Page 1

Gecko Frames

8900 SIGNAL PROCESSING SYSTEM

Instruction Manual

071063603

MARCH 2005

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2Gecko Frames Instruction Manual

Page 3

Contents

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terms in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FCC Emission Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 1 — Gecko 8900 Series Frames

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Frame Options and Upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8900TX Convection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8900TF Forced-air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8900TFN Networked System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Frame Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Network Configuration Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Frame Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Calculating Frame Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Frame Monitor and Network Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 2 — Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Rack Mounting the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rear Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Loop-through Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Direct Input/Output Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame Alarm Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Frame Alarm Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Frame Alarm Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Gecko Frames Instruction Manual 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 4

Contents

Section 3 — Power Up

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

120 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

240 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Line Cord Retainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 4 — Monitoring and Control

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Frame Monitor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Enabling Alarms and Fan Speed Control Option . . . . . . . . . . . . . . . . . . . . . . . . 39

Frame Monitor Module Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Section 5 — Specifications

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Frame Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix – 8900 Frames Archive

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Identifying Frame Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Network Configuration Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Video Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

SMPTE Alarm Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Audio Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4Gecko Frames Instruction Manual

Page 5

Preface

About This Manual

This manual provides installation and safety and regulatory information

for the Gecko 8900 Series Video and Audio frames for housing Grass Valley

8900 Series modules.

An Appendix to this manual provides summary archive information on

previously released 8900 frames.

Gecko Frames Instruction Manual 5

Page 6

Preface

6Gecko Frames Instruction Manual

Page 7

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Terms on the Product

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

CAUTION Caution statements identify conditions or practices that may result in damage

The following terms may appear on the product:

DANGER

the marking.

WARNING

sible as you read the marking.

sonal injury or loss of life.

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

— A personal injury hazard is immediately accessible as you read

— A personal injury hazard exists but is not immediately acces-

CAUTION

Gecko Frames Instruction Manual 7

— A hazard to property, product, and other equipment is present.

Page 8

Safety Summary

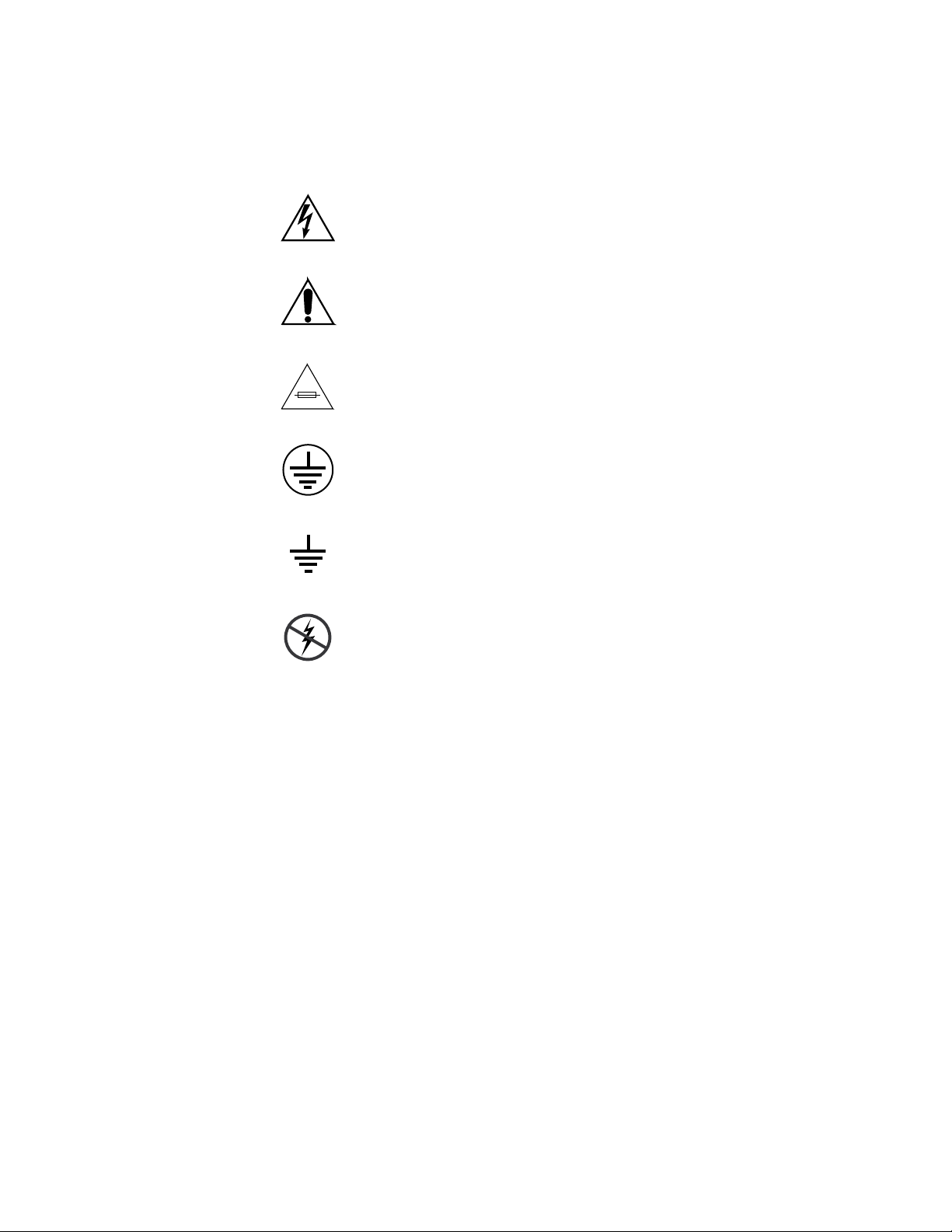

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Warnings

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other equipment

connections.

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present

battery (if applicable) before removing protective panels, soldering, or

replacing components.

— Disconnect power and remove

Do not service alone

person capable of rendering first aid and resuscitation is present.

Remove jewelry

and other metallic objects.

Avoid exposed circuitry

circuitry when power is present.

8Gecko Frames Instruction Manual

— Do not internally service this product unless another

— Prior to servicing, remove jewelry such as rings, watches,

— Do not touch exposed connections, components or

Page 9

Safety Summary

Use proper power cord

this product.

Ground product

earth ground.

Operate only with covers and enclosure panels in place

product when covers or enclosure panels are removed.

Use correct fuse

product.

Use only in dry environment

Use only in non-explosive environment

explosive atmosphere.

High leakage current may be present

before connecting power.

Dual power supplies may be present

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Double pole neutral fusing

— Use only the power cord supplied or specified for

— Connect the grounding conductor of the power cord to

— Do not operate this

— Use only the fuse type and rating specified for this

— Do not operate in wet or damp conditions.

— Do not operate this product in an

— Earth connection of product is essential

— Be certain to plug each power supply

— Disconnect mains power prior to servicing.

Cautions

Use proper lift points

Avoid mechanical hazards

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source

that applies more than the voltage specified for the product.

Use correct voltage setting

plies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation

ment ventilation in accordance with installation instructions.

Use anti-static procedures

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

— Do not use door latches to lift or move equipment.

— Allow all rotating devices to come to a stop before

— Do not operate this product from a power source

— If this product lacks auto-ranging power sup-

— To prevent product overheating, provide equip-

— Static sensitive components are present which

Gecko Frames Instruction Manual 9

Page 10

Safety Summary

Do not operate with suspected equipment failure

damage or equipment failure, have the equipment inspected by qualified

service personnel.

Ensure mains disconnect

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

— If mains switch is not provided, the power cord(s)

— Route power cords and other cables so that they ar not

— Power cords for this equipment, if provided,

— This product may contain batteries. To

— If you suspect product

Troubleshoot only to board level

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot systems beyond the board level.

