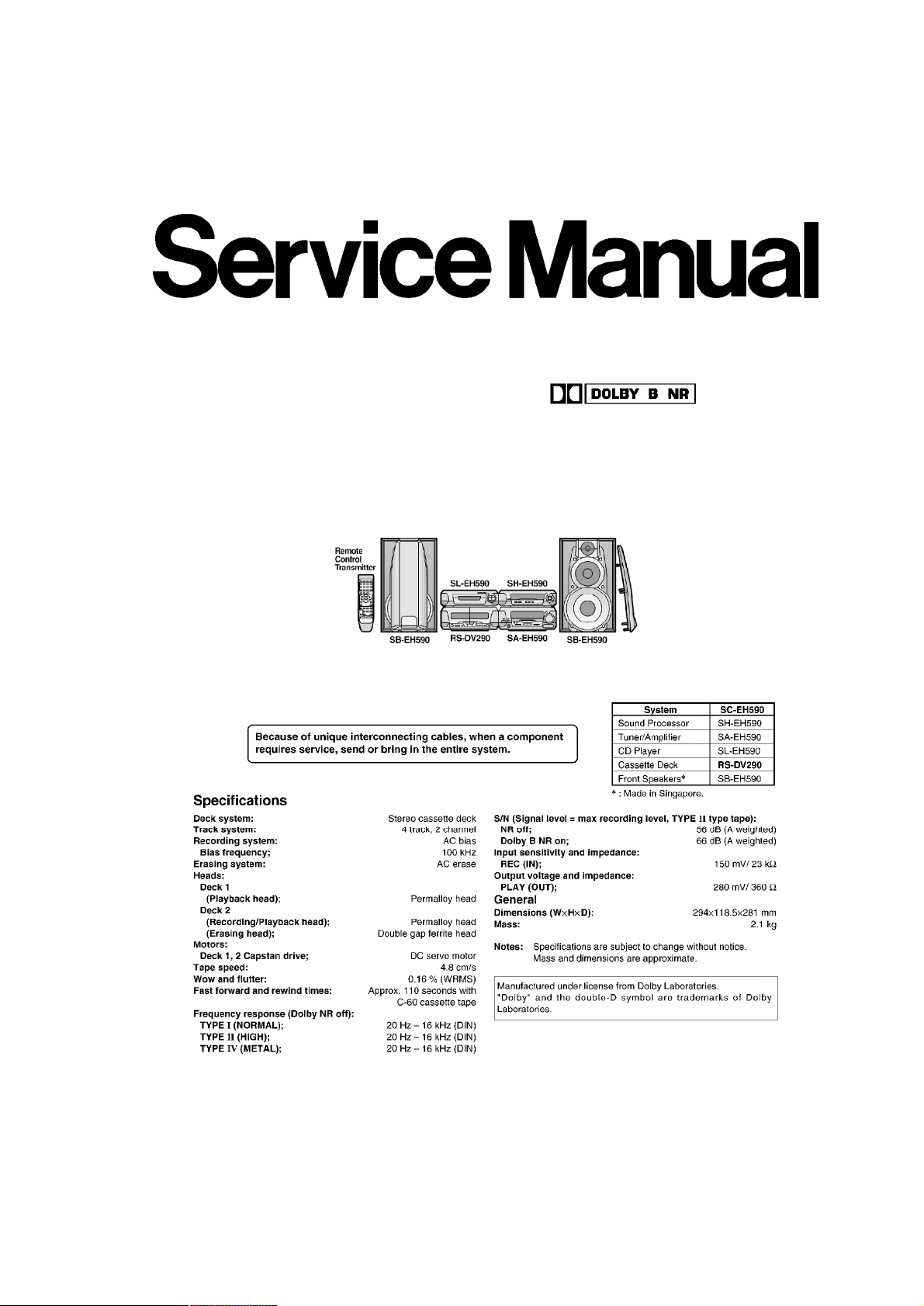

Cassette Deck

RS-DV290EG

Colour

(S)..........Silver Type

SPECIFICATIONS

Page 2

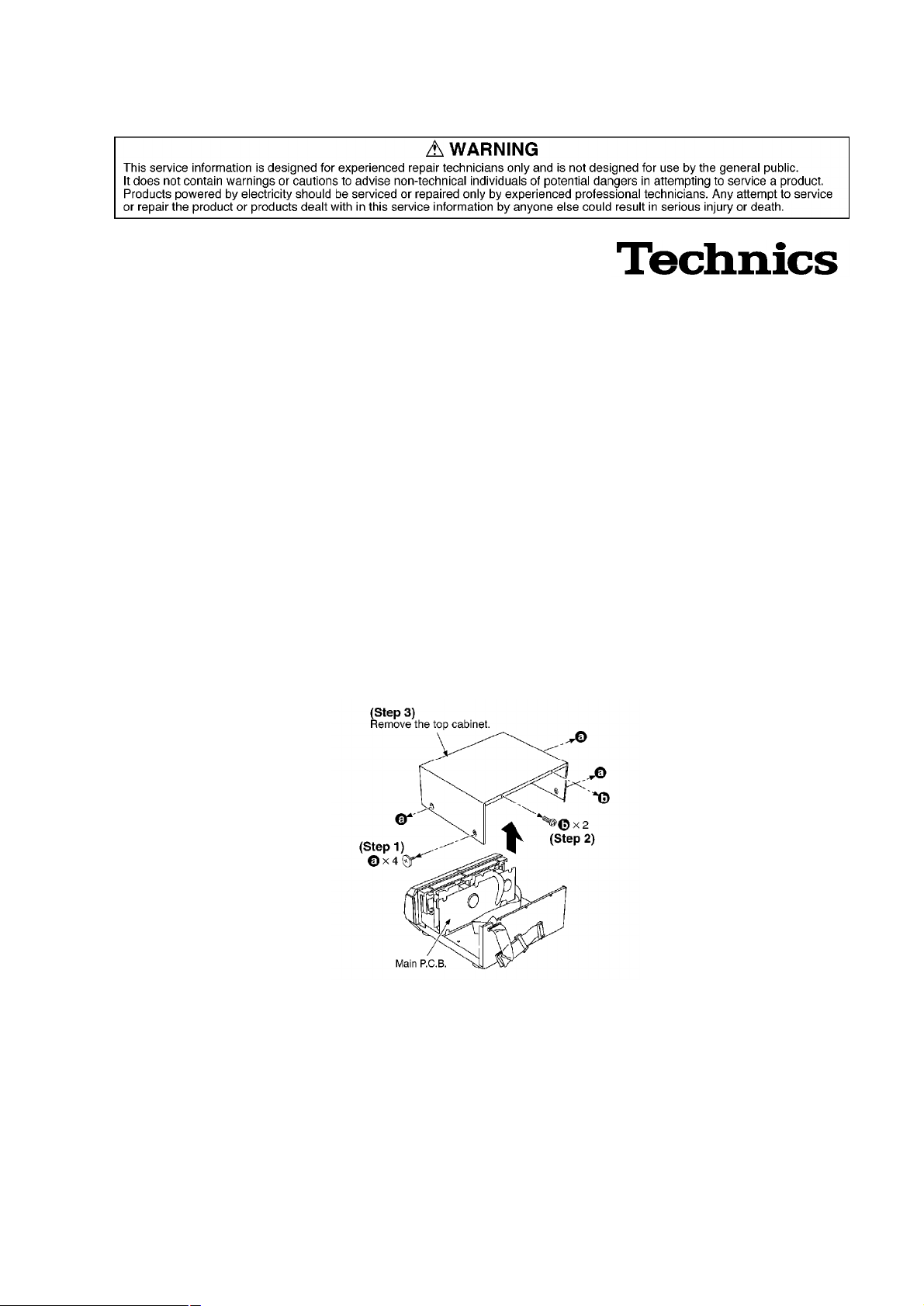

1. Note

Refer to the service manual for Model No. SA-EH590EG, SA-EH590EP (Order No. AD0302008C8)

for information on Accessories and Packaging.

2. Location of Controls

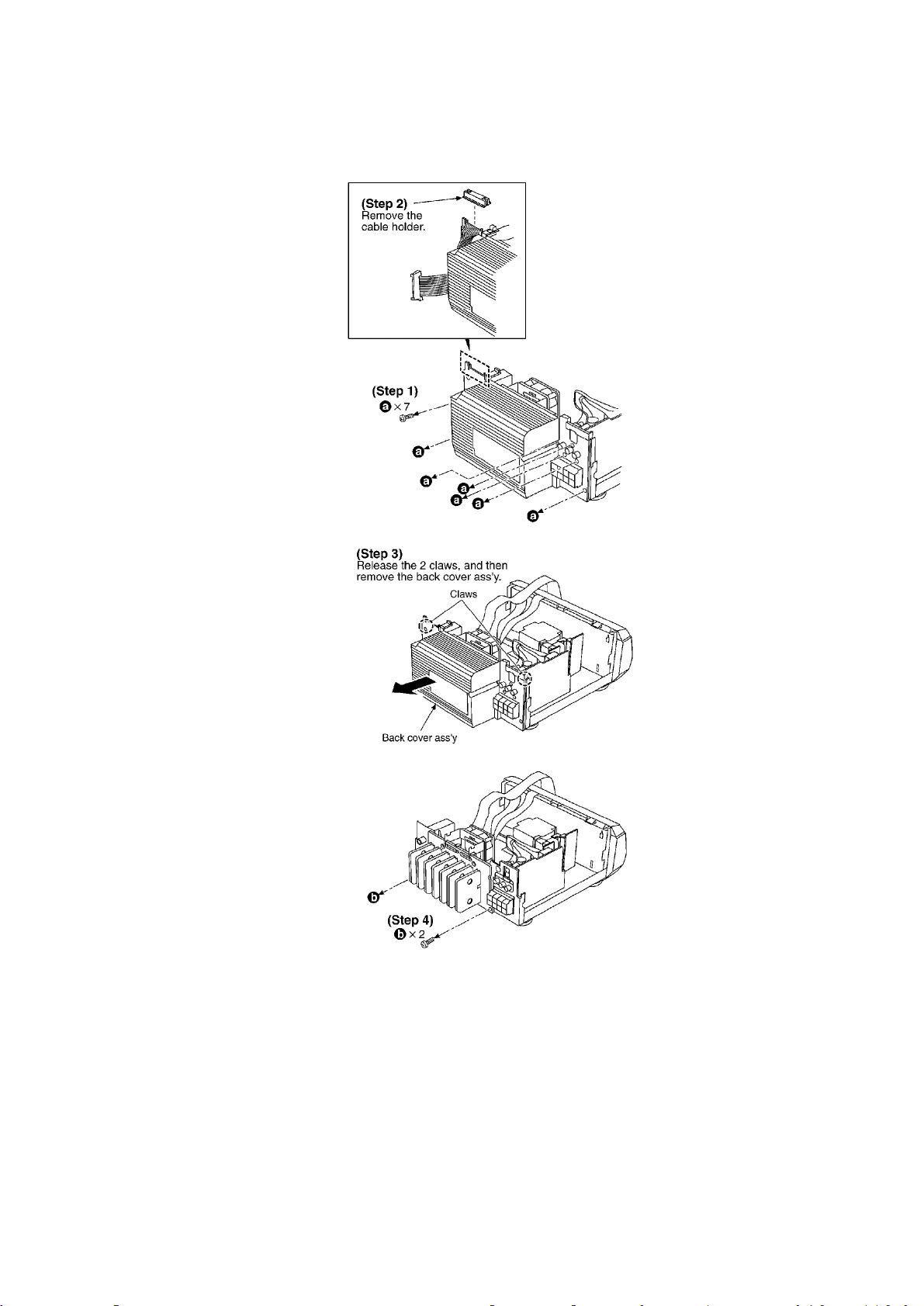

3. Operation Checks and Component Replacement /

Procedures

- This section describes procedures for checking the operation of

the major printed circuit boards and replacing the main

components.

- For reassembly after operation checks or replacement, reverse the

respective procedures. Special reassembly procedures are

described only when required.

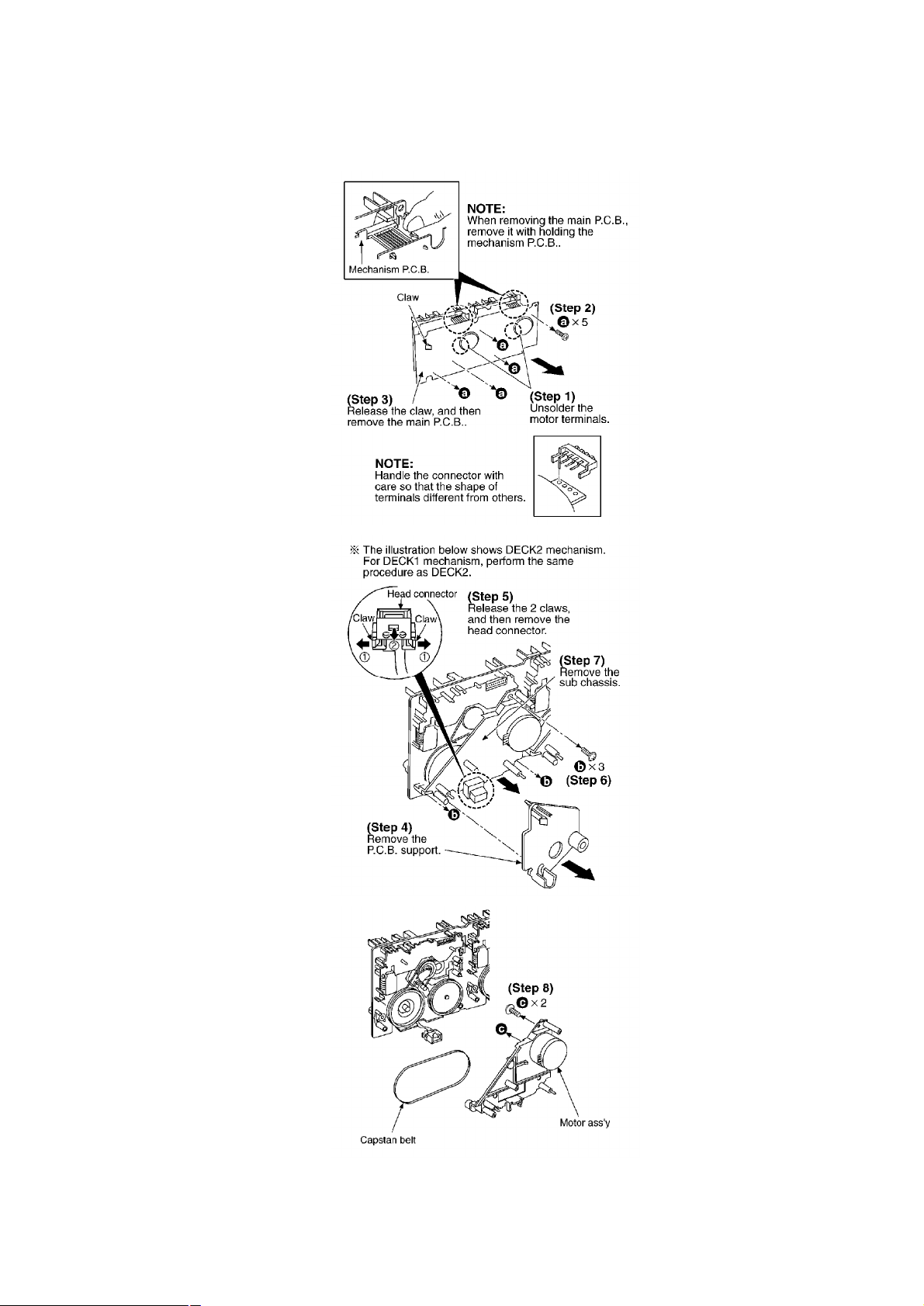

3.1. Checking for the main P.C.B.

- Check the main P.C.B. as shown above.

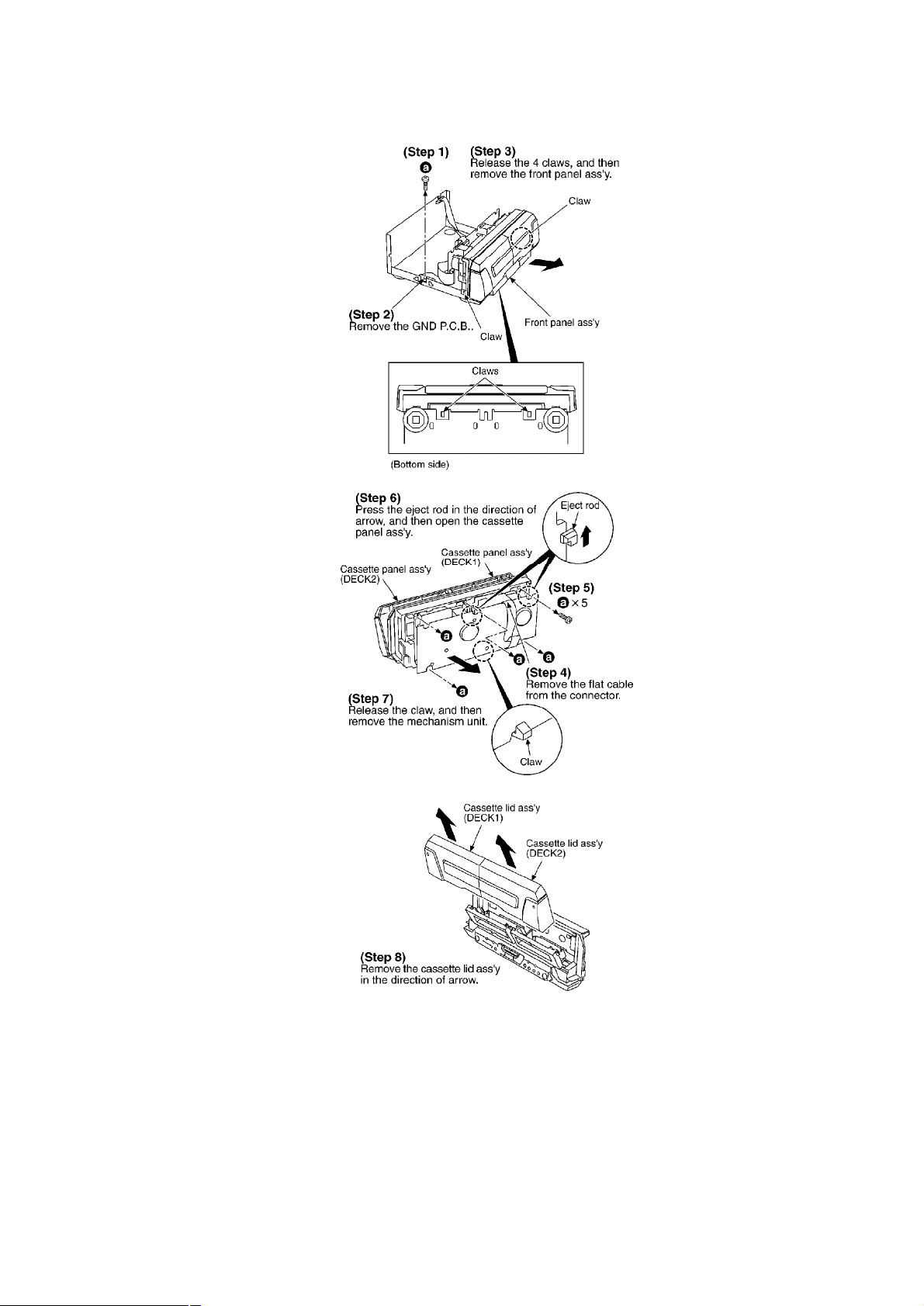

3.2. Checking for the operation P.C.B.

- Follow the (Step 1) - (Step 3) of item 3.1.

2

Page 3

3

Page 4

- Check the operation P.C.B. as shown below.

