Page 1

Service Manual

TOP NEXT

AD0102028C2

Cassette Deck

l RS-DV250

AR-2 Mechanism series

Colour

(S)..........Silver Type

Area

(E)..........Europe.

© 2001 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

@

TOP NEXT

http://servis-manual.com/

Page 2

5 Service Mode Function of Cassette

Mechanism

TOP PREVIOUS NEXT

This unit is equipped with a service mode function of cassette mechanism, so that if the unit operates

incorrectly, the fault displayed using an error code on the FL display of the Tuner/Amplifier (SAEH770). The system control IC and FLdisplay are part of the Tuner/Amplifier so make sure the

system has been connected properly before using this function. Use this function during maintenance

to check faults of items below.

5.1 Cassette tape to be prepared

5.2 Selecting service mode

5.3 Deck 1 mechanism check

5.4 Deck 2 mechanism check

5.5 Exiting service mode

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 3

5.1 Cassette tape to be prepared

TOP PREVIOUS NEXT

l

Metal tape:

Recorded music tape with only one erasure prevention tab intact./(use middle portion of tape)

l Normal tape: /CrO2 tape:

Recorded music tape with both erasure prevention tabs intact./(use middle portion of tape)

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 4

5.2 Selecting service mode

TOP PREVIOUS NEXT

1.Turn on the power to the unit.

2.Make sure that no tape is inserted in the cassette deck. (Service mode cannot be selected with a

tape inserted in the cassette deck.)

3.Press the DOLBY NR button for about 2 seconds, and keep pressing it, also press the STOP

button for about 2 seconds. Refer to Fig. 5-1.

Fig. 5-1.