— Circuit boards in this product are densely

10 Gecko Frames Instruction Manual

Page 11

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

Gecko Frames Instruction Manual 11

Page 12

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Laser Compliance

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

Laser Safety Requirements

The device used in this product is a Class 1 certified laser product. Operating this product outside specifications or altering from its original design

may result in hazardous radiation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S. regulations contained in 21CFR Chapter1, subchapter J or CENELEC regulations

in HD 482 S1. People performing such an act are required by law to recertify and reidentify this product in accordance with provisions of 21CFR

subchapter J for distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The international Electrotechnical Commission (IEC) Standard 825, “Radiation of Laser Products, Equipment Classification, Requirements and

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected trough a 7 mm aperture at a

distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compliance: The radiant power is detected trough a 7 mm aperture

at a distance of 100 mm from the source focused through a lens with a focal

length of 100 mm.

12 Gecko Frames Instruction Manual

Page 13

FCC Emission Limits

Certification

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may no cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

Category Standard Designed/tested for compliance with:

Safety ANSI/UL60950 Safety of Information Technology Equipment, including Electrical

IEC 60950 Safety of Information Technology Equipment, including Electrical

CAN/CSA C22.2, No. 60950-00Safety of Information Technology Equipment, including Electrical

BSEN60950 Safety of Information Technology Equipment, including Electrical

Business Equipment (Third edition, 2000).

Business Equipment (Third edition, 1999).

Business Equipment.

Business Equipment.

Gecko Frames Instruction Manual 13

Page 14

Regulatory Notices

14 Gecko Frames Instruction Manual

Page 15

Gecko 8900 Series Frames

Introduction

The Grass Valley Gecko™ 8900 Signal Processing System is a family of conversion, distribution, timing, and processing modules which provides

support for a wide variety of signal processing applications.

Two Gecko 8900 Series frame types are available to support these modules:

• 8900 BNC/Video – providing BNC input/output connectors for video

modules, and

• 8900 Balanced Audio – providing four BNC connectors and 10 three terminal audio connectors for balanced input/output connections for

audio modules.

Section

1

Note

Key features of the Gecko 8900 Series frames include:

• Support of all Grass Valley 8900 Series modules,

•Wide range of analog and digital functions,

• 10 module slots in each 2 RU frame,

•Analog/digital passive loop-through inputs,

• 100 W power supplies, each with independent AC main inputs and

• LEDs on front cover for fault and power supply status,

• Self-contained variable speed cooling,

• Ethernet control and monitoring,

• Serial interface for IP Address configuration and Frame Alarm output,

•IP network identity stored in non-volatile frame memory.

Refer to the documentation for each 8900 module for frame compatibility

information.

integrated cord retention,

and

Gecko Frames Instruction Manual 15

Page 16

Section 1 — Gecko 8900 Series Frames

The power usage of 8900 modules varies greatly from less complex analog

to higher complexity digital modules. To handle these power requirements

and offer more control and monitoring flexibility, both frame types are

offered in 8900TX, TF, and TFN models.

These models provide:

• 8900TX-V/TX-A – Vented cover for passive cooling and single 100 W

power supply for modules outputting up to 30 W power,

• 8900TF-V/TF-A – Fan front cover with a variable fan speed mode and

a single 100 W power supply, and

• 8900TFN-V/TFN-A – Fan front cover, 100W power supply, and

Ethernet capability for remote control and monitoring using a webbased GUI (Graphical User Interface) with the 8900NET Network Interface Module.

An 8900 Video frame can house 8900 Series video modules and Grass

Valley 8500 or 8800 analog distribution amplifiers (except the 8510R). The

frame can house from one to ten 8900 video modules depending upon

power requirements.

The 8900 Audio frame offers the same power, cooling, and control options

as the 8900 Video frame while providing a backplane with three-terminal

connectors for balanced audio inputs and outputs. Each audio module slot

provides 10 three-terminal connectors and four BNC connectors for functions determined by the specific audio module installed.

Frame Options and Upgrades

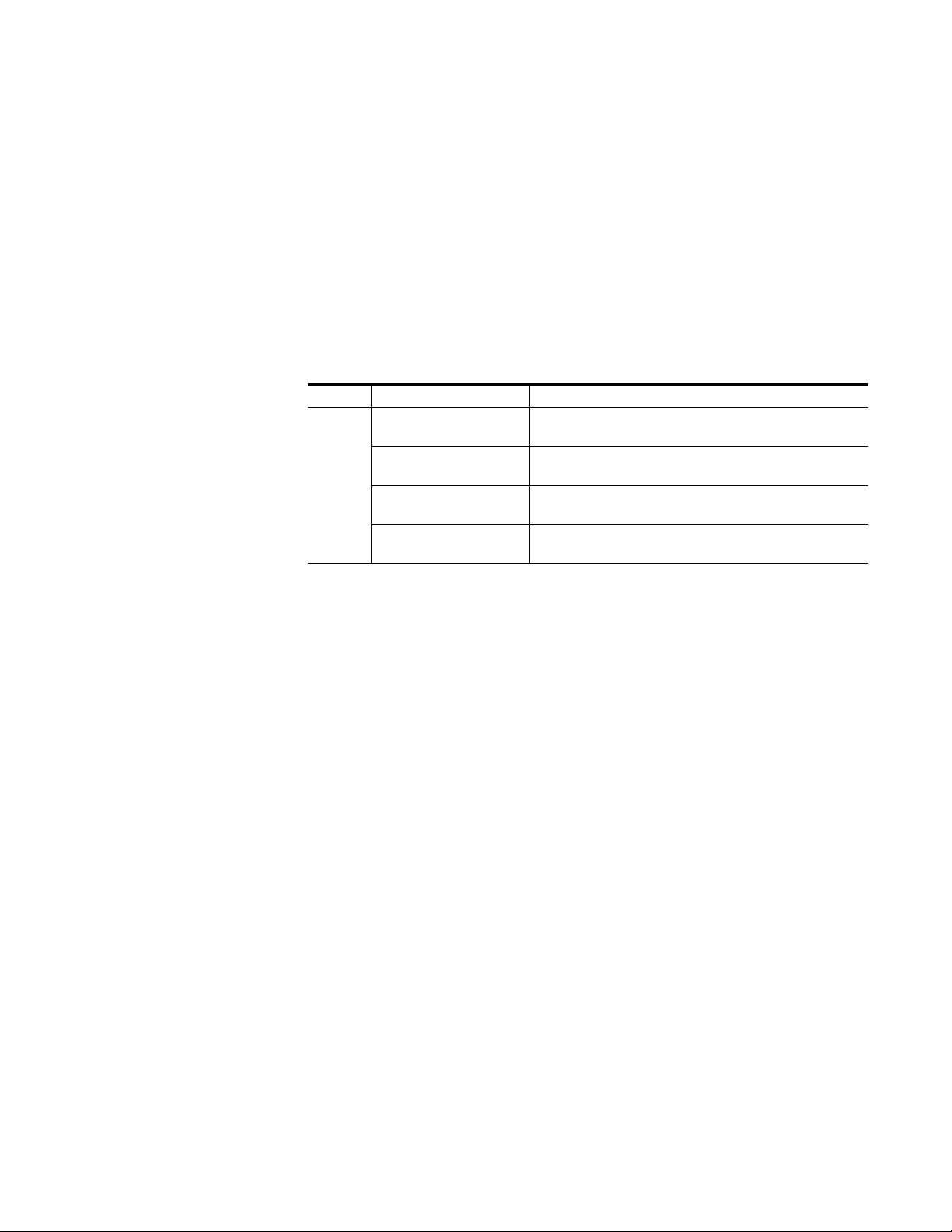

Table 1 shows the Gecko 8900 Series frame models available. Table 2 pro-

vides the upgrade options available to extend the frame capabilities.

Table 1.