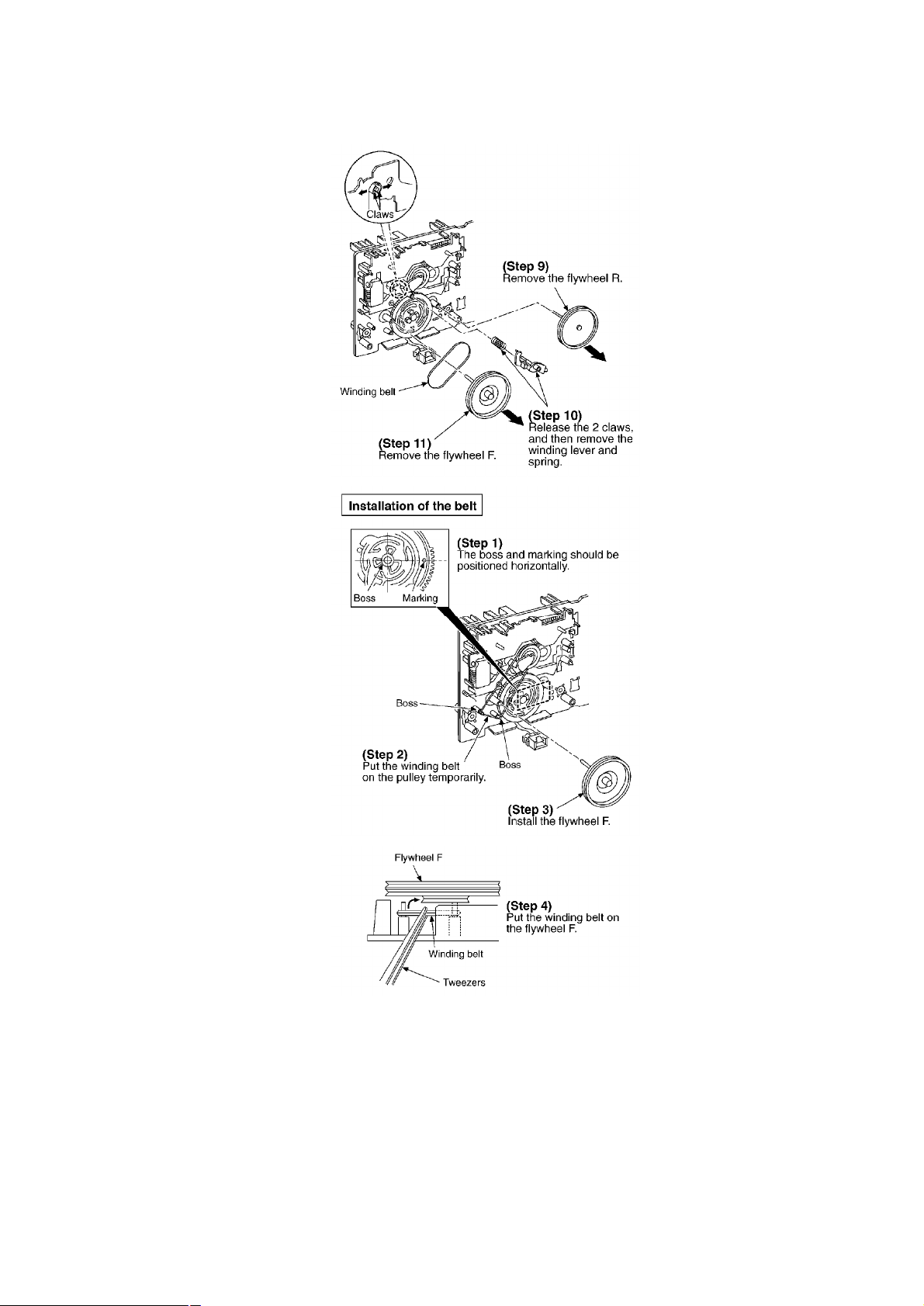

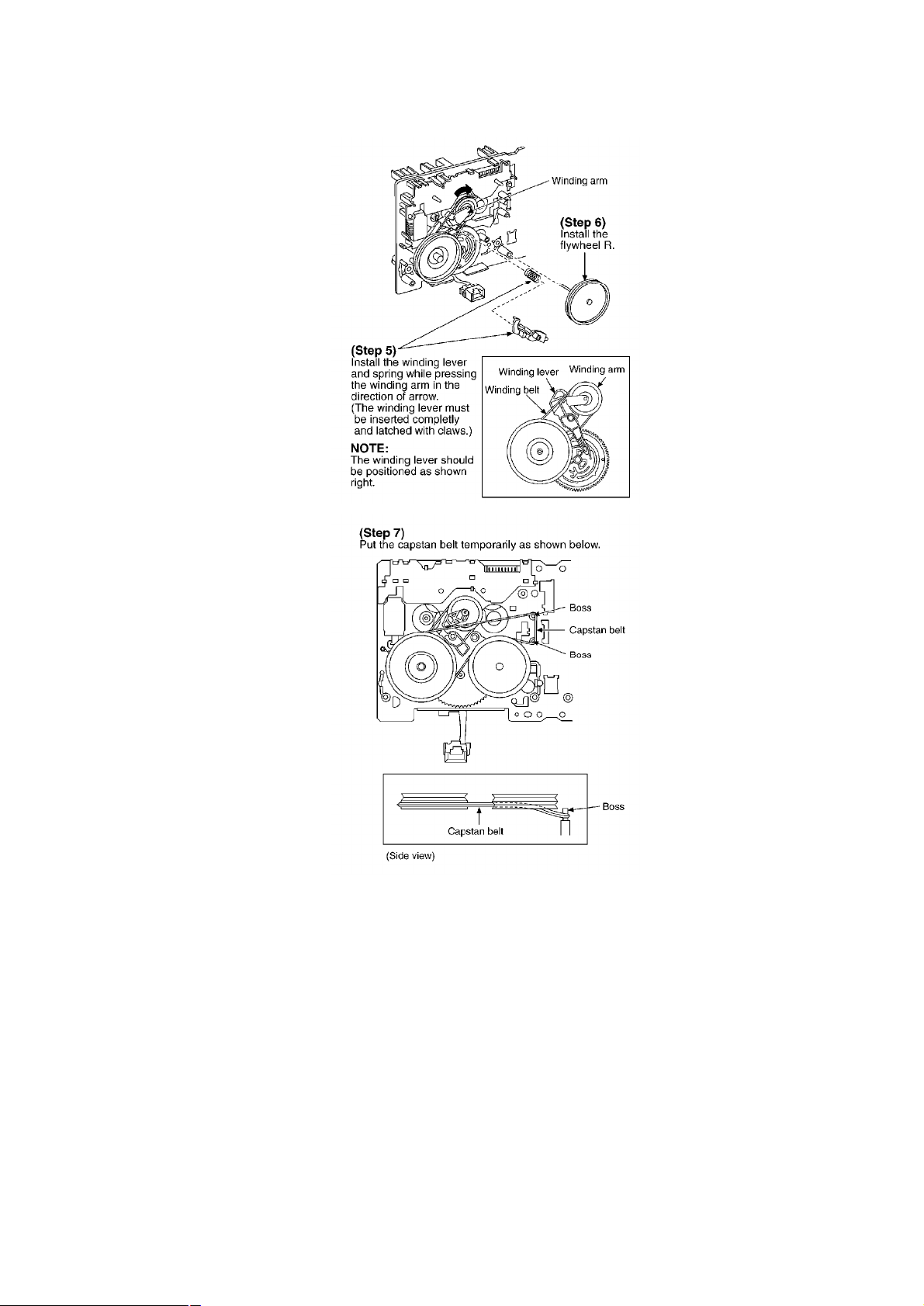

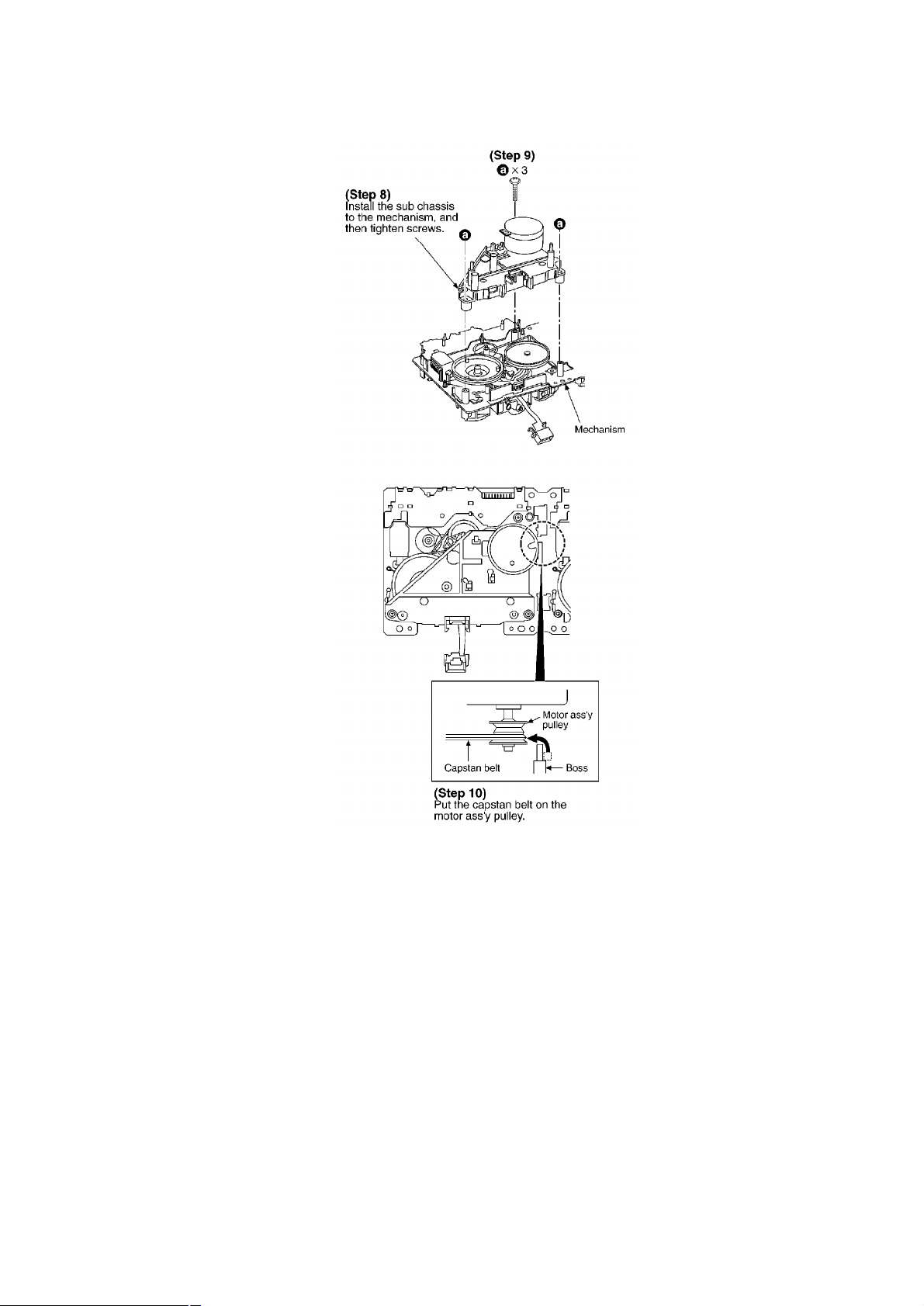

3.3. Replacement for the motor ass’y, capstan belt and winding belt

- Follow the (Step 1) - (Step 3) of item 3.1.

4

Page 5

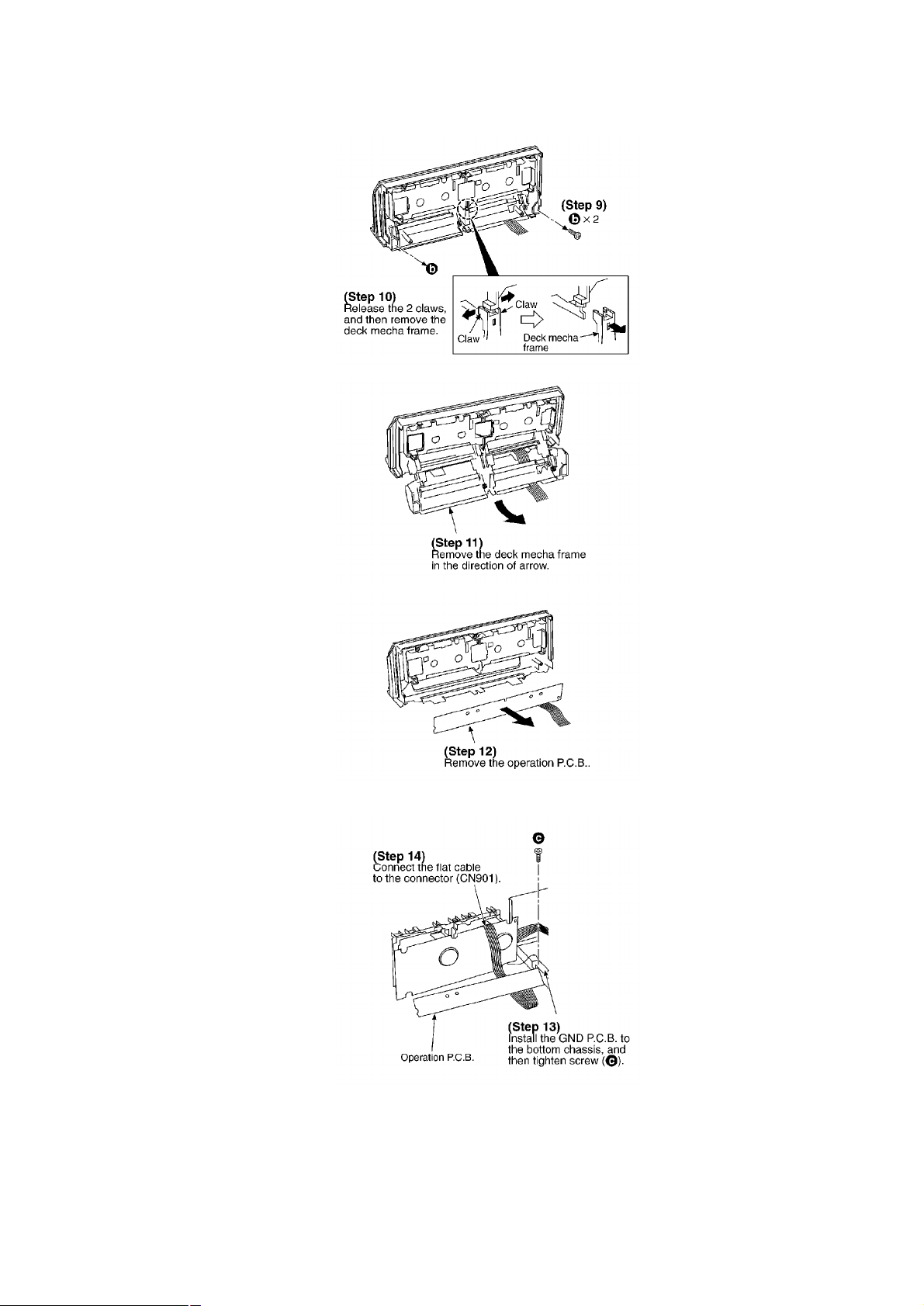

- Follow the (Step 1) - (Step 7) of item 3.2.

567

Page 6

Page 7

Page 8

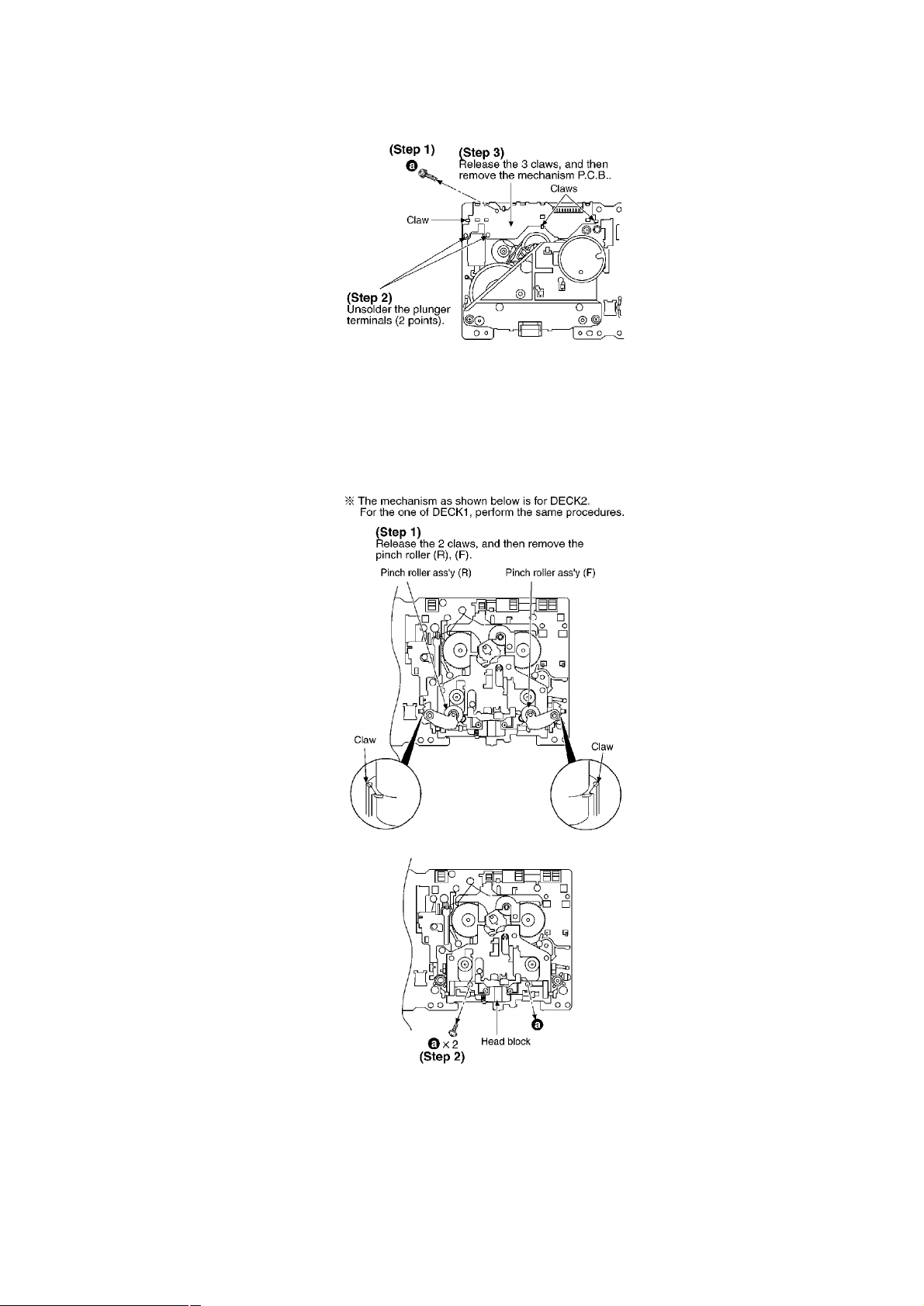

3.4. Replacement for the components parts on the mechanism P.C.B.

- Follow the (Step 1) - (Step 3) of item 3.1.

- Follow the (Step 1) - (Step 7) of item 3.2.

- Follow the (Step 1) - (Step 4) of item 3.3.

8

Page 9

3.5. Replacement for the pinch roller ass’y and head block

- Follow the (Step 1) - (Step 3) of item 3.1.

- Follow the (Step 1) - (Step 7) of item 3.2.

- Follow the (Step 1) - (Step 5) of item 3.3.

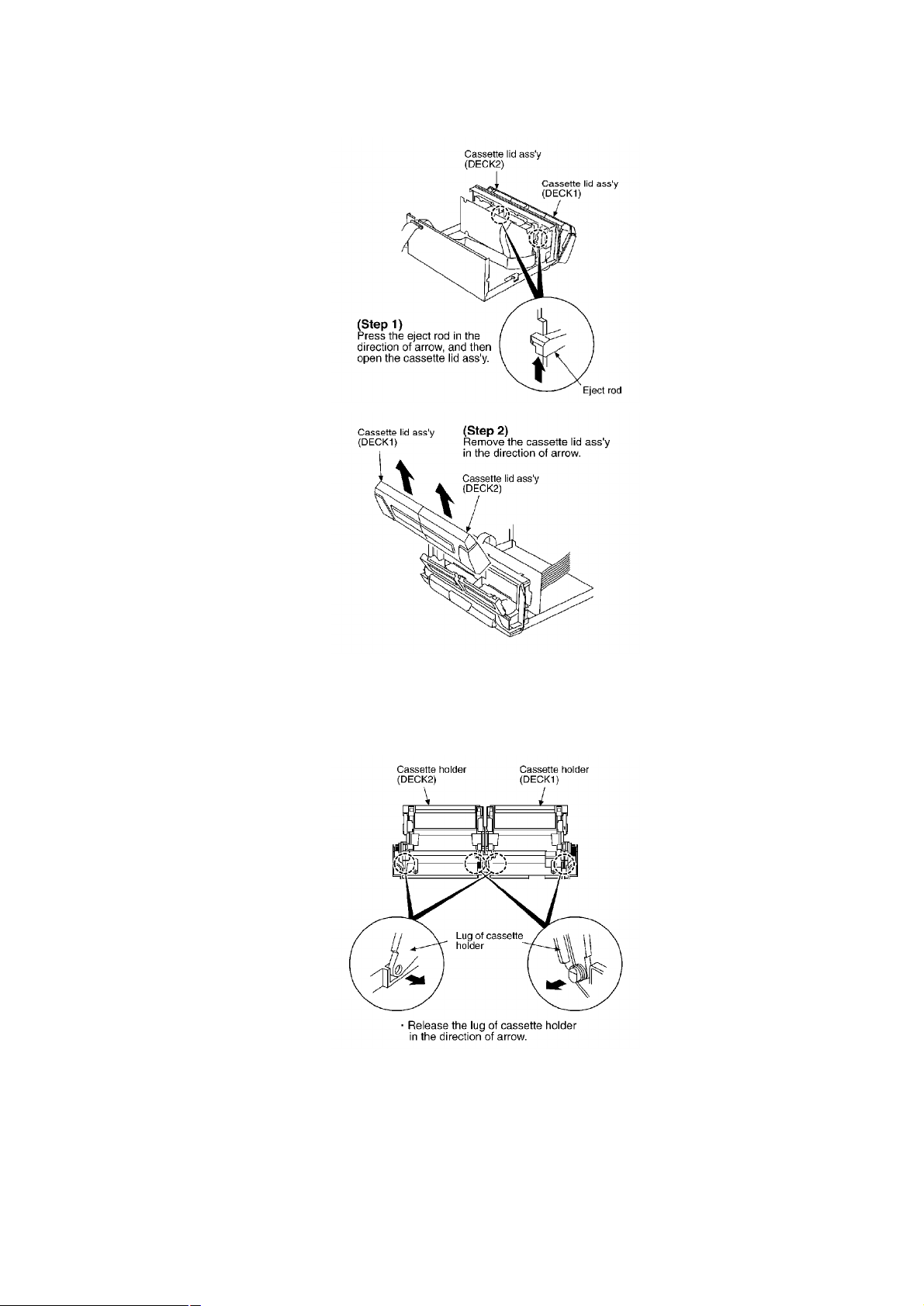

3.6. Replacement for the cassette lid ass’y

- Follow the (Step 1) - (Step 3) of item 3.1.

