Page 1

®

02 • 07 • 01

Model EAP 110

GENERATOR SET ANNUNCIATOR

• 20 Light annunciator meets or

exceeds requirements of NFPA 110,

NFPA 99 & CSA 282-00 building code

standards for Emergency Standby

Generator systems

• RS 422 Data Communication capability

saves installation time & reduces costs

• Programmable annunciation & labeling

allows excellent flexibility for different

applications

• Automatic “ringback” & flashing

annunciator lights provides excellent

status indication of existing & incoming

fault conditions

DESCRIPTION

he EAP 110 annunciator is designed for remote fault

annunciation of emergency standby generator sets

T

utilizing Thomson Technology MEC 2 & MEC 20 Engine

Controllers. The advanced design uses a RS 422

communication data link to provide the control &

monitoring signals between the engine controller and

remote annunciator. The communication link allows a

simple, cost effective system installation at any building

site. Up to 20 individual fault conditions are remotely

monitored utilizing both visual LED lights & audible

alarm annunciation. Lamp test and alarm horn silence

pushbuttons are provided. Each fault is individually

programmable for audible horn operation and alarm

labels are field configurable. Operation logic includes a

•4 fault annunciation circuits can be

activated from external hardwired

contacts for added system capability

• Multiple EAP 110 Annunciators can be

easily interconnected to provide up to 40

remote annunciation lights from a single

MEC 20 engine controller

“auto-ringback” feature to annunciate subsequent alarm

conditions. For applications requiring additional alarm

annunciation from remote sensing contacts, the EAP 110

can accept up to 4 hardwired contact inputs dependant

upon the alarm configuration. The EAP 110 is DC powered

typically from a 12 or 24V engine starting battery. Two

EAP 110 annunciators can be interconnected together via

the communication link to allow up to 40 remote

annunciator points from a single MEC 20 engine controller

(consult Thomson Technology for further details). The

standard features of the EAP 110 meet and exceed all

requirements of NFPA 110, NFPA 99 & CSA 282-00

building code standards for Emergency Standby

Generator systems.

THOMSON TECHNOLOGY INC. • 9087A - 198th STREET, LANGLEY, BC CANADA V1M 3B1

TELEPHONE: (604) 888-0110 • FAX: (604) 888-3381 • E-MAIL: info@thomsontechnology.com • www.thomsontechnology.com

ISO 9001-2000

Page 2

SPECIFICATIONS

SUPPLY VOLTAGE 12V or 24V nominal (± 20%), negative ground

SUPPLY CURRENT 100 ma (maximum), (± 20%)

COMMUNICATION PORT RS 422, 4.8 KBaud, Thomson Technology T-Net Protocol

to MEC 2/MEC 20 8 conductor #22 AWG (min) Shielded/

Twisted cable (1000 ft Max), Plug-in RJ45 Connector

DIGITAL CONTACT INPUT Close to DC Negative

TEMPERATURE RANGE -40° C to +50° C

ENVIRONMENTAL Faceplate NEMA 12, Rear Enclosure NEMA 1

DIMENSIONS 6.0” W x 6.0” H x 3.0” D

Flush mount adapter option (7.0” w x 7.0” H)

MOUNTING Surface Mount (Standard), Flush-mount (Optional) Rear

Enclosure conduit box c/w Qty 8 1/2” knockouts

ORDERING INFORMATION

The EAP 110 may be ordered separately or in conjunction with unit mount control panels or engine controllers.

When ordering for use with existing MEC 2/MEC 20 engine controller applications in the field, contact Thomson

Technology for additional information regarding software/hardware compatibility.

The EAP 110 is supplied from the factory with standard alarm labeling for MEC 2* or MEC 20* engine controllers which

are applied to meet NFPA 110 Level 1/NFPA 99 or CSA 282 alarm requirements. The standard EAP 110 can be labeled and

programmed for alternate alarm configurations (consult Thomson Technology for further information). When specified, the

optional flush mount adapter plate is supplied loose with the standard Annunciator for field installation.

