Page 1

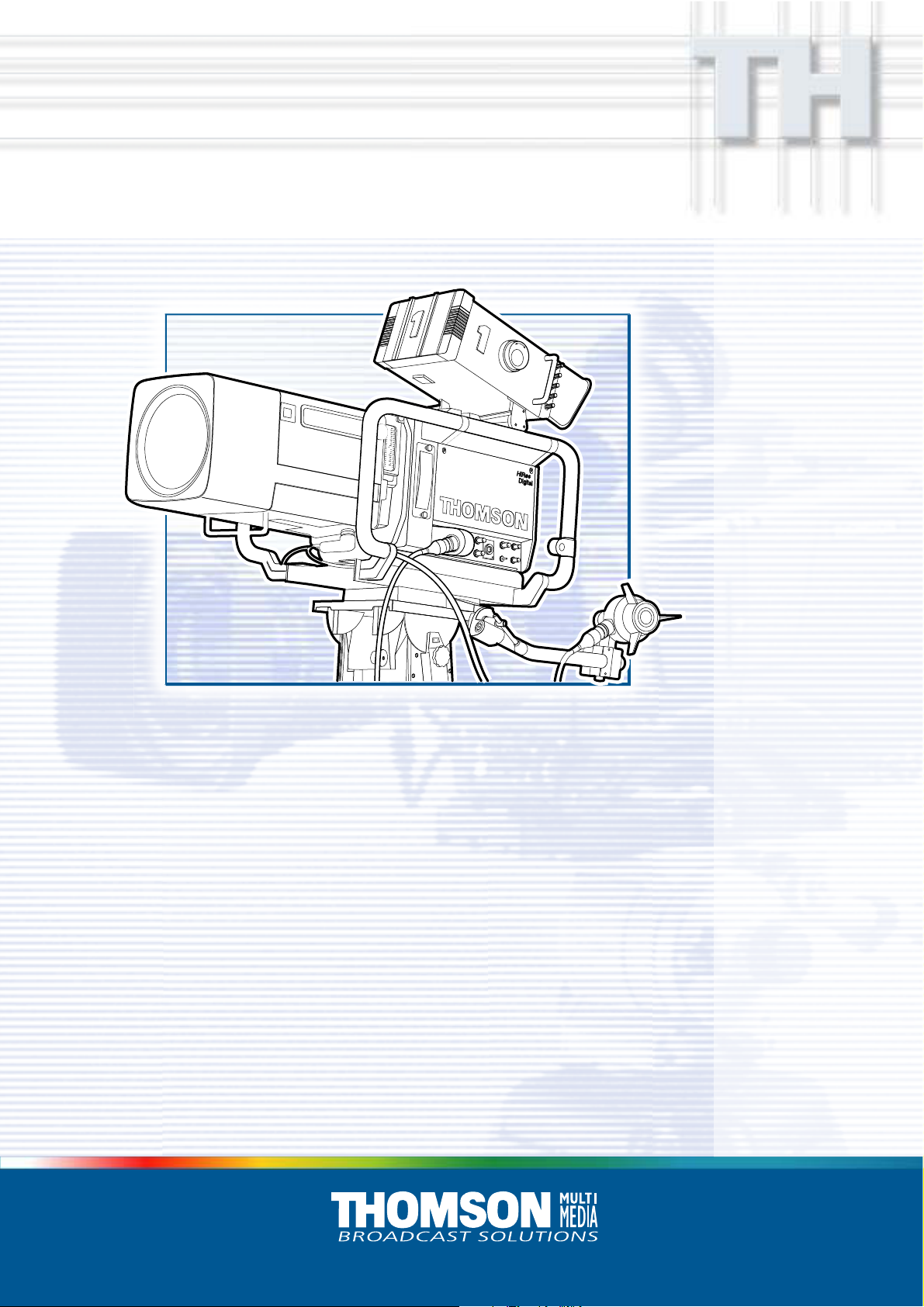

LDK 20(S)LDK 20(S)

LDK 20(S)

LDK 20(S)LDK 20(S)

Studio Camera

Technical Manual

3922 496 48591 St.00

Page 2

Declaration of Conformity

We, Thomson Broadcast Solutions Nederland B.V., Kapittelweg 10, 4827 HG Breda, The Netherlands declare under

our sole responsibility that this product is in compliance with the following standards:

EN60065

EN55103-1

EN55103-2

following the provisions of:

a. the Safety Directives 73/23//EEC and 93/68/EEC

b. the EMC Directives 89/336/EEC and 93/68/EEC

: Safety

: EMC (Emission)

: EMC (Immunity)

FCC Class A Statement

This product generates, uses, and can radiate radio frequency energy and if not installed and used in accordance with

the instructions, may cause interference to radio communications.

It has been tested and found to comply with the limits for a class A computing device pursuant to Subpart J of part 15

of FCC rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment.

Operation of this product in a residential area is likely to cause interference in which case the user at his own expense

will be required to take whatever measures may be required to correct the interference.

Copyright

Für diese Unterlage behalten wir uns

alle Rechte vor (Gemäß DIN 34).

Technische Änderungen im Zuge der

Weiterentwicklung vorbehalten.

© Thomson Multimedia Broadcast Solutions 2002

Copying of this document and giving

it to others, and the use or communication of the contents thereof,

are forbidden without express authority. Offenders are liable to the

payment of damages. All rights are

reserved in the event of the grant of

a patent or the registration of a utility

model or design. Liable to technical

alterations in the course of further

development.

Toute communication ou reproduction de ce document, toute exploitation ou communication de son

contenu sont interdites, sauf autorisation expresse. Tout manquement à cette règle est illicite et

expose son auteur au versement de

dommages et intérêts. Tous nos

droits sont réservés pour le cas de la

délivrance d'un modèle d'utilité. Sous

réserve de modification au cours de

l'évolution technique.

Page 3

LDK 20(S)

Studio Camera

Technical Manual

Contents

About This Manual ................................................ II

Safety Instructions ........................................... 1-1

Safety Summary ................................................ 1-2

Cautions and Warnings ...................................... 1-2

Earthing ............................................................. 1-3

Installation ........................................................ 2-1

Packing/Unpacking ............................................ 2-2

Local / Remote Power Supply ............................ 2-2

Hardware Setup and Customization ................... 2-3

Test Sawtooth .................................................... 2-4

Lens matching ................................................... 2-4

Analogue Ch1-Ch2 ............................................. 2-5

External Aspect Ratio Switch............................. 2-5

Dipswitch Settings ............................................. 2-5

Viewfinder Cadre Indication ................................ 2-6

Audio / Intercom settings ................................... 2-7

Private Data ....................................................... 2-8

Connectors and Cables ...................................... 2-9

Specifications LDK20 ....................................... 2-14

Replacements ................................................... 3-1

Introduction ........................................................ 3-2

Printed circuit boards ......................................... 3-2

Front module ...................................................... 3-3

Filterwheel Cassette ........................................... 3-4

Power supply ..................................................... 3-4

Adjustments ..................................................... 4-1

Introduction ........................................................ 4-2

Test Equipment ................................................. 4-3

Set-up Instructions ............................................. 4-3

Video Processor 1 Board ................................... 4-5

Digital Video Processor .................................... 4-10

Digital Video Processor .................................... 4-11

Digital Video Processor Subboard ................... 4-12

Digital Video Processor Subboard ................... 4-13

Digital Video Processor .................................... 4-14

Digital Video Processor .................................... 4-15

Video Miscellaneous Board .............................. 4-17

Sync./Shading Board ....................................... 4-27

Video Miscellaneous Board .............................. 4-35

Encoder Board PAL ......................................... 4-37

Encoder Board NTSC ....................................... 4-43

Audio/Intercom LF Board ................................. 4-51

Audio/Intercom LF Board RTS MODE ............. 4-55

Pre-Processor Board ........................................ 4-57

Drawings ........................................................... 5-1

Block Diagram Power Signals ............................ 5-2

Block Diagram Video Signals .............................5-3

Block Diagram Transmission Signals ................. 5-4

Block Diagram Control Signals ........................... 5-5

02.34.5 Technical Manual LDK 20(S) - Studio Camera I

Page 4

About This Manual

Service policy

The LDK 20(S) is a sophisticated camera containing

state-of-the-art electronic components which are

designed to provide long-life operation without the

need for maintenance. With this in mind, the service

policy of Thomson Multimedia Broadcast Solutions

endeavours to ensure that help will be quickly on hand

in the unlikely event of anything going wrong. The

guiding principles of the Thomson Multimedia Broadcast

Solutions first line maintenance philosophy are speed

and cost effectiveness. First line maintenance is

dedicated to keeping your camera operational, despite

a fault, by module replacement and the replacement of

minor mechanical parts by the user.

Purpose of this manual

The provision of correct information is the first step in

ensuring the operational integrity of the camera.

Information on the operation of the camera is to be

found in the User’s Guide.

This installation and first line maintenance manual is

an integral part of the service policy. It ensures that

you will be able to install and set-up your camera to

meet the requirements of your environment. This

information on the installation of the camera is contained

in Section 2 of the manual. The remaining sections of

the manual provide first line service information so that

suitably qualified service personnel can detect and

repair faults, normally by module replacement.

Intended audience

The manual is intended as a guide to those with a

working knowledge of camera systems and installation

techniques. The first line detection and repair of faults

requires a general knowledge of test and measurement

techniques.

Structure of this manual

The manual is divided into five sections:

Section 1: Safety Information.

Contains important safety information and should be

read before carrying out any work on the camera.

Section 2: Installation.

Gives instructions on the integration of the camera into

the operating environment and the customization of

certain hardware functions

Section 3: Replacements.

Gives information on the replacement of components

at first line level.

Section 4: Adjustments.

Contains the adjustment procedures to be followed to

obtain the best performance from the camera.

Section 5: Drawings.

Contains block diagrams of the camera.

Because of the complexity of some of the components,

second line service can only be carried out at the

specially equipped service centres and information

concerning second line maintenance is not supplied

in this manual.

II Technical Manual LDK 20(S) - Studio Camera 02.34.5

Page 5

Section 1

Safety Instructions

This section outlines the precautions that must be taken into account when using the LDK 20(S)

Studio Camera.

Contents

Safety Summary ........................................................ 1-2

Cautions and Warnings ............................................. 1-2

Safety Instructions Technical Manual LDK 20(S) - Studio Camera 1-1

Earthing ..................................................................... 1-3

Page 6

Safety Summary

Cautions and Warnings

This informaton is intended as a guide for trained and

qualified personnel who are aware of the dangers involved

in handling potentially hazardous electrical/electronic

equipment. It is not intended to contain a complete list of

all safety precautions which should be observed by

personnel in using this or other electronic equipment.

The installation, maintenance and service of this equipment

involves risks both to personnel and equipment and must

be performed only by qualified personnel exercising due

care.

Personnel engaged in the installation, operation,

maintenance or servicing of this equipment are urged to

become familiar with First Aid theory and practises.

During installation and operation of this equipment, local

building safety and fire protection standards must be

observed.

Before connecting the equipment to the power supply of

the installation, the proper functioning of the protective

earth lead of the installation needs to be verified.

Whenever it is likely that safe operation is impaired, the

apparatus must be made inoperative and secured against

any unintended operation. The appropriate servicing

authority must then be informed. For example, safety is

likely to be impaired if the apparatus fails to perform the

intended function or shows visible damage.

This product has been designed and tested according to

EN60065.

When performing service, be sure to read and comply with

the warning and caution notices appearing in the manuals.

Warnings indicate danger that requires correct procedures

or practices to prevent death or injury to personnel. Cautions

indicate procedures or practices that should be followed

to prevent damage or destruction to equipment or property.

WARNING

THE CURRENT AND VOLTAGES PRESENT IN THIS

EQUIPMENT ARE DANGEROUS. ALL PERSONNEL

MUST AT ALL TIMES FOLLOW THE SAFETY

REGULATIONS.

ALWAYS DISCONNECT POWER BEFORE REMOVING

COVERS OR PANELS.

ALWAYS DISCHARGE HIGH VOLTAGE POINTS

BEFORE SERVICING.

NEVER MAKE INTERNAL ADJUSTMENTS, PERFORM

MAINTENANCE OR SERVICE WHEN ALONE OR WHEN

FATIGUED.

IN CASE OF AN EMERGENCY ENSURE THAT THE

POWER IS DISCONNECTED.

ANY INTERRUPTION OF THE PROTECTION

CONDUCTOR INSIDE OR OUTSIDE THE APPARATUS,

OR DISCONNECTION OF THE PROTECTIVE EARTH

TERMINAL, IS LIKELY TO MAKE THE APPARATUS

DANGEROUS. INTENTIONAL INTERRUPTION IS

PROHIBITED.

FOR SAFETY REASONS THE CPU MUST BE MOUNTED

IN A 19-inch RACK WHICH HAS SAFETY COVERS

ACCORDING TO IEC65.

WHEN TWO CPUs ARE MOUNTED ABOVE EACH

OTHER THE MINIMUM DISTANCE BETWEEN THEM

MUST BE 50MM OR THE RACK MUST BE FORCE-AIR

COOLED.

USE ONLY FUSES OF THE TYPE AND RATING

SPECIFIED.

CAUTION

To prevent risk of overheating, ventilate the product

correctly.

Connect the product only to a power source with the

specified voltage rating.

Only connect a Triax cable from the LDK 6 camera

family to an LDK 6 CPU. Never connect it to any other

base station.

Never connect the Triax cable from a camera to a

CPU of a different family; never connect the LDK

family to the TTV family.

Do not allow system ground currents to exceed 1.5A

in the outer shield of the triax cable or 0.2A in other

cable shields.

It is strickly prohibited to short circuit the inner and

outer shields of a triax cable used to connect a

camera to a base station.

1-2 Technical Manual LDK 20(S) - Studio Camera Safety Instructions

Page 7

Earthing

Symbol Colour Explanation

Red High voltage terminal at which a

voltage, with respect to an other

terminal, exists or may be

adjusted to 1000V or more.

Yellow/Black Live part.

Yellow/Black This marking indicates that the

operator must refer to an

explanation in the Instruction

Manual, or that a specific

component must be replaced by

the component specified in the

documentation for safety

reasons.

White/Black Protective earth (ground)

terminal.

Cathode ray tubes

Components marked

for safety and include those specified to comply with X-ray

emission standards for units using cathode ray tubes and

those specified for compliance with various regulations

regarding spurious radiation emission.

When servicing units that use cathode ray tubes (CRTs),

the cathode ray tubes themselves, the high voltage circuits

and related circuits are specifically chosen so that they

comply with recognized codes pertaining to X-ray emission.