9

Page 10

3.7. Replacement for the cassette holder

- Follow the (Step 1) - (Step 3) of item 3.1.

- Follow the (Step 1) - (Step 11) of item 3.2.

10

Page 11

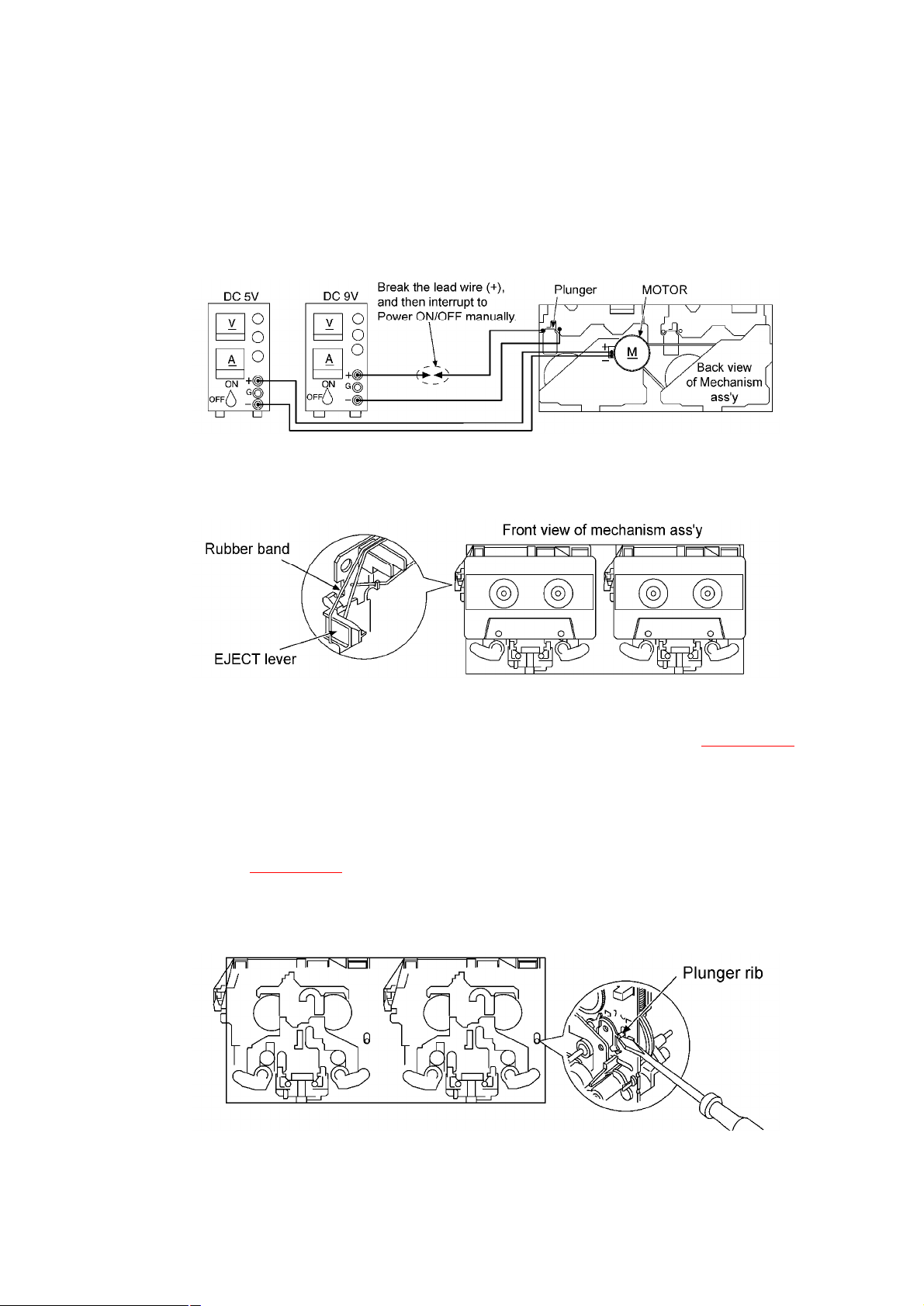

4. To Supply Power Source

This unit is designed to operate on power supplied from system connected. / When a component

requires service, use the system connections to supply power source. / For system connections,

refer to Fig.4-1.

Fig. 4-1.

5. Service Mode Function of Cassette Mechanism

This unit is equipped with a service mode function of cassette mechanism, so that if the unit

operates incorrectly, the fault displayed using an error code on the FL display of the Tuner/

Amplifier (SA-EH590). The system control IC and FLdisplay are part of the Tuner/Amplifier so

make sure the system has been connected properly before using this function. Use this function

during maintenance to check faults of items below.

5.1. Cassette tape to be prepared

Metal tape:

Recorded music tape with only one erasure prevention tab intact. /

(use middle portion of tape)

Normal tape: / CrO2 tape:

Recorded music tape with both erasure prevention tabs intact. /

(use middle portion of tape)

11

Page 12

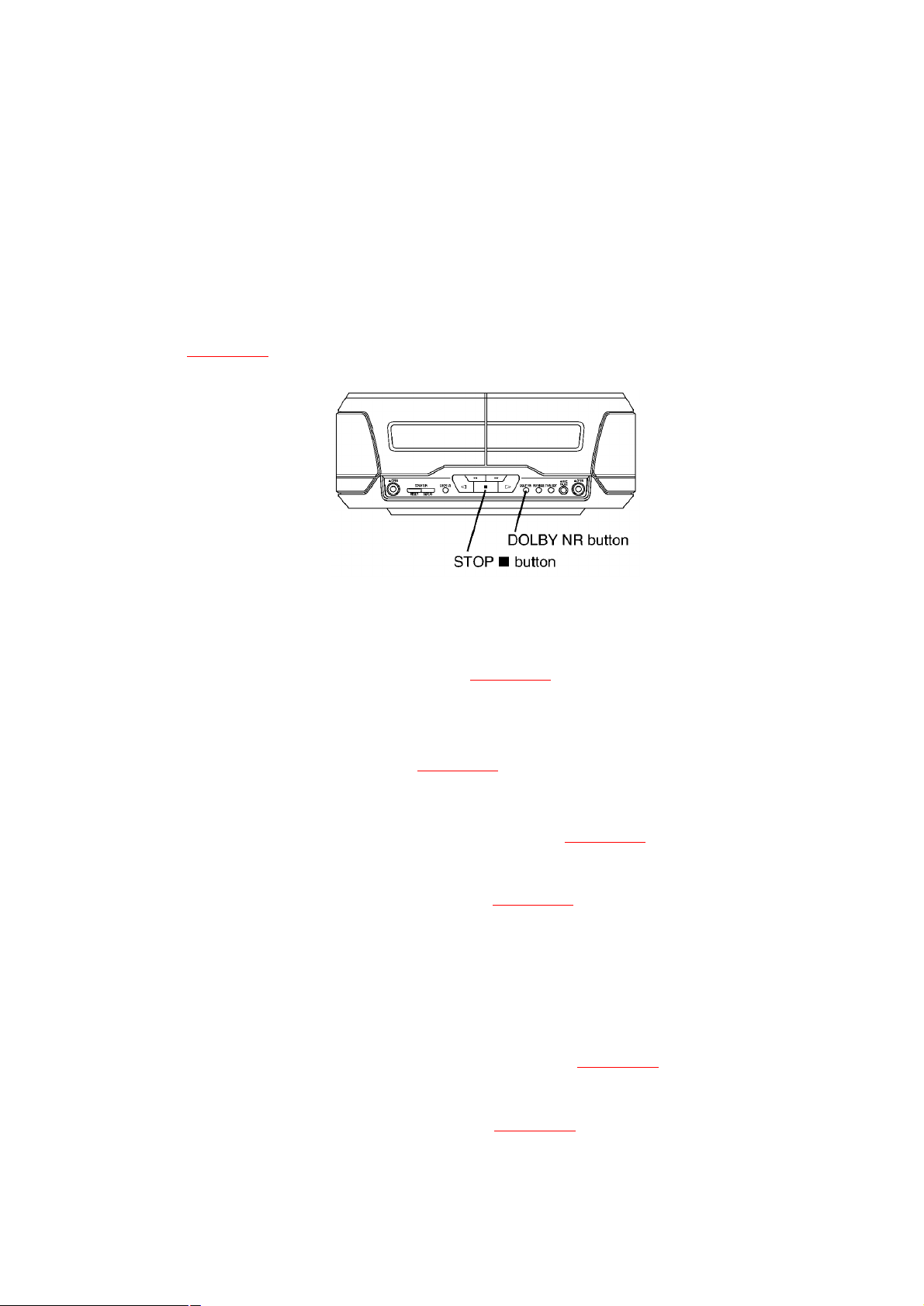

5.2. Selecting service mode

1. Turn on the power to the unit.

2. Make sure that no tape is inserted in the cassette deck. (Service

mode cannot be selected with a tape inserted in the cassette deck.)

3. Press the DOLBY NR button for about 2 seconds, and keep

pressing it, also press the STOP button for about 2 seconds. Refer

to Fig. 5-1.

Fig. 5-1.

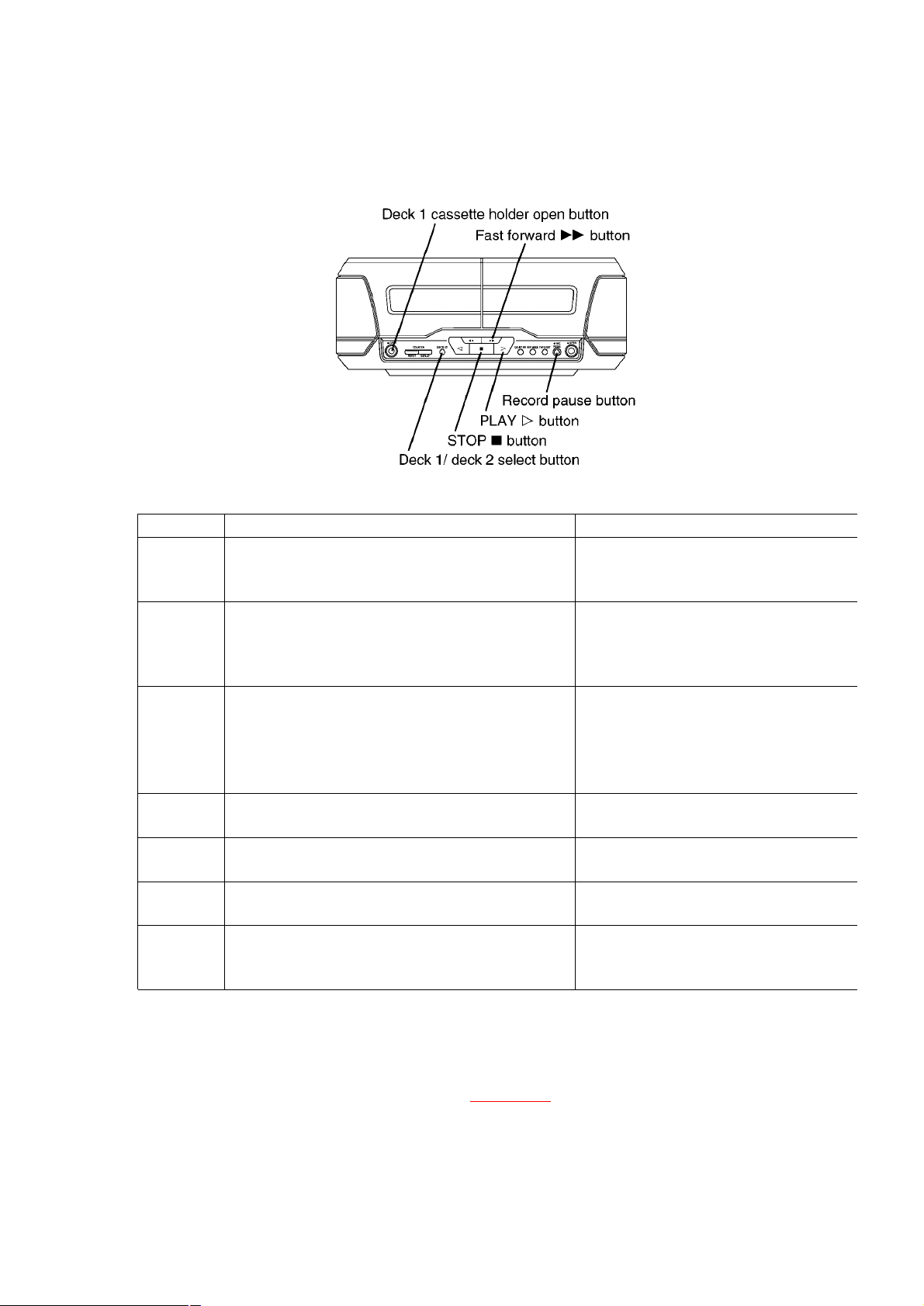

5.3. Deck 1 mechanism check

1. Press the Deck 1/deck 2 select button to change the flashing Deck

2 indicator to Deck 1. Refer to Fig. 5-2. / (No change required if

Deck 1 indicator already flashing.)

2. Press the Deck 1 cassette holder open button to open the Deck 1

cassette holder. Refer to Fig. 5-2.

3. Insert a CrO2 tape into the Deck 1 and close the cassette holder.

4. Press the Fast forward button. Refer to Fig. 5-2. / (Tape fast

forwards for about 2 seconds then stops.)

5. Press the PLAY button. Refer to Fig. 5-2. / (After TPS operation

and check, the tape stops.)

6. Open the Deck 1 cassette holder and replace the tape with a

normal tape.

7. Close the Deck 1 cassette holder.

8. Press the Record pause button. Refer to Fig. 5-2. / (No record

operation.)

9. Press the STOP button. Refer to Fig. 5-2. A mechanism error code

is displayed. Refer to Table 5-1. Each time the STOP button is

12

Page 13

pressed, the fault items are displayed in sequence.

mode

plunger

replace)

switch

and

S952

replace)

1

S976).

Check

plunger

mechanism

Fig. 5-2.

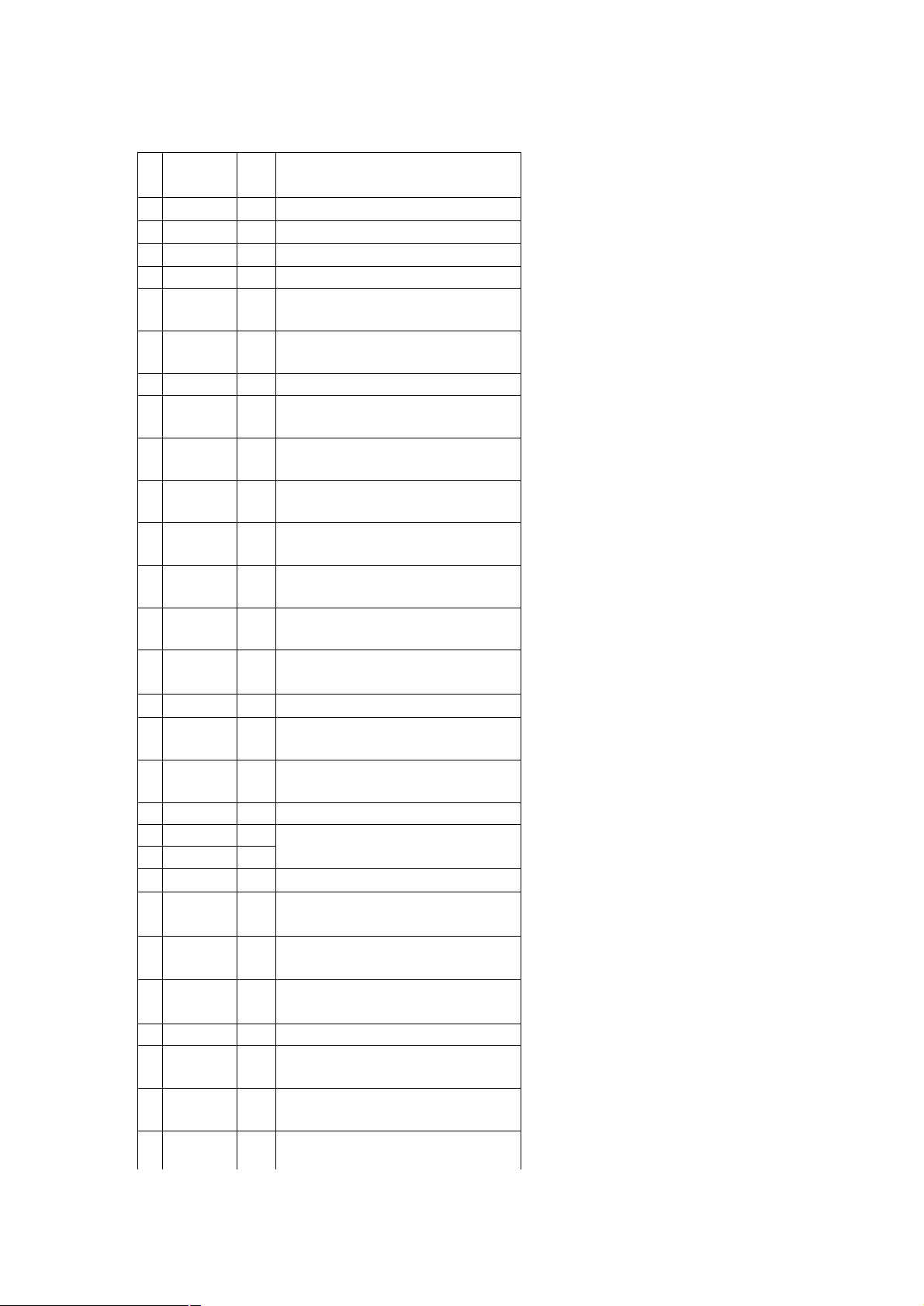

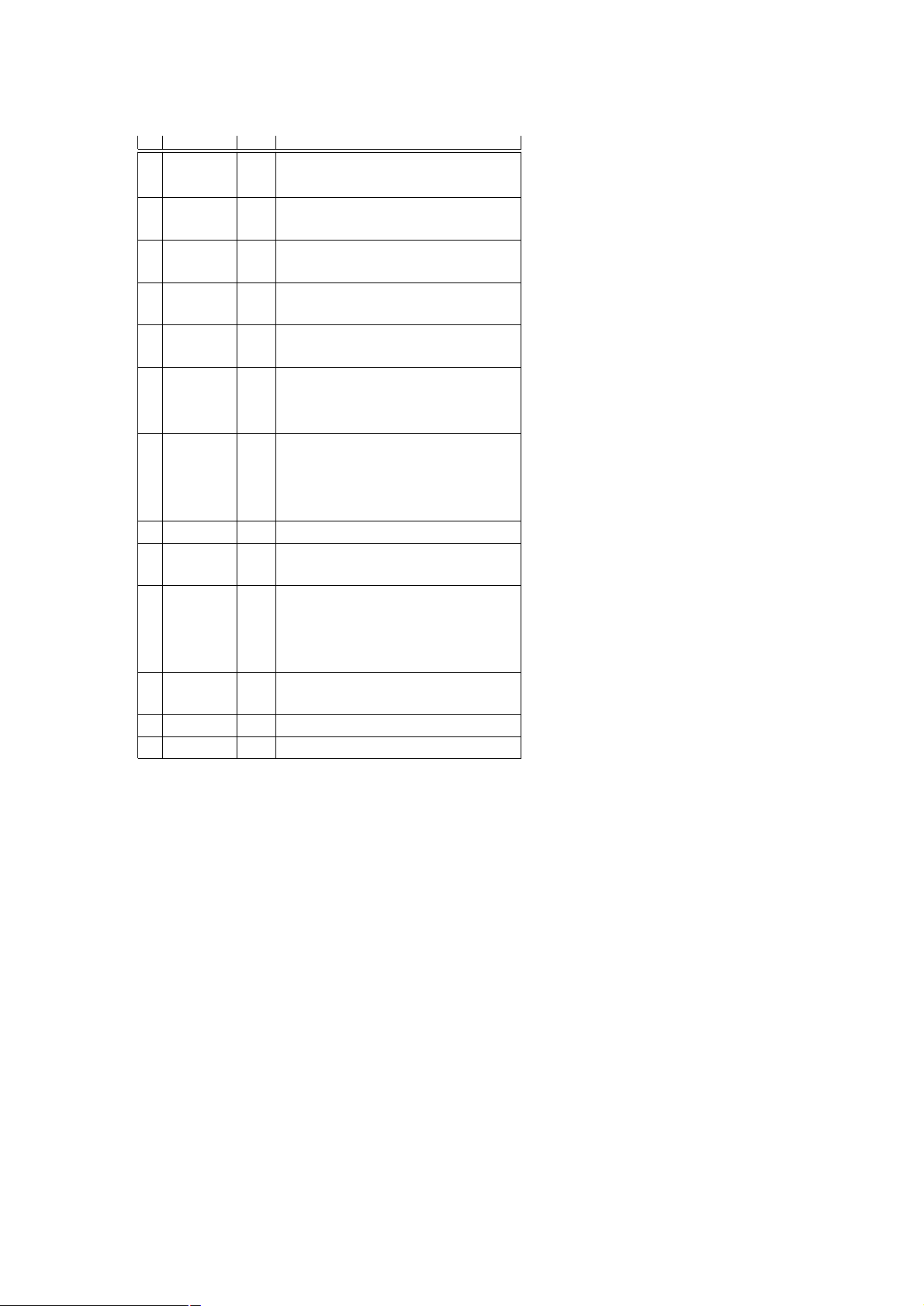

Table 5-1.