Model # Cover type/power max. Controller Active Comm. Ports

8900TX-V/TX-A Convection/30 Watts None None

8900TF-V/TF-A Fan Front Cover/100 Watts Frame Monitor Module Frame Alarm

8900TFN-V/TFN-A Fan Front Cover/100 Watts 8900NET Network Interface Module Frame Alarm, RS-232, Ethernet

Table 2. Frame Upgrade Options and Features for Both Video and Audio Frames

Model # Upgrade Cover type/power max. Controller Active Comm. Ports

8900FAN

8900FN 8900TX to 8900TFN Fan/100 Watts 8900NET Network Interface Module Frame Alarm, RS-232, Ethernet

8900NET 8900TF to 8900TFN Fan/100 Watts 8900NET Network Interface Module Frame Alarm, RS-232, Ethernet

8900TX to 8900TF

Frame Models and Features

Fan/100 Watts Frame Monitor Module Frame Alarm

16 Gecko Frames Instruction Manual

Page 17

8900TX Convection System

The convection system consists of the following:

• 8900TX-V/TX-A, convection frame, and one power supply

• 8900PSX, redundant power supply (optional)

The convection frame has a vented front cover and filter for convective air

flow. This frame is used primarily for analog and a limited quantity of

digital modules with a total power requirement less than 30 watts. Refer to

Frame Cooling on page 21.

The convection frame is illustrated in Figure 1.

Figure 1. Convection Frame

8900TX Convection System

LOCK

LOCK

PS 1 PS 2

0636-06

Power Indicator LEDs

Note A convection frame can be upgraded to a forced-air or a networked frame.

This requires the use of model 8900FAN retrofit kit which provides fans and

the Fault indication window in the cover (see Figure 2 on page 14) and the

8900NET for networking capability.

Gecko Frames Instruction Manual 17

Page 18

Section 1 — Gecko 8900 Series Frames

8900TF Forced-air System

The forced-air system (Figure 2) consists of the following:

• 8900TF-V/TF-A, forced-air frame, Frame Monitor module, and one

power supply

• 8900PSX, 100 W redundant power supply (optional)

The forced-air system has a front cover that is equipped with three fans for

air circulation. The fan speed varies with the ambient frame temperature to

extend fan life and reduce noise when the frame is used in cooler configurations and environments. The fan speed control voltage is generated on

the Frame Monitor module and can be disabled so that the fan runs at

maximum speed only. This frame is recommended for power requirements

greater than 30 watts or when Frame alarm reporting (via the Frame

Monitor module) is required. Refer to Frame Cooling on page 21.

Note A forced-air TF-V or TF-A frame can be converted to a networked TFN-V or

TFN-A frame with the 8900NET option.

Figure 2. Forced-air or Networked Frame

LOCK

Fault Condition Indicator LED Power Indicator LEDs

8900TFN Networked System

The networked system consists of the following:

• 8900TFN-V/TFN-A, forced-air frame, 8900NET Network Interface

Module, and one power supply

FAULT

0636-07

LOCK

PS 1 PS 2

• 8900PSX, 100 W redundant power supply (optional)

The networked system has the same features as the forced-air system

including the fan cover (Figure 2) and fault and power indicators. Also

included is the 8900NET Network Interface module allowing the frame to

communicate over an Ethernet LAN to the web browser GUI interface for

remote control of 8900 modules.

18 Gecko Frames Instruction Manual

Page 19

Frame Connections

Two types of connector backplanes are available in the Gecko 8900 Series

frames. The 8900 BNC/Video frame provides ten module slots, each with

a loop-through input and up to eight connectors for input/output functions as needed for a specific module type (Figure 3).

Figure 3. 8900 Video Frame Module I/O Connectors

Frame Connections

DA10

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

10

DA9

J2

J1 J2

O

J4

J3 J4

U

T

J6

J5 J6

J8

J7 J8

J9 J10

IN

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

9

DA8

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA7

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

DA6

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA5

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

DA4

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA3

J2

J1 J2

O

J4

J3 J4

U

J6

J5 J6

J8

J7 J8

J9 J10

IN

T

DA2

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA1

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

0636 -03

The 8900 Balanced Audio frame provides 10 three-terminal connectors and

4 BNC connectors (Figure 4). As in the Video frame, two of the BNCs are for

loop-through connection.

Figure 4. 8900 Audio Frame Module I/O Connectors

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

8

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

7

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

6

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

5

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

4

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

3

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

2

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

0636 -17

J14

IN

1

Gecko Frames Instruction Manual 19

Page 20

Section 1 — Gecko 8900 Series Frames

The power/communication backplane section of the frame (Figure 5 and

Figure 6) provides:

• AC power plug connections

•DB-9 connector labeled RS-232 (requires the 8900NET module) with

Frame Alarm connections (pins 8 and 9 of RS-232 connector)

• Ethernet RJ-45 connector (requires the 8900NET module)

The RS-232 port provides connection to a PC used for initial network configuration. Pins 8 and 9 of the RS-232 port can be used for Frame Alarm

reporting. The RJ-45 Ethernet connector provides a 10Base-T Ethernet

network connection with the 8900NET Network Interface module.

Figure 5. Power/Communication Connectors on 8900 Video/BNC Frames

RS232

Frame Alarm

J102 pins 8 and 9

J102

U2

J1 J2

ETHERNET

J103

0636 -23

U1

Figure 6. Power/Communication Connectors on 8900 Balanced Audio Frames

Frame Alarm

J7 pins 8 and 9

0636 -18

U1

J1

RS232

J7

J2

ETHERNET

J10

20 Gecko Frames Instruction Manual

Page 21

Network Configuration Storage

Frame Cooling

Frame Cooling

Both the 8900 BNC/Video and Balanced Audio frames are equipped with

IP address storage capability on the rear backplane. When an 8900NET

module is installed (with version 3.0 software or later), the IP address

assignments made on the 8900NET module for network configuration are

stored on the frame. The current network configuration information will

then stay with the frame if the 8900NET module is moved.

Note Older version 8900 frames do not have IP address storage capability. IP

address information is stored only on the 8900NET module. Refer to Video

Frame on page 46 for more information.

The convection frame and the forced-air frame provide a great deal of flexibility in the type of modules that can be installed. Conventional low power

analog DAs can be used alongside higher power serial digital modules

with all modules performing to their full specifications.

For installations that require only low power modules or modules that

have a combined total dissipation of less than 30 watts, the convection

frame will provide adequate cooling.

Note The 30 watt TX-A/-V frame is best used for modules with less than 5.5 watts

power dissipation. When total power dissipation approaches maximum,

provide as much space as possible between the modules.

For installations where the modules dissipate greater than 30 watts, a

forced air frame must be used.

CAUTION Do not leave a fan front cover off of an air-cooled frame for extended periods.

For reliable operation, the forced-air cover should not be removed for longer

than five minutes when cooling more that 30 watts.

Gecko Frames Instruction Manual 21

Page 22

Section 1 — Gecko 8900 Series Frames

Calculating Frame Power

To calculate the power required for your frame, you must total all the

power dissipated for each individual module.

Table 3 provides the power dissipation for many of the modules compat-

ible with the 8900 Video and Audio frames. For newer modules not listed,

refer to the Specifications table in the specific module instruction manual.