Consequently, when servicing, replace the cathode ray

tubes and other parts with specified parts only. Do not

attempt to modify these circuits as any unauthorized

modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

Handle the cathode ray tube only when wearing shatterproof

goggles and after discharging the high voltage completely.

on the circuit diagram are critical

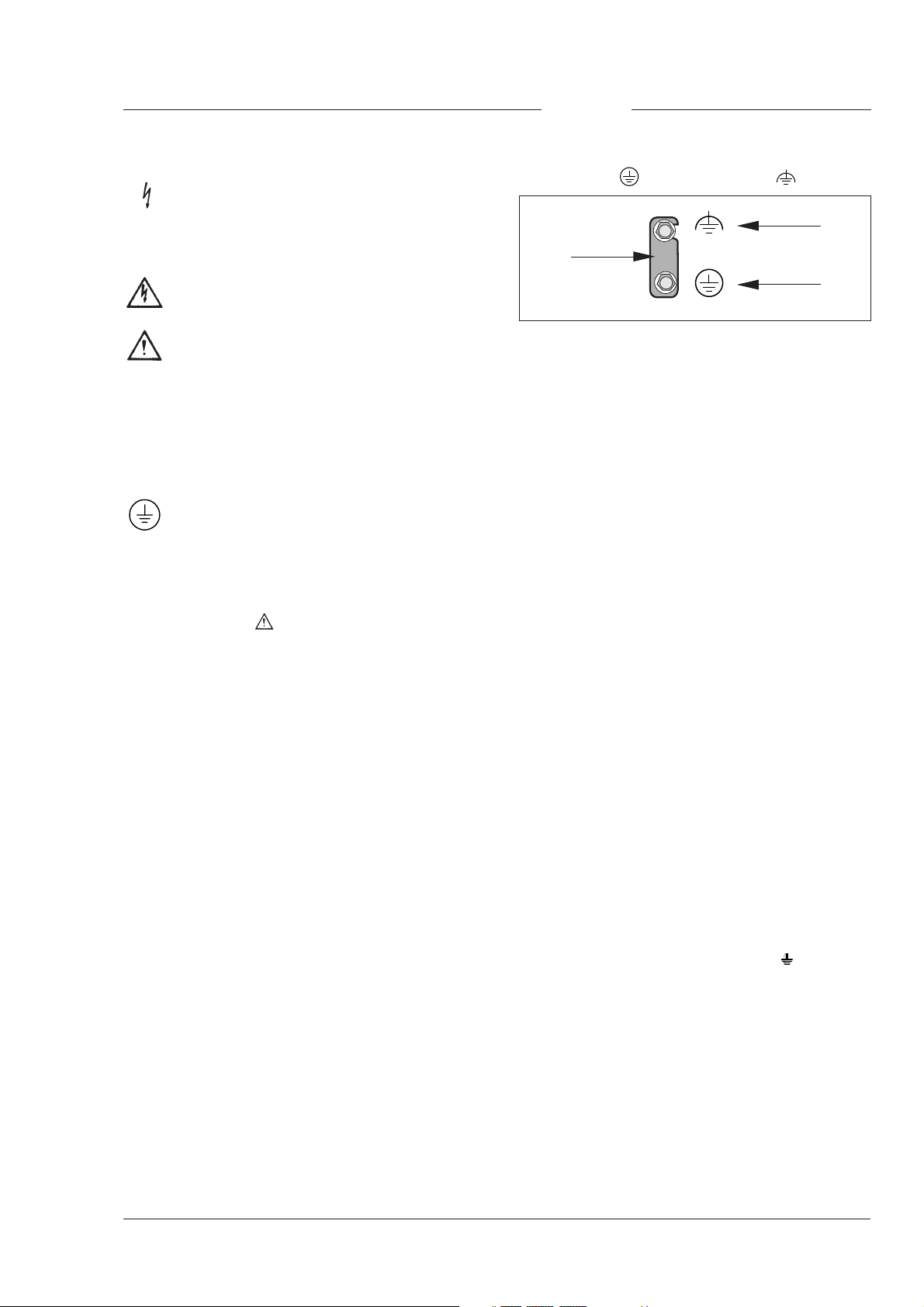

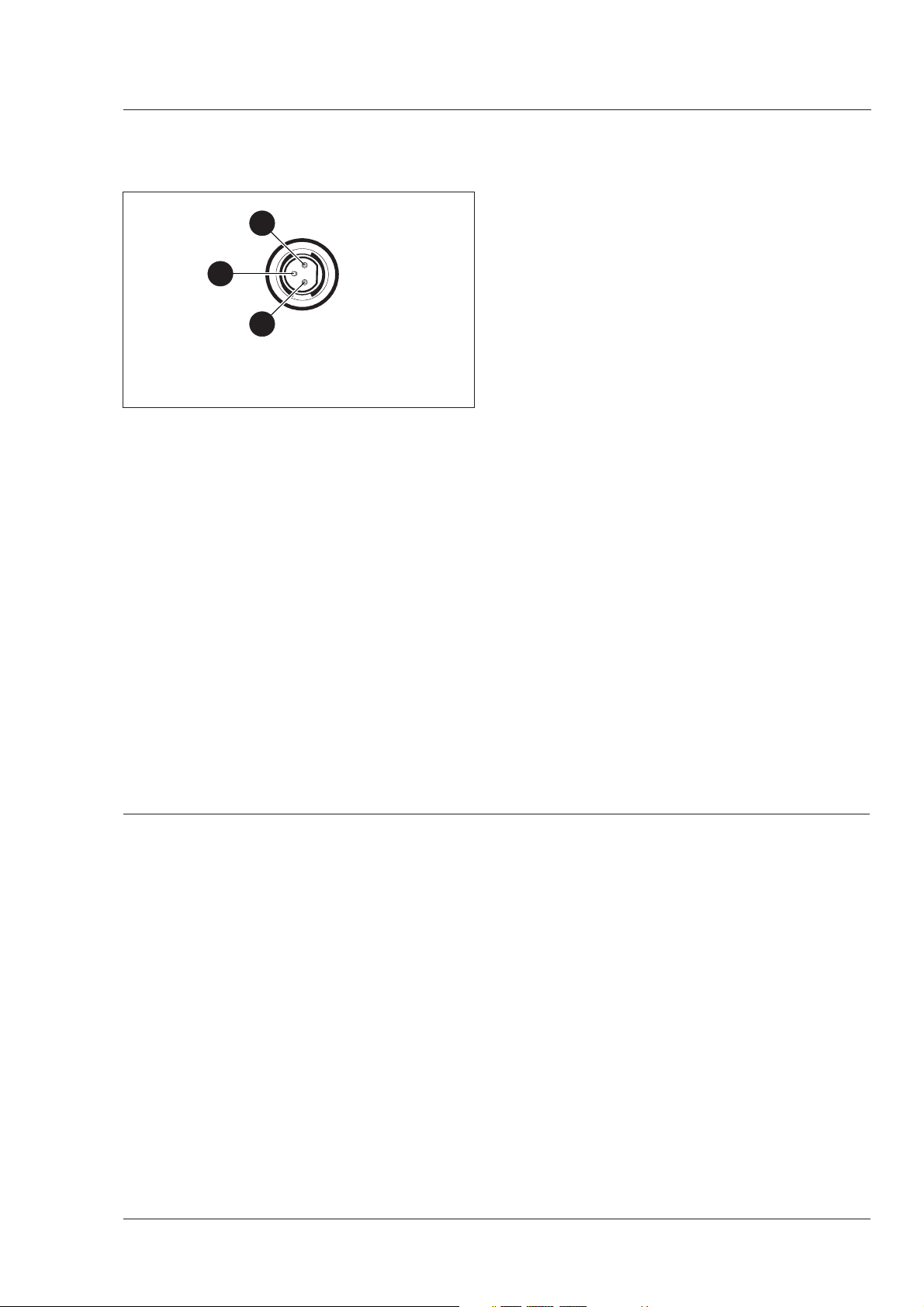

The rear of a CPU has two separate screw terminals for

protective earth (PE) and video earth (VE).

VE

Metal

strap

PE

These are normally connected by a metal strap. The

protective earth terminal is internally connected to the

protective earth conductor of the power cable. If required,

the central earth connection wire of the studio can be

connected to terminal PE.

In normal circumstances the connection between the

protective earth and the video earth should not be broken.

The metal strap may be removed only if the studio (or OB

van) is equipped with separate protective and video earth

systems. Under these circumstances the video earth

terminal must be connected to the central functional earth

potential (video earth) of the studio. This earth potential

should have functional protective and noiseless earth

(FPE) qualities as stated in the VDE regulation 0800/part2.

A low impedance interconnection of both earth conductors

must be provided at the central studio earthing point.

WARNING

THE UNIT MUST ALWAYS BE CONNECTED TO

PROTECTIVE EARTH.

Mains Lead Wiring for UK Users

The wires in the mains lead are coloured in accordance

with the following code:

GREEN AND YELLOW - EARTH

BLUE - NEUTRAL

BROWN - LIVE

As the colours of the wires in the mains lead of this

apparatus may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

• The wire coloured GREEN AND YELLOW must be

connected to the terminal on the plug marked with the

letter E or by the safety earth symbol

GREEN or GREEN AND YELLOW.

• The wire coloured BROWN must be connected to the

terminal marked with the letter L or coloured RED.

• The wire coloured BLUE must be connected to the

terminal marked with the letter N or coloured BLACK.

Ensure that your equipment is connected correctly - if you

are in any doubt consult a qualified electrician.

or coloured

Safety Instructions Technical Manual LDK 20(S) - Studio Camera 1-3

Page 8

1-4 Technical Manual LDK 20(S) - Studio Camera Safety Instructions

Page 9

Section 2

Installation

This section provides information which is relevant when the camera is to be used for the first time.

Packing and unpacking instructions together with information on the integration of the camera into

your studio system are provided. The procedures for the customization of certain hardware functions

and connector information is also provided.

Contents

Packing/Unpacking ............................................ 2-2

Local / Remote Power Supply ............................ 2-2

Hardware Setup and Customization ................... 2-3

Test Sawtooth .................................................... 2-4

Lens matching ................................................... 2-4

Analogue Ch1-Ch2 ............................................. 2-5

External Aspect Ratio Switch............................. 2-5

Installation Technical Manual LDK 20(S) - Studio Camera 2-1

Dipswitch Settings ............................................. 2-5

Viewfinder Cadre Indication ................................ 2-6

Audio / Intercom settings ................................... 2-7

Private Data ....................................................... 2-8

Connectors and Cables ...................................... 2-9

Specifications LDK20 ....................................... 2-14

Page 10

Packing/Unpacking

Inspect the shipping container for evidence of damage

immediately after receipt. If the shipping container or

cushioning material is damaged, it should be kept until

the contents of the shipment have been checked for

completeness and the units have been checked

mechanically and electrically.

The shipping container should be placed upright and

opened from the top. Remove the cushioning material

and lift out the contents.

The contents of the shipment should be checked

against the packing list. If the contents are incomplete,

if there is mechanical damage or defect, or if the units

do not perform correctly when unpacked, notify your

Thomson Multimedia Broadcast Solutions sales or

service centre within eight days. If the shipping

container shows signs of damage or stress, notify the

carrier as well.

If a unit is being returned to Thomson Multimedia

Broadcast Solutions for servicing, try to use the

containers and materials of the original packaging.

Attach a tag indicating the type of service required,

return address, model number, full serial number and

the return number which will be supplied by your

Thomson Multimedia Broadcast Solutions service

centre.

If the original packing can no longer be used, the

following general instructions should be used for

repacking with commercially available materials:

a. Wrap unit in heavy paper or plastic.

b. Use strong shipping container.

c. Use a layer of shock-absorbing material around all

sides of the unit to provide firm cushioning and

prevent movement inside container.

d. Seal shipping container securely.

e. Mark shipping container FRAGILE to ensure careful

handling.