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 5

5.3 Deck 1 mechanism check

TOP PREVIOUS NEXT

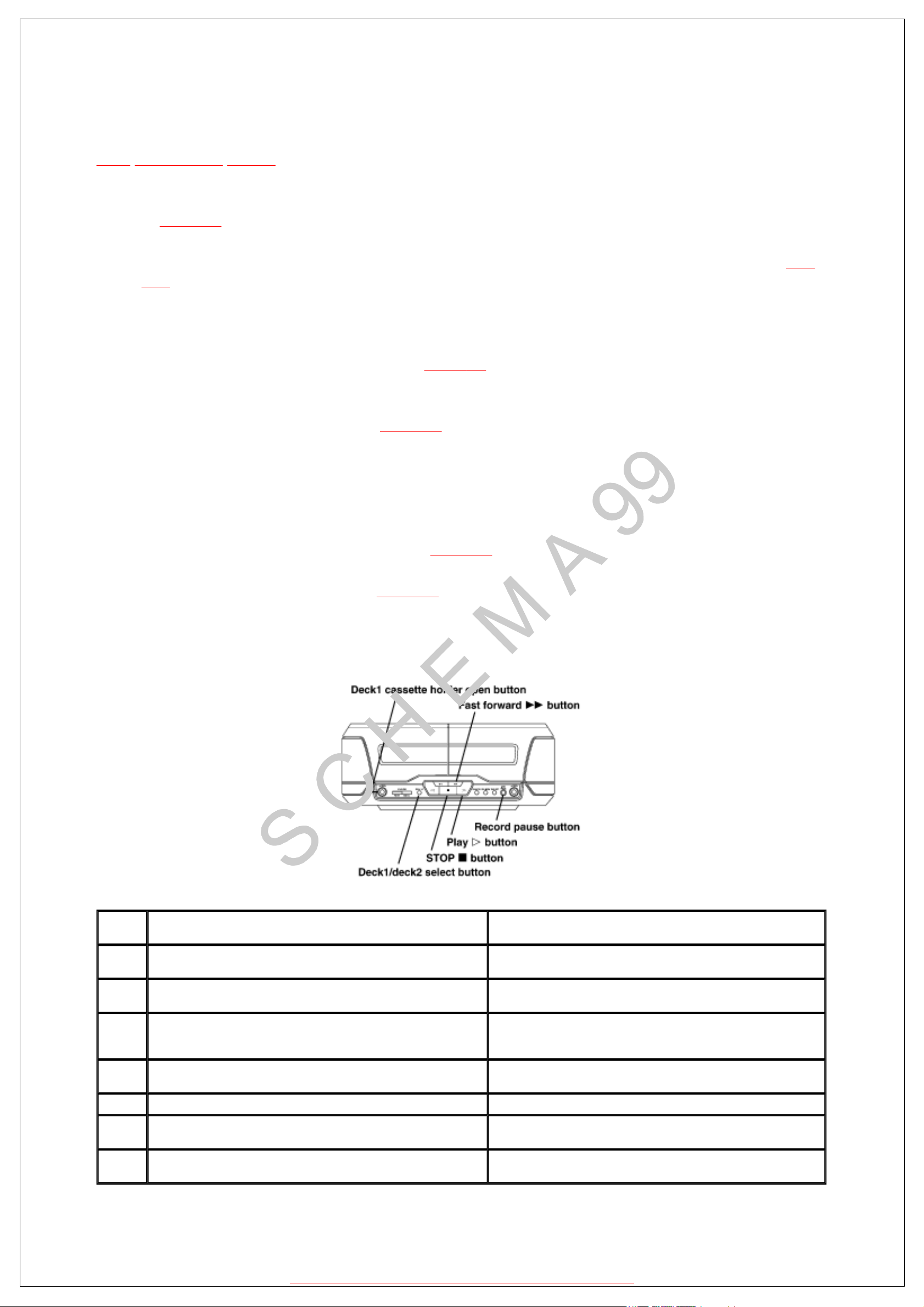

1.Press the Deck 1/deck 2 select button to change the flashing Deck 2 indicator to Deck 1. Refer

to Fig. 5-2. /(No change required if Deck 1 indicator already flashing.)

2.Press the Deck 1 cassette holder open button to open the Deck 1 cassette holder. Refer to Fig.

5-2.

3.Insert a CrO2 tape into the Deck 1 and close the cassette holder.

4.Press the Fast forward button. Refer to Fig. 5-2. /(Tape fast forwards for about 2 seconds then

stops.)

5.Press the PLAY button. Refer to Fig. 5-2. /(After TPS operation and check, the tape stops.)

6.Open the Deck 1 cassette holder and replace the tape with a normal tape.

7.Close the Deck 1 cassette holder.

8.Press the Record pause button. Refer to Fig. 5-2. /(No record operation.)

9.Press the STOP button. Refer to Fig. 5-2. A mechanism error code is displayed. Refer to Table

5-1. Each time the STOP button is pressed, the fault items are displayed in sequence.

Fig. 5-2.

Table 5-1.

FL

display

H01 Cassette deck does not operate correctly. Faulty cassette deck mechanism mode detect switch (Deck 1: S951,

H02 Unit does not record or the unit goes into recording mode even when the

erasure prevention tabs have been removed from the cassette.

H03 Tape does not play even when the tape deck play button is pressed.

The motor operates when the tape deck play button is pressed even if

cassette is loaded in the deck.

H06 Cassette deck does not detect CrO2 tape. Faulty CrO2 tape detect switch (Deck 1: S953, Deck 2: S973)./(Check

H07 Cassette deck does not detect Metal tape. Faulty Metal tape detect switch (S976). (Check and replace)

F01 When the tape play button is pressed, tape advances only slightly and

then stops.

F02 TPS (tape program search) does not work. Faulty TPS signal detection or faulty plunger control. /(Check and

Symptom Cause

Deck 2: S971), plunger and capstan motor. /(Check and replace)

Faulty erasure prevention tabs detect switch (S974, S975) or shortcircuit. (Check and replace)

Faulty tape detect switch (Deck 1: S952 Deck 2: S972) or short-circuit.

(Check and replace)

and replace)

Reel pulse error (Faulty Hall IC). (Check and replace)

replace mechanism control IC)

http://servis-manual.com/

Page 6

5.4 Deck 2 mechanism check

TOP PREVIOUS NEXT

1.Press the Deck 1/deck 2 select button to change the flashing Deck 1 indicator to Deck 2. Refer

to Fig. 5-3.