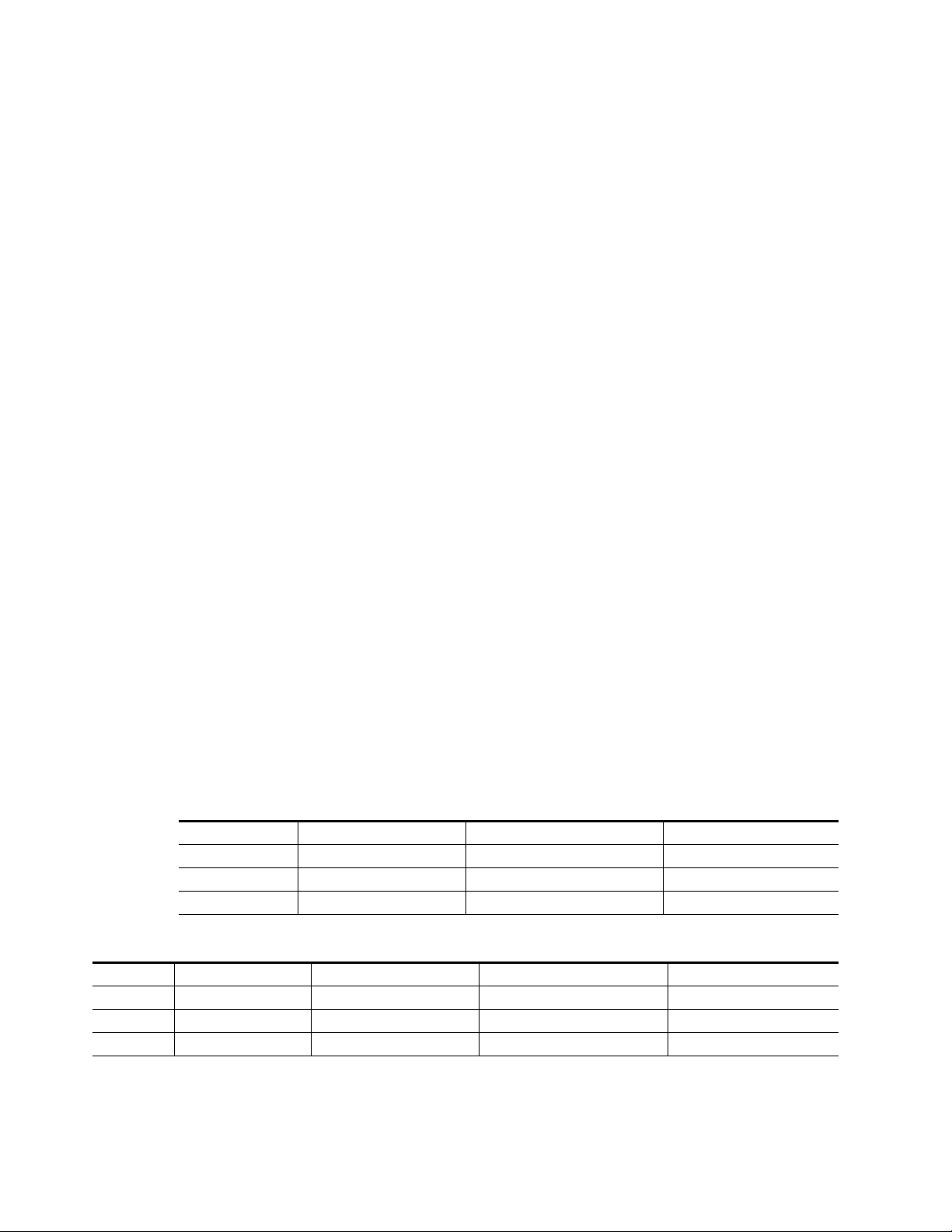

Table 3. Module Power Dissipation

Module Power Dissipation Module Power Dissipation

All 8500 Modules 2 Watts 8920Mux 7 Watts

All 8800 Modules 2 Watts 8931 2 Watts

8910ADA-M/ST 3 Watts 8936 3 Watts

8910ADA-SR 5 Watts 8941 6 Watts

8911 3 Watts 8942 5 Watts

8912RDA/-D 4 Watts 8950ADC 7.2 Watts

8914 3.5 Watts 8950DAC 7.5 Watts

8916 6 Watts 8960DEC

8920ADC 4.2 Watts 8960ENC

8920ADT 6 Watts 8981FS 4.5 Watts

8920DAC 3.1 Watts 8990ARC 6.5 Watts

8920DMX 7 Watts

6.5 Watts, 8.5 Watts

with Frame Sync option

6.5 Watts, 8.5 Watts

with Frame Sync option

Two examples of power calculations are shown in Table 4 and Table 5.

Table 4. Module Power Dissipation, example 1

Module Quantity

8800 5 2 Watts 10 Watts

8960DEC

without Frame Sync

8936 2 3 Watts 6 Watts

Total Frame Power 29 Watts

2 6.5 Watts 13 Watts

Power Per

Module

Total Power

22 Gecko Frames Instruction Manual

Page 23

Frame Monitor and Network Interface Modules

The total frame power required is less than 30 watts; therefore, the convection frame may be used.

Table 5. Module Power Dissipation, example 2

Module Quantity

8836 1 3 Watts 3 Watts

8916 2 6 Watts 12 Watts

8960DEC

without Frame Sync

8941 4 6 Watts 24 Watts

Total Frame Power 58.5 Watts

3 6.5 19.5

Power Per

Module

Total Power

With ten modules, the total frame power required is greater than 30 watts

and an 8900TF or 8900TFN forced-air frame must be used.

Frame Monitor and Network Interface Modules

8900 frame configuration supports the use of either the Frame Monitor or

the 8900NET Network Interface module. The Frame Monitor module provides alarm reporting for the Frame Alarm only. The 8900NET Network

Interface module provides full functionality of the frame communication

buses including:

• Frame Alarm,

•RS-232 Configuration, and

• 10Base-T Ethernet.

Refer to the 8900NET Network Interface Module Instruction Manual.

Gecko Frames Instruction Manual 23

Page 24

Section 1 — Gecko 8900 Series Frames

24 Gecko Frames Instruction Manual

Page 25

Installation

Introduction

This section contains information about:

•Rack mounting the frame,

•Module installation,

•Rear connectors, and

• Frame Alarm.

Rack Mounting the Frame

Section 2

After carefully unpacking this equipment, check the box for a power cords

and other hardware, and examine the equipment for damage. Any damage

should be promptly reported to the carrier.

The frame is designed to mount in a standard 19-inch equipment rack.

Mounting space of 3.5 inches (89 mm) vertically and mounting depth of 14

inches (356 mm) are required. Mount the frame in a standard 19-inch rack

using customer-supplied rack mounting screws.

CAUTION Before lifting the frame, verify that the power supplies are fully seated in their

slots. Front ejector tabs should click into place when snapped on the locking

pin on the module (see Figure 7).