FL display Symptom Cause

H01 Cassette deck does not operate correctly. Faulty cassette deck mechanism

switch (Deck 1: S951, Deck 2: S971),

and capstan motor. / (Check and

H02 Unit does not record or the unit goes into

recording mode even when the erasure

prevention tabs have been removed from the

cassette.

H03 Tape does not play even when the tape deck

play button is pressed.

The motor operates when the tape deck play

button is pressed even if cassette is loaded in

the deck.

H06 Cassette deck does not detect CrO2 tape. Faulty CrO2 tape detect switch (Deck

H07 Cassette deck does not detect Metal tape. Faulty Metal tape detect switch (

F01 When the tape play button is pressed, tape

advances only slightly and then stops.

F02 TPS (tape program search) does not work. Faulty TPS signal detection or faulty

Faulty erasure prevention tabs detect

(S974, S975) or short-circuit. (Check

replace)

Faulty tape detect switch (Deck 1:

S972) or short-circuit. (Check and

Deck 2: S973). / (Check and replace)

and replace)

Reel pulse error (Faulty Hall IC). (

replace)

control. / (Check and replace

control IC)

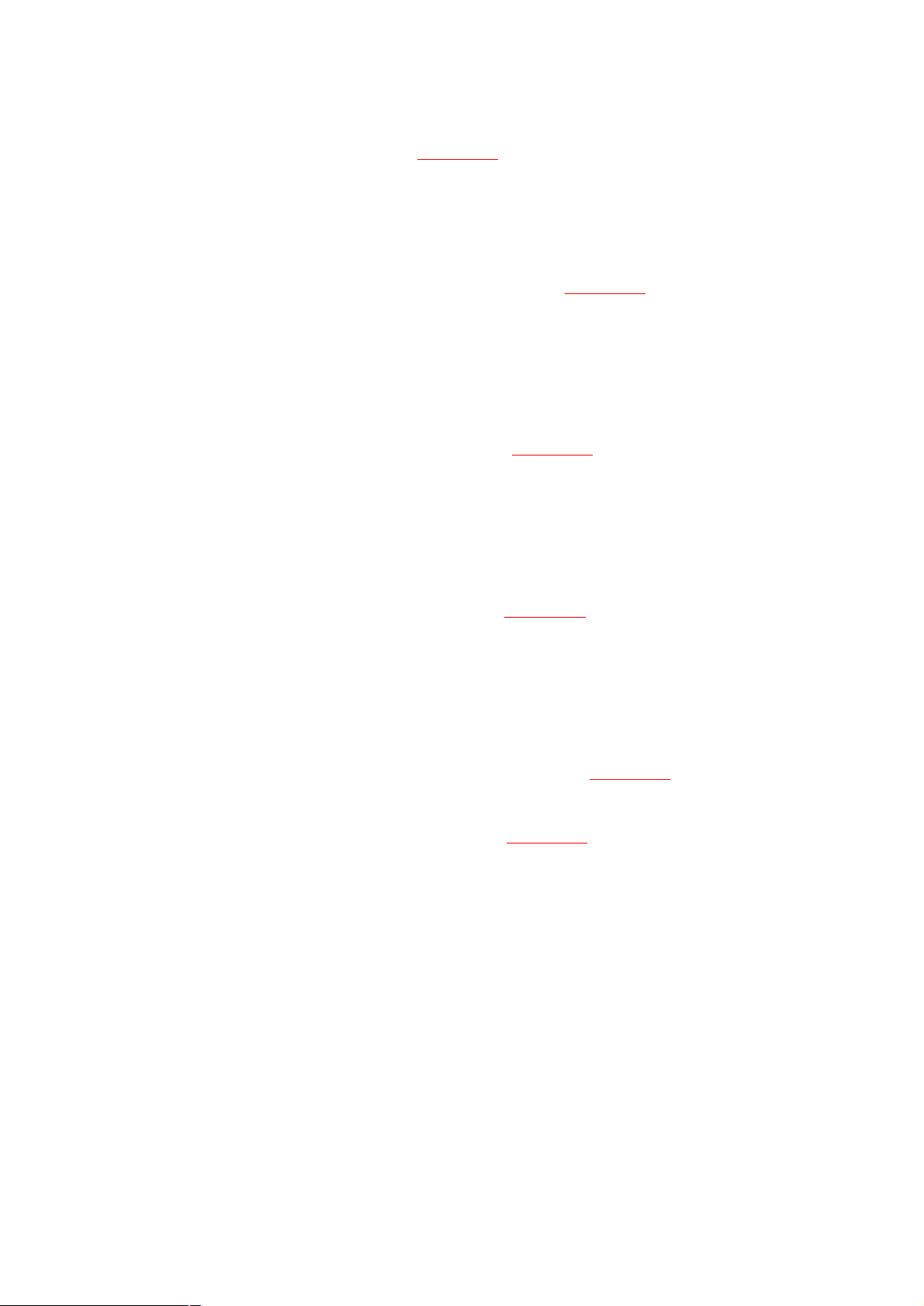

5.4. Deck 2 mechanism check

1. Press the Deck 1/deck 2 select button to change the flashing Deck

1 indicator to Deck 2. Refer to Fig. 5-3.

2. Press the Deck 2 cassette holder open button to open the Deck 2

13

Page 14

cassette holder. Refer to Fig. 5-3.

3. Insert a metal tape into the Deck 2 with an intact erasure

prevention tab on the right side.

4. Close the Deck 2 cassette holder.

5. Press the Fast forward button. Refer to Fig. 5-3. / (Tape fast

forwards for about 2 seconds then stops.)

6. Open the Deck 2 cassette holder and turn over the metal tape.

(intact erasure prevention tab on the left side.)

7. Close the Deck 2 cassette holder.

8. Press the Rewind button. Refer to Fig. 5-3. / (Tape rewinds for

about 2 seconds then stops.)

9. Open the Deck 2 cassette holder and replace the metal tape with a

CrO2 tape.

10. Close the Deck 2 cassette holder.

11. Press the PLAY button. Refer to Fig. 5-3. / (After TPS operation

and check, the tape stops.)

12. Open the Deck 2 cassette holder and replace the CrO2 tape with a

normal tape.

13. Close the Deck 2 cassette holder.

14. Press the Record pause button. Refer to Fig. 5-3. / (No record

operation.)

15. Press the STOP button. Refer to Fig. 5-3. A mechanism error

code is displayed. Refer to Table 5-1. Each time the STOP button is

pressed, the fault items are displayed in sequence.

Fig. 5-3.

14

Page 15

5.5. Exiting service mode

1. Press the STOP button for more than 5 seconds. (Diagnostic

contents stored in memory for both Deck 1 and 2 are erased.)

2. Remove the cassette tape from the cassette holder.

3. Turn off the unit.

6. Schematic Diagram Notes

- This schematic diagram may be modified at any time with the

development of new technology.

Notes:

S900:

Stop switch ( )

S901:

Deck 2 cassette holder open switch ( OPEN)

S903:

Tape edit switch (TAPE EDIT)

S904:

Record pause switch / ( REC PAUSE)

S905:

Dolby noise reduction switch / (DOLBY NR)

S906:

15

Page 16

Fast forward, TPS switch ( )

S907:

Forward side playback switch ( )

S909:

Reverse side playback switch ( )

S910:

Rewind, TPS switch ( )

S911:

Reverse mode switch / (REV MODE)

S912:

Deck 1/deck 2 select switch / (DECK 1/2)

S913:

Counter display switch / (COUNTER DISPLAY)

S914:

Counter reset switch / (COUNTER RESET)

S915:

Deck 1 cassette holder open switch ( OPEN)

S951:

Deck 1 mode detect switch

S952:

Deck 1 half detect switch

S953:

Deck 1 CrO2 tape detect switch

S971:

Deck 2 mode detect switch

S972:

Deck 2 half detect switch

S973:

Deck 2 CrO2 tape detect switch

16

Page 17

S974:

Deck 2 reverse side record prevention tab detect switch

S975:

Deck 2 forward side record prevention tab detect switch

S976:

Deck 2 METAL tape detect switch

VR101:

Deck 1 playback gain adjustment VR / (R ch)

VR102:

Deck 2 playback gain adjustment VR / (L ch)

VR103:

Deck 2 playback gain adjustment VR / (R ch)

VR104:

Deck 1 playback gain adjustment VR / (L ch)

VR801:

Deck 1 tape speed adjustment VR (normal)

VR803:

Deck 2 tape speed adjustment VR (normal)

- Indicated voltage values are the standard values for the unit

measured by the DC electronic circuit tester (high-impedance) with

the chassis taken as standard. Therefore, there may exist some

errors in the voltage values, depending on theinternal impedance

of the DC circuit tester.

No mark

: Playback

( )

: Recording

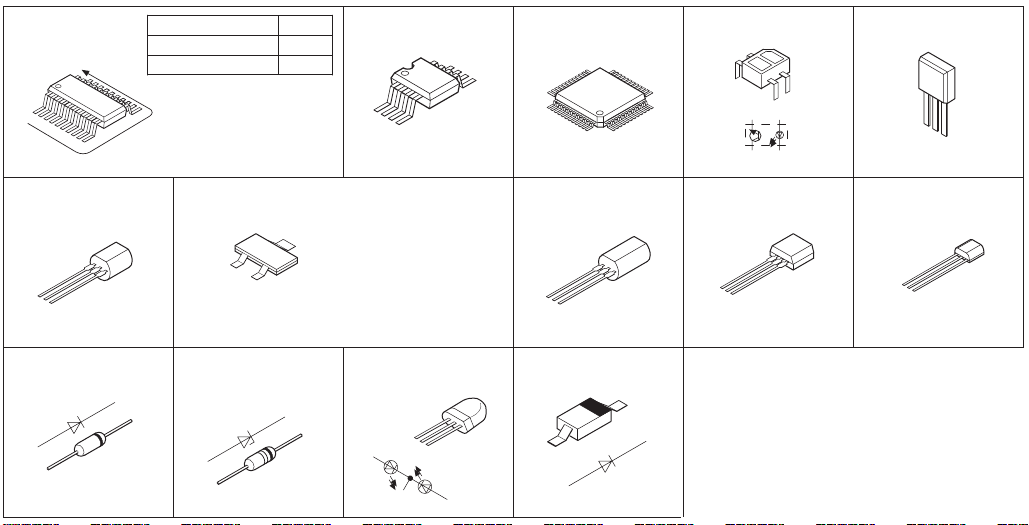

- Important safety notice:

Components identified by mark have special characteristics

important for safety.

Furthermore, special parts which have purposes of fire-retardant

(resistors), high-quality sound (capacitors), low-noise (resistors),

etc. are used.

17

Page 18

When replacing any of components, be sure to use only

manufacturer’s specified parts shown in the parts list.

- The supply part number is described alone in the replacement parts

list.

- Caution!

IC and LSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

Cover the parts boxes made of plastics with aluminum foil.

Ground the soldering iron.

Put a conductive mat on the work table.

Do not touch the legs of IC or LSI with the fingers directly.

- Voltage and signal line

: Positive voltage line

: Playback signal line

: Recording signal line

7. Schematic Diagram

8. Printed Circuit Board Diagram

9. Type Illustration of ICs, Transistors and Diodes

10. Wiring Connection Diagram

11. Block Diagram

12. Terminal Function of ICs

12.1. IC701 (M38503M2406F): / System Control

18

Page 19

Pin

101

No.

1

Terminal

Name

V

CC

I/O Function

I Power supply terminal

2 VREF I Reference voltage input

3

AV

SS

- GND terminal

4 LMT O Muting control signal output

5 PL1 O Deck 1 solenoid control signal

output

6 M1 O Deck 1 motor drive control

signal output

7 HALT I Power failure detect signal input

8 REQ I Serial communication request

signal input

9 CS I Serial communication complete

signal input

10 CLK O Serial communication clock

signal output

11 DATA

OUT

O Serial communication data

signal output

12 DATA IN I Serial communication data

signal input

13 METAL 2 I Deck 2 tape detect switch signal

(METAL) input

14

CRO2 2

I

Deck 2 tape detect switch signal

(CrO2) input

15

V

SS

- GND terminal

16 FWD LED O LED drive control signal (FWD)

output

17 REV LED O LED drive control signal (REV)

output

18 RESET I Reset signal input

19 XIN I Oscillator connected terminal (F

20 XOUT O

21

V

SS

22

CRO2 1

=8 MHz)

- GND terminal

I

Deck 1 tape detect switch signal

(CrO2) input

23 MODE I

Deck 1 mechanism switch

signal (MODE) input

24 HALF1 I

Deck 1 mechanism switch

signal (Half) input

25 TPS I TPS signal input

26 A DATA O Serial data signal output for IC

101

27 A CLK O Serial clock signal output for IC

101

28 A LATCH O Serial latch signal output for IC

19

Page 20

101

Terminal

Pin

Name

No.

29 PL2 O Deck 2 solenoid control signal

30 M2 O Deck 2 motor drive control

31 ENC/DEC O Dolby NR record/playback mode

32 DOLBY

ON/OFF

33 E CS -

34

|

36

37 LED CNT O LED color control signal output

38

39 AD SW I

40

41 KEY2 I Operation key signal input

42 KEY1 I Operation key signal input

NC

PHOTO2T

PHOTO1T

I/O Function

output

signal output

select signal output

O Dolby NR ON/OFF control signal

output

EEPROM chip select signal

output

(Not used, open)

-

Not used, open

I Deck 2 reel pulse detect signal

input

Deck 2 mechanism switch

signal input

(Half, Mode, F REC INH., R REC

INH.)

I Deck 1 reel pulse detect signal

input

13. Measurements and Adjustments

Note:

This unit RS-DV290 is designed to operate on power supplied from

system connected.

13.1. Measurement condition

- Dolby NR switch is OFF

- Make sure heads are clean

- Make sure capstan and pressure roller are clean

- Temperature is 20 ± 5 °C

13.2. Measurement instrument and special tool

- Electronic Voltmeter

- Frequency Counter

20

Page 21

- AF Oscillator

- Test tape

- Head azimuth adjustment (8 kHz, -20 dB): QZZCFM

- Tape speed adjustment (3 kHz, -10 dB): QZZCWAT

- Playback gain adjustment (315 Hz, 0 dB): QZZCFM

- Recording/playback frequency response check:

QZZCFM / (315 Hz, -20 dB, 12.5 kHz~63 Hz, -20 dB)

QZZCRA4 (Normal blank tape)

QZZCRX2 (CrO2 blank tape)

QZZCRZ6 (Metal blank tape)