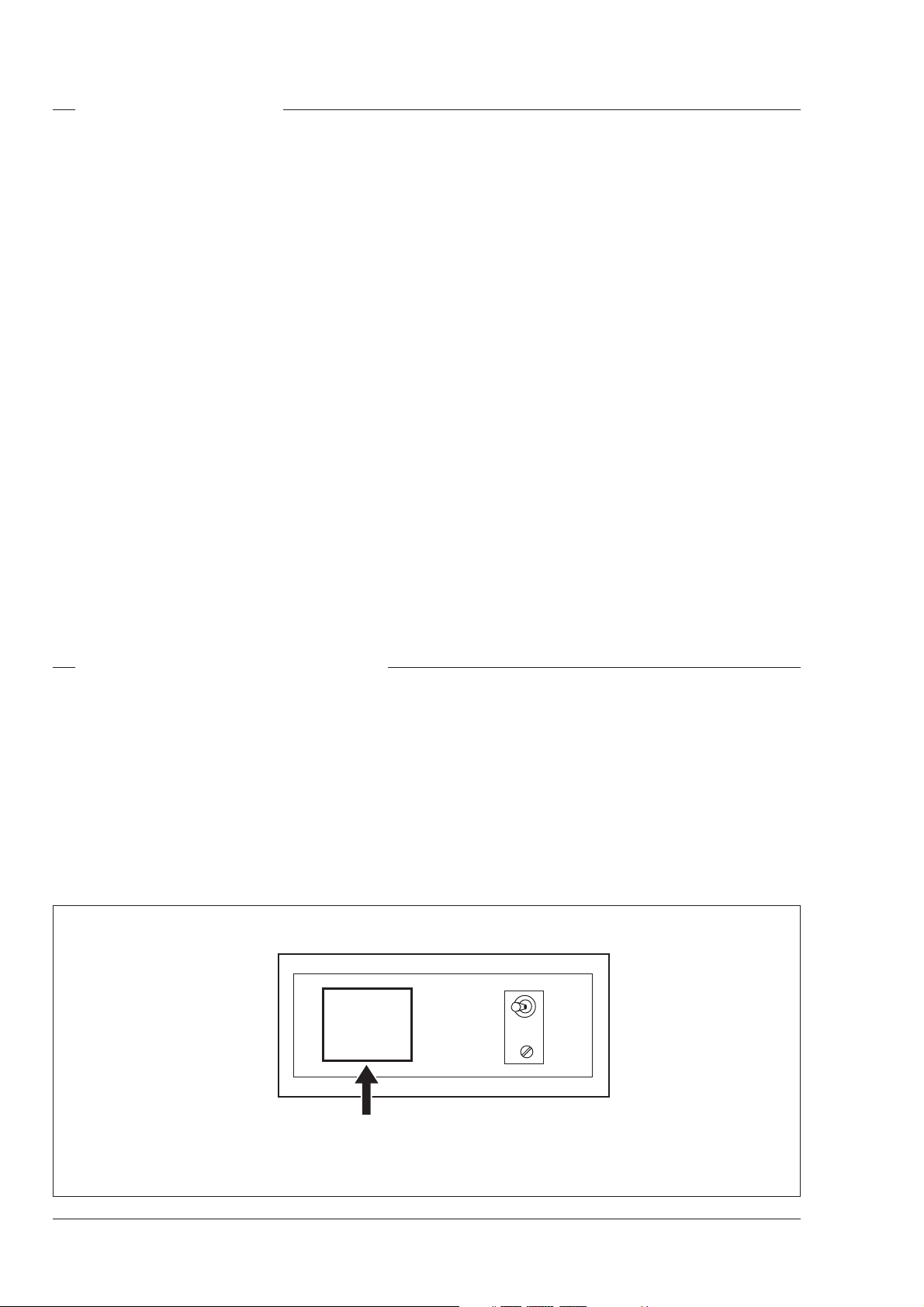

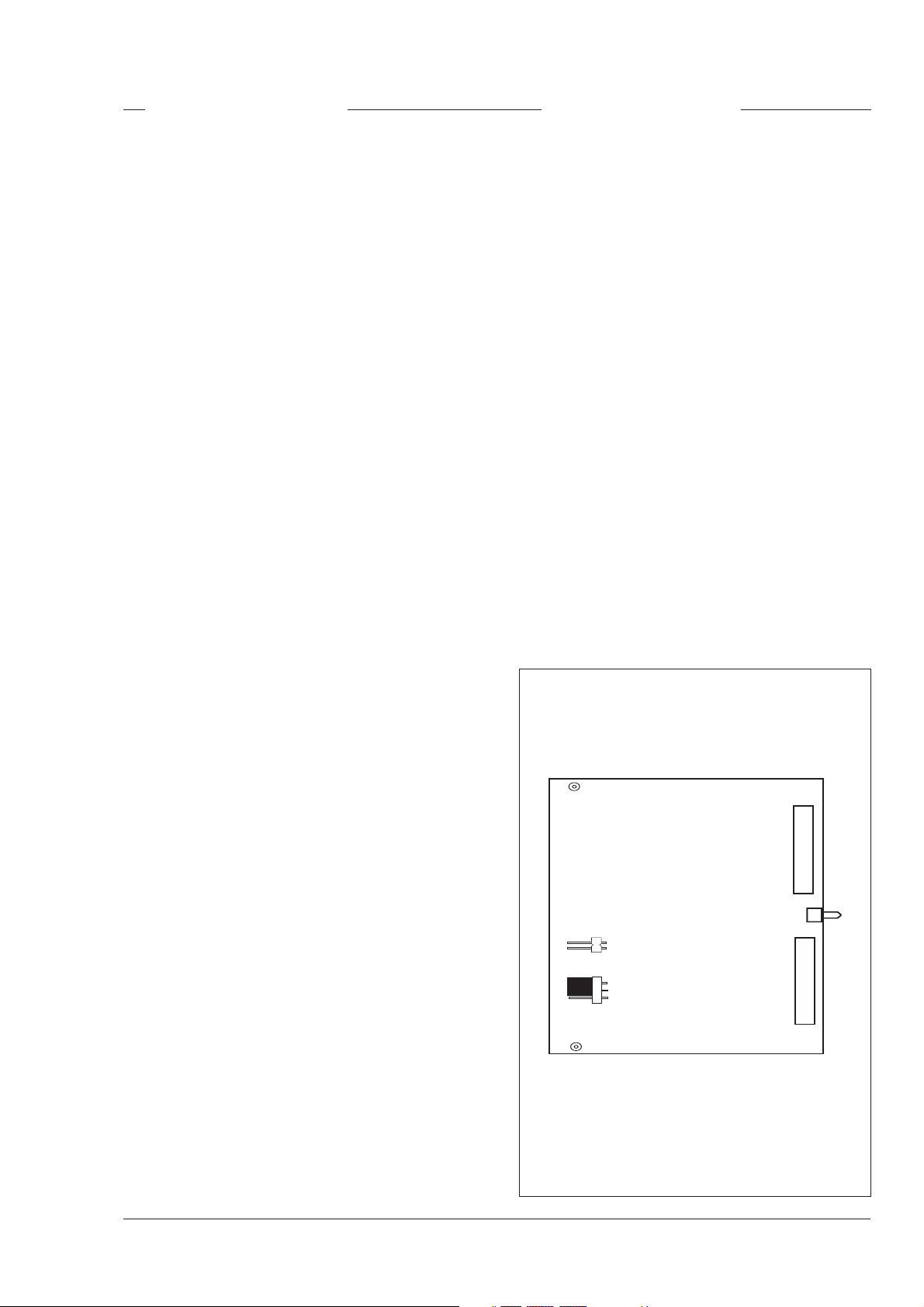

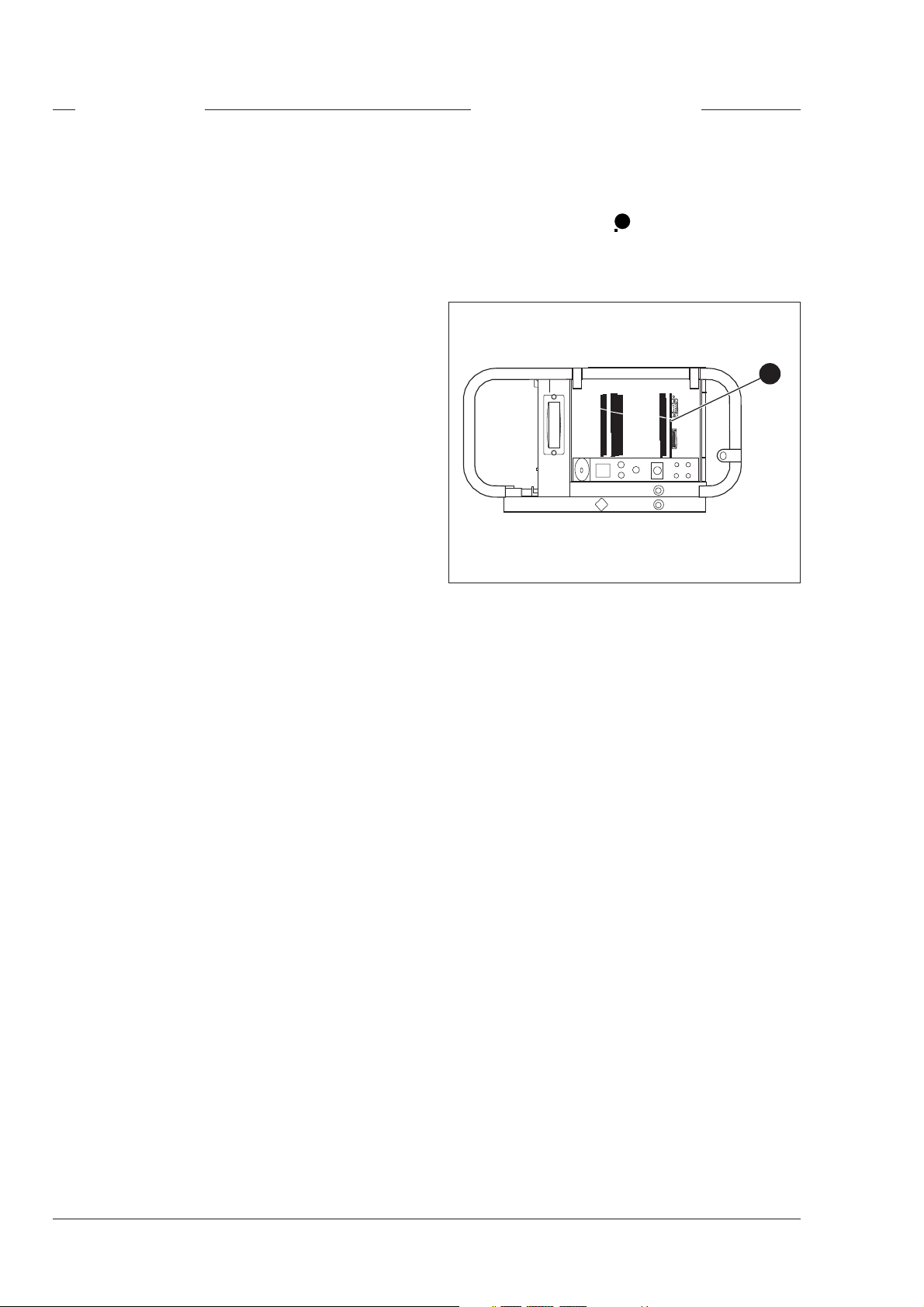

Local / Remote Power Supply

The LDK 20 camera is delivered ready to operate in the

remote mode. If the camera has to be used in the local

(stand-alone) mode, carry out the following instructions

to allow the power to be supplied via the mains power

supply input connector on the right side connector

panel:

a. Disconnect the mains power supply or the triax

cable, whichever is connected.

b. Loosen two screws and remove the rear connector

panel of the camera.

c. Locate the remote/local switch - a large black

plastic box.

d. Set the switch to the local position. The camera is

delivered with the switch in the remote position.

f. Return the rear connector panel to its position.

R

E

M

O

T

E

230V 115V

Local/remote

Switch

2-2 Technical Manual LDK 20(S) - Studio Camera Installation

Page 11

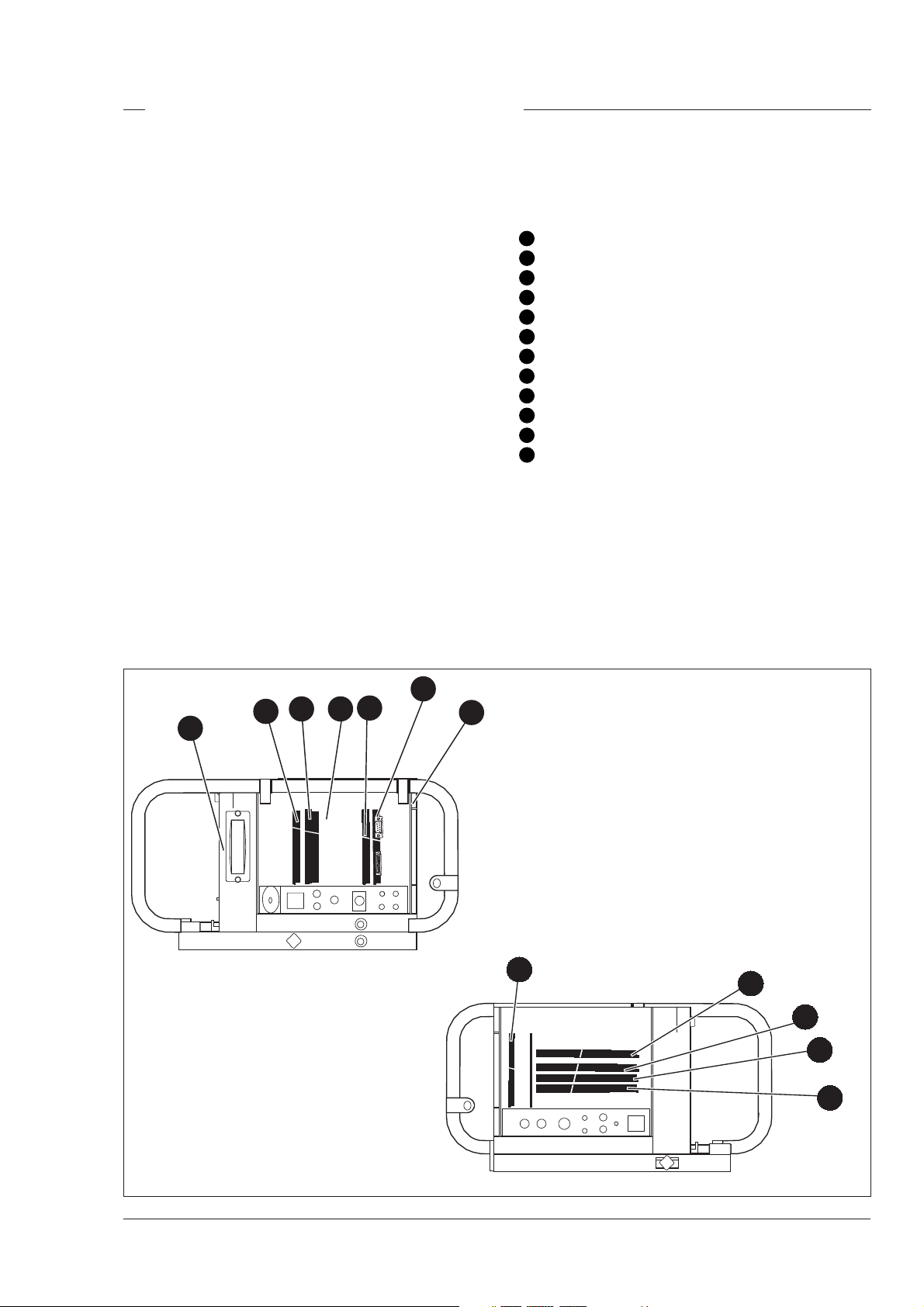

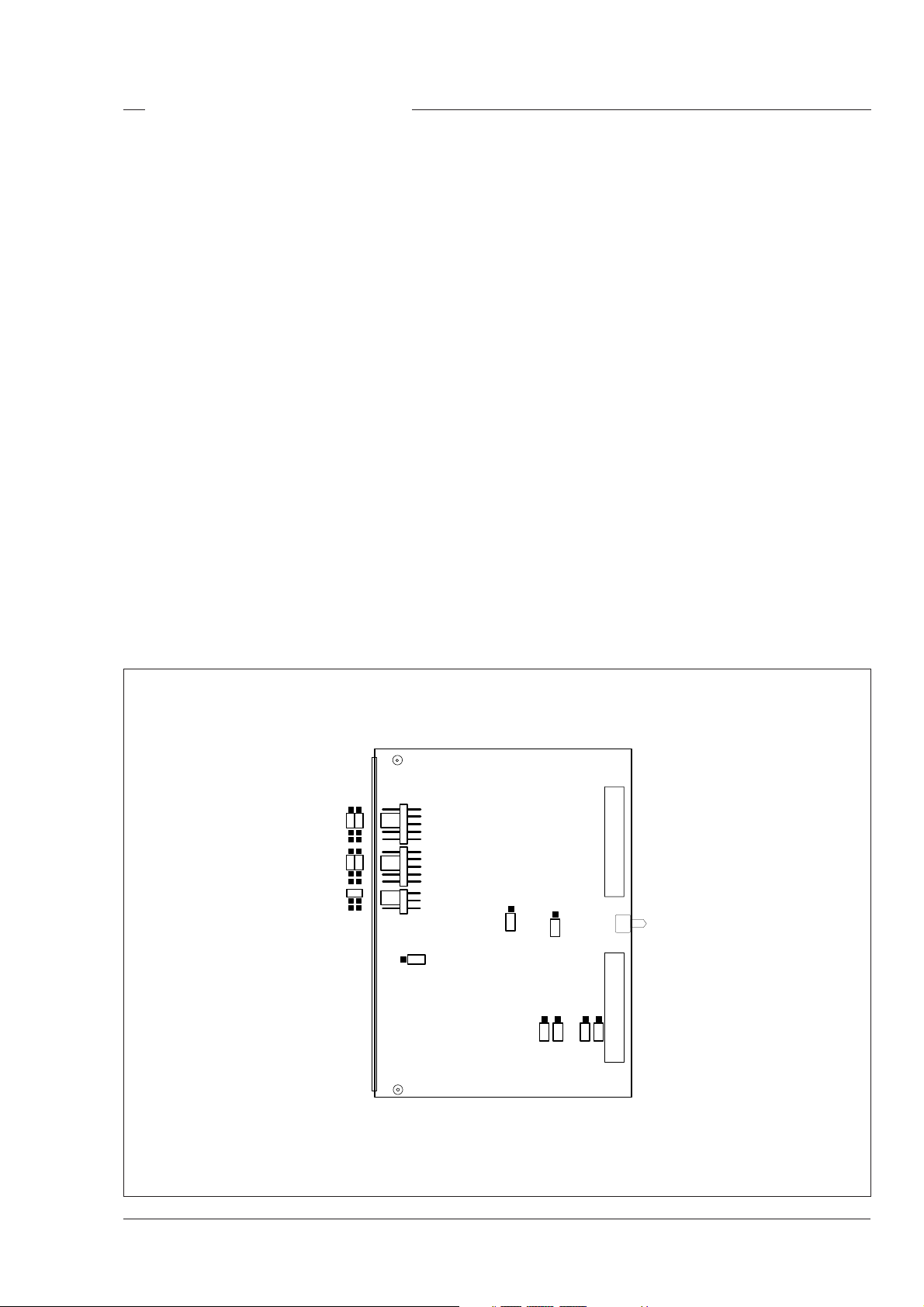

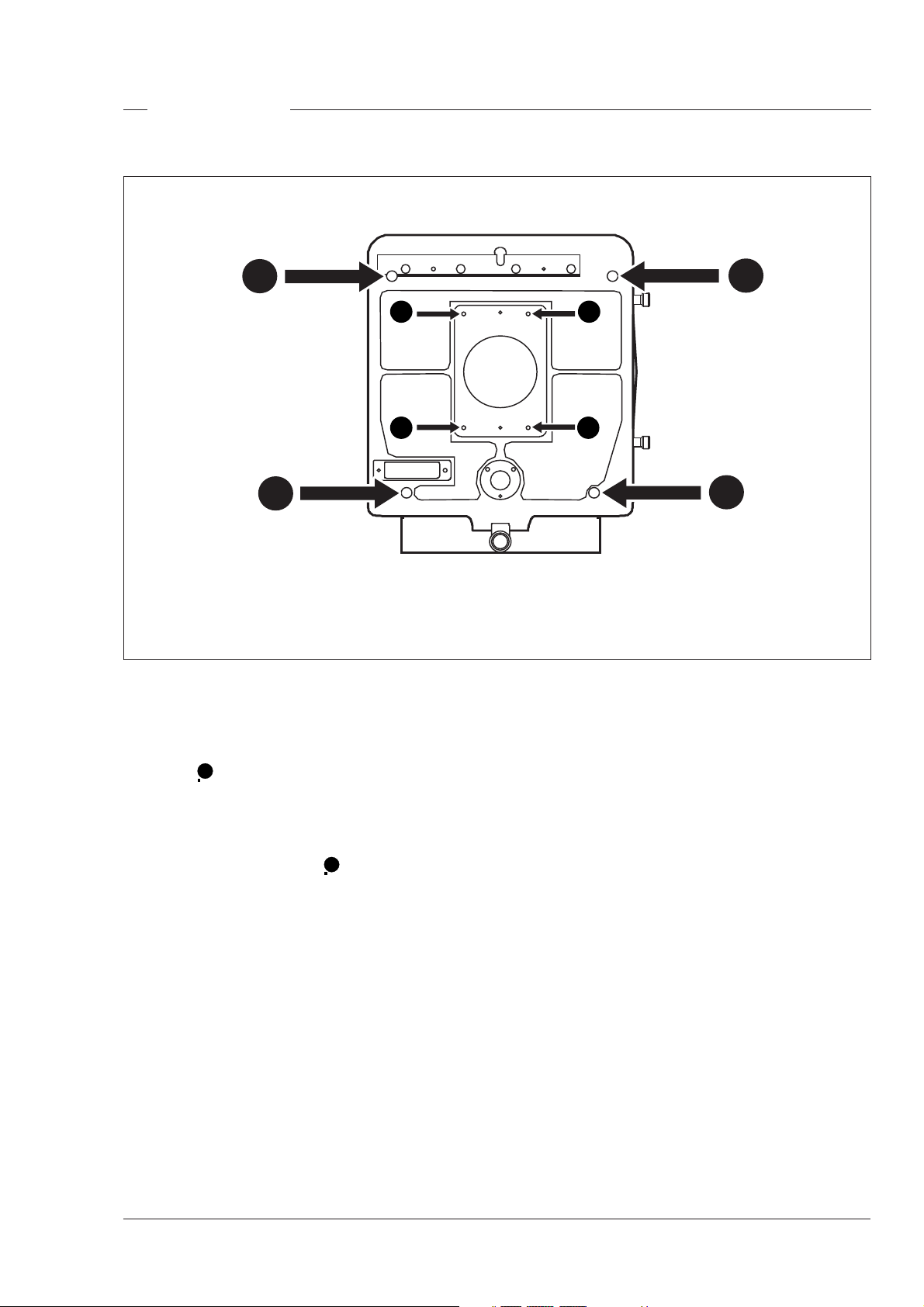

Hardware Setup and Customization

The camera is delivered in a ready-to-use state,

however, there are occasions when it might be

necessary to re-adjust some functions after, for

example, fitting a new lens.