Figure 7. Power Supply Ejector Tab Locking Pin

Ejector

tab

lock pin

0636 -13

Gecko Frames Instruction Manual 25

Page 26

Section 2 — Installation

Module Installation

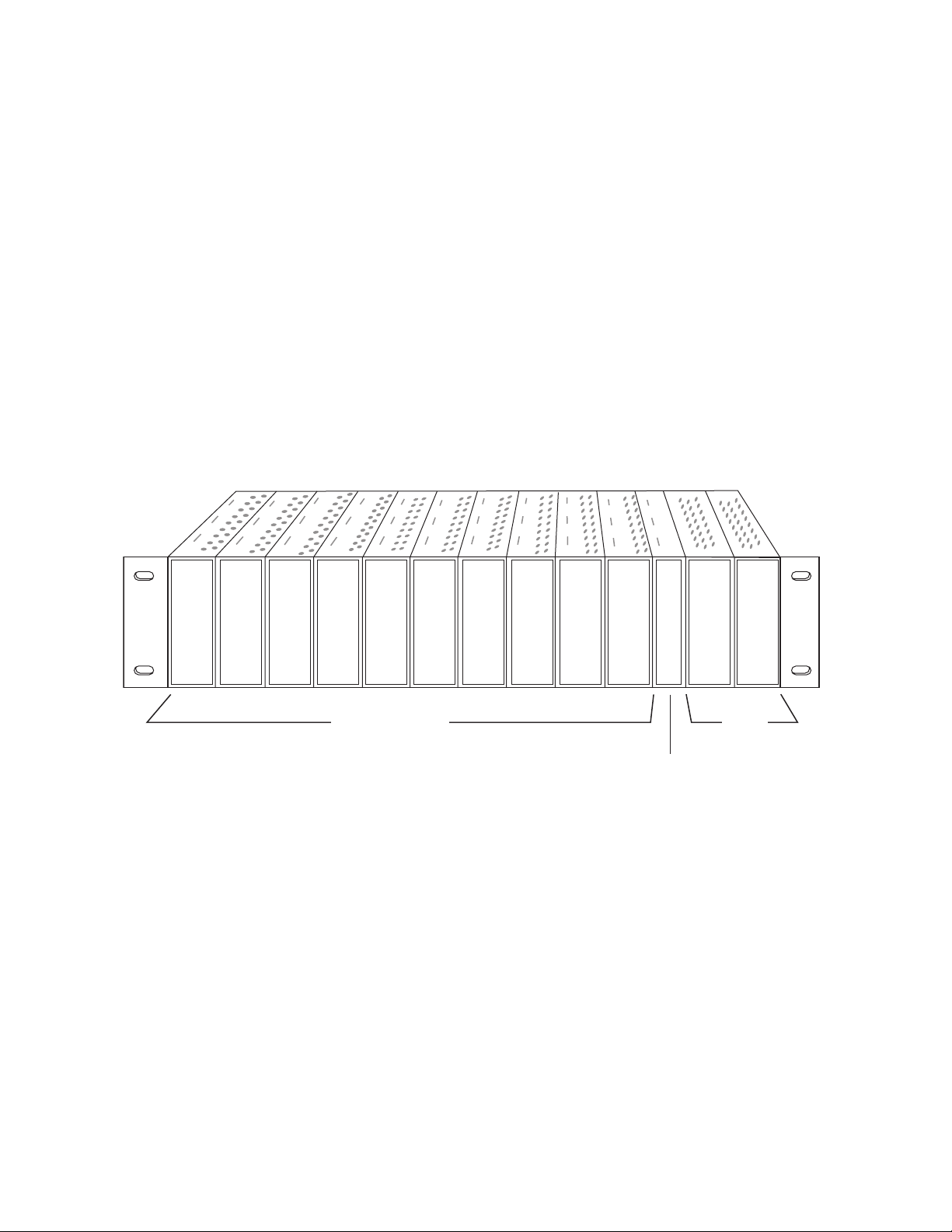

There are ten cell locations in each frame to accommodate either video or

audio modules (module types cannot be mixed in a frame). These are the

ten cells located on the left side of the frame. Refer to Figure 8.

Modules can be configured for up to eight outputs. The 8500 modules have

six outputs. The 8800 and 8900 modules have eight outputs. Refer to individual module manuals for input/output configuration information.

The two cells on the right are allocated for the power supplies only.

The third cell from the right, is allocated only for the Frame Monitor or

8900NET Network Interface module. This module provides the interface

for the forced-air cover, as well as the Frame Alarm reporting. For additional information concerning the Frame Monitor and Network Interface

modules, refer to Section 4-Monitoring and Control.

Figure 8. Gecko 8900 Series Frame

0636-04r2

Any 8900 Module

Frame Monitor or

8900NET Network

Interface Module

To install a module into the frame, follow these steps:

1. Insert the module into the frame, connector-end first, with component

side of the module facing to the right with the ejector tab at the top. The

Frame Monitor and the 8900NET module have a connector tab with a

circular finger-hole for pulling the module rather than an ejector tab.

The connector tab should be oriented in the top half of the frame.

2. Verify that the module connector seats properly against the backplane.

3. Press the ejector tab or connector tab in to seat the module in place.

Power

Supplies

(only)

4. Install a module template overlay from the Instruction Manual if

present.

26 Gecko Frames Instruction Manual

Page 27

Rear Connectors

Modules may be configured for a variety of inputs and outputs. The 8500

modules have six outputs. The 8800 and 8900 modules have up to eight

outputs. Refer to individual module manuals for specific configuration

information.

Note Connector configuration overlays are available for many 8900 modules that

Figure 9 illustrates the rear backplane of the 8900 BNC/Video frame.

Figure 9. 8900 Series Rear Connector Plate

Rear Connectors

do not use the standard DA configuration (one looping input and eight BNC

outputs). These overlays are found at the back of the module Instruction

Manual.

DA10

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

10

DA9

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

9

DA8

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA7

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

DA6

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA5

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

DA4

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA3

J2

J1 J2

O

J4

J3 J4

U

T

J6

J5 J6

J8

J7 J8

J9 J10

IN

DA2

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA1

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

Figure 10 illustrates the 8900 Balanced Audio Frame three-terminal and

BNC connectors on the rear backplane.

Figure 10. 8900 Series Audio Frame Rear Connector Plate

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

8

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

7

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

6

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

5

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

4

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

3

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

2

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

IN

1

0636 -03

0636 -17

The rear connector backplane will be discussed in the following order:

• Loop-through Input

•Direct Input/Output Connectors

• Frame Alarm Connection

Gecko Frames Instruction Manual 27

Page 28

Section 2 — Installation

Loop-through Input Connectors

Input signals are routed through the rear of the frame. There is one loopthrough input for each module cell refer to Figure 9 and Figure 10 on

page 27.

Note No more than five digital modules should be looped. Use cables less than

two meters in length, and an input cable of less than 200 meters of Belden

8281 (or equivalent).

If not used for looping, the unused loop-through connector must be externally terminated. The recommended termination for serial digital signals is

CONARE BCP-TA (or equivalent).

Performance of looping inputs to equipment other than 8900 modules has

not been verified; monitor signal quality carefully when configuring such

a system.

Serial digital video is a wideband RF signal. Be sure to protect the data from

environmental noise. The serial digital signal is attenuated by as much as

30 dB after traveling through 1000 feet of 8281 cable. An equalizer must be

used to restore the signal so data can be recovered. The equalizer boosts the

serial digital video signal and any environmental noise on the line. Data

corruption takes place if the environmental noise is large enough to cause

pick-off errors in the equalizer.

When connecting serial digital video signals to and from the 8900 Series

frame:

•Use high quality BNC connectors to ensure continuous shield connections.

•Use high quality cable (8281 or 1694A).

•Use one continuous cable for long cable runs. Avoid using patch panels

or BNC barrel connectors.

Note These recommendations become even more important in noisy environ-

ments (subject to radio frequencies and static) with long cable runs.

Direct Input/Output Connectors

In the video frame (refer to Figure 11) there are eight direct (not looping)

input/output BNC connectors provided for each module slot (J1 – J8).

Refer to the Instruction Manual for the specific module for input/output

connector information.

Note If 8500 modules are used in the frame, there are six outputs provided for each

module, J1 through J6.

28 Gecko Frames Instruction Manual

Page 29

Video Frame

Connectors

Rear Connectors

Figure 11. Video Frame Rear Input and Output Connector Labeling

Slot Number (1-10)

10

J10

J2

J2

J4

J4

J6

J6

J8

J8

0636-02r1

J1

J3

J5

J7

O

U

T

J9

IN

The audio frame provides two direct input/output BNCs (J11 and J12), two

looping BNCs (J13 and J14), and ten three-terminal input/output connectors (J1 – J10) shown in Figure 12. A pack of 100 audio connectors is provided with the frame for connecting audio cable to the rear connectors.

Refer to the specific audio module Instruction Manual for cabling information. Pinout information for each module may also be silkscreened on the

module circuit board.

Wiring for

Audio Connector

(top view)

Cable Tie

Audio

Cable

Figure 12. Audio Frame Rear Input and Output Connector Labeling

+ - G

+ - G

J11

J13

J1

J2

J3

J5

J7

J9

J10

IN

1

J4

J6

J8

J12

J14

J2

0636_24

Gecko Frames Instruction Manual 29

Page 30

Section 2 — Installation

Frame Alarm Connector

Use of the Frame Alarm requires the presence of either the Frame Monitor

or 8900NET Network Interface module in the frame. Frame Monitor

module features are discussed in Section 4-Monitoring and Control in this

manual. For information on the 8900NET module see the 8900 Network

Interface Module Instruction Manual.

The Frame Alarm is accessed through pins 8 and 9 of the RS-232 DB-9 connector (Video Frame – J102, Audio Frame – J7) as shown in Figure 13. Refer

to Frame Alarm Example on page 32 for using the port in an alarm circuit.

Note Earlier model 8900 frames had a SMPTE ALARM BNC for accessing the

Frame Alarm output. Refer to SMPTE Alarm Connector on page 46 for

cabling information on older frames.

Figure 13. Frame Alarm Connector Location

Frame Alarm

RS232

(Video – J102 pins 8 and 9)

(Audio – J7 pins 8 and 9)

J1 J2

ETHERNET

0636 -20r0

The pinout for the RS-232 DB-9F connector is given in Table 6.