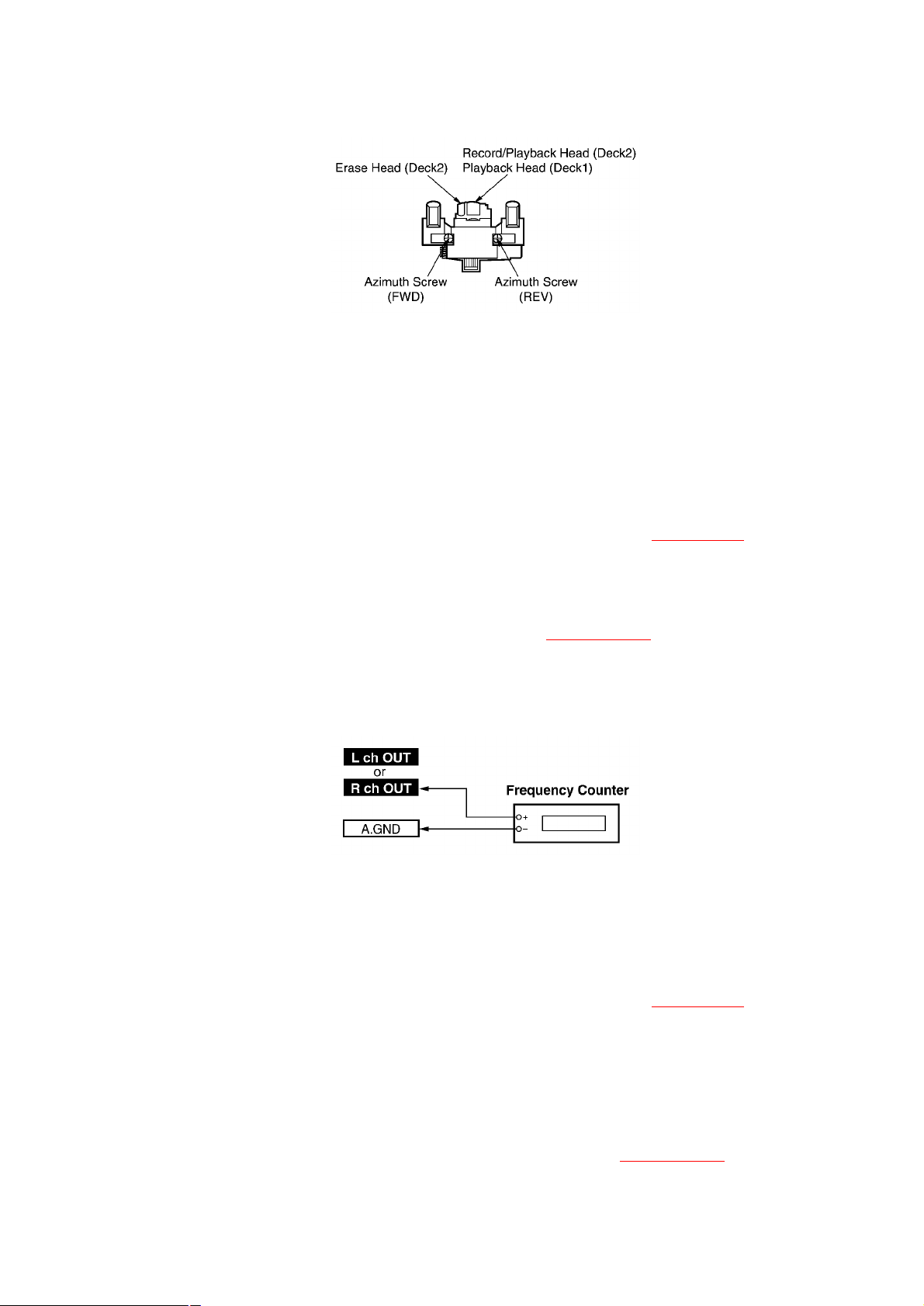

13.3. Head azimuth adjustment (Deck 1/2)

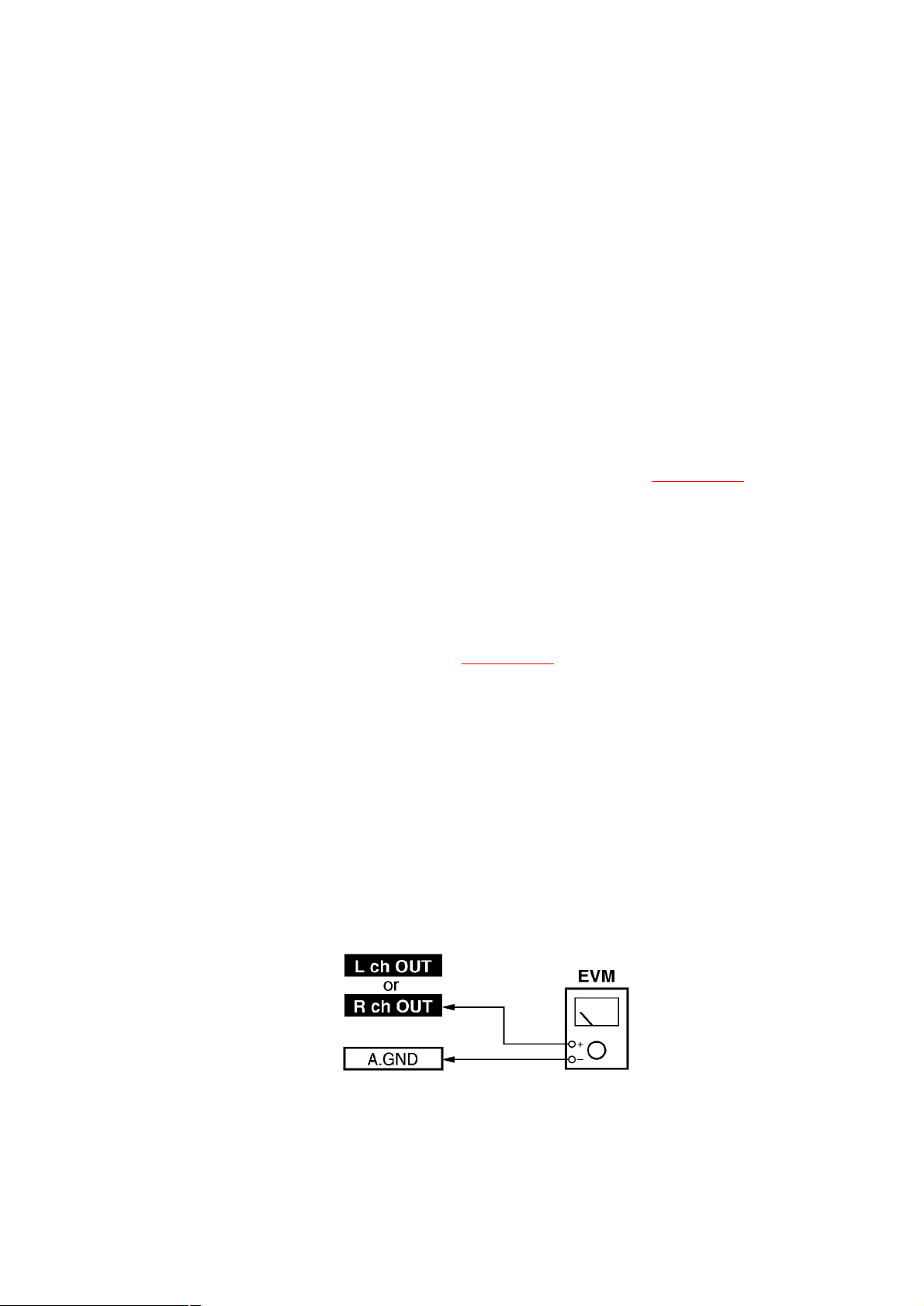

1. Connect the measuring instrument as shown in Fig. 13-1.

2. Replace azimuth screws for both forward and reverse directions

after removing the screw-locking bond left on the head base.

(Supply part No. of azimuth screw: RHD17015 )

3. Playback the azimuth adjustment portion (8 kHz, -20 dB) of test

tape (QZZCFM). Adjust the azimuth screw until the outputs of the L/

R ch are maximized. Refer to Fig. 13-2. Make sure that

thedifference in the peak level between the left and right channels

does not exceed 0.5 dB.

4. Perform the same adjustment in reverse playback mode.

Check of the level difference forward and reverse directions.

5. Playback the playback gain adjustment portion (315 Hz, 0 dB) of

test tape (QZZCFM). Check if level difference between forward and

reverse direction is within 1.5 dB.

6. After the adjustment, apply screw lock to the azimuth screw.

Fig. 13-1.

Fig. 13-2.

21

Page 22

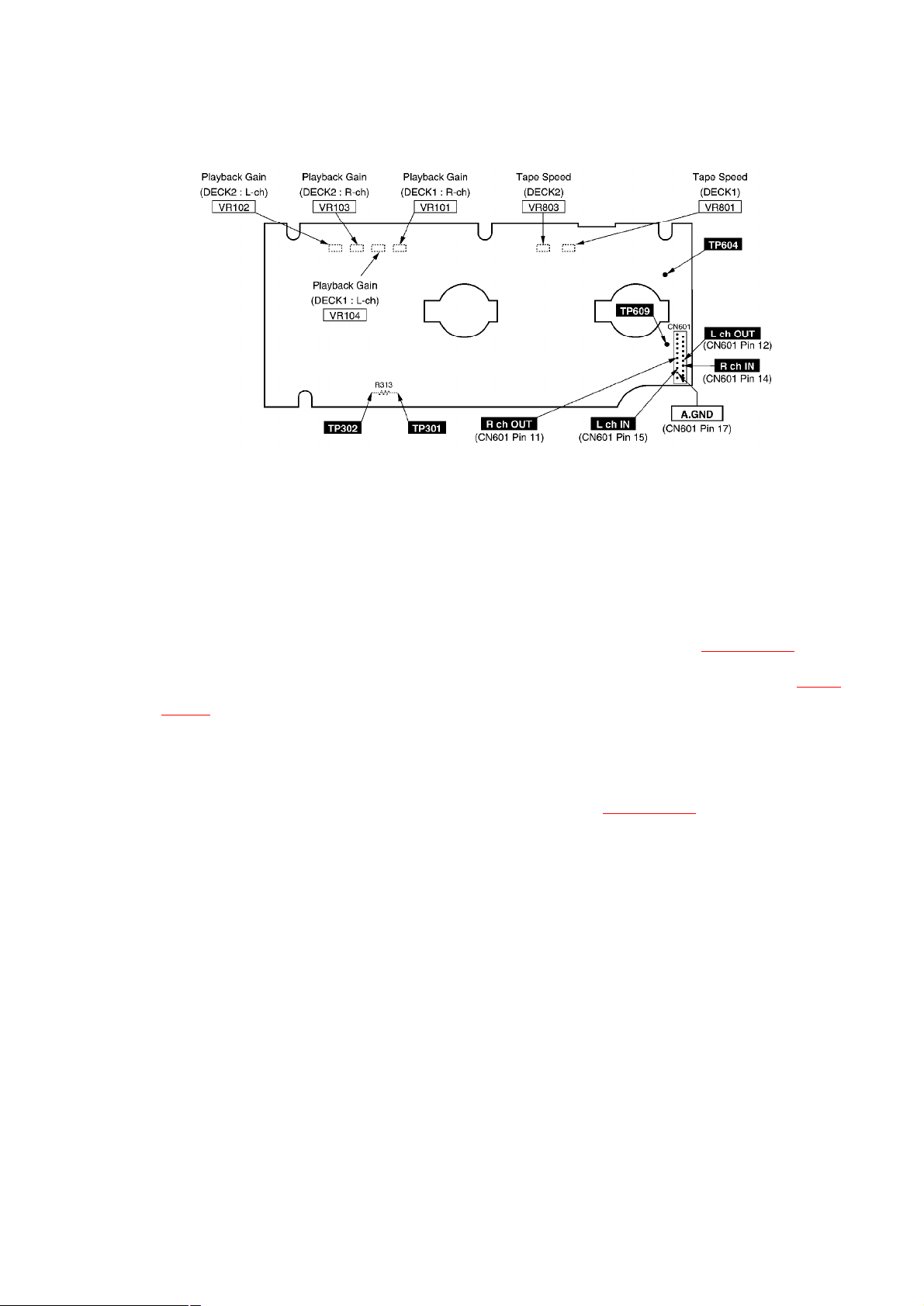

13.4. Tape speed adjustment / (Deck 1/2)

Note:

When connecting the unit to other system components for test,

short the section between the test point TP604 and TP609 and turn

on the entire system. (The unit is set to the TEST mode, and either

Deck 1 or Deck 2 indicatorwill blink.)

Normal speed (Standard value: 3000 ± 45 Hz)

1. Connect the measuring instrument as shown in Fig. 13-3.

2. Playback the middle portion of test tape. (QZZCWAT)

3. Adjust VR801 (Deck 1) and VR803 (Deck 2) for output value shown

below. (For adjustment point, refer to Fig. 13-11. )

Adjustment target: 3000 ± 15 Hz (Normal speed)

Standard value: 3000 ± 45 Hz (Normal speed)

Fig. 13-3.

Note:

When the unit is finished for adjusting, disconnect the short section

between TP604 and TP609 .

13.5. Playback gain adjustment (Deck 1/2)

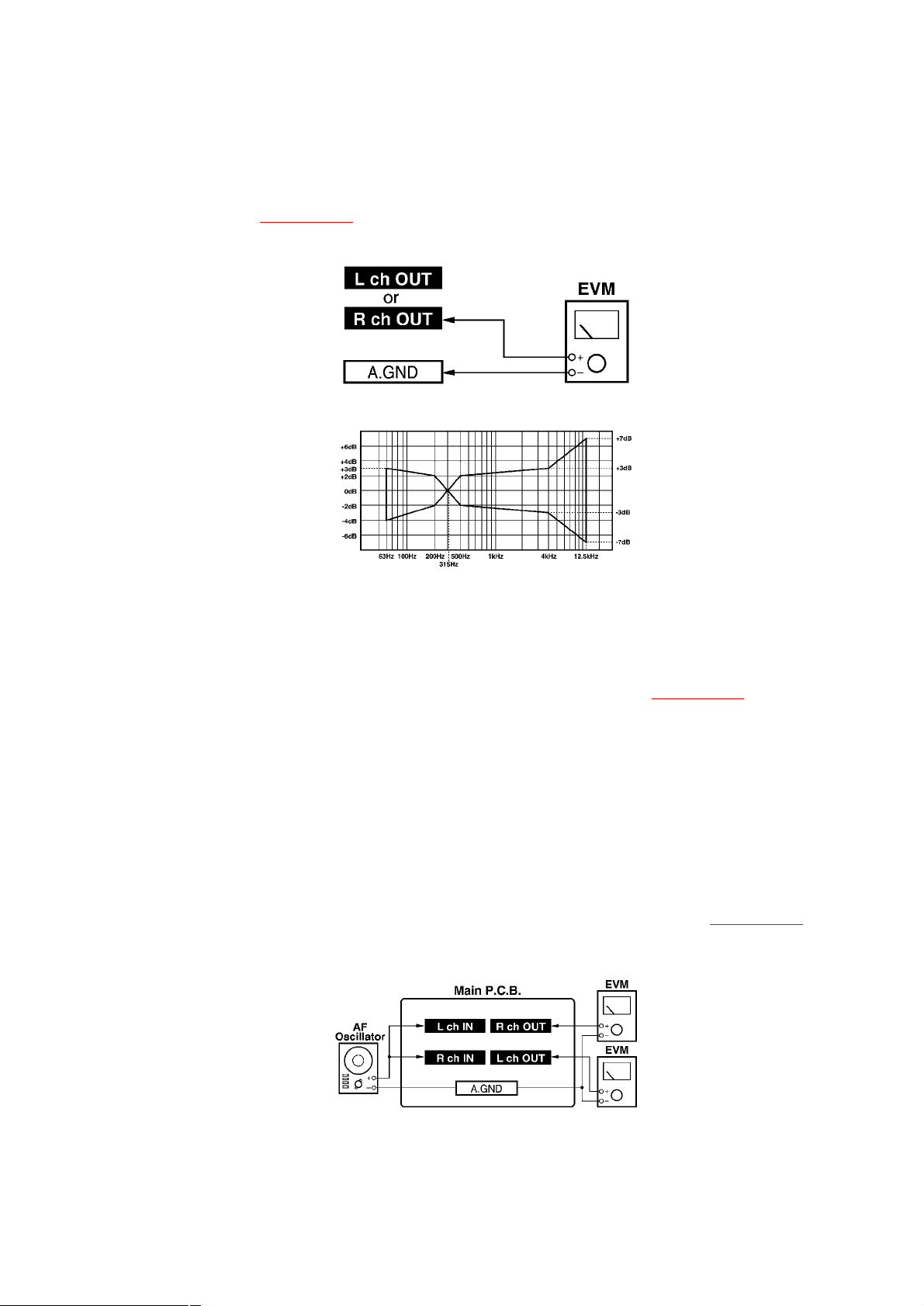

1. Connect the measuring instrument as shown in Fig. 13-4.

2. Find the start of the 315 Hz, 0 dB section of test tape (QZZCFM),

insert the tape into Deck 1 and 2, and play it back (FWD).

3. Adjust Deck 2: VR102 (L ch) [VR103 (R ch)] and Deck 1: VR104 (L

ch) [VR101 (R ch)] so that the output is within the standard value

shown below. (For adjustment point, refer to Fig. 13-11. )

22

Page 23

[Standard value:265 mV ~ 300 mV]

Fig. 13-4.

13.6. Erase current confirmation (Deck 2)

1. Connect the measuring instrument as shown in Fig. 13-5.

2. Insert the blank tape into Deck 2, and press the Record pause

button.

3. Check if the output at this time between the erase current

confirmation point TP301 and TP302 (the output on both edged of

R313) is within the standard value shown below. (For the erase

current confirmation point, referto Fig. 13-11. )

Standard Value EVM reading

Normal tape

:

CrO2 tape:

Metal tape:

Note:

85 ± 25 mA (85 ± 25 mV)

150 ± 25 mA (150 ± 25

mV)

185 ± 25 mA (185 ± 25

mV)

Fig. 13-5.

The test tape is not required when confirming the erase current.

13.7. Playback frequency response check (Deck 1/2)

1. Connect the measuring instrument as shown in Fig. 13-6.

2. Playback the 315 Hz, -20 dB and 12.5 kHz to 63 Hz, -20 dB sections

of test tape (QZZCFM) and then, using the 315 Hz, -20 dB playback

23

Page 24

output as a reference (0 dB).

3. Confirm the playback frequency response is within the range

shown in Fig. 13-7.

Fig. 13-6.

Fig. 13-7.

13.8. Recording/playback / frequency response and gain check

(Deck 2)

13.8.1. Normal tape check

1. Connect the measuring instrument as shown in Fig. 13-8.

2. Insert a Normal type blank tape (QZZCRA4) into Deck 2.

3. Record signals at 50 Hz, 100 Hz, 200 Hz, 500 Hz, 1 kHz, 2 kHz, 10

kHz and 12.5 kHz (28 mV).

4. Set the playback frequency of recorded signals at 1 kHz as a

reference response (0 dB).

5. Playback the recorded signal to confirm that the output is within

the range of the overall frequency response shown in Fig. 13-9.

Fig. 13-8.

Fig. 13-9.

24

Page 25

13.8.2. CrO2/Metal tape check

1. Connect the measuring instrument as shown in Fig. 13-8.

2. Insert a CrO2/Metal tape into Deck 2.

3. Record signals at 50 Hz, 100 Hz, 200 Hz, 500 Hz, 1 kHz, 2 kHz, 10

kHz and 12.5 kHz (28 mV).

4. Set the playback frequency of recorded signals at 1 kHz as a

reference response (0 dB).

5. Playback the recorded signal to confirm that the output is within

the range of the overall frequency response shown in Fig. 13-10.

Fig. 13-10.

13.9. Adjustment point and test point

25

Page 26

Fig. 13-11.

14. Checking Procedure for Self-operation of

Cassette Mechanism Ass’y

- This procedure describes simple methods independent of

mechanism controller or governor circuit.

14.1. Operation Check Providing with Cassette Tape

1. Push up the EJECT lever with rubber band. (Refer to Fig. 14-2. )

2. Apply DC 5V to the MOTOR. (MOTOR will be rotated) (Refer to Fig.

14-1. )

3. Provide the cassette tape with mechanism ass’y.

4. Apply DC 9V to the plunger, and then operate it by switching

power ON/OFF. (Power: +PL, -PL) (Refer to Fig. 14-1. )

A. FWD PLAY: Supply power to the plunger momentary. (Duration:

approx. 50msec.)

B. FWD FF: At FWD PLAY mode, supply power to the plunger

momentary. (Duration: approx. 50msec.)

C. STOP: At FWD FF mode, supply power to the plunger

momentary. (Duration: approx. 50msec.)

D. REV PLAY: At STOP mode, supply power to the plunger for

ordinary duration. (Duration: approx. 200msec.)

E. REV REW: At REV PLAY mode, supply power to the plunger

momentary. (Duration: approx. 50msec.)

F. STOP: At REV REW mode, supply power to the plunger

momentary. (Duration: approx. 50msec.)

26

Page 27

Repeat the above operation to FWD PLAY mode.

Note: Incorrect duration for power supply may be operated to other mode.

14.1.1. Connection Diagram Between the Mechanism Ass’y and Power Supply /

(MOTOR and Plunger)

Fig. 14-1.

14.1.2. Detail View of EJECT Lever / (EJECT lever fixed by rubber band, Plunger

rib operation)

Fig. 14-2.

14.2. Operation Check Not Provided with Cassette Tape

1. Push up the EJECT lever with rubber band. (Refer to Fig. 14-2. )

2. Apply DC 5V to the MOTOR. (MOTOR will be rotated)

3. Lift up the plunger rib of mechanism ass’y with the tip of minus

screwdriver, and then operate it same as power supply duration.

(Refer toFig. 14-3. )

Note: Operation order is same as the “Operation Check Providing with

Cassette Tape” item 4. above.

Fig. 14-3.

27

Page 28

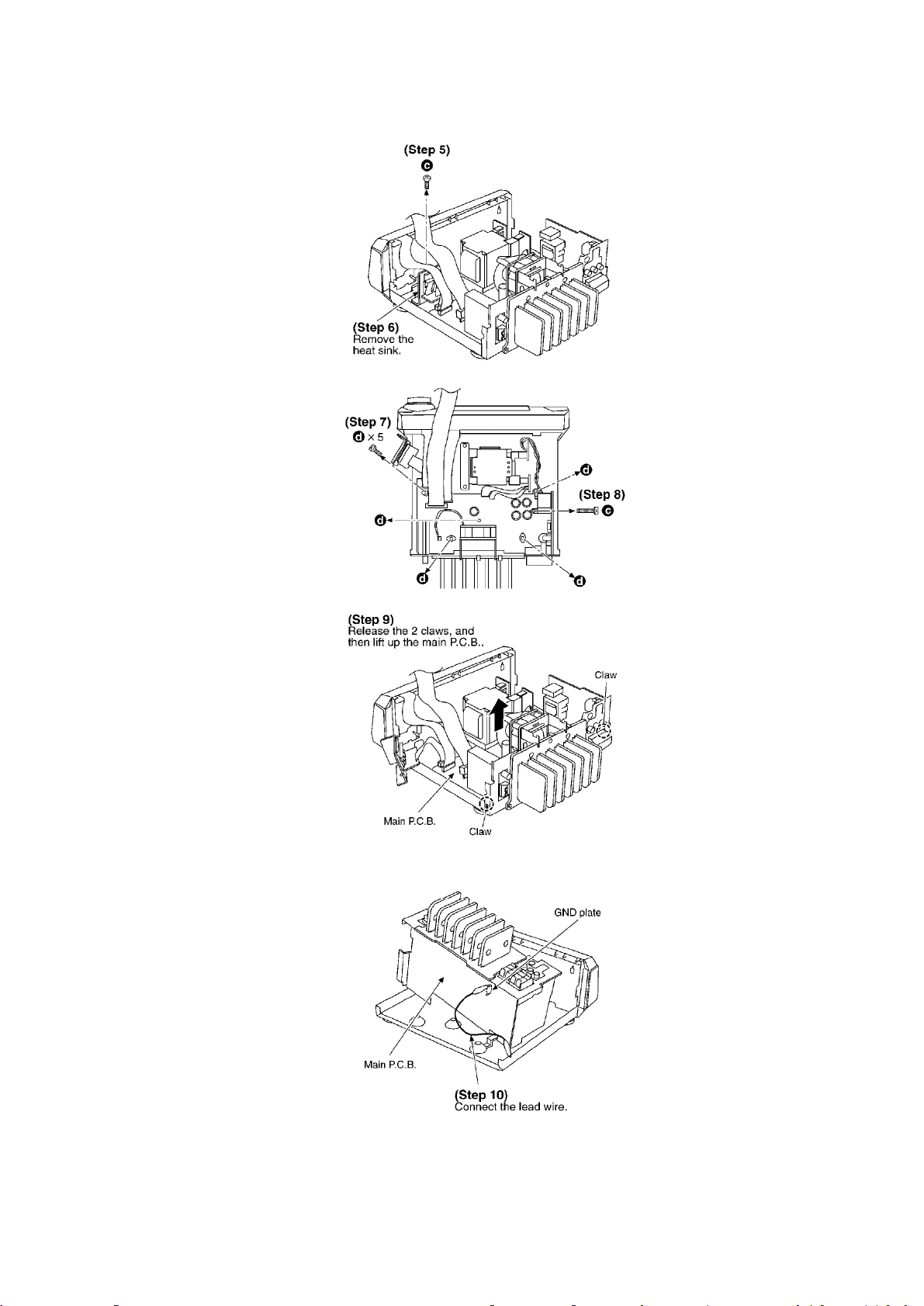

15. Replacement Parts List

Notes:

- Important safety notice:

Components identified by mark have special characteristics

important for safety.