2.Press the Deck 2 cassette holder open button to open the Deck 2 cassette holder. Refer to Fig.

5-3.

3.Insert a metal tape into the Deck 2 with an intact erasure prevention tab on the right side.

4.Close the Deck 2 cassette holder.

5.Press the Fast forward button. Refer to Fig. 5-3. /(Tape fast forwards for about 2 seconds then

stops.)

6.Open the Deck 2 cassette holder and turn over the metal tape. (intact erasure prevention tab on

the left side.)

7.Close the Deck 2 cassette holder.

8.Press the Rewind button. Refer to Fig. 5-3. /(Tape rewinds for about 2 seconds then stops.)

9.Open the Deck 2 cassette holder and replace the metal tape with a CrO2 tape.

10.Close the Deck 2 cassette holder.

11.Press the PLAY button. Refer to Fig. 5-3. /(After TPS operation and check, the tape stops.)

12.Open the Deck 2 cassette holder and replace the CrO2 tape with a normal tape.

13.Close the Deck 2 cassette holder.

14.Press the Record pause button. Refer to Fig. 5-3. /(No record operation.)

15.Press the STOP button. Refer to Fig. 5-3. A mechanism error code is displayed. Refer to Table

5-1. Each time the STOP button is pressed, the fault items are displayed in sequence.

Fig. 5-3.

http://servis-manual.com/

Page 7

5.5 Exiting service mode

TOP PREVIOUS NEXT

1.Press the STOP button for more than 5 seconds (Diagnostic contents stored in memory for

both Deck 1 and 2 are erased.)

2.Remove the cassette tape from the cassette holder.

3.Turn off the unit.

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 8

13.3 Head azimuth adjustment (Deck 1/2)

TOP PREVIOUS NEXT

1.Connect the measuring instrument as shown in Fig. 13-1.

2.Replace azimuth screws for both forward and reverse directions after removing the screwlocking bond left on the head base. (Supply part No. of azimuth screw: RHD17015 )

3.Playback the azimuth adjustment portion (8 kHz, -20 dB) of test tape (QZZCFM). Adjust the

azimuth screw until the outputs of the L/R ch are maximized. Refer to Fig. 13-2. Make sure

that thedifference in the peak level between the left and right channels does not exceed 0.5 dB.

4.Perform the same adjustment in reverse playback mode.

Check of the level difference forward and reverse directions.

5.Playback the playback gain adjustment portion (315 Hz, 0 dB) of test tape (QZZCFM). Check

if level difference between forward and reverse direction is within 1.5 dB.

6.After the adjustment, apply screw lock to the azimuth screw.

Fig. 13-1.

Fig. 13-2.

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 9

13.4 Tape speed adjustment/(Deck 1/2)

TOP PREVIOUS NEXT

Note:

When connecting the unit to other system components for test, short the section between the test

point TP604 and TP609 and turn on the entire system. (The unit is set to the TEST mode, and either

Deck 1 or Deck 2 indicatorwill blink.)

Normal speed (Standard value: 3000 ± 45 Hz)

1.Connect the measuring instrument as shown in Fig. 13-3.

2.Playback the middle portion of test tape. (QZZCWAT)

3.Adjust VR801 (Deck 1) and VR803 (Deck 2) for output value shown below. (For adjustment

point, refer to Fig. 13-11. )

Adjustment target: 3000 ± 15 Hz (Normal speed)

Standard value: 3000 ± 45 Hz (Normal speed)

Fig. 13-3.

Note:

When the unit is finished for adjusting, disconnect the short section between TP604 and TP609 .

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 10

14.1.1 Connection Diagram Between the Mechanism Ass’y and Power

Supply/(MOTOR and Plunger)

TOP PREVIOUS NEXT

@

TOP PREVIOUS NEXT

Fig. 14-1.

http://servis-manual.com/

Page 11

14.1.2 Detail View of EJECT Lever /(EJECT

lever fixed by rubber band, Plunger rib

operation)

TOP PREVIOUS NEXT

Fig. 14-2.