A large number of functions can be set-up using the

control facilities of the menu system. In addition to this

software set-up there are some functions which can be

selected or adjusted internally in the camera.

Refer to the next chapters for instructions.

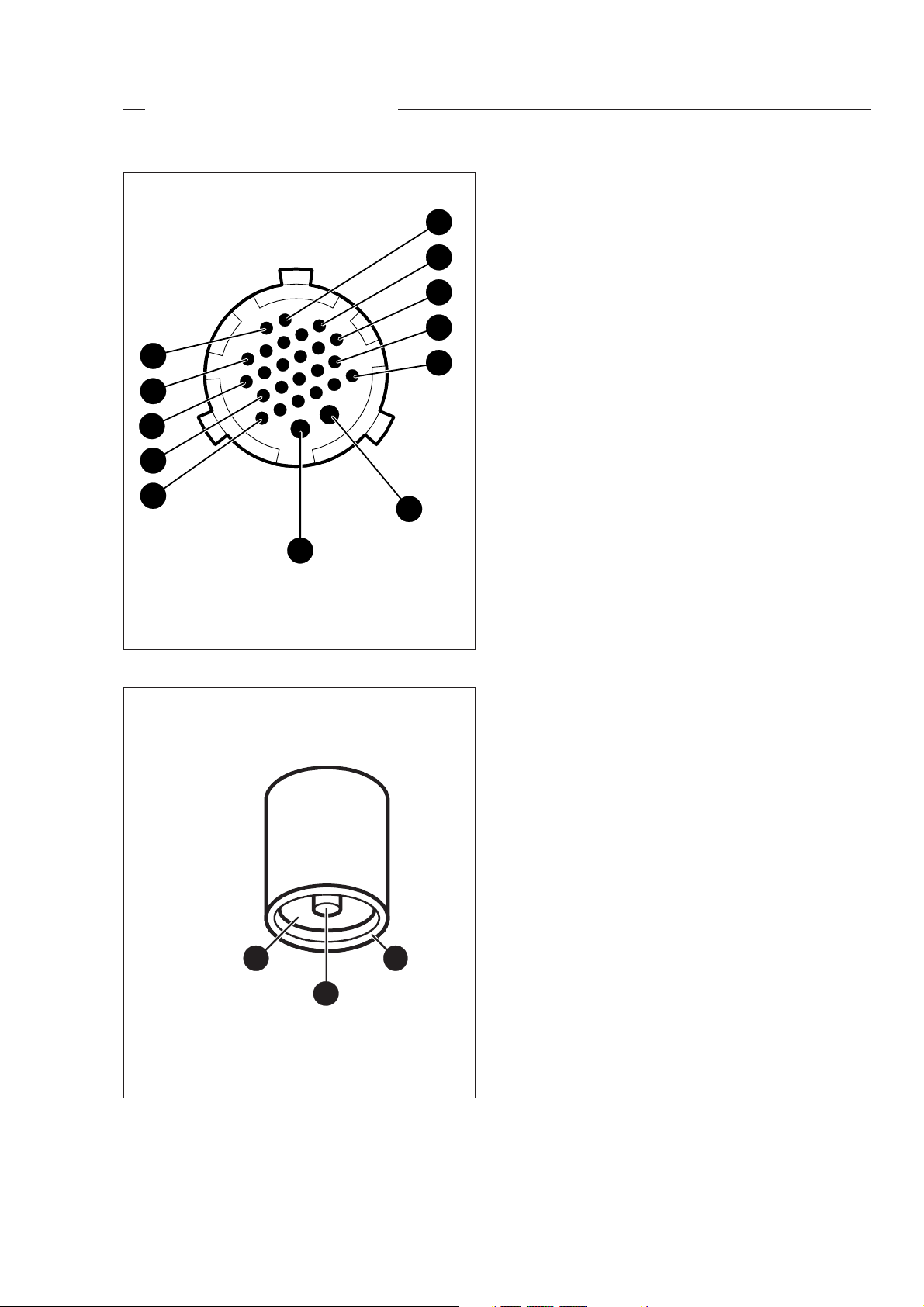

Location of adjustments

Turn the two screws on the left side panel 90°

counterclockwise and swing down the cover. Turn the

two screws on the right side panel 90° counterclockwise

and swing down the cover.

Unless mentioned otherwise the adjustments for

hardware setup and customization are located at the

side of the following modules:

1

Front Module

2

Video Processor 1

3

Digital Video Processing

4

Subboard DSP

5

Sync. Shading

6 Data Processor

7

Power

8

Video Miscellaneous

9

Encoder

10

Video Mux Ext-TP Rec

11

Audio/Intercom TX-Rec

12

RTS Power Miscellaneous

6

3

2

5

4

7

1

12

8

9

10

11

Installation Technical Manual LDK 20(S) - Studio Camera 2-3

Page 12

Test Sawtooth

Lens matching

A test sawtooth signal is normally only used for

adjustment procedures. Jumper X3 on Video processor

1 board provides a choice between two internal signals

or an external signal.

Internal signals

Set jumper X3 to position BC to get the nominal

sawtooth. This is used for checking amplitudes.

Set jumper X3 to position AB to get a small sawtooth

(approximately 25% nom.). This small sawtooth is

used for checking painting or colour temperature

ranges.

External signal

To inject an external test signal first set jumper X3 to

position CD (test input). Connect the external test

signal to connector X4-1/2. The nominal value of this

signal is 700 mV without sync.

The test sawtooth signal is switched on by means of

the Operate menu of the camera or the Setup 1 menu

of the MCP.

When a camera is supplied with a lens it is not

necessary to perform any of the following adjustments

as the lens is already matched to the camera. However,

if you wish to change to a different type of lens or the

lens is not supplied with your camera, back focus,

white shading and auto iris adjustment procedures

may have to be performed.

• Colour balance.

If required, perform the gain adjustment of the

preprocessor board and/or white shading adjustment

procedures, described in section 4.

• Auto Iris Adjustment

If a different lens either works too slow or overshoots

too much with the auto iris control, adjust the

potentiometer on the lens to obtain acceptable

operation. Refer to the lens documentation.

• Back Focus Adjustment

To adjust the back focus of the lens refer to the

documentation of the lens.

A1

5

5

X

X4

2

1

TEST IN

6

B

X3

A

C

TOP SIDE

2-4 Technical Manual LDK 20(S) - Studio Camera Installation

Video processor 1

5

X

Page 13

Analogue Ch1-Ch2

Dipswitch Settings

Two analogue channels (AN 0 and AN 1) are available

from the base station to the camera via the triax cable

and can be used to transmit L.F. signals. For example,

joystick control or pan and tilt. The input signals are

applied to the Auxiliary connector of the base station.

The output signals are available on the Auxiliary

connector of the camera. The input signal and output

signal voltage is between 0 and 5Vdc.

The AN 1 channel is sometimes used for switching the

aspect ratio. This is selected by means of the software.

See next chapter for instructions.

External Aspect Ratio Switch

On the Digital Video Processor 3922 406 84951 the

following functions can be selected with dipswitches

ZS110 and ZS111:

ZS110-1 Leaking Pixel Corrector

ZS110-2 Noise Reducer

ZS110-3 HW Gamma Low Pass Filter

ZS110-4 Contour Boost (Viewfinder)

ZS111-1 Status Bar (only LDK20P) Focus

value remains present.

The analogue channel 1 (AN 1) input on the base

station can be used to switch the aspect ratio. This

allows multiple camera switching.

This function can be selected in the menu system of

the camera or MCP. To select this function on the

camera, set the Aspect ratio of the Operate/Sensor/

AspRatio menu to External.

Apply a voltage at TTL level to the Auxiliary base

station connector. See Installation Manual Base

Station.

Input high: aspect ratio 4:3

Input low: aspect ratio 16:9

TEST IN

TOP SIDE

X55

X4

2

1

B

A

C

Video processor 1

X56

Installation Technical Manual LDK 20(S) - Studio Camera 2-5

Page 14

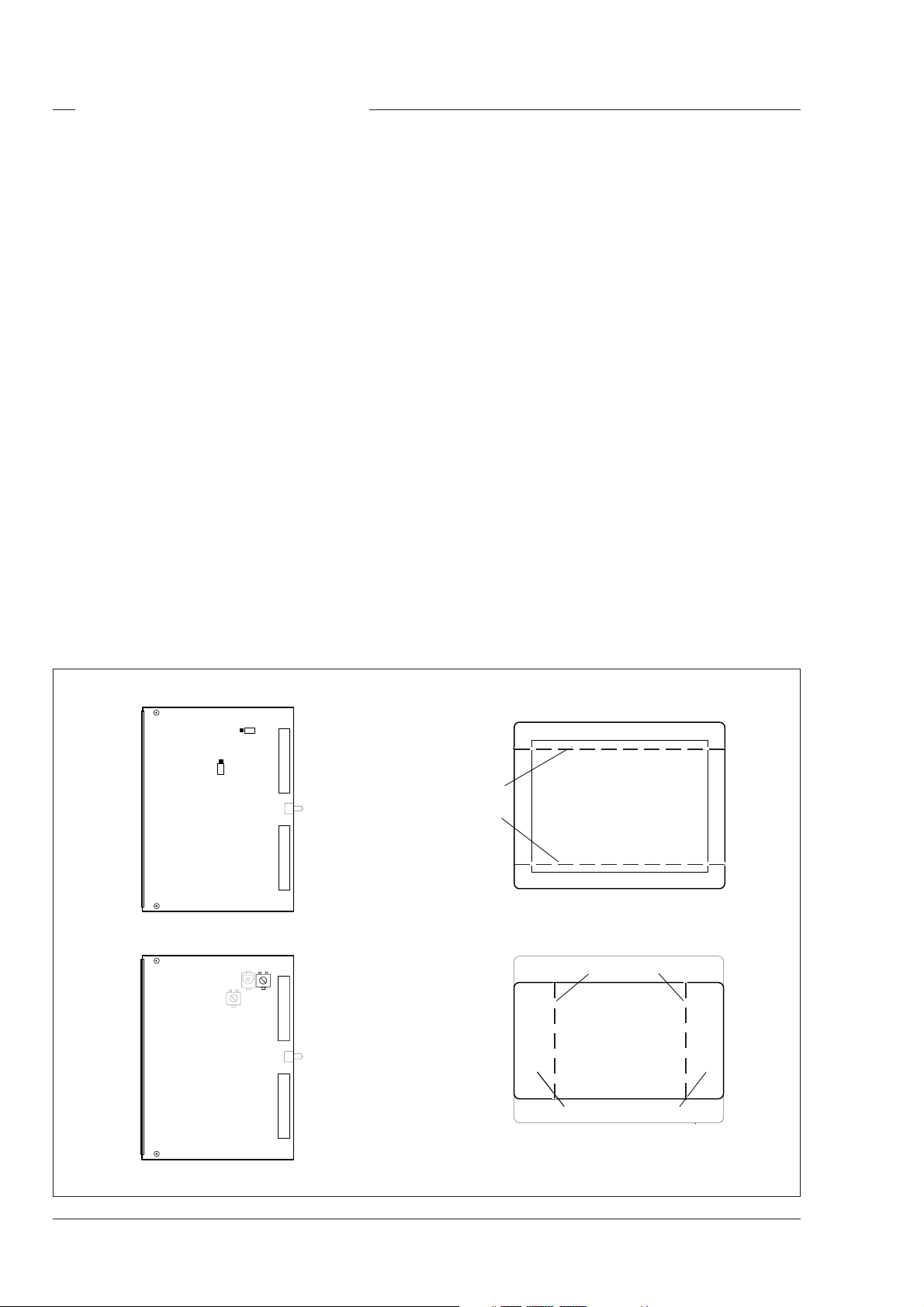

Viewfinder Cadre Indication

Cadre On/Off

Switch S6 on the Sync./shading board allows the

cadre in the viewfinder to be switched on permanently

or to be controlled by the menu system. Position AB

selects (remote-) menu control (factory setting);

position AC switches the cadre on permanently.

If S6 is in the remote position then you can select in

Menu VF/Lens Cadre On or Off. The cadre is switched

to the 4:3 format or to the 16:9 format depending on the

position of the aspect ratio switch.

Cadre appearance

Switch S7 on the Sync./shading board allows the

cadre in the viewfinder to take the form of two dotted

lines or two low-contrast areas outside the picture

area. Position AB selects the dotted lines; position AC

selects the low-contrast areas.

The contrast of the cadre strips is adjusted with

potentiometer ZR247 on the Video/Miscellaneous

board.

C A B

S7

C

A

B

S6

TOP SIDE Sync / Shading board

ZR247

Cadre

contrast

TOP SIDE

Video / Miscellaneous board

low-contrast area

1

6

X

dotted

lines

2

6

X

16:9

low-contrast area

dotted lines

A

7

1

X

4:3

B

7

1

X

low-contrast areas

2-6 Technical Manual LDK 20(S) - Studio Camera Installation

Page 15

Audio / Intercom settings

Audio microphone signals

The high-pass filters in the audio channels reduce the

background noise in the audio microphone signals.

The high-pass filters can be set as follows:

Audio 1 at MCP on/off (off=default setting)

Audio 2 at MCP on/off (off=default setting)

The phantom power for different types of microphones

can be set as follows:

Audio 1 S100: D1-E1/D2-E2 +12Vdc

B1-C1/B2-C2 Ground *

A1-B1/A2-B2 +48Vdc

Audio 2 S200: D1-E1/D2-E2 +12Vdc

B1-C1/B2-C2 Ground *

A1-B1/A2-B2 +48Vdc

(* factory setting)

Intercom headset signals

The signal to the headset of the tracker can be

selected by S420 on the Audio/Intercom LF board.

Position AB (the factory setting) selects the tracker

microphone sidetone signal; position AC selects the

ENG signal.

Intercom microphone signals

The gain of the cameraman microphone signal can be

set at Camera Menu as follows:

40db (default setting) 0db

The gain of the tracker microphone signal can be set

at Camera Menu as follows:

40db (default setting) 0db

The factory settings are for headsets with a dynamic

microphone.