Furthermore, special parts which have purposes of fire-retardant

(resistors), high-quality sound (capacitors), low-noise (resistors),

etc. are used.

When replacing any of components, be sure to use only

manufacture’s specified parts shown in the parts list.

- The marking [RTL] indicates the retention time is limited for this

Item. After the discontinuation of this assembly in production, it

will no longer available.

- All parts are supplied by SPC.

28

Page 29

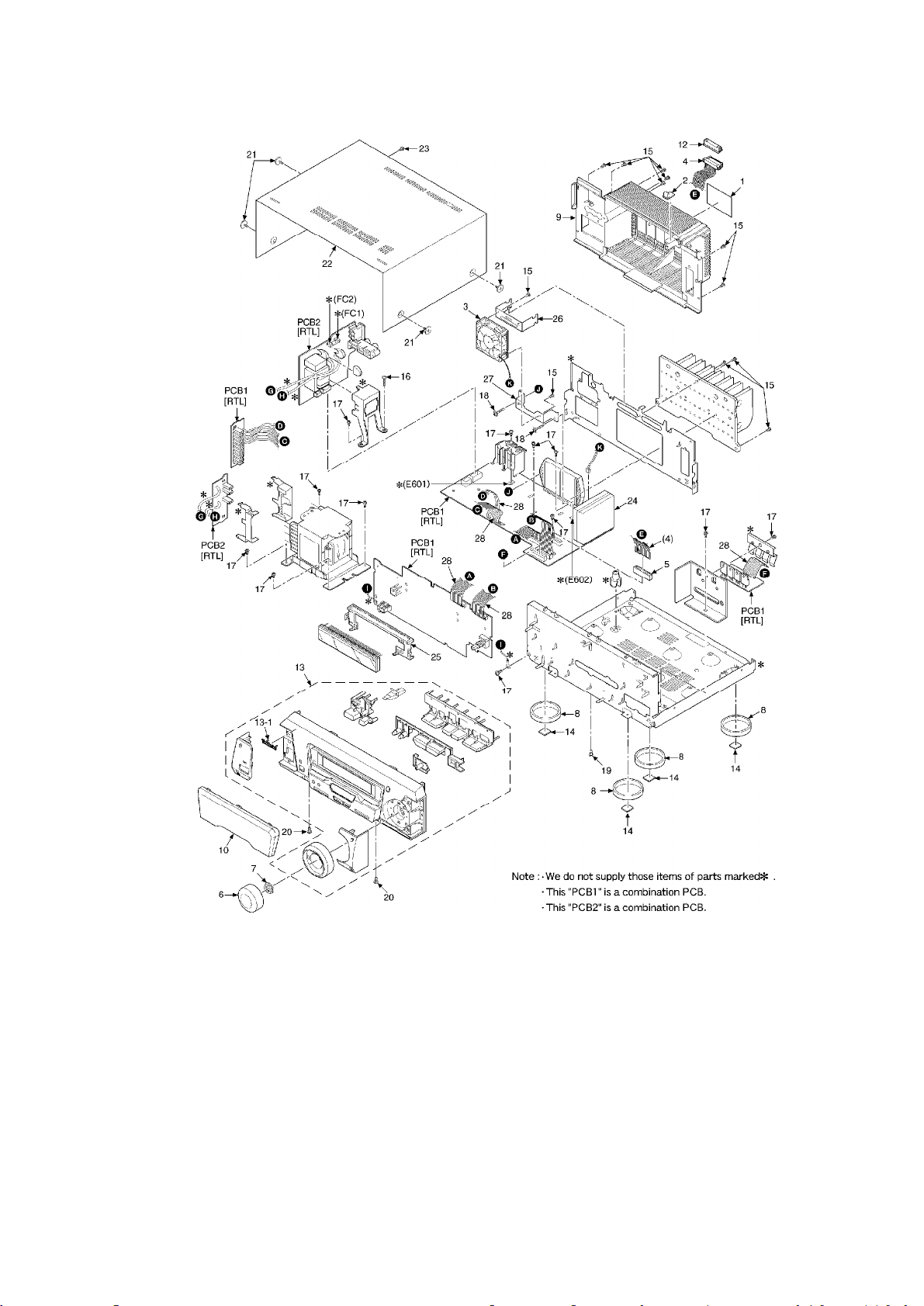

Ref. No. Part No. Part Name & Description Pcs Remarks

1 RKM0392-S1 CABINET 1

2 RHD30007-1S SCREW 4

3 XTBS3+10JFZ1 SCREW 2

4 RGR0287A-P REAR PANEL 1

5 RKA0105-K RUBBER 4

6 RKA0106-N FOOT RING 4

7 RMN0539 CABLE HOLDER 1

8 RDG0129-1 DAMPER GEAR 2

9 REX0966-1 WIRE ASS'Y 1

10 RGB0025-A TECHNICS BADGE 1

11 RGK1131-2S ORNAMENT(L) 1

12 RGK1132-2S ORNAMENT(R) 1

13 RGL0441-Q PANEL LIGHT 1

14 REZ1194 WIRE ASS'Y 1

15 RKF0462-K2 CASSETTE HOLDER(L) 1

16 RKF0463-K2 CASSETTE HOLDER(R) 1

17 RKF0587G-2S CASSETTE LID(L) 1

18 RKF0588-2S CASSETTE LID(R) 1

19 RKW0577-Q CASSETTE WINDOW(L) 1

20 RKW0578-Q CASSETTE WINDOW(R) 1

21 RMB0474 SPRING 2

22 RMQ0577A-3 FRAME 1

23 RUS757ZA SPRING 4

24 RYP1179-S FRONT PANEL 1

25 XTBS26+10J SCREW 7

26 XTB3+10JFZ SCREW 5

27 XTBS3+8JFZ1 SCREW 3

28 RMG0161 RUBBER 1

29

Page 30

Ref. No. Part No. Part Name & Description Pcs Remarks

29 RMR0909-X PCB HOLDER 1

101 RED0037 HEAD BLOCK ASS'Y / (R/P) 1 L1AA00000008

101-1 RHD17015 SCREW 2

102 RED0038 HEAD BLOCK ASS'Y / (P.B) 1

102-1 RHD17015 SCREW 2

103 RDG0300 REEL TABLE BASE 4

104 RDG0301 GEAR 2

105 RDK0026 GEAR 2

107 RDV0033-4 BELT1 2

108 RDV0034-1 BELT2 2

110 RUW147ZA SPRING 2

111 RMB0400 SPRING 4

112 RMB0403 SPRING 2

113 RMB0404 SPRING 2

114 RMB0406 SPRING 2

115 RMB0408 SPRING 2

116 RML0370-J LEVER 2

117 RML0371 LEVER 2

118 RML0372 LEVER 2

119 RML0374 LEVER 2

120 RMM0131 ROD 2

121 RMM0133-1 ROD 2

122 RMQ0519 REEL CAP 4

123 RMS0398-1 SHAFT 2

124 RSJ0003 PLUNGER ASS'Y 2

125 RUS609ZC SPRING 2

126 RXF0049 FLY WHEEL ASS'Y 2

127 RXF0050 FLY WHEEL ASS'Y 2

128 RXG0040 GEAR 4

129 RMK0283A-J SUB CHASSIS 2

130 RXL0124 PINCH ROLLER ASS'Y 2

130-1 RMB0401 SPRING 2

131 RXL0125 PINCH ROLLER ASS'Y 2

131-1 RMB0402 SPRING 2

132 RXL0126 ARM GEAR 2

133 RXQ0412 CHASSIS ASS'Y 2

133-1 RMB0405 SPRING 2

133-2 RMM0132-J FR ROD 2

134 REM0055-1 MOTOR ASS'Y 2

135 RHD26022 SCREW 4

136 XTW2+5L SCREW 4

137 XTW26+10S SCREW 6

138 XYC2+JF17 SCREW 2

140 RFKJSCH770EK MAIN CHASSIS ASS'Y 1

C101-04 ECUV1H681KBN 50V 680P 4 F1J1H681A021

C109,10 ECQB1H183JF3 50V 0.018U 2

C111,12 ECEA0JKS470 6.3V 47U 2

C113,14 ECEA1HKS2R2 50V 2.2U 2

C115,16 ECJ2VB1H471K 50V 470P 2

C117,18 ECUX1H331KBX 50V 330P 2

C119,20 ECA1HAK010XI 50V 1U 2

C123,24 ECEA1EKS4R7 25V 4.7U 2

C125,26 ECJ2VB1H332K 50V 3300P 2

30

Page 31

Ref. No. Part No. Part Name & Description Pcs Remarks

C129 ECEA1AKS220 10V 22U 1

C130 F2A1C101A133 16V 100U 1

C131-34 ECJ2VB1H471K 50V 470P 4

C135,36 ECA1HAK010XI 50V 1U 2

C137 ECEA1HKS0R1 50V 0.1U 1

C138 F1J1E4730004 25V 0.047U 1

C139 ECEA0JKS470 6.3V 47U 1

C140 ECEA1CKS100 16V 10U 1

C141 ECA1HAK010XI 50V 1U 1

C142 ECUVNE104ZFN 25V 0.1U 1 F1J1E1040017

C143,44 ECJ2VB1H471K 50V 470P 2

C150 RCE1AKA101BG 10V 100U 1 F2A1A1010020

C203,04 ECEA1EKS4R7 25V 4.7U 2

C205,06 ECA1HAK010XI 50V 1U 2

C207,08 ECUV1H271KBN 50V 270P 2

C211,12 ECUV1H152KBN 50V 1500P 2 ECJ2VB1H152K

C213,14 ECEA1EKS4R7 25V 4.7U 2

C215,16 ECEA1CKS100 16V 10U 2

C217,18 ECEA1HKS0R1 50V 0.1U 2

C219 F2A1C101A133 16V 100U 1

C220 RCE1ARS471BJ 10V 470U 1 F2A1A471A111

C221,22 ECEA1HKAR68B 50V 0.68U 2

C223 ECEA1EKS4R7 25V 4.7U 1

C225,26 ECEA1EKS4R7 25V 4.7U 2

C239,40 ECUV1H681KBN 50V 680P 2 F1J1H681A021

C241 ECJ2VB1H103K 50V 0.01U 1

C301 ECA1CAM471XB 16V 470U 1

C302 ECEA2AN2R2S 100V 2.2U 1

C303 ECQP2E682JZT 250V 6800P 1 F0A2E682A002

C304 F2A1C101A133 16V 100U 1

C305 ECEA1HKS0R1 50V 0.1U 1

C306 ECQB1H393JF3 50V 0.039U 1

C307 ECUV1H102KBN 50V 1000P 1 ECJ2VB1H102K

C308 ECJ2VB1H332K 50V 3300P 1

C309 ECEA0JKS470 6.3V 47U 1

C310,11 ECJ2VB1H103K 50V 0.01U 2

C323 ECUV1H102KBN 50V 1000P 1 ECJ2VB1H102K

C602 ECA1CAM221XB 16V 220U 1

C603 RCE1CKA470BG 16V 47U 1 F2A1C470A017

C604 ECUV1E103ZFN 25V 0.01U 1 F1J1E103A007

C605 ECA1CAM221XB 16V 220U 1

C701 ECJ2VB1H103K 50V 0.01U 1

C702 ECEA0JKS101 6.3V 100U 1

C705 ECUV1E103ZFN 25V 0.01U 1 F1J1E103A007

C706 RCE1HKA3R3BG 50V 3.3U 1 F2A1H3R3A015

C707 ECUV1E103ZFN 25V 0.01U 1 F1J1E103A007

CN601 RJS2A5520-1 CONNECTOR(20P) 1 K1MP20A00005

CN901 RJS8T6ZA CONNECTOR(8P) 1 K1MP08B00006

CP101,02 RJS1A6805 CONNECTOR(5P) 2

CP901,02 RJT071K09A CONNECTOR(9P) 2 K1KA09B00058

CS951 RJU071H09M CONNECTOR(9P) 1 K1KB09C00001

31

Page 32

Ref. No. Part No. Part Name & Description Pcs Remarks

CS971 RJU071H09M CONNECTOR(9P) 1 K1KB09C00001

D101,02 MA2J11100L DIODE 2

D301 MA2J11100L DIODE 1

D606 MAZ40560MF DIODE 1

D651,52 MA165TA5 DIODE 2 MA2C16500E

D701 MA2J11100L DIODE 1

D705,06 MA2J11100L DIODE 2

D707 MA4051M DIODE 1 MAZ40510M

D708-10 MA2J11100L DIODE 3

D904 MA2J11100L DIODE 1

D905 B3AHA0000012 LED 1

D907 B3AHA0000012 LED 1

D951 MA165TA5 DIODE 1 MA2C165

D971 MA165TA5 DIODE 1 MA2C165

IC101 CXA1998BQT6 IC 1 C1BB00000319

IC102 MC14066BFEL IC 1 C0JBAR000248

IC103 BA7755AF IC 1 C1AB00001381

IC201 CXA1552M-T4 IC 1 C1BB00000311

IC202 MC14066BFEL IC 1 C0JBAR000248

IC701 M38503M2406F IC 1 C2BBDD000003

IC951 0N2180RLC1 IC 1

IC971 0N2180RLC1 IC 1

L201,02 ELELN103KA COIL 2

L301 RL08B006-K COIL 1 G2A142C00002

L302 RLQZB101KT-D COIL 1 G0C101K00017

L701 G0C100JA0019 COIL 1

L702 J0JBC0000041 COIL 1

PCB1 REP2827E-M MAIN P.C.B. 1 [RTL]

PCB2 REPX0108A MECHA.SW.P.C.B. / (P.B.) 1 [RTL]

PCB3 REPX0108B MECHA.SW.P.C.B. / (R/P) 1 [RTL]