EXAMPLE:

EAP 110 – S

BASIC MODEL

MOUNTING

S=SURFACE(Standard)

F=FLUSH(Optional)

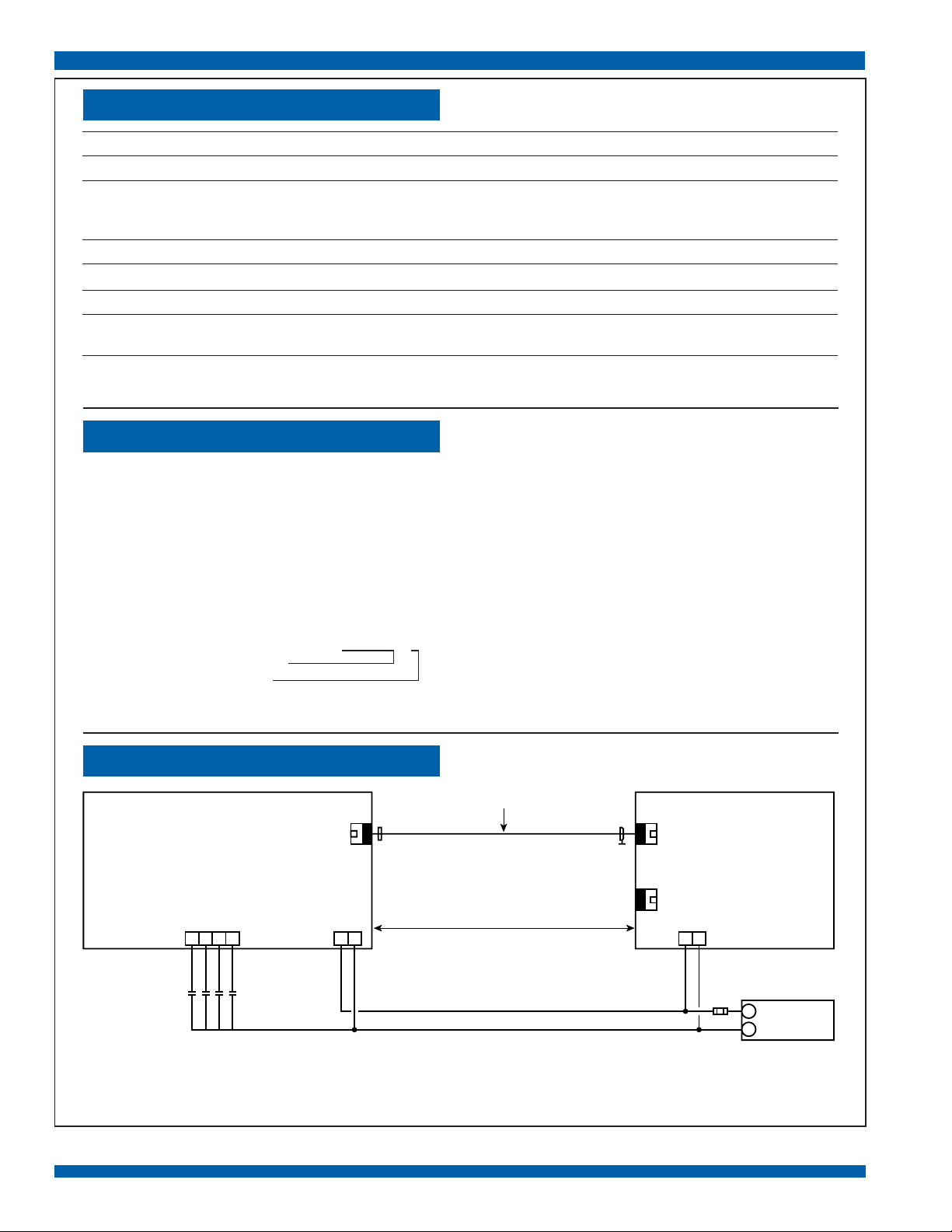

EXTERNAL CONNECTIONS

EAP 110

J1

Annunciator

Ext1 Ext2 Ext3 Ext4 B+ B- B+ B-

OOOOOO

External Alarm

Sensing Contacts

(optional use

as required)

** 8 conductor Shielded Twisted Cable c/w RJ45 connectors.

NOTE: Specifications subject to change without notice.

CL057 REV 0 02/07/01

*Note: For MEC 2 / MEC 20 details refer to separate brochures.

Communication

Cable**

J6

MEC 2/20

Engine

Controller

J7

OO

12-24V Engine

Cranking Battery

1000' maximum cable length

Connection

GRD

No

Expansion

Port

Communication

Port

+

-

THOMSON TECHNOLOGY INC. • 9087A - 198th STREET, LANGLEY, BC CANADA V1M 3B1

TELEPHONE: (604) 888-0110 • FAX: (604) 888-3381 • E-MAIL: info@thomsontechnology.com • www.thomsontechnology.com

Loading...

Loading...