The phantom power for both cameraman and tracker

microphones can be set with S300 as follows:

AC +12Vdc

AB Ground (factory setting)

E

D

C

B

A

E

D

C

B

A

B

A

C

S200

S100

S300

B A C

S740

signal choice

prog or private data

TOP SIDE

signal choice

sidetone or eng

B

A

C

S470

S450

B

A

C

signal choice

tracker mic or

private data

1

0

6

6

9

9

S

S

B

A

C

signal choice

head set or RTS

Audio Intercom LF

A

9

1

X

1

0

8

8

B

9

9

9

1

S

S

X

Installation Technical Manual LDK 20(S) - Studio Camera 2-7

Page 16

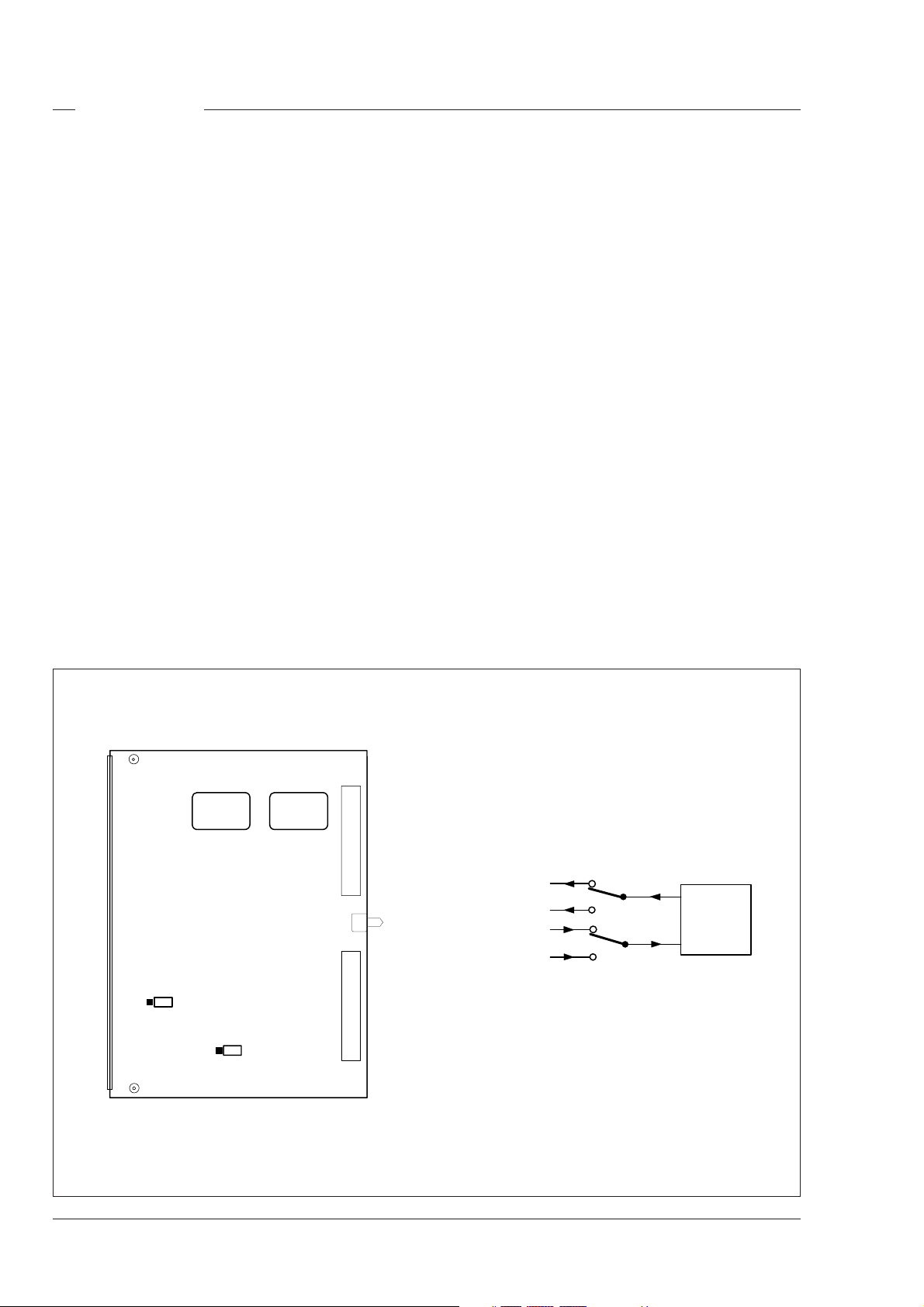

Private Data

Private data channels can be used for the transmission

of serial data via the triax cable. For example, electronic

scriptboard or character data for a video display unit

can be transmitted to the camera.

The tracker microphone intercom channel is used for

the data channel from camera head to base station.

The program intercom channel is used for the data

channel from base station to camera head. The input

and output signals are available on the auxiliary

connectors of the camera and base station (for camera

see the connectors and cables section). If a channel

is used for private data, then of course the original

functions are no longer available.

To select the function of the base station to camera

channel use S801 on the Audio/intercom board. Position

AB selects the Progr function (factory setting); position

AC selects the private data function.

To select the function of the camera to base station

channel use S802 on the Audio/intercom board. Position

AB selects the tracker microphone function (factory

setting); position AC selects the private data function.

Remember that the propagation-delay times are different

for different triax cable lengths, especially if a return

signal is involved. At maximum lengths of 2400

metres the total delay is at least 25 µsec. and can be

more than 30 µsec, depending on the type of triax

cable.

Data signal specifications:

Baudrate: 2400

Input level: TLL, possible RS232

Input impedance: 100Kohm

Output impedance: ~300 ohm

Max load: ~1Kohm

A1

A

9

1

X

Program

Private data

Tracker

Private data

C A B

S801

C A B

S802

TOP SIDE

2-8 Technical Manual LDK 20(S) - Studio Camera Installation

Audio Intercom LF

B

9

1

X

S801

S802

Basestation

Page 17

Connectors and Cables

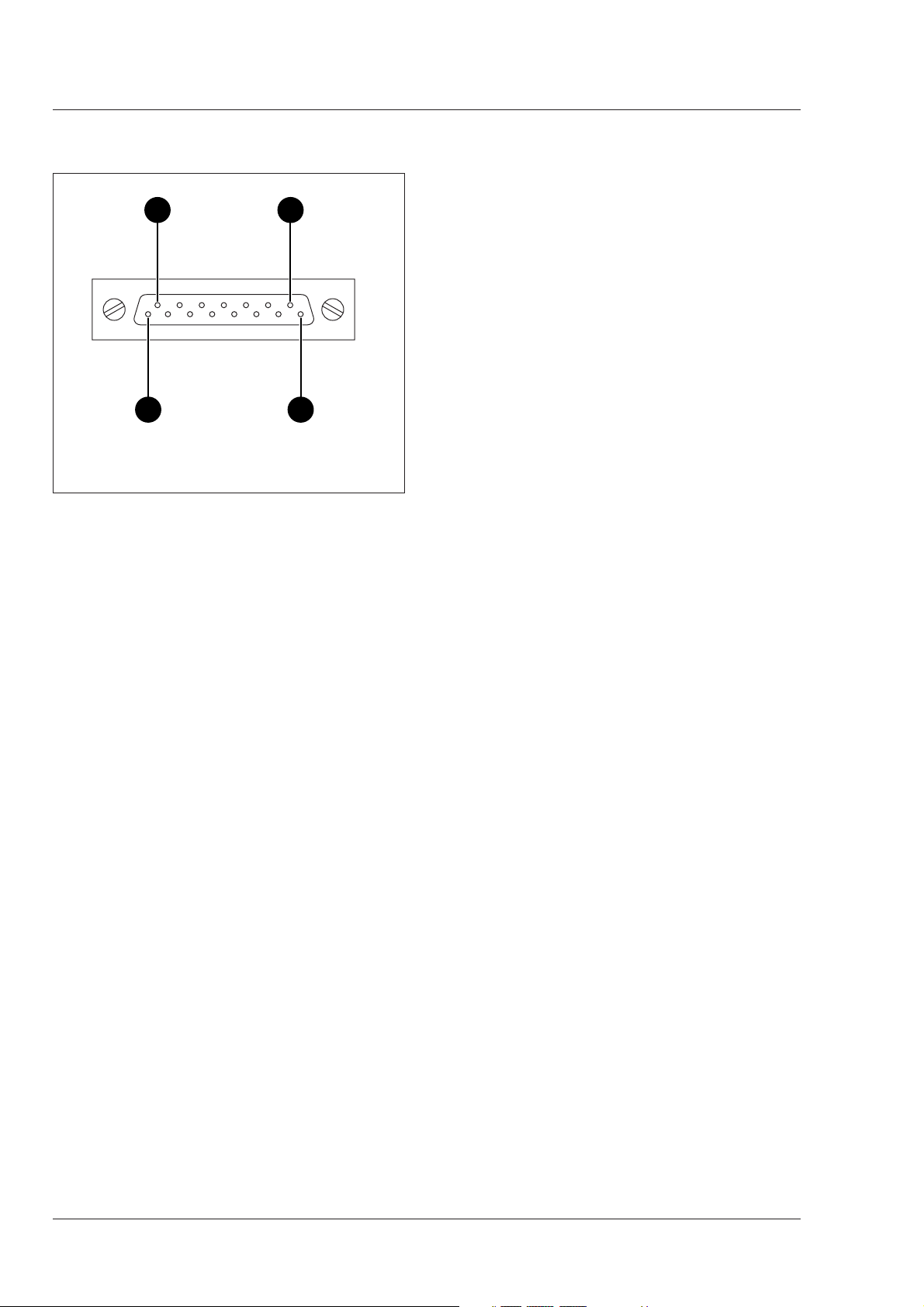

VTR connector

23

18

12

7

1

A

26-pin male; panel view

part number 3922 040 02551

A. + Battery from VTR (10.7 to 17V)

24

22

17

11

6

B

B. Ground

1. CVBS (only available with encoder option present)

2. CVBS Return (only available with encoder option present)

3. Y + S Return

4. Y + S (luminance + sync.)

5. Pr: NTSC 700mV 75% saturated colour bar

Cr: PAL 525mV (EBU N10)

6. Pr/Cr Return

7. Pb: NTSC 700mV 75% saturated colour bar

Cb: PAL 525mV (EBU N10)