Q101,02 2SJ164RTA TRANSISTOR 2 2SJ01640RA

Q103,04 2SJ164QTA TRANSISTOR 2 2SJ01640QA

Q105,06 2SD1819ARTX TRANSISTOR 2 2SD1819ARL

Q107 DTA143EUT106 TRANSISTOR 1 B1GDCFGG0008

Q108 DTC143EUT106 TRANSISTOR 1 B1GBCFGG0006

Q201,02 DTA143EUT106 TRANSISTOR 2 B1GDCFGG0008

Q301 2SD1819ARTX TRANSISTOR 1 2SD1819ARL

Q302 2SD1328STW TRANSISTOR 1 2SD13280S2RA

Q303,04 2SD14500HA TRANSISTOR 2

Q305,06 DTC144EUT106 TRANSISTOR 2 B1GBCFNN0013

Q602 2SD2144S TRANSISTOR 1 B1AAGC000006

Q604 2SC3940AQSTA TRANSISTOR 1 2SC3940ARA

Q701-03 2SD1819ARTX TRANSISTOR 3 2SD1819ARL

Q706 DTC114EUT106 TRANSISTOR 1 B1GBCFJJ0009

Q803,04 2SD592AR TRANSISTOR 2 2SD0592AR

Q805,06 DTA143EUT106 TRANSISTOR 2 B1GDCFGG0008

Q807,08 2SB0621AHA TRANSISTOR 2

Q809,10 DTC143EUT106 TRANSISTOR 2 B1GBCFGG0006

Q901 DTA143EUT106 TRANSISTOR 1 B1GDCFGG0008

32

Page 33

Ref. No. Part No. Part Name & Description Pcs Remarks

Q902-04 DTC143EUT106 TRANSISTOR 3 B1GBCFGG0006

R101,02 ERJ6GEYJ562V 1/10W 5.6K 2

R103,04 ERJ6GEYJ104V 1/10W 100K 2

R105,06 ERJ6GEYJ334V 1/10W 330K 2

R107,08 ERJ6GEYJ103V 1/10W 10K 2

R109,10 ERJ6GEYJ102V 1/10W 1K 2

R111 ERJ6GEYJ820V 1/10W 82 1 D0GD820JA012

R112 ERJ8GEYJ820V 1/8W 82 1

R113 ERJ6GEYJ123V 1/10W 12K 1

R114 ERJ6GEYJ273V 1/10W 27K 1

R117 ERJ6GEYJ102V 1/10W 1K 1

R118,19 ERDS2FJ220 1/4W 22 2

R120 ERJ6GEYJ104V 1/10W 100K 1

R121,22 ERJ6GEYJ103V 1/10W 10K 2

R125 ERJ6GEYJ104V 1/10W 100K 1

R126 ERJ6GEYJ223V 1/10W 22K 1

R127 ERJ6GEYJ472V 1/10W 4.7K 1

R130 ERJ6GEYJ475V 1/10W 4.7M 1

R131 ERJ6GEYJ334V 1/10W 330K 1

R132 ERJ6GEYJ273V 1/10W 27K 1

R133 ERJ6GEYJ333V 1/10W 33K 1

R134 ERJ6GEYJ392V 1/10W 3.9K 1

R135 ERJ6GEYJ682V 1/10W 6.8K 1

R136,37 ERJ6GEYJ222V 1/10W 2.2K 2

R138 ERJ6GEYJ472V 1/10W 4.7K 1

R139,40 ERJ6GEYF473 1/10W 47K 2

R141 ERJ8GEYJ101V 1/8W 100 1

R142 ERJ6GEYJ101V 1/10W 100 1

R143 ERDS2FJ101 1/4W 100 1

R144 ERJ6GEYJ101V 1/10W 100 1

R147-50 ERJ6GEYJ562V 1/10W 5.6K 4

R151,52 ERJ6GEYJ104V 1/10W 100K 2

R153,54 ERJ6GEYJ272V 1/10W 2.7K 2

R157,58 ERJ6GEYJ223V 1/10W 22K 2

R207,08 ERJ6GEYF473 1/10W 47K 2

R209,10 ERJ6GEYJ102V 1/10W 1K 2

R211,12 ERJ6GEYJ103V 1/10W 10K 2

R213,14 ERJ6GEYJ302V 1/10W 3K 2

R215,16 ERJ6GEYJ123V 1/10W 12K 2

R217,18 ERJ6GEYJ222V 1/10W 2.2K 2

R219 ERJ6GEYJ183V 1/10W 18K 1

R220 ERDS2FJ220 1/4W 22 1

R221,22 ERJ6GEYJ101V 1/10W 100 2

R223,24 ERJ6GEYJ103V 1/10W 10K 2

R225,26 ERJ6GEYF473 1/10W 47K 2

R230,31 ERJ6GEYJ102V 1/10W 1K 2

R232 ERJ6GEYJ103V 1/10W 10K 1

R233,34 ERJ6GEYJ101V 1/10W 100 2

R237 ERDS2FJ220 1/4W 22 1

R301 ERJ6GEYJ103V 1/10W 10K 1

R302 ERJ6GEYJ182V 1/10W 1.8K 1

R303 ERJ6GEYJ222V 1/10W 2.2K 1

R304 ERJ6GEYJ153V 1/10W 15K 1

33

Page 34

Ref. No. Part No. Part Name & Description Pcs Remarks

R305 ERJ6GEYJ183V 1/10W 18K 1

R306 ERJ6GEYJ333V 1/10W 33K 1

R307 ERDS1FJ2R2 1/2W 2.2 1

R308 ERJ6GEYJ102V 1/10W 1K 1

R309-11 ERJ6GEYJ472V 1/10W 4.7K 3

R313 ERDS2TJ1R0 1/4W 1.0 1

R602 ERQ16NKWR33E 1/6W 0.33 1

R603 ERD2FCG100 1/4W 10 1

R604 ERJ6GEYJ331V 1/10W 330 1

R606 ERJ6GEYJ152V 1/10W 1.5K 1

R609 ERDS2FJ101 1/4W 100 1

R630 ERQ16NKWR33E 1/6W 0.33 1

R632 ERDS2FJ473 1/4W 47K 1

R701,02 ERJ6GEYJ103V 1/10W 10K 2

R703 ERJ6GEYJ562V 1/10W 5.6K 1

R704 ERJ6GEYJ472V 1/10W 4.7K 1

R705 ERJ6GEYF473 1/10W 47K 1

R708 ERJ6GEYJ472V 1/10W 4.7K 1

R710 ERJ6GEYJ102V 1/10W 1K 1

R711 ERJ6GEYJ104V 1/10W 100K 1

R712 ERJ8GEYJ683V 1/8W 68K 1

R718 ERJ8GEYJ683V 1/8W 68K 1

R721 ERJ6GEYJ472V 1/10W 4.7K 1

R722 ERJ6GEYJ101V 1/10W 100 1

R723,24 ERJ6GEYJ102V 1/10W 1K 2

R725,26 ERJ6GEYJ222V 1/10W 2.2K 2

R727 ERJ6GEYJ472V 1/10W 4.7K 1

R728 ERJ6GEYJ103V 1/10W 10K 1

R729 ERJ6GEYJ472V 1/10W 4.7K 1

R730 ERJ6GEYJ222V 1/10W 2.2K 1

R732 ERJ6GEYJ104V 1/10W 100K 1

R735 ERJ6GEYJ472V 1/10W 4.7K 1

R736 ERJ6GEYJ103V 1/10W 10K 1

R737 ERJ8GEYJ103V 1/8W 10K 1

R738 ERJ6GEYJ102V 1/10W 1K 1

R741 ERJ6GEYJ223V 1/10W 22K 1

R743 ERJ6GEYF473 1/10W 47K 1

R744 ERJ6GEYJ102V 1/10W 1K 1

R745 ERJ6GEYJ101V 1/10W 100 1

R747 ERJ8GEYJ102V 1/8W 1K 1

R802 ERJ6GEYJ561V 1/10W 560 1

R803 ERJ6GEYJ103V 1/10W 10K 1

R805 ERJ6GEYJ392V 1/10W 3.9K 1

R806 ERJ6GEYJ103V 1/10W 10K 1

R808 ERJ6GEYJ392V 1/10W 3.9K 1

R810,11 ERJ6GEYJ103V 1/10W 10K 2

R812 ERJ6GEYJ561V 1/10W 560 1

R813,14 ERJ6GEYJ471V 1/10W 470 2

R818 ERDS2FJ2R2 1/4W 2.2 1

R820 ERDS2FJ2R2 1/4W 2.2 1

R823,24 ERJ6GEYJ561V 1/10W 560 2

R900 ERJ6GEYJ821V 1/10W 820 1

R901 ERJ6GEYJ102V 1/10W 1K 1

R902 ERJ6GEYJ122V 1/10W 1.2K 1 D0GD122JA003

34

Page 35

Ref. No. Part No. Part Name & Description Pcs Remarks

R903 ERJ6GEYJ152V 1/10W 1.5K 1

R904 ERJ6GEYJ182V 1/10W 1.8K 1

R905 ERJ6GEYJ222V 1/10W 2.2K 1

R906 ERJ6GEYJ332V 1/10W 3.3K 1 D0GD332JA003

R908 ERJ6GEYJ122V 1/10W 1.2K 1 D0GD122JA003

R909 ERJ6GEYJ152V 1/10W 1.5K 1

R910 ERJ6GEYJ182V 1/10W 1.8K 1

R911 ERJ6GEYJ222V 1/10W 2.2K 1

R914 ERJ6GEYJ331V 1/10W 330 1

R915 ERJ6GEYJ681V 1/10W 680 1

R916 ERJ6GEYJ331V 1/10W 330 1

R917 ERJ6GEYJ681V 1/10W 680 1

R924 ERJ6GEYJ821V 1/10W 820 1

R925 ERJ6GEYJ102V 1/10W 1K 1

R952 ERDS2FJ821 1/4W 820 1

R953 ERDS2FJ393 1/4W 39K 1

R972 ERDS2FJ821 1/4W 820 1

R973 ERDS2FJ393 1/4W 39K 1

RJ504 ERJ6GEY0R00V CHIP JUMPER 1

RJ507-09 ERJ8GEY0R00V CHIP JUMPER 3 D0YFR0000002

S900,01 EVQ11G05R SW,PUSH 2

S903-07 EVQ11G05R SW,PUSH 5

S909-15 EVQ11G05R SW,PUSH 7

S951 RSH1A018-3U SW,MECHA DET 1

S952,53 RSH1A019-2U SW,MECHA DET 2

S971 RSH1A018-3U SW,MECHA DET 1

S972-76 RSH1A019-2U SW,MECHA DET 5

VR101-04 EVNDCAA03B24 V.R.,PLAYBACK GAIN / ADJ. 4

VR801 EVNDCAA03B53 V.R.,TAPE SPEED / ADJ. 1

VR803 EVNDCAA03B53 V.R.,TAPE SPEED / ADJ. 1

X701 RSXY8M00D01T OSCILLATOR 1 H2B800400005

Z971 EXBF7L355SYV COMPONENT / COMBINATION 1

16. Cabinet Parts Location

35

Page 36

17. Mechanism Parts Location

36

Page 37

37

Page 38

18. Schematic Diagram for printing with letter size

F0302KH

38

Page 39

OPERATION CIRCUIT

E

S912

(

)

DECK 1/2

S911

(

)

REV MODE

S910

)

(

S909

(

)

S915

(

)

OPEN

S914

(

COUNTER

)

RESET

S913

(

COUNTER

)

DISPLAY

FW901

1

2

3

4

5

6

7

8

R911

R910

R909

R908

R925

R924

2.2K

1.8K

1.5K

1.2K

1K

820

(

5V

S907

(

)

S906

(

S905

(

DOLBY NR

S904

REC PAUSE

S903

(

TAPEEDIT

S901

(

OPEN

S900

(

)

:POSITIVE VOLTAGELINE

Q901

DTA143EUT106

LED DRIVE

R915

680

R917

680

STOP :0V

MA111TX

5V

5V

0V

D904

)

)

3.3K

R906

)

2.2K

R905

)

1.8K

R904

)

1.5K

R903

1.2K

R902

1K

R901

820

R900

R916

5V

R914

0V

Q902

DTC143EUT106

LED DRIVE

0V

330

330

:PLAYBACKSIGNAL LINE

D907

SML79455C

(

)

D905

SML79455C

(

)

2.6V

Q903

DTC143EUT106

LED DRIVE(FWD)

0V

0V

Q904

DTC143EUT106

LED DRIVE(REV)

0V

4.2V

0V

H

G

F

E

MAIN CIRCUIT

A

D

A

47K

47K

47K

C215

R233

16V10

B

C

D

E

F

G

100

R234

100

IC202

MC14066BFEL

SIGNAL CONT.

Q108

DTC143EUT106

SWITCHING

(5V) 0V

C216

16V10

8.3V(0V)

R226

R208

4.7V 8.3V

8 9 10 11 12 13

7 6 5 4 3 2 1

8.3V

(0V)

22K

R126

R225

R207

47K

9.6V

(0V)

C

9.6V4.7V 4.7V 4.7V

14

B

A

RS-DV290(EG) OPERATION, MAIN CIRCUIT DIAGRAM

25 26 27 28 29 30 31 32 33 34 35 36

Page 40

H

G

F

E

D

C

B

A

PLAYBACK

HEAD

DECK1

Lch

Rch

R107

10K

R131

330K

DECK2

Lch

R/P HEAD

Rch

ERASE

HEAD

IC103

BA7755AF

R/P SELECT

1 2 4

9.6V 0V

C301

16V470

R313

1

ERASE CURRENT

CHECK POINT

S

SGD

C302

100V2.2

C303

6800P

TP302TP301

G

Q103

Q104

N

(8.9V)

0V

0V

(8.9V)

A

MAIN CIRCUIT

CP101

1

2

3

4

5

D

0V0V

680P

C103

0V0V

Q105,106

2SD1819ARTX

MUTING

10K

R108

CP102

1

2

3

4

5

R132

27K

6V

678

5

3

0V

(9.5V)

1.8K

R302

Q101

2SJ164RTA

HEAD SELECT

(REC:ON)

C102

C101

Q105

(0.7V)

0V

R143

100

Q103,104

2SJ164QTA

HEAD SELECT

(PLAY:ON)

0V

(0.7V)

(0.7V)

0V

R301

10K

MA111TX

Q306

DTC144EUT106

BIAS OSC CONT.

SGD

(0.2V)

9V

680P

330K

R105

680P

0V

0V

Q106

C144

R106

470P

330K

(0.2V)

9V

G

D

S

0V0V

Q102

2SJ164RTA

HEAD SELECT

(REC:ON)

C116

470P

L301

4

6

Q302

0V

2SD1328STXRA

SWITCHING

(REC:ON)

D301

C305

50V0.1

R303

2.2K

0V0V

R144

100

R102

R104

(0.6V)

C143

470P

5.6K

100K

R305

0V

18K

3

25

1

C125

3300P

R101

5.6K

C115

470P

IC101

CXA1998BQT6

R/P EQ AMP

R111

82

C111

6.3V47

R141

100

R142

100

680P

C104

C110

0.018

C112

6.3V47

82

R112

1K

R110

C124

25V4.7

C114

C113

50V2.2

50V2.2

C126

3300P

L302

100 H

C304

16V100

0V

C123

25V4.7

C150

100K

R103

10V100

470P

C131

C130

16V100

R113

12K

1.2V

R109

1K

2.6V

38

C109

0.018

2.6V

39

1.3V

40

0V

41

0V

42

0V

43

0V

44

1.3V

45

2.6V

46

2.6V

47

1.2V

48

27K

R114

R133 33K

R130 4.7M

C139 6.3V47

A

B

9.6V

Q303

(0.1V)

R307

(0.1V)

2.2

C306

0.039

Q303,304

2SD1450RSTA

BIAS OSC

Q305

DTC144EUT106

BIAS OSC CONT.

:POSITIVE VOLTAGELINE : PLAYBACK SIGNAL LINE: RECORDING SIGNAL LINE

9.6V

22

R119

22

R118

C129

R117

10V22

1K

C140

RFS

IREF

210K 210K

210K

210K

1 2 3 4 5 6 7 8 9 10 11 12

5V 0V 4.5V 4.5V 4.5V 4.5V 4.5V 8.6V 5V0V

(1.6V)

C307

1000P

(0.6V)

9.5V

0V

0V

1K

R308

(0.6V)

0V

0V

9.5V

Q304

R304

(0.6V)

C323

1000P

15K

R306

0V

C119

50V1

C117

330P

16V10

4.5V9V9V 4.5V 4.5V 4.5V 4.5V 0V5V 0V

10K

AGC

GAIN

RECEQ

40K

SHIFT

REGISTERS

PBEQ

CTL

AGC

REQEQ

CTL

MUTE

0.01

C311

(0.7V)

0V

33K

Q301

2SD1819ARTX

BIAS OSC CONT.

0V

0V

(0.2V)

C118

330P

R154

2.7K

C308

C310

10K

3300P

0.01

(0.8V)

0V

AGC

GAIN

R310

4.7K

R311

4.7K

C120

R309

C309

40K

50V1

4.7K

6.3V47

20K 20K

R127

C138

R158 22K

R134

3.9K

4.7K

R138

AMSRECEQ

4.7K

0.047

R135

6.8K

R137

R136

R153

2.2K

2.2K

2.7K

C137

50V0.1

R157

22K

252627282930313233343536

LATCHES

20K 20K

100K

R125

D102

MA111TX

D101

MA111TX

C132

A

B

C

470P

2437

23

22

21

20

19

18

17

16

15

14

13

5V

5V

(9.6V)

0.1V

(0.1V)

9.6V

(0.2V)

9.6V

(0.2V)

5V

(5V)

0.2V

R120

C135 50V1

100K

C136 50V1

E

D

F

CNRMO

R725

2.2K

470P

C134

470P

C133

10K

R122

Q107

DTA143EUT106

R/P SELECT

(0.2V)

9.6V

Page 41

C132

470P

2437

23

22

21

20

19

18

17

16

15

14

13

5V

5V

(9.6V)

0.1V

(0.1V)

9.6V

(0.2V)

9.6V

(0.2V)

5V

(5V)

0.2V

R120

100K

E

D

F

CNRMO

R725

2.2K

R726

2.2K

470P

C134

0.1

470P

C133

C142

10K

10K

R122

R121

Q107

DTA143EUT106

R/P SELECT

(0.2V)

9.6V

R730

A

B

9.6V

0V

(9.5V)

2.2K

9.6V

5V

12K

R2133KR215

C221

50V0.68

C207

270P

R209

C203

1K

25V4.7

R23722R220

22

0.01

C241

5V

C204

25V4.7

R210

1K

L201

C219

16V100

IC201

CXA1552M-T4

DOLBY B NR

C208

270P

L202

R211

10K

C211

1500P

R212

10K

R218

2.2K

R217

C220

2.2K

1 2 3 4 5 8

10V470

680P

C239

4.8V 9.6V 4.7V 4.7V 4.6V 4.7V 0.4V 4.8V

ATT2

ATT2

4.8V 4.7V 1.2V 4.7V 0.4V 4.8V4.6V

C205

50V1

ON/OFF

ATT1

ATT3

ATT3

ATT1

R/P

DOLBY

ON : 0V

(0V)

R221

100

6 7

SC DET

SC DET

101116

C225

25V4.7

C218

50V0.1

C213

25V4.7

912131415

DOLBY

Lch

R2301KR223

10K

C223

BA

C

25V4.7

680P

20K(B)

5.6K

C240

1 2 3 4 5 6 7

9.6V 9.6V

50V1

C141

C212

1500P

C135 50V1

C136 50V1

C214

R216

25V4.7

12K

3K

R214

C222

50V0.68

B

PLAYBACK

GAIN ADJ.

(DECK1/Lch)

A

A

B

PLAYBACK

C

GAIN ADJ.

(DECK1/Rch)

VR101

20K(B)

5.6K

R147

DOLBY

Rch

VR104

20K(B)

5.6K

R150

PLAYBACK

GAIN ADJ.

(DECK2/Lch)

IC102

MC14066BFEL

DECK 1/2 SELECT

VR103

20K(B)

5.6K

R149

VR102

R148

PLAYBACK

GAIN ADJ.

(DECK2/Rch)

C206

(0.1V)

R219

10K

R224

B

A

0V0V0V 0V

(0.1V)

18K

50V1

100

R222

1K

R231

(0V)

5V

Q202

DTA143EUT106

R/P SELECT

47K

R140

(9.6V)

0.1V

(5V)

0V

(9.6V)

0.1V

0V0V0V 0V9.6V

C217

50V0.1

C226

25V4.7

891011121314

R139

47K

R152

100K

5V

5V5V

Q201

DTA143EUT106

DOLBY ON/OFF

0V

I

J

100K

R151

RS-DV290(EG) MAIN CIRCUIT DIAGRAM

121110987654321

Page 42

MAIN CIRCUIT

A

Q807

2SB621ARSTA

SOLENOID DRIVE

10.3V

10.3V

0V

10K

R806

R802

560

5V

Q809

DTC143EUT106

SOLENOID DRIVE

R823

560

10.2V

0V

:POSITIVE VOLTAGELINE

DL

Q810

DTC143EUT106

SOLENOID DRIVE

0V

0V

10.2V

0V

R824

560

10.3V

R812

560

Q808

2SB621ARSTA

SOLENOID DRIVE

10K

R811

10.3V

: PLAYBACK SIGNAL LINE: RECORDING SIGNAL LINE

10.3V

0V

MECHANISM CIRCUIT (DECK1)

B

50K

4.7K

S972

S974

(R.REC.INH.)

D951

MA165TA

SOLENOID

D971

MA165TA

SOLENOID

50K

(HALF)

5V

50K

R973

R952

820

R953

39K

IC951

0N2180RLC1

PHOTO

INTERRUPTER

3 4

1 2

MECHANISM CIRCUIT (DECK2)

C

R972

820

Z971

1 2 3 4 5 6 7

25K

50K

50K

4.7K

4.7K

S971

S975

(MODE)

(F.REC.INH.)

IC971

0N2180RLC1

PHOTO

INTERRUPTER

12

34

25K 25K

4.7K

39K

S951

(MODE)

S976

Q803

2SD592ARSTA

MOTOR DRIVE

9.8V

0V

CS951

1

2

3

4

5

6

7

8

9

S953

S952

(CrO2)

(HALF)

CAPSTAN

MOTOR

(DECK1)

M

5V

1

2

3

4

5

A

6

B

7

C

8

D

9

S973

(CrO2)

(METAL)

D

B

C

CAPSTAN

MOTOR

(DECK2)

M

A

CP901

1

2

3

4

5

6

7

8

9

CP306

1

2

A

3

B

4

CP902CS971

1

2

3

4

5

6

7

8

9

CP305

1

2

A

3

B

4

2.2

R818

R805

R803

3.9K

10K

TAPESPEED

ADJ.(DECK1)

AGHB

R820

R810

R808

10K

3.9K

5V

2.2

0V

VR801

5K(B)

K

VR803

Q805

DTA143EUT106

MOTOR DRIVE

R814

470

5V

10.3V

5V

5K(B)

TAPESPEED

ADJ.(DECK2)

5V0V

E

P

S

F

Q

A

B

C

Q806

DTA143EUT106

MOTOR DRIVE

0V

Q804

2SD592ARSTA

MOTOR DRIVE

10.3V

5V

5V

470

R813

0.8V

0V 0V

L701

10 H

C706

50V3.3

Q706

DTC114EUT106

RESET

13 14 15 16 17 18 19 20 21 22 23 24

Page 43

5V

0.01

C707

D706

MA111TX

L701

10 H

C702

6.3V100

0.01

C701

C706

50V3.3

0V

D705

MA111TX

Q706

DTC114EUT106

RESET

R711

100K

5ms. 2V/DIV.

16ms.

T

T 16ms.

R737 10K

R736 10K

5V

0.01

C705

0V

T 16ms.

R712 68K

R718 68K

R701 10K

R702 10K

4.8V

0V

4.8V

0V

3.6V

AC E

BD

0V

D701

MA111TX

5V5V0V5V1.4V

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

SS

AV

VREF

KEY1 VCC

KEY2

3V

0V

PHOTO1 T

5V0V5V

2.9V

0V(5V)

LMT

AD SW

0V

M1

PL1

T 16ms.

LED CNT

PHOTO2 T

5V

2.7V

JEDG

R738

1K

D710

MA111TX

100

R745

D707

R710 1K

L702

2.2V

2.5V

0V

0.5V

1.6V

1V

CS

CLK

REQ

HALT

NC

STOP : 0V

DATA IN

4.8V

0V

NC

METAL2

DATA OUT

M2

ENC/DEC

DOLBY ON/OFF

ECS

NC

313233343536373839404142 222324252627282930

0V

0V

(5V) 0V

MA4051MTA

0V

CRO2 2

PL2

0V

R723 1K

0V

5V5V2V

SS

V

FWD LED

A LATCH

A CLK

5V

0V

Q701,703

2SD1819ARTX

R747

INTERFACE

1K

1K

R727

2.3V

XOUT

MODE

5V

4.7K

0V

VSS

CRO2 1

5V

R744

1.9V

0.1V

0V

Q701

1.2V

P-P

R722

100

X701

(8MHz)

F=8MHz

IC701

M38503M2406F

SYSTEM CONTROL

R703

5.6K

R708

4.7K

13

R704

4.7K

R724 1K

F=8MHz

0V

XIN

RESET

REV LED

HALF1

TPS

A DATA

5V

5V

0V

0V

4.7K

R729

Q703

2

2.4V

P-P

R735 4.7K

R721 4.7K

R732 100K

22K

R741

D708

MA111TX

0.2V

Q702

2SD1819ARTX

INTERFACE

F

H

I

1.8V

47K

R743

0V

R705

47K

D709

MA111TX

0.6V

0V

R728

10K

CN901

1

A

B

C

D

E

2

3

4

5

6

7

8

R232

10K

F

G

5V

10.3V

Q602

2SD2144STA

POWER SUPPLY

10.3V9.6V

10.3V

C602

16V220

CBAFIOJKLMNGH

R630

0.33

R602

0.33

330

R604

R609

C605

100

16V220

D651

MA165TA

D652

MA165TA

9.6V

Q604

2SC3940AQSTA

REGULATOR

5.7V

C603

16V47

+

10V

EDABC

A

B

C

D

E

F

PQR

S

R603

C604

D606

0.01

MA4056MTA

R606

1.5K

(D.GND)

TP609

Rch

OUT

CT.GND

10

A.GND

W601 E1

CN601

1

SYNC

2

NC

3

NC

4

CS

5

+B(10V

6

D.GND

7

SCLK

8

DATA

9

DECK REQ

10

NC

11

TAPERch OUT

12

TAPELch OUT

13

RS A.GND

14

TAPERch IN

15

TAPELch IN

16

NC

17

A.GND

18

NC

19

NC

20

NC

R632

47K

Lch

OUT

TP604

RchINLch

F

G

H

I

J

IN

EARTH

TERMINAL

D

CIRCUIT

)

ToDVD CHANGER(SL-DV290)

CD CHANGER (SL-EH790)

CD PLAYER(SL-EH590) &

SOUND PROCESSOR

(SH-DV290,SH-EH790,590)

9.4V5V

RS-DV290(EG) MAIN,MECHANISM(DECK1,2), EARTH TERMINAL CIRCUIT DIAGRAM

Page 44

OPERATION CIRCUIT

E

S912

(

)

DECK 1/2

S911

(

)

REV MODE

S910

(

)

S909

)

(

S915

(

)

OPEN

S914

(

COUNTER

)

RESET

S913

(

COUNTER

)

DISPLAY

FW901

1

2

3

4

5

6

7

8

R911

R910

R909

R908

R925

R924

2.2K

1.8K

1.5K

1.2K

1K

820

(

5V

S907

)

(

S906

(

)

S905

(

DOLBY NR

S904

REC PAUSE

S903

(

TAPEEDIT

S901

(

OPEN

S900

(

)

:POSITIVE VOLTAGELINE

Q901

DTA143EUT106

LED DRIVE

R915

680

R917

680

STOP : 0V

MA111TX

5V

5V

0V

D904

3.3K

R906

)

2.2K

R905

)

1.8K

R904

)

1.5K

R903

1.2K

R902

R901

R900

1K

820

)

R916

5V

R914

0V

Q902

DTC143EUT106

LED DRIVE

0V

330

330

:PLAYBACKSIGNAL LINE

D907

SML79455C

(

)

D905

SML79455C

(

)

2.6V

Q903

DTC143EUT106

LED DRIVE(FWD)

0V

0V

Q904

DTC143EUT106

LED DRIVE(REV)

0V

4.2V

0V

MAIN CIRCUIT

A

A

47K

47K

47K

C215

R233

16V10

B

C

D

E

F

G

100

R234

100

IC202

MC14066BFEL

SIGNAL CONT.