@

TOP PREVIOUS NEXT

http://servis-manual.com/

Page 12

DECK1

Lch

PLAYBACK

HEAD

Rch

DECK2

Lch

R/P HEAD

Rch

ERASE

HEAD

IC103

BA7755AF

R/P SELECT

C301

ERASE CURRENT

CHECK POINT

R107

10K

(8.9V)

0V

G

S

0V0V

Q103

Q104

0V0V

SGD

R131

330K

1 2 4

16V470

R313

1

9.6V 0V

C302

100V2.2

C303

6800P

TP302TP301

0V

(8.9V)

678

3

N

MAIN CIRCUIT

A

CP101

1

2

3

4

5

(0.7V)

D

680P

C103

Q105,106

2SD1819ARTX

MUTING

(0.7V)

10K

R108

CP102

1

2

3

4

5

R132

27K

6V

5

0V

(9.5V)

1.8K

R302

(0.7V)

R301

Q101

2SJ164RTA

HEAD SELECT

(REC:ON)

680P

C102

680P

C101

Q105

0V

R143

100

Q103,104

2SJ164QTA

HEAD SELECT

(PLAY:ON)

0V

0V

0V

D301

10K

MA111TX

Q306

DTC144EUT106

BIAS OSC CONT.

0V0V

SGD

(0.2V)

9V

330K

R105

0V

0V

Q106

R106

330K

(0.2V)

Q102

2SJ164RTA

HEAD SELECT

(REC:ON)

R144

100

C144

470P

9V

G

D

S

0V0V

C116

470P

R102

R104

L301

4

6

Q302

2SD1328STXRA

SWITCHING

(REC:ON)

R303

2.2K

C305

50V0.1

(0.6V)

C143

470P

5.6K

100K

R305

0V

18K

3

25

1

C125

3300P

R101

5.6K

C115

470P

IC101

CXA1998BQT6

R/P EQ AMP

R111

82

C111

6.3V47

R141

100

R142

100

680P

C104

C110

0.018

C112

6.3V47

82

R112

1K

R110

C124

25V4.7

C114

C113

50V2.2

50V2.2

C126

3300P

L302

100 H

C306

C304

16V100

0V

:POSITIVE VOLTAGELINE : PLAYBACK SIGNAL LINE: RECORDING SIGNAL LINE

C123

25V4.7

C119

C308

C310

50V1

10K

10K

3300P

0.01

(0.8V)

0V

AGC

GAIN

AGC

AGC

GAIN

R310

4.7K

R311

4.7K

C120

R309

C309

9.6V

40K

40K

50V1

4.7K

6.3V47

RECEQ

R158 22K

4.7K

R138

C150

100K

R103

10V100

470P

C130

C131

16V100

R113

12K

1.2V

R109

1K

2.6V

38

C109

0.018

2.6V

39

1.3V

40

0V

41

0V

42

0V

43

0V

44

1.3V

45

2.6V

46

2.6V

47

1.2V

48

27K

R114

R133 33K

R130 4.7M

C139 6.3V47

A

B

9.6V

9.5V

Q303

(0.1V)

R307

(0.1V)

2.2

9.5V

0.039

Q303,304

2SD1450RSTA

BIAS OSC

Q305

DTC144EUT106

BIAS OSC CONT.

22

R119

C117

22

R118

C129

R117

10V22

1K

RFS

210K 210K

210K

210K

1 2 3 4 5 6 7 8 9 10 11 12

(1.6V)

C307

1000P

(0.6V)

0V

0V

(0.6V)

0V

0V

Q304

15K

R304

(0.6V)

0V

330P

C140

16V10

4.5V9V9V 4.5V 4.5V 4.5V 4.5V 0V5V 0V

IREF

MUTE

5V 0V 4.5V 4.5V 4.5V 4.5V 4.5V 8.6V 5V0V

R308

C323

1000P

1K

R306

33K

C311

(0.7V)

0V

0.01

0V

0V

(0.2V)

C118

330P

R154

2.7K

Q301

2SD1819ARTX

BIAS OSC CONT.