8. Pb/Cb Return

9. Not connected

10. Not connected

11. Not connected

12. VTR start/stop: +5V = recording; 0V = stop

13. Not connected

14. Not connected

15. Record/Tally

16. Not connected

17. Camera ground (shield)

18. Playback video input

19. Playback video return

20. Audio monitoring / VTR Save

21. Not connected

22. Not connected

23. Not connected

24. Not connected

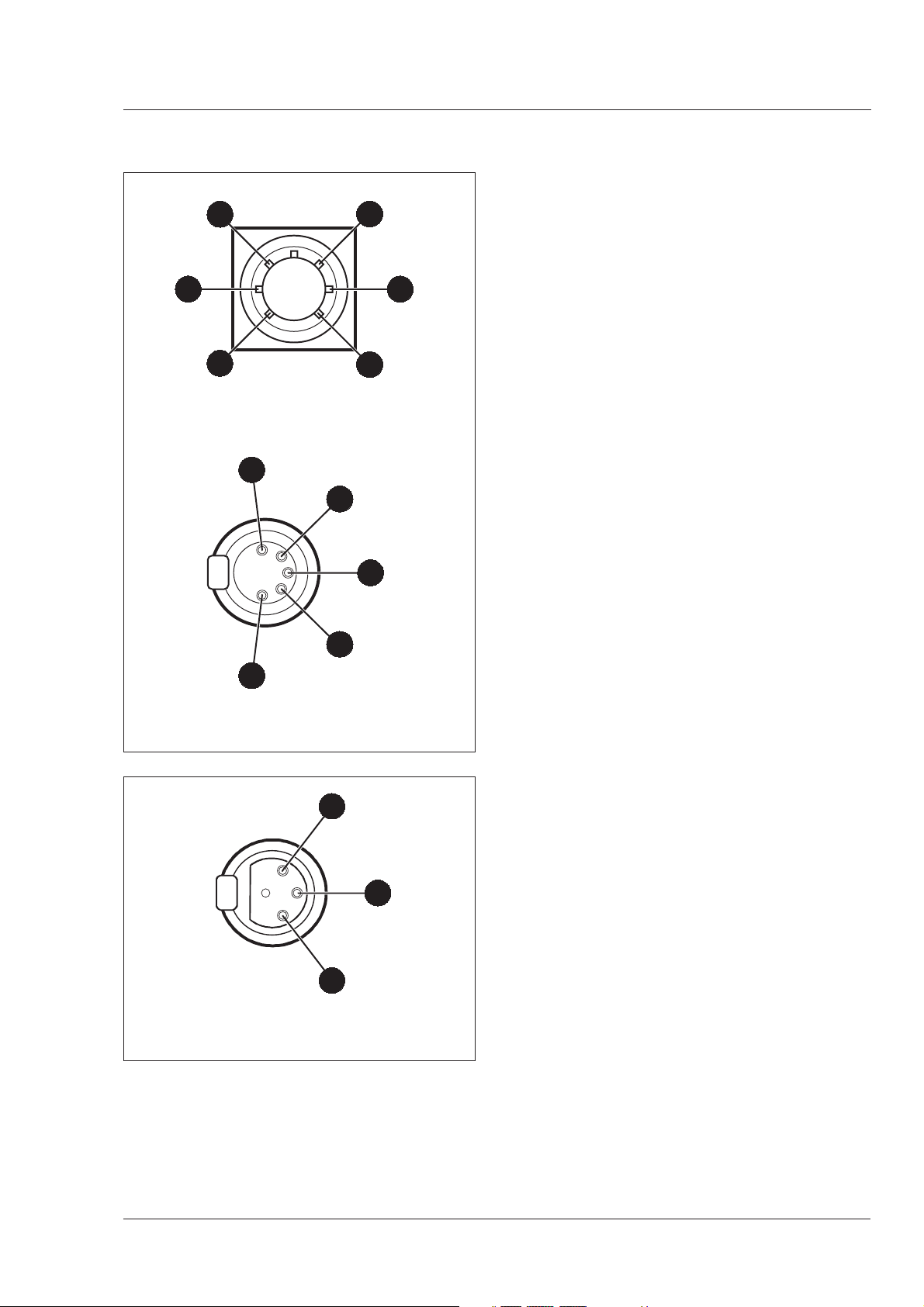

Triax connector

3-pin; panel view

Fischer

1. Inner pin: Signals + power

2. Inner shield: Return

3. Outer shield: Camera housing

part number 2432 020 00009

Trilock

1. Inner pin: Signals + power

2. Inner shield: Return

3. Outer shield: Camera housing

part number 3922 040 02682

ARD

1. Inner pin: Signals + power

2

3

2. Inner shield: Return

3. Outer shield: Camera housing

part number 3922 040 01492

1

LEMO

1. Inner pin: Signals + power

2. Inner shield: Return

3. Outer shield: Camera housing

part number 3922 040 02541

Installation Technical Manual LDK 20(S) - Studio Camera 2-9

Page 18

Viewfinder connector

15-pin female; panel view

part number 3922 406

159

81

1. Video VF (Y + Sync)

2. (R-Y) Video

3. (B-Y) Video

4. Power return

5. Housing

6. +12 Vdc

7. SCL

8. INTN

9. Video VF return

10. (R-Y)/(B-Y) return

11. +12 Vdc

12. Power return

13. Housing

14. On air lamp

15. SDA

2-10 Technical Manual LDK 20(S) - Studio Camera Installation

Page 19

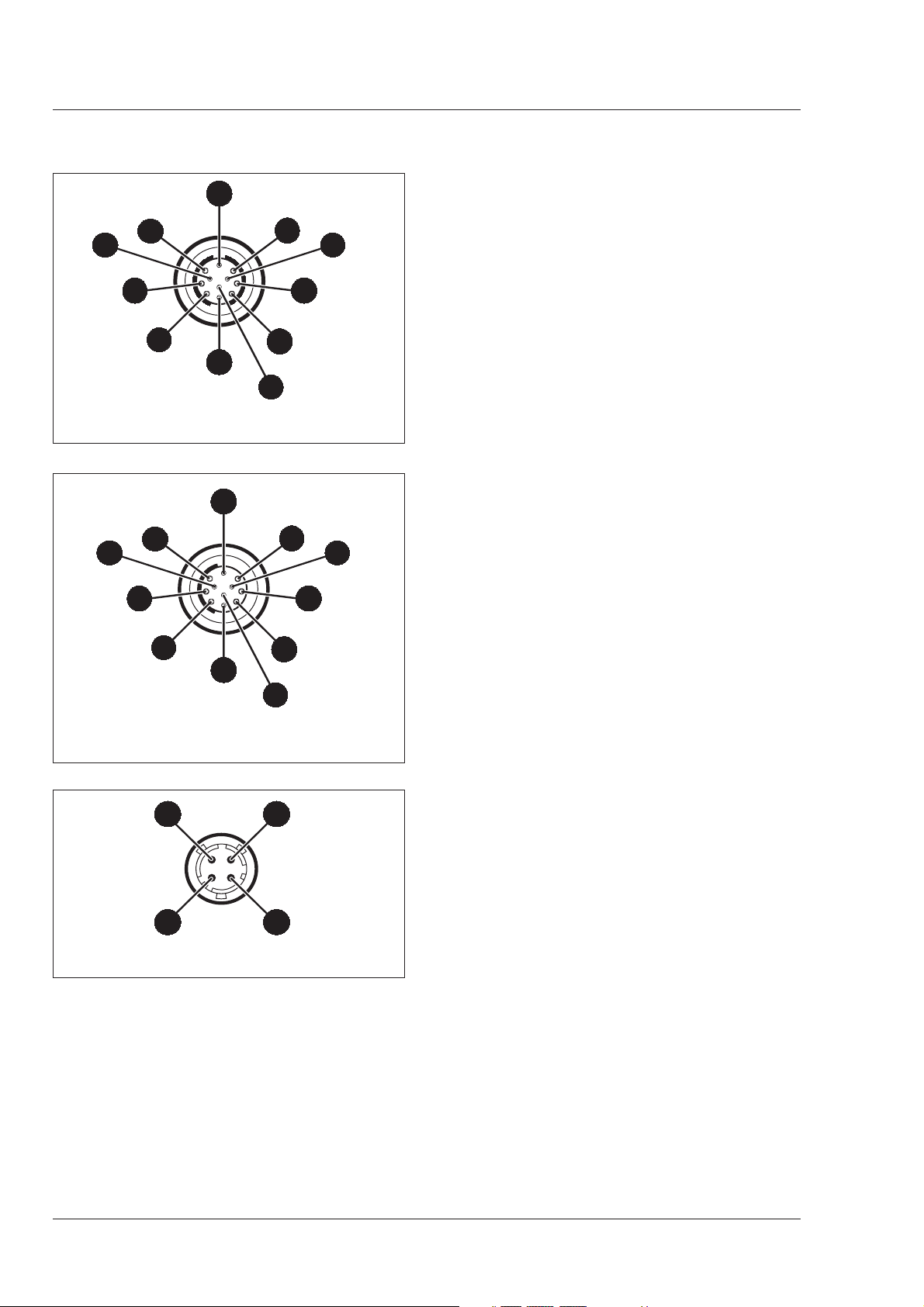

Camera headset connector

1

2

3

Tuchel 6-pin female; panel view

part number 2422 026 02902

1

5

6

1. Telephone left

5

2. Not connected

3. Microphone

4. Microphone return

5. Telephone right

6. Telephone return

4

2

1. Microphone return

2. Microphone

3. Telephone return

4. Telephone left

5. Telephone right

3

• Microphone level -58dBm/-20dBm switchable

• Microphone impedance 200 ohm

4

• Telephone level +6dBm nominal

• Telephone output impedance <10 ohm

XLR 5-pin female; panel view

part number 2432 026 00176

Audio microphone connectors

1

2

XLR 3-pin female; panel view

part number 2422 026 02984

1. Audio Screen

2. Audio In

3. Audio Return

3

• Microphone impedance > 200 ohm

• Sensitivity remote controlled via base station:

range: -70 to -28 dBm

maximum input = -6 dBm

• Signal at pin 2 of audio input is in phase with

signal at pin 2 of audio output on Base Station

Installation Technical Manual LDK 20(S) - Studio Camera 2-11

Page 20

Auxiliary connector

10

11

9

3

4

5

7

6

1

Fischer 11-pin female; panel view

part number 3922 040 02512

Tracker communication connector

1. +5VL

2

8

2. 0VL

3. AN0

4. AN1

5. Spare

6. Not connected

7. Private Data Camera - Base Station

8. Ground

9. Private Data Base Station - Camera

10. Ground

11. Shield

10

11

3

4

5

6

Fischer 11-pin female; panel view

part number 3922 040 02463

Data connector

Souriau 4-pin male; panel view

part number 2411 020 11367

1. On-air signal return

2. Tracker microphone return

3. Tracker microphone input

9

2

8

7

1

4. Production tracker

5. Sidetone tracker

6. Return

7. Program tracker

8. Cameraman microphone

9. Tally control tracker

(Cmos level, R out = 1k)

10. +12V; I max. = 100mA

11. +12V return

• Microphone level -58dBu/-20dBu switchable

• Microphone impedance 200 ohm

• Telephone level + 6dBu

• Telephone output impedance <10 ohm

DA

A. Data

B. Data not

C. Not Connected

D. Shield

CB

2-12 Technical Manual LDK 20(S) - Studio Camera Installation

Page 21

Script light connector

1

2

3

Fischer 3-pin female; panel view

part number 3922 040 02881

1. +12V (Maximum Dissipation 3W)

2. Power Return

3. Shield

Cable connector part numbers

Panel Connector Type Part number Cable part number

VTR 26-pin male 3922 040 02551 VTR cable LDL 2110/ *

Triax 3-pin Fischer female 2432 020 00009 LDK 8200/ **

Triax 3-pin Trilock 3922 040 02682 -Triax 3-pin ARD 3922 040 01492 -Triax 3-pin Lemo 3922 040 02541 -Viewfinder 15-pin Female 3922 406 -Headset 6-pin Tuchel female 2422 026 02902 -Headset 5-pin XLR female 2432 026 00176 -Audio Mic 3-pin XLR female 2422 026 02984 -Auxiliary 11-pin Fischer female (two slot) 3922 040 02512 2432 026 00254 male

Tracker 11-pin Fischer female (one slot) 3922 040 02463 2432 026 00252 male

Data 4-pin Souriau male 2411 020 11367 2411 020 12025 female

Script Light 3-pin Fischer female 3922 040 02881 2432 026 00253 male

Ext video/Tp 2-pin Coax female 2422 031 10529 --

* /02 is 2 m ** /00 for 8 mm cable

/05 is 5 m /10 for 11 mm cable

/10 is 10 m /20 for 14 mm cable

Installation Technical Manual LDK 20(S) - Studio Camera 2-13

Page 22

Specifications LDK20

Camera system

Transmission system

NTSC/PAL

Pick-up device

3 x 2/3-inch Thomson DPM Frame Transfer CCDs

Smear performance

No vertical smear

Aspect ratio

4:3/ 16:9 switchable

Picture elements

4:3 and 16:9 aspect ratio

NTSC: 1000(h) x 498(v)

PAL: 1000(h) x 594(v)

Optical system

F1.4 with quartz filter

Filter cassette with Optical filters

Exchangeable filter cassette with remote selectable 6

positions: Clear; ND 0.6; ND 1.2; ND 1.8; 4-point star;

6-point star

Video performance

Video processing

Hires Digital Processing with 12 bit A/D and 14 bit DSP

technology

Digital features

Flare; White shading; Contrast; Highlight Handling; 6 point

var. Matrix; Matrix-pos.; Gamma; Gamma Curve; Contour

include Skin detail and Extended Contour Gamma;

Leaking Pixel Corr.; VF video

Sensitivity

2000 lux (186 ft cd) at F8.0

Condition: 3200K, reflectance 89.9%, 0 dB gain

Minimum illumination

Approx. 2 lux at F 1.4 and +30 dB gain

S/N ratio at normal gain

Typical: 61 dB PAL and 63 dB NTSC

Remark: +6dB S/N improvement with High Resolution

Digital Noise Slicer

Modulation depth

>70% at 5Mhz in RGB Centre

equivalent 800 TV lines

Remark: >65% at 5Mhz in RGB Centre with High

Resolution Digital Noise Slicer

Registration

<25 ns (0.05%) in all three zones, normal operation and

not including lens errors

Exposure control

Down to 1/1000s

Lighting control

NTSC: nominal, 60 Hz +/-4 Hz

PAL: nominal, 50 Hz +/- 3 Hz

Clean scanning

NTSC: between 61.1 and 151.0 Hz

PAL: between 51.0 and 103.0 Hz

General data

Concept

Studio configuration with PIP on 7-inch VF

Triax cable length

2,400m (7,875 ft) max. with 16mm (0.63") cable

Options for Long Triax available

Head weight (approx.)

26 kg (57.4 lb) excl. 7-inch VF

Head dimensions (lxhxw) in mm (inches) - approx.

367 x 305 x 240 (14.4 x 12 x 9.4)

Ergonomics

Moving VF position for easy camera fixing

Operating ambient temperatures

-20 to +45°C (-4 to +113°F) for Camera Head

0 to +45°C (32 to +113°F) for all other items

Stand alone power required 115/230V ac +/- 15%

Utility power Nominal 70VA

Max. 200VA (cable/system

dep.)

Power consumption 50 W

(Head + VF)

Power consumption 220W incl. Camera Head, VF,

(Average system) 70VA Utility; 700m (2.297ft)

Triax cable and lens

Audio performance

Audio channels 2 channels

Microphone power Selectable 0/+12V/+48V

Input levels at Camera Head -64 dB/ -24 dB/0 dB

Output levels at Base Station 0/+6 dB

Intercom performance

Intercom Headsets on Head Cam.Man

Intercom Channels ENG/PROD/PROG

Input levels at Camera Head -64 dB/-24 dB

Output levels at Base Station 0/+6 dB

Connectors Camera Head

Triax Option: Fischer/ARD/Lemo/

Trilock

Power AC-power connector

Lens 36p

Viewfinder 15p D

Mic In (Audio) 2 x XLR3

Cameraman headset Option: XLR5/Tuchel

Video out Option: 1 Vpp; 75 Ohm; BNC

Genlock in 1 Vpp; 75 Ohm; BNC

VF-out 1 Vpp; 75 Ohm; BNC

TP-video out 1 Vpp; 75 Ohm; BNC

External Camera Control 4p DATA

VTR 26p SMPTE

Scriptlight power 3p; 12V

AUX 11p; private data

Tracker 11p; Communication/Signalling

Connectors Base Station

Triax Option: Fischer/ARD/Lemo/

Trilock

Power AC-power connector

Audio out 2x XLR3

Intercom ENG/PROD/PROG

via 15p D-connector

Signalling Call/Tally R/Y via 15p D-conn.

CVBS (3x) 1 Vpp; 75 Ohm; BNC

RGB 700 mVpp; 75 Ohm; BNC

Y, R-Y, B-Y 700, 525, 525 mVpp; 75 Ohm;

BNC

PXM 1 Vpp; 75 Ohm; BNC

WFM 1 Vpp; 75 Ohm; BNC

Serial Digital (2x) 270 MB/s Option: 800 mV; 75 Ohm; BNC

Ext 1, 2 1 Vpp; 75 Ohm; BNC

Genlock in 1 Vpp; 75 Ohm; BNC

TP-video input 1 Vpp; 75 Ohm; BNC

Ext. Camera Control 4p DATA

Viewfinder

Type 7-inch B/W

Features Picture in Picture; Crosshairs;

Cursorbox

Resolution > 700 TVL

Weight 7 kg (15.4 lb)

Power 30 W

These typical specifications are valid for PAL and NTSC

systems and are subject to change without notice

2-14 Technical Manual LDK 20(S) - Studio Camera Installation

Page 23

Section 3

Replacements

This section gives information on the procedures to follow when replacing printed circuit boards and

mechanical components at first line level.

Contents

Introduction ........................................................ 3-2

Printed circuit boards ......................................... 3-2

Front module ...................................................... 3-3

Replacements Technical Manual LDK 20(S) - Studio Camera 3-1

Filterwheel Cassette ........................................... 3-4

Power supply ..................................................... 3-4

Page 24

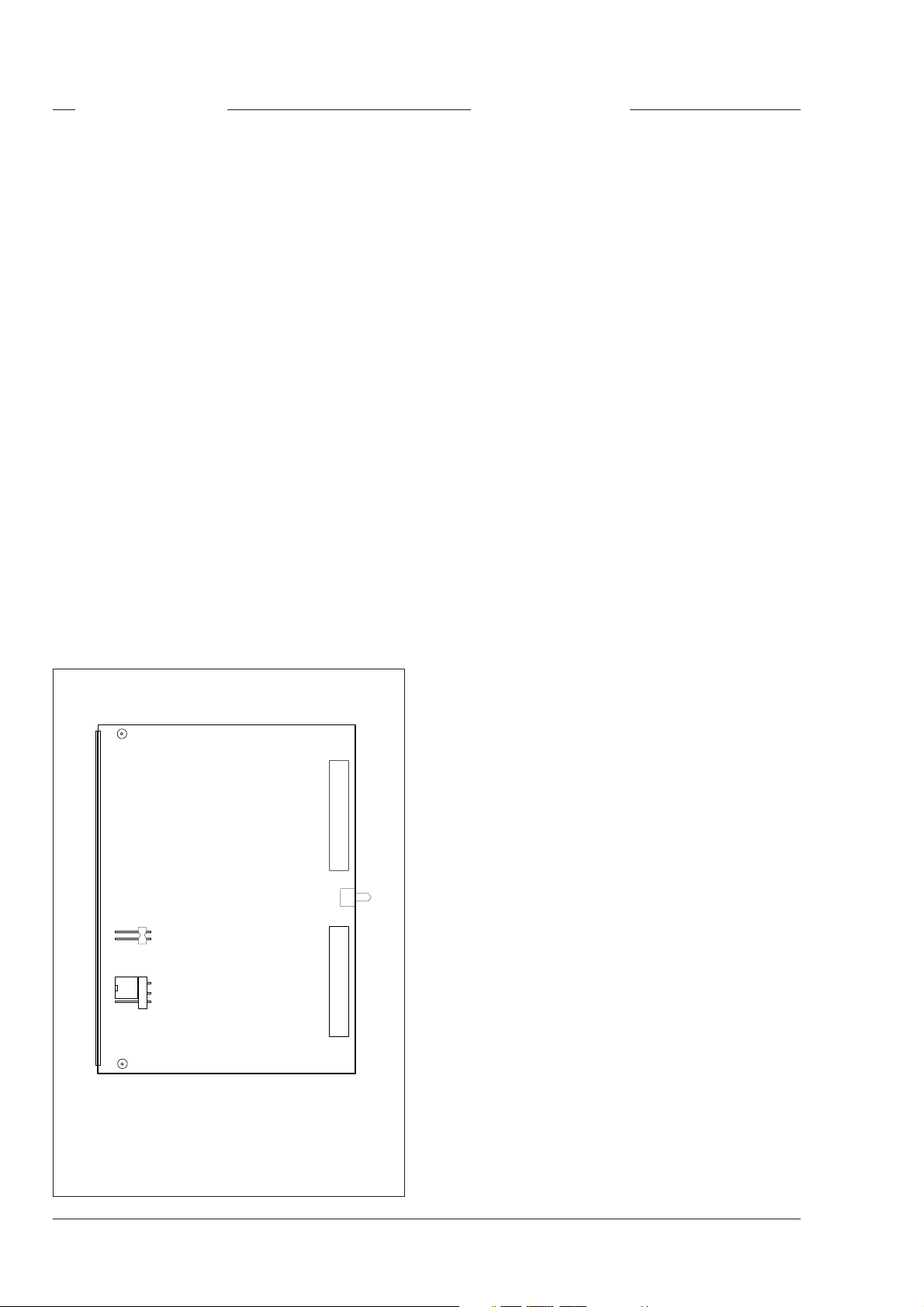

Introduction Printed circuit boards

The instructions given in this section are restricted to

those modules which can be replaced at the first line

level. After a printed circuit board has been replaced it

is sometimes necessary to carry out adjustments to

match the new boards to your camera and so maintain

the performance levels. The relevant adjustment

procedures are referenced in section 4.

The procedures for removing the modules should be

followed in reverse order when remounting the units.