Table 6. RS-232 Connector Pinouts

Video Frame – J102

Pin

Audio Frame – J7

1 N/C

2TX

3RX

4 N/C

5 Gnd

6 N/C

7 N/C

8 Frame Alarm

9 Frame Alarm

Pin 1

Pin 5

Frame

RS-232 Port

D-9 Female

Pin 6

Pin 9

30 Gecko Frames Instruction Manual

Page 31

Frame Alarm Conditions

The conditions monitored by Frame Alarm reporting are:

• Frame Health

• Power supply 1 voltage

• Power supply 2 voltage

• Fan rotation

• Frame temperature

•Module Health Bus (8900 Video Frames only)

• Power supply voltage

• Signal present at input

•EQ warning

The Module Health bus provides a means for older (legacy) or less capable

modules (such as DAs with no microprocessor) that cannot communicate

over the Frame serial bus to report alarm conditions to the Frame Monitor

or 8900NET module. The reporting is done using a voltage level sent by the

module to the Frame Alarm connector. When a problem exists on the

module, the Module Health bus will indicate that a problem exists on the

module but will not indicate what the problem is.

Rear Connectors

Alarm conditions are enabled or disabled by using the Alarm Reporting

DIP switch(es) on either the Frame Monitor or 8900NET modules. Refer to

Enabling Alarms and Fan Speed Control Option on page 39 for the Frame

Monitor module. For information on setting the 8900NET switches, refer to

the 8900 Network Interface Module Instruction Manual.

In addition to fault reporting through the Frame Alarm connector, there is

a red Fault LED on the 8900TF/TFN front cover. This LED is off when no

fault conditions are detected and on when either an internal fault or a

signal error is detected.

Gecko Frames Instruction Manual 31

Page 32

Section 2 — Installation

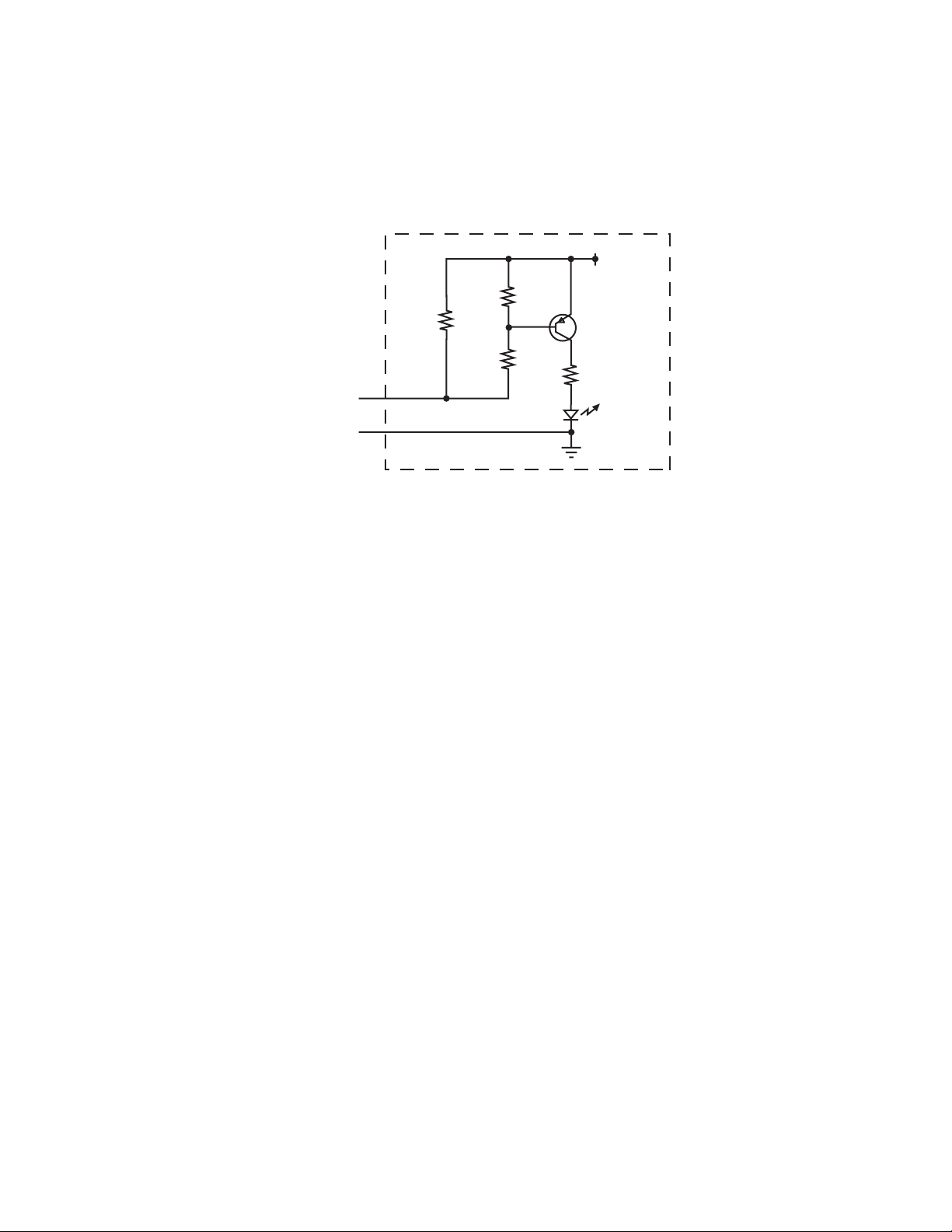

Frame Alarm Example

Refer to Figure 14 for an example of a typical alarm schematic using pins 8

and 9 of the RS-232 port.

Figure 14. Typical Alarm Schematic for Frame Alarm

+5V

4.7 kΩ

470 Ω

4.7 kΩ

330 Ω

RS-232 Pin 8

RS-232 Pin 9

2N4126

(or equivalent)

Alarm

LED

The impedance between the pins 8 and 9 of the RS-232 connector can be in

one of two states:

•Open – less than 100 µA of current will flow with 5 volts across the pins,

and

•Closed – less than 0.2 V will appear from pin 8 to pin 9 with 20 mA of

current flowing.

There are three operational conditions (capability is module dependent,

refer to specific module instruction manual):

•Open – no faults,

•Closed – there is an internal fault, and

• Pulsing – there is a missing or invalid signal on one or more of the modules.

32 Gecko Frames Instruction Manual

Page 33

Power Up

Introduction

This section contains information about:

• Power Connections

•Applying Power

CAUTION Verify that the power supplies are fully seated in their slots. Ejector tabs

Section 3

should click into place when snapped on the locking pin on the module (see

Figure 15).

Figure 15. Power Supply Ejector Tab Locking Pin

Ejector

tab

lock pin

0636 -13

Gecko Frames Instruction Manual 33

Page 34

Section 3 — Power Up

Power Connections

There are two types of power cords supplied with the 8900 Series frames

for 120 V and 240 V operation. Line voltage selection is not required for this

power supply. Optional redundant power supplies are also shipped with

both types of power cord.

120 VAC

This cord has a molded grounding plug at one end and a molded grounded

receptacle at the other end. Conductors are color-coded white (neutral),

black (line), and green or green/yellow (ground).

240 VAC

This cord has a molded grounding receptacle at one end and stripped conductors at the other end. Conductors are color-coded light blue (neutral),

brown (line), and green/yellow (ground).

For each power supply installed, AC power is fed through a line cord to a

socket (J1 and J2) on the rear of the frame (Figure 16).

Figure 16. AC Power Connectors

RS232

J1

ETHERNET

Note To maintain maximum redundant power, ensure that each power supply cord

is plugged into a separate branch circuit.

J2

0636 -05r1

34 Gecko Frames Instruction Manual

Page 35

Line Cord Retainer

To help prevent accidental loss of power, the AC line cord is held in place

by a retainer clip (Figure 17).

Figure 17. Cable Retainer Clip

To properly install the line cord, follow these steps:

Power Connections

0636 -08

Retention Clip

1. Ensure that the retainer clip is inserted properly into the holes of the

screw caps.

2. Rotate the retainer clip sideways, and plug the power cord into the

receptacle.