SHIFT

REGISTERS

PBEQ

CTL

REQEQ

CTL

20K 20K

AMSRECEQ

4.7K

R127

C138

0.047

R135

6.8K

R134

3.9K

2.2K

R137

2.2K

R136

R153

2.7K

C137

50V0.1

R157

22K

252627282930313233343536

LATCHES

20K 20K

100K

R125

D102

MA111TX

D101

MA111TX

C132

A

B

C

470P

2437

23

22

21

20

19

18

17

16

15

14

13

5V

5V

(9.6V)

0.1V

(0.1V)

9.6V

(0.2V)

9.6V

(0.2V)

5V

(5V)

0.2V

R120

C135 50V1

100K

C136 50V1

Page 13

E

D

F

CNRMO

R725

2.2K

R726

2.2K

470P

C134

0.1

470P

C133

C142

10K

10K

R122

R121

Q107

DTA143EUT106

R/P SELECT

(0.2V)

9.6V

R730

A

B

9.6V

0V

(9.5V)

2.2K

9.6V

:POSITIVE VOLTAGELINE : PLAYBACK SIGNAL LINE: RECORDING SIGNAL LINE

5V

12K

R2133KR215

C221

50V0.68

C207

270P

R209

C203

1K

25V4.7

R23722R220

22

0.01

C241

5V

C204

25V4.7

R210

1K

L201

C219

16V100

IC201

CXA1552M-T4

DOLBY B NR

C208

270P

L202

R211

10K

C211

1500P

R212

10K

R218

2.2K

R217

C220

2.2K

1 2 3 4 5 8

10V470

680P

C239

4.8V 9.6V 4.7V 4.7V 4.6V 4.7V 0.4V 4.8V

ATT2

ATT2

4.8V 4.7V 1.2V 4.7V 0.4V 4.8V4.6V

C205

50V1

ON/OFF

ATT1

ATT3

ATT3

ATT1

DOLBY

ON : 0V

R/P

(0V)

R221

100

6 7

SC DET

SC DET

25V4.7

C218

50V0.1

101116

C225

C213

25V4.7

912131415

DOLBY

Lch

R2301KR223

10K

C223

C

25V4.7

BA

R216

12K

3K

R214

C222

50V0.68

B

PLAYBACK

GAIN ADJ.

(DECK1/Lch)

A

PLAYBACK

GAIN ADJ.

(DECK1/Rch)

C214

25V4.7

VR101

20K(B)

5.6K

R147

DOLBY

Rch

VR104

20K(B)

5.6K

R150

PLAYBACK

GAIN ADJ.

(DECK2/Lch)

IC102

MC14066BFEL

DECK 1/2 SELECT

VR103

20K(B)

5.6K

R149

C212

1500P

VR102

20K(B)

5.6K

R148

PLAYBACK

GAIN ADJ.

(DECK2/Rch)

680P

C240

1 2 3 4 5 6 7

9.6V 9.6V

50V1

C141

C206

(0.1V)

R219

10K

R224

B

A

0V0V0V 0V

(0.1V)

R222

1K

R231

(0V)

5V

Q202

DTA143EUT106

ENC/DEC SELECT

47K

R140

(9.6V)

0.1V

18K

50V1

100

(5V)

0V

(9.6V)

0.1V

0V0V0V 0V9.6V

C217

50V0.1

C226

25V4.7

891011121314

R139

47K

R152

100K

5V

5V5V

Q201

DTA143EUT106

DOLBY ON/OFF

0V

I

J

100K

R151

Page 14

MAIN CIRCUIT

A

Q807

2SB621ARSTA

SOLENOID DRIVE

10.3V

10.3V

0V

MECHANISM CIRCUIT (DECK1)

B

R952

820

R953

39K

IC951

0N2180RLC1

PHOTO

INTERRUPTER

3 4

1 2

D951

MA165TA

SOLENOID

S951

(MODE)

R806

10K

S953

:POSITIVE VOLTAGELINE

5V

DL EK

Q809

DTC143EUT106

SOLENOID DRIVE

R802

R823

560

560

10.2V

0V

CS951

S952

(CrO2)

(HALF)

5V

0V

1

2

3

4

5

6

7

8

9

CAPSTAN

Q810

DTC143EUT106

SOLENOID DRIVE

0V

MOTOR

(DECK1)

M

Q808

2SB621ARSTA

R812

560

R803

10K

SOLENOID DRIVE

10K

R811

10.3V

Q805

DTA143EUT106

MOTOR DRIVE CONT.