To remove a printed circuit board proceed as follows:

a. Open the side cover (see section 2).

b. Swing the black cover 1 of the printed circuit board

open.

c. Pull horizontally on this cover to free the board from

its connector and slide it clear of the camera.

1

3-2 Technical Manual LDK 20(S) - Studio Camera Replacements

Page 25

Front module

1

1

1

2

2

2

2

1

To remove the front module proceed as follows:

a. On the frontside of the camera remove the four

screws 1 securing the front assembly.

b. Remove the front assembly from the camera.

c. Remove the Front Interconnection Board by

unscrewing two screws from the backside of the

front module.

d. Loosen the four screws 2 securing the front

module.

e. Slide the front module straight out of the front

assembly.

Replacements Technical Manual LDK 20(S) - Studio Camera 3-3

Page 26

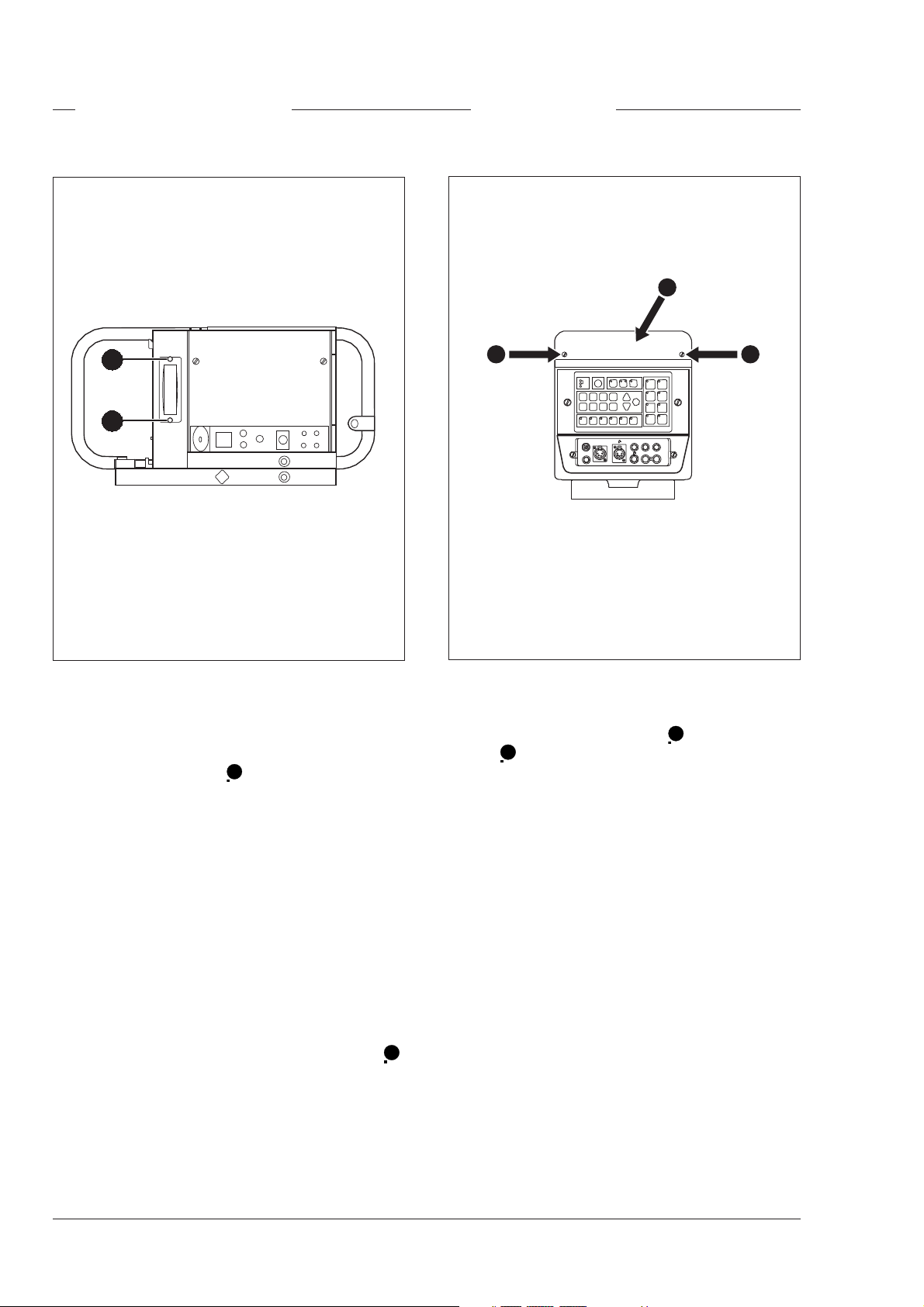

Filterwheel Cassette

Power supply

1

1

1

To remove the filterwheel cassette proceed as follows:

a. Loosen the two screws 1 securing the cover to the

body of the front assembly.

b. Loosen the two screws securing the cassette to the

body of the front module.

c. Use the grip to pull the cassette horizontally out of

the camera.

2 2

On Air

Power

Auto

light Sys/Iso R

T

V

Remote

Camera

install

Function

ABCD

Filter1Filter2Filter3Filter4Filter5Filter

white

View

Audio

Intercom

finder

Select

Function Function Function

6

Script light Progr Prod E

12V 0.25A

R

G

B

-G Call

Ext.1

Ext.2

Y/Ext.

n

g

On

Off

PTT

Before removing the power unit 1 unscrew the two

screws 2 on the top of the camera which secure the

power unit to the camera.

To replace the filtherwheel cassette proceed as follows:

a. Push the cassette horizontally into the camera.

b. Tighten the two screws to secure the cassette to

the body of the front module.

c. Replace the cover and tighten the two screws 1.

3-4 Technical Manual LDK 20(S) - Studio Camera Replacements

Page 27

Section 4

Adjustments

This section contains the adjustment procedures to be followed to obtain the best performance from

the camera. These procedures need only be used if, following a module replacement, the camera

does not perform according to specifications.

Contents

Introduction .......................................................... 4-2

Test Equipment ................................................... 4-3

Set-up Instructions............................................... 4-3

Video Processor 1 Board ..................................... 4-5

Digital Video Processor ..................................... 4-10

Digital Video Processor ..................................... 4-11

Digital Video Processor Subboard .................... 4-12

Digital Video Processor Subboard .................... 4-13

Digital Video Processor ..................................... 4-14

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-1

Digital Video Processor ..................................... 4-15

Video Miscellaneous Board ............................... 4-17

Sync./Shading Board ......................................... 4-27

Video Miscellaneous Board ............................... 4-35

Encoder Board PAL ........................................... 4-37

Encoder Board NTSC ........................................ 4-43

Audio/Intercom LF Board ................................... 4-51

Audio/Intercom LF Board RTS MODE .............. 4-55

Pre-Processor Board ......................................... 4-57

Page 28

Introduction

This camera is factory tested and adjusted for operational

use. Under normal circumstances, the internal

potentiometers do not need to be adjusted.

If it is discovered that the camera is misaligned, the

following procedures are given as a guide for competent

service personnel, who have a thorough knowledge of

the camera and have the use of calibrated equipment,

to realign the camera.

If no improvement can be achieved or an adjustment is

out of range, please contact your local supplier or the

nearest Thomson Multimedia Broadcast Solutions

Service Centre.

The camera head adjustment procedures are designed

as separate units. Within a numbered procedure do not

change the position of switches or jumpers unless

instructed to do so in the procedure.

These adjustment procedures are for the Camera Head.

The adjustments require the use of a Master Control

Panel in combination with an Operational Control

Panel if possible. The intercom adjustments are given

for a four-wire system.

4-2 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 29

Test Equipment

Set-up Instructions

The following is a list of equipment required to carry out

the adjustment procedure:

• Set of board extenders LDK 4830/21

• Oscilloscope (with cursor measurement)

• Spotlight 3200K

• Gamma Test chart 4:3 / 16:9

• Waveform monitor

• Colour monitor

• Multimeter

• Master Control Panel LDK 4607 / LDK 4609

• Operational Control Panel LDK 4624 / LDK 4628 /

LDK 4629

• Audio Analyser

• Base Station LDK 4053

Before carrying out any adjustments the following steps

are recommended:

• Install the camera on a tripod.

• Attach the lens and the necessary cables.

• Allow the camera to warm-up.

• Operate the camera in stand-alone mode

• Connect an MCP and OCP to the data connector on

the right connector panel of the camera.

• When the camera is used in the stand-alone mode,

MCP and OCP always operate in camera select

position 1 (OCP camera select switch in position 1).

CAUTION:

Do not attempt to improve camera performance

by adjusting individual potentiometers, jumpers or switches

as this may lead to complete misalignment of the camera.

CAUTION:

Do not realign individual potentiometers, jumpers or switches

not mentioned in this chapter or earlier in this manual.

These adjustment points are for factory use only.

CAUTION:

Switch off the power supply to the camera

before removing or replacing printed circuit boards.

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-3

Page 30

Extender Board

BA

23

24

22

20

18

16

14

12

10

8

6

4

2

1

3

56

7

9

11

13

15

17

19

21

23

MP

MP

21

19

17

15

13

11

9

7

5

3

1

2

4

8

10

12

14

16

18

20

22

24

MP

MP

S24

S22

S20

S18

S16

S14

S12

S10

S8

S6

S3

S5

S7

S9

S11

S13

S15

S17

S19

S21

S23

S4

S2

S1

BA BA

BA

S23

S21

S19

S17

S15

S13

S11

S9

S7

S5

S3

S1

S4

S6

S8

S10

S12

S14

S16

S18

S20

S22

S24

S2

B - CONNECTOR

A - CONNECTOR

23 24

1

2

24

2

1

23

TOP SIDE

4-4 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 31

Video Processor 1 Board

Setting-up the Camera

Note:

Video Processor 1 must be adjusted in combination with the Sync./Shading board.

1. For local powering of the camera in the stand-alone mode (see User Guide, Section 4).

2. Recall Factory Standard File on MCP or OCP.

On MCP set:

OPERATE MENU

Knee : Off

Contour : Off

Gamma : Lin.

Blk. Str. : Off

Auto Iris : Off

SETUP 1 MENU

Studio mode: Off

Flare : Off

White clip : Off

SETUP 2 MENU

Soft cont. : Off

SETUP 3 MENU

Skin cont. : Off

SETUP 4 MENU

Notch : Off

Chroma : Off

Asp. Ratio : 4:3

SETUP 5 MENU

Matrix sel. : 1:1

MAINT. 1 MENU

Wh. shading: Off

Oscilloscope: 10mV/div. probe 10:1

3. Put Video Processor 1 on a service extender.

4. Remove jumpers 7, 9, 11, 13, 17 and 19 from connector B of the service extender to interrupt the input from

the front and jumpers 6, 12 and 15 to interrupt the black shading correction.

5. Short circuit the input to video processor 1 by connecting the following jumpers on connector B of the service

extender:

B7 to B9

B11 to B13

B17 to B19

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-5

Page 32

Video Processor 1 Board

VP 1

VP1

Slope

Shift

Test

Test

X3

MP630

MP230

MP430

MP0

2

1

B

A

C

MP110

MP100

R112

Slope Test

R108

Shift Test

ZR614

ZR614

offset B

offset B

ZR214

ZR214

offset R

offset R

ZR414

ZR414

offset G

offset G

MP41

MP40

MP450

MP250

MP650

Saw

Saw

Saw

Saw

Saw

Saw

MP80

MP44

ZR611

ZR211

ZR411

MP411

MP411

Dummy

offset B

Dummy

offset R

MP

MP

211

211

Dummy

offset G

MP90

MP611

MP611

23

23

X55

X55

1

1

X56

X56

24

24

R - 12

G - 6

G - 6

R - 12

B - 15

B - 15

2

2

1

12

G - 8

R - 14

B - 20

23

2324

ZR608

MP620

MP220

MP420

X4

ZR111

Ampl

Test

R456

R456

R256

R256

R656

R656

MP610

MP210

MP410

MP240

MP640

Shading

Shading

crosstalk G

crosstalk G

Shading

Shading

crosstalk R

crosstalk R

Shading

Shading

crosstalk B

crosstalk B

ZR608

Black

Black

offset B

offset B

ZR208

ZR208

Black

Black

offset R

offset R

ZR408

ZR408

Black

Black

offset G

offset G

ZR606

Ampl B

ZR206

Ampl R

ZR406

Ampl G

TOP SIDE

Sync./Shading Board

Sync

Shad

ZR137

ZR300

ZR237

ZR238

ZR239

ZR265

ZR266

ZR436

ZR437

ZR438

ZR439

ZR465

ZR466

ZR636

ZR637

ZR638

ZR639

ZR665

ZR236

MP609

ZR666

MP217

MP209

MP417

MP409

MP707

MP706

ZR263

ZR263

ZR463

ZR463

ZR663

ZR663

MP703

MP704

MP705

ZR700

Video Processor 1

ZR710

654321

S1

MP0

ZR92

ZR73

MP10

MP11

3922 406 85840

MP13

MP9

MP12

MP1

23

24

X61

2

1

2

1

X62

24

23

TOP SIDE

Sync./Shading

3922 406 85860

4-6 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 33

Video Processor 1 Board

Black Offset

6. In the Install/Gain menu set the gain for + to 12dB and for ++ to 30dB (the standard values are 6dB and 12dB).

7. While switching between 0dB gain and 30dB gain, adjust black level during the active line to the same as the

clamp level.

Measure at: Adjust with: Required result: Correct: Incorrect:

X56-14(R) ZR208 (R) 0mV (R)

X56-8(G) ZR408 (G) 0mV (G)

10mV

100

90

X56-20(B) ZR608 (B) 0mV (B)

10

0%

Note:

When the standard file is recalled the black levels are set as follows: Master=50, R=50, G=50, B=50.

Vertical sawtooth offset

8. Adjust for no sawtooth information.

Measure at: Adjust with: Required result: Correct: Incorrect:

MP211 ZR214

MP411 ZR414

MP611 ZR614

50mV

100

90

10

0%

10µS

2mS

10mV

100

90

10

0%

50mV

100

90

10

0%

10µS

2mS

9. In the Install/Gain menu reset the gain for + to 6dB and for ++ to 12dB.

10. On service extender, return jumpers 6, 12 and 15 to their positions.

Horizontal Sawtooth

11. Place Sync./Shading board on extender and minimise the horizontal spike information.

Measure at: Adjust with: Required result: Correct: Incorrect:

VP1 Sync/Shad.

X55-12 (R) ZR263 (R) No spike

50mV 20µS

100

90

50mV

100

90

X55-6 (G) ZR463 (G) No spike

X55-15 (B) ZR663 (B) No spike

10

0%

10

0%

12. Remove Sync./Shading board from service extender and return it to its position in the camera.

20µS

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-7

Page 34

Video Processor 1 Board

VP 1

VP1

Slope

Shift

Test

Test

X3

MP630

MP230

MP430

MP0

2

1

B

A

C

MP110

MP110

MP100

R112

R112

Slope Test

Slope Test

R108

R108

Shift Test

Shift Test

MP620

MP220

MP420

X4

Ampl

ZR111

ZR111

Test

Ampl

Test

R456

R256

R656

MP610

MP210

MP410

MP240

MP640

Shading

crosstalk G

Shading

crosstalk R

Shading

crosstalk B

ZR608

Black

offset B

ZR208

Black

offset R

ZR408

Black

offset G

ZR606

Ampl B

Ampl B

ZR206

Ampl R

Ampl R

ZR406

Ampl G

Ampl G

ZR614ZR606

offset B

ZR214ZR206

offset R

ZR414ZR406

offset G

MP41

MP40

MP450

MP250

MP650

Saw

Saw

Saw

MP80

MP44

ZR611

ZR211

ZR411

MP411

Dummy

offset B

Dummy

offset R

MP

211

Dummy

offset G

MP90

MP611

23

X55

1

X56

X56

24

G - 6

R - 12

B - 15

2

1

12

G - 8

G - 8

R - 14

R - 14

B - 20

B - 20

23

2324

TOP SIDE

Video Processor 1

3922 406 85840

4-8 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 35

Video Processor 1 Board

S

Test Sawtooth Nominal Settings

15. Sawtooth amplitude

Measure at: Adjust with: Required result: Correct:

MP110 ZR111 -1000mV

0.2V

100

90

10

0%

16. Sawtooth slope

Set sawtooth amplitude to 100% on oscilloscope, measure between 10% and 90% and adjust slope test.