3. Rotate the retainer clip back onto the plug body to hold the power cord

in place.

Gecko Frames Instruction Manual 35

Page 36

Section 3 — Power Up

Applying Power

Upon applying power to the frame, verify that the green power LED for

each power supply (assuming a redundant supply is present)PS1 and PS2

is illuminated (Figure 18). If the frame is a TF or TFN model (with fans),

check the red FAULT LED. It should be off if the fans are operating correctly.

Figure 18. Power Indicator LEDs (TF frame shown)

LOCK

PS 1 PS 2FAULT

0636-15

Power Indicator LEDs

Fault LED

Other indicator LEDs can be viewed on the controller module (Frame

Monitor or 8900NET module) with the front cover removed. Frame

Monitor module indicators are discussed in Section 4-Monitoring and Con-

trol. If you have a 8900NET module installed in the frame, see the 8900NET

Network Interface Module Instruction Manual for indicator details.

36 Gecko Frames Instruction Manual

Page 37

Monitoring and Control

Introduction

The Gecko 8900TF/8900TFN frames offer monitoring and remote control

capability by providing two types of frame communication modules that

can reside in the controller cell of the frame:

• Frame Monitor module (8900TF Frame), or

• 8900NET Network Interface module (8900TFN Frame).

The 8900NET Network Interface module supports all the functionality of

the Frame Monitor module plus the 10 Base-T Ethernet bus for web-based

GUI control and monitoring. For information on the 8900NET module and

GUI refer to the 8900NET Network Interface Module Instruction Manual.

Section 4

The Frame Monitor module is described in this manual. The Frame

Monitor module is an interface for the forced-air cover and Frame Alarm

fault reporting.

The Frame Monitor module provides:

•Variable power to the fan front cover to regulate fan speed

•Analog module presence indication

• LED display for quick diagnostics of alarm conditions

•DIP switch for enabling and disabling alarms and the variable fan

speed option

Gecko Frames Instruction Manual 37

Page 38

Section 4 — Monitoring and Control

Frame Monitor Module

The Frame Monitor module comes installed in the 8900TF frame. It provides indicator LEDs on the front of the module (visible when fan front

cover is removed) that report alarm conditions and module power status.

When on, the LEDs indicate:

•TEMP — Over-temperature problem

• PS2 — Power supply position 2 health problem

• PS1 — Power supply position 1 health problem

•FAN — Cooling fan is not rotating

• MOD — Module health bus error

•INHIB — Disabled module health bus

•FAULT — Reports that one or more of the above alarm conditions is

present and the other Fault LEDs on the module should be checked.

This LED is visible through the fan front cover Fault window.

Note When an analog module in installed, the module health alarm bus is inhibited.

The front edge of the Frame Monitor module is shown in Figure 19.

Figure 19. Frame Monitor Module Front View

Temperature (red)

PS2 (red)

PS1 (red)

Fan (red)

Module Health (red)

Fault detected (red)

Configuration DIP switch S1

S1

1

2

3

4

5

6

7

8

Power (green)

Module Health Inhibited (yellow)

LED Color Key

Red = Fault

Green = OK

Yellow = Mode Active

0636 -16

38 Gecko Frames Instruction Manual

Page 39

Enabling Alarms and Fan Speed Control Option

The Frame Monitor module has an eight position DIP switch (S1) that

enables or disables the alarm functions and the variable fan speed function.

Refer to Figure 19 on page 38 for the location of S1 and Table 7 for the pos-

sible settings. A settings table is also silkscreened on the module.

Table 7. Configuration DIP Switch Settings

Segment Left Position (open) Right Position (closed)

1 PS1 Fault Reporting Enabled PS1 Fault Reporting Disabled

2 PS2 Fault Reporting Enabled PS2 Fault Reporting Disabled

3 Overtemp Fault Reporting Enabled Overtemp Fault Reporting Disabled

4 Fan Fault Reporting Enabled Fan Fault Reporting Disabled

5 Module Fault Reporting Enabled Module Fault Reporting Disabled

6 Fan Speed Controlled by Temperature Fan Speed Fixed at Maximum

7 Not Used

8 Not Used

Frame Monitor Module

Frame Monitor Module Indicator LEDs

The possible LED status and conditions indicated are shown in Table 8.

Table 8. Indicator LEDs and Conditions Indicated

LED LED State Condition

Power

(green)

PS2

(red)

PS1

(red)

FAN

(red)

MOD

(red)

INHIB

(yellow)

FAULT

(red)

Off Power is off or onboard regulator has failed

On continuously Module is powered

Off Normal operation or alarm disabled

On continuously Power supply 2 is present and reporting an alarm condition

Off Normal operation or alarm disabled

On continuously Power supply 1 is present and reporting an alarm condition

Off Normal operation or alarm disabled

On continuously One or more fans in the front cover assembly is not rotating

Off Normal operation or alarm disabled

On continuously Module health bus is not disabled and one or more modules is reporting an internal fault

Flashing One or more modules is reporting a data error

Off Normal operation or alarm disabled

On continuously A non-compliant module in the frame has disabled the module health bus

Off Normal operation

On continuously One or more of the onboard fault LEDs is illuminated or flashing

Gecko Frames Instruction Manual 39

Page 40

Section 4 — Monitoring and Control

40 Gecko Frames Instruction Manual

Page 41

SpeciÞcations

Introduction

This section discusses specifications for the Gecko 8900 frames and the

8900PSX 100 W power supply. Refer to the module instruction manual for

the specifications for a particular audio/video module.

Frame Specifications

See Table 9 for a list of the 8900 Series frame specifications. Specifications

are subject to change without prior notice.

Section 5

Table 9. 8900 Series Frame Specifications

Parameter Value

Module Cells

Input Type 75 Ω loop through BNCs (shield-isolated from ground)

Termination (Serial Digital) CONARE BCP-TA (or equivalent,

Output Type Eight 75 Ω BNCs

Frame Fault Reporting

Connector Type DB-9F pins 8 and 9 of RS-232 connector

Maximum Current — Alarm OFF 100 µA when voltage < 24 V is applied

Maximum Voltage — Alarm ON 2 V with current < 20 mA

Maximum allowable voltage —

center conductor to shield

Maximum allowable current 20 mA

Front Panel Indicators

PS 1 & PS 2 Green LED — ON indicates operating correctly

Fault (TF/TFN front covers only) Red LED — ON indicates an error or failure

customer-supplied)

24 V

Gecko Frames Instruction Manual 41

Page 42

Section 5 — Specifications

Table 9. 8900 Series Frame Specifications - (continued)

Parameter Value

Operating Conditions

Input voltage range 100 V to 240 VAC, 47 Hz to 63 Hz

Maximum input current 1.5 A

Operating temperature range 0 to 45 degrees C

Non-operating temperature range -10 to +70 degrees C

Humidity Up to 95% non-condensing

Mechanical

Height 2 RU, 3.5 inches (89 mm)

Width 19 inches (483 mm)

Depth 13.25 inches (337 mm)

Weight with no modules, 1 power supply TX frame: 18.55 lbs (8.4 kg)

TF frame: 19.2 lbs (8.7 kg)

TFN frame: 20.2 lbs (9.16 kg)

Weight with no modules, 2 power supplies TX frame: 19.75 lbs (8.96 kg)

TF frame: 20.4 lbs (9.2 kg)

TFN frame: 21.4 lbs (9.7 kg)

Power

Inputs Two independent AC inputs

Connector Type IEC with cord retention

AC voltage 100 V to 240 V, 50/60 Hz

Maximum power dissipation TX frame: 30 W

TF- and TFN frames: 100 W

Environmental

Operating temperature 0 to 45 degrees C

Non-operating temperature -10 to +70 degrees C

Humidity < 90% non-condensing

42 Gecko Frames Instruction Manual

Page 43

Power Supply

Power Supply

See Table 10 for a list of power supply specifications. Specifications are

subject to change without prior notice.