R814

470

0V

P

S

F

Q

10.3V

VR801

5K(B)

5V

0V

5V

TAPESPEED

ADJ.(DECK1)

10.3V

0V

5V

CAB

10.3V

R824

560

10.2V

0V

Q803

2SD592ARSTA

MOTOR DRIVE

9.8V

0V

CP901

1

2

3

4

5

6

7

8

9

2.2

R818

CP306

1

2

A

3

R805

B

3.9K

4

MECHANISM CIRCUIT (DECK2)

C

50K

4.7K

4.7K

S972

S974

(R.REC.INH.)

D971

MA165TA

SOLENOID

50K

(HALF)

5V

50K

R973

R972

820

Z971

1 2 3 4 5 6 7

25K

50K

50K

4.7K

4.7K

S971

S975

(MODE)

(F.REC.INH.)

IC971

0N2180RLC1

PHOTO

INTERRUPTER

12

34

25K 25K

39K

S976

H

G

B

R820

3.9K

A

5V

Q806

DTA143EUT106

MOTOR DRIVE CONT.

Q804

2SD592ARSTA

VR803

5K(B)

MOTOR DRIVE

TAPESPEED

ADJ.(DECK2)

2.2

5V

5V

470

R813

0.8V

0V 0V

10.3V

0V

1

2

3

4

5

A

6

B

7

C

8

D

9

2)

S973

(CrO

(METAL)

D

B

C

CAPSTAN

MOTOR

(DECK2)

M

A

CP902CS971

1

2

3

4

5

6

7

8

9

CP305

1

2

A

3

R810

R808

B

10K

4

Page 15

:POSITIVE VOLTAGELINE : PLAYBACK SIGNAL LINE: RECORDING SIGNAL LINE

5V

0.01

C707

D706

MA111TX

L701

10 H

C702

C706

50V3.3

Q706

DTC114EUT106

RESET SIGNAL

GENERATOR

6.3V100

0.01

C701

0V

D705

MA111TX

R711

100K

5ms. 2V/DIV.

16ms.

T

T 16ms.

R737 10K

R736 10K

5V

0.01

C705

0V

T 16ms.

R712 68K

R718 68K

R701 10K

R702 10K

4.8V

0V

4.8V

0V

3.6V

AC E

BD

0V

D701

MA111TX

5V5V0V5V1.4V

1 2 3 4 5 6 7 8 9 10 11 1213 14 15 16 17 18 19 20 21

SS

AV

VREF

KEY1 VCC

KEY2

3V

0V

PHOTO1 T

4142 222324252627282930

5V0V5V

2.9V

0V(5V)

LMT

T 16ms.

AD SW

0V

2.7V

PL1

PHOTO2 T

JEDG

R738

1K

D710

MA111TX

100

R745

D707

R710 1K

L702

2.2V

2.5V

0.5V

1.6V

1V

M1

CS

CLK

REQ

HALT

NC

LED CNT

5V

STOP : 0V

DATA IN

METAL2

4.8V

DATA OUT

0V

M2

ENC/DEC

DOLBY ON/OFF

ECS

NC

NC

31323334353637383940

0V

0V

0V

(5V) 0V

MA4051MTA

CRO2 2

PL2

0V0V0V

SS

V

A LATCH

5V

R724 1K

R723 1K

0V

5V5V2V

RESET

REV LED

FWD LED

TPS

A CLK

ADATA

5V

0V

0V

R704

4.7K

F=8MHz

XIN

HALF1

5V

R747

R727

2.3V

5V

1K

4.7K

0V

XOUT

MODE

5V

Q701,703

2SD1819ARTX

INTERFACE

1K

R744

0.1V

Q701

1.2V

P-P

R722

100

VSS

IC701

CRO2 1

M38503M2406F

SYSTEM CONTROL

R703

5.6K

1.9V

0V

R708

4.7K

13

X701

(8MHz)