Measure at: Adjust with: Required result: Correct:

MP110 R112 25 µS

0.2V

100

90

10µS

VA+1.00V

5µS

90%

17. Sawtooth horizontal shift

Set master black level to +10%.

Adjust start sawtooth for 4.5 µS after system blanking.

Measure at: Adjust with: Required result: Correct:

CVBS out R108

Video output

18. Adjust the video output amplitude

Measure at: Adjust with: Required result: Correct:

X56-14 (R) ZR206 (R) 450mV (R)

X56-8 (G) ZR406 (G) 450mV (G)

X56-20 (B) ZR606 (B) 450mV (B)

10

0%

100

90

10

0%

100

90

10

0%

0.2V

t+25.0µS

25µS

0.2V

t+4.50µS

4.5µS

0.1V

VA+450mV

10%

5µS

CVB

10µS

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-9

Page 36

Digital Video Processor

ZR741

MP700

G - 11

R - 21

B - 22

2423

X51

21

21

X52

24 23

ZR341

MP300

ZR541

ZR841

MP500

MP840

ZR725

Black off set

limiter sharp B

ZR325

Black off set

limiter sharp R

ZR525

Black off set

limiter sharp G

ZR830

Black off set

limiter sharp Y

ZR432

Amplitude

Black G

ZR232

Amplitude

Black R

ZR632

Amplitude

Black B

MP430

MP230

MP630

BOTTOM SIDE

Digital Video Processing

3922 406 84950

4-10 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 37

Digital Video Processor

1. Place Digital Video Processor on service extender. Set master black level to 50. Check that individual R, G

and B black levels are set to 50. Switch off test sawtooth.

Black Offset Level

2. Switch on colour bar.

3. Adjust black offset during the active line to the same as the clamp level.

Measure at: Adjust with: Required result: Correct:

VA+1.40V

10µS

10µS

Clamp

level

X51-21 (R) ZR325 (R) 0mV (R)

0.2V

100

90

10

0%

Measure at: Adjust with: Required result: Correct:

X51-11 (G) ZR525 (G) 0mV (G)

0.2V

100

90

10

0%

Measure at: Adjust with: Required result: Correct:

X51-22 (B) ZR725 (B) 0mV (B)

0.2V

100

90

10

0%

VA+1.40V

VA+1.40V

10µS

Clamp

level

Clamp

level

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-11

Page 38

Digital Video Processor Subboard

ZR471

ZR271

ZR671

BOTTOM SIDE

Subboard DSP

Digital Video Processor

ZR741

MP700

G - 11

R - 21

B - 22

2423

X51

21

21

X52

24 23

ZR341

MP300

ZR541

ZR841

MP500

MP840

3922 406 84960

ZR725

Black off set

limiter sharp B

ZR325

Black off set

limiter sharp R

ZR525

Black off set

limiter sharp G

ZR830

Black off set

limiter sharp Y

ZR432

Amplitude

Black G

ZR232

Amplitude

Black R

ZR632

Amplitude

Black B

MP430

MP230

MP630

BOTTOM SIDE

Digital Video Processing

3922 406 84950

4-12 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 39

Digital Video Processor Subboard

Gain DAC.

1. Adjust bar output amplitude.

PAL

Measure at: Adjust with: Required result: Correct:

X51-21 ZR271 (R) +1400mV (R)

Measure at: Adjust with: Required result: Correct:

X51-11 ZR471 (G) +1400mV (G)

Measure at: Adjust with: Required result: Correct:

X51-22 R671 (B) +1400mV (B)

1400 mV

1400 mV

1400 mV

0.2V

100

90

10

0%

0.2V

100

90

10

0%

0.2V

100

90

10

0%

10µS

VA+1.40V

10µS

VA+1.40V

10µS

VA+1.40V

NTSC

Measure at: Adjust with: Required result: Correct:

X51-21 ZR271 (R) +1050mV (R)

1050 mV

Measure at: Adjust with: Required result: Correct:

X51-11 ZR471 (G) +1050mV (G)

1050 mV

Measure at: Adjust with: Required result: Correct:

X51-22 R671 (B) +1050mV (B)

1050 mV

0.2V

100

90

10

0%

0.2V

100

90

10

0%

0.2V

100

90

10

0%

10µS

VA+1.05V

10µS

VA+1.05V

10µS

VA+1.05V

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-13

Page 40

Digital Video Processor

ZR741

G - 11

R - 21

B - 22

Y - 24

2423

X51

21

21

X52

24 23

ZR341

ZR541

MP700

MP300

ZR841

MP500

MP840

ZR725

Black off set

limiter sharp B

ZR325

Black off set

limiter sharp R

ZR525

Black off set

limiter sharp G

ZR830

Black off set

limiter sharp Y

ZR432

Amplitude

Black G

ZR232

Amplitude

Black R

ZR632

Amplitude

Black B

MP430

MP230

MP630

BOTTOM SIDE

Digital Video Processing

3922 406 84950

4-14 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 41

Digital Video Processor

Gain Video

1. Place Digital Video Processor on service extender.

2. Switch off colour bar and Test sawtooth on.

3. Adjust white output amplitude.

Measure at: Adjust with: Required result: Correct:

X51-21 (R) ZR232 (R) +1400mV (R)

X51-11 (G) ZR432 (G) +1400mV (G)

X51-22 (B) ZR632 (B) +1400mV (B)

White limiter

4. Set gain to +6dB. In setup 1 menu set white clip on.

Set individual white limiter to: Master G = 60, R = 60, B = 60.

5. Adjust output for a video clip level of 102%.

Measure at: Adjust with: Required result: Correct:

X51-21 (R) ZR341 (R) +1428mV (R)

X51-11 (G) ZR541 (G) +1428mV (G)

X51-22 (B) ZR741 (B) +1428mV (B)

0.5V

100

90

10

0%

0.5V

100

90

10

0%

10µS

VA+1.40V

10µS

VA+1.43V

Output amplitude readjustment

6. Set gain to 0dB. In setup 1 menu set white clip off.

7. Readjust white output amplitude.

Measure at: Adjust with: Required result: Correct:

X51-21 (R) ZR232 (R) +1400mV (R)

X51-11 (G) ZR432 (G) +1400mV (G)

X51-22 (B) ZR632 (B) +1400mV (B)

VF-Mon output

8. Test sawtooth on.

9. Adjust Y-output amplitude.

10. Adjust output dc level

Measure at: Adjust with: Required result: Correct:

X52-24 ZR841 +1400mV

ZR830 0mVdc

0.5V

100

90

10

0%

0.2V

100

90

10

0%

VA+1400mV

10µS

VA+1.40V

10µS

11. Return Digital Video Processor to its position in the camera.

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-15

Page 42

Video Miscellaneous Board

Video

Video

Misc

Misc

ZR600

ZR601

ZR200

ZR201

Wh. Pulse

BMux Ampl.

Gain

BMux

ZR400

ZR401

White Pulse

RMux Ampl.

Gain

RMux

MP3

MP11

MP10

MP8

ZL4

ZL4

ZR94 B-Y Level

ZR93 R-Y Level

White Pulse GMux Ampl.

Gain GMux

ZR85

ZR85

MP0

MP2

MP9

ZR283

End Stop

Viewfinder

MP4

Indicator

ZR187

ZR91

ZR91

Balance

Balance

Sync.

Sync.

Ampl.

Ampl.

Peak/Average

ZR111

White

White

Mon.Video Level

R/G/B/Y/VFCNT

ZR92

ZR92

Composite

Composite

Y Level

Y Level

Black

ZR47

Indicator

Level

ZR88

ZR90

ZR247

Cadre

Contrast

Start

Focus Bar

Start

Zoom Bar

MP6

MP5

MP7

36

36

12

12

12

36

Y - 11

TOP SIDE

Video Miscellaneous

3922 406 85070

4-16 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 43

Video Miscellaneous Board

1. Place Video Miscellaneous Board on service extender.

VF sync. oscillator

2. Test sawtooth off.

3. Adjust VF sync. frequency.

Measure at: Adjust with: Required result:

MP2 ZL4 +2.5V DC level

Output amplitude

4. Test sawtooth on.

5. Adjust Y output amplitude.

Measure at: Adjust with: Required result: PAL NTSC

X17A-11 ZR92 +1400mV PAL

+1428mV NTSC

0.2V

100

90

10µS

0.2V

100

90

10µS

10

0%

VA+1400mV

10

0%

VA+1428mV

6. Adjust Y sync. output amplitude.

Measure at: Adjust with: Required result: PAL NTSC

X17A-11 ZR85 -600mV PAL

-572mV NTSC

0.2V

100

90

10

0%

10µS

VA-600mV

0.2V

100

90

10

0%

10µS

VA-572mV

R-Y / B-Y white balance

7. Test sawtooth off

8. Colour bar on.

9. Connect oscilloscope, via a vectorscope terminated with 75 Ohm, to the CVBS output of the camera and

adjust for a minimum unbalance in white.

Measure at: Adjust with: Required result: Correct: Incorrect:

CVBS out ZR91

11

10

0.9

0.8

0.7

0.6

0.5

0.4

0.2

0.1

11

10

0.9

0.8

0.7

0.6

0.5

0.4

0.2

0.1

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-17

Page 44

Video Miscellaneous Board

0

Video

Video

Misc

Misc

ZR600

ZR601

ZR601

ZR200

ZR201

ZR201

Wh. Pulse

BMux Ampl.

Gain

Gain

BMux

BMux

ZR400

ZR401

ZR401

White Pulse

RMux Ampl.

Gain

Gain

RMux

RMux

MP3

MP11

MP10

ZL4

MP8

ZR94 B-Y Level

ZR94 B-Y Level

ZR93 R-Y Level

ZR93 R-Y Level

White Pulse GMux Ampl.

Gain GMux

Gain GMux

ZR85

MP0

MP2

MP9

ZR283

End Stop

Viewfinder

MP4

Indicator

ZR187

ZR91

Balance

Sync.

Ampl.

Peak/Average

ZR111

White

Mon.Video Level

R/G/B/Y/VFCNT

ZR92

Composite

Y Level

Black

ZR47

Indicator

Level

ZR88

ZR90

ZR247

Cadre

Contrast

Start

Focus Bar

Start

Zoom Bar

MP6

MP5

MP7

36

36

12

12

12

36

R/Y - 1

B/Y - 16

R -27

G - 19

B - 23

TOP SIDE

Video Miscellaneous

3922 406 85070

4-18 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 45

Video Miscellaneous Board

R-Y amplitude

10. Adjust R-Y output amplitude.

Measure at: Adjust with: Required result: Correct:

X17A-10 ZR93 1400mV

B-Y amplitude

11. Adjust B-Y output amplitude.

Measure at: Adjust with: Required result: Correct:

X17A-16 ZR94 1400mV

0.2V

100

90

10

0%

0.2V 10µS

100

90

10

0%

10µS

VA+1400mV

VA+1400mV

Video Mux output

12. Colour bar off.

13. Test sawtooth on.

14. Adjust R-Mux output.

Measure at: Adjust with: Required result: Correct:

X17A-27 ZR200 700mV

15. Adjust G-Mux output.

Measure at: Adjust with: Required result: Correct:

X17A-19 ZR400 700mV

16. Adjust B-Mux output.

0.1V

100

90

10

0%

0.2V 10µS

100

90

10

0%

10µS

VA+700mV

VA+700mV

Measure at: Adjust with: Required result: Correct:

X17A-23 ZR600 700mV

0.1V

100

90

10

0%

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-19

10µS

VA+700mV

Page 46

Video Miscellaneous Board

Video

Video

Misc

Misc

ZR600

ZR600

ZR601

ZR200

ZR200

ZR201

Wh. Pulse

Wh. Pulse

BMux Ampl.

BMux Ampl.

Gain

BMux

ZR400

ZR400

ZR401

White Pulse

White Pulse

RMux Ampl.

RMux Ampl.

Gain

RMux

MP3

MP11

MP10

ZL4

MP8

ZR94 B-Y Level

ZR93 R-Y Level

White Pulse GMux Ampl.

White Pulse GMux Ampl.

Gain GMux

ZR85

MP0

MP2

MP9

ZR283

End Stop

Viewfinder

MP4

Indicator

ZR187

ZR91

Balance

Sync.

Ampl.

Peak/Average

ZR111

ZR111

White

Mon.Video Level

Mon.Video Level

R/G/B/Y/VFCNT

R/G/B/Y/VFCNT

ZR92

Composite

Y Level

Black

ZR47

Indicator

Level

ZR88

ZR90

ZR247

Cadre

Contrast

Start

Focus Bar

Start

Zoom Bar

MP6

MP5

MP7

36

36

12

12

12

36

R -27

G - 19

B - 23

TOP SIDE

Video Miscellaneous

3922 406 85070

4-20 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 47

Video Miscellaneous Board

White pulse amplitude

17. Connect camera to a base station and switch to Triax mode.

18. Adjust the white pulse in line 10 (PAL), in line 13 (NTSC) for the R-Mux output.

Measure at: Adjust with: Required result: Correct:

X17A-27 ZR201 700mV

100

90

10

0%

19. Adjust the white pulse in line 10 (PAL), in line 13 (NTSC) for the G-Mux output.

Measure at: Adjust with: Required result: Correct:

X17A-19 ZR401 700mV

100

90

10

0%

20. Adjust the white pulse in line 11 (PAL), in line 14 (NTSC) for the B-Mux output.

Measure at: Adjust with: Required result: Correct:

X17A-23 ZR601 700mV

100

90

10

0%

21. Set up camera in the stand-alone mode again.

Monitoring camera output

22. Use the controls at the rear panel of the camera to select the Y signal for the monitoring output by navigating

through the menu system.

23. Connect oscilloscope terminated with 75 Ohm to the VF output of the camera.

24. Adjust the amplitude of the VF output signal.

Measure at: Adjust with: Required result: Correct:

VF output ZR111 PAL 700mV

NTSC 714mV

(100IRE)

0.2V

100

90

10

0%

10µS

VB+700mV

Adjustments Technical Manual LDK 20(S) - Studio Camera 4-21

Page 48

Video Miscellaneous Board

Video

Video

Misc

Misc

ZR600

ZR601

ZR200

ZR201

Gain

BMux

Wh. Pulse

BMux Ampl.

ZR400

ZR401

Gain

RMux

White Pulse

RMux Ampl.

MP3

MP11

MP10

MP8

ZR94 B-Y Level

ZR93 R-Y Level

Gain GMux

White P ulse GMux Ampl.

ZR85

MP0

MP2

MP9

ZR283

End Stop

Viewfinder

MP4

Indicator

ZR187

ZR91

Balance

Sync.

Ampl.

Peak/Average

ZR111

White

Mon.Video Level

R/G/B/Y/VFCNT

ZR92

Composite

Black

ZR47

Indicator

Level

ZR88

ZR90

Y Level

Start

Focus Bar

Start

Zoom Bar

ZR247

Cadre

Contrast

MP6

MP5

MP7

36

X17A

12

12

X17B

36

Extender Board

BA

23

24

22

20

18

16

14

12

10

8

6

4

2

1

3

56

7

9

11

13

15

17

19

21

23

MP

MP

21

19

17

15

13

11

9

7

5

3

1

2

4

8

10

12

14

16

18

20

22

24

MP

MP

S24

S22

S20

S18

S16

S14

S12

S10

S8

S6

S3

S5

S7

S9

S11

S13

S15

S17

S19

S21

S23

S4

S2

S1

BA BA

Video Miscellaneous

BA

S23

S21

S19

S17

S15

S13

S11

S9

S7

S5

S3

S1

S2

S4

S6

S8

S10

S12

S14

S16

S18

S20

S22

S24

B - CONNECTOR

A - CONNECTOR

3922 406 85070TOP SIDE

23 24

2

1

1

2

23

24

TOP SIDE

4-22 Technical Manual LDK 20(S) - Studio Camera Adjustments

Page 49

Video Miscellaneous Board

Black indicator level