Table 10. Power Supply Specifications

Parameter Value

Inputs

Voltage Range 100 V to 240 V, continuous range

Frequency 47 Hz to 63 Hz

Outputs

Voltage/Current +12.4 V @ 8 A and –12.4 V @ 1.5 A, common ground

(total not to exceed 100 W)

Load/Line Regulation ± 3% for loads from 100 mA to 5 A

+ 7%, – 3% for loads from 0 to 100 mA

Current Limit +12 V < 10 A under short circuit conditions

–12 V < 7 A under short circuit conditions

Status Range (healthy) +12 V + 8% – 4%; –12 V + 8% – 4%

Test Points Three: +12 V, –12 V, and ground

Power Factor Correction Complies with EN61000-3-2 Class D

Gecko Frames Instruction Manual 43

Page 44

Section 5 — Specifications

44 Gecko Frames Instruction Manual

Page 45

Appendix – 8900 Frames Archive

Introduction

This appendix provides reference information for previously released 8900

frames. Use this archive to access a summary of cabling and configuration

information for earlier versions of the 8900 frames.

Identifying Frame Types

There are a number of ways to determine what type of frame you have.

Table 11 lists all available frame types and how they can be identified. The

assembly number of the frame is printed on a label located inside the frame

on the front of the chassis.

Network Configuration Storage

One of the important differences between current and earlier version 8900

frames is the location of network configuration storage. 8900NET software

version 3.0.0 and later enabled storage of the IP addresses (network configuration) on the frame backplane on frames that are equipped with storage

capability. In earlier versions of software and frame types with no storage

capacity, the IP addresses are stored on the 8900NET module and stay with

the module when it is moved to another frame.

Table 11. 8900 Frames Types IP Storage Capability

Model Number Backplane Assembly Number

8900TFN-A Audio backplane with 1 IC 610-0960-00 8900NET module

8900TFN Video backplane with 1 IC 630-0063-00 8900NET module

8900TFN-A Audio backplane with 2 ICs 610-0960-01 Frame backplane

8900TFN-V Video backplane with 2 ICs 610-0984-00 Frame backplane

Network Config

Storage

Gecko Frames Instruction Manual 45

Page 46

Appendix – 8900 Frames Archive

To determine what frame model you have and where IP addresses are

stored, you may also access the Frame Status page with the web browser.

All frames with 8900NET cards with software version 3.0.0 and later will

report a

following:

•Network configuration stored on 8900NET module, or

•Network configuration stored on frame.

Video Frame

Earlier versions of the 8900 BNC/Video TX/TF/TFN frames have a backplane configuration as shown in Figure 20. The earlier frames differ from

the current frames in two main areas:

•The Frame Alarm Port on earlier modules is accessed by an external

•There is no network configuration (IP address) storage capability on

Network Config status message on the Frame Status page as one of the

BNC connector on the backplane labeled SMPTE ALARM J101.

these frames.

SMPTE Alarm Connector

Use of the SMPTE Alarm bus requires the Frame Monitor or 8900NET

Network Interface module be installed in the frame. For more information

on the 8900NET module, see the 8900NET Network Interface Module Instruc-

tion Manual.

The SMPTE Alarm reporting is accessed through J101 shown in Figure 20.

Figure 20. 8900 Video Frame Backplane With SMPTE Alarm BNC

Alarm BNC (J101)

J1 J2

ETHERNET

J103

RS232

J102

SMPTE

ALARM

J101

DA10

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA9

J1 J2

J2

J3 J4

J4

J5 J6

J6

J7 J8

J8

J9 J10

IN

O

U

T

0636 -19

46 Gecko Frames Instruction Manual

Page 47

Video Frame

The conditions monitored by SMPTE Alarm reporting are:

• Frame Health

• Power supply 1 voltage

• Power supply 2 voltage

• Fan rotation

• Frame temperature

•Module Health (capability module dependent, refer to specific module

instruction manual).

• Power supply voltage

• Signal present at input

•EQ warning

•EDH Monitoring (capability module dependent, refer to specific

module instruction manual).

•EDH error detected

The impedance between the center conductor and shield of J101 can be in

one of two states:

•Open – less than100 µA of current will flow, and

•Closed – less than 2 V will appear from center conductor to shield with

less than 20 mA of current flowing.

There are three operational conditions (capability is module dependent,

refer to specific module instruction manual):

•Open – no faults,

•Closed – there is an internal fault, and

• Pulsing – there has been a signal error detected in one of the modules.

In addition to fault reporting through the SMPTE Alarm connector, there is

a RED Fault LED on the Frame Monitor and 8900NET Network Interface

modules that is visible through the Fault window of the 8900TF/TFN front

cover. This LED is OFF when no fault conditions are detected and ON

when either an internal fault or a signal error is detected.

A number of frames can be coupled together as one alarm circuit by using

a T-connector. Refer to Figure 21 on page 48 for a typical alarm circuit interconnect diagram.

Gecko Frames Instruction Manual 47

Page 48

Appendix – 8900 Frames Archive

BNC T-connector

Up to 20 Frames

Figure 21. SMPTE Alarm Fault Reporting Connections

J101

J101

J101

4.7 kΩ

470 Ω

4.7 kΩ

Last Frame

First Frame

330 Ω

+5V

2N4126

(or equivalent)

Alarm

LED

Note Refer to “SMPTE Fault Reporting in Television System” standard for further

details.

48 Gecko Frames Instruction Manual

Page 49

Audio Frame

Audio Frame

Earlier versions of the 8900 Audio TX/TF/TFN frames have a backplane

configuration as shown in Figure 22. The earlier frames differ from the

current frames in one main area:

• There is no network configuration (IP address) storage capability on

these frames.

The Frame Alarm connection is on pins 8 and 9 of the RS-232 connector as

discussed in Frame Alarm Connector on page 30.

Figure 22. 8900 Audio Frames Backplane

Frame Alarm

RS232

J1 J2

(pins 8 and 9)

ETHERNET

J10

0636 -11r1

U1

Gecko Frames Instruction Manual 49

Page 50

Appendix – 8900 Frames Archive

50 Gecko Frames Instruction Manual

Page 51

Index

Numerics

120V line cord 34

240V line cord 34

8900 models

FAN

FN 16

TF 16

TFN 16

TX 16

8900TF frame

description

overview 16

upgrading 18

8900TFN frame

description

overview 16

8900TX frame

description

overview 16

upgrading 17

16

18

18

17

connector configurations 27

controller cell 37

controller modules 26

cord retainer 35

D

direct input/output connectors 27, 28

disables 39

disabling alarms 37

documentation online 2

E

enables 39

equipment rack 25

Ethernet 37

capability 18

connection 20

A

alarms

conditions

example 32

Frame Alarm (RS-232 connector) 30

SMPTE Alarm BNC 47

analog module presence 37

applying power 36

audio frames

earlier versions

31

49

B

branch circuit 34

C

communication ports 16

conditions indicated 39

F

FAQ database 2

Fault LED 38

features 15

Frame alarm 20

frame connections 19

Frame Monitor Module 26, 30, 37, 46

frame options 16

frame types 45

identifying 45

frequently asked questions 2

front covers 16

G

Grass Valley web site 2

Gecko Frames Instruction Manual 51

Page 52

Index

I

indicator LEDs 38

input/output configuration 26

input/output connectors 28

IP Address

storage

45

L

line voltage 34

loop-through input 28

M

maximum power 16

module health 31, 47

module health alarm 38

Module Health Bus 31

monitoring 37

N

network configuration storage 21, 45

Network Interface Module 26, 30, 37, 46

impedance 32

S

SMPTE alarm 30, 46

impedance 47

software download from web 2

specifications

frame

41

power supply 43

T

termination 28

typical alarm circuit 47

U

upgrade options 16

V

variable fan speed 39

W

O

online documentation 2

options 16

output connectors 27

over-temperature 38

P

power 42

power calculations 22

power cords 34

power supply cells 26

R

redundant power 34

remote control 37

retainer clip 35

RS-232 Connector 30

web site

documentation

FAQ database 2

Grass Valley 2

software download 2

2

52 Gecko Frames Instruction Manual

Loading...

Loading...