F=8MHz

0V

4.7K

R729

Q703

2

2.4V

P-P

R735 4.7K

R721 4.7K

R732 100K

22K

R741

D708

MA111TX

1.8V

R743

0V

R705

47K

D709

0.2V

0.6V

0V

R728

Q702

2SD1819ARTX

INTERFACE

F

H

I

47K

MA111TX

10K

CN901

1

A

B

C

D

E

2

3

4

5

6

7

8

R232

10K

F

G

5V

10.3V

Q602

2SD2144STA

POWER SUPPLY

10.3V9.6V

10.3V

C602

16V220

CBAFIOJKLMNGH

R630

0.33

R602

0.33

330

R604

R609

C605

100

16V220

D651

MA165TA

D652

MA165TA

9.6V

Q604

2SC3940AQSTA

REGULATOR

5.7V

C603

16V47

+

10V

EDABC

A

B

C

D

E

F

PQR

S

R603

C604

D606

0.01

MA4056MTA

R606

(D.GND)

TP609

Rch

OUT

CT.GND

10

1.5K

R632

47K

Lch

OUT

TP604

RchINLch

EARTH

TERMINAL

D

A.GND

W601 E1

CN601

1

F

G

H

I

J

IN

SYNC

2

NC

3

NC

4

CS

5

+B(10V

6

D.GND

7

SCLK

8

DATA

9

DECK REQ

10

NC

11

TAPERch OUT

12

TAPELch OUT

13

RS A.GND

14

TAPERch IN

15

TAPELch IN

16

NC

17

A.GND

18

NC

19

NC

20

NC

CIRCUIT

)

To

SOUND PRCESSOR

(SH-EH770) &

CD CHANGER

(SL-EH770)

9.4V5V

Page 16

OPERATION CIRCUIT

E

:POSITIVE VOLTAGELINE

:PLAYBACKSIGNAL LINE

1

2

3

4

5

6

7

8

FW901

S912

(

DECK 1/2

S911

(

REV MODE

S910

(

S909

(

S915

(

OPEN

S914

(

COUNTER

RESET

S913

(

COUNTER

DISPLAY

S907

( )

5V

S906

( )

S905

(

DOLBY NR

S904

(

REC PAUSE

S903

(

TAPEEDIT

S901

(

OPEN

S900

(

3.3K

R906

)

2.2K

R905

)

1.8K

R904

)

1.5K

R903

1.2K

R902

R901

R900

1K

820

)

)

)

)

2.2K

R911

)

)

)

)

)

R910

R909

R908

R925

R924

1.8K

1.5K

1.2K

1K

820

Q901

DTA143EUT106

LED DRIVE

R915

680

R917

MA111TX

680

STOP : 0V

5V

5V

D904

0V

0V

0V

R916

330

5V

R914

330

Q902

DTC143EUT106

LED DRIVE

D907

SML79455C

(

)

D905

SML79455C

)

(

Q903

DTC143EUT106

LED DRIVE

0V

0V

2.6V

0V

4.2V

Q904

DTC143EUT106

LED DRIVE

0V

MAIN CIRCUIT

A

A

47K

47K

47K

C215

R233

16V10

B

C

D

E

F

G

100

R234

100

IC202

MC14066BFEL

SIGNAL CONT.

Q108

DTC143EUT106

SWITCHING

(5V) 0V

C216

16V10

8.3V(0V)

R226

R208

4.7V 8.3V

8 9 10 11 12 13

7 6 5 4 3 2 1

8.3V

(0V)

22K

R126

R225

R207

47K

9.6V

(0V)

9.6V4.7V 4.7V 4.7V

14

Loading...

Loading...