Q108

DTC143EUT106

SWITCHING

(5V) 0V

C216

16V10

8.3V(0V)

R226

R208

4.7V 8.3V

8 9 10 11 12 13

7 6 5 4 3 2 1

8.3V

(0V)

22K

R126

R225

R207

47K

9.6V

(0V)

9.6V4.7V 4.7V 4.7V

14

RS-DV290(EG) OPERATION, MAIN CIRCUIT DIAGRAM

25 26 27 28 29 30 31 32 33 34 35 36

Page 45

H

G

F

E

D

C

B

A

Page 46

No.1

CXA1552M-T4

MC14066BFEL

M38503M2406F

16PIN

14PIN

42PIN

BA7755AF CXA1998BQT6 0N2180RLC1 2SD1450RSTA

8

5

36

1

4

37

24

25

13

12

1

48

4

1

3

2

3

2

1

4

E

C

B

2SB621ARSTA

2SD592ARSTA

B

E

C

B

MA165TA MA4051MTA

MA4056MTA

A

Anode

A

Anode

Ca

Cathode

2SD1819ARTX

2SD1328STXRA

DTA143EUT106

C

DTC114EUT106

2SC3940AQSTA 2SD2144STA 2SJ164QTA

2SJ164RTA

DTC143EUT106

E

DTC144EUT106

B

E

C

B

C

E

D

G

S

SML79455C MA111TX

Cathode

Ca

Cathode

Anode

Cathode

Ca

Anode

A

Anode

A

A

Ca

Page 47

[DECK 2]

R/P HEAD,

ERASE HEAD

1 . . . 5

2

1 . 5

CP102

4

CP305

1

.

.

4

1 . . . . . . . 9

MAIN P.C.B.

A

CAPSTAN

MOTOR

[DECK 2]

CP902

[DECK 1]

PLAYBACK

HEAD

1 . . . 5

4

2

1 . 5

CP101

CP306

CN901

1 . . . . . . 8

1

.

.

4

1 . . . . . . . 9

CP901

W601

CAPSTAN

MOTOR

[DECK 1]

EARTH TERMINAL P.C.B.

D

W601

BLACK

To DVD CHANGER, CD CHANGER,

CD PLAYER & SOUND PROCESSOR

1 . . . . . . . 9

CS971

MECHANISM P.C.B. (DECK 2)

C

OPERATION P.C.B.

E

1 . . . . . . 8

FW901

1 . . . . . . . 9

CS951

MECHANISM P.C.B. (DECK 1)

B

Page 48

Page 49

NOTES :PLAYBACK SIGNAL LINE

DECK1

PLAYBACKHEAD

DECK2

R/P HEAD

BA7755AF

IC103

R/P SELECT

3

21

+B1

DECK2

ERASE HEAD

TP301 TP302

: RECORDING SIGNAL LINE

( ) indicates pin No. Right channel.

VR102(VR103)

PLAYBACK GAIN ADJ.

(DECK2)

VR104(VR101)

PLAYBACK GAIN ADJ.

(DECK1)

CXA1998BQT6

IC101

R/P EQ AMP

5

4

REC

EQ

R101,

C115

(R102,

C116)

MC14066BFEL

IC102

DECK 1/2 SELECT

1

(11)

4

(8)

7

+B1

Q103

Q105

(Q104)

(Q106)

Q101

(Q102)

+B1

Q302

L301

14

+B1

11

42

(43)

41

(44)

40

(45)

39

(46)

29

(8)

Q303,304

BIAS

OSC

D301

(12)

(10)

(6)

(9)

13

5

3

2

23

+B3

3

(14)

1

(16)

RFS

12

38

(47)

31

(6)

S953(CrO2,DECK1)

S973(CrO2,DECK2)

S976(METAL,DECK2)

Q807,809

SOLENOID

30

(7)

SOLENOID

AMS

REC

EQ AMP

35 36 34 448 1 2

+B1

Q107

R/P

SELECT

+B1

Q301,305,306

BIAS OSC

CONTROL

(CrO2/

METAL)

CXA1552M-T4

IC201

DOLBY B NR

ATT2

15

22 21 20 19

AGC

P.B. EQ

CONT.

REC EQ

CONT.

MUTE

3

D101

D102

DRIVE

D951

CAPSTAN

(DECK1)

+B1

2

ATT1

ATT3

ON/OFF

5124

+B3

15 161718

0N2180RLC1

IC951

PHOTO

INTERRUPTER

MOTOR

SC DET

R/P

DOLBY

L(R)ch

DOLBY

ON/OFF

Q201

SHIFT

REGISTER

LATCH

M

6

(11)

(10)

8

(9)

SELECT

S951(MODE)

S952(HALF)

Q803,805

CAPSTAN

MOTOR

DRIVE

VR801

(TAPESPEED ADJ.)

7

+B3

R/P

Q202

MC14066BFEL

IC202

SIGNAL CONT.

10

(8)

7

2

VREF

+B3

RESET

15,21

20

19

1

31

32

25

3

18

26

27

28

13

22

14

23

24

40

5

6

ENC/DEC

DOLBY

ON/OFF

TPS

Vss

AVss

RESET

A DATA

A CLK

A LATCH

X OUT

XIN

METAL2

CRO2 1

CRO2 2

MODE

HALF1

PHOTO1 T

PL1

M1

M38503M2406F

IC701

SYSTEM CONTROL

+B3 Vcc

32

Q706,

(5)

27

26

25

24

D705

X701

(8MHz)

14

+B1

DATAIN

DATAOUT

HALT

KEY2

KEY1

FWD LED

REV LED

LED CNT

AD SW

PHOTO2 T

LMT

CLK

REQ

PL2

CS

M2

12

(6)

11

(9)

Q108

SWITCH-

ING

4

10

INTERFACE

Q702,703

12

INTERFACE

11

8

7

9

KEY SWITCH

(S900,901,903~907,

41

42

16

17

37

39

38

29

30

Q701

D710

909~915)

2

1

+B3

7

Q804,806

CAPSTAN

MOTOR

DRIVE

VR803

(TAPESPEED ADJ.)

+B1

+B2

+B3

TP604

+B3

LED

DRIVE

LED

DRIVE

Z971

LADDER

RESISTOR

0N2180RLC1

INTERRUPTER

M

Q901,902

Q903,904

IC971

PHOTO

Q602

POWER

SUPPLY

Q604,D606

REGULATOR

D707

D905,907

()

S975(F.REC. INH.)

3

S971(MODE)

4

S974(R. REC. INH.)

5

S972(HALF)

6

CAPSTAN

MOTOR

(DECK2)

RCH

RCH

Q808,810

SOLENOID

D971 SOLENOID

Rch OUT

Lch OUT

Rch IN

Lch IN

A.GND

DRIVE

+10V

(D.GND)

TP609

CT.GND

ToDVD CHANGER,

CD CHANGER,

CD PLAYER

BLOCK DIAGRAM &

SOUND PROCESSOR

BLOCK DIAGRAM

CN601

SYNC1

2

NC

3

4

CS

+B(10V)

5

D.GND

6

7

SCLK

DATA

8

9

DECK REQ

10

NC

11

TAPERch OUT

12

TAPELch OUT

RS A.GND13

14

TAPERch IN

15

TAPELch IN

16

NC

17

A.GND

18

NC

NC

19

20NCNC

+B2

+B2

RS-DV290(EG) BLOCK DIAGRAM

Page 50

Note: This printed circuit board diagram may be modified at any time with the development of new technology.

EARTH TERMINAL P.C.B.

OPERATION P.C.B.

MAIN P.C.B.

L ch

R ch

R ch

OUT

L ch

IN

R ch

IN

L ch

OUT

A

Q302

L301

6

3

R301

5

2

C302

41

N

C303

J

C123

Q101

C143

C115

SGD

J

SGD

J

IC103

R313

2

4

CP102

C207

C241

2

4

CP101

J

J

R158

C602

C144

Q102

C

58

R132

EB

R302

4

1

R131

J

SGD

1

J

J

J

3

SGD

5

Q103

J

C150

J

R215

C221

C118

C301

C203

L201

R209

C208

C212

15

R218

R211

16

C219

J

J

R220

1

1

3

R217

5

R237

C211

R153

C119

J

602

Q

B

R154

R157

C

E

R233

C120

C605

R609

D651

D652

W601

20

To DVD CHANGER, CD CHANGER,

CD PLAYER & SOUND PROCESSOR

C306

R103

R101

C116

C

R107

B

C

R108

C213

R213

C222

L202

R212

IC201

C220

C215

R630

R602

R603

R309

R104

R105

R102

E

EB

C103

C214

J

R210

C240

58

C239

R207

14

RJ504

1

R604

R606

D606

C304

C111

R106

Q105

Q106

Q104

RJ507

R216

R214

J

J

J

Q202

Q201

R231

R219

R224

10

R223

R225

IC202

R234

B

C

C604

E

C129

R111

C109

R143

C104

9

J

R632

L302

ECB

Q304

C124

C140

J

R144

C101

C204

C206

R152

J

J

C223

C217

J

R222

R221

C225

R208

810

57

R126

Q

J

C603

J

CN601

R117

J

35

36

37

R141

Q806

C

C

R230

604

D301

R113

C130

30

40

R112

R142

C102

Q804

ECB

R813

EB

EB

Q108

C

B

Q809

C218

Q807

R307

J

45

C110

C112

J

J

J

E

L701

R232

C226

Q805

R226

C216

C307

J

C131

48

C

EB

J

J

J

R818

Q

Q303

ECB

C323

J

J

J

IC101

J

R114

42

J

C701

C702

Q701

J

C

B

C

EB

J

B

C

E

803

12345678910111213141516171819

C308

R310

R308

J

J

J

C

J

Q107

C142

2425

20

5

1

R133

C117

1234

R820

IC701

1510

J

D701

J

J

R704

C

EB

R727

R744

E

R806

R823

R814

1234

CP306

+

10V

CT.GND

(

D.GND

TP609

C310

C311

R311

R109

EB

15

13

12

10

J

CP305

R705

B

R708

Q703

R802

BCE

)

C113

R121

J

J

J

J

303540

15

J

D706

R741

D708

C

E

J

TP604

C305

J

R122

C138

J

J

D709

B

R303

R110

R118

R127

25

20

R711

C

R728

R743

J

C136

J

R736

E

R729

C309

C137

C141

C205

22

21

D707

R306

C

EB

Q301

C114

C135

R125

R139

14

IC102

157

R151

J

J

Q808

ECB

R812

R811

B

R721

R735

R703

J

J

1

2

X701

3

R722

Q702

R737

C707

R738

R723

R724

J

L702

R747

R710

J

J

J

J

C139

R824

C

C

Q706

C705

R701

J

J

J

J

J

J

Q306

R305

J

J

J

Q810

E

J

J

J

EB

J

J

J

R712

C

R140

810

R138

J

R702

J

J

J

JJ

D710

EB

C126

R119

R130

J

J

J

C706

R745

R304

C134

C125

R148

R149

R147

R732

J

R137

J

CN901

J

J

C

Q305

EB

C132

R120

C133

R726

VR102

R725

VR103

R150

VR104

R730

VR101

J

R135

R134

D101

D102

R136

J

R718

CP902

RJ508

RJ509

J

J

D705

J

J

VR803

R803

VR801

R805

1

2

3

4

5

6

7

8

CP901

J

(REP2827E-M)

1

2

3

4

5

6

7

8

9

R810

R808

1

2

3

4

5

6

7

8

9

H

G

TP302

TP301

F

E

DOLBY

D

DOLBY

C

A.GND

B

A

E

S901

( OPEN)

S904

( REC PAUSE)

S903

(TAPE EDIT)

S911

(REV MODE)

S907

( )

Q903

S900

( )

R900

R911

S909

( )

S912

(DECK1/2)

S913

(COUNTER

DISPLAY)

FW901

S914

(COUNTER

1

RESET)

2

3

4

5

6

7

8

S915

( OPEN)

(REP2827E-M)

R901

R902

R904

(DOLBY NR)

R905

R906

B

J

R909

D904

R916

Q901

B

B

R924

R903

S905

C

R915

C

C

R910

E

R917

R914

E

Q902

E

R908

D907

( )

D905

( )

B

J

R925

S906

( )

J

S910

( )

C

J

J

Q904

E

MECHANISM P.C.B. (DECK1)

B

SOLENOID

S953

D951

J

R953

(REPX0108A)

S952

1

4

IC951

2

3

J

Note for IC951 replacement

Two different types (old or new) parts are mounted on P.C.B.

as for IC951.

When servicing, care to replace the parts due to those shape.

Replacement procedures

Parts No.

Old

New

0N2180RLC

0N2180RLC1

Mount the parts on given position.

(Printed pattern on P.C.B.)

For IC951: Mount the parts so the cut

corner is located upper right.

(Component side) (Component side)

J

Old

0N2180RLC

4

1

23

1

4

Direction

3

2

123456789101112

D

E1

(REP2827E-M)

1

S951

23456789

CS951

R952

Remarks

Refer to

the figure

below.

IC951

Old Old

14

23

New New

14

23

New

0N2180RLC 1

4

1

3

2

23

1

4

W601

MECHANISM P.C.B. (DECK2)

C

S974

SOLENOID

S973

J

D971

R973

(REPX0108B)

Z971

7

6

5

4

3

2

1

4

32

S972 S976

1

IC971

J

Note for IC971 replacement

Two different types (old or new) parts are mounted on P.C.B.

as for IC971.

When servicing, care to replace the parts due to those shape.

Replacement procedures

Old

New

Parts No.

0N2180RLC

0N2180RLC1

Mount the parts on given position.

(Printed pattern on P.C.B.)

For IC971: Mount the parts so the cut

corner is located upper right.

Old

0N2180RLC

4

1

23

1

4

RS-DV290(EG) MAIN, OPERATION,EARTH TERMINAL, MECHANISM(DECK1,2) P.C.B.

Direction

3

2

123456789

S971

R972

IC971

14

23

New

0N2180RLC 1

4

1

2

23

1

4

3

CS971

J

S975

Remarks

Refer to

the figure

below.

14

23

13

Page 51

H

G

F

E

D

C

B

A

PLAYBACK

HEAD

DECK1

Lch

Rch

R107

10K

R131

330K

DECK2

Lch

R/P HEAD

Rch

ERASE

HEAD

IC103

BA7755AF

R/P SELECT

1 2 4

9.6V 0V

C301

16V470

R313

1

ERASE CURRENT

CHECK POINT

S

SGD

C302

100V2.2

C303

6800P

TP302TP301

G

Q103

Q104

N

(8.9V)

0V

0V0V

0V0V

0V

(8.9V)

678

3

A

MAIN CIRCUIT

CP101

1

2

3

4

5

(0.7V)

D

R132

27K

R143

680P

C103

Q105,106

2SD1819ARTX

MUTING

(0.7V)

10K

R108

CP102

1

2

3

4

5

6V

5

0V

(9.5V)

1.8K

R302

(0.7V)

R301

10K

Q101

2SJ164RTA

HEAD SELECT

(REC:ON)

680P

C102

680P

C101

Q105

0V

0V

100

Q103,104

2SJ164QTA

HEAD SELECT

(PLAY:ON)

0V

Q106

0V

R106

330K

(0.2V)

Q102

2SJ164RTA

HEAD SELECT

(REC:ON)

0V

0V

D301

MA111TX

Q306

DTC144EUT106

BIAS OSC CONT.

0V0V

SGD

(0.2V)

C143

9V

470P

330K

R105

R144

100

C144

470P

9V

G

D

S

0V0V

5.6K

C116

470P

R102

100K

R104

C125

L301

R303

2.2K

(0.6V)

R305

0V

3

25

1

18K

4

6

Q302

2SD1328STXRA

SWITCHING

(REC:ON)

C305

50V0.1

R101

3300P

5.6K

C115

470P

R111

C104

L302

C304

82

R141

100

R142

100

680P

C124

25V4.7

C113

100 H

16V100

100K

R103

C130

16V100

IC101

CXA1998BQT6

R/P EQ AMP

R113

12K

R109

C111

6.3V47

1K

C109

0.018

C110

0.018

C112

6.3V47

82

R112

1K

R114

R110

C114

50V2.2

50V2.2

C126

3300P

C306

0.039

Q303,304

2SD1450RSTA

BIAS OSC

0V

Q305

DTC144EUT106

BIAS OSC CONT.

C123

25V4.7

C150

10V100

470P

C131

1.2V

2.6V

38

2.6V

39

1.3V

40

0V

41

0V

42

0V

43

0V

44

1.3V

45

2.6V

46

2.6V

47

1.2V

48

27K

R133 33K

R130 4.7M

C139 6.3V47

A

B

9.6V

Q303

(0.1V)

(0.1V)

2.2

R307

:POSITIVE VOLTAGELINE : PLAYBACK SIGNAL LINE: RECORDING SIGNAL LINE

9.6V

22

R119

22

R118

C129

R117

10V22

1K

C140

RFS

IREF

210K 210K

210K

210K

1 2 3 4 5 6 7 8 9 10 11 12

5V 0V 4.5V 4.5V 4.5V 4.5V 4.5V 8.6V 5V0V

(1.6V)

C307

1000P

(0.6V)

9.5V

0V

0V

1K

R308

(0.6V)

0V

0V

9.5V

Q304

R304

(0.6V)

C323

1000P

15K

R306

0V

C119

50V1

C117

330P

16V10

4.5V9V9V 4.5V 4.5V 4.5V 4.5V 0V5V 0V

10K

AGC

GAIN

RECEQ

40K

SHIFT

REGISTERS

PBEQ

CTL

AGC

REQEQ

CTL

MUTE

0.01

C311

(0.7V)

0V

33K

Q301

2SD1819ARTX

BIAS OSC CONT.

0V

0V

(0.2V)

C118

330P

R154

2.7K

C308

C310

10K

3300P

0.01

(0.8V)

0V

AGC

GAIN

R310

4.7K

R311

4.7K

C120

R309

C309

40K

50V1

4.7K

6.3V47

20K 20K

R127

C138

R158 22K

R134

3.9K

4.7K

R138

AMSRECEQ

4.7K

0.047

R135

6.8K

R137

R136

R153

2.2K

2.2K

2.7K

C137

50V0.1

R157

22K

252627282930313233343536

LATCHES

20K 20K

100K

R125

D102

MA111TX

D101

MA111TX

C132

A

B

C

470P

2437

23

22

21

20

19

18

17

16

15

14

13

5V

5V

(9.6V)

0.1V

(0.1V)

9.6V

(0.2V)

9.6V

(0.2V)

5V

(5V)

0.2V

R120

C135 50V1

100K

C136 50V1

E

D

F

CNRMO

R725

2.2K

R726

2.2K

470P

C134

0.1

470P

C133

C142

10K

10K

R122

R121

Q107

DTA143EUT106

R/P SELECT

(0.2V)

9.6V

R730

A

B

9.6V

0V

(9.5V)

2.2K

5V

9.6V

PLAYBACK

GAIN ADJ.

(DECK1/Rch)

C203

25V4.7

0.01

C241

R214

C222

R209

1K

R23722R220

C204

25V4.7

R216

12K

3K

50V0.68

B

PLAYBACK

GAIN ADJ.

(DECK1/Lch)

A

22

R210

1K

C214

25V4.7

VR101

20K(B)

5.6K

R147

C207

270P

L201

R211

10K

C219

16V100

IC201

CXA1552M-T4

DOLBY B NR

C208

270P

L202

DOLBY

VR104

20K(B)

5.6K

R150

PLAYBACK

GAIN ADJ.

(DECK2/Lch)

VR103

R149

2.2K

R218

C211

1500P

R